Prediction of Surface Roughness of an Abrasive Water Jet Cut Using an Artificial Neural Network

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Setup Description

2.2. Experimental Results

2.3. Artificial Neural Networks

2.4. Pre-Processing Validation and Performance Metrics

3. Results and Discussion

3.1. ANN Results

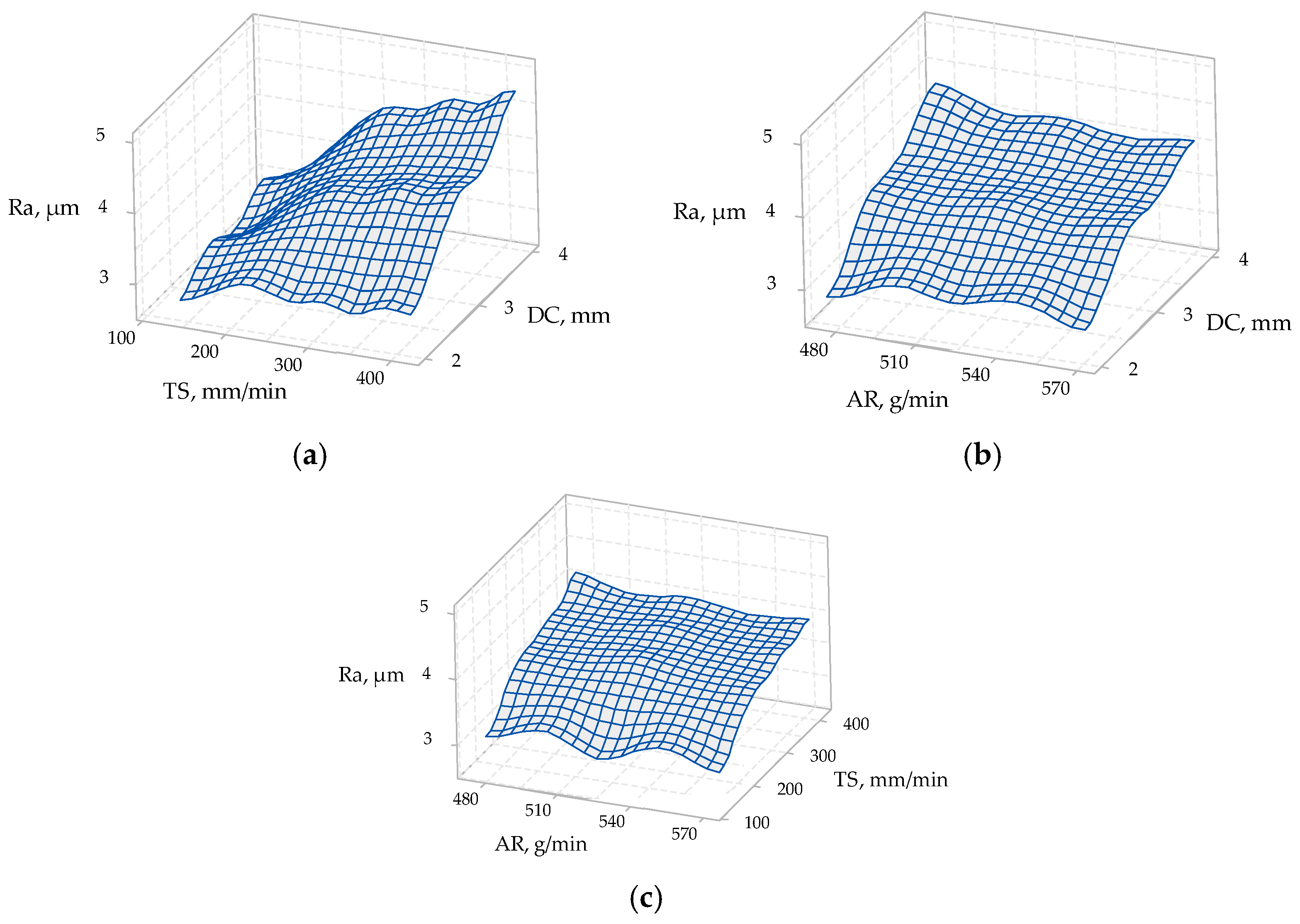

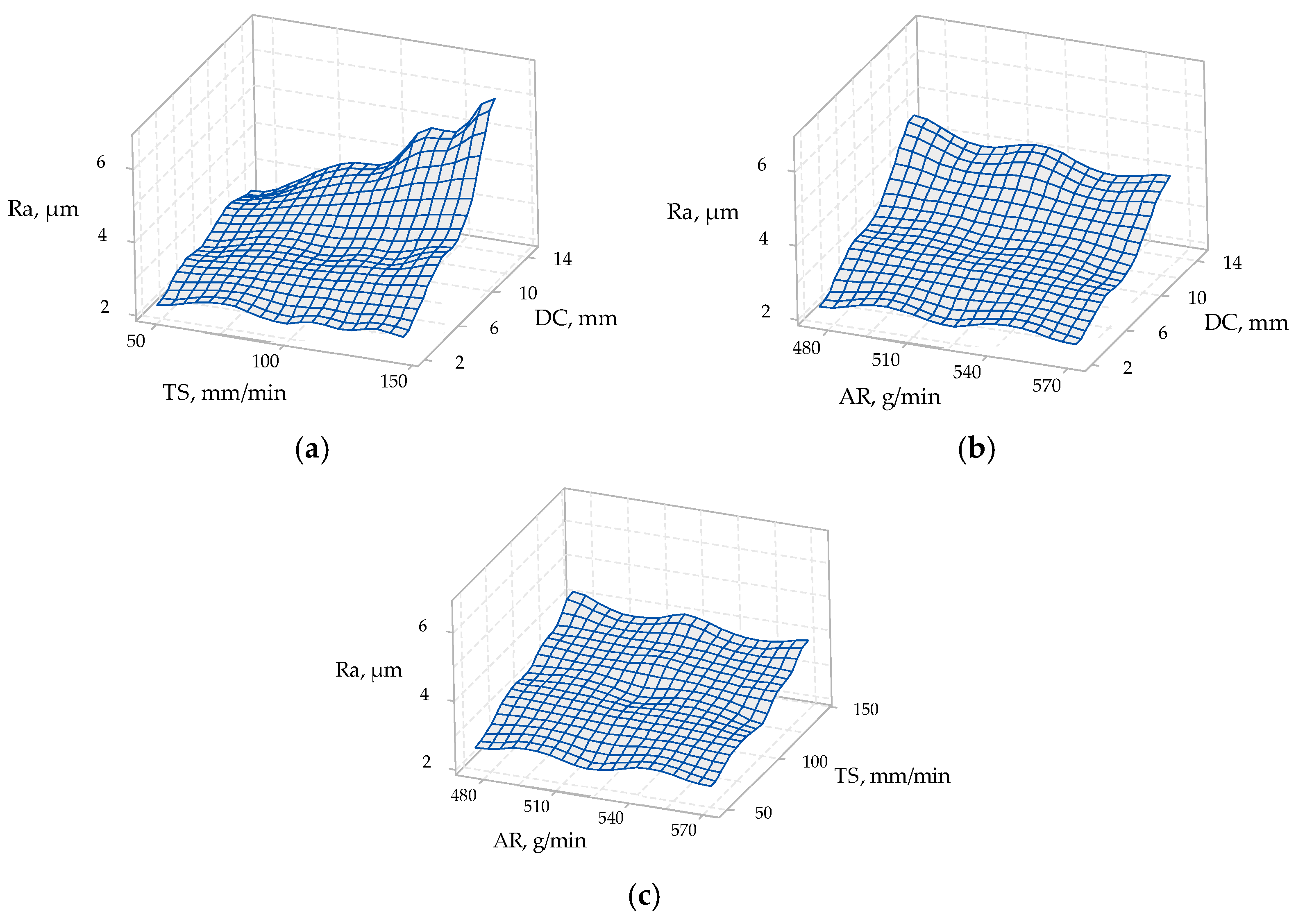

3.2. Analysis of Variance

3.3. ANN Concerning ANOVA

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Natarajan, Y.; Murugesan, P.K.; Mohan, M.; Khan, S.A.L.A. Abrasive Water Jet Machining process: A state of art of review. J. Manuf. Process 2020, 49, 271–322. [Google Scholar] [CrossRef]

- Saravanan, S.; Vijayan, V.; Suthahar, S.T.J.; Balan, A.V.; Sankar, S.; Ravichandran, M. A review on recent progresses in machining methods based on abrasive water jet machining. Mater. Today-Proc. 2020, 21, 116–122. [Google Scholar] [CrossRef]

