Technology and Properties of Peripheral Laser-Welded Micro-Joints

Abstract

1. Introduction

2. Experimental Tests

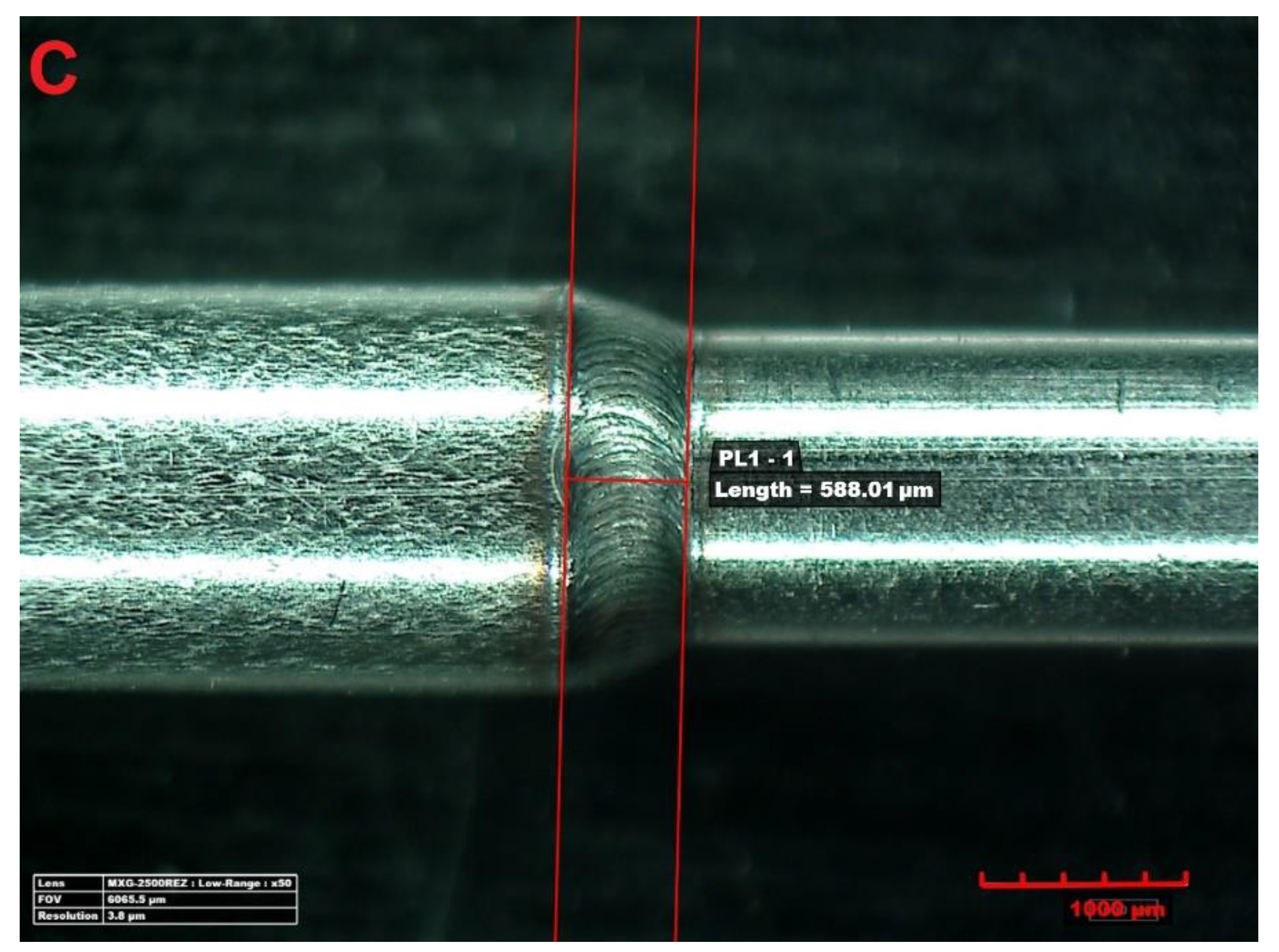

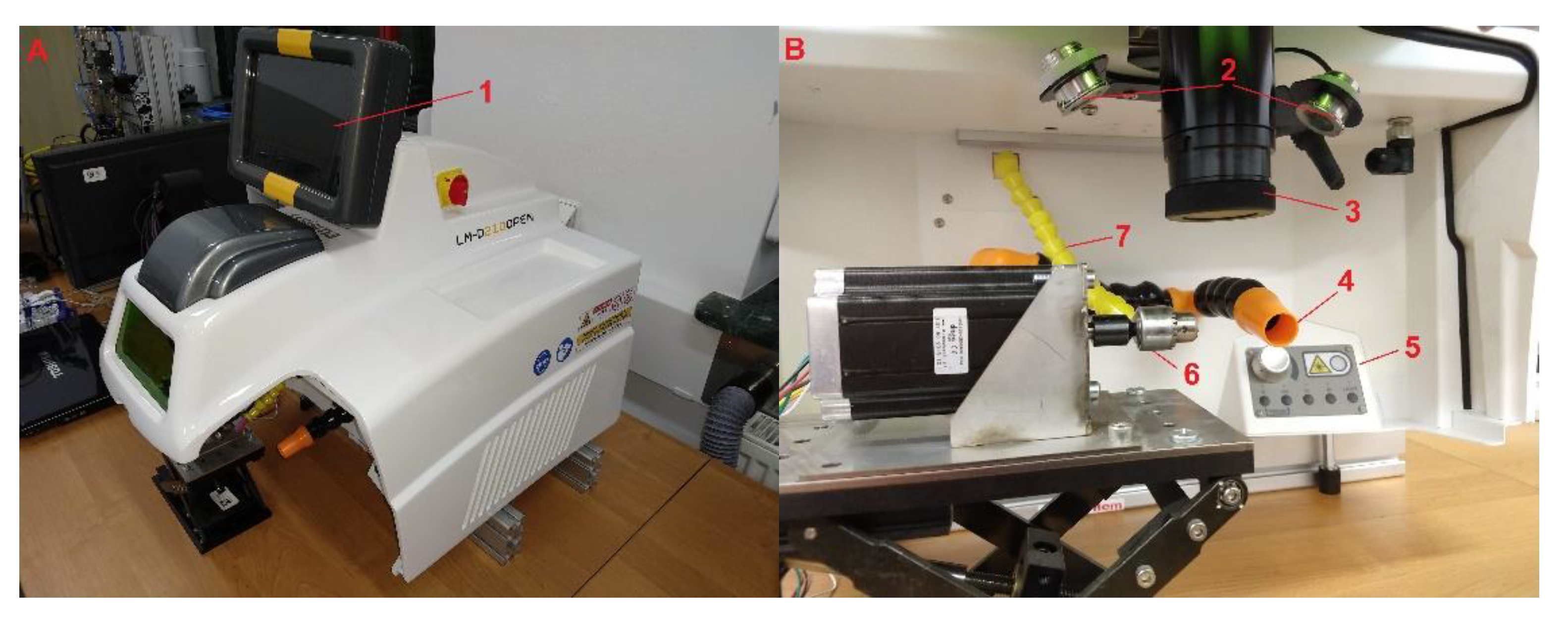

2.1. Methodology

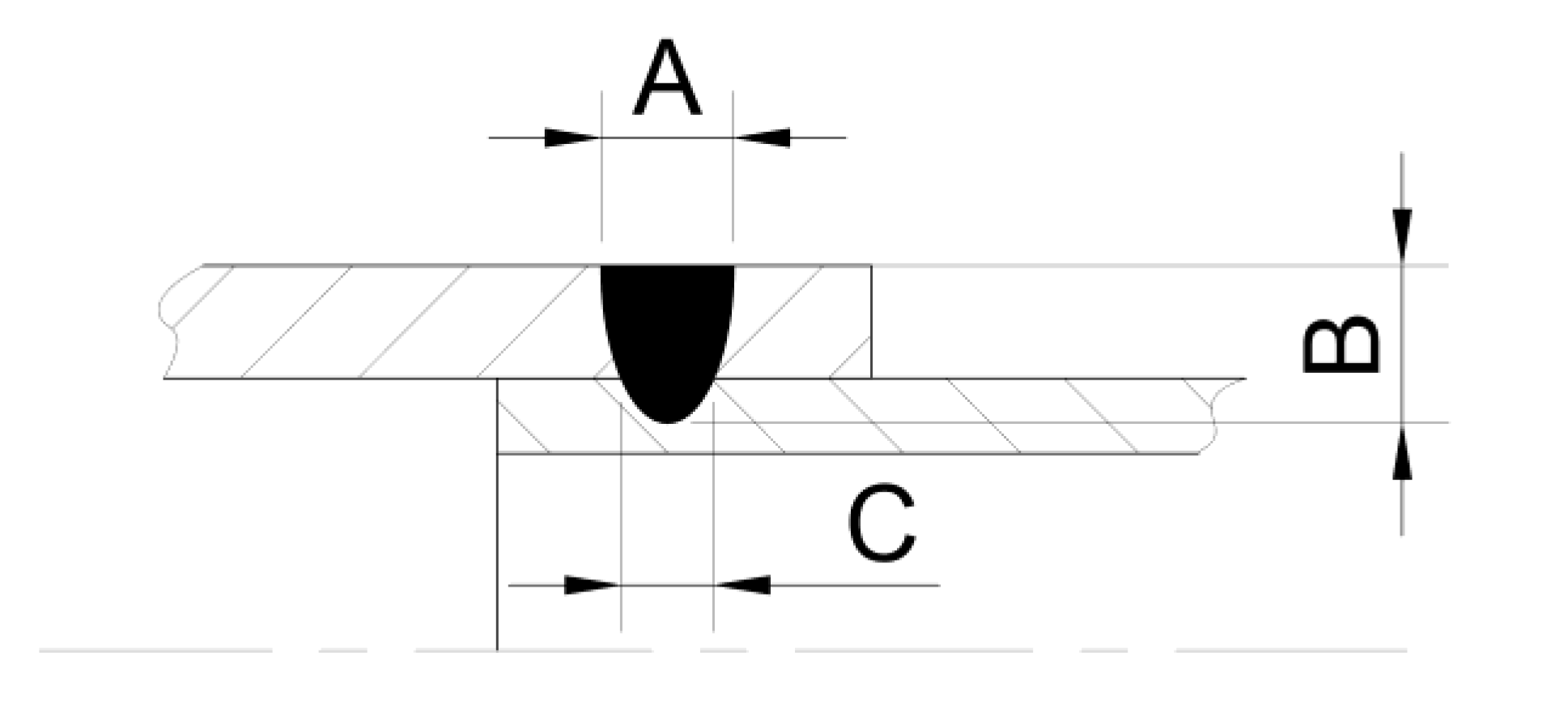

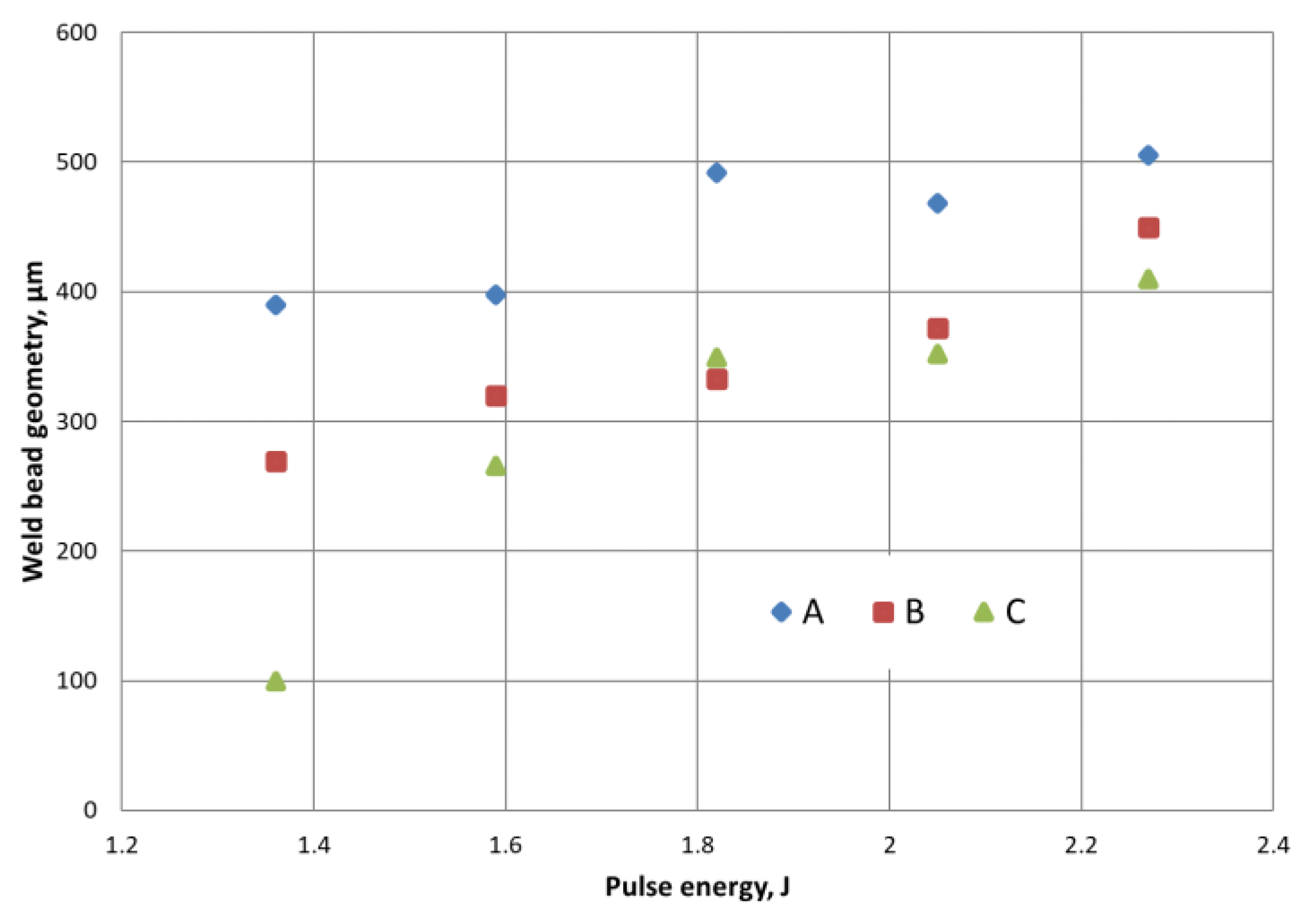

2.2. Technological Experiment

3. Properties of Laser Micro-Joints—Results and Discussion

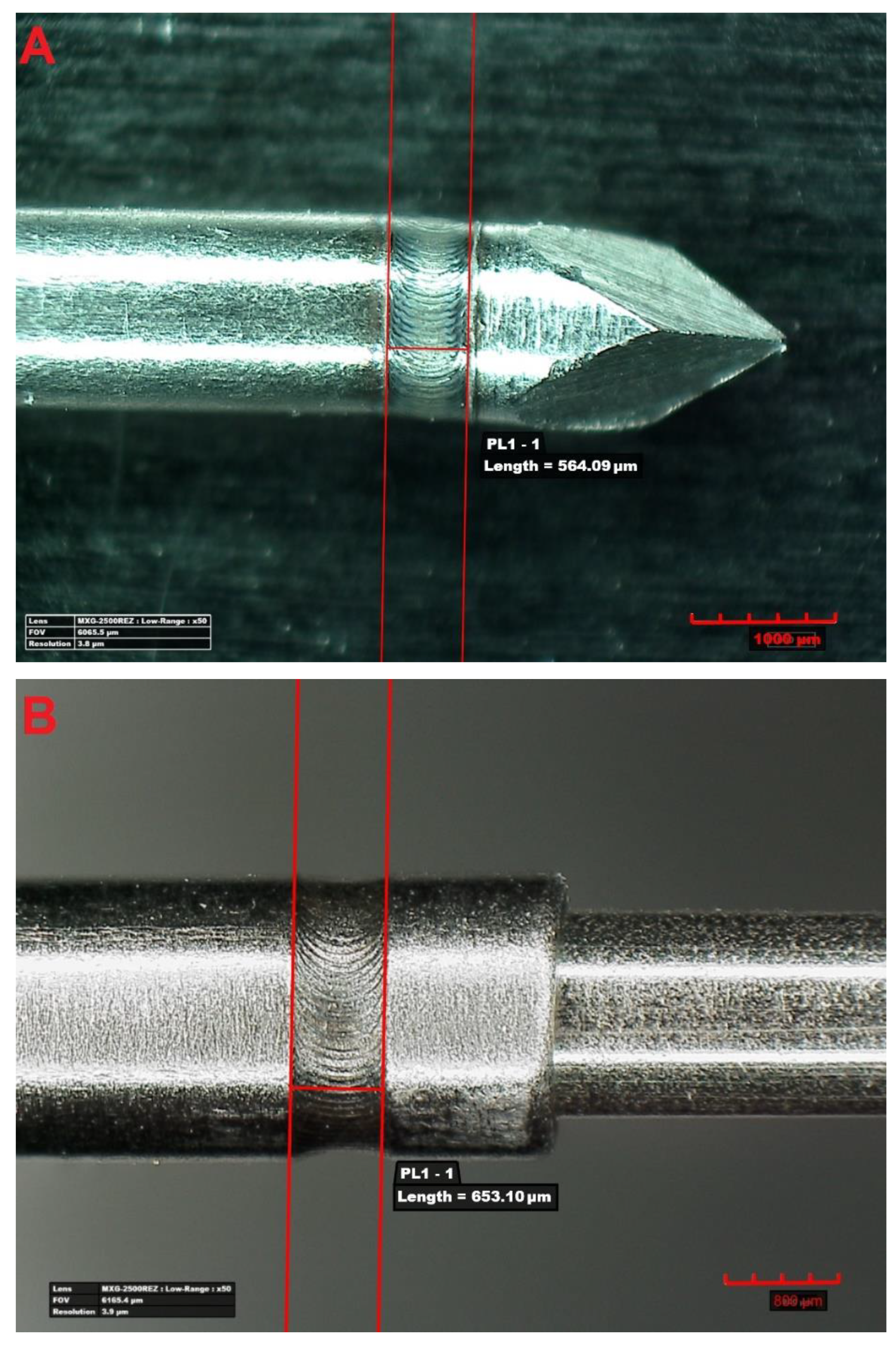

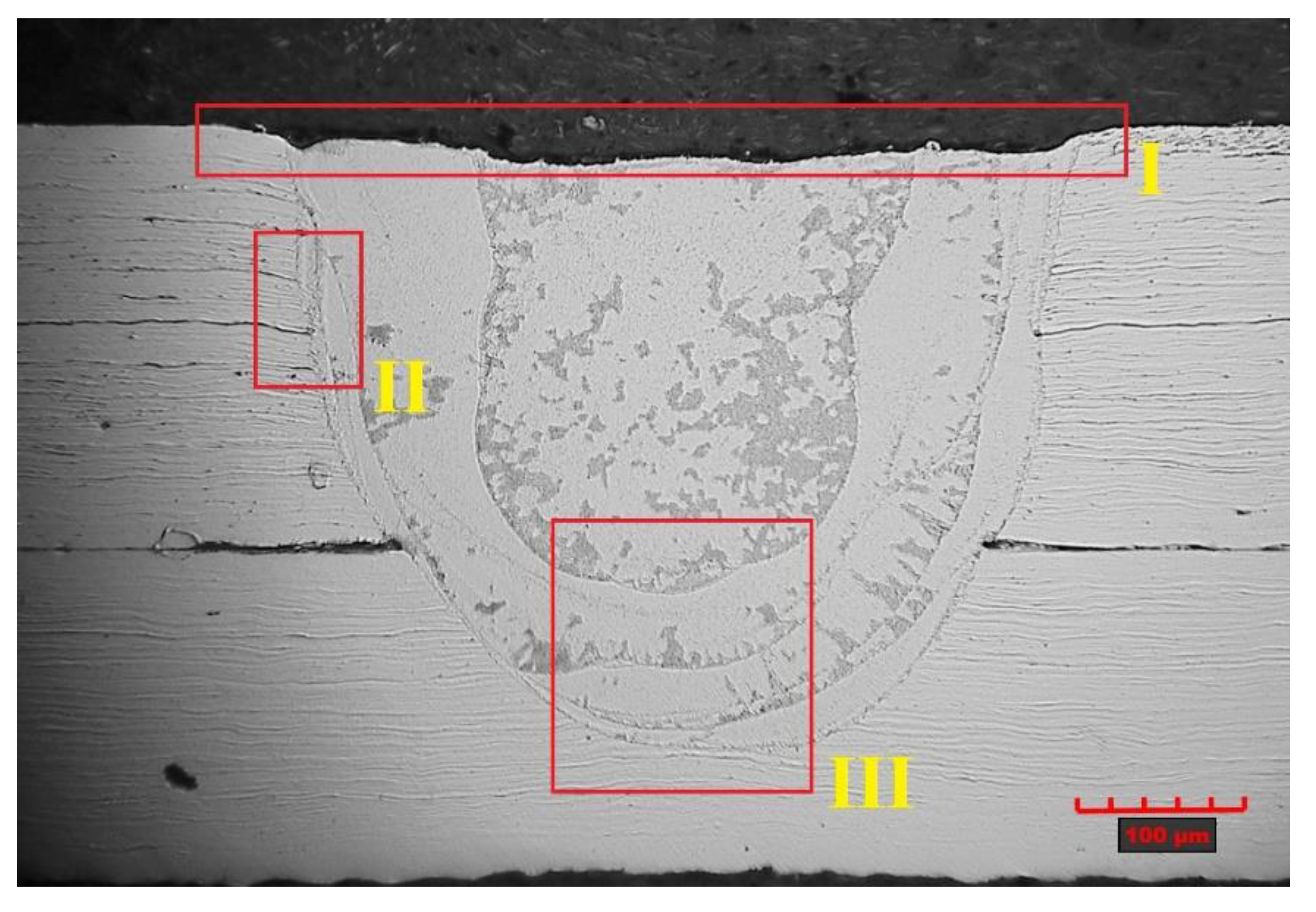

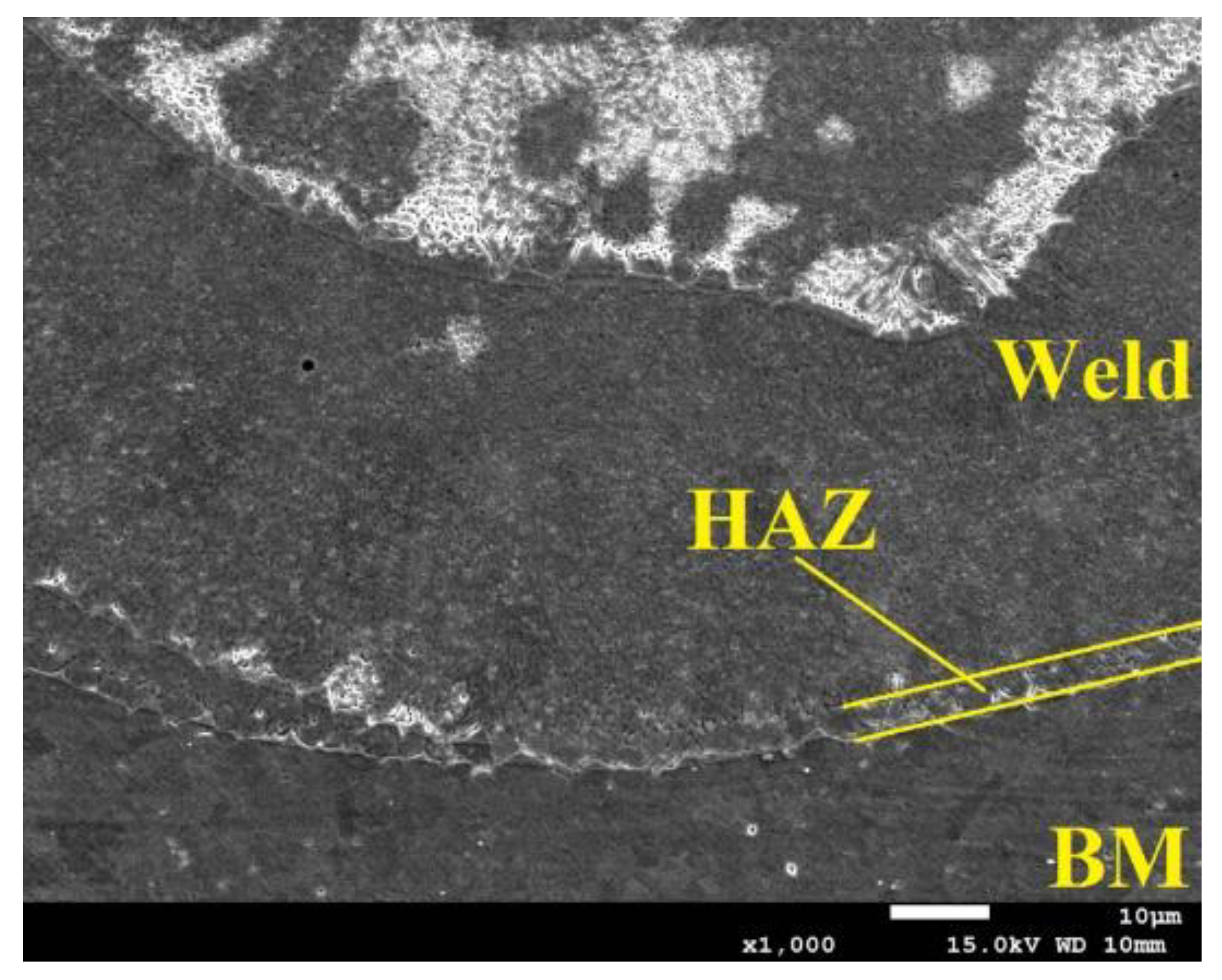

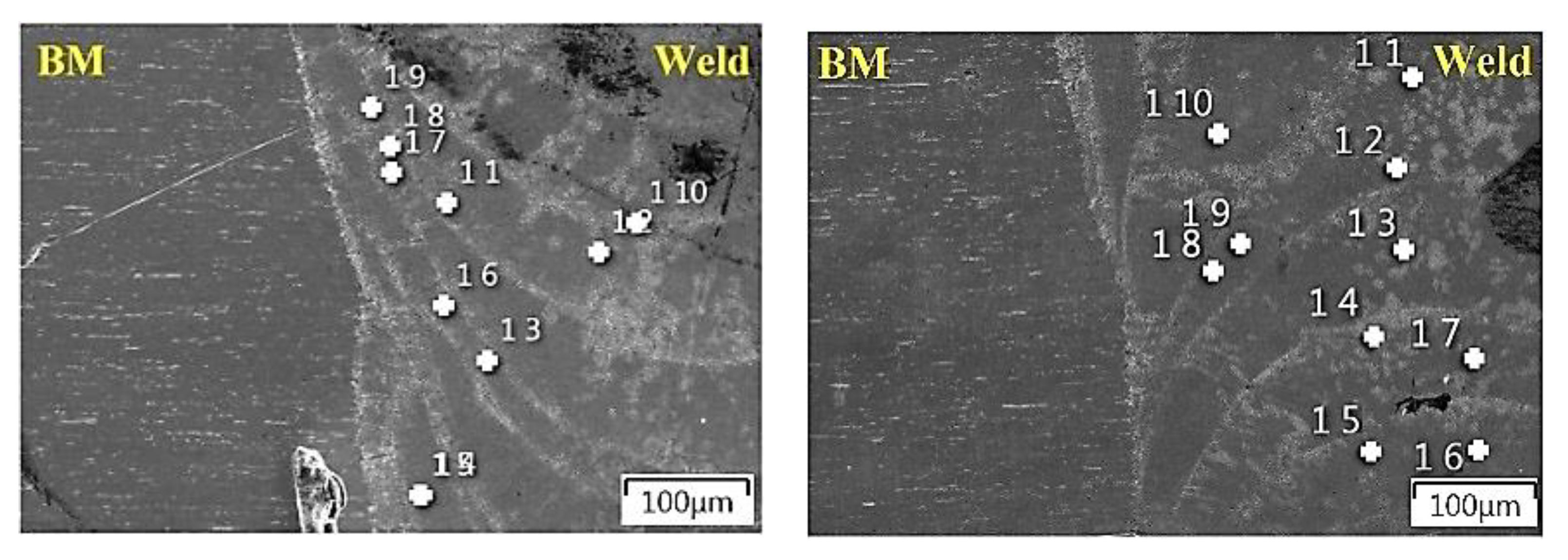

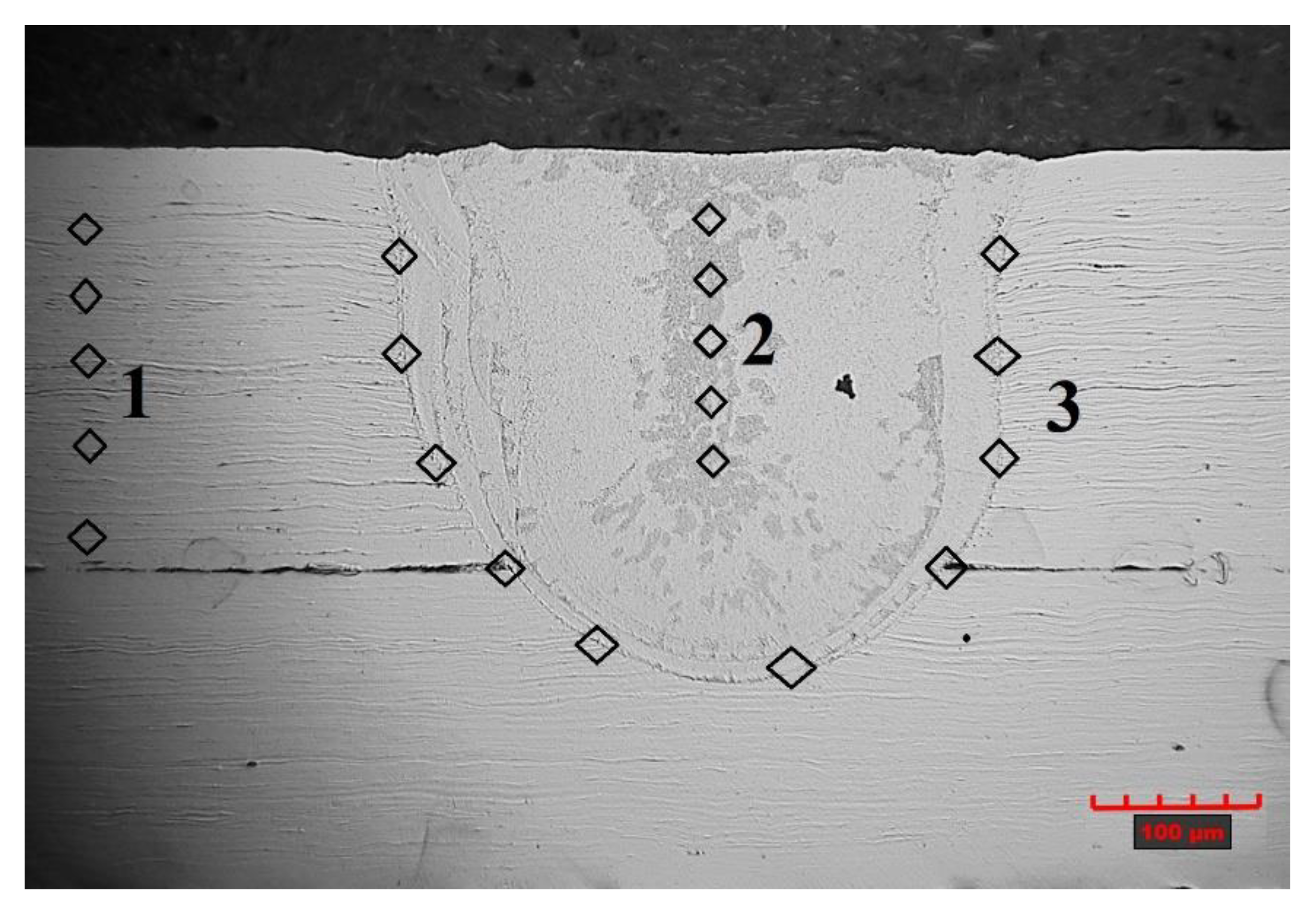

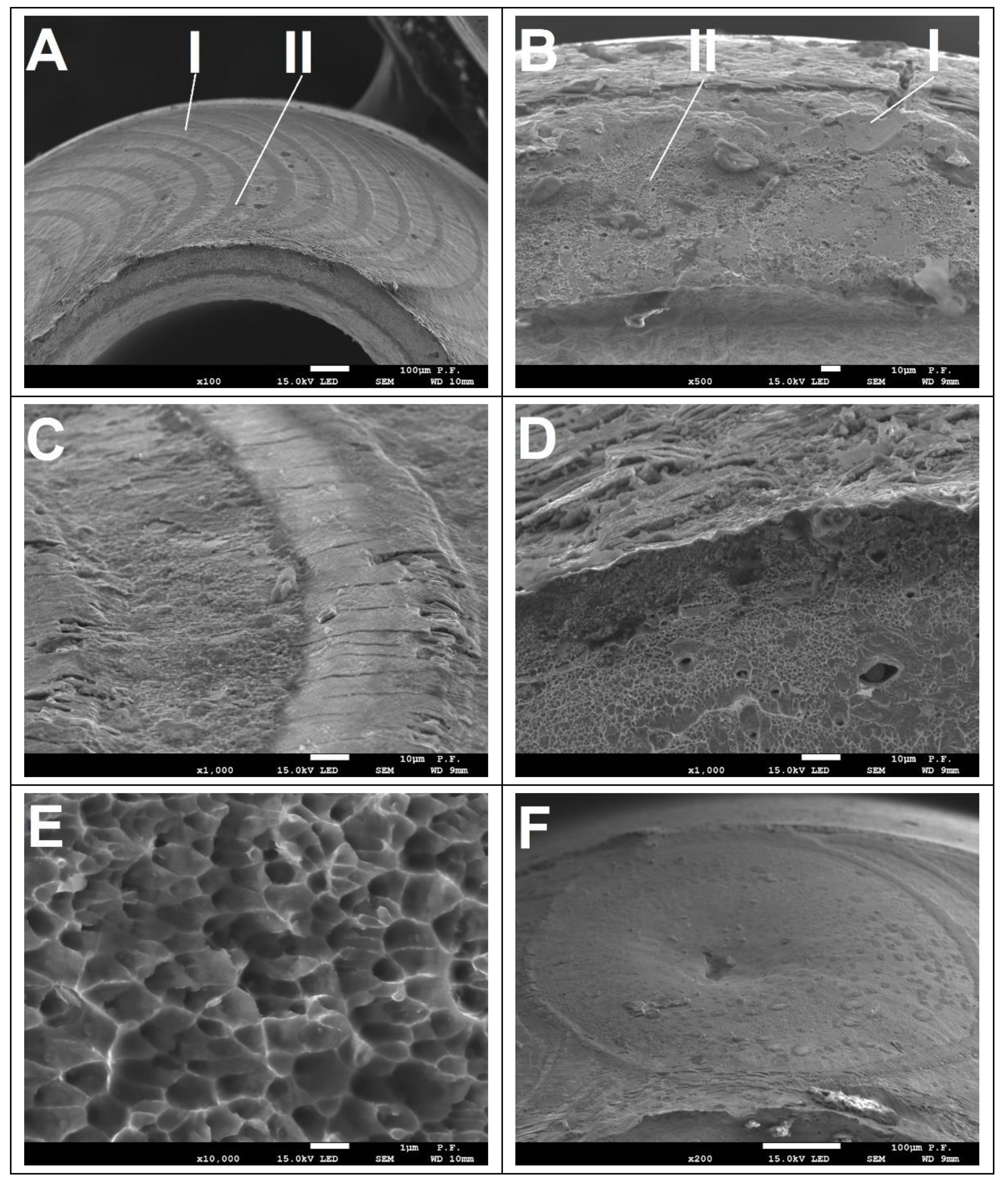

