Study of an Organic Binder of Cold-Bonded Briquettes with Two Different Iron Bearing Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Iron Ore Raw Material

2.1.2. Binder

2.2. Experimental

2.2.1. Binder Characterizations

2.2.2. Preparation of Mixtures and Briquettes

2.2.3. Testing of Mechanical Strength and Decrepitation Index of CBB

3. Results and Discussion

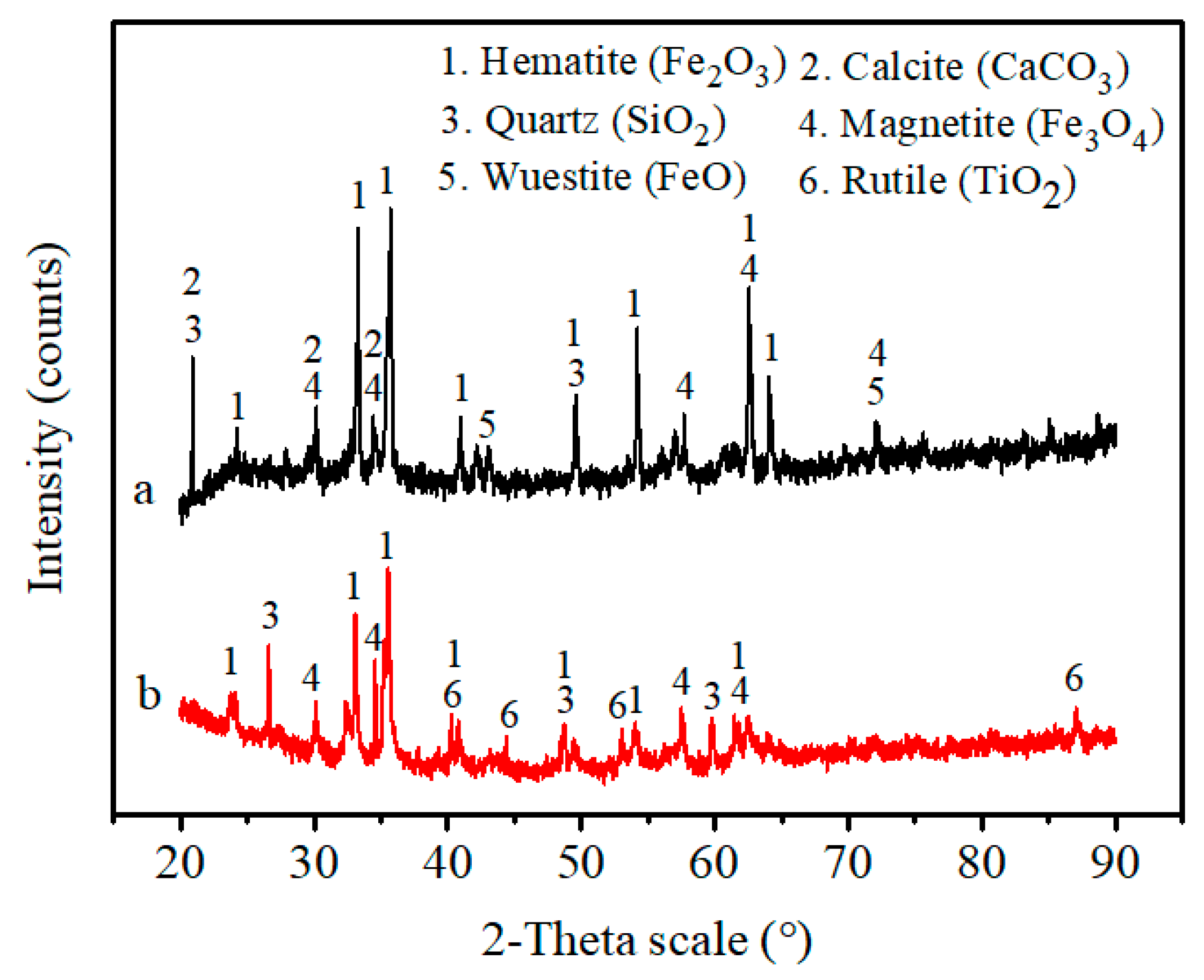

