2.1. Materials and Mix Proportions

Structural concretes are designed for structures and elements for building or for public works, usually designed for compressive stresses of 25 MPa at 28 days [

8]. It is made up by of natural siliceous aggregates, Portland cement and chemical additives such as fluidizers. Within the scope of this study, we focus on evaluating the use of wastes from crushing of this type of concrete in selective demolitions processed at the CDW treatment plant in Calvarrasa de Abajo (Salamanca, Spain) as recycled aggregates for the manufacture of non-structural concrete. More specifically, this study evaluates two potential types of recycled concrete for non-structural applications (borders and sidewalks): (i) a concrete coming from Construction and Demolition Waste from Recycled Concrete (CDWRCon) and; (ii) a concrete made up by the Construction and Demolition Waste from Recycled Ceramic (CDWRCer). In both cases, cement, water and additive were mixed.

On the one hand, CDWRCon is obtained from concrete, cement mortar and prefabricated concrete parts, including untreated aggregates and natural stone aggregates treated with hydraulic binders and other fractions (content < 0.1%) of floating material, cohesive materials (clay and soil), metals (ferrous and non-ferrous), wood, gypsum and non-floating plastics and rubber. Meanwhile CDWRCer is obtained from concrete, including concrete products, cement mortar, prefabricated concrete parts and ceramic materials, showing a continuous granulometry with concrete and ceramic material aggregates. The CDWRCer components are the same as CDWRCon with the addition of other materials as parts of clay (bricks and tiles), calcium silicate masonry, non-floating aerated concrete and glass.

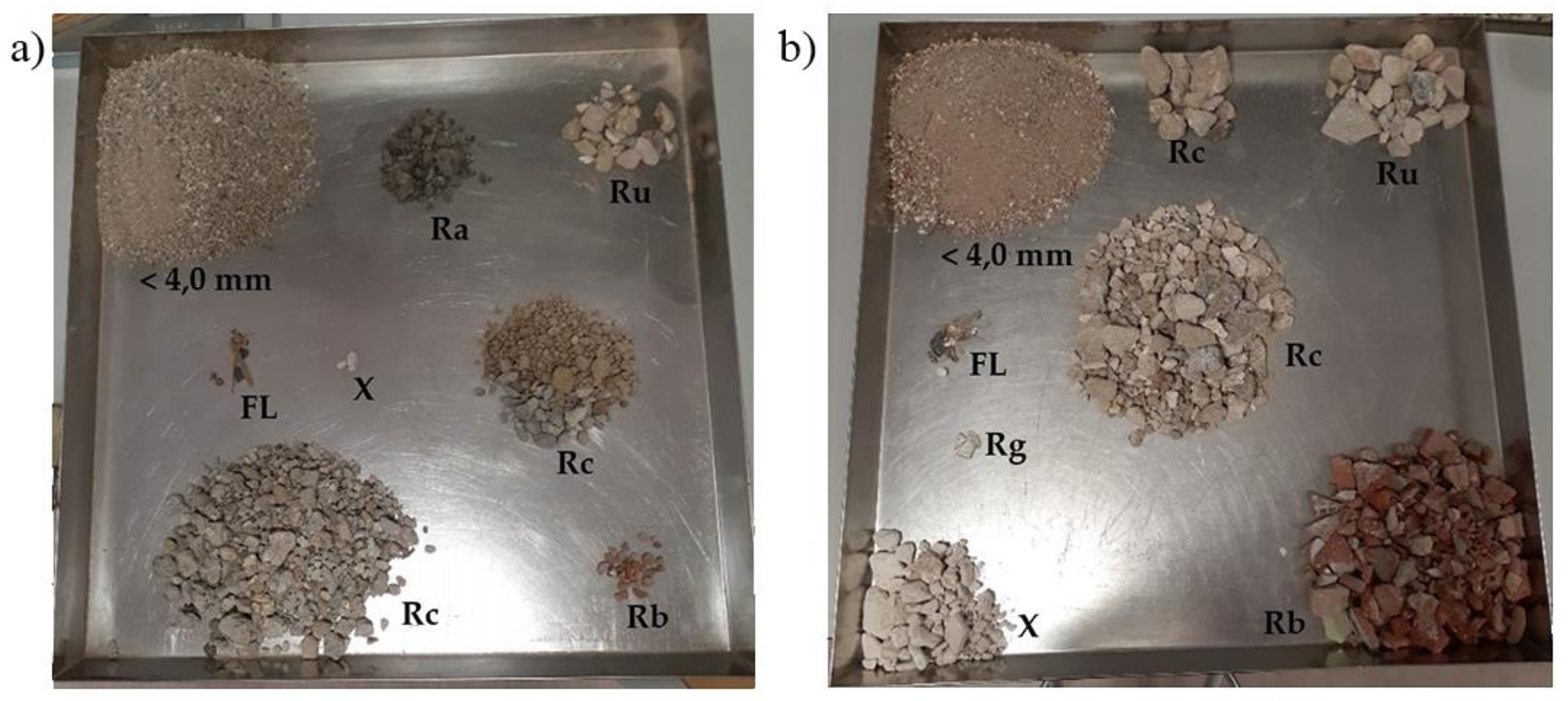

According to the categories established in the UNE-EN 13242 standard [

38], the CDWRCon aggregates are classified as

Rc80,

Rcu90,

Rb10−,

Ra10−,

X1−,

FL5− and the CDWRCer aggregates are classified as

Rc40,

Rcu50,

Rb50−,

Rg2−,

FL5− (

Table 1) (

Figure 1), where:

Rc = Concrete and mortar (natural aggregates with cement mortar attached).

Ru = Unbound aggregates (natural aggregates without cement mortar attached).

Rb = Ceramics (bricks, tiles, stoneware and sanitary ware).

Ra = Asphalt.

Rg = Glass.

FL = Floating materials.

X = Other impurities (wood, paper, metals, plastic, etc.).

It is noteworthy that the UNE-EN 13242 [

38] standard establishes a maximum of 1% for class

X, which includes cohesive materials (clay and soil), metals (ferrous and non-ferrous), wood, gypsum, non-floating plastics and rubber. The CDWRCer has an amount of gypsum that represents 5.2% in the general classification of the components, not corresponding to the class established by the standard for this type of material. The gypsum is prejudicial to concrete due to its composition of sulphate and, therefore, it is necessary to consider a sulphate resistant cement.

Table 2 shows the particle size distribution. In CDWRCon, values of uniformity coefficient,

Cu = 75.0, and curvature coefficient,

Cc = 2.1, were obtained. The high value of the uniformity coefficient shows the high size variation obtained in the unclassified crushing. The curvature coefficient, 1.0 ≤

Cc ≤ 3.0, defines the CDWRCon and the CDWRCer as well-graded and with a low compressibility, a high compactness and correspondingly suitable for use on construction sites.

