Structure and Properties of Heat-Resistant Alloys NiAl–Cr–Co–X (X = La, Mo, Zr, Ta, Re) and Fabrication of Powders for Additive Manufacturing

Abstract

1. Introduction

- (I)

- synthesizing the alloy from oxide raw materials by centrifugal SHS casting, vacuum induction melting (VIM) of billets (SHS ingots), casting of long size electrodes, plasma rotating electrode process (PREP), classification of narrow-fraction spherical powder, and SLM of complex-shaped products followed by hot isostatic pressing (HIP) [23,24,25,26,27];

- (II)

2. Materials and Methods

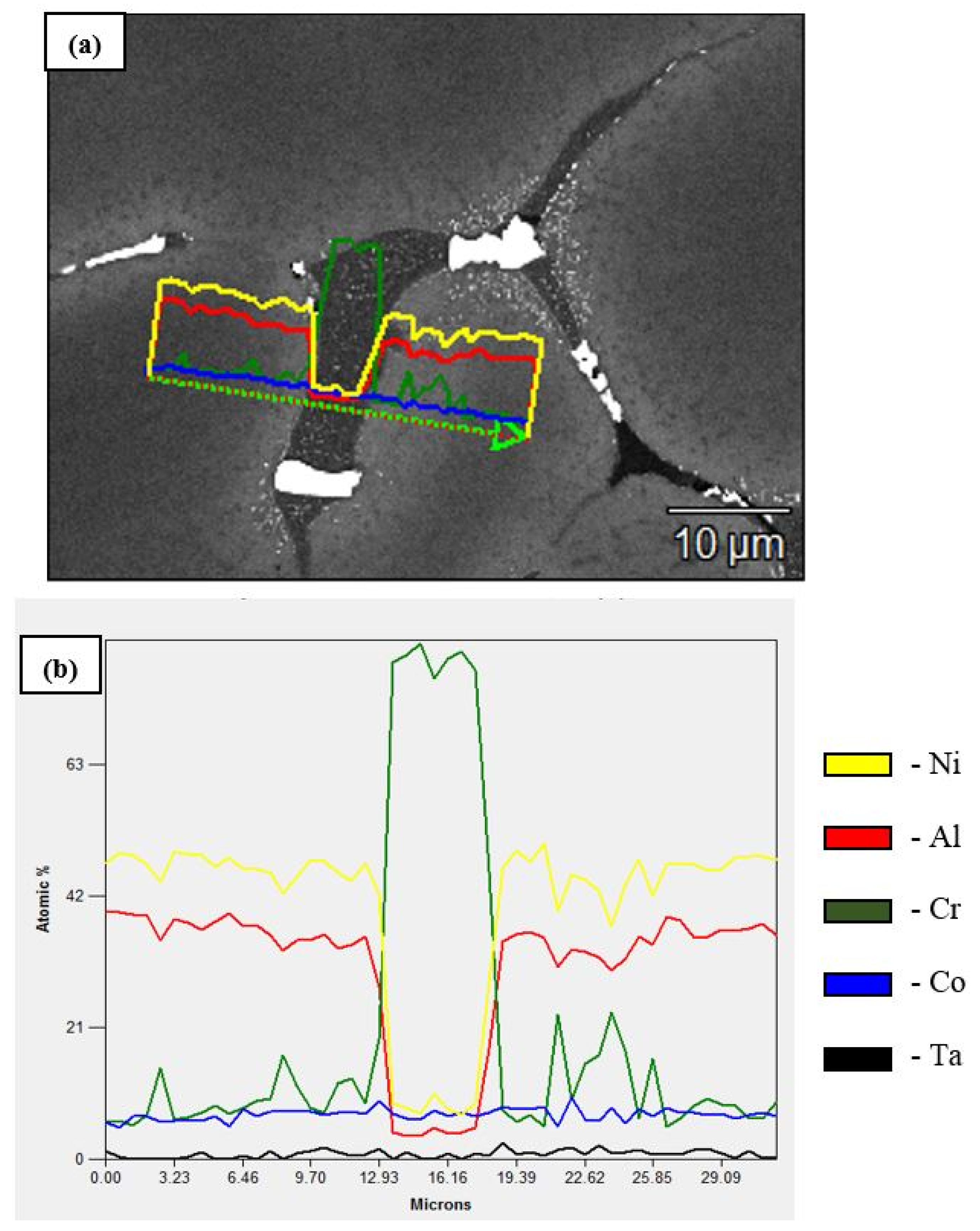

3. Results and Discussion

4. Conclusions

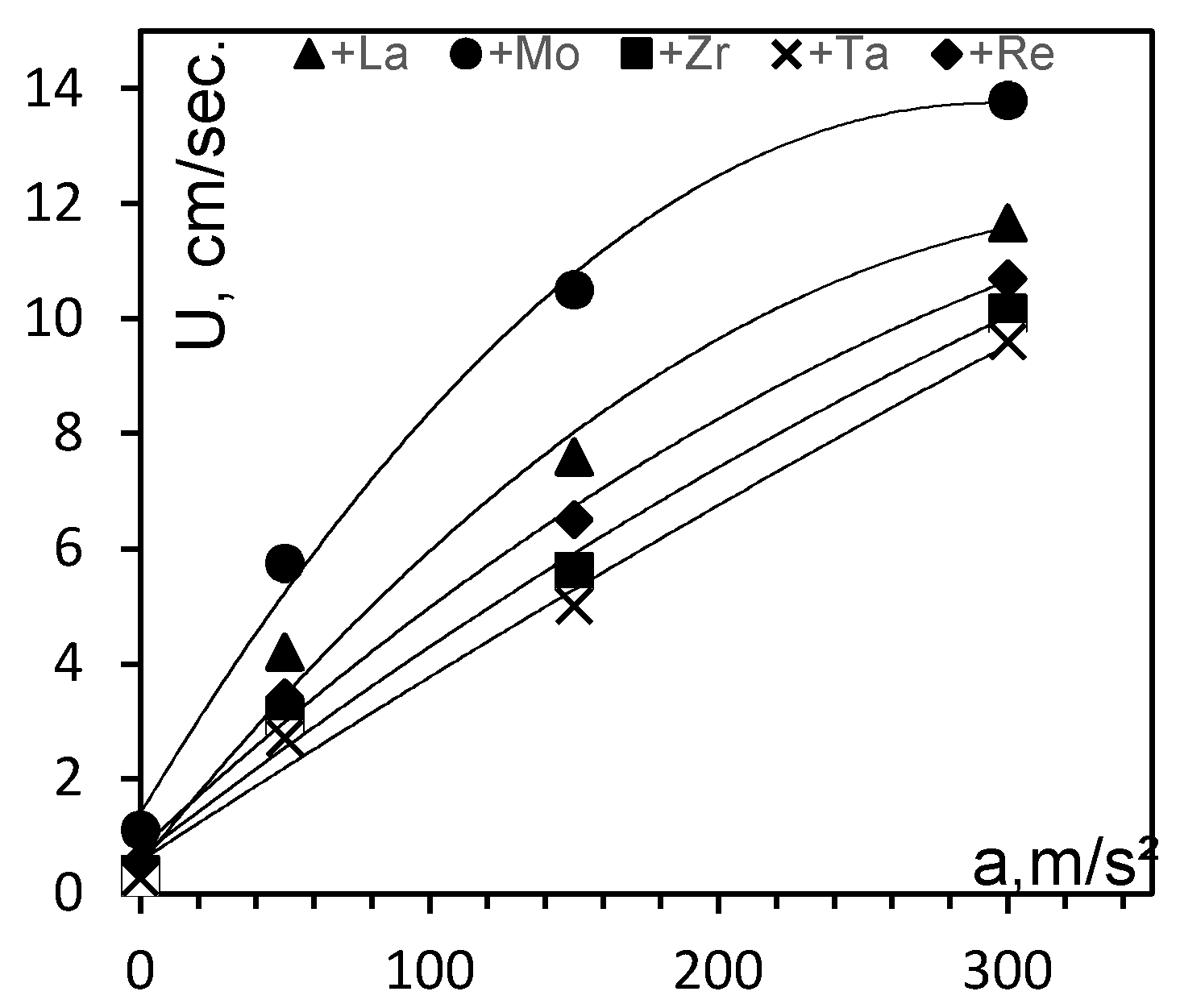

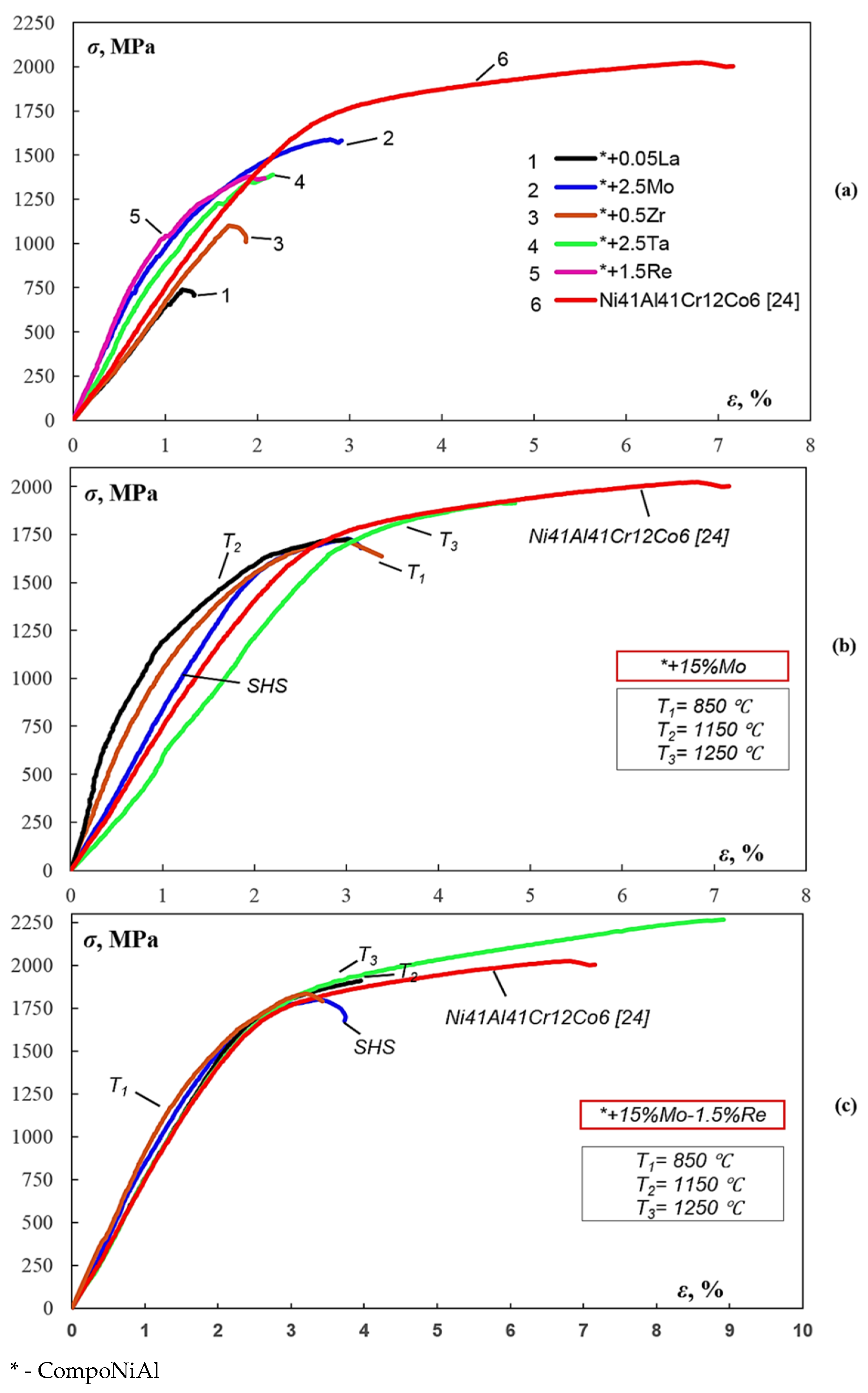

- Alloys in the NiAl–Cr–Co–(X) system have been produced by centrifugal SHS casting. The effects of dopants X = La, Mo, Zr, Ta, and Re on combustion, as well as the phase composition, structure, and properties of the resulting cast alloys, have been studied. A eutectic cellular structure is formed in the alloys co-doped with Mo and Re. Co-doping with 15% Mo and 1.5% Re has ensured the greatest improvement in overall properties. In the alloy doped with 15% Mo, molybdenum forms a ductile matrix and enhances the strength characteristics up to the following values: σucs = 1604 ± 80 MPa, σys = 1520 ± 80 MPa, and εpd = 0.79%. Annealing at T = 1250 and t = 180 min improves strength characteristics to the following level: σucs = 1800 ± 80 MPa, σys = 1670 ± 80 MPa, and εpd = 1.58%. Rhenium modifies the structure of the NiAl–Cr–Co+15Mo1.5Re alloy and improves properties (σucs = 1682 ± 60 MPa, σys = 1538 ± 60 MPa, and εpd = 0.87%), while annealing additionally enhances them (σucs = 2019 ± 60 MPa, σys = 1622 ± 60 MPa, and εpd = 5.88%).

