Optimization of Properties for Alumina-Spinel Refractory Castables by CMA (CaO-MgO-Al2O3) Aggregates

Abstract

1. Introduction

2. Materials and Methods

3. Results

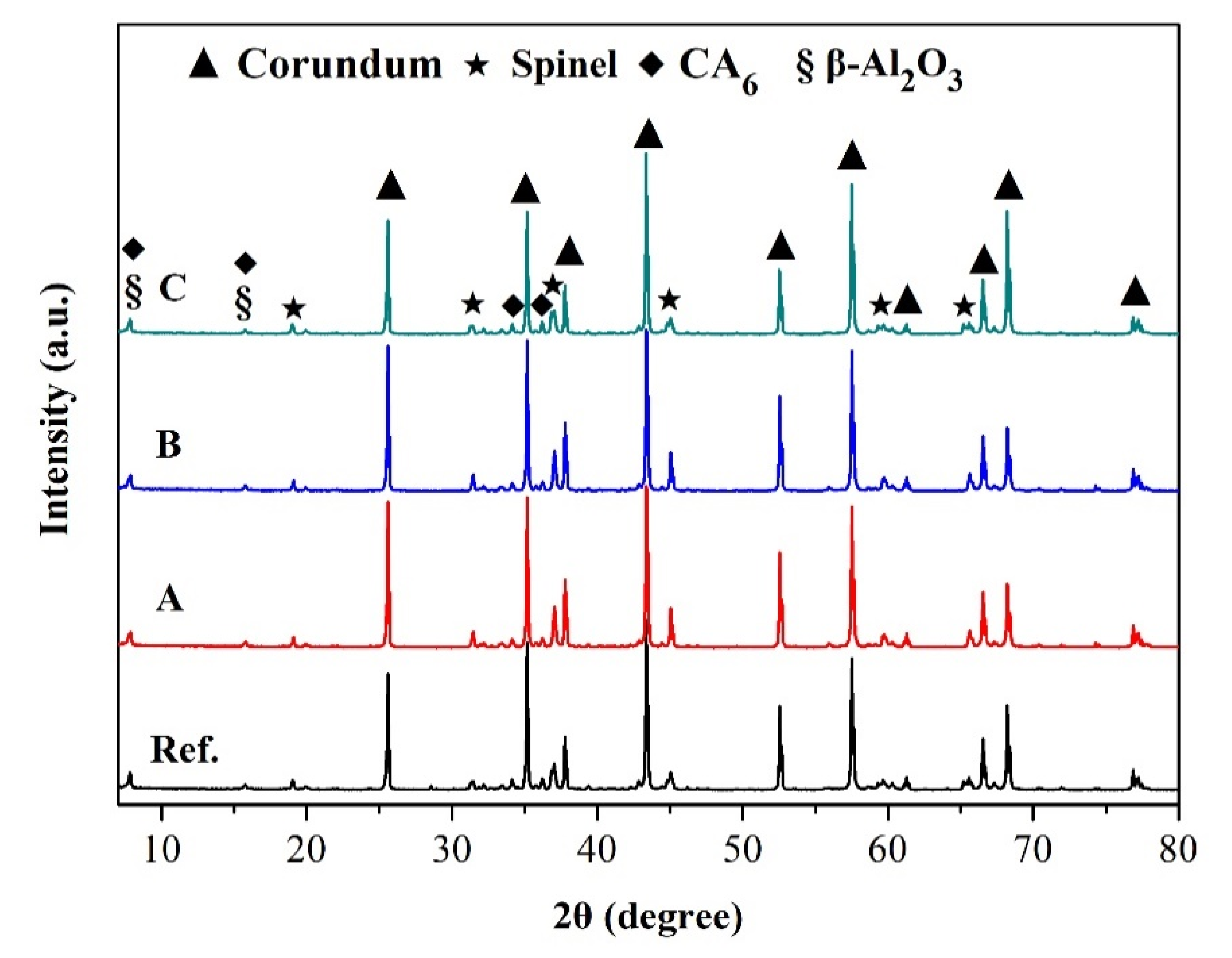

3.1. Phase Composition

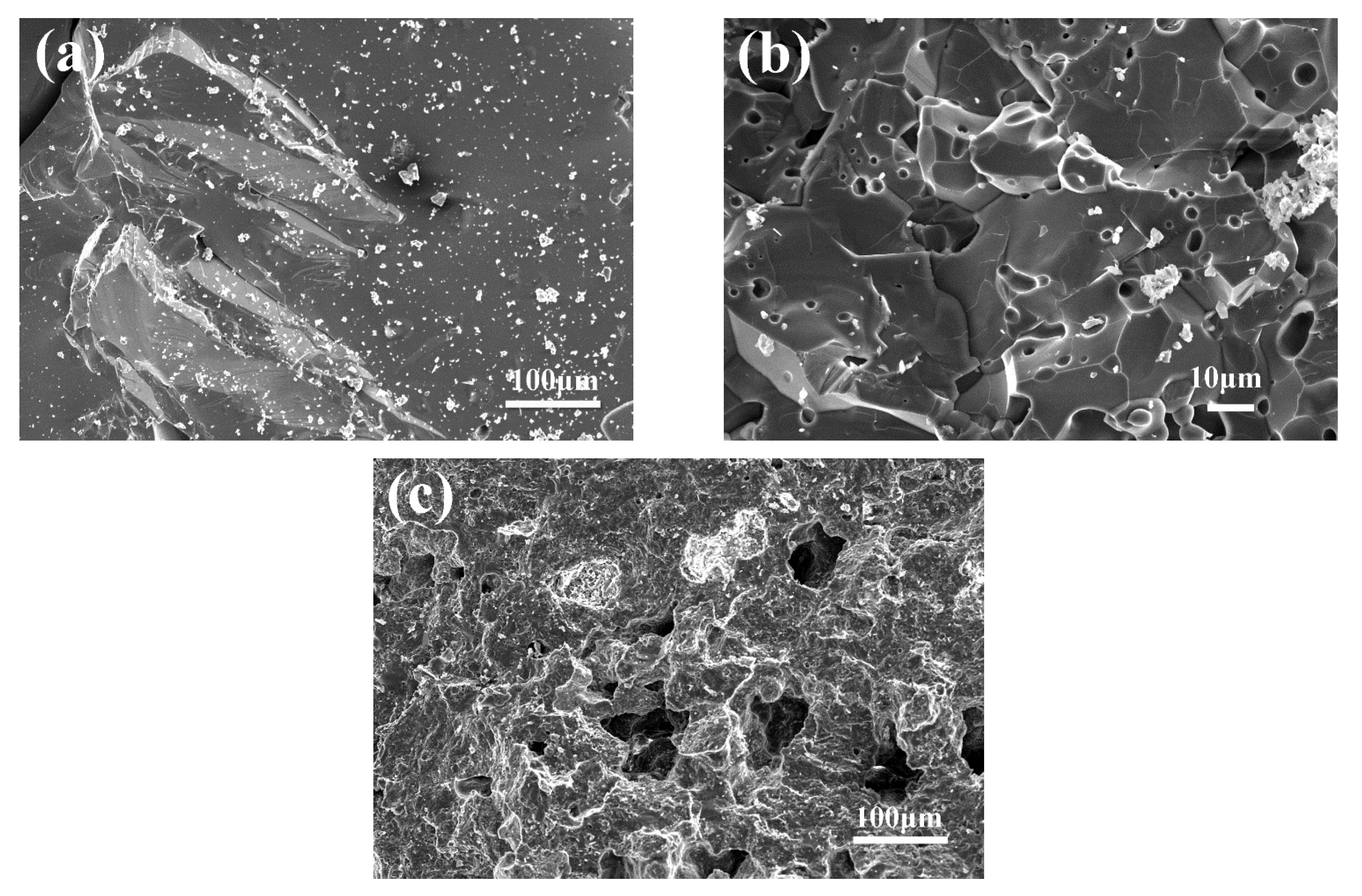

3.2. Microstructure