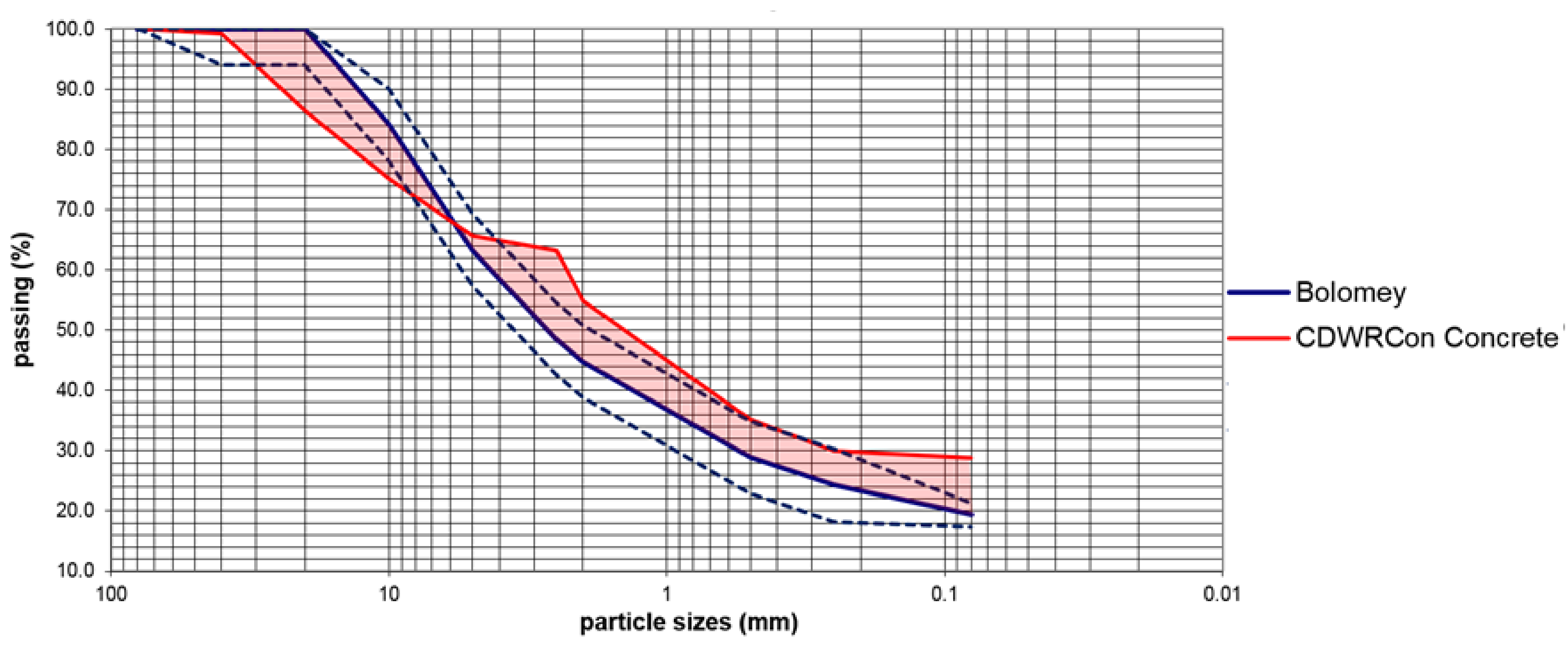

Additionally, a granulometric study was carried out. In this case it was compared the granulometric curves of both concretes (CDWRCon and CDWRCer) with respect to the Bolomey dosing (reference curve) in accordance to the standard UNE EN 933-1 [

39]. This reference curve, which is considered as an improvement of the Fuller law, is adequate for mass concrete (i.e., non-structural concrete), where the resistance is not the determining characteristic.

The results of this comparison are shown in

Figure 2. It is worth mentioning that the granulometric curve of the CDWRCon concrete includes the cement used as an aggregate (20% of the total volume of aggregates). The Bolomey curve was estimated by considering a wet mix macadam with the following proportions [

40]: (i) ±2% for the 0.063 mm; and (ii) ± 6% for the rest. As this research aims to investigate the manufacture of a sustainable concrete, promoting the use of recycled aggregates replacing natural aggregates in concrete, the continuous granulometry obtained in the crushing of the CDWs has been used in the production of the concrete. Thus, better particle size adjustments have been avoided by classifying it into different fractions, as this would be a commercial disadvantage for its implementation in practice. In the CDWRCon the biggest deviations are in the 20 mm sieve with 13.6% above and 14.7% on the 2.5 mm sieve. There is a little standard error of 2.5% below the medium curve. This curve has the typical form of crushing siliceous aggregates, with a deficit of intermediate sizes in the sand fraction, between the #5–2.5 mm sieves. Even with the logical limitations associated with the heterogeneity of the recycled aggregates, the theoretical dosage curve was close to the bottom of the sieve stack for sizes larger than 6 mm in the case of CDWRCon, while the smaller sizes are above the average stack. It can be seen how the areas between the medium spindle and the particle size curve of the CDWRCon are partially compensated, below the medium spindle in the larger sieves and above in the smaller ones (

Figure 2).