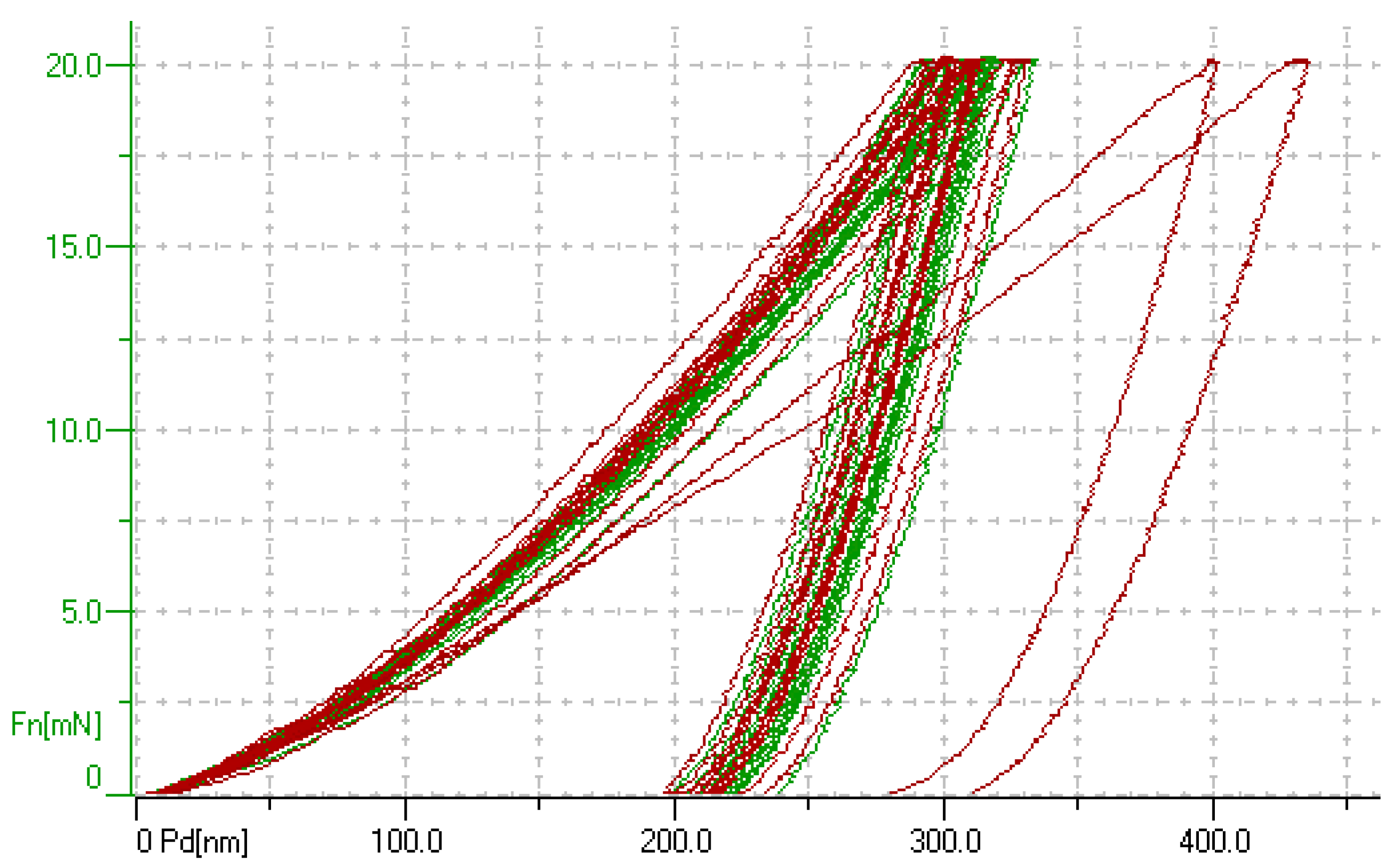

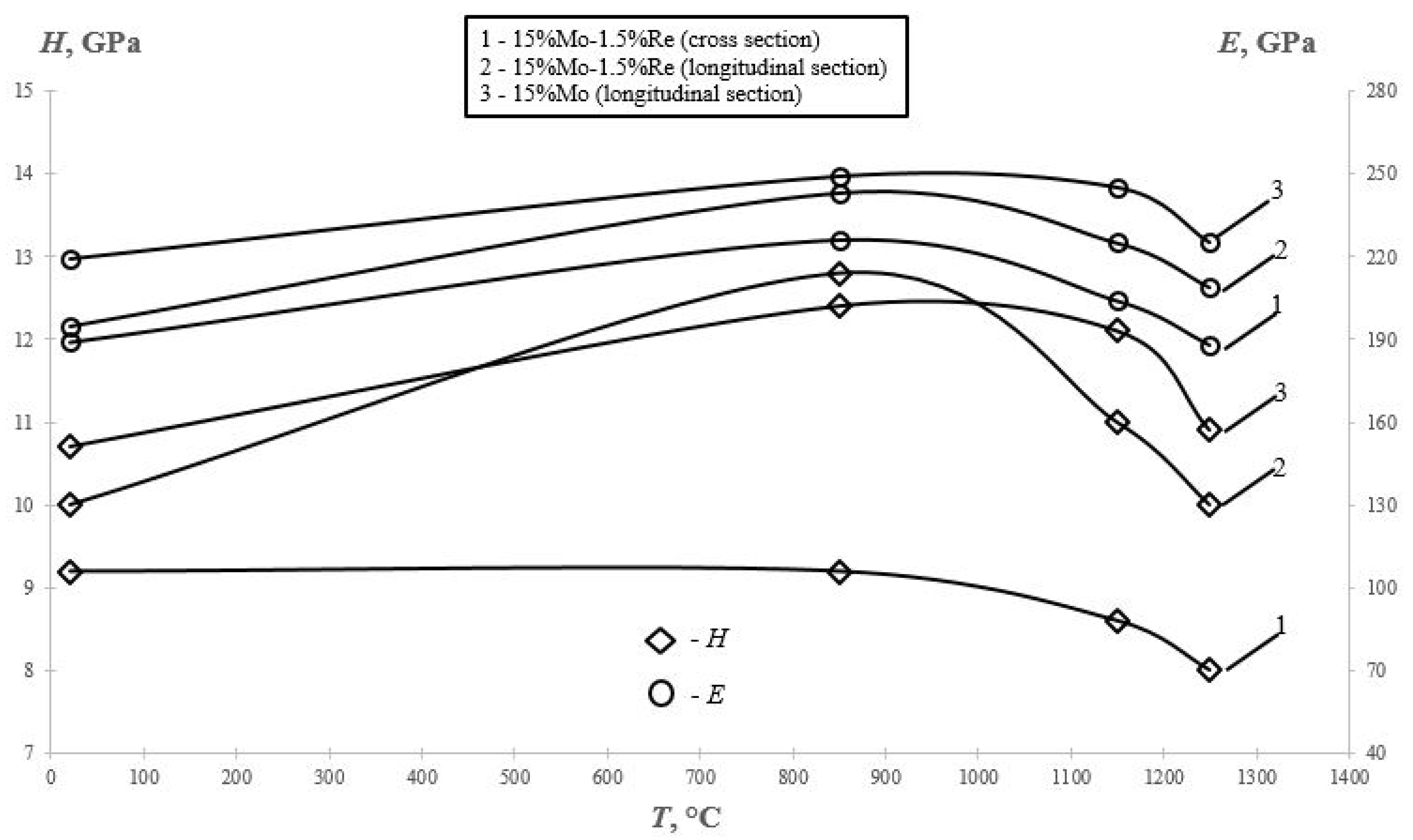

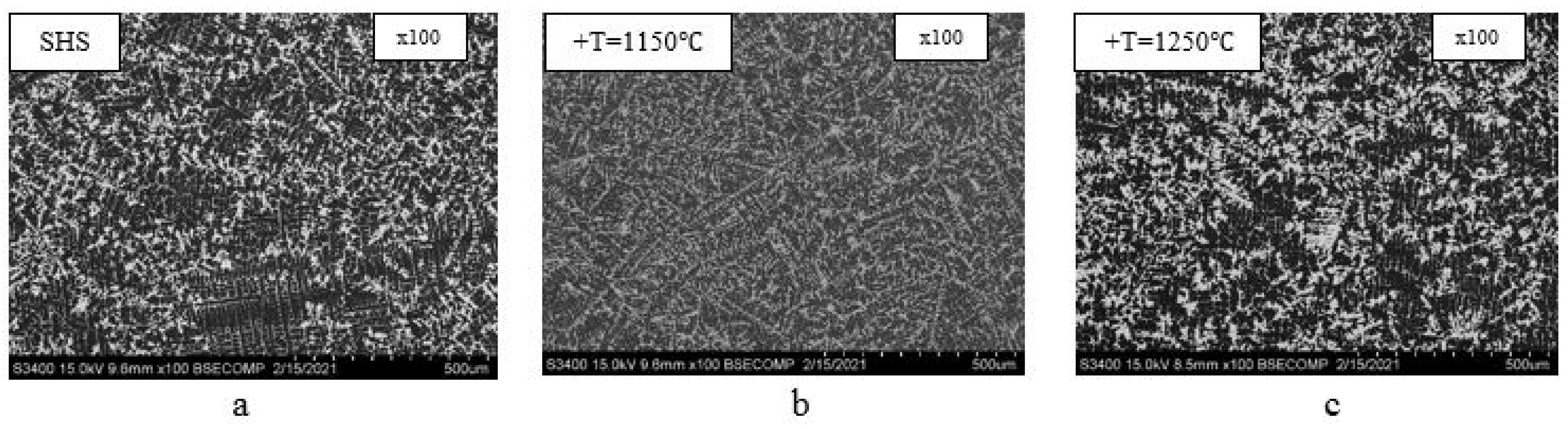

- The mechanical properties of the NiAl, ZrNi5, Ni0.92Ta0.08, and (Al,Ta)Ni3 phases, as well as the hypothetical Al(Re,Ni)3 phase, have been determined by nanoindentation of the alloys. Local disordering upon annealing above 850 °C increases the rate of plastic deformation in the compression tests due to the coherence loss at the interface between nanosized disc-shaped Cr-based precipitates and supersaturated solid solution via the mechanism of Guinier–Preston structural transformation.