3.3. Physical and Mechanical Properties

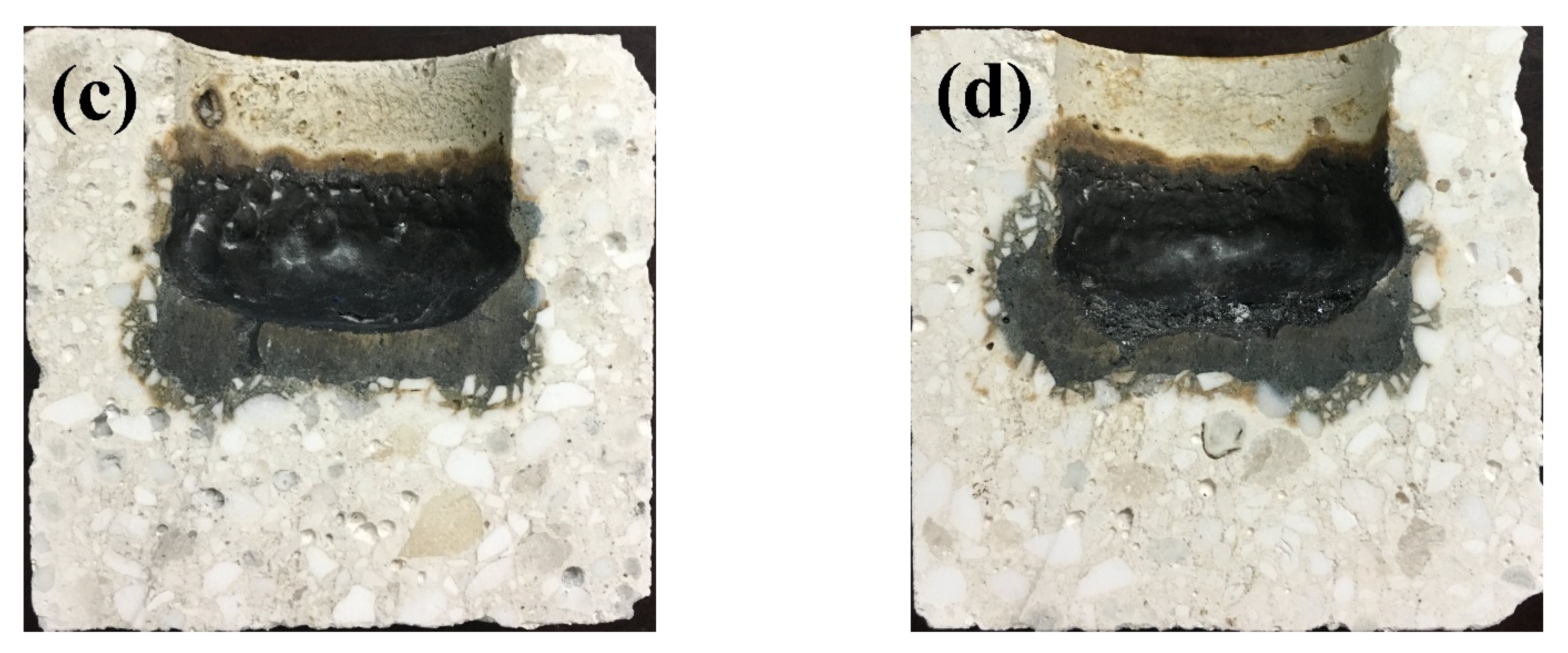

3.4. Slag Corrosion Resistance

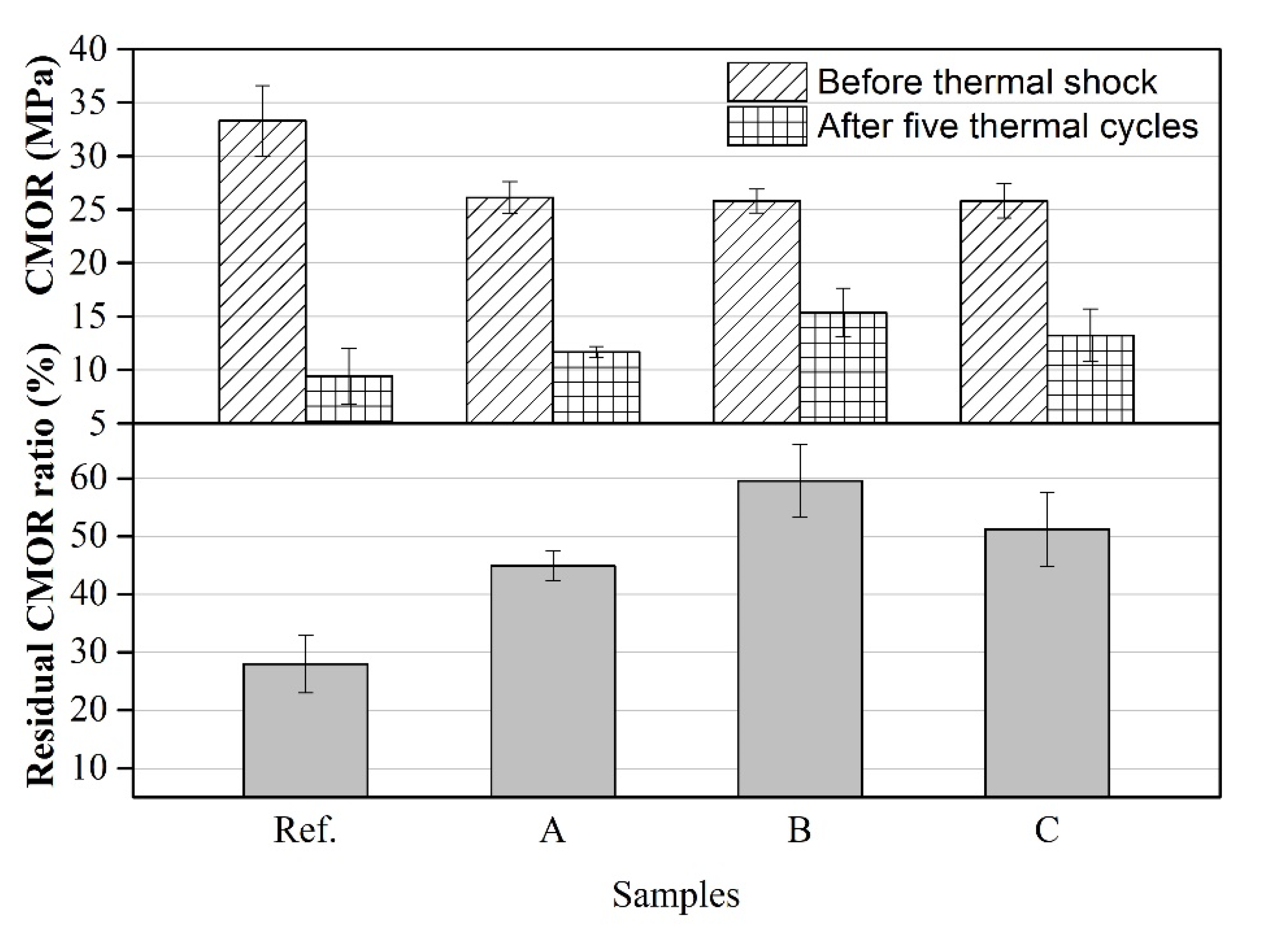

3.5. Thermal Shock Resistance

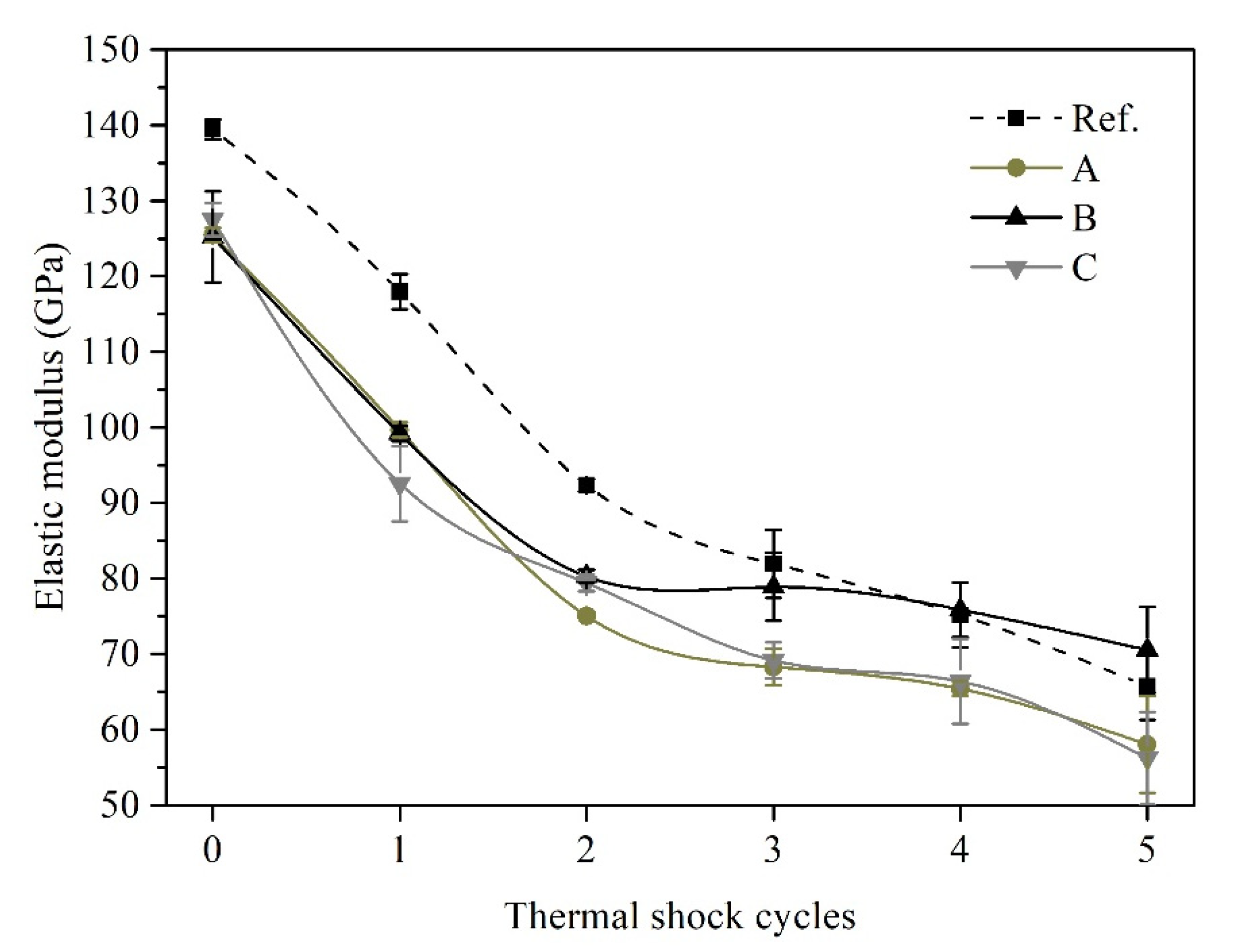

3.6. Thermal Fatigue Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, D.Y.; Li, C.X.; Jiang, N.; Gao, J.Y.; Touzo, B.; Yuan, W.J. Influence of powder characteristics of reactive alumina on properties of alumina-spinel castables. Ceram. Int. 2018, 44, 9984–9990. [Google Scholar] [CrossRef]

- Yuan, W.J.; Tang, H.; Zhou, Y.H.; Zhang, D.Y. Effects of fine reactive alumina powders on properties of alumina-magnesia castables with TiO2 addition. Ceram. Int. 2018, 44, 5032–5036. [Google Scholar] [CrossRef]

- Gu, H.Z.; Fu, L.P.; Ma, L.Y. Preparation of microporous corundum aggregates and their applications in lightweight alumina-magnesia castables. Int. Ceram. Rev. 2014, 3, 121–124. [Google Scholar]

- Zou, Y.; Huang, A.; Gu, H.Z.; Zhang, M.J.; Lian, P.F. Effects of particle distribution of matrix on microstructure and slag resistance of lightweight Al2O3-MgO castables. Ceram. Int. 2016, 42, 1964–1972. [Google Scholar] [CrossRef]