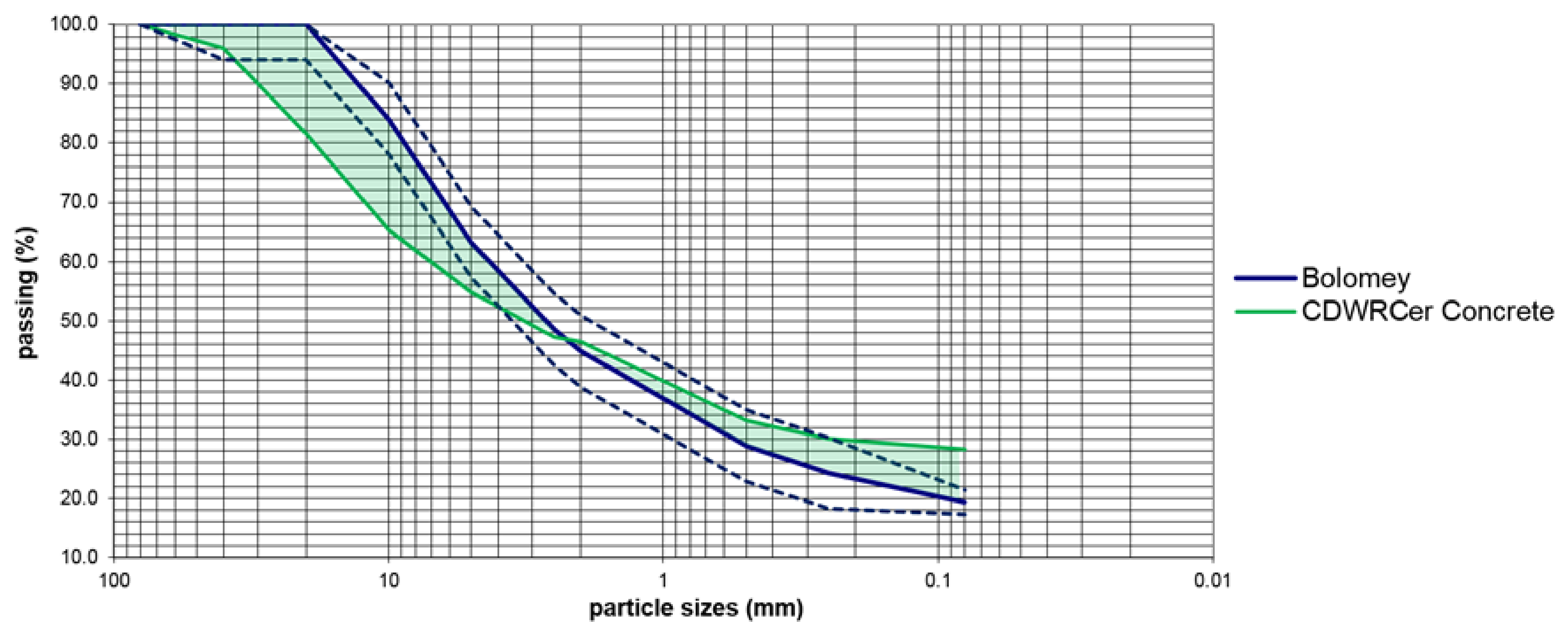

Identically, the granulometric curves of the CDWRCer and Bolomey dosing are shown in

Figure 3. In this case, the biggest deviations are in the 10 mm sieve with 18.9% above and 9.0% on the 0.08 mm sieve. There is a small standard error of 3.1% above the medium curve. Even with the logical limitations associated with the heterogeneity of the recycled aggregates, the theoretical dosage curve was close to the bottom of the sieve stack for sizes larger than 2.5 mm in the case of CDWRCon, while the smaller sizes are above the average stack. It can be seen how the areas between the medium spindle and the particle size curve of the CDWRCon are partially compensated, below the medium spindle in the larger sieves and above in the smaller ones.

From the results obtained it is possible to conclude that both groups have the right proportions of sand and gravel to make the necessary concrete for non-structural applications.

Table 3 shows the main physical and chemical parameters of CDWRCon and CDWRCer.

where:

SE4 = Sand Equivalent, UNE-EN 933-8 [

41].

LA = Los Angeles coefficient, UNE-EN 1097-2 [

42].

AM = Methylene blue (UNE EN 933-9) [

43].

OM = Organic Matter content, UNE 103204 [

44].

SS = Soluble Salt content, UNE 103205 [

45].

WAf = Water Absorption Fine aggregate, UNE-EN 1097-6 [

46].

WAc = Water Absorption Coarse aggregate, UNE-EN 1097-6 [

46].

SO3 = acid soluble sulphate content, UNE-EN 1744-1 [

47].

S = sulfur compounds total content, UNE-EN 1744-1 [

47].

mlpc = light contaminant content, UNE-EN 1744-1 [

47].

Humus = light organic contaminant in humus content, UNE-EN 1744-1 [

47].

The quality of the fines, expressed as SE4 sand equivalent, gives a value of 55.9 in CDWRCon. This value is lower than the common values of natural aggregates. The sand equivalent for CDWRCer is even lower than the CDWRCon with a value of 45.3. This difference is motivated by the existence of parts of clays (bricks and tiles), as well as calcium silicate masonry elements that reduce the sand lecture and SE4 value. Since non-structural recycled concretes (NSRC) are not subjected to any specific exposure class, the aggregates shall be accepted if satisfy the requirement AM ≤ 0.3 f/100.

Fragmentation resistance offers an LA coefficient of 43.0 for CDWRCon. The resistance to fragmentation in CDWRCer, with LA = 52.0, is lower than CDWRCon. This difference is motivated by the presence of bricks, tiles and calcium silicate masonry. So, the coarse aggregates have an abrasion resistance between 40 and 55, being possible to make non-structural concrete with a minimum characteristic strength of 15 N/mm2.

The organic matter test provided a 0.14% value in CDWRCon. The content of soluble salts dissolved in distilled water for CDWRCon was 1.1%. The CDW has a high-water absorption coefficient, higher than natural aggregates. In the CDWRCon, the high absorption was associated with the porosity of the concrete. The water absorption coefficients are bigger in CDWRCer. In the coarse fraction, the absorption coefficient was 6.2% for CDWRCon and 10.7% for CDWRCer. This difference is associated with the absorption of clay materials, bricks and tiles. The fine fractions have absorption coefficients similar for both materials.

According to UNE-EN 13242 standard [

38], the CDWRCon corresponds to the

AS0.8 class of acid soluble sulphate. The CDWRCer presents a greater content of these parameters, relating to the declared classes (

ASDeclared and

SDeclared), with a content of 2.1 and 1.2 to acid soluble sulphate and of sulphur compounds, respectively.

The blinder used for manufacturing the concrete was a cement type BL II/B-LL 42,5 R. This cement has the following components: (i) a Clinker content comprised between 65–79%; (ii) a Limestone content of 21–35%; (iii) a Chloride content: ≤0.10; (iv) a Sulphate content: ≤4.0; and (v) a soluble toilet chromium VI content ≤ 0.0002%. It has a beginning setting of: ≥60 min and an end setting of: ≤720 min. The expansion is less than 10 mm. Resistance at 2 days: ≥20 MPa and resistance at 28 days in the interval 42.5 ≤ R ≤ 62.5 MPa. As an additional feature looking for the best termination, a white cement has been chosen, with a whiteness content ≥85%.