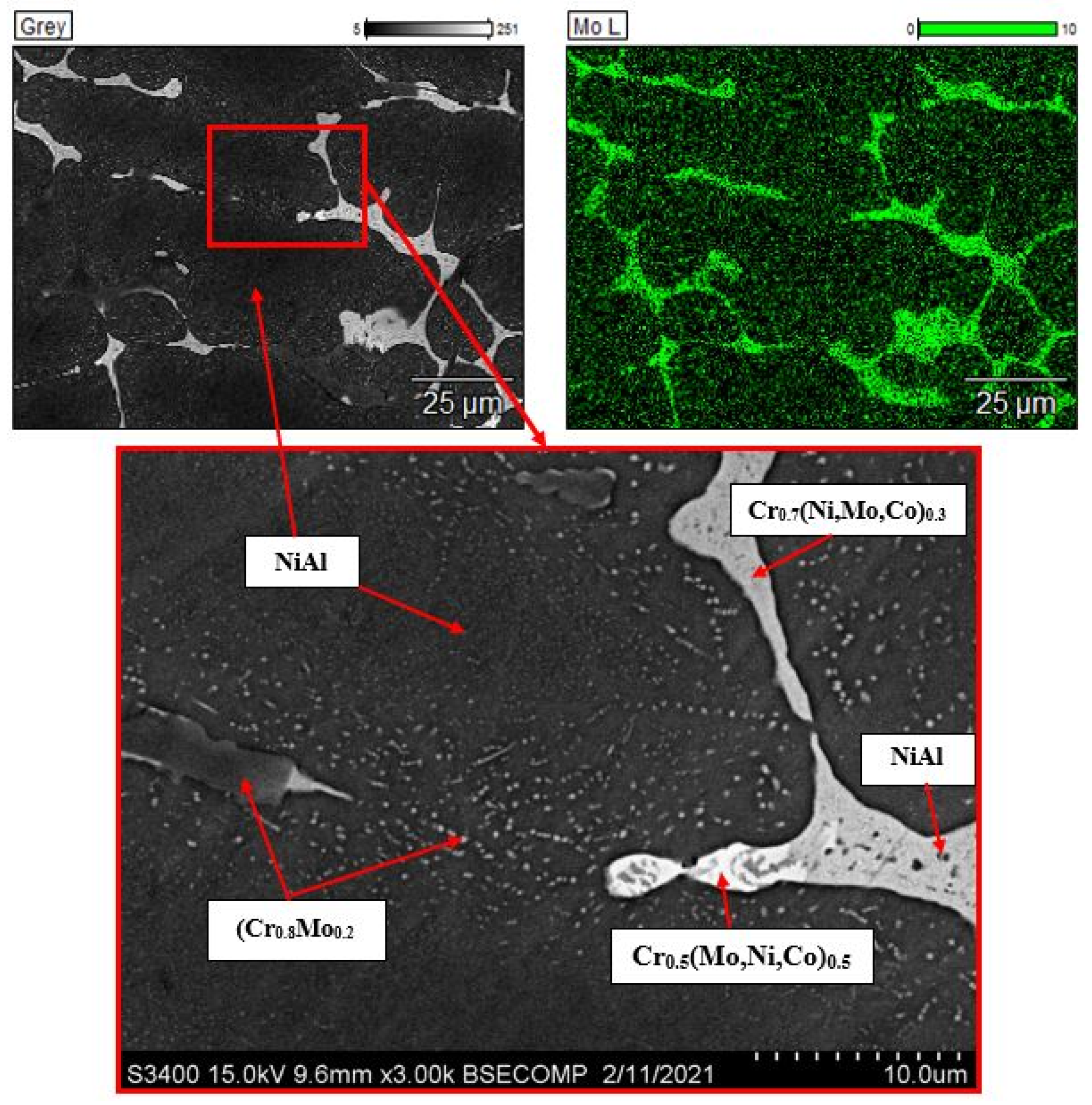

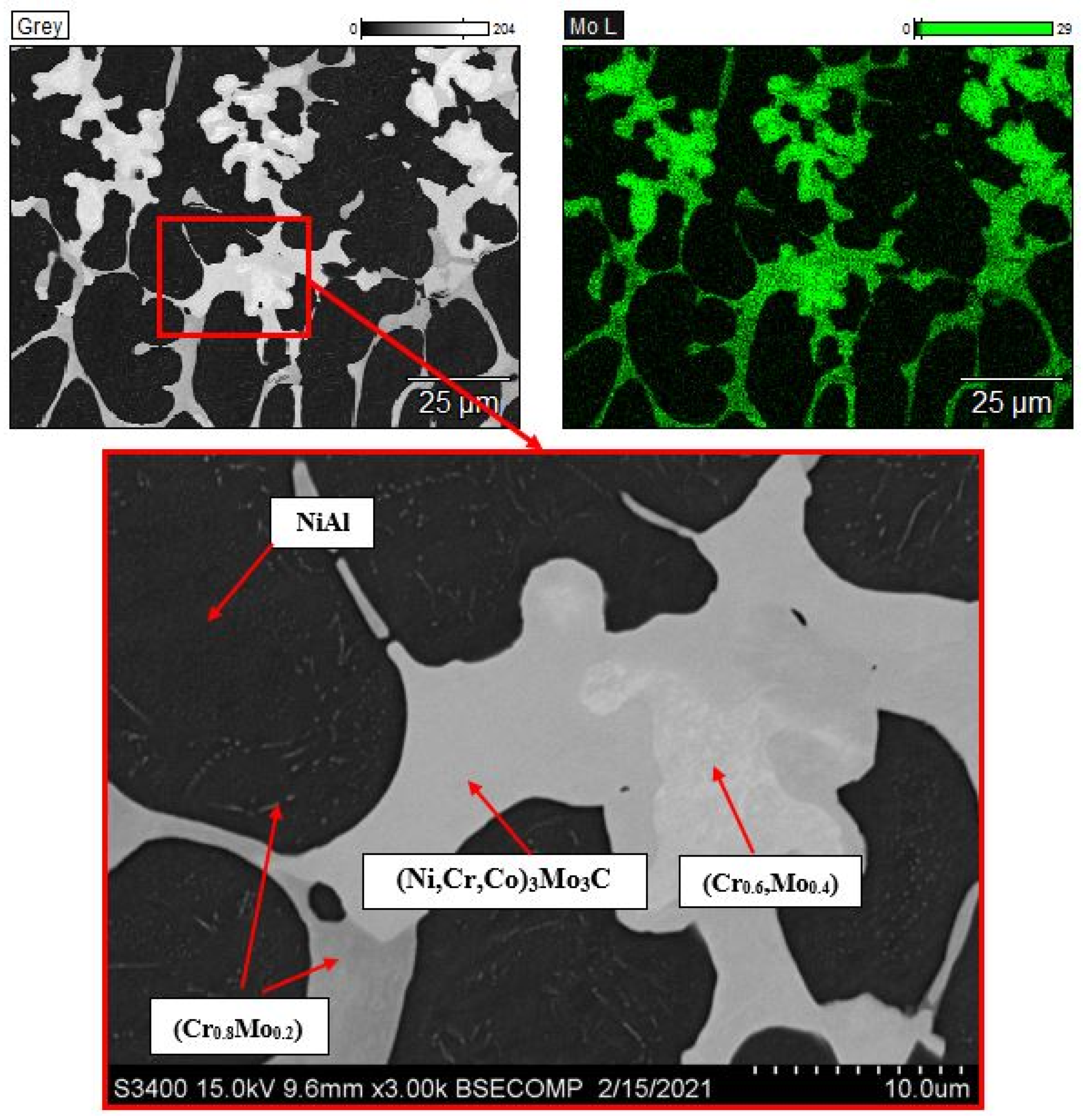

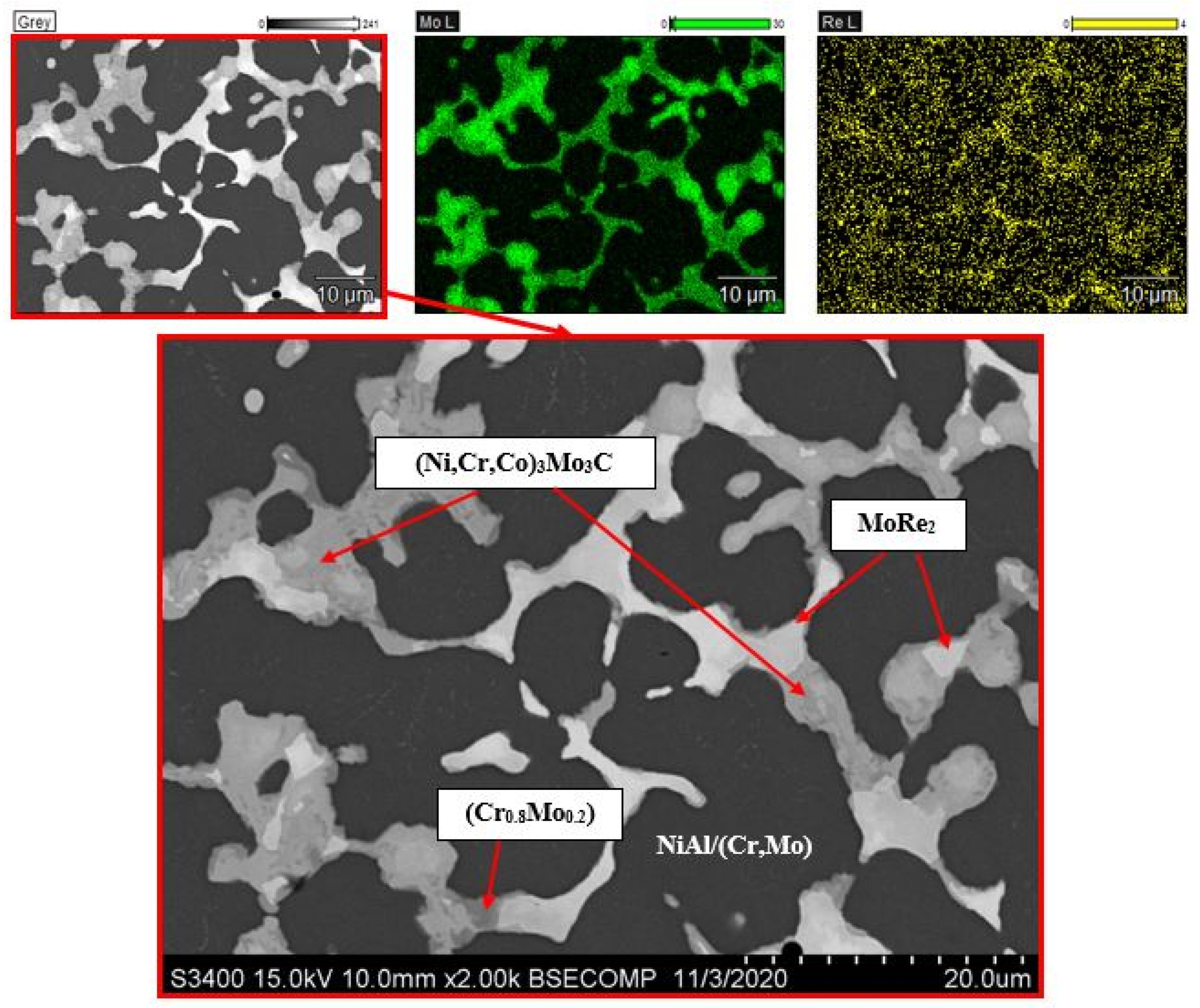

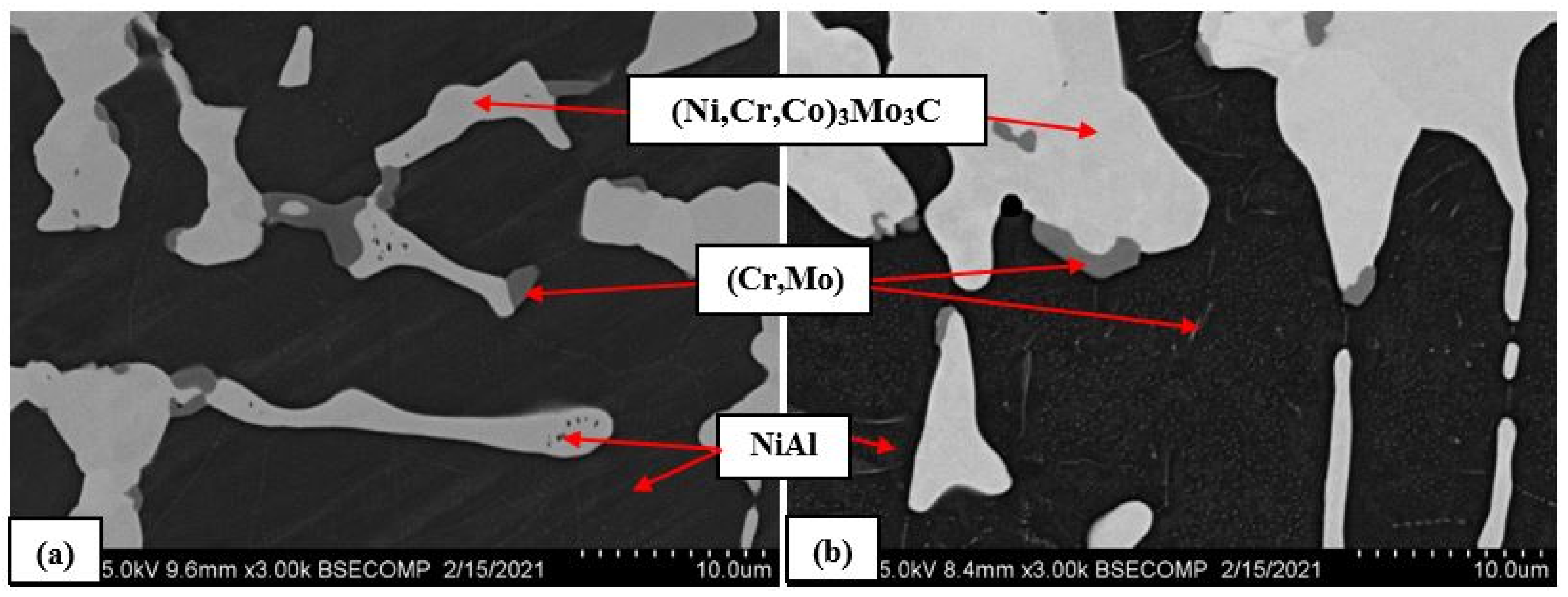

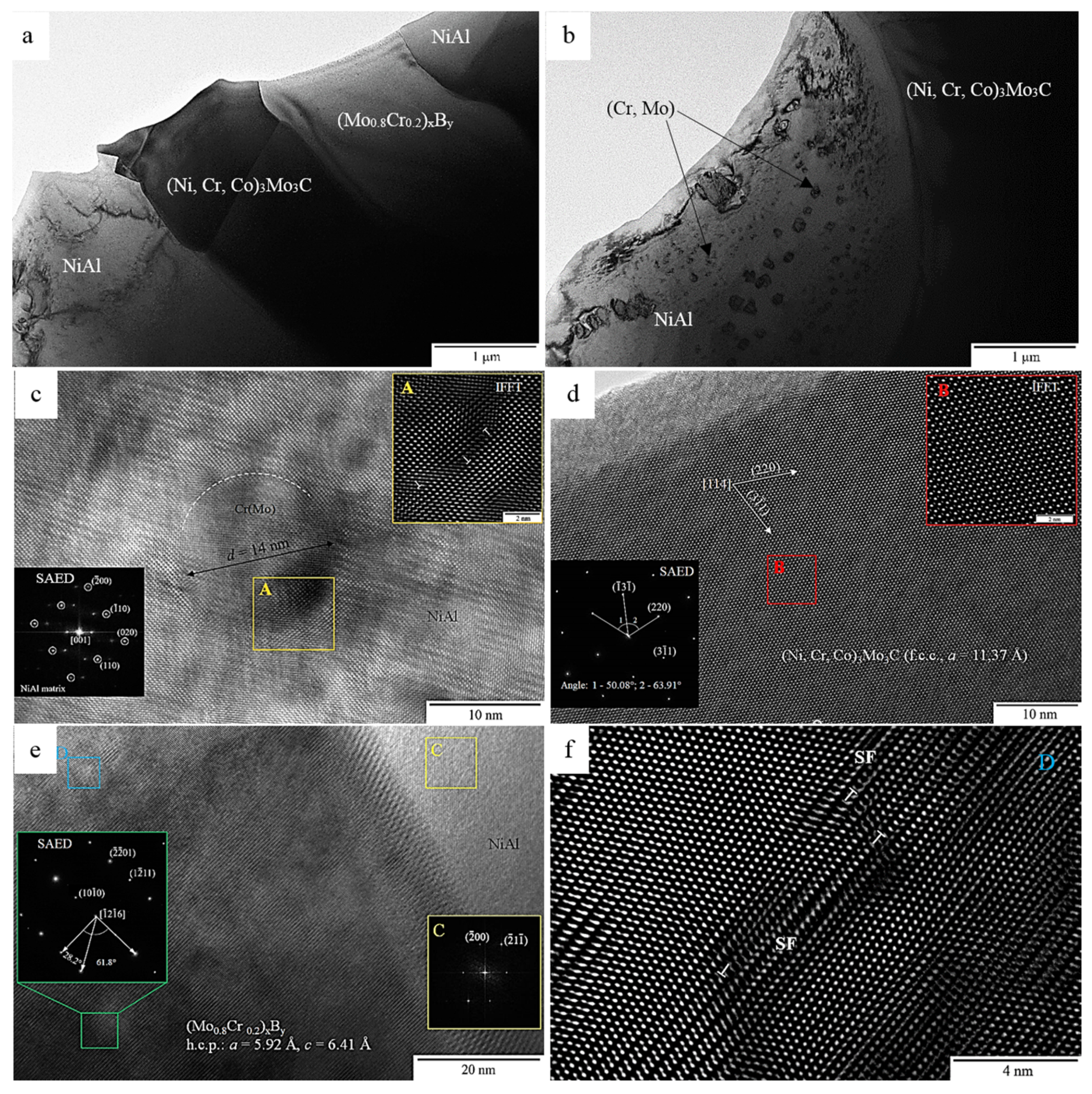

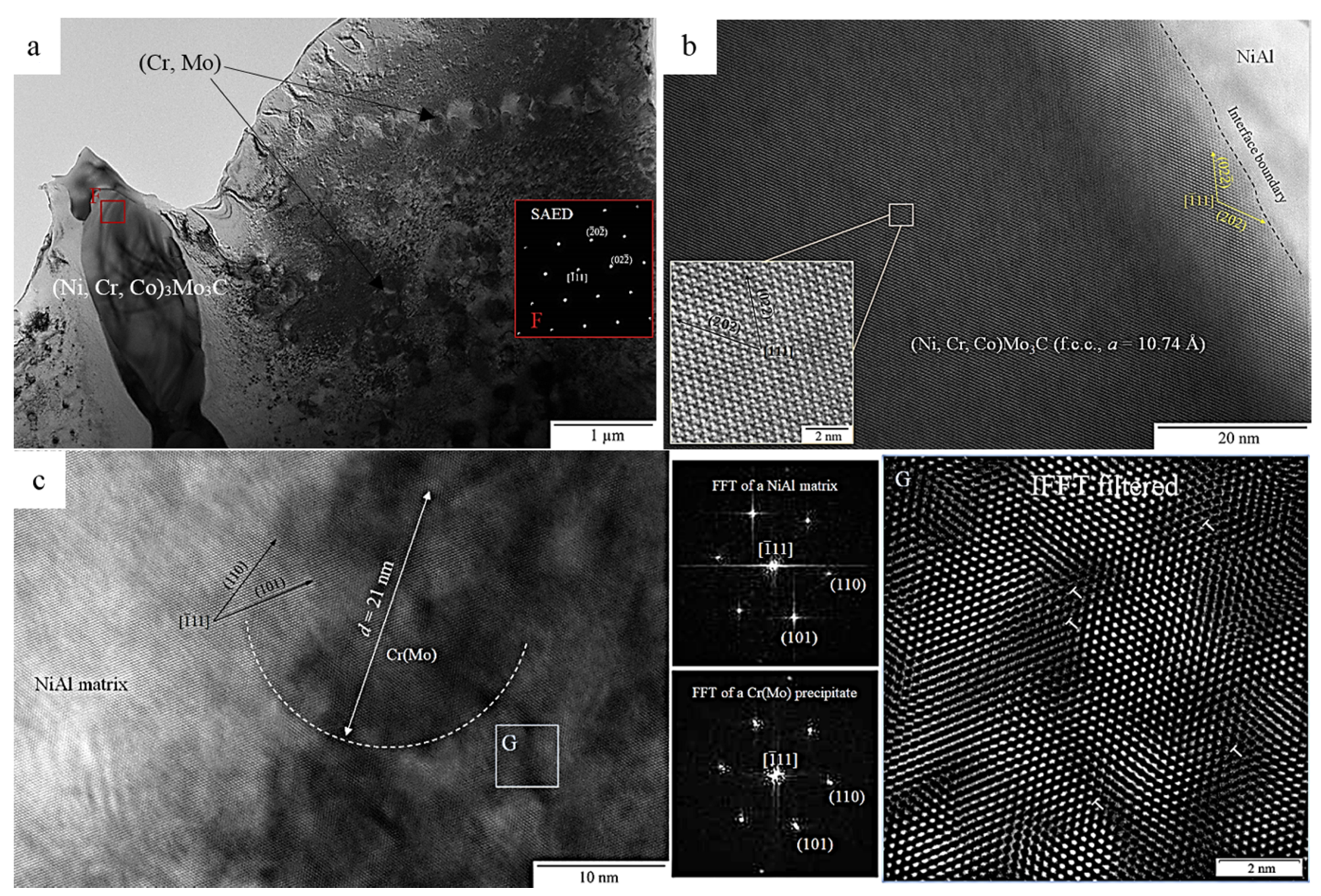

- The three-level hierarchical architecture of the NiAl–Cr–Co+15%Mo alloy has been identified: the first level is formed by dendritic β-NiAl grains with the interlayers of molybdenum-containing phases (Ni,Co,Cr)3Mo3C and (Mo0.8Cr0.2)xBy (cell dimension < 50 µm); the second level is formed by strengthening submicron-sized Cr(Mo) particles distributed along the grain boundaries; and the third level consists of coherent Cr(Mo) nanoprecipitates (10–40 nm) within the bodies of β-NiAl dendrites.