- Yuvaraj, N.; Pavithra, E.; Shamli, C.S. Investigation of Surface Morphology and Topography Features on Abrasive Water Jet Milled Surface Pattern of SS 304. J. Test Eval. 2020, 48, 2981–2997. [Google Scholar] [CrossRef]

- Spaic, O.; Krivokapic, Z.; Kramar, D. Development of family of artificial neural networks for the prediction of cutting tool condition. Adv. Prod. Eng. Manag. 2020, 15, 164–178. [Google Scholar] [CrossRef]

- Klancnik, S.; Begic-Hajdarevic, D.; Paulic, M.; Ficko, M.; Cekic, A.; Husic, M.C. Prediction of Laser Cut Quality for Tungsten Alloy Using the Neural Network Method. Stroj. Vestn-J. Mech. E 2015, 61, 714–720. [Google Scholar] [CrossRef]

- Alajmi, M.S.; Almeshal, A.M. Prediction and Optimization of Surface Roughness in a Turning Process Using the ANFIS-QPSO Method. Materials 2020, 13, 2986. [Google Scholar] [CrossRef] [PubMed]

- Hribersek, M.; Berus, L.; Pusavec, F.; Klancnik, S. Empirical Modeling of Liquefied Nitrogen Cooling Impact during Machining Inconel 718. Appl. Sci. 2020, 10, 3603. [Google Scholar] [CrossRef]

- Alkhalefah, H. Precise Drilling of Holes in Alumina Ceramic (Al2O3) by Rotary Ultrasonic Drilling and its Parameter Optimization using MOGA-II. Materials 2020, 13, 1059. [Google Scholar] [CrossRef] [PubMed]

- Caydas, U.; Hascalik, A. A study on surface roughness in abrasive waterjet machining process using artificial neural networks and regression analysis method. J. Mater. Process Tech. 2008, 202, 574–582. [Google Scholar] [CrossRef]

- Srinivasan, R.; Jacob, V.; Muniappan, A.; Madhu, S.; Sreenevasulu, M. Modeling of surface roughness in abrasive water jet machining of AZ91 magnesium alloy using Fuzzy logic and Regression analysis. Mater. Today-Proc. 2020, 22, 1059–1064. [Google Scholar] [CrossRef]

- Maneiah, D.; Shunmugasundaram, M.; Reddy, A.R.; Begum, Z. Optimization of machining parameters for surface roughness during abrasive water jet machining of aluminium/magnesium hybrid metal matrix composites. Mater. Today-Proc. 2020, 27, 1293–1298. [Google Scholar] [CrossRef]

- Balamurugan, K.; Uthayakumar, M.; Sankat, S.; Hareesh, U.S.; Warrier, K.G.K. Predicting correlations in abrasive waterjet cutting parameters of Lanthanum phosphate/Yttria composite by response surface methodology. Measurement 2019, 131, 309–318. [Google Scholar] [CrossRef]

- Kale, A.; Singh, S.K.; Sateesh, N.; Subbiah, R. A review on abrasive water jet machining process and its process parameters. Mater. Today-Proc. 2020, 26, 1032–1036. [Google Scholar] [CrossRef]

- Radovanovic, M. Multi-Objective Optimization of Abrasive Water Jet Cutting Using MOGA. Procedia Manuf. 2020, 47, 781–787. [Google Scholar] [CrossRef]

- Filip, A.C.; Morariu, C.O.; Mihail, L.A.; Oancea, G. Research on Surface Roughness of Hardox Steels Parts Machined by Abrasive Waterjet. Stroj. Vestn. J. Mech. Eng. 2019, 65, 8. [Google Scholar] [CrossRef]

- Liu, D.; Huang, C.Z.; Wang, J.; Zhu, H.T.; Yao, P.; Liu, Z.W. Modeling and optimization of operating parameters for abrasive waterjet turning alumina ceramics using response surface methodology combined with Box-Behnken design. Ceram. Int. 2014, 40, 7899–7908. [Google Scholar] [CrossRef]

- Begic-Hajdarevic, D.; Cekic, A.; Mehmedovic, M.; Djelmic, A. Experimental Study on Surface Roughness in Abrasive Water Jet Cutting. Procedia Eng. 2015, 100, 394–399. [Google Scholar] [CrossRef]