3.1. Microstructural Tests

3.2. Microhardness and Joint Strength Testing

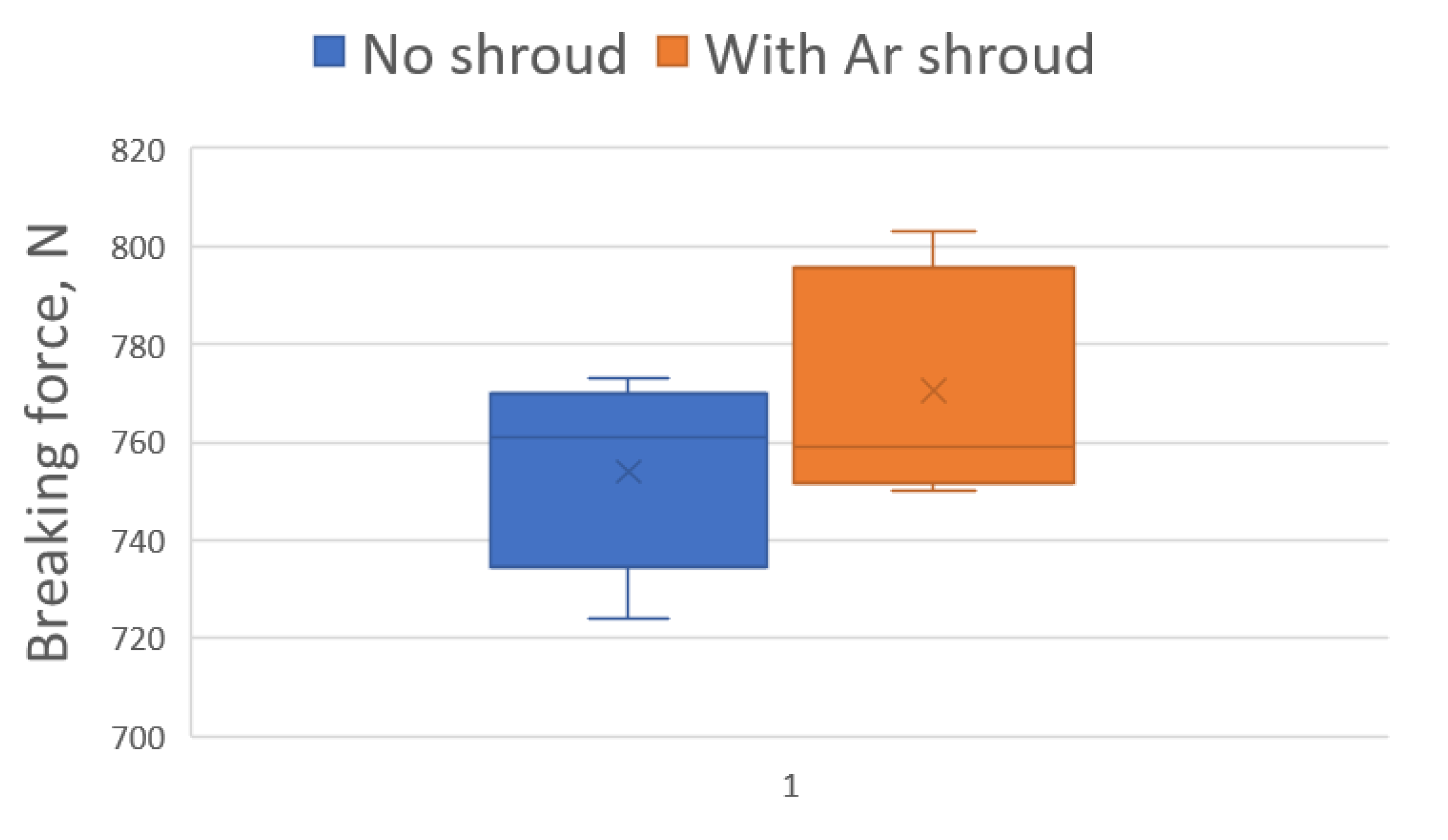

3.3. Test Results for Joint Strength

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Naeem, M. Developments in Laser Microwelding Technology Handbook of Laser Welding Technologies, 1st ed.; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Baruah, M.; Bag, S. Influence of pulsation in thermo-mechanical analysis on laser micro-welding of Ti6Al4V alloy. Opt. Laser Technol. 2017, 90, 40–51. [Google Scholar] [CrossRef]