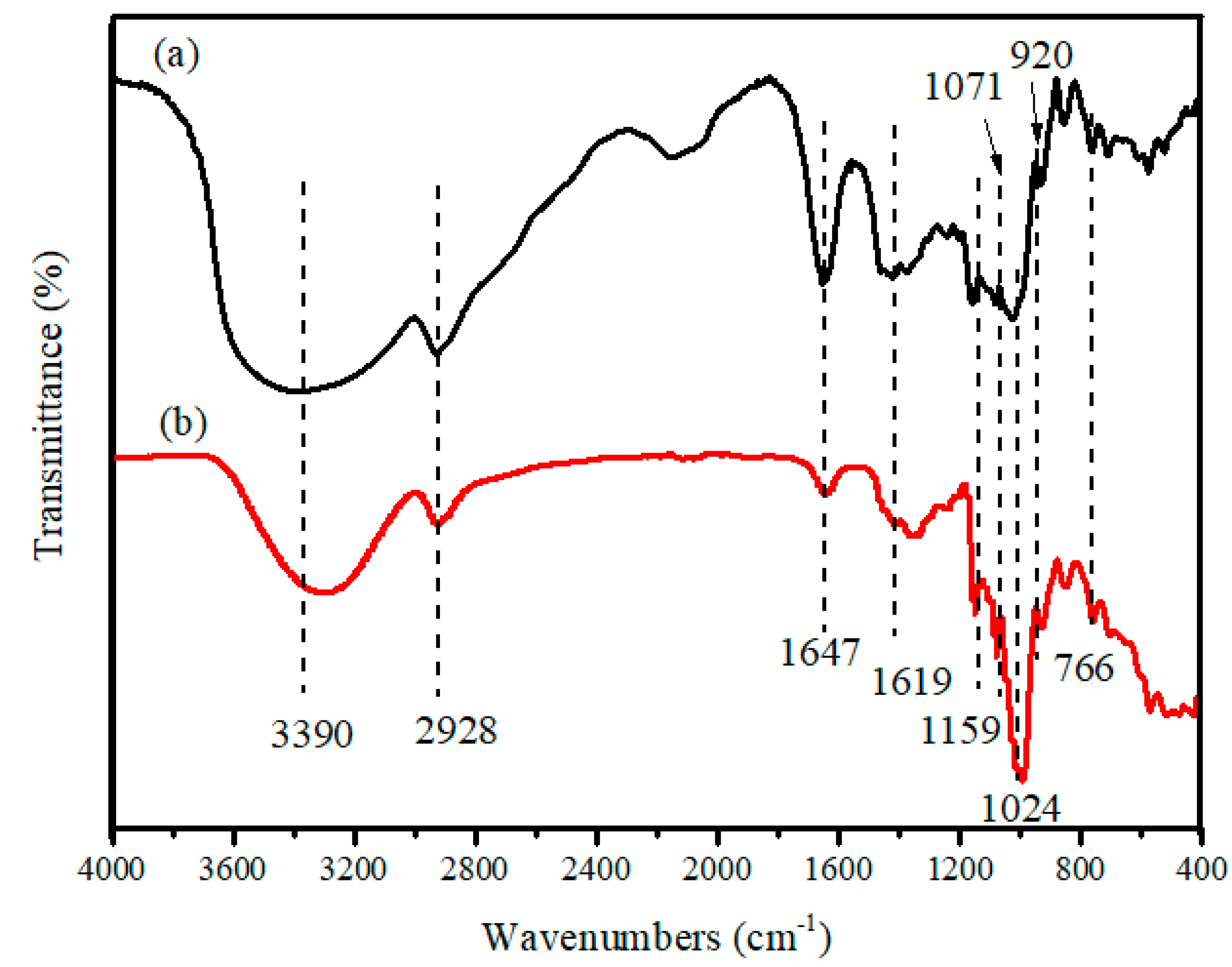

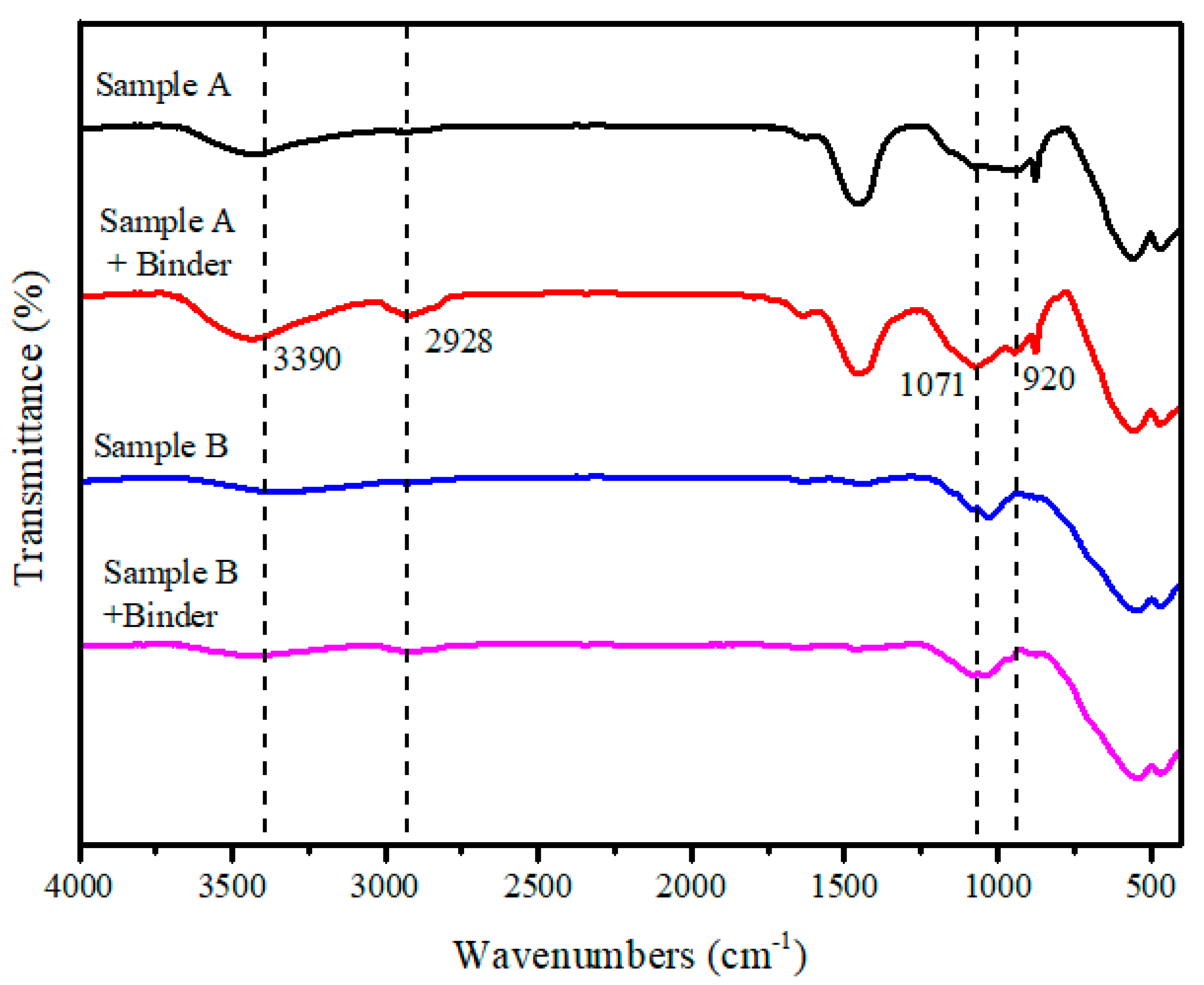

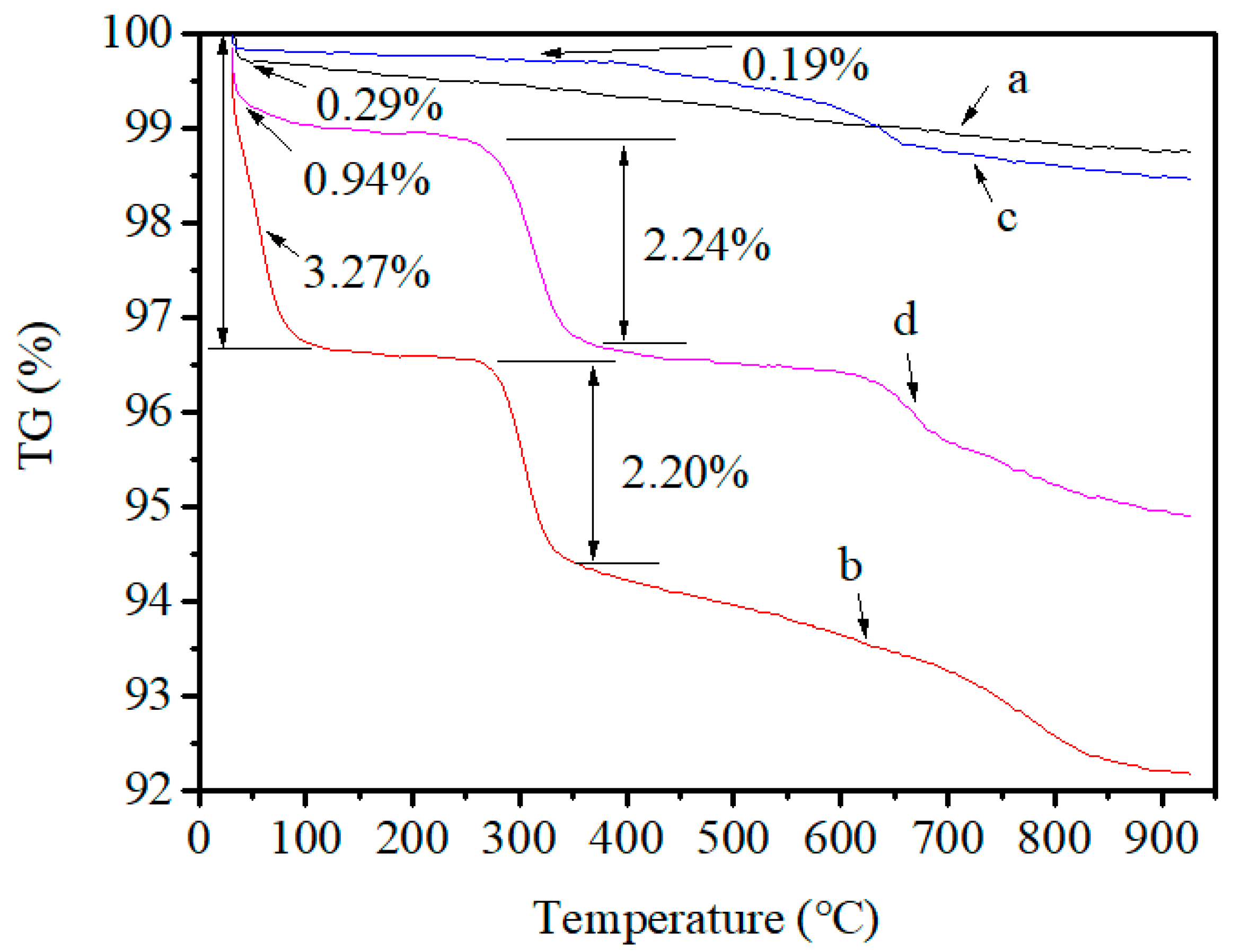

3.1. Binder Characterizations

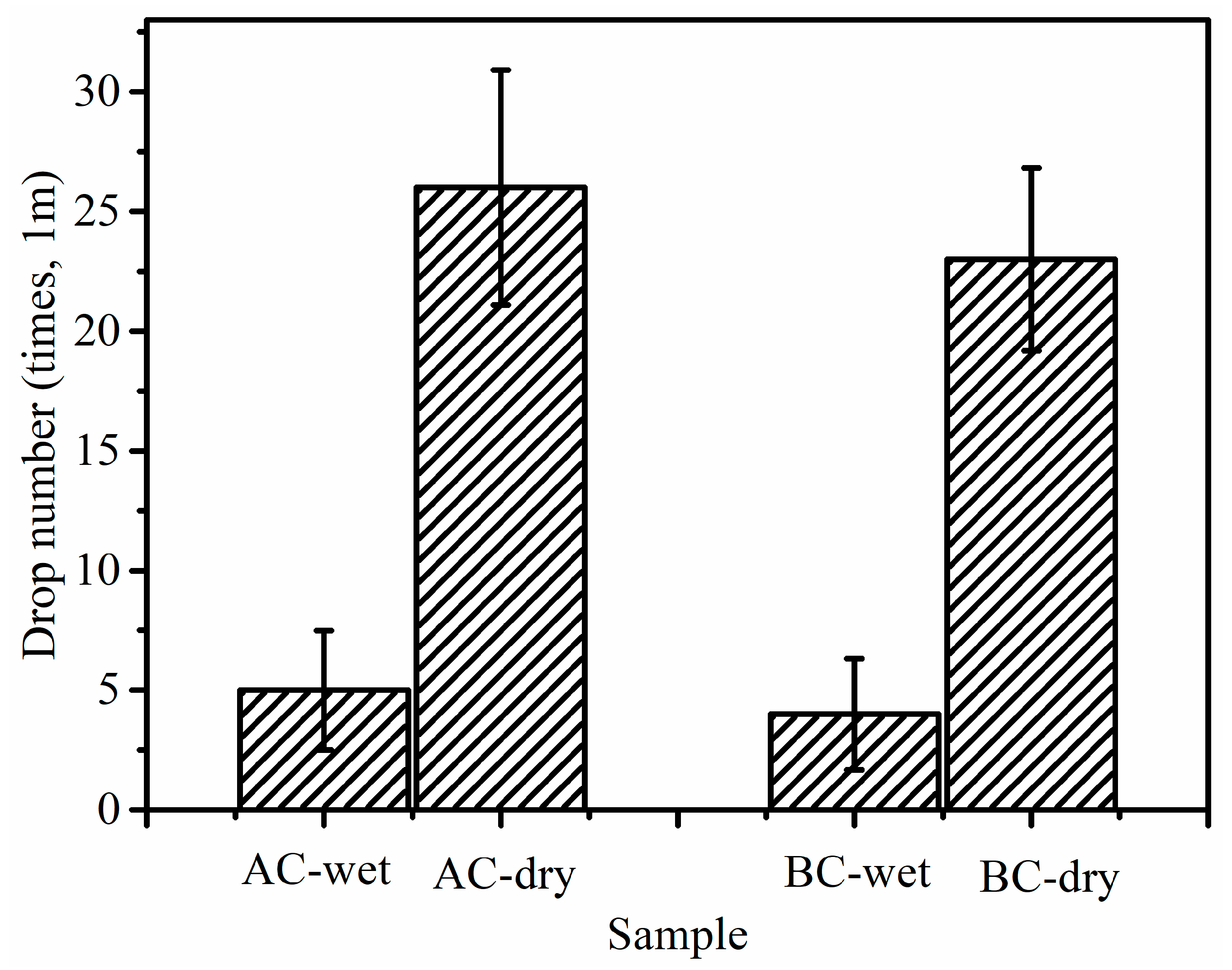

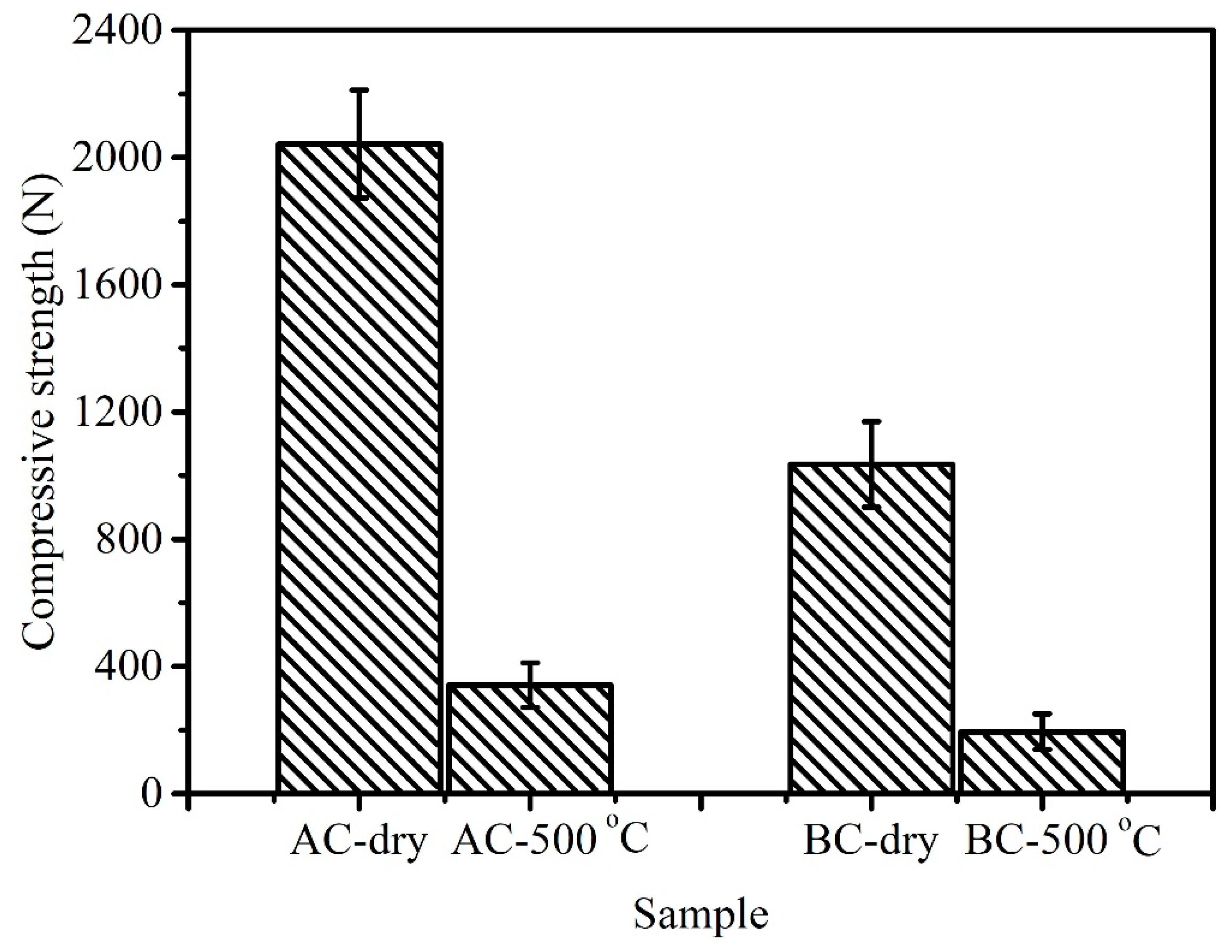

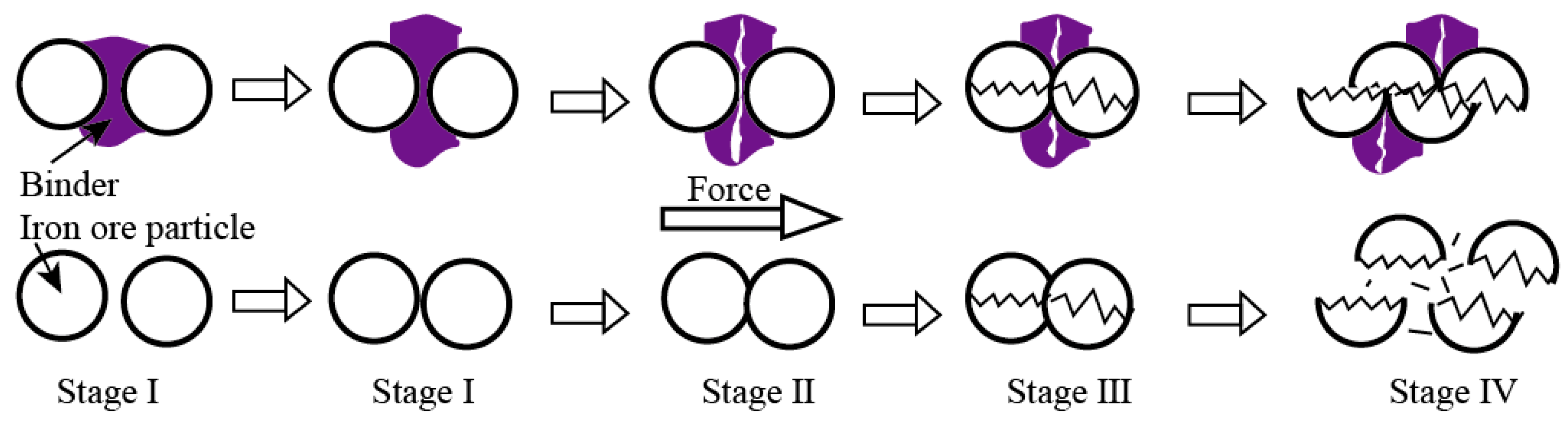

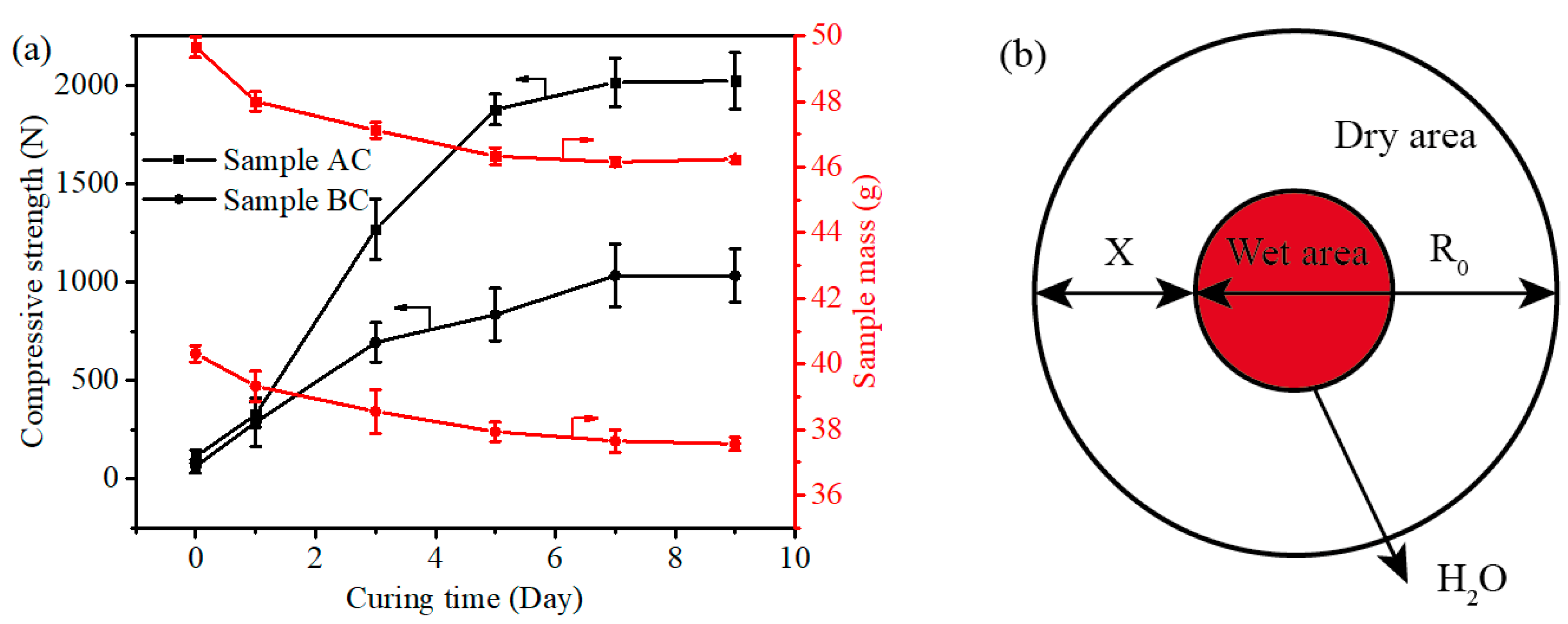

3.2. Relationship between Mechanical Properties and the Binder