- Salomão, R.; Bôas, M.O.C.V.; Pandolfelli, V.C. Porous alumina-spinel ceramics for high temperature applications. Ceram. Int. 2011, 37, 1393–1399. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, W.; Dai, Y.J.; Schafföner, S.; Han, B.Q.; Li, N. Effect of microporous corundum aggregates on microstructure and mechanical properties of lightweight corundum refractories. Ceram. Int. 2019, 45, 8533–8538. [Google Scholar] [CrossRef]

- Zhou, Y.; Gu, H.Z.; Huang, A.; Zhang, M.J.; Zhang, M.T. Effects of aggregate microstructure on slag resistance of lightweight Al2O3-MgO castable. Ceram. Int. 2017, 43, 16495–16501. [Google Scholar] [CrossRef]

- Yan, W.; Li, N.; Miao, Z. Influence of the properties of corundum aggregates on the strength and slag resistance of refractory castables. J. Ceram. Process. Res. 2012, 13, 278–282. [Google Scholar]

- Yan, W.; Chen, J.F.; Li, N.; Han, B.Q.; Wei, Y.W. Lightweight cordierite-mullite refractories with low coefficients of thermal conductivity and high mechanical properties. Bull. Mater. Sci. 2015, 38, 409–415. [Google Scholar] [CrossRef]

- Yan, W.; Wu, G.Y.; Ma, S.B.; Schafföner, S.; Dai, Y.J.; Chen, Z. Energy efficient lightweight periclase-magnesium alumina spinel castables containing porous aggregates for the working lining of steel ladles. J. Eur. Ceram. Soc. 2018, 38, 4276–4282. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, L.; He, X.; Fang, W.; Lei, Z.X.; Chen, H. The fabrication of porous corundum spheres with core-shell structure for corundum-spinel castables. Mater. Des. 2015, 85, 574–581. [Google Scholar] [CrossRef]

- Wu, G.Y.; Yan, W.; Schafföner, S.; Lin, X.L.; Ma, S.B.; Zhai, Y.J.; Liu, X.J.; Xu, L.L. Effect of magnesium aluminate spinel content of porous aggregates on cement clinker corrosion and adherence properties of lightweight periclase-spinel refractories. Constr. Build. Mater. 2018, 185, 102–109. [Google Scholar] [CrossRef]

- Liang, Y.H.; Huang, A.; Zhu, X.W.; Gu, H.Z.; Fu, L.P. Dynamic slag/refractory interaction of lightweight Al2O3-MgO castable for refining ladle. Ceram. Int. 2015, 41, 8149–8154. [Google Scholar] [CrossRef]

- Gao, J.Y.; Wöhrmeyer, C.; Deteuf, C. Role of calcium magnesium aluminate in carbon-containing bricks for steel ladle. China’s Refract. 2021, 30, 23–30. [Google Scholar]

- Wöhrmeyer, C.; Gao, S.; Ping, Z.F.; Parr, C.; Aneziris, C.G.; Gehre, P. Corrosion mechanism of MgO-CMA-C ladle brick with high service life. Steel Res. Int. 2020, 91, 1900436. [Google Scholar] [CrossRef]

- Wöhrmeyer, C.; Gao, J.Y.; Parr, C.; Szepizdyn, M.; Mineau, R.M.; Zhu, J.H. Corrosion mechanism of a density-reduced steel ladle lining containing porous spinel-calcium aluminate aggregates. Ceramics 2020, 3, 155–170. [Google Scholar] [CrossRef]

- Refractories standard compilation. Test Method for Bulk Density, Apparent Porosity and True Porosity of Dense Shaped Refractory Products, 4th ed.; Standards Press of China: Beijing, China, 2010; Volume 2, pp. 3–8. [Google Scholar]

- Refractories standard compilation. Refractory Products-Determination of Modulus of Rupture at Ambient Temperature, 4th ed.; Standards Press of China: Beijing, China, 2010; Volume 2, pp. 35–42. [Google Scholar]

- Refractories standard compilation. Refractory-Determination of Slag Resistance, 4th ed.; Standards Press of China: Beijing, China, 2010; Volume 2, pp. 147–161. [Google Scholar]

- Refractories standard compilation. Test Method for Thermal Shock Resistance of Castable Refractory-Compressed Air Flow Quenching, 4th ed.; Standards Press of China: Beijing, China, 2010; Volume 2, pp. 332–335. [Google Scholar]