- Chen, X.; Brox, D.; Assadsangabi, B.; Ali, M.S.M.; Takahata, K. A stainless-steel-based implantable pressure sensor chip and its integration by microwelding. Sens. Actuators A Phys. 2017, 257, 134–144. [Google Scholar] [CrossRef]

- Heinen, P.; Haeusler, A.; Mehlmann, B.; Olowinsky, A. Laser Beam Microwelding of Lithium-ion Battery Cells with Copper Connectors for Electrical Connections in Energy Storage Devices. Lasers Eng. 2017, 36, 24. [Google Scholar] [CrossRef]

- Seiler, M.; Patschger, A.; Bliedtner, J. Investigations of welding instabilities and weld seam formation during laser microwelding of ultrathin metal sheets. In Proceedings of the 34th International Congress on Applications of Lasers and Electro-Optics (ICALEO), Atlanta, GA, USA, 18–22 October 2015. J. Laser Appl. 2016, 28, 022417. [Google Scholar] [CrossRef]

- Carter, R.M.; Troughton, M.; Chen, J.; Elder, I.; Thomson, R.R.; Esser, M.J.D.; Lamb, R.A.; Hand, D.P. Towards industrial ultrafast laser microwelding: SiO_2 and BK7 to aluminum alloy. Appl. Opt. 2017, 56, 4873–4881. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Chandrasekar, S.; Wang, C. A laser microwelding method for assembly of polymer based microfluidic devices. Opt. Lasers Eng. 2015, 66, 98–104. [Google Scholar] [CrossRef]