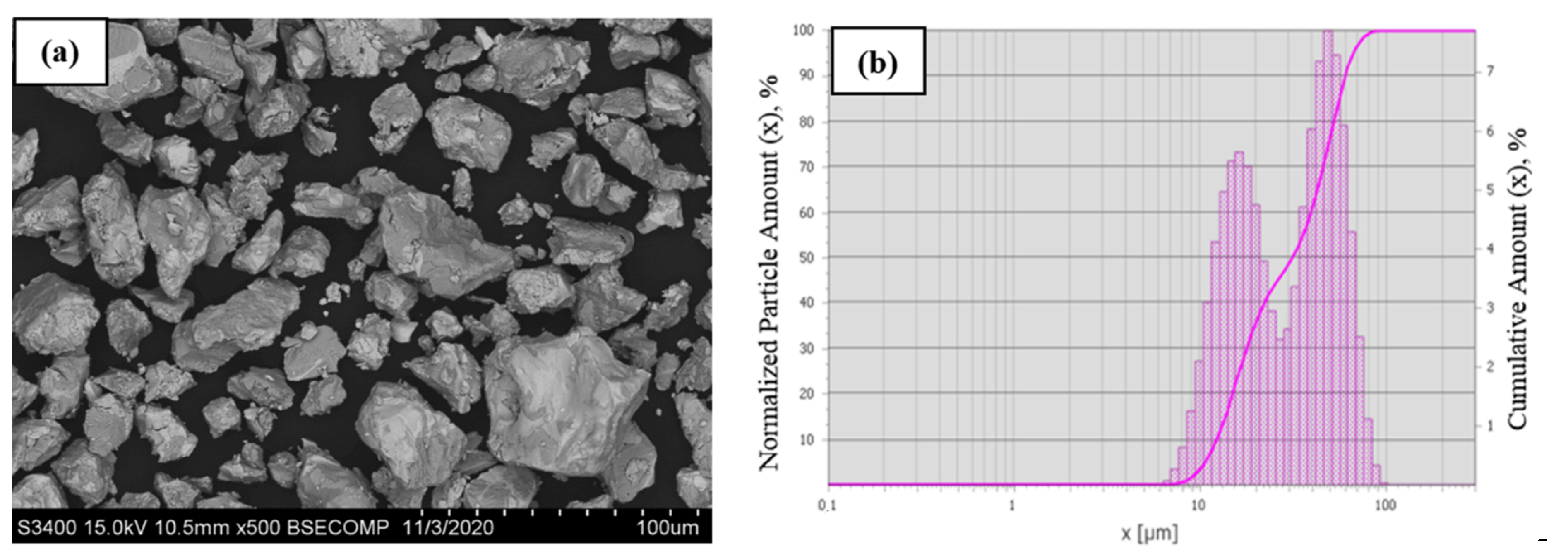

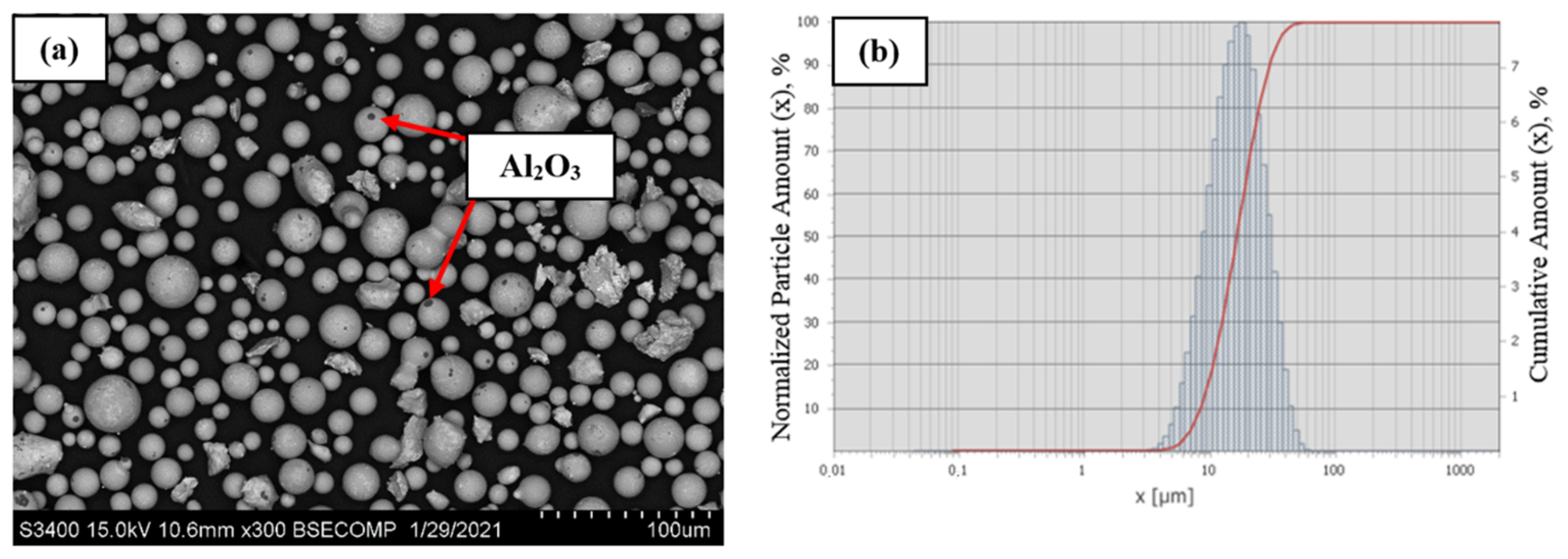

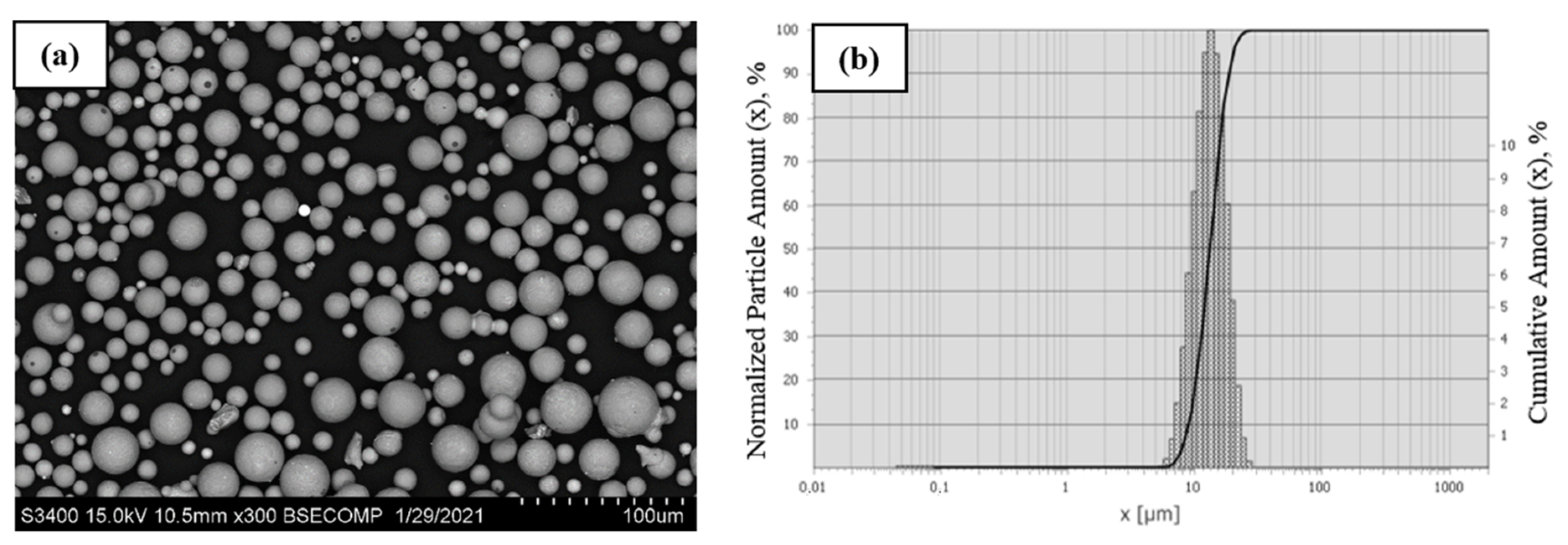

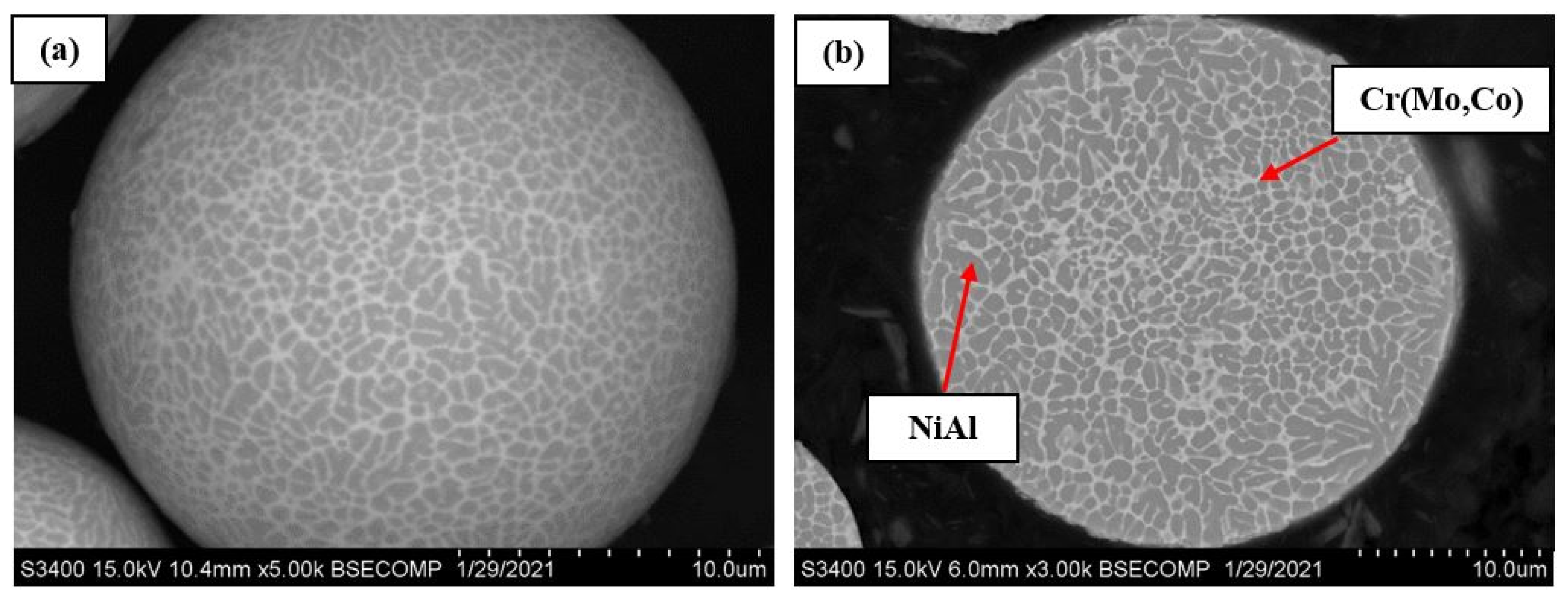

- The optimal plasma treatment regime has been identified, and narrow-fraction powders (fraction 8–27 µm) characterized by 95% degree of spheroidization and the content of nano-sized fraction <5 have been obtained. The powder has a characteristic dendritic structure with the grain size of 0.2–3 µm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Darolia, R. Ductility and fracture toughness issues related to implementation of NiAl for gas turbine applications. Intermetallics 2000, 8, 1321–1327. [Google Scholar] [CrossRef]

- Lasalmonie, A. Intermetallics: Why is it so difficult to introduce them in gas turbine engines? Intermetallics 2006, 14, 1123–1129. [Google Scholar] [CrossRef]

- Wang, L.; Shen, J.; Zhang, Y.; Fu, H. Microstructure, fracture toughness and compressive property of as-cast and directionally solidified NiAl-based eutectic composite. Mater. Sci. Eng. A 2016, 664, 188–194. [Google Scholar] [CrossRef]

- Razumovskii, I.M.; Ruban, A.V.; Razumovskiy, V.I.; Logunov, A.V.; Larionov, V.N.; Ospennikova, O.G.; Poklad, V.A.; Johansson, B. New generation of Ni-based superalloys designed on the basis of first-principles calculations. Mater. Sci. Eng. A 2008, 497, 18–24. [Google Scholar] [CrossRef]

- Hu, X.L.; Zhang, Y.; Lu, G.H.; Wang, T.; Xiao, P.H.; Yin, P.G.; Xu, H. Effect of O impurity on structure and mechanical properties of NiAl intermetallics: A first-principles study. Intermetallics 2009, 17, 358–364. [Google Scholar] [CrossRef]

- Misra, A.; Gibala, R. Plasticity in multiphase intermetallics. Intermetallics 2000, 8, 1025–1034. [Google Scholar] [CrossRef]

- Li, N.; Huang, S.; Zhang, G.; Qin, R.; Liu, W.; Xiong, H.; Shi, G.; Blackburn, J. Progress in additive manufacturing on new materials: A review. J. Mater. Sci. Technol. 2019, 35, 242–269. [Google Scholar] [CrossRef]

- Eyers, D.R.; Potter, A.T. Industrial Additive Manufacturing: A manufacturing systems perspective. Comput. Ind. 2017, 92–93, 208–218. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Saadlaoui, Y.; Milan, J.-L.; Rossi, J.-M.; Chabrand, P. Topology optimization and additive manufacturing: Comparison of conception methods using industrial codes. J. Manuf. Syst. 2017, 43, 178–186. [Google Scholar] [CrossRef]

- Kamal, M.; Rizza, G. Design for metal additive manufacturing for aerospace applications. Addit. Manuf. Aerosp. Ind. 2019, 67–86. [Google Scholar] [CrossRef]

- Seabra, M.; Azevedo, J.; Araújo, A.; Reis, L.; Pinto, E.; Alves, N.; Santos, R.; Mortágua, J.P. Selective laser melting (SLM) and topology optimization for lighter aerospace componentes. Procedia Struct. Integr. 2016, 1, 289–296. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. 2—Review of additive manufacturing technologies and applications in the aerospace industry. Addit. Manuf. Aerosp. Ind. 2019. [Google Scholar] [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A comparison of traditional manufacturing vs. additive manufacturing, the best method for the job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing, 1st ed.; Springer: Boston, MA, USA, 2010; Volume XXII, p. 459. [Google Scholar] [CrossRef]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef]

- Pleass, C.; Jothi, S. Influence of powder characteristics and additive manufacturing process parameters on the microstructure and mechanical behaviour of Inconel 625 fabricated by Selective Laser Melting. Addit. Manuf. 2018, 24, 419–431. [Google Scholar] [CrossRef]

- Liu, P.; Hu, J.; Sun, S.; Feng, K.; Zhang, Y.; Cao, M. Microstructural evolution and phase transformation of Inconel 718 alloys fabricated by selective laser melting under different heat treatment. J. Manuf. Process. 2019, 39, 226–232. [Google Scholar] [CrossRef]

- Levashov, E.A.; Mukasyan, A.S.; Rogachev, A.S.; Shtansky, D.V. Self-Propagating High-Temperature Synthesis of Advanced Materials and Coatings. Int. Mater. Rev. 2017, 62, 203–239. [Google Scholar] [CrossRef]

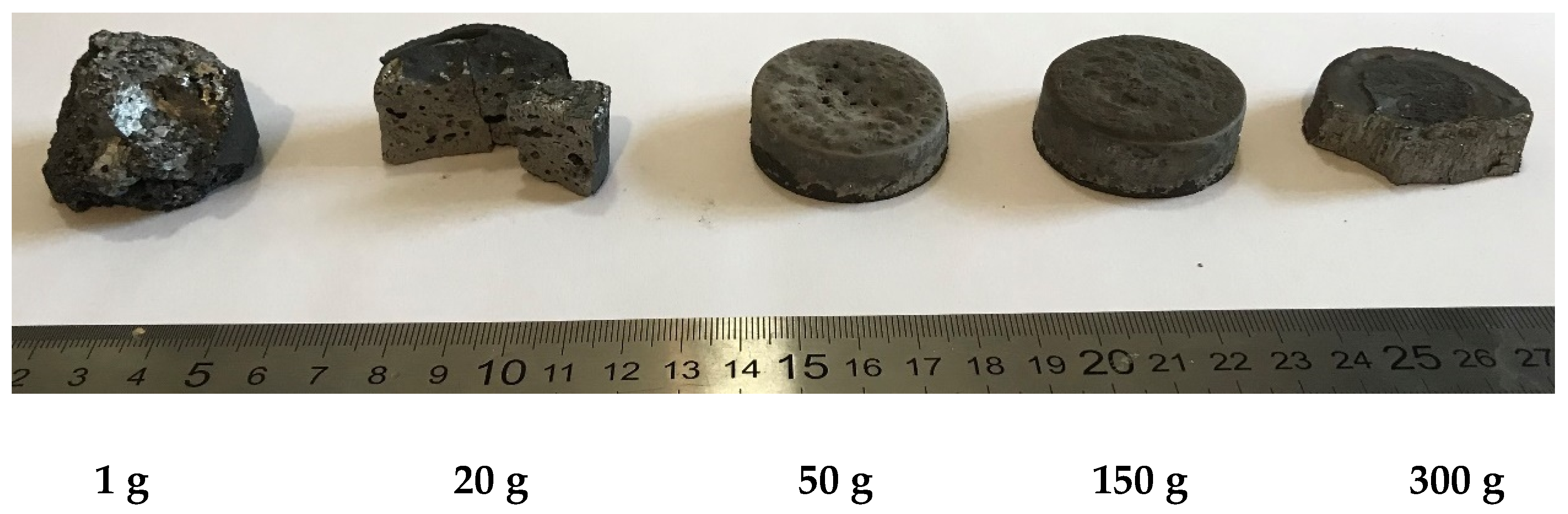

- Sanin, V.; Andreev, D.; Ikornikov, D.; Yukhvid, V. Cast Intermetallic Alloys and Composites Based on Them by Combined Centrifugal Casting—SHS Process. Open J. Metal. 2013, 3, 12–24. [Google Scholar] [CrossRef]