- Shibin, R.; Anandakrishnan, V.; Sathish, S.; Sujana, V.M. Investigation on the abrasive water jet machinability of AA2014 using SiC as abrasive. Mater. Today-Proc. 2020, 21, 519–522. [Google Scholar] [CrossRef]

- Boud, F.; Carpenter, C.; Folkes, J.; Shipway, P.H. Abrasive waterjet cutting of a titanium alloy: The influence of abrasive morphology and mechanical properties on workpiece grit embedment and cut quality. J. Mater. Process Tech. 2010, 210, 2197–2205. [Google Scholar] [CrossRef]

- Aydin, G.; Kaya, S.; Karakurt, I. Utilization of solid-cutting waste of granite as an alternative abrasive in abrasive waterjet cutting of marble. J. Clean. Prod. 2017, 159, 241–247. [Google Scholar] [CrossRef]

- Bagchi, A.; Srivastava, M.; Tripathi, R.; Chattopadhyaya, S. Effect of different parameters on surface roughness and material removal rate in abrasive water jet cutting of Nimonic C263. Mater. Today-Proc. 2020, 27, 2239–2242. [Google Scholar] [CrossRef]

- Deaconescu, A.; Deaconescu, T. Response Surface Methods Used for Optimization of Abrasive Waterjet Machining of the Stainless Steel X2 CrNiMo 17-12-2. Materials 2021, 14, 2475. [Google Scholar] [CrossRef]

- Kmec, J.; Gombar, M.; Harnicarova, M.; Valicek, J.; Kusnerova, M.; Kriz, J.; Kadnar, M.; Karkova, M.; Vagaska, A. The Predictive Model of Surface Texture Generated by Abrasive Water Jet for Austenitic Steels. Appl. Sci. 2020, 10, 3159. [Google Scholar] [CrossRef]

- Kulisz, M.; Zagorski, I.; Korpysa, J. The Effect of Abrasive Waterjet Machining Parameters on the Condition of Al-Si Alloy. Materials 2020, 13, 3122. [Google Scholar] [CrossRef]

- Ganovska, B.; Molitoris, M.; Hosovsky, A.; Pitel, J.; Krolczyk, J.B.; Ruggierio, A.; Krolczyk, G.M.; Hloch, S. Design of the model for the on-line control of the AWJ technology based on neural networks. Indian J. Eng. Mater. S 2016, 23, 279–287. [Google Scholar]

- Gaidhani, Y.B. Abrasive water jet review and parameter selection by AHP method. IOSR J. Mech. Civ. Eng. 2013, 8, 1–6. [Google Scholar] [CrossRef]

- Khalid, A.; Noureldien, N.A. Determining the Efficient Structure of Feed-Forward Neural Network to Classify Breast Cancer Dataset. Int. J. Adv. Comput. Sci. Appl. 2014, 5. [Google Scholar] [CrossRef]

- Kasabov, N.K. Foundations of Neural Networks, Fuzzy Systems, and Knowledge Engineering; MIT Press: Cambridge, MA, USA, 1996; 550p. [Google Scholar]

- Cheng, B.; Titterington, D.M. Neural Networks—A Review from a Statistical Perspective. Stat. Sci. 1994, 9, 2–30. [Google Scholar]

- Liu, Y.Y.; Starzyk, J.A.; Zhu, Z. Optimized approximation algorithm in neural networks without overfitting. IEEE Trans. Neural Netw. 2008, 19, 983–995. [Google Scholar] [CrossRef]

- Berus, L.; Klancnik, S.; Brezocnik, M.; Ficko, M. Classifying Parkinson’s Disease Based on Acoustic Measures Using Artificial Neural Networks. Sensors 2019, 19, 16. [Google Scholar] [CrossRef] [PubMed]

- Blum, A. Neural Networks in C++: An Object-Oriented Framework for Building Connectionist Systems; Wiley: New York, NY, USA, 1992. [Google Scholar]

| Constant Parameters | Orifice Diameter | Focusing Tube Diameter | Water Jet Pressure | Abrasive Type | Abrasive Size (grit no) |

|---|---|---|---|---|---|

| Value | 0.33 mm | 1.016 mm | 350 MPa | GMT garnet | 80 mesh |

| Process Parameters | Traverse Speed (TS) (mm/min) | Abrasive Mass Flow Rate (AR) (g/min) |

