Factors of Stress Concentration around Spherical Cavity Embedded in Cylinder Subjected to Internal Pressure

Abstract

1. Introduction

2. Theoretical Background

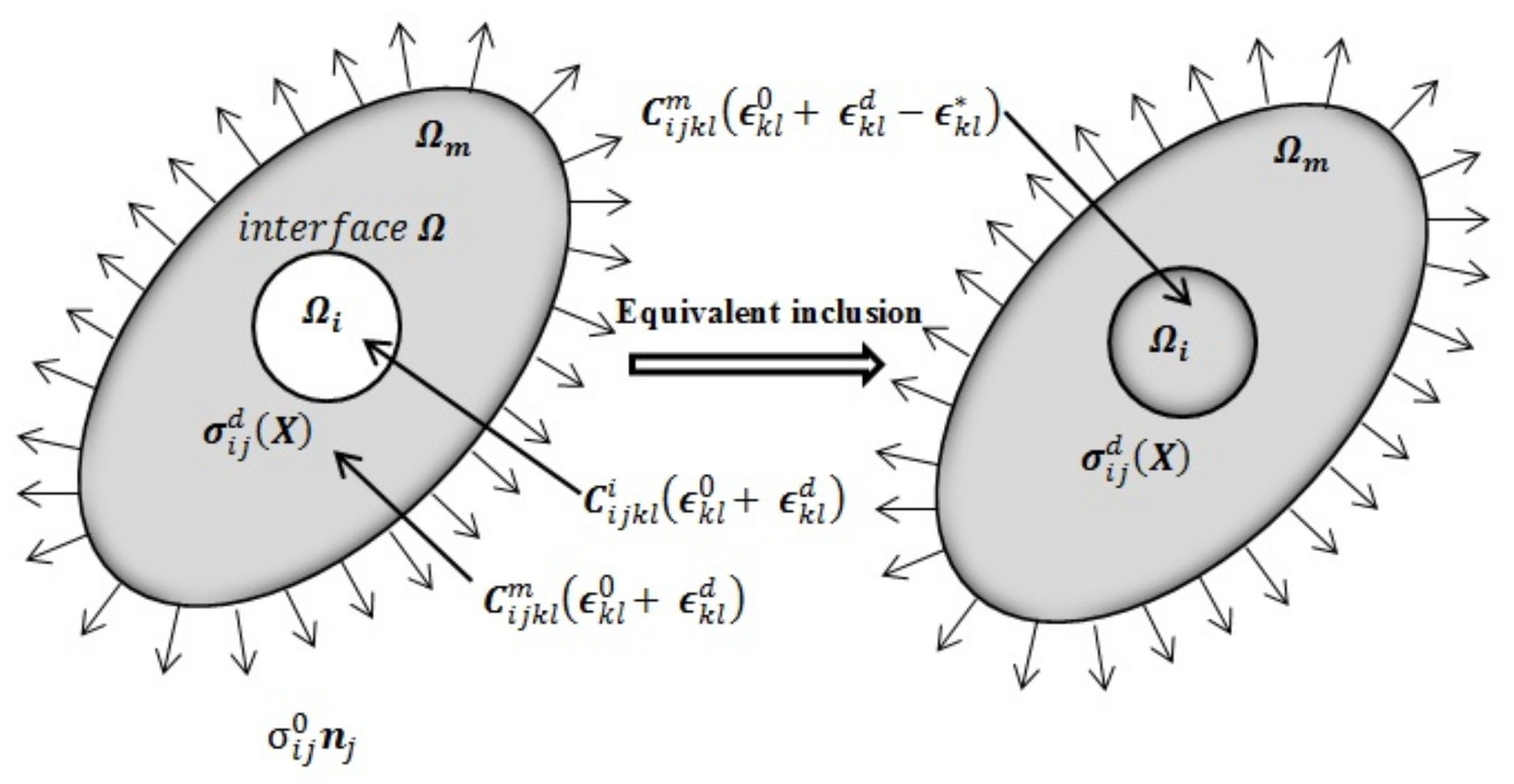

2.1. Eshelby’s Homogenization Principle

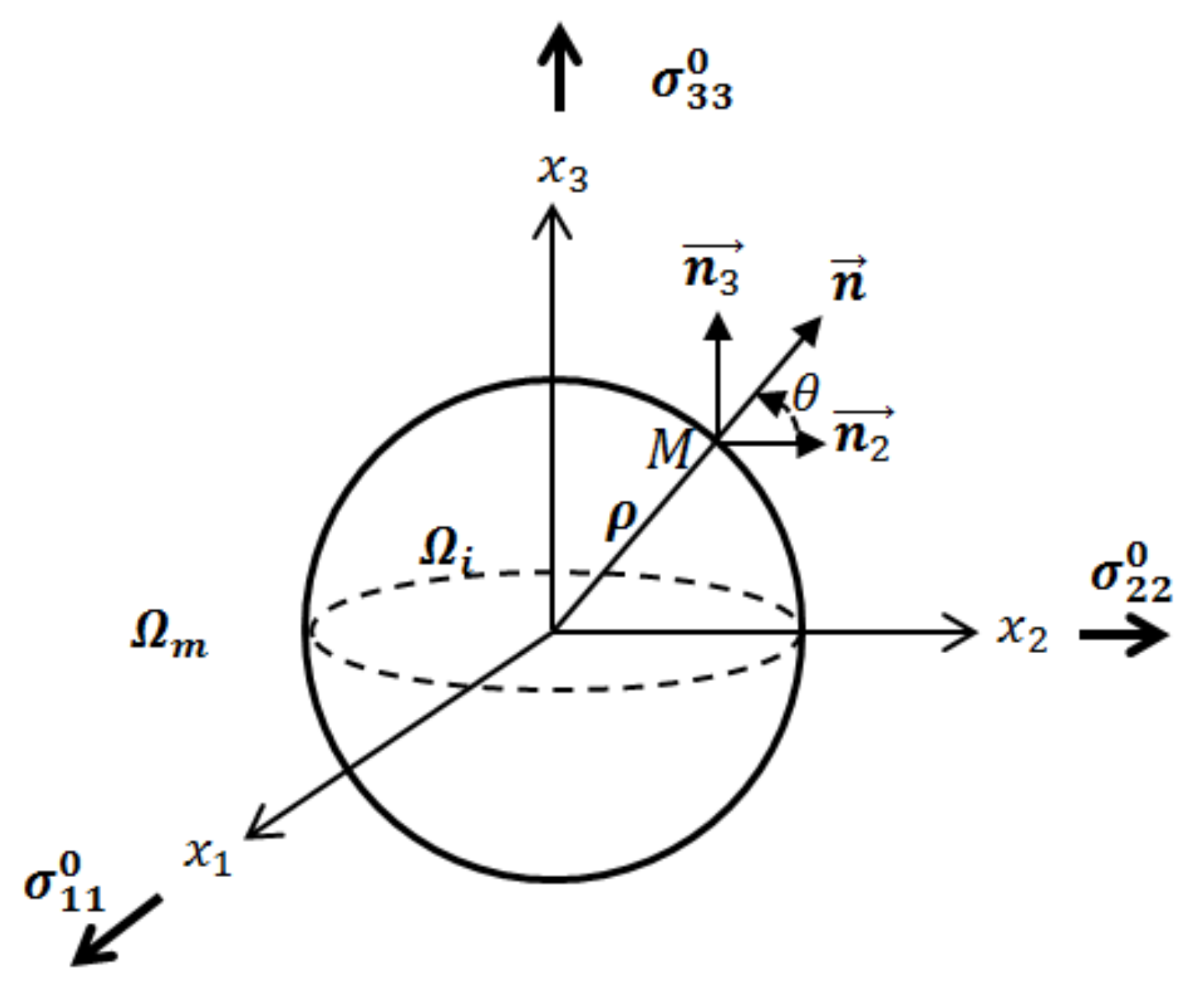

2.2. Jump Condition across Interface

2.3. Inhomogeneity in the Form of Spherical Cavity

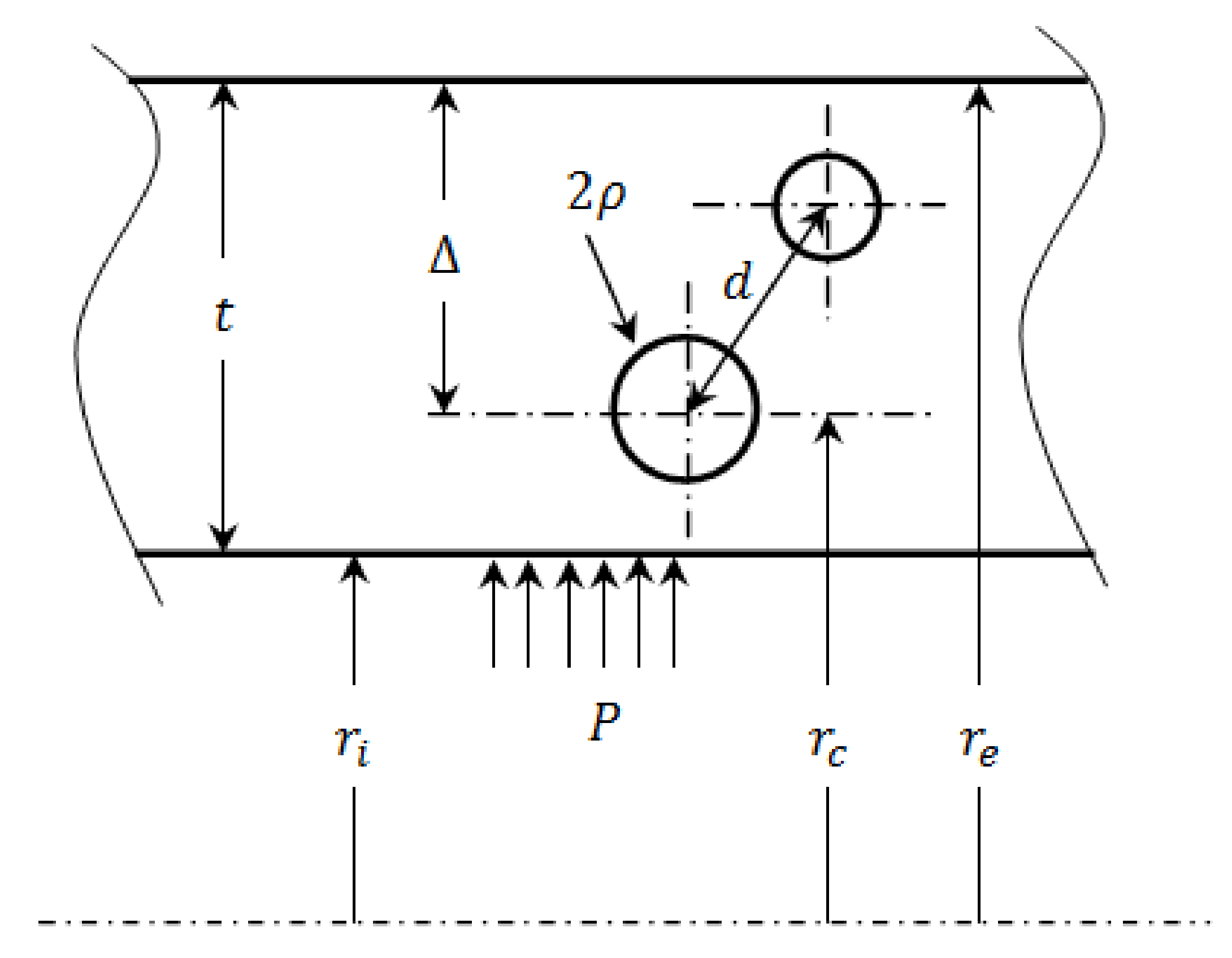

3. Spherical Cavity Embedded in a Cylinder Wall

4. Factors of Stress Concentration around a Cavity within the Tube Wall

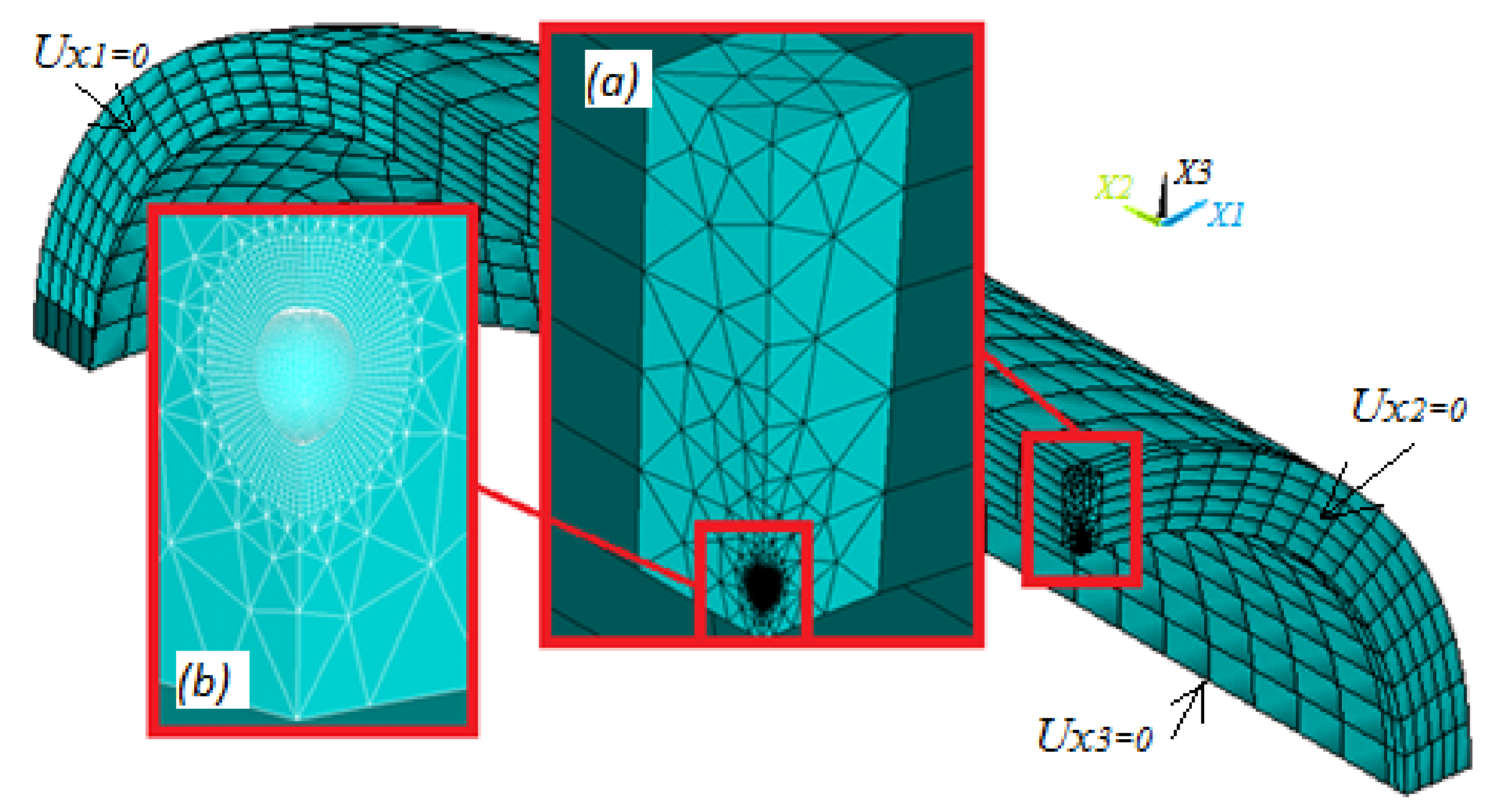

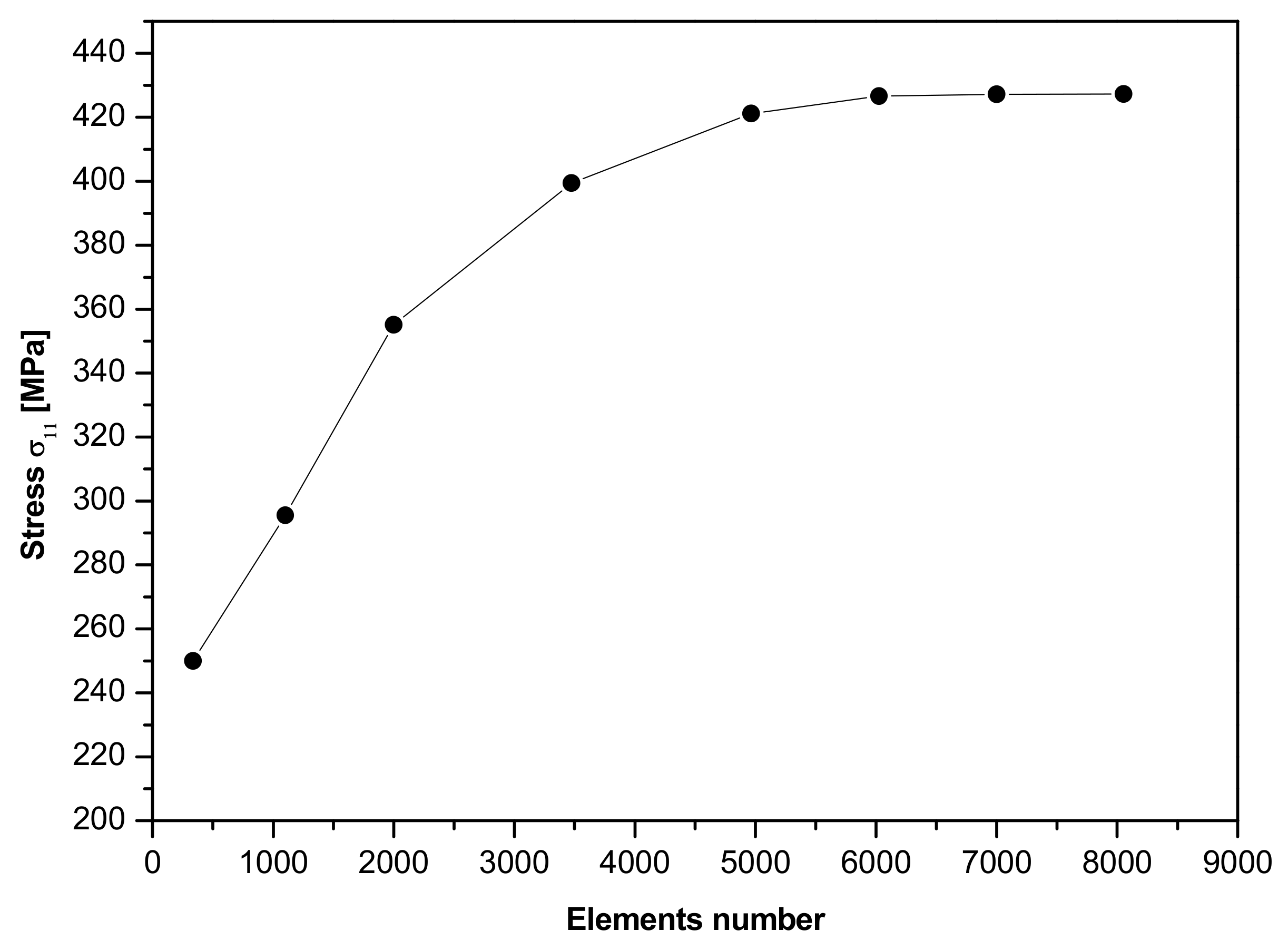

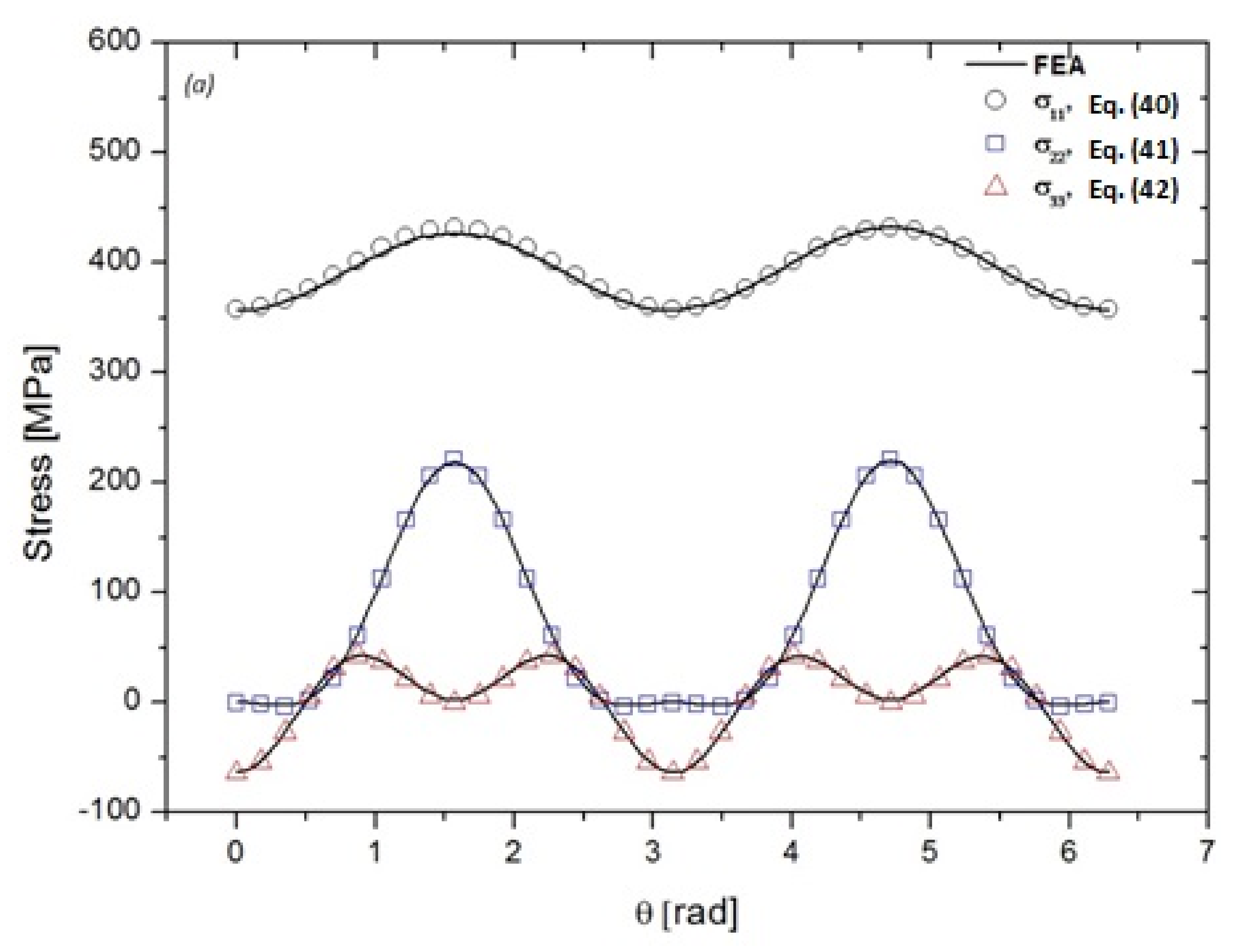

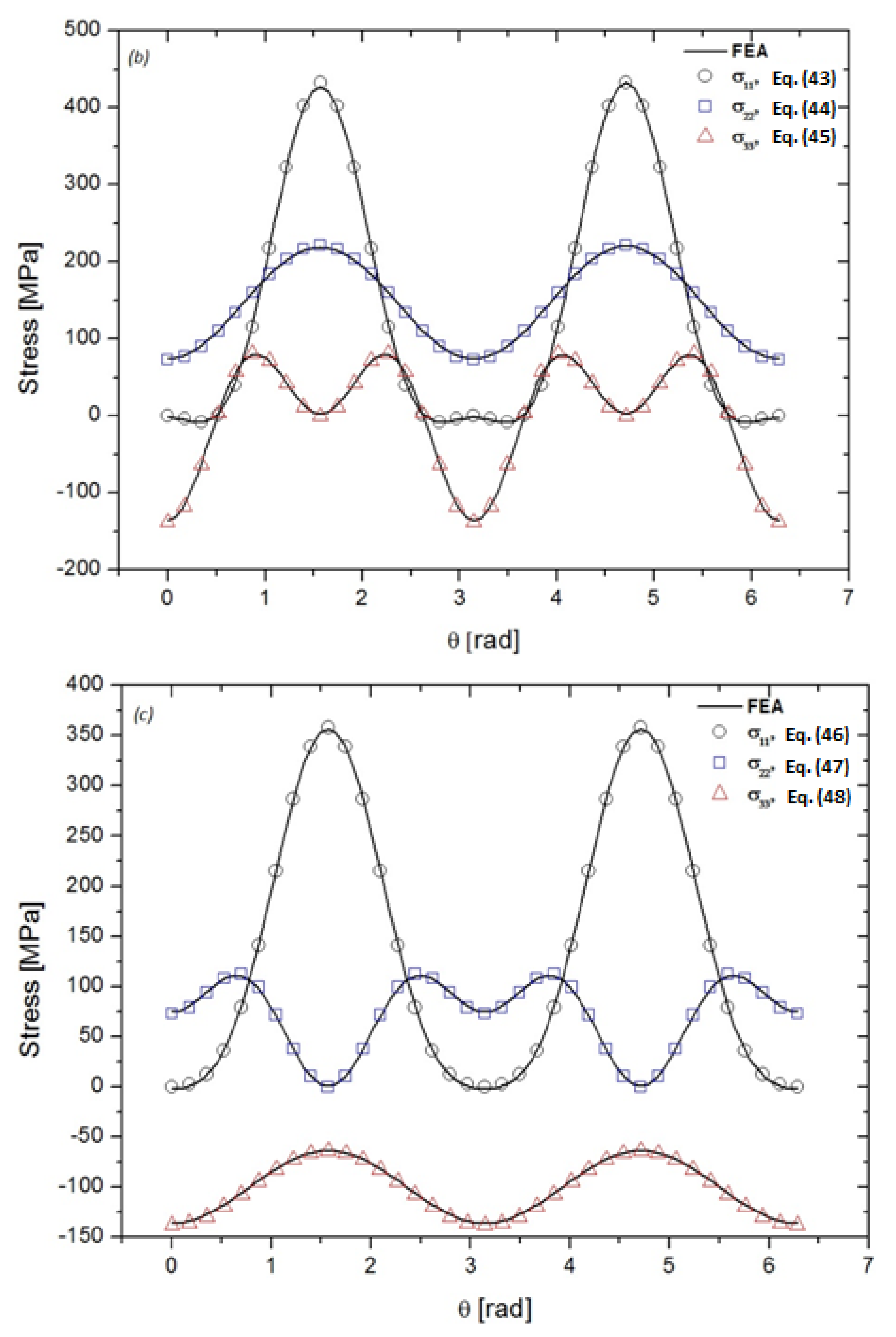

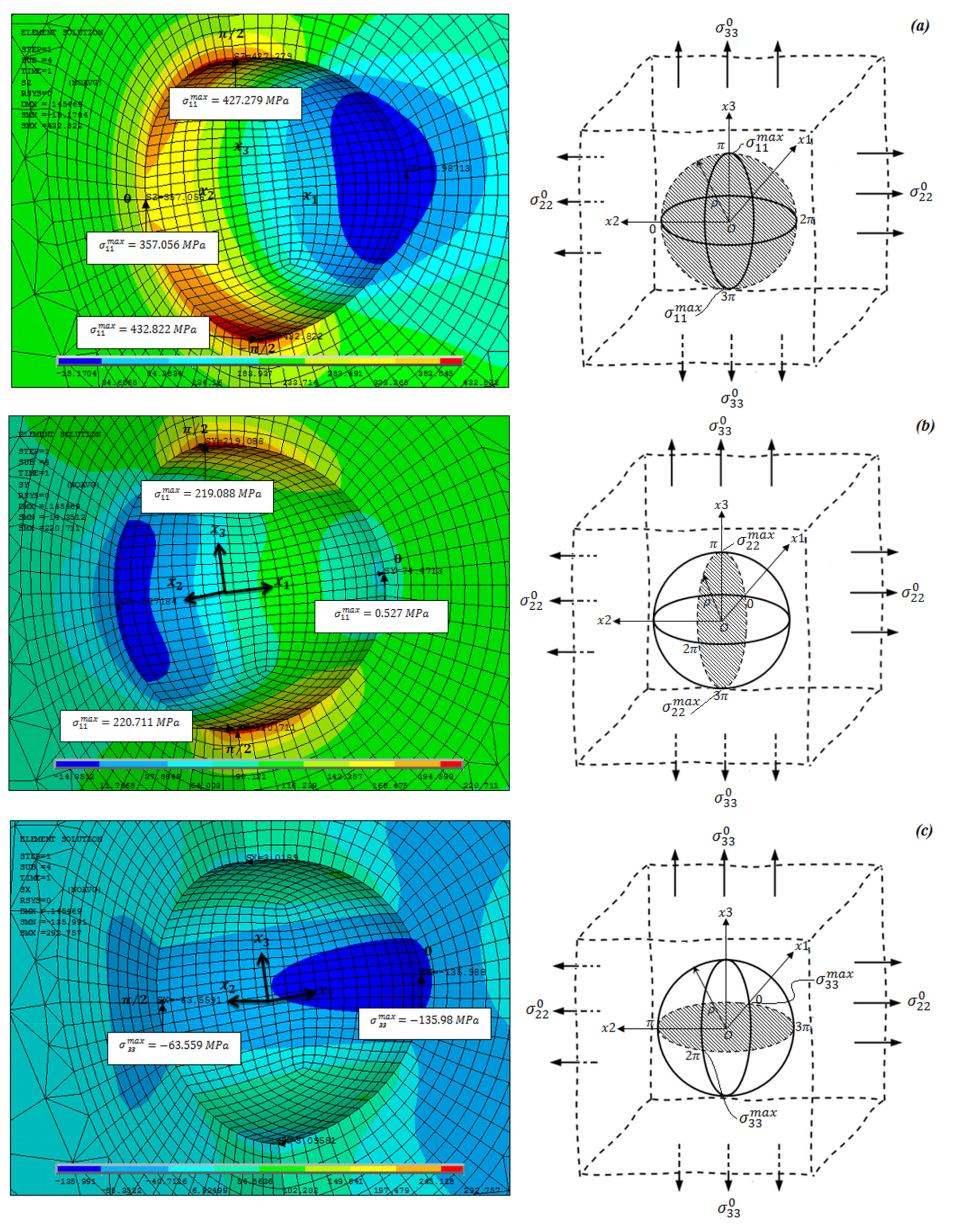