- Pogozhev, Y.S.; Sanin, V.N.; Ikornikov, D.M.; Andreev, D.E.; Yukhvid, V.I.; Levashov, E.A.; Sentyurina, Z.A.; Logacheva, A.I.; Timofeev, A.N. NiAl-Based electrodes by Combined use of centrifugal SHS and induction remelting. Int. J. Self-Propagating High-Temp. Synth. 2016, 25, 186–199. [Google Scholar] [CrossRef]

- Sanin, V.V.; Filonov, M.R.; Yukhvid, V.I.; Anikin, Y.A.; Mikhailov, A.M. Investigation into the influence of the remelting temperature on the structural heredity of alloys fabricated by centrifugal SHS metallurgy. Russ. J. Non-Ferr. Met. 2016, 57, 124–130. [Google Scholar] [CrossRef]

- Zaitsev, A.A.; Sentyurina, Z.A.; Levashov, E.A.; Pogozhev, Y.S.; Sanin, V.N.; Loginov, P.A.; Petrzhik, M.I. Structure and properties of NiAl-Cr(Co,Hf) alloys prepared by centrifugal SHS casting. Part 1—Room temperature investigations. Mater. Sci. Eng. A 2017, 690, 463–472. [Google Scholar] [CrossRef]

- Zaitsev, A.A.; Sentyurina, Z.A.; Levashov, E.A.; Pogozhev, Y.S.; Sanin, V.N.; Sidorenko, D.A. Structure and properties of NiAl-Cr(Co,Hf) alloys prepared by centrifugal SHS casting followed by vacuum induction remelting. Part 2—Evolution of the structure and mechanical behavior at high temperature. Mater. Sci. Eng. A 2017, 690, 473–481. [Google Scholar] [CrossRef]

- Kaplanskii, Y.Y.; Zaitsev, A.A.; Sentyurina, Z.A.; Levashov, E.A.; Pogozhev, Y.S.; Loginov, P.A.; Logacheva, A.I. The Structure and Properties of Pre-Alloyed NiAl-Cr(Co,Hf) Spherical Powders Produced by Plasma Rotating Electrode Processing for Additive Manufacturing. J. Mater. Res. Technol. 2018, 7, 461–468. [Google Scholar] [CrossRef]

- Kaplanskii, Y.Y.; Zaitsev, A.A.; Levashov, E.A.; Loginov, P.A.; Sentyurina, Z.A. NiAl based alloy produced by HIP and SLM of pre-alloyed spherical powders. Evolution of the structure and mechanical behavior at high temperatures. Mater. Mater. Sci. Eng. A 2018, 717, 48–59. [Google Scholar] [CrossRef]

- Kurbatkina, V.V. Nickel Aluminides. In Concise Encyclopedia of Self-Propagating High-Temperature Synthesis; Elsevier: Amsterdam, The Netherlands, 2017; pp. 212–213. [Google Scholar] [CrossRef]

- Kurbatkina, V.V.; Patsera, E.I.; Levashov, E.A.; Kaplanskii, Y.Y.; Samokhin, A.V. Fabrication of Narrow-Fraction Micropowders of NiAl-Based Refractory Alloy CompoNiAl-M5-3. Int. J. Self-Propagating High-Temp. Synth. 2018, 27, 236–244. [Google Scholar] [CrossRef]

- Tsvetkov, Y.V.; Samokhin, A.V.; Alekseev, N.V.; Fadeev, A.A.; Sinaiskii, M.A.; Levashov, E.A.; Kaplanskii, Y.Y. Plasma Spheroidization of Micropowders of a Heat-Resistant Alloy Based on Nickel Monoaluminide. Dokl. Chem. 2018, 483, 312–317. [Google Scholar] [CrossRef]

- Kaplanscky, Y.Y.; Levashov, E.A.; Korotitskiy, A.V.; Loginov, P.A.; Sentyurina, Z.A.; Mazalov, A.B. Influence of aging and HIP treatment on the structure and properties of NiAl-based turbine blades manufactured by laser powder bed fusion. Addit. Manuf. 2020, 31, 100999. [Google Scholar] [CrossRef]

- Kaplanskii, Y.Y.; Sentyurina, Z.A.; Loginov, P.A.; Levashov, E.A.; Korotitskiy, A.V.; Travyanov, A.Y.; Petrovskii, P.V. Microstructure and mechanical properties of the (Fe,Ni)Al-based alloy produced by SLM and HIP of spherical composite powder. Mater. Sci. Eng. A 2019, 743, 567–580. [Google Scholar] [CrossRef]

- Khomutov, M.; Potapkin, P.; Cheverikin, V.; Petrovskiy, P.; Travyanov, A.; Logachev, I.; Sova, A.; Smurov, I. Effect of hot isostatic pressing on structure and properties of intermetallic NiAl–Cr–Mo alloy produced by selective laser melting. Intermetallics 2020, 120, 106766. [Google Scholar] [CrossRef]

- Chen, R.S.; Guo, J.T.; Zhou, J.Y. Elevated temperature compressive behavior of cast NiAl–9Mo(1Hf) eutectic alloys. Mater. Lett. 2000, 42, 75–80. [Google Scholar] [CrossRef]

- Geramifard, G.; Gombola, C.; Franke, P.; Seifert, H.J. Oxidation behaviour of NiAl intermetallics with embedded Cr and Mo. Corros. Sci. 2020, 177, 108956. [Google Scholar] [CrossRef]

- Wang, L.; Shen, J.; Shang, Z.; Fu, H. Microstructure evolution and enhancement of fracture toughness of NiAl–Cr(Mo)–(Hf,Dy) alloy with a small addition of Fe during heat treatment. Scr. Mater. 2014, 89, 1–4. [Google Scholar] [CrossRef]

- Krasnowski, M.; Gierlotka, S.; Ciołek, S.; Kulik, T. Nanocrystalline NiAl intermetallic alloy with high hardness produced by mechanical alloying and hot-pressing consolidation. Adv. Powder Technol. 2019, 30, 1312–1318. [Google Scholar] [CrossRef]

- Wang, L.; Shen, J. Effect of heat treatment on the microstructure and elevated temperature tensile property of Fe-doped NiAl–Cr(Mo)–(Hf,Dy) eutectic alloy. Mater. Sci. Eng. A 2016, 654, 177–183. [Google Scholar] [CrossRef]

- Xie, Y.; Guo, J.; Zhou, L.; Chen, H.; Long, Y. Microstructural evolution and mechanical properties of new multi-phase NiAl-based alloy during heat treatments. Trans. Nonferrous Met. Soc. China 2010, 20, 2265–2271. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Xie, Y.; Xi, T.F.; Guo, J.T.; Zheng, Y.F.; Ye, H.Q. Microstructure characteristics and compressive properties of NiAl-based multiphase alloy during heat treatments. Mater. Sci. Eng. A 2011, 528, 8324–8331. [Google Scholar] [CrossRef]

- He, J.-Q.; Wang, Y.; Yan, M.-F.; Yang, Y.; Wang, L. First-principles study of NiAl microalloyed with Sc, Y, La and Nd. Comput. Mater. Sci. 2010, 50, 545–549. [Google Scholar] [CrossRef]

- Baohong, H.; Hui, P.; Lei, Z.; Hongbo, G. Effect of Mo, Ta, and Re on high-temperature oxidation behavior of minor Hf doped β-NiAl alloy. Corros. Sci. 2016, 102, 222–232. [Google Scholar] [CrossRef]

- Hamadi, S.; Baco, M.-P.; Poulain, M.; Seyeux, A.; Maurice, V.; Marcus, P. Oxidation resistance of a Zr-doped NiAl coating thermochemically deposited on a nickel-based superalloy. Surf. Coatings Technol. 2009, 204, 756–760. [Google Scholar] [CrossRef]

- Guo, J.T.; Qi, Y.H.; Li, G.S.; Wu, W.T. Tensile properties and microstructure of in situ NiAl–Cr (Zr) eutectic composite. Compos. Struct. 2003, 62, 323–327. [Google Scholar] [CrossRef]

- Zeumert, B.; Sauthoff, G. Intermetallic NiAl-Ta alloys with strengthening Laves phase for high-temperature applications. I. Basic properties. Intermetallics 1997, 5, 563–577. [Google Scholar] [CrossRef]

- Misra, A.; Wu, Z.L.; Kush, M.T.; Gibala, R. Microstructures and mechanical properties of directionally solidified NiAl–Mo and NiAl–Mo(Re) eutectic alloys. Mater. Sci. Eng. A 1997, 239–240, 75–87. [Google Scholar] [CrossRef]

- Ponomareva, V.; Vekilova, Y.; Abrikosov, I. Effect of Re content on elastic properties of B2 NiAl from ab initio calculations. J. Alloy. Compd. 2014, 586, S274–S278. [Google Scholar] [CrossRef]

- Filonov, M.R.; Sanin, V.V.; Anikin, Y.A.; Kostitsynaa, E.V.; Vidineev, S.N. Investigation of Two-Phase State of Fe-Cu Melts during Cooling in a Viscometer. Steel Transl. 2019, 49, 732–737. [Google Scholar] [CrossRef]

- Shang, Z.; Zhang, Q.; Shen, J.; Bai, H.; Dong, X.; Bai, W.; Zhong, L.; Liu, G.; Xu, Y. Effects of Nb/Ti additions and heat treatment on the microstructure evolution and hardness of as-cast and directionally solidified NiAl–Cr(Mo) alloy. J. Mater. Res. Technol. 2021, 10, 905–915. [Google Scholar] [CrossRef]

- Kaplanskii, Y.Y.; Loginov, P.A.; Korotitskiy, A.V.; Bychkova, M.Y.; Levashov, E.A. Influence of heat treatment on the structure evolution and creep deformation behavior of a precipitation hardened B2-(Ni, Fe)Al alloy. Mater. Sci. Eng. A 2020, 786, 139451. [Google Scholar] [CrossRef]

- Hawkes, P.W. Advances in Imaging and Electron Physics: Preface; Elsevier: San Diego, CA, USA, 2011; Volume 165, pp. 1–369. [Google Scholar] [CrossRef]

- Wu, S.K.; Khachaturyan, A.G.; Wayman, C.M. Superstructure of interstitial ordering of oxygen in TiNi alloys. Acta Met. 1988, 36, 2065–2070. [Google Scholar] [CrossRef]

- Pu, S.; Zheng, H.; Chen, Z.; Li, M.; Hu, Z.; Wang, J.; Zou, H. The microstructure and ferroelectric property of Nd-doped multiferroic ceramics Bi0.85Nd0.15FeO3. Ceram. Int. 2015, 41, 5498–5504. [Google Scholar] [CrossRef]

- Hu, C.; Zhang, Z.; Chen, H.; He, J.; Guo, H. Reactive elements dependence of elastic properties and stacking fault energies of γ-Ni, β-NiAl and γ′-Ni3Al. J. Alloy. Compd. 2020, 843, 155799. [Google Scholar] [CrossRef]