|---|---|---|

| Material thickness 5 mm | 139, 278, 347, 417 | 475, 522, 571 |

| Material thickness 10 mm | 76, 152, 190, 228 | 475, 522, 571 |

| Material thickness 15 mm | 48, 96, 120, 144 | 475, 522, 571 |

| AR (g/min) | TS (mm/min) | Position throughout the Depth of the Cut (DC) | Ra (µm) | |||||

|---|---|---|---|---|---|---|---|---|

| (mm) | Section | P1 | P2 | P3 | P4 | Mean | ||

| 475 | 139 | 2 | top | 2.74 | 2.24 | 2.9 | 2.66 | 2.635 |

| 3 | middle | 3.28 | 2.9 | 3.46 | 2.57 | 3.053 | ||

| 4 | bottom | 3.36 | 3.02 | 3.11 | 3.14 | 3.158 | ||

| 278 | 2 | top | 3.02 | 2.91 | 3.06 | 2.87 | 2.965 | |

| 3 | middle | 3.48 | 3.94 | 3.53 | 3.89 | 3.710 | ||

| 4 | bottom | 4.87 | 3.71 | 4.72 | 3.86 | 4.290 | ||

| 347 | 2 | top | 2.81 | 2.6 | 2.61 | 3.18 | 2.800 | |

| 3 | middle | 3.79 | 3.64 | 3.91 | 4.3 | 3.910 | ||

| 4 | bottom | 4.58 | 4.34 | 4.95 | 4.65 | 4.630 | ||

| 417 | 2 | top | 2.95 | 3.23 | 2.67 | 3.29 | 3.035 | |

| 3 | middle | 4.05 | 4.65 | 3.94 | 3.98 | 4.155 | ||

| 4 | bottom | 4.74 | 5.39 | 5.09 | 4.71 | 4.983 | ||

| 522 | 139 | 2 | top | 2.7 | 3.21 | 2.67 | 2.79 | 2.843 |

| 3 | middle | 2.86 | 2.91 | 2.89 | 2.92 | 2.895 | ||

| 4 | bottom | 2.8 | 2.59 | 3.09 | 3.16 | 2.910 | ||

| 278 | 2 | top | 3.24 | 2.65 | 3.21 | 2.74 | 2.960 | |

| 3 | middle | 3.92 | 4.01 | 4.51 | 3.67 | 4.028 | ||

| 4 | bottom | 4.2 | 4.33 | 4.59 | 4.26 | 4.345 | ||

| 347 | 2 | top | 3.07 | 3.05 | 3.31 | 3.15 | 3.145 | |

| 3 | middle | 3.82 | 4.05 | 4.32 | 4.25 | 4.110 | ||

| 4 | bottom | 4.2 | 4.3 | 4.45 | 4.55 | 4.375 | ||

| 417 | 2 | top | 3.41 | 3.04 | 3.11 | 3.44 | 3.250 | |

| 3 | middle | 3.85 | 4.34 | 3.88 | 3.8 | 3.968 | ||

| 4 | bottom | 4.37 | 4.68 | 4.48 | 5.07 | 4.650 | ||

| 571 | 139 | 2 | top | 3.37 | 2.64 | 3.19 | 2.29 | 2.873 |

| 3 | middle | 2.67 | 2.93 | 3.01 | 3.33 | 2.985 | ||

| 4 | bottom | 3.1 | 3.15 | 3.04 | 3.01 | 3.075 | ||

| 278 | 2 | top | 2.97 | 3.61 | 2.82 | 2.85 | 3.063 | |

| 3 | middle | 3.53 | 3.63 | 4.14 | 3.97 | 3.818 | ||

| 4 | bottom | 4.01 | 4.33 | 3.72 | 4.33 | 4.098 | ||

| 347 | 2 | top | 2.54 | 2.92 | 3.25 | 3.07 | 2.945 | |

| 3 | middle | 3.54 | 4.25 | 4.09 | 4.32 | 4.050 | ||

| 4 | bottom | 4.26 | 4.17 | 5.07 | 4.32 | 4.455 | ||

| 417 | 2 | top | 3.01 | 2.94 | 2.99 | 2.98 | 2.980 | |

| 3 | middle | 4.08 | 4.08 | 4.01 | 4.62 | 4.198 | ||

| 4 | bottom | 4.31 | 4.89 | 4.43 | 4.66 | 4.573 | ||

| AR (g/min) | TS (mm/min) | Position throughout the Depth of the Cut (DC) | Ra (µm) | |||||