- Mao, J.; Huang, Y.; He, P. Study on joint formation evolution in laser microwelding of Pt-10% Ir and 316 LVM SS crossed wires. In Proceedings of the International Symposium on Mechanical Engineering and Material Science (ISMEMS), Jeju Island, South Korea, 17–19 November 2016; AER-Advances in Engineering Research. Volume 93, pp. 11–16. [Google Scholar] [CrossRef][Green Version]

- Kim, S.; Park, J.; So, S.; Ahn, S.; Choi, J.; Koo, C.; Joung, Y.-H. Characteristics of an Implantable Blood Pressure Sensor Packaged by Ultrafast Laser Microwelding. Sensors 2019, 19, 1801. [Google Scholar] [CrossRef]

- Haeusler, A.; Schuermann, A.; Schoeler, C.; Olowinsky, A.; Gillner, A.; Poprawe, R. Quality improvement of copper welds by laser microwelding with the usage of spatial power modulation. J. Laser Appl. 2017, 29, 022422. [Google Scholar] [CrossRef]

- Danielewski, H.; Skrzypczyk, A.; Hebda, M.; Tofil, S.; Witkowski, G.; Długosz, P.; Nigrovič, R. Numerical and Metallurgical Analysis of Laser Welded, Sealed Lap Joints of S355J2 and 316L Steels under Different Configurations. Materials 2020, 13, 5819. [Google Scholar] [CrossRef] [PubMed]

- Saha, P.; Waghmare, D. Parametric optimization for autogenous butt laser welding of sub-millimeter thick SS 316 sheets using central composite design. Opt. Laser Technol. 2020, 122, 105833. [Google Scholar] [CrossRef]