- Jha, S.C.; Ray, R. Carbide-dispersion-strengthened B2 NiAl. Mater. Sci. Eng. A 1989, 119, 103–111. [Google Scholar] [CrossRef]

| Compound | Grade | Standard/ Specifications | Particle Size, µm | Chemical Composition, % |

|---|---|---|---|---|

| Main components | ||||

| NiO | special purity grade | TU 6-09-02439-87 | <40 | 99.0 |

| Cr2O3 | pure | TU 6-09-4272-84 | <20 | 99.0 |

| Co3O4 | special purity grade | GOST 18671-73 | <30 | 99.0 |

| Al | PA-4 | GOST 6058-73 | <140 | 98.0 |

| Al | ASD-1 | TU 48-5-226-87 | <50 | 99.7 |

| Modifying agents (MA) | ||||

| MoO3 | pure for analysis | TU 6-09-4471-77 | <50 | 99.0 |

| Zr | E635 | TU 95.166-83 | ⩽600 | 99.8 |

| Ta | TaPM | TU 48-19-72-92 | <20 | 98.0 |

| Re | Re-0 | TU 48-4-195-87 | <150 | 99.99 |

| La | LaM-1 | TU 48-4-218-72 | ⩽600 | 99.85 |

| B | Boron | TU 113-12-11.106-88 | ⩽90 | 98.6 |

| NiAl–Cr–Co (basic alloy), wt.% | Doping Agents (X), wt.% | ||

|---|---|---|---|

| Ni | main element | La | 0.3 |

| Mo | 2.5–15.0 | ||

| Al | 22.5 | Zr | 0.5 |

| Co | 8.0 | Ta | 2.5 |

| Cr | 13.5 | Re | 1.5 |

| Concentration, wt.%/at. % | X wt.%/at. % | |||||

|---|---|---|---|---|---|---|

| Ni | Al | Cr | Co | B | ||

| 54/43 | 22.30/37.90 | 14.01/12.35 | 8.34/6.49 | 0.015/0.06 | La | 0.083/0.03 |

| 22.04/37.46 | 13.67/12.05 | 8.05/6.26 | 0.017/0.07 | Mo | 2.44/1.18 | |

| 22.68/38.55 | 13.03/11.49 | 8.33/6.48 | 0.015/0.06 | Zr | 0.48/0.24 | |

| 21.78/37.02 | 14.17/12.50 | 8.02/6.24 | 0.011/0.05 | Ta | 2.11/1.07 | |

| 21.91/37.24 | 13.98/12.33 | 8.18/6.36 | 0.016/0.07 | Re | 1.48/0.75 | |

| X | Concentration, wt.% | |||||||

|---|---|---|---|---|---|---|---|---|

| W | C | Si | Fe | P | S | N | O | |

| La | 0.0273 | 0.011 | 0.053 | 0.094 | 0.0025 | 0.0128 | 0.00342 | 0.0210 |

| Mo | 0.0257 | 0.011 | 0.044 | 0.110 | 0.0029 | 0.0126 | 0.00368 | 0.0321 |

| Zr | 0.0257 | 0.013 | 0.079 | 0.102 | 0.0023 | 0.0126 | 0.00351 | 0.0216 |

| Ta | 0.0321 | 0.010 | 0.085 | 0.102 | 0.0024 | 0.0131 | 0.00296 | 0.0334 |

| Re | 0.0284 | 0.008 | 0.071 | 0.102 | 0.0024 | 0.0131 | 0.00305 | 0.0327 |

| Alloy | Phase | Phase Content, % | Lattice Parameter, Å | Sample | Phase | ||

|---|---|---|---|---|---|---|---|

| H, GPa | E, GPa | H, GPa | E, GPa | ||||

| NiAl-Cr-Co+2.5%Mo | NiAl | 100.0 | 2.879 | 8.2 ± 1.3 | 187 ± 20 | 8.2 ± 1.3 | 187 ± 20 |

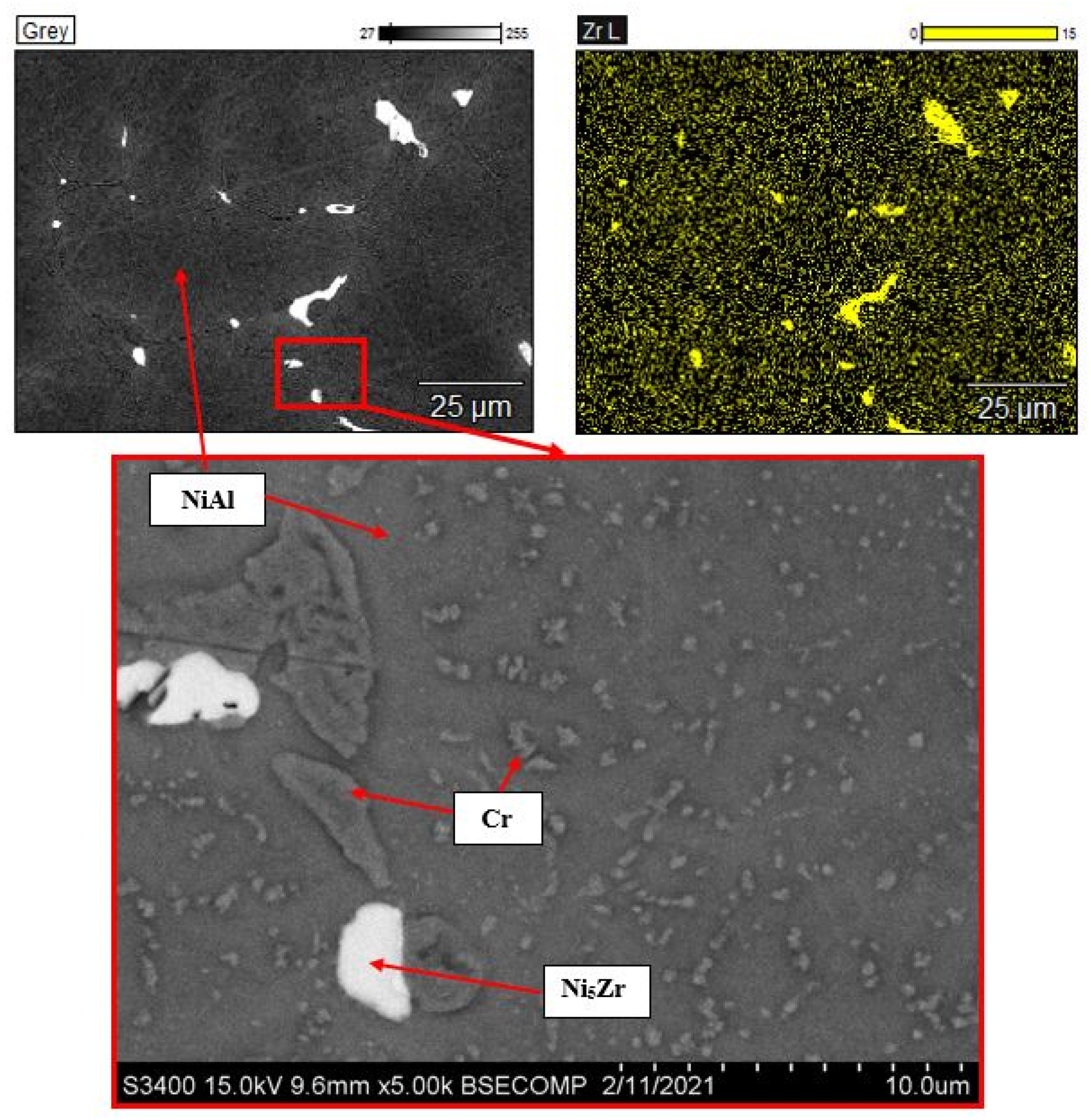

| NiAl-Cr-Co+0.5%Zr | NiAl | 94.7 | 2.887 | 7.6 ± 1.3 | 173 ± 23 | 8.1 ± 0.5 | 181 ± 8 |

| ZrNi5 | 5.3 | 6.687 | 4.6 ± 0.2 | 119 ± 14 | |||

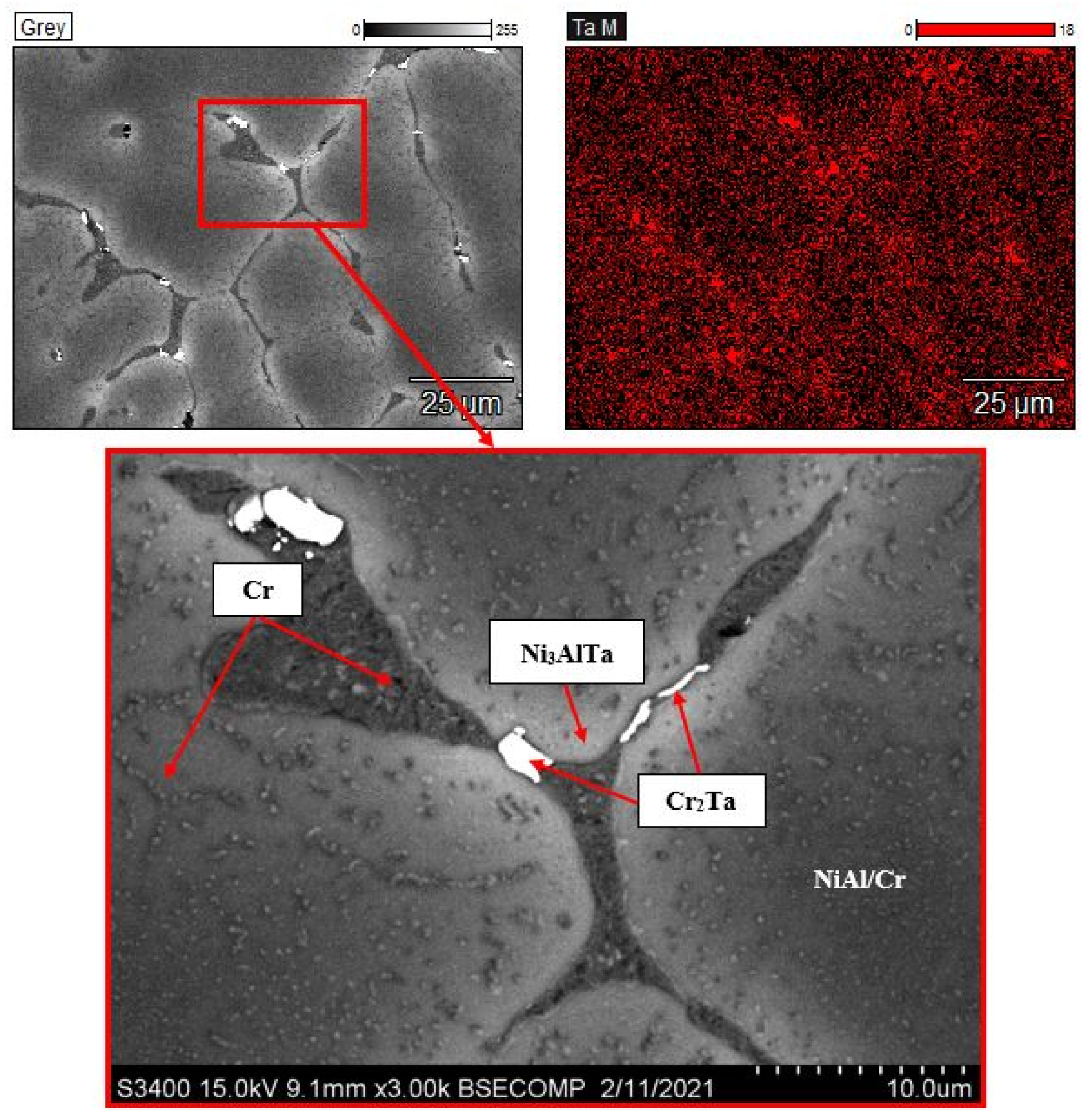

| NiAl-Cr-Co+2.5%Ta | NiAl | 85.9 | 2.894 | 10.6 ± 4.9 | 207 ± 40 | 9.2 ± 0.6 | 191 ± 7 |