5. Numerical Validation of the Presented Methodology

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Eigenstrain | |

| , | Domain occupied by the matrix and the inclusion, respectively |

| , | Elastic stiffness of the matrix and the inclusion |

| , | Applied stress and the corresponding deformation |

| , | Total stress and the corresponding deformation |

| , | Perturbation stress and the corresponding deformation |

| Fourth rank Elshby’s tensor | |

| Stress jump across the interface | |

| Unit vector normal to the interface | |

| , | Average applied stress and corresponding deformation |

| Reference stress | |

| Applied internal pressure | |

| , | Internal and external radius of the tube |

| Cavity position with respect to the cylinder axis | |

| Porosity radius | |

| ,, | Poisson ratio, Young and shear modulus of the cylinder |

| ,, | Poisson ratio, Young and shear modulus of the inclusion |

| Stress concentration factor | |

| Geometric ratio of the cylinder | |

| Cavity depth | |

| Distance between two inclusions | |

| Cylinder wall thickness |

Appendix A

Appendix A.1. Expressions of the Coefficients to

Appendix A.2. Components of Normal Constraint across a Spherical Porosity

References

- Witek, M.; Uilhoorn, F. Influence of gas transmission network failure on security of supply. J. Nat. Gas Sci. Eng. 2021, 90. [Google Scholar] [CrossRef]

- Yu, W.; Song, S.; Li, Y.; Min, Y.; Huang, W.; Wen, K.; Gong, J. Gas supply reliability assessment of natural gas transmission pipeline systems. Energy 2018, 126, 853–870. [Google Scholar] [CrossRef]