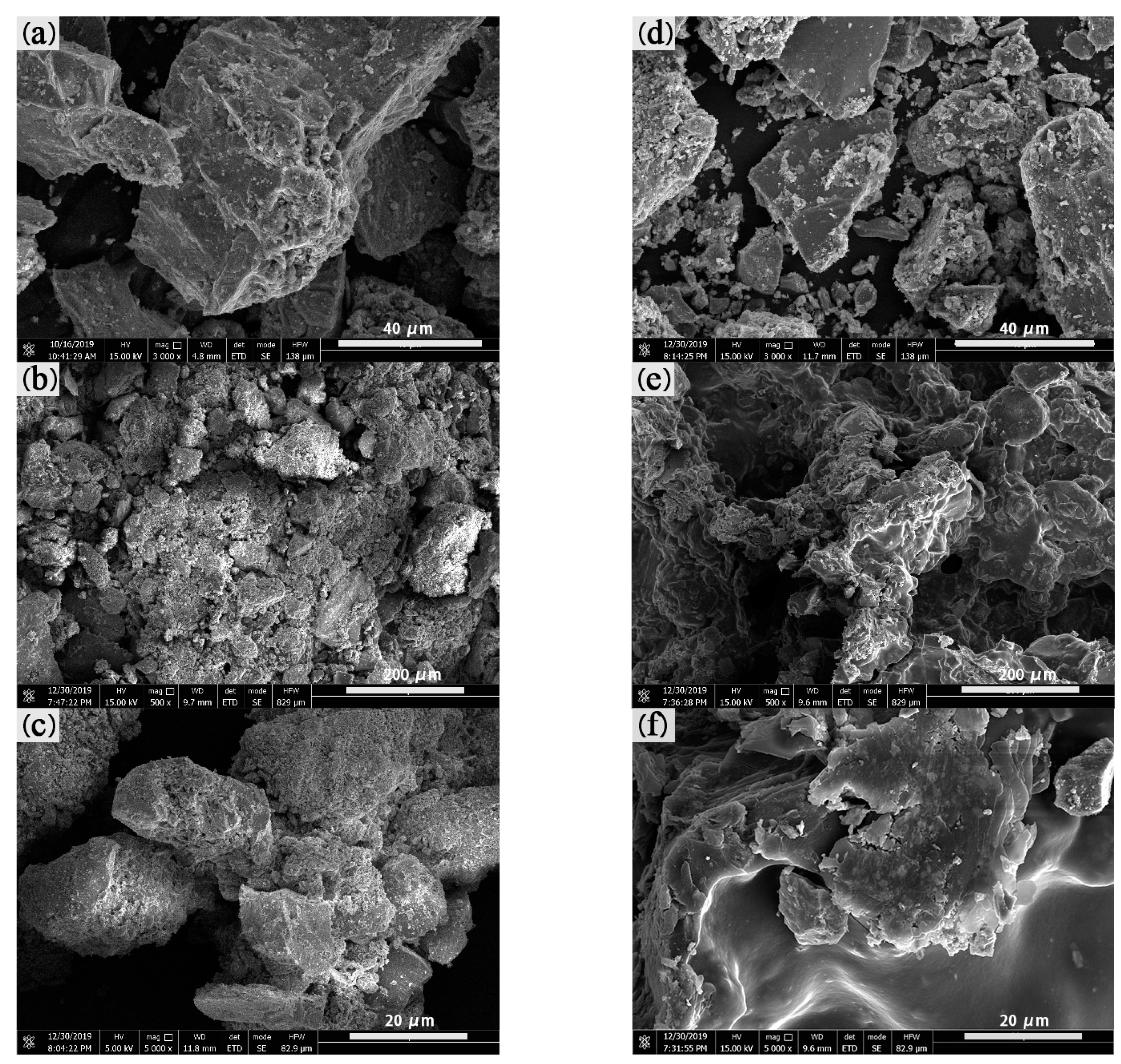

3.3. Microstructure and Bonding Mechanism

4. Conclusions

- The chemical composition, iodine-starch staining and Fourier transform infrared analyses indicated that the binder was a type of starch. During the heating procedure, the mass loss of the binder reached 15% at 150 °C and 90% at 500 °C. The binder pyrolysis underwent four stages: moisture desorption, ash volatilization, pyrolysis of macromolecular organic matter and decomposition of materials with high activation energy when heated.

- The compressive strength values of heat-treated CBBs are nearly one-fifth of the compressive strength values of the dry CBBs. The difference between the dry and heat-treated sample was owing to the instability propagation of the crack. Return fines of CBBs containing binder were applied in the two blast furnaces. The industrial experiment results show that return fines of CBBs did not influence the performance of the blast furnace and can reduce the fuel rate to some degree.

- The curing rate of the binder decreases and the rate of compressive strength decreases during the curing process. The edges and corners of the particles become blurred, and the original surface of the particles are covered with binder film, the surface of which is covered with fine particles. The multi-branched structure of amylopectin provides omnibearing adhesion sites, thus forming binder agglomeration and film leading to a strong adhesion between binder and iron ore particles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- El-Hussiny, N.A.; Shalabi, M.E.H. A self-reduced intermediate product from iron and steel plants waste materials using a briquetting process. J. Powder Technol. 2011, 205, 217–223. [Google Scholar] [CrossRef]

- Paknahad, P.; Askari, M.; Shahahmadi, S.A. Cold-Briquetted Iron and Carbon (CBIC), investigation of steelmaking behavior. J. Mater. Res. Technol. 2020, 9, 6655–6664. [Google Scholar] [CrossRef]