2.3. Predictive Modelling Strategy

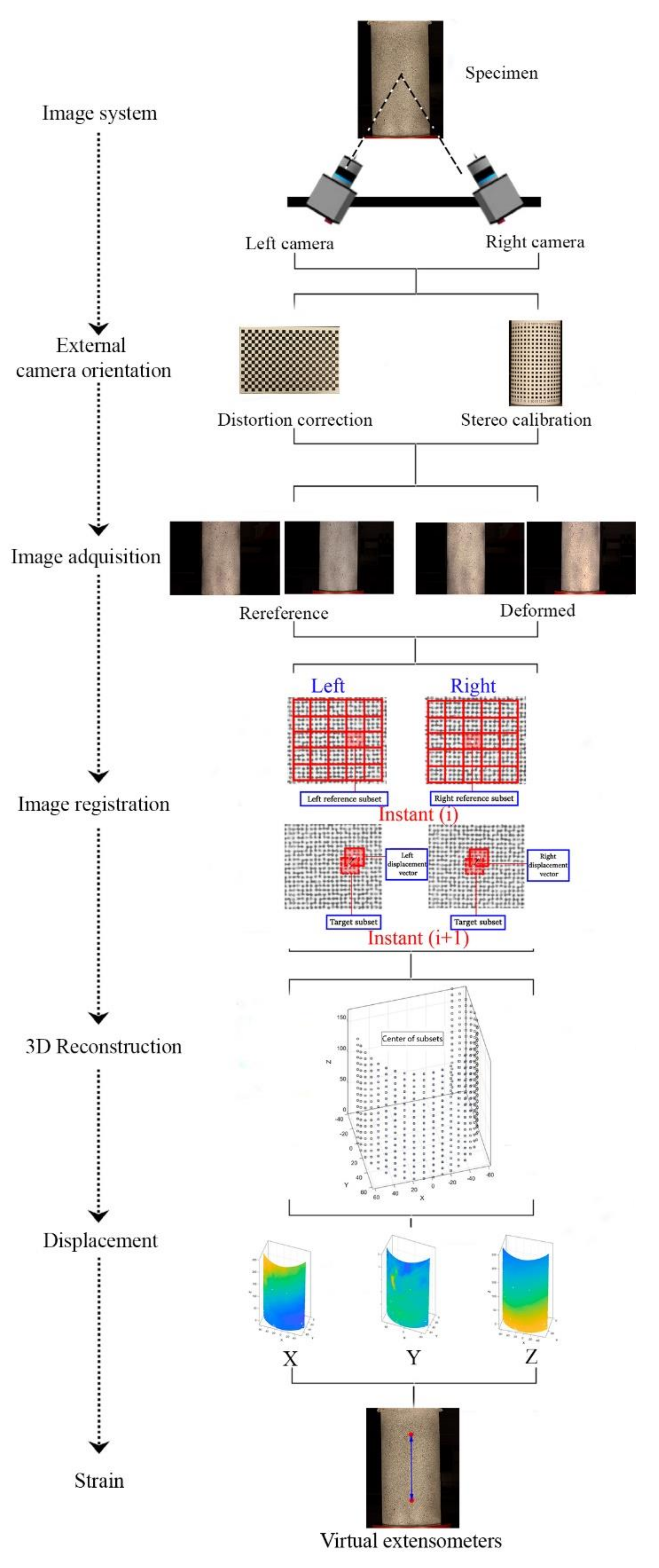

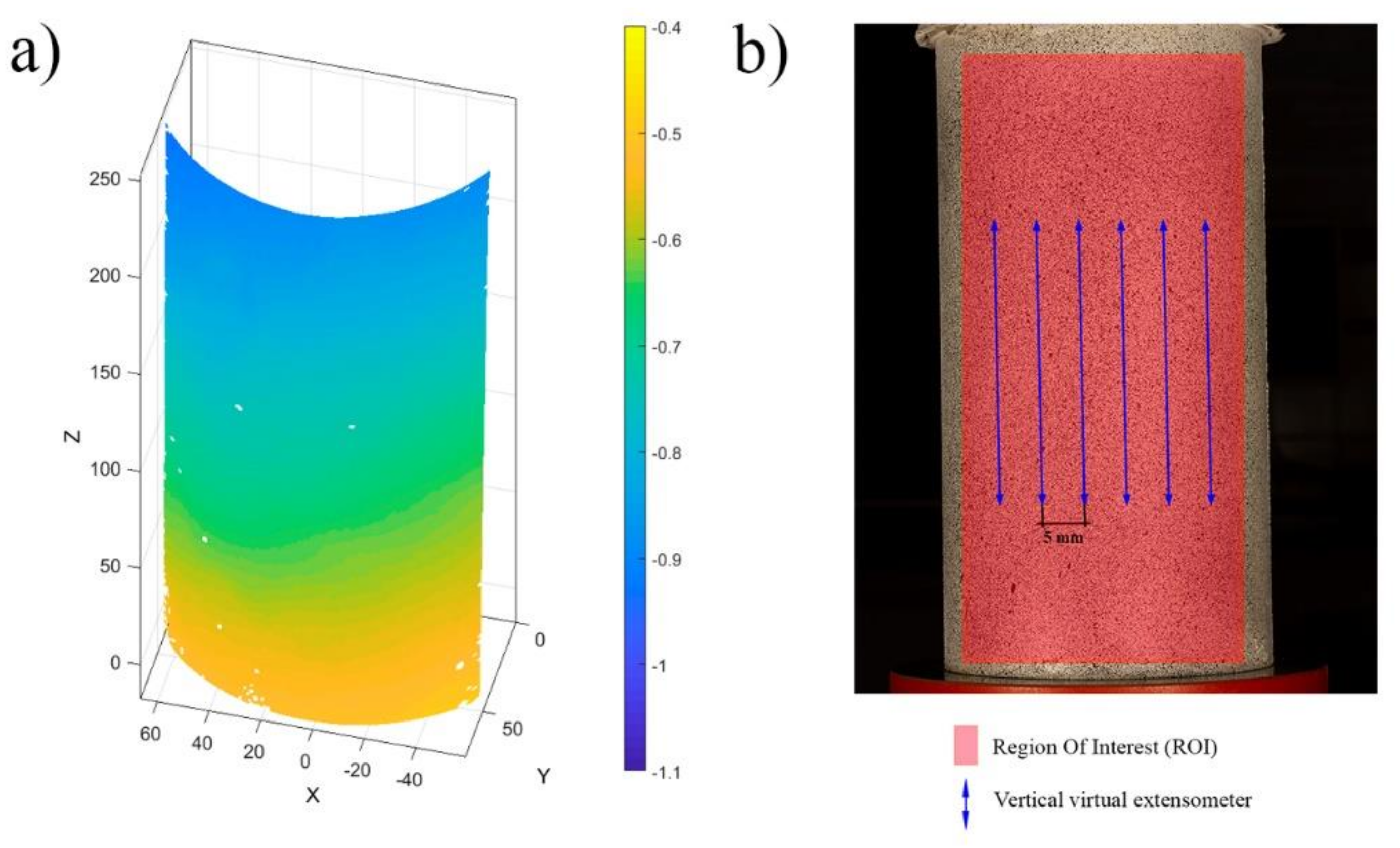

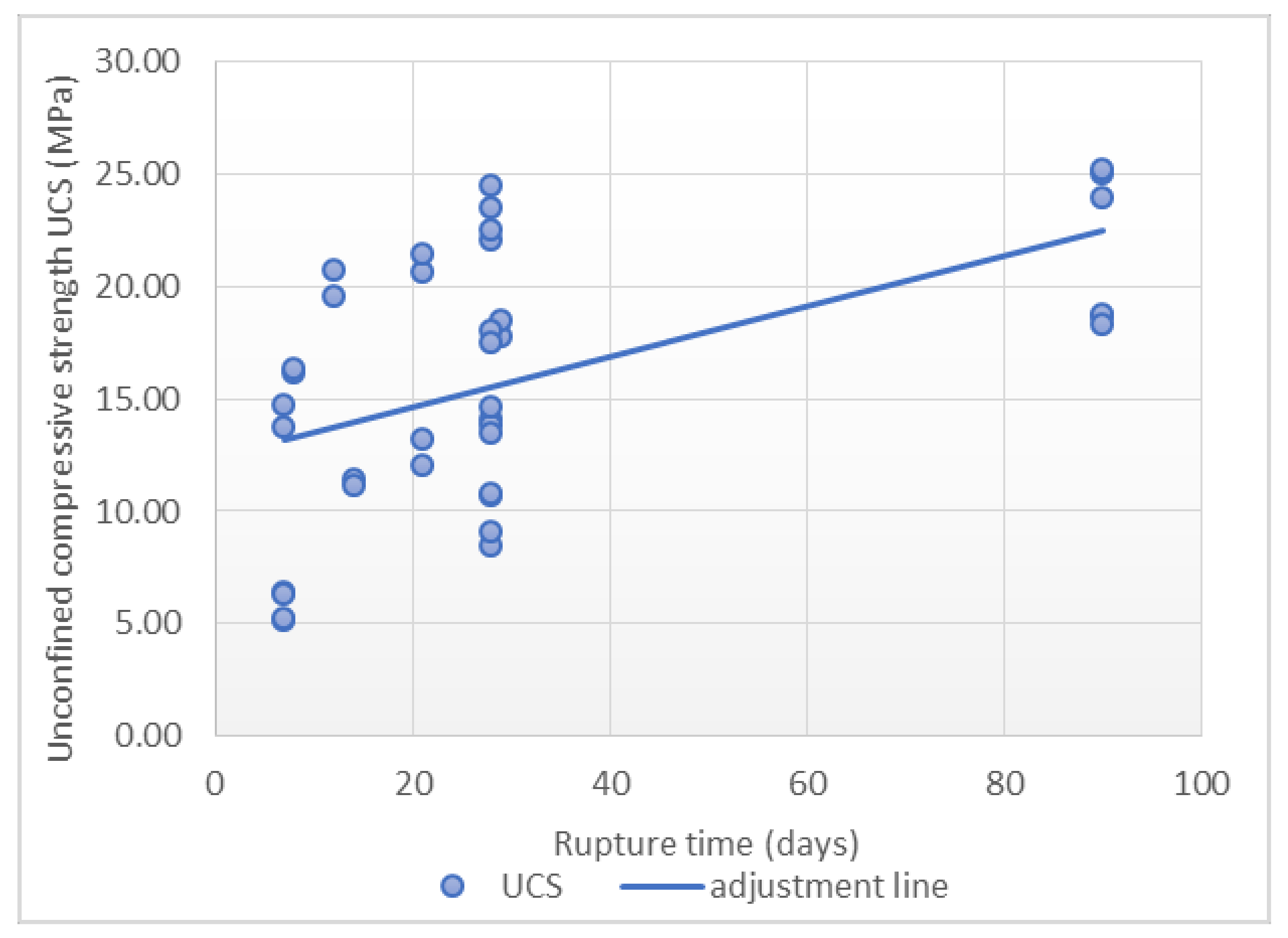

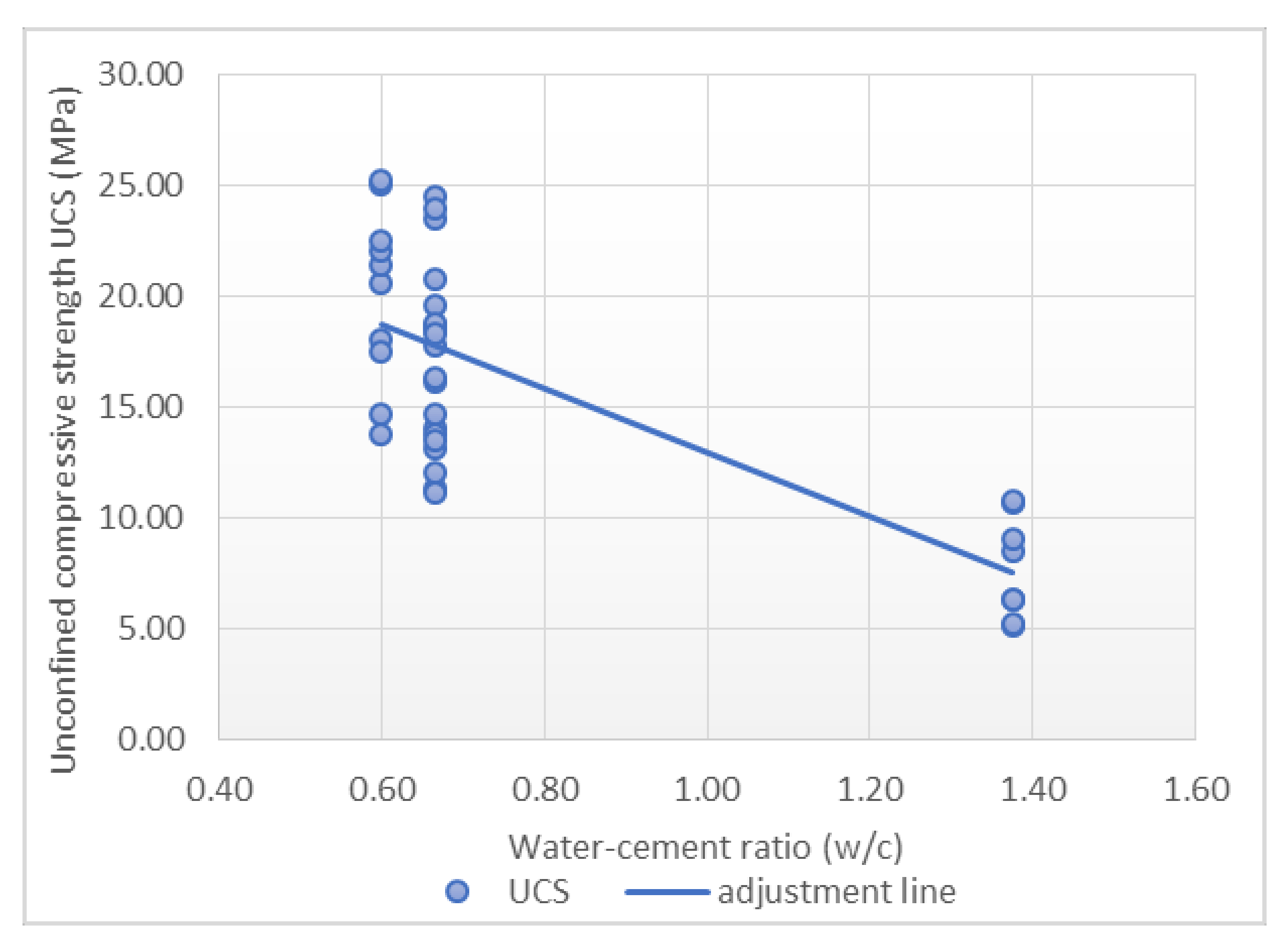

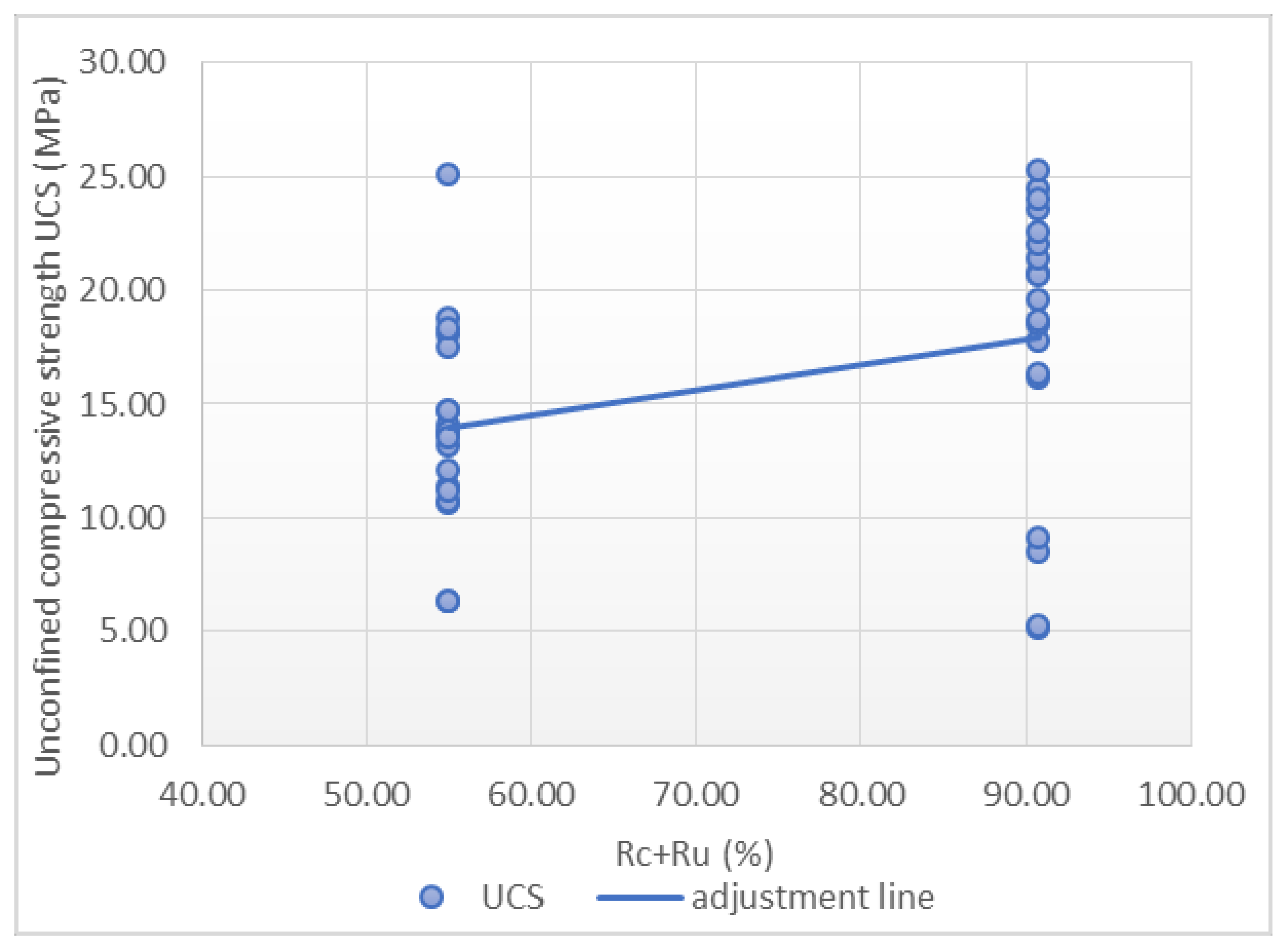

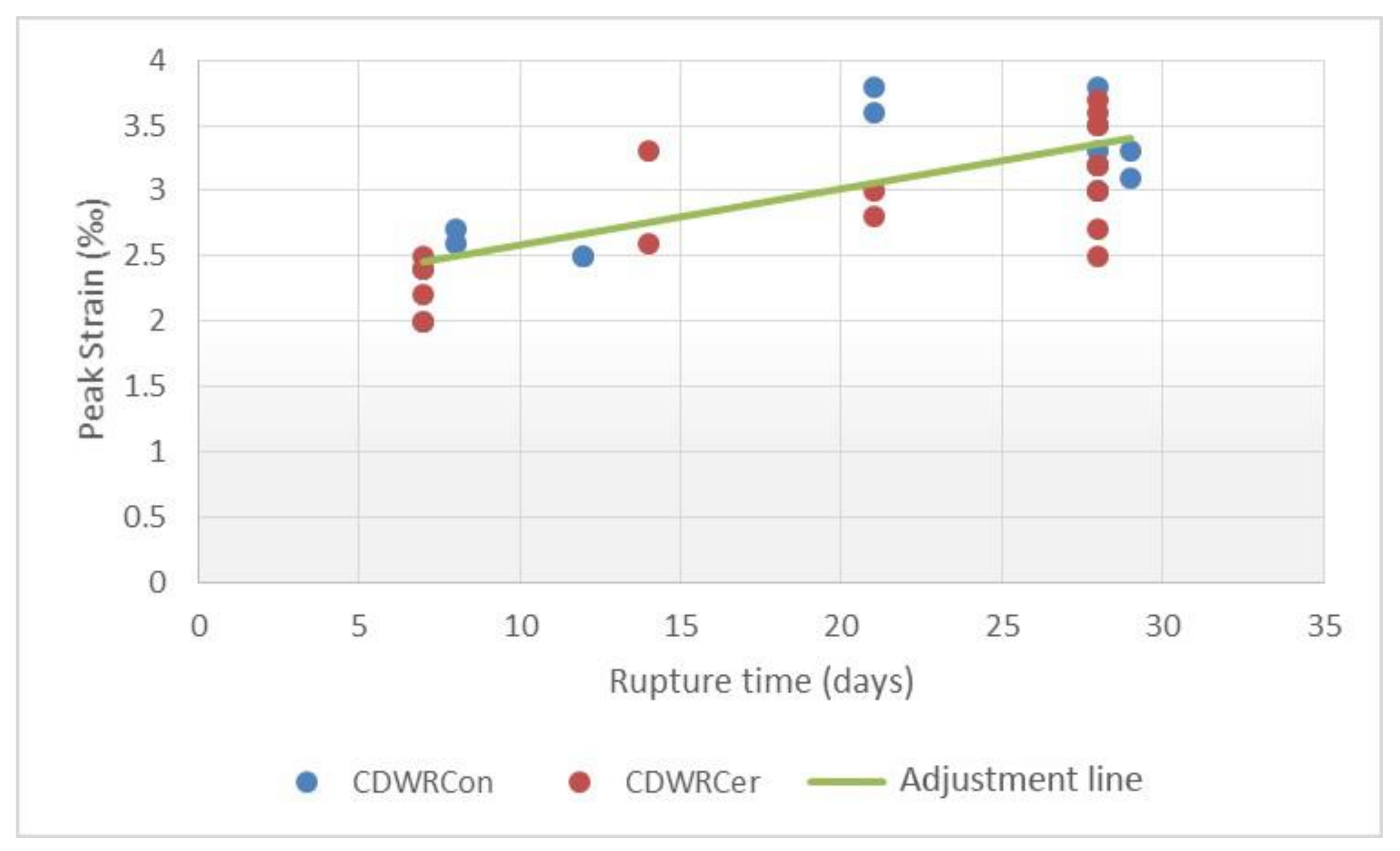

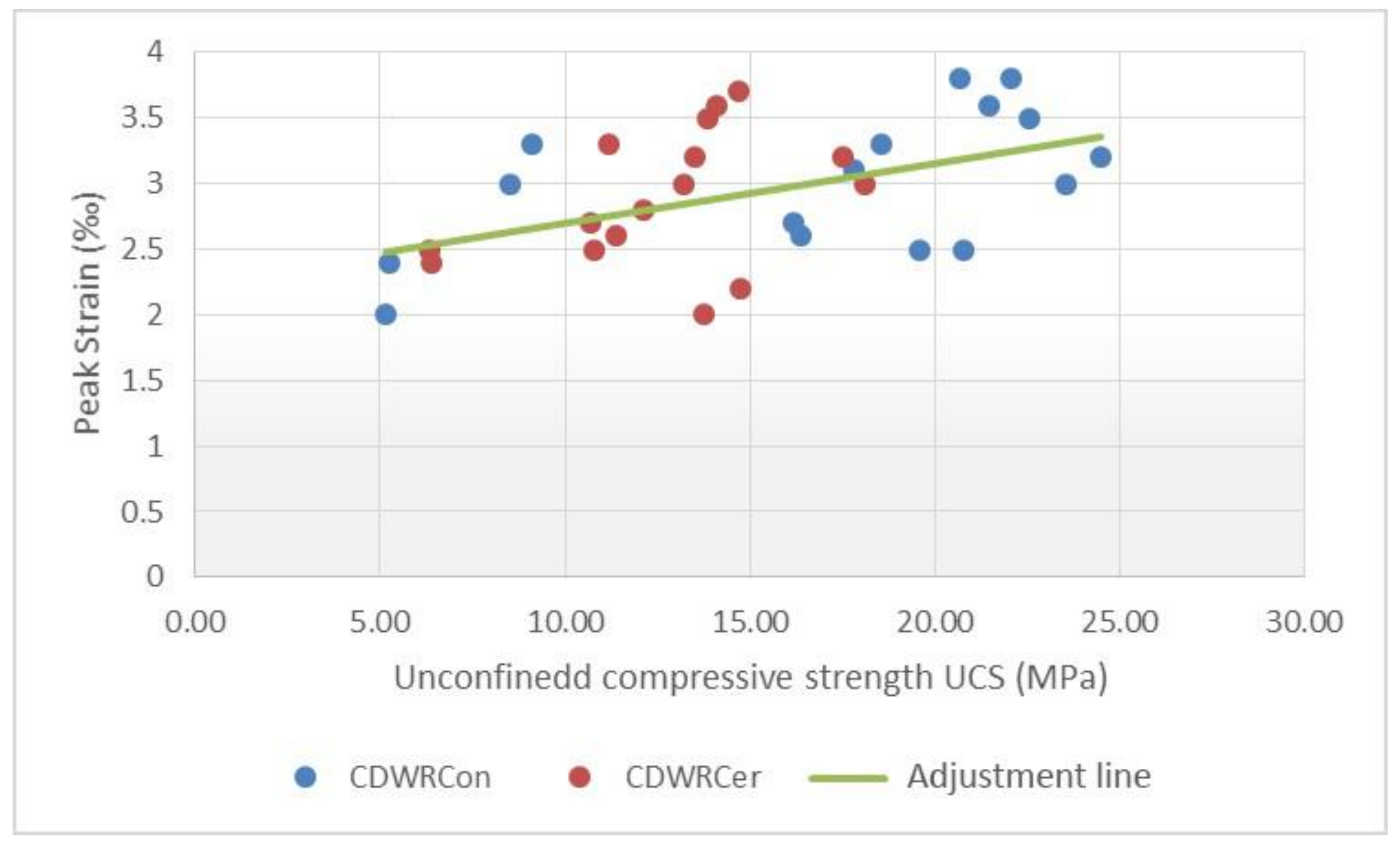

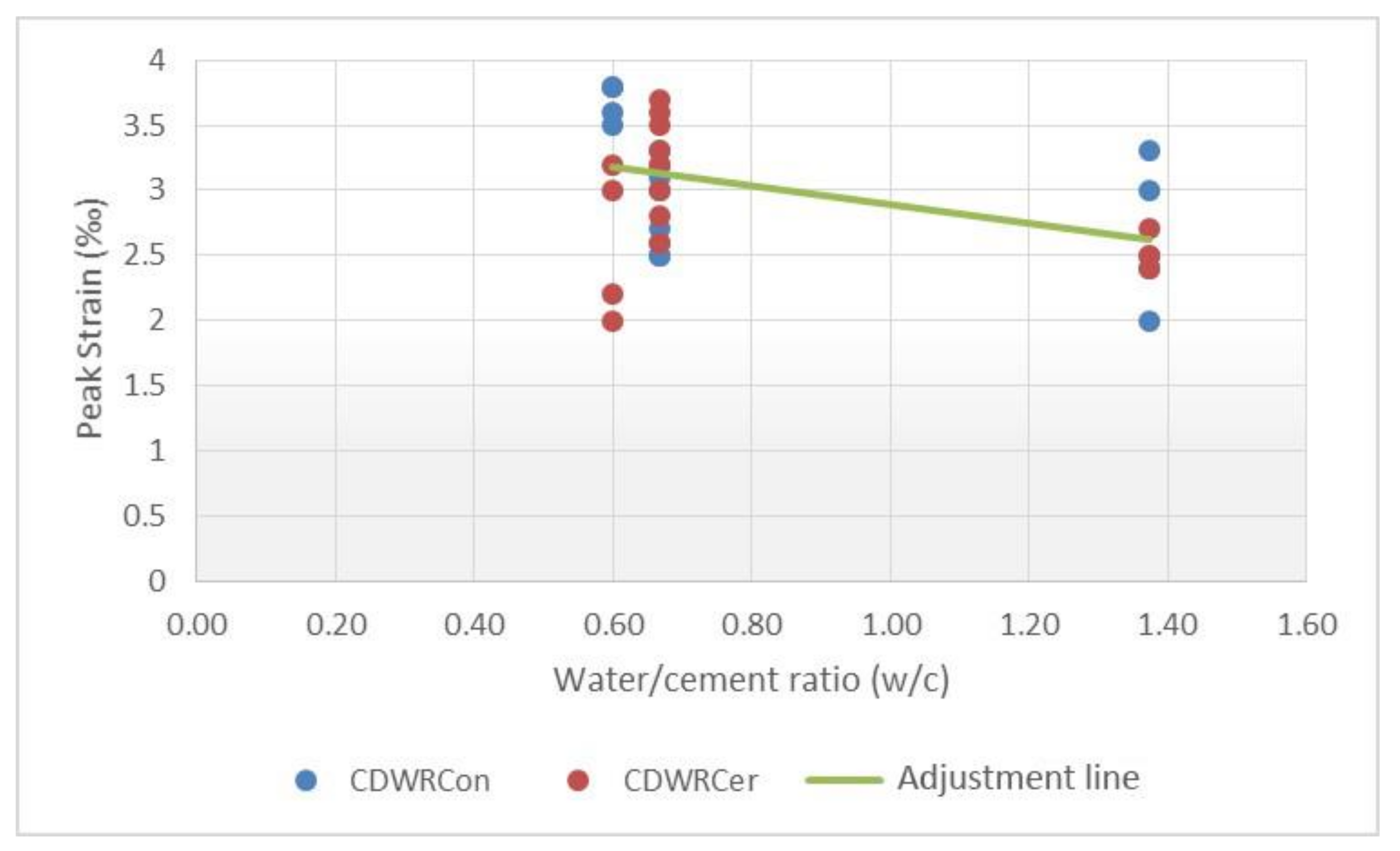

This section describes the strategy used for fitting both predictive models: (i) the predictive model for the unconfined compressive strength (UCS); and (ii) the predictive model for the maximum strain. As stated in the Introduction, the DIC approach is an added value in terms of the possibility of analysing the heterogeneous behaviour of the material and studying the maximum strains in the closest area to failure. This advantage allows us to establish a model to predict peak strain more precisely from the compressive strength of the concrete studied.