- An, L.; Chan, H.M. R-curve behavior of in-situ-toughened Al2O3: CaAl12O19 ceramic composites. J. Am. Ceram. Soc. 1996, 79, 3142–3148. [Google Scholar] [CrossRef]

- Yuan, W.J.; Deng, C.J.; Zhu, H.X. Effects of TiO2 addition on the expansion behavior of alumina-magnesia refractory castables. Mater. Chem. Phys. 2015, 162, 724–733. [Google Scholar] [CrossRef]

- Frueh, T.; Kupp, E.R.; Compson, C.; Atria, J.; Messing, G.L. The effects of Na2O and SiO2 on liquid phase sintering of Bayer Al2O3. J. Am. Ceram. Soc. 2016, 99, 2267–2272. [Google Scholar] [CrossRef]

- Harmuth, H.; Bradt, R.C. Investigation of refractory brittleness by fracture mechanical and fractographic methods. Int. Ceram. Rev. 2010, 62, 6–10. [Google Scholar]

- Biswas, S.; Sarkar, D. Introduction to Refractories for Iron- and Steelmaking; Springer Nature Switzerland AG: Cham, Switzerland, 2020. [Google Scholar]

- Yan, W.; Li, N.; Han, B.Q. An investigation on slag resistance of castable refractories containing porous spinel aggregates. Int. Ceram. Rev. 2009, 58, 25–28. [Google Scholar]

- Luz, A.P.; Martinez, A.G.T.; Braulio, M.A.L.; Pandolfelli, V.C. Thermodynamic evaluation of spinel containing refractory castables corrosion by secondary metallurgy slag. Ceram. Int. 2011, 37, 1191–1201. [Google Scholar] [CrossRef]

- Braulio, M.A.L.; Rigaud, M.; Buhr, A.; Parr, C.; Pandolfelli, V.C. Spinel-containing alumina-based refractory castables. Ceram. Int. 2011, 37, 1705–1724. [Google Scholar] [CrossRef]

- Chen, J.J.; Xiao, G.Q.; Ding, D.H.; Zang, Y.F.; Lei, C.K.; Luo, J.Y.; Chong, X.C.; Ren, Y. Thermal shock resistance properties of refractory castables bonded with a CaO-free binder. Ceram. Int. 2021, 47, 4238–4248. [Google Scholar] [CrossRef]

- Moritz, K.; Aneziris, C.G. Enhancing the thermal shock resistance of alumina-rich magnesium aluminate spinel refractories by an aluminum titanate phase. Ceram. Int. 2016, 42, 14155–14160. [Google Scholar] [CrossRef]

- Fu, L.P.; Gu, H.Z.; Huang, A.; Zhang, M.J.; Hong, X.Q.; Jin, L.W. Possible improvements of alumina-magnesia castable by lightweight microporous aggregates. Ceram. Int. 2015, 41, 1263–1270. [Google Scholar] [CrossRef]

- Boccaccini, D.N.; Romagnoli, M.; Kamseu, E.; Veronesi, P.; Leonelli, C.; Pellacani, G.C. Determination of thermal shock resistance in refractory materials by ultrasonic pulse velocity measurement. J. Eur. Ceram. Soc. 2007, 27, 1859–1863. [Google Scholar] [CrossRef]

- Luz, A.P.; Santos, T., Jr.; Medeiros, J.; Pandolfelli, V.C. Thermal shock damage evaluation of refractory castables elastic modulus measurements. Ceram. Int. 2013, 39, 6189–6197. [Google Scholar] [CrossRef]