- Witek, M. Possibilities of using X80, X100, X120 high strength steels for onshore gas transmission pipelines. J. Nat. Gas Sci. Eng. 2015, 27, 374–384. [Google Scholar] [CrossRef]

- Witek, M. Structural Integrity of Steel Pipeline with Clusters of Corrosion Defects. Materials 2021, 14, 852. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Xia, M.; Bolati, D.; Liu, J.; Zheng, Q.; Zhang, H. An ANN-based failure pressure prediction method for buried high-strength pipes with stray current corrosion defect. Energy Sci. Eng. 2019, 8, 248–259. [Google Scholar] [CrossRef]

- Singh, R. Weld defects and inspection. In Applied Welding Engineering: Processes, Codes, and Standards; Elsevier Inc.: Amsterdam, The Netherlands, 2016; pp. 229–243. [Google Scholar] [CrossRef]

- BS 7910 Guide to Methods for Assessing the Acceptability of Flaws in Metallic Structures; BSI Standards Publication: London, UK, 2015. [CrossRef]

- Anderson, T.L.; Osage, D.A. API 579: A comprehensive fitness-for-service guide. Int. J. Press. Vessel. Pip. 2000, 77, 953–963. [Google Scholar] [CrossRef]

- Mura, R.; Ting, T.C.T. Micromechanics of Defects in Solids (2nd rev. ed.). J. Appl. Mech. 1989. [Google Scholar] [CrossRef]

- Eshelby, J.D. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. A Math. Phys. Eng. Sci. 1957, 241, 376–396. [Google Scholar] [CrossRef]

- Eshelby, J.D. The elastic field outside an ellipsoidal inclusion. Proc. R. Soc. A Math. Phys. Eng. Sci. 1959, 252, 561–569. [Google Scholar] [CrossRef]