On the one hand, different models have been proposed for predicting the compressive strength [

21,

22,

23] for different types and mix proportions of conventional and recycled concrete. However, the total replacement of coarse and fine aggregates represents a challenge that has not been addressed in the extensive bibliography and that aims to be solved with the predictive models proposed in this work.

Concerning the strain predictions, some design codes assumed a constant value of 0.002, meanwhile other models directly relate compressive strength with peak strain, such as the one provided by González-Fonteboa et al. [

25] (Equation (5)), which has been established based on Eurocode 2 [

24], considering the percentage of substitution of coarse aggregates for recycled aggregates:

where

εc1 is the peak strain;

fcm is the compressive strength at 28 days; and

%RCA is the percentage of replacement with recycled coarse aggregates.

However, the strain at compressive strength depends on other variables that do not take into account models, such as mix composition, shape and size of specimen or age of curing [

56]. The difference in the properties of the aggregates can be decisive in the final behaviour of the recycled concretes, so there are prediction models that incorporate other variables related to the properties of the aggregates, such as the mortar content, volume, density crushing strength and shape index [

23]. In this sense, the properties with the greatest influence on the final result will be studied to incorporate them into the models.

2.3.1. Model Fitting

The model fitting strategy used was the Multiple Linear Regression (MLR) [

57]. This fitting strategy allows us to predict the UCS and the maximum strain of the concretes by means of different inputs, such as the mix proportions and the specific characteristics