|---|---|---|---|---|---|---|---|---|

| (mm) | Section | P1 | P2 | P3 | P4 | Mean | ||

| 475 | 76 | 2 | top | 2.91 | 2.09 | 2.4 | 2.44 | 2.460 |

| 5 | middle | 3.08 | 2.72 | 2.9 | 3.34 | 3.010 | ||

| 8 | bottom | 4.57 | 2.85 | 2.92 | 3.29 | 3.408 | ||

| 152 | 2 | top | 2.54 | 2.28 | 2.49 | 2.59 | 2.475 | |

| 5 | middle | 2.63 | 3.35 | 3.66 | 2.85 | 3.123 | ||

| 8 | bottom | 4.35 | 3.83 | 4.22 | 3.91 | 4.078 | ||

| 190 | 2 | top | 2.37 | 2.3 | 2.39 | 2.32 | 2.345 | |

| 5 | middle | 3.85 | 4.15 | 3.39 | 3.69 | 3.770 | ||

| 8 | bottom | 4.93 | 5.1 | 4.69 | 4.88 | 4.900 | ||

| 228 | 2 | top | 2.45 | 2.74 | 2.7 | 2.99 | 2.720 | |

| 5 | middle | 5.15 | 4.87 | 4.88 | 4.6 | 4.875 | ||

| 8 | bottom | 6.84 | 6.79 | 6.35 | 6.3 | 6.570 | ||

| 522 | 76 | 2 | top | 2.43 | 2.87 | 2.26 | 2.7 | 2.565 |

| 5 | middle | 2.86 | 2.71 | 3.1 | 2.95 | 2.905 | ||

| 8 | bottom | 2.91 | 2.89 | 2.96 | 2.94 | 2.925 | ||

| 152 | 2 | top | 2.44 | 2.56 | 2.4 | 2.52 | 2.480 | |

| 5 | middle | 3.41 | 3.22 | 3.47 | 3.28 | 3.345 | ||

| 8 | bottom | 4.28 | 4.14 | 4.8 | 4.66 | 4.470 | ||

| 190 | 2 | top | 2.47 | 2.44 | 2.25 | 2.28 | 2.360 | |

| 5 | middle | 3.45 | 3.39 | 3.71 | 3.65 | 3.550 | ||

| 8 | bottom | 4.83 | 5.01 | 4.69 | 4.87 | 4.850 | ||

| 228 | 2 | top | 2.34 | 2.34 | 2.6 | 2.6 | 2.470 | |

| 5 | middle | 4.15 | 3.91 | 4.34 | 4.1 | 4.125 | ||

| 8 | bottom | 6.58 | 7.03 | 5.95 | 6.4 | 6.490 | ||

| 571 | 76 | 2 | top | 2.69 | 2.44 | 2.81 | 2.49 | 2.608 |

| 5 | middle | 3.76 | 3.03 | 3.01 | 2.54 | 3.085 | ||

| 8 | bottom | 3.32 | 3.1 | 2.88 | 3.55 | 3.213 | ||

| 152 | 2 | top | 2.23 | 2.55 | 2.96 | 2.38 | 2.530 | |

| 5 | middle | 3.1 | 3.12 | 3.25 | 3.27 | 3.185 | ||

| 8 | bottom | 3.86 | 4.51 | 3.9 | 4.55 | 4.205 | ||

| 190 | 2 | top | 2.17 | 3.2 | 2.86 | 2.56 | 2.698 | |

| 5 | middle | 2.63 | 3.24 | 4.26 | 3.17 | 3.325 | ||

| 8 | bottom | 4.79 | 4.36 | 5.42 | 4.99 | 4.890 | ||

| 228 | 2 | top | 2.47 | 2.7 | 2.83 | 2.3 | 2.575 | |

| 5 | middle | 3.63 | 3.24 | 4.22 | 3.75 | 3.710 | ||

| 8 | bottom | 6.47 | 6.26 | 6.31 | 6.1 | 6.285 | ||

| AR (g/min) | TS (mm/min) | Position throughout the Depth of the Cut (DC) | Ra (µm) | |||||