- Christensen, R.M. Mechanics of Composite Materials, 1st ed.; Wiley-Interscience: New York, NY, USA, 1980. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue—Effects of Small Defects and Nonmetallic Inclusions, 1st ed.; Elsevier Ltd.: Oxford, UK, 2002; p. 561. ISBN 0-08-044064. [Google Scholar]

- Nemat-Nasser, S.; Lori, M.; Datta, S.K. Micromechanics: Overall properties of heterogeneous materials. J. Appl. Mech. 1996. [Google Scholar] [CrossRef]

- Qu, J.; Cherkaoui, M. Inclusions and inhomogeneities. In Fundamentals of Micromechanics of Solids; Wiley: Hoboken, NJ, USA, 2007; pp. 71–98. [Google Scholar] [CrossRef]

- Li, S.; Gao, X.L. Micromechanical homogenization theory. In Introduction to Micromechanics and Nanomechanics; World Scientific Publishing Co. Pte Ltd.: Singapore, 2013; pp. 77–141. [Google Scholar] [CrossRef]

- Moschovidis, Z.A.; Mura, T. Two-ellipsoidal inhomogeneities by the equivalent inclusion method. J. Appl. Mech. Trans. ASME 1975, 42, 847–852. [Google Scholar] [CrossRef]

- Fond, C.; Riccardi, A.; Schirrer, R.; Montheillet, F. Mechanical interaction between spherical inhomogeneities: An assessment of a method based on the equivalent inclusion. Eur. J. Mech. A/Solids 2001, 20, 59–75. [Google Scholar] [CrossRef]

- Sabina, F.J.; Bravo-Castillero, J.; Guinovart-Díaz, R.; Rodríguez-Ramos, R.; Valdiviezo-Mijangos, O.C. Overall behavior of two-dimensional periodic composites. Int. J. Solids Struct. 2001. [Google Scholar] [CrossRef]