| Ni0.92Ta0.08 | 9.2 | 3.584 | 10.6 ± 0.4 | 208 ± 9 | |||

| (Al0.72Ta0.28)Ni3 | 5.0 | 3.604 | 31.3 | 353 | |||

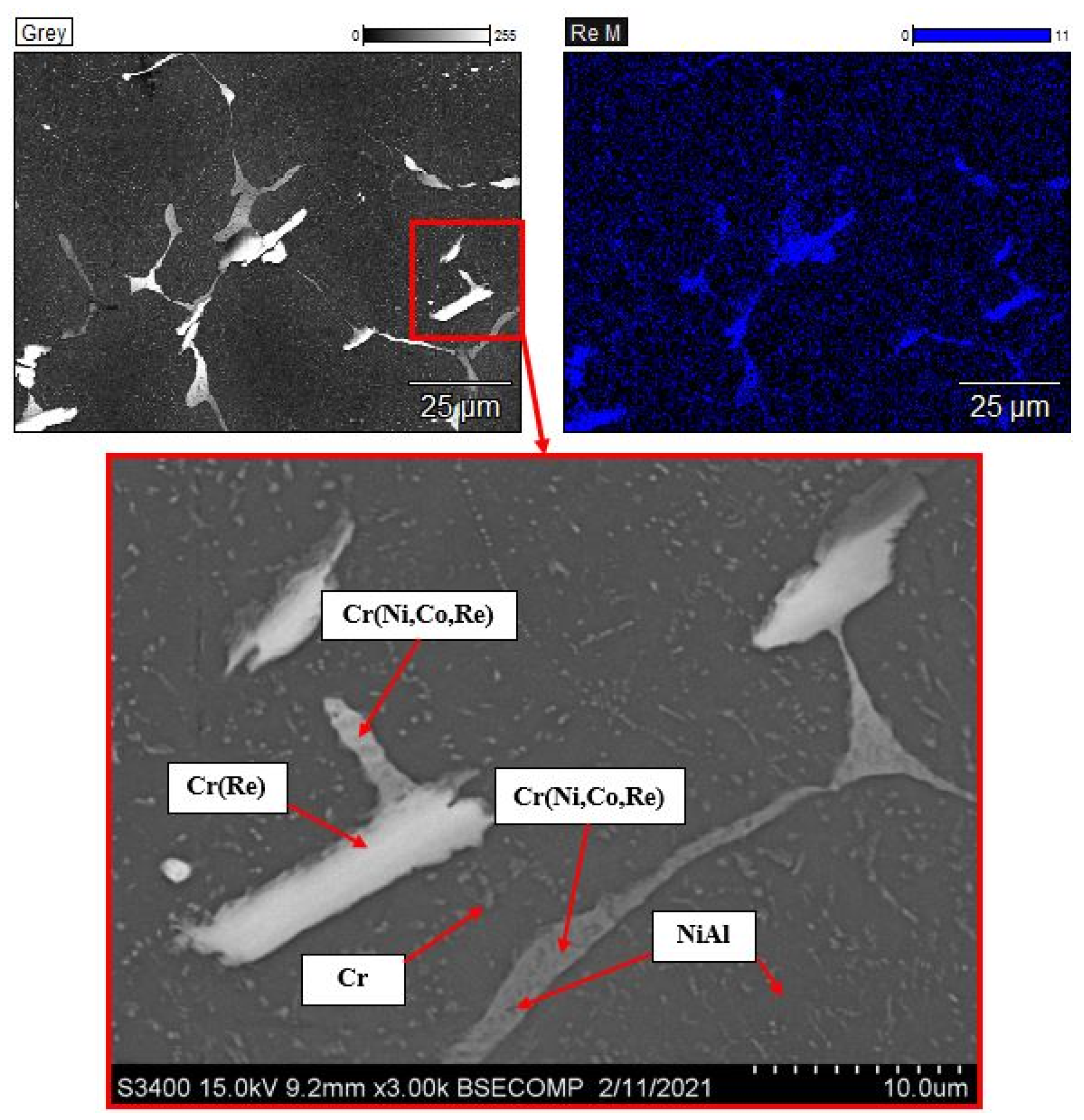

| NiAl-Cr-Co+1.5%Re | NiAl | 100.0 | 2.875 | 11.4 ± 6.0 | 199 ± 57 | 9.5 ± 0.2 | 181 ± 6 |

| Al(Re,Ni)3 | - | - | 30.1 | 378 | |||

| * X | Concentration, wt.%/at. % | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni | Al | Cr | Co | Mo | B | Re | ||||||||

| 15%Mo | 47 ± 1.0 | 40 ± 1.0 | 19.6 | 35.94 | 11.3 | 10.75 | 6.11 | 5.13 | 15.2 | 7.84 | 0.015 | 0.07 | - | |

| 15%Mo-1.5%Re | 45 ± 1.0 | 38 ± 1.0 | 18.7 | 34.88 | 12.3 | 11.90 | 6.8 | 5.81 | 15.40 | 8.08 | 0.019 | 0.09 | 1.49 | 0.4 |

| Matrix | Concentration, wt.% | |||||||

|---|---|---|---|---|---|---|---|---|

| W | C | Si | Fe | P | S | N | O | |

| 15%Mo | 0.0211 | 0.011 | 0.045 | 0.092 | 0.0025 | 0.0124 | 0.00359 | 0.0215 |

| 15%Mo-1.5%Re | 0.0218 | 0.011 | 0.041 | 0.114 | 0.0029 | 0.0121 | 0.00317 | 0.0188 |

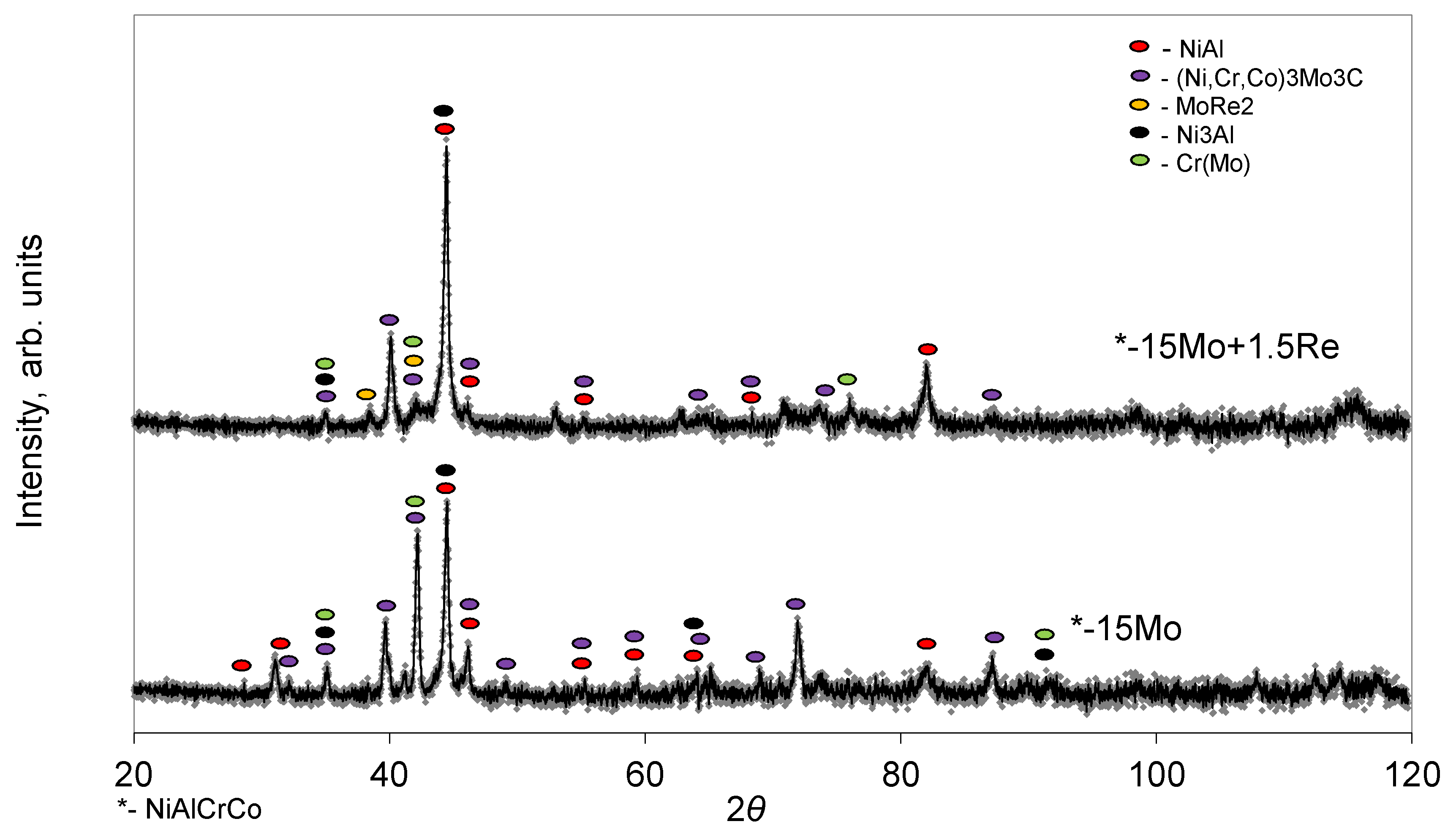

| Alloy | Phase | Phase Content, % | Lattice Parameters, Å | ||

|---|---|---|---|---|---|

| a | b | c | |||

| NiAl-Cr-Co+15%Mo | NiAl | 60.0 | 2.897 | - | - |

| (Ni,Cr,Co)3Mo3C | 31.2 | 11.093 | - | - | |

| Ni3Al | 5.1 | 3.756 | - | 3.276 | |

| (Cr, Mo) | 3.7 | 3.118 | - | - | |

| NiAl-Cr-Co+15%Mo-1.5%Re | NiAl | 54.5 | 2.866 | - | - |

| Ni3Al | 6.6 | 3.765 | - | 3.270 | |

| (Ni,Cr,Co)3Mo3C | 32.4 | 11.081 | - | - | |

| MoRe2 | 2.8 | 9.579 | - | 4.974 | |

| (Cr, Mo) | 3.7 | 3.035 | - | - | |

| No. | * +X | Tmelt, °C | ρ, g/cm3 | Cv, J/kg K | σucs, MPa | σys, MPa | εpd, % |

|---|---|---|---|---|---|---|---|

| 1 | 0.3La | 1570 | 6.36 | 636 | 738 | - | ˂1 ** |

| 2 | 2.5Mo | 1580 | 6.44 | 644 | 1586 | - | ˂1 ** |

| 3 | 0.5Zr | 1600 | 6.37 | 680 | 1099 | - | ˂1 ** |

| 4 | 2.5Ta | 1590 | 6.49 | 671 | 1388 | - | ˂1 ** |

| 5 | 1.5Re | 1585 | 6.55 | 580 | 1378 | - | ˂1 ** |

| 6 | 15Mo | 1580 | 7.06 | 706 | 1728 | 1566 | 0.95 |

| 7 | 15Mo-1.5Re | 1585 | 7.25 | 615 | 1800 | 1618 | 1.10 |

| No. | * +X | σucs, MPa | σys, MPa | εpd, % |

|---|---|---|---|---|

| 1.1 | 15Mo | 1728 | 1566 | 0.95 |

| 1.2 | T = 850 °C, t = 180 min | 1721 | 1636 | ˂1 ** |

| 1.3 | T = 1150 °C, t = 180 min | 1726 | 1642 | ˂1 ** |

| 1.4 | T = 1250 °C, t = 180 min | 1916 | 1653 | 2.01 |

| 2.1 | 15Mo-1.5Re | 1800 | 1618 | 1.10 |

| 2.2 | T = 850 °C, t = 180 min | 1833 | 1628 | 1.98 |

| 2.3 | T = 1150 °C, t = 180 min | 1910 | 1634 | 1.59 |

| 2.4 | T = 1250 °C, t = 180 min | 2267 | 1740 | 6.15 |

| EDXS Area | |||||

|---|---|---|---|---|---|

|  | ||||

| Spectrum | Ni | Al | Cr | Co | Mo |

| +15Mo | |||||

| 1 | 50.77 | 35.75 | 6.37 | 6.38 | 0.74 |

| 2 | 18.87 | - | 22.86 | 7.48 | 50.78 |

| 3 | 20.66 | - | 22.41 | 7.60 | 49.33 |

| 4 | - | - | 23.31 | - | 76.69 |

| 5 | - | - | 20.56 | - | 79.44 |

| +15Mo + annealing at 1250 °C | |||||

| 6 | 21.13 | - | 24.81 | 9.62 | 44.44 |

| 7 | 23.95 | - | 22.02 | 9.18 | 44.85 |

| 8 | 20.53 | - | 35.70 | 13.72 | 30.05 |

| 9 | - | - | 84.66 | - | 15.34 |

| 10 | 50.38 | 39.71 | 4.67 | 5.24 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanin, V.V.; Kaplansky, Y.Y.; Aheiev, M.I.; Levashov, E.A.; Petrzhik, M.I.; Bychkova, M.Y.; Samokhin, A.V.; Fadeev, A.A.; Sanin, V.N. Structure and Properties of Heat-Resistant Alloys NiAl–Cr–Co–X (X = La, Mo, Zr, Ta, Re) and Fabrication of Powders for Additive Manufacturing. Materials 2021, 14, 3144. https://doi.org/10.3390/ma14123144

Sanin VV, Kaplansky YY, Aheiev MI, Levashov EA, Petrzhik MI, Bychkova MY, Samokhin AV, Fadeev AA, Sanin VN. Structure and Properties of Heat-Resistant Alloys NiAl–Cr–Co–X (X = La, Mo, Zr, Ta, Re) and Fabrication of Powders for Additive Manufacturing. Materials. 2021; 14(12):3144. https://doi.org/10.3390/ma14123144

Chicago/Turabian StyleSanin, Vitaliy V., Yury Yu. Kaplansky, Maksym I. Aheiev, Evgeny A. Levashov, Mikhail I. Petrzhik, Marina Ya. Bychkova, Andrey V. Samokhin, Andrey A. Fadeev, and Vladimir N. Sanin. 2021. "Structure and Properties of Heat-Resistant Alloys NiAl–Cr–Co–X (X = La, Mo, Zr, Ta, Re) and Fabrication of Powders for Additive Manufacturing" Materials 14, no. 12: 3144. https://doi.org/10.3390/ma14123144

APA StyleSanin, V. V., Kaplansky, Y. Y., Aheiev, M. I., Levashov, E. A., Petrzhik, M. I., Bychkova, M. Y., Samokhin, A. V., Fadeev, A. A., & Sanin, V. N. (2021). Structure and Properties of Heat-Resistant Alloys NiAl–Cr–Co–X (X = La, Mo, Zr, Ta, Re) and Fabrication of Powders for Additive Manufacturing. Materials, 14(12), 3144. https://doi.org/10.3390/ma14123144