- Wang, L.; Wei, Y.; Chen, J.; Zhao, W. Macro-micro modeling and simulation on columnar grains growth in the laser welding pool of aluminum alloy. Int. J. Heat Mass Transf. 2018, 123, 826–838. [Google Scholar] [CrossRef]

- Wang, L.; Wang, K. Investigation on microstructural patterns and hot crack in the molten pool via integrated finite-element and phase-field modeling. J. Manuf. Process. 2019, 48, 191–198. [Google Scholar] [CrossRef]

- Salleh, M.N.M.; Ishak, M.; Quazi, M.M.; Aiman, M.H. Microstructure, mechanical, and failure characteristics of laser-microwelded AZ31B Mg alloy optimized by response surface methodology. Int. J. Adv. Manuf. Technol. 2018, 99, 985–1001. [Google Scholar] [CrossRef]

- Hummel, M.; Haeusler, A.; Olowinsky, A.; Gillner, A.; Poprawe, R. Comparing 1070 nm and 515 nm Wavelength Laser Beam Sources in Terms of Efficiency for Laser Microwelding Copper. Lasers Eng. 2020, 46, 187–202. Available online: https://www.oldcitypublishing.com/journals/lie-home/lie-issue-contents/lie-volume-46-number-1-4-2020/lie-46-1-4-p-187-202/ (accessed on 20 January 2021).

- Geng, S.; Jiang, P.; Guo, L.; Gao, X.; Mi, G. Multi-scale simulation of grain/sub-grain structure evolution during solidification in laser welding of aluminum alloys. Int. J. Heat Mass Transf. 2020, 149, 119252. [Google Scholar] [CrossRef]

- Huang, S.-H.; Huang, Y.-J.; Hsieh, C.-H.; Chen, H.-Z.; Chui, H.-C. Visual-assisted laser microwelding of carbon microfiber on metal plates. Opt. Laser Technol. 2018, 108, 368–371. [Google Scholar] [CrossRef]

- Patschger, A.; Bliedtner, J. Constraints and optimization of the laser microwelding process of thin metal foils. J. Laser Appl. 2017, 29, 22408. [Google Scholar] [CrossRef]

- Okamoto, Y.; Nishi, N.; Nakashiba, S.; Sakagawa, T.; Okada, A. Smart laser micro-welding of difficult-to-weld materials for electronic industry. Laser-based Micro Nanoprocessing IX 2015, 9351, 935102. [Google Scholar] [CrossRef]

- Anming, H.; Jolanta, J.-R.; Tomokazu, S. Joining Technology Innovations at the Macro, Micro, and Nano Levels. Appl. Sci. 2019, 9, 3568. [Google Scholar] [CrossRef]

- Gao, Z.; Shao, X.; Jiang, P.; Cao, L.; Zhou, Q.; Yue, C.; Liu, Y.; Wang, C. Parameters optimization of hybrid fiber laser-arc butt welding on 316L stainless steel using Kriging model and GA. Opt. Laser Technol. 2016, 83, 153–162. [Google Scholar] [CrossRef]

- Miyamoto, I.; Kosumi, T.; Park, S.; Uragishi, H.; Watanabe, K.; Ooie, T. Applications of single-mode fiber-lasers to novel micro welding. In Proceedings of the Fifth International Symposium on Laser Precision Microfabrication, Nara, Japan, 11–14 May 2004; Volume 5662, pp. 507–514. [Google Scholar]

- Ventrella, V.A.; Berretta, J.R.; de Rossi, W. Pulsed Nd:YAG laser seam welding of AISI 316L stainless steel thin foils. J. Mater. Process. Technol. 2010, 210, 1838–1843. [Google Scholar] [CrossRef]

- Landowski, M.; Świerczyńska, A.; Rogalski, G.; Fydrych, D. Autogenous fiber laser welding of 316L austenitic and 2304 lean duplex stainless steels. Materials 2020, 13, 2930. [Google Scholar] [CrossRef]

- Lisiecki, A.; Klimpel, A. Laser welding of butt joints of austenitic stainless steel AISI 321. J. Achieve. Mater. Manufact. Eng. 2007, 25, 63–66. [Google Scholar]

- Dontu, O.; Ganatsios, S.; Alexandrescu Nicolae, D.B. Laser micro-welding of stainless steel components used in mechatronic systems. Mecatronica 2006, 40–42. [Google Scholar]

- Kumar, A.; Gupta, M.P.; Banerjee, J.; Neogy, S.; Keskar, N.; Bhatt, R.B.; Behere, P.; Biswas, D.J. Micro-Welding of Stainless Steel and Copper Foils Using a Nano -Second Pulsed Fiber Laser. Lasers Manuf. Mater. Process. 2019, 6, 158–172. [Google Scholar] [CrossRef]

- Liao, H.T.; Chen, Z.W. A study on fiber laser micro-spot welding of thin stainless steel using response surface methodology and simulated annealing approach. Int. J. Adv. Manuf. Technol. 2012, 67, 1015–1025. [Google Scholar] [CrossRef]

- Türkan, M.; Karakaş, Ö. The influence of corrosion on the mechanical behavior of AISI 316L stainless steel welds. Mechanika 2019, 25, 114–118. [Google Scholar] [CrossRef]

- Kumar, N.; Mukherjee, M.; Bandyopadhyay, A. Comparative study of pulsed Nd:YAG laser welding of AISI 304 and AISI 316 stainless steels. Opt. Laser Technol. 2017, 88, 24–39. [Google Scholar] [CrossRef]

- Chatterjee, S.; Mahapatra, S.S.; Bharadwaj, V.; Upadhyay, B.N.; Bindra, K.S.; Thomas, J. Parametric appraisal of mechanical and metallurgical behavior of butt welded joints using pulsed Nd:YAG laser on thin sheets of AISI 316. Opt. Laser Technol. 2019, 117, 186–199. [Google Scholar] [CrossRef]

- Sathiya, P.; Abdul Jaleel, M.Y. Measurement of the bead profile and microstructural characterization of a CO2 laser welded AISI 904 L super austenitic stainless steel. Opt. Laser Technol. 2010, 42, 960–968. [Google Scholar] [CrossRef]

- Anawa, E.M.; Olabi, A.G. Using Taguchi method to optimize welding pool of dissimilar laser-welded components. Opt. Laser Technol. 2008, 40, 379–388. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y.; Li, X.; Wang, W.; Yang, X. Influence of assembly gap size on the structure and properties of SUS301L stainless steel laser welded lap joint. Materials 2021, 14, 996. [Google Scholar] [CrossRef] [PubMed]

| %C | %Si | %Mn | %P | %S | %Cr | %Ni | %Mo | %N |

|---|---|---|---|---|---|---|---|---|

| 0.009 | 0.485 | 1.615 | 0.0307 | 0.0041 | 16.763 | 11.208 | 2.041 | 0.0619 |

| Weld No. | Power Setting % | Pulse Energy (J) | Pulse Power (kW) | Welding Linear Energy (J/mm]) |