- Benedikt, B.; Lewis, M.; Rangaswamy, P. On elastic interactions between spherical inclusions by the equivalent inclusion method. Comput. Mater. Sci. 2006, 37, 380–392. [Google Scholar] [CrossRef]

- Ru, C.Q. Eshelby inclusion of arbitrary shape in an anisotropic plane or half-plane. Acta Mech. 2003, 160, 219–234. [Google Scholar] [CrossRef]

- Sun, Y.F.; Peng, Y.Z. Analytic solutions for the problems of an inclusion of arbitrary shape embedded in a half-plane. Appl. Math. Comput. 2003, 140, 105–113. [Google Scholar] [CrossRef]

- He, L.H.; Li, Z.R. Impact of surface stress on stress concentration. Int. J. Solids Struct. 2006, 43, 6208–6219. [Google Scholar] [CrossRef]

- Seo, K.; Mura, T. Elastic field in a half space due to ellipsoidal inclusions with uniform dilatational eigenstrains. J. Appl. Mech. 1979, 46, 568–572. [Google Scholar] [CrossRef]

- Mi, C.; Kouris, D. Stress concentration around a nanovoid near the surface of an elastic half-space. Int. J. Solids Struct. 2013, 50, 2737–2748. [Google Scholar] [CrossRef][Green Version]

- Mura, T.; Cheng, P.C. The elastic field outside an ellipsoidal inclusion. J. Appl. Mech. 1977, 44, 591–594. [Google Scholar] [CrossRef]

- Timoshenko, S.; Goodier, J.N. Theory of Elasticity, 2nd ed.; McGraw-Hill: New York, NY, USA, 1951. [Google Scholar]

| SCF | Proposed Approach (Equations (49)–(51)) | FEA Results | |||||

|---|---|---|---|---|---|---|---|

| 0.35 | 0.3 | 0.25 | 0.35 | 0.3 | 0.25 | ||

| 2.190 | 2.124 | 2.063 | 2.181 | 2.116 | 2.056 | ||

| 0.50 | 2.201 | 2.134 | 2.073 | 2.189 | 2.124 | 2.064 | |

| 2.212 | 2.144 | 2.082 | 2.217 | 2.149 | 2.087 | ||

| 2.533 | 2.345 | 2.174 | 2.520 | 2.333 | 2.162 | ||

| 0.50 | 2.568 | 2.374 | 2.196 | 2.550 | 2.358 | 2.182 | |

| 2.604 | 2.404 | 2.220 | 2.601 | 2.398 | 2.213 | ||

| 43.913 | 39.855 | 36.149 | 43.155 | 39.165 | 35.516 | ||

| 0.50 | 22.881 | 20.835 | 18.967 | 22.030 | 20.094 | 18.310 | |

| 15.872 | 14.496 | 13.241 | 15.661 | 14.307 | 13.066 | ||

| SCF | Presented Solution (Equations (49)–(51)) | FEA Results | |||||

|---|---|---|---|---|---|---|---|

| 0.35 | 0.3 | 0.25 | 0.35 | 0.3 | 0.25 | ||

| 2.190 | 2.124 | 2.063 | 2.189 | 2.125 | 2.066 | ||

| 0.50 | 2.297 | 2.220 | 2.151 | 2.304 | 2.228 | 2.158 | |

| 2.416 | 2.329 | 2.249 | 2.444 | 2.355 | 2.227 | ||

| 2.533 | 2.345 | 2.174 | 2.492 | 2.305 | 2.134 | ||

| 0.50 | 2.912 | 2.663 | 2.427 | 2.909 | 2.651 | 2.414 | |

| 3.579 | 3.201 | 2.857 | 3.615 | 3.232 | 2.834 | ||

| 43.913 | 39.855 | 36.149 | 43.519 | 39.463 | 35.921 | ||

| 0.50 | 6.076 | 5.638 | 5.238 | 5.980 | 5.549 | 5.154 | |

| 4.115 | 3.865 | 3.636 | 4.095 | 3.845 | 3.617 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdelghani, M.; Tewfik, G.; Witek, M.; Djahida, D. Factors of Stress Concentration around Spherical Cavity Embedded in Cylinder Subjected to Internal Pressure. Materials 2021, 14, 3057. https://doi.org/10.3390/ma14113057

Abdelghani M, Tewfik G, Witek M, Djahida D. Factors of Stress Concentration around Spherical Cavity Embedded in Cylinder Subjected to Internal Pressure. Materials. 2021; 14(11):3057. https://doi.org/10.3390/ma14113057

Chicago/Turabian StyleAbdelghani, Mechri, Ghomari Tewfik, Maciej Witek, and Djouadi Djahida. 2021. "Factors of Stress Concentration around Spherical Cavity Embedded in Cylinder Subjected to Internal Pressure" Materials 14, no. 11: 3057. https://doi.org/10.3390/ma14113057

APA StyleAbdelghani, M., Tewfik, G., Witek, M., & Djahida, D. (2021). Factors of Stress Concentration around Spherical Cavity Embedded in Cylinder Subjected to Internal Pressure. Materials, 14(11), 3057. https://doi.org/10.3390/ma14113057