|---|---|---|---|---|---|---|---|---|

| (mm) | Section | P1 | P2 | P3 | P4 | Mean | ||

| 475 | 48 | 2 | top | 2.14 | 2.22 | 2.13 | 2.21 | 2.175 |

| 7 | middle | 2.63 | 2.48 | 2.78 | 2.63 | 2.630 | ||

| 13 | bottom | 2.28 | 2.99 | 2.57 | 3.28 | 2.780 | ||

| 96 | 2 | top | 2.21 | 2.04 | 2.18 | 2.01 | 2.110 | |

| 7 | middle | 2.99 | 2.78 | 3.22 | 3.01 | 3.000 | ||

| 13 | bottom | 4.43 | 4.57 | 4.39 | 4.53 | 4.480 | ||

| 120 | 2 | top | 2.46 | 2.37 | 2.2 | 2.11 | 2.285 | |

| 7 | middle | 3.05 | 3.33 | 2.99 | 3.27 | 3.160 | ||

| 13 | bottom | 5.02 | 5.34 | 5.46 | 5.78 | 5.400 | ||

| 144 | 2 | top | 2.59 | 2.3 | 2.54 | 2.25 | 2.420 | |

| 7 | middle | 3.39 | 3.08 | 4.08 | 3.77 | 3.580 | ||

| 13 | bottom | 6.42 | 6.79 | 6.55 | 6.92 | 6.670 | ||

| 522 | 48 | 2 | top | 2.15 | 1.95 | 2.31 | 2.11 | 2.130 |

| 7 | middle | 2.45 | 2.51 | 2.56 | 2.62 | 2.535 | ||

| 13 | bottom | 2.81 | 2.43 | 2.92 | 2.54 | 2.675 | ||

| 96 | 2 | top | 2.17 | 2.31 | 2.26 | 2.4 | 2.285 | |

| 7 | middle | 2.58 | 2.62 | 3.13 | 3.17 | 2.875 | ||

| 13 | bottom | 3.75 | 3.86 | 3.92 | 4.03 | 3.890 | ||

| 120 | 2 | top | 2.61 | 2.32 | 2.54 | 2.25 | 2.430 | |

| 7 | middle | 3.01 | 3.06 | 3.11 | 3.22 | 3.100 | ||

| 13 | bottom | 5.4 | 5.24 | 5.35 | 5.19 | 5.295 | ||

| 144 | 2 | top | 2.22 | 2.25 | 2.36 | 2.39 | 2.305 | |

| 7 | middle | 3.8 | 3.34 | 3.7 | 3.24 | 3.520 | ||

| 13 | bottom | 6.34 | 6.88 | 5.92 | 6.46 | 6.400 | ||

| 571 | 48 | 2 | top | 2.24 | 2.09 | 2.48 | 2.33 | 2.285 |

| 7 | middle | 2.46 | 2.51 | 2.52 | 2.57 | 2.515 | ||

| 13 | bottom | 2.69 | 2.76 | 2.6 | 2.67 | 2.680 | ||

| 96 | 2 | top | 2.3 | 2.2 | 2.35 | 2.25 | 2.275 | |

| 7 | middle | 2.76 | 2.7 | 2.6 | 2.54 | 2.650 | ||

| 13 | bottom | 3.47 | 3.42 | 3.63 | 3.58 | 3.525 | ||

| 120 | 2 | top | 2.2 | 2.26 | 2.26 | 2.32 | 2.260 | |

| 7 | middle | 2.61 | 2.93 | 2.54 | 2.86 | 2.735 | ||

| 13 | bottom | 5.01 | 4.74 | 5.81 | 4.64 | 5.050 | ||

| 144 | 2 | top | 2.36 | 2.35 | 2.75 | 2.42 | 2.470 | |

| 7 | middle | 3.27 | 3.24 | 3.43 | 3.4 | 3.335 | ||

| 13 | bottom | 5.78 | 6.05 | 5.74 | 5.99 | 5.890 | ||

| ANN Information | Config 1 | Config 2 | Config 3 | Config 4 | Config 5 |

|---|---|---|---|---|---|

| Training procedure | Trainscg | Trainscg | Traingda | Trainlm | Trainbr |

| Learning epochs | 200 | 200 | 200 | 9 | 14 |

| Transfer function | logsig | purelin | logsig | logsig | logsig |

| Architecture | ANN 4_8 | ANN 4_8 | ANN 4_8 | ANN 4_8 | ANN 4_8 |

| Cross validation | 36-fold | 36-fold | 36-fold | 36-fold | 36-fold |

| Test MAE | 0.2046 | 0.4399 | 0.6057 | 0.2525 | 0.2093 |

| Train MAE | 0.1390 | 0.4251 | 0.5388 | 0.1709 | 0.1715 |

| Test RMSE | 0.2397 | 0.5197 | 0.6956 | 0.2955 | 0.2477 |

| Train RMSE | 0.1772 | 0.5699 | 0.6980 | 0.2217 | 0.2209 |

| Time (s) | 118.7 | 124.6 | 101.4 | 60.4 | 68.5 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value | PC (%) |