of the concrete. This regression model was complemented by a variable transformation, which allows us to study the input-output relation from a non-linear perspective.

Complementary to both regression strategies, several statistical analyses were carried out with the aim of evaluating the statistical significance of the inputs. These tests were: (i) the analysis of variance (ANOVA) test, (ii) the Levene´s test; and (iii) t-Student test.

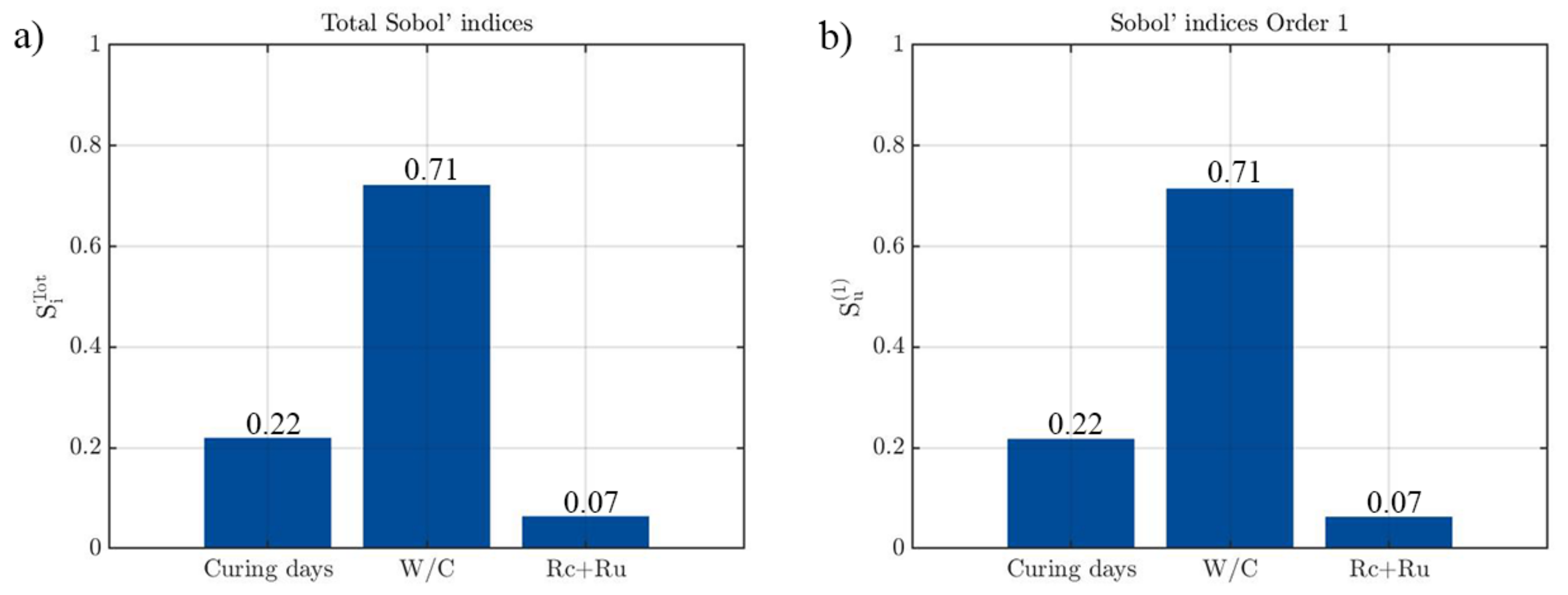

2.3.2. Sensitivity Analysis

The mathematical model can be finally expressed as a relationship in which there are three inputs bounded by the experimental data, which allows us to obtain a prediction of the final output value. According to this, a good practice compromises the analysis of the influence of each input in the final output. From the present study, it was decided to carry out a sensitivity analysis based on the Monte Carlo simulation (MCS). This method allows us to generate equiprobable situations, which could be considered as suitable sampling points for a subsequent sensitivity analysis. Within this context, one of the most used strategies to carry out sensitivity analysis is the estimation of the Sobol’indices [

58]. These indices assume that the variance of the model (output) can be described as a sum of the variances of the inputs (Equation (6)). The normalized version of each variance with respect to the total one allows us to obtain de Sobol’indices with different orders (from 1 to 2

n−1) (Equation (7)). The sum of these indices is the total Sobol’ index whose value is equal to 1.

where

V(Y) is the variance of the model;

Vi = V(E(Y|Xi)) is the first order partial variance;

Vij = V(E(Y|Xi,Xj)) is the second order partial variance, etc.

where

Si is the first order Sobol’ index and

Sij is the second-order Sobol’indices.