|---|---|---|---|---|

| 1 | 7 | 1.36 | 0.34 | 8.69 |

| 2 | 8 | 1.59 | 0.4 | 10.13 |

| 3 | 9 | 1.82 | 0.45 | 11.58 |

| 4 | 10 | 2.05 | 0.51 | 13.03 |

| 5 | 11 | 2.27 | 0.57 | 14.47 |

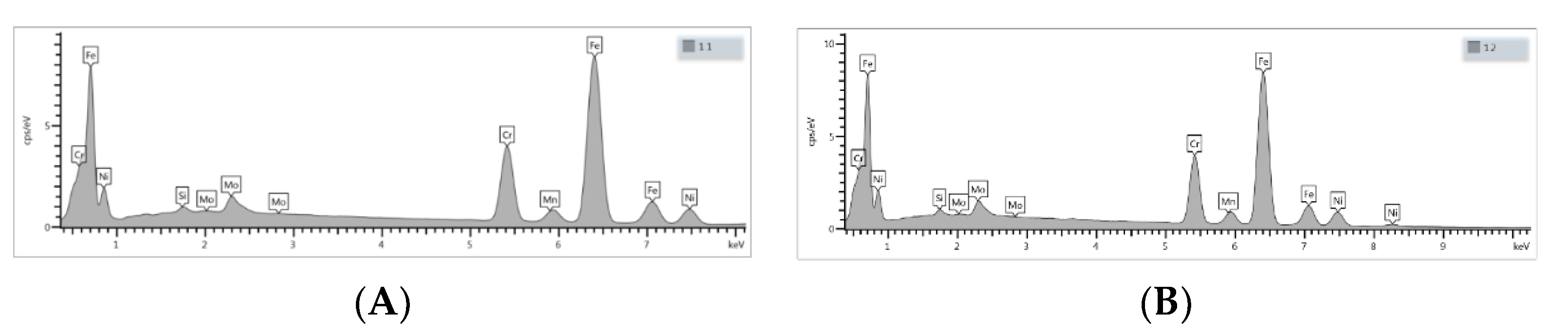

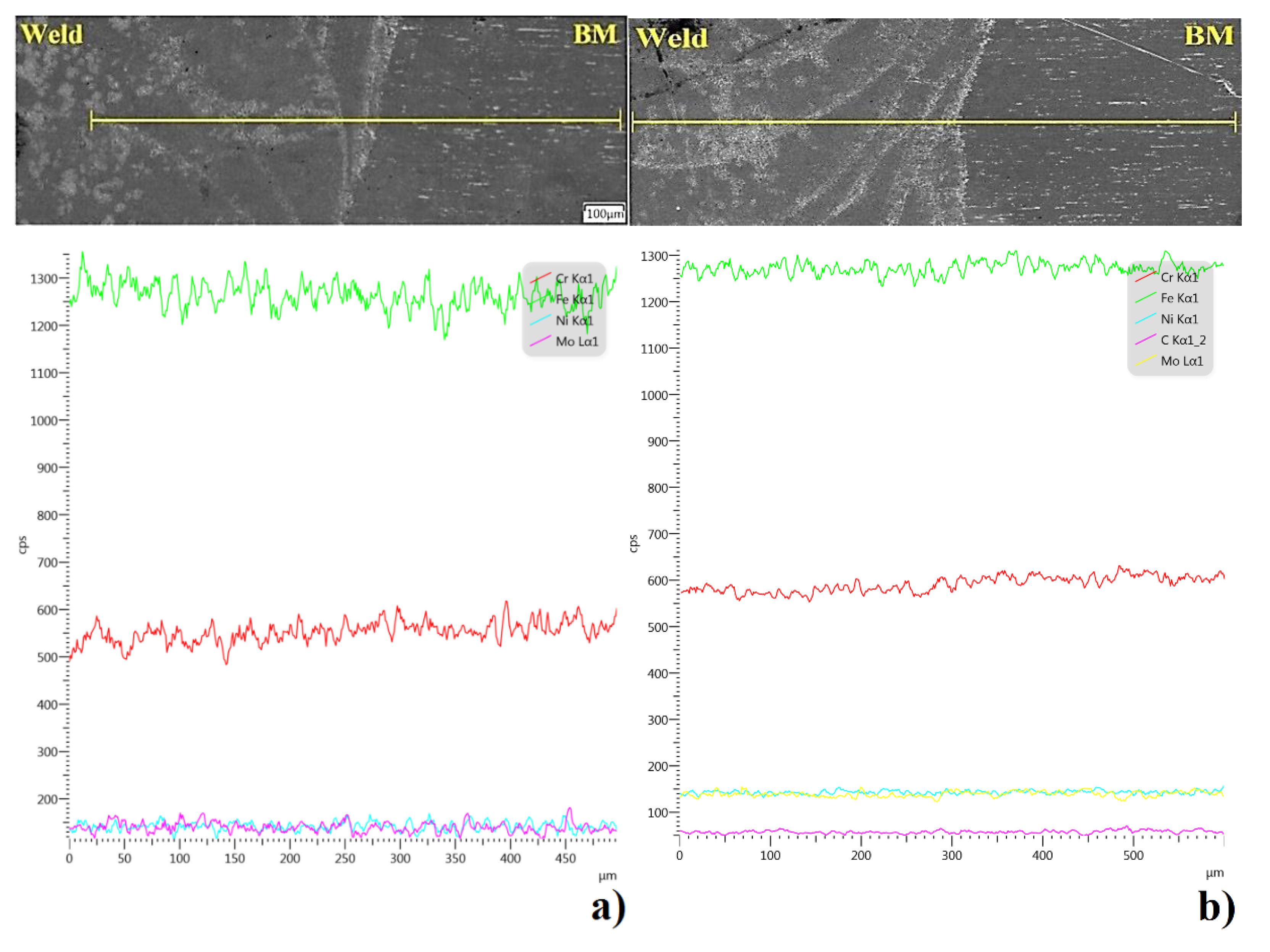

| Welding Atmosphere | Measurement Point | Si % | Mn % | Cr % | Ni % | Mo % |

|---|---|---|---|---|---|---|

| in air | 1 1 | 0.31 | 1.06 | 16.75 | 10.26 | 2.54 |

| 1 2 | 0.32 | 1.07 | 16.76 | 10.49 | 2.42 | |

| in argon | 11 | 0.39 | 1.25 | 16.78 | 10.40 | 2.45 |

| 12 | 0.26 | 0.86 | 16.9 | 10.58 | 2.15 |

| Sample No | Sisma No Shroud (N) | Sisma With Ar Shroud (N) |

|---|---|---|

| Sample 1 | 773 | 759 |

| Sample 2 | 767 | 788 |

| Sample 3 | 724 | 753 |

| Sample 4 | 761 | 803 |

| Sample 5 | 745 | 750 |

| Mean value (N) | 754 | 770.6 |

| Standard deviation (N) | 19.74 | 23.56 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tofil, S.; Danielewski, H.; Witkowski, G.; Mulczyk, K.; Antoszewski, B. Technology and Properties of Peripheral Laser-Welded Micro-Joints. Materials 2021, 14, 3213. https://doi.org/10.3390/ma14123213

Tofil S, Danielewski H, Witkowski G, Mulczyk K, Antoszewski B. Technology and Properties of Peripheral Laser-Welded Micro-Joints. Materials. 2021; 14(12):3213. https://doi.org/10.3390/ma14123213

Chicago/Turabian StyleTofil, Szymon, Hubert Danielewski, Grzegorz Witkowski, Krystian Mulczyk, and Bogdan Antoszewski. 2021. "Technology and Properties of Peripheral Laser-Welded Micro-Joints" Materials 14, no. 12: 3213. https://doi.org/10.3390/ma14123213

APA StyleTofil, S., Danielewski, H., Witkowski, G., Mulczyk, K., & Antoszewski, B. (2021). Technology and Properties of Peripheral Laser-Welded Micro-Joints. Materials, 14(12), 3213. https://doi.org/10.3390/ma14123213