|---|---|---|---|---|---|---|

| AR | 2 | 0.0056 | 0.00281 | 0.03 | 0.966 | 0.03 |

| TS | 3 | 5.7789 | 1.92618 | 23.72 | 0.000 | 34.83 |

| DC | 2 | 8.5327 | 4.26635 | 52.53 | 0.000 | 51.43 |

| Error | 28 | 2.2742 | 0.08122 | 13.71 | ||

| Total | 35 | 16.5911 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value | PC (%) |

|---|---|---|---|---|---|---|

| AR | 2 | 0.0978 | 0.0489 | 0.14 | 0.866 | 0.2 |

| TS | 3 | 11.0971 | 3.6990 | 10.97 | 0.000 | 22.70 |

| DC | 2 | 28.2529 | 14.1265 | 41.88 | 0.000 | 57.79 |

| Error | 28 | 9.4451 | 0.3373 | 19.31 | ||

| Total | 35 | 48.8930 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value | PC (%) |

|---|---|---|---|---|---|---|

| AR | 2 | 0.3838 | 0.1919 | 0.46 | 0.639 | 0.67 |

| TS | 3 | 12.3679 | 4.1226 | 9.78 | 0.000 | 21.60 |

| DC | 2 | 32.7138 | 16.3569 | 38.80 | 0.000 | 57.12 |

| Error | 28 | 11.8049 | 0.4216 | 20.61 | ||

| Total | 35 | 57.2704 |

| ANN Information | Config 1 | Config 2 | Config 3 | Config 4 | config 5 |

|---|---|---|---|---|---|

| Training procedure | Trainscg | Trainscg | Traingda | Trainlm | Trainbr |

| Learning epochs | 200 | 200 | 200 | 9 | 14 |

| Transfer function | logsig | purelin | logsig | logsig | logsig |

| Architecture | ANN 4_8 | ANN 4_8 | ANN 4_8 | ANN 4_8 | ANN 4_8 |

| Cross validation | 36-fold | 36-fold | 36-fold | 36-fold | 36-fold |

| Test MAE | 0.1939 | 0.4366 | 0.5195 | 0.2280 | 0.2117 |

| Train MAE | 0.1468 | 0.4233 | 0.4652 | 0.1848 | 0.1828 |

| Test RMSE | 0.2282 | 0.5166 | 0.6045 | 0.2660 | 0.2496 |

| Train RMSE | 0.1946 | 0.5724 | 0.6042 | 0.2440 | 0.2356 |

| Time (s) | 107.1 | 115.3 | 87.4 | 51.0 | 58.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ficko, M.; Begic-Hajdarevic, D.; Cohodar Husic, M.; Berus, L.; Cekic, A.; Klancnik, S. Prediction of Surface Roughness of an Abrasive Water Jet Cut Using an Artificial Neural Network. Materials 2021, 14, 3108. https://doi.org/10.3390/ma14113108

Ficko M, Begic-Hajdarevic D, Cohodar Husic M, Berus L, Cekic A, Klancnik S. Prediction of Surface Roughness of an Abrasive Water Jet Cut Using an Artificial Neural Network. Materials. 2021; 14(11):3108. https://doi.org/10.3390/ma14113108

Chicago/Turabian StyleFicko, Mirko, Derzija Begic-Hajdarevic, Maida Cohodar Husic, Lucijano Berus, Ahmet Cekic, and Simon Klancnik. 2021. "Prediction of Surface Roughness of an Abrasive Water Jet Cut Using an Artificial Neural Network" Materials 14, no. 11: 3108. https://doi.org/10.3390/ma14113108

APA StyleFicko, M., Begic-Hajdarevic, D., Cohodar Husic, M., Berus, L., Cekic, A., & Klancnik, S. (2021). Prediction of Surface Roughness of an Abrasive Water Jet Cut Using an Artificial Neural Network. Materials, 14(11), 3108. https://doi.org/10.3390/ma14113108