- Rendtorff, N.M.; Aglietti, E.F. Thermal shock resistance (TSR) and thermal fatigue resistance (TFR) of refractory materials. Evaluation method based on the dynamic elastic modulus. In Encyclopedia of Thermal Stresses; Hetnarski, R.B., Ed.; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Rendtorff, N.M.; Garrido, L.B.; Aglietti, E.F. Thermal shock resistance and fatigue of zircon-mullite composite materials. Ceram. Int. 2011, 37, 1427–1434. [Google Scholar] [CrossRef]

| Raw Materials | Content (wt%) | |||

|---|---|---|---|---|

| Ref. | A | B | C | |

| White fused alumina(5–8 mm) | 15 | 15 | 15 | 7 |

| Tabular alumina (3–6 mm) | 17 | 17 | 9 | 17 |

| Tabular alumina (1–3 mm) | 20 | 12 | 20 | 20 |

| Tabular alumina (≤1 mm) | 25 | 33 | 33 | 33 |

| Spinel (≤1 mm) | 8 | 0 | 0 | 0 |

| Reactive alumina (BMP) | 5 | 5 | 5 | 5 |

| Cement (CMA72) | 9 | 9 | 9 | 9 |

| CMA aggregates (1–3 mm) | 0 | 8 | 0 | 0 |

| CMA aggregates (3–5 mm) | 0 | 0 | 8 | 0 |

| CMA aggregates (5–8 mm) | 0 | 0 | 0 | 8 |

| Additives (REFPAC288 and REFPAC388B) | 1 | 1 | 1 | 1 |

| Phase | MA | CA | CA2 | Others |

|---|---|---|---|---|

| Content (wt%) | 73.2 | 16.9 | 7.8 | 2.2 |

| Compositions | CaO | Fe2O3 | SiO2 | MgO | Al2O3 | Others |

|---|---|---|---|---|---|---|

| Content (wt%) | 43.8 | 29.9 | 11.8 | 5.4 | 3.6 | 5.5 |

| Temperature | No. | Apparent Porosity (%) | Bulk Density (g/cm3) | Cold Compressive Strength (MPa) | Cold Modulus of Rupture (MPa) |

|---|---|---|---|---|---|

| 1100 °C | Ref. | 14.6 ± 0.3 | 3.16 ± 0.01 | 91.2 ± 7.1 | 10.1 ± 1.1 |

| A | 15.9 ± 0.1 | 3.10 ± 0.01 | 87.2 ± 6.6 | 10.0 ± 1.7 | |

| B | 15.8 ± 0.6 | 3.10 ± 0.02 | 87.6 ± 2.1 | 10.2 ± 1.3 | |

| C | 15.7 ± 0.3 | 3.09 ± 0.02 | 86.0 ± 1.8 | 10.4 ± 0.1 | |

| 1550 °C | Ref. | 15.4 ± 0.1 | 3.18 ± 0.01 | 220.2 ± 0.2 | 33.3 ± 3.3 |

| A | 16.8 ± 0.3 | 3.11 ± 0.01 | 206.1 ± 1.1 | 26.1 ± 1.5 | |

| B | 16.4 ± 0.1 | 3.11 ± 0.01 | 200.7 ± 1.9 | 25.8 ± 1.1 | |

| C | 16.7 ± 0.2 | 3.09 ± 0.01 | 200.6 ± 4.4 | 25.8 ± 1.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, H.; Li, C.; Gao, J.; Touzo, B.; Liu, C.; Yuan, W. Optimization of Properties for Alumina-Spinel Refractory Castables by CMA (CaO-MgO-Al2O3) Aggregates. Materials 2021, 14, 3050. https://doi.org/10.3390/ma14113050

Tang H, Li C, Gao J, Touzo B, Liu C, Yuan W. Optimization of Properties for Alumina-Spinel Refractory Castables by CMA (CaO-MgO-Al2O3) Aggregates. Materials. 2021; 14(11):3050. https://doi.org/10.3390/ma14113050

Chicago/Turabian StyleTang, Hai, Chunxue Li, Jianying Gao, Bruno Touzo, Chunfeng Liu, and Wenjie Yuan. 2021. "Optimization of Properties for Alumina-Spinel Refractory Castables by CMA (CaO-MgO-Al2O3) Aggregates" Materials 14, no. 11: 3050. https://doi.org/10.3390/ma14113050

APA StyleTang, H., Li, C., Gao, J., Touzo, B., Liu, C., & Yuan, W. (2021). Optimization of Properties for Alumina-Spinel Refractory Castables by CMA (CaO-MgO-Al2O3) Aggregates. Materials, 14(11), 3050. https://doi.org/10.3390/ma14113050