- Paknahad, P.; Askari, M.; Shahahmadi, S.A. Cold-Briquetted Iron and Carbon (CBIC): Investigation of the Influence of Environmental Condition on Its Chemical and Physical Properties. J. Sustain. Metall. 2019, 5, 497–509. [Google Scholar] [CrossRef]

- Andersson, A.; Gullberg, A.; Kullerstedt, A.; Wedholm, A.; Wikström, J.; Ahmed, H.; Sundqvist, Ö.L. Recycling of Blast Furnace Sludge to the Blast Furnace via ColdBonded Briquettes: Evaluation of Feasibility and Influence on Operation. ISIJ Int. 2019, 59, 1786–1789. [Google Scholar] [CrossRef]

- Zhang, H.; Hui, L.; Dong, J.; Xiong, H. Optimization of the Stainless Steel Dust Briquette Reduction Process for Iron, Chromium, and Nickel Recovery. High. Temp. Mater. Process. 2018, 37, 785–791. [Google Scholar] [CrossRef]

- Wu, S.; Chang, F.; Zhang, J.; Hua, L.; Mingyin, K. Cold strength and high temperature behaviors of self-reducing briquette containing electric arc furnace dust and anthracite. ISIJ Int. 2017, 57, 1364–1373. [Google Scholar] [CrossRef]

- Kumar, D.S.; Sah, R.; Sekhar, V.R.; Vishwanath, S.C. Development and use of mill scale briquettes in BOF. Ironmak. Steelmak. 2016, 44, 134–139. [Google Scholar] [CrossRef]

- Kemppainen, A.; Iljana, M.; Heikkinen, E.P.; Paananen, T.; Mattila, O.; Fabritius, T. Reduction Behavior of Cold-bonded Briquettes under Simulated Blast Furnace Conditions. ISIJ Int. 2014, 54, 1539–1545. [Google Scholar] [CrossRef]

- Peng, C.; Zhang, F.; Huifang, L.I. Removal Behavior of Zn, Pb, K and Na from Cold Bonded Briquettes of Metallurgical Dust in Simulated RHF. ISIJ Int. 2009, 49, 1874–1881. [Google Scholar] [CrossRef]

- Hongliang, H.; Dongping, D.; Peng, Y. Binders and Bonding Mechanism for RHF Briquette Made from Blast Furnace Dust. ISIJ Int. 2014, 54, 1781–1789. [Google Scholar]

- Drobíková, K.; Plachá, D.; Motyka, O.; Gabor, R.; Kutláková, K.M.; Vallová, S.; Seidlerová, J. Recycling of blast furnace sludge by briquetting with starch binder: Waste gas from thermal treatment utilizable as a fuel. Waste Manag. 2016, 48, 471–477. [Google Scholar] [CrossRef]

- Bizhanov, A.; Kurunov, I.; Dalmia, Y.; Mishra, B.; Mishra, S. Blast Furnace Operation with 100% Extruded Briquettes Charge. ISIJ Int. 2015, 55, 175–182. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, Y.; Xu, Y. Review of briquette binders and briquetting mechanism. Renew. Sustain. Energy Rev. 2018, 82, 477–487. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, W. Synthesis of cationic starch with a high degree of substitution in an ionic liquid. Carbohydr. Polym. 2010, 80, 1172–1177. [Google Scholar] [CrossRef]

- Kumar, S.V.; Kumar VA, S.; Kumar, S. The Influence of Bound Water on the FTIR Characteristics of Starch and Starch Nanocrystals Obtained from Selected Natural Sources. Starch Starke 2018, 19, 1700026. [Google Scholar] [CrossRef]

- Warren, F.J.; Gidley, M.J.; Flanagan, B.M. Infrared spectroscopy as a tool to characterise starch ordered structure—A joint FTIR–ATR, NMR, XRD and DSC study. Carbohydr. Polym. 2016, 139, 35–42. [Google Scholar] [CrossRef]

- Chen, L.; Zeng, C.; Guo, X.; Mao, Y.; Zhang, Y.; Zhang, X.; Li, W.; Long, Y.; Zhu, H.; Eiteneer, B.; et al. Gas evolution kinetics of two coal samples during rapid pyrolysis. Fuel Process. Technol. 2010, 91, 848–852. [Google Scholar] [CrossRef]

- Ogasawara, Y.; Sato, T.; Ishii, J.; Murai, R.; Watakabe, S. Agglomeration of Return Fines of Sinter for Blast Furnace Raw Materials. ISIJ Int. 2020, 60, 1389–1394. [Google Scholar] [CrossRef]

- Khasraw, D.; Spooner, S.; Hage, H.; Koen, M.; Li, Z. Devolatilisation characteristics of coal and biomass with respect to temperature and heating rate for HIsarna alternative ironmaking process. Fuel 2021, 284, 119101. [Google Scholar] [CrossRef]

- Eisele, T.C.; Kawatra, S.K. A review of binders in iron ore pelletization. Miner. Process. Extr. Metall. Rev. 2003, 24, 1–90. [Google Scholar] [CrossRef]

- Cai, M.; Kaiser, P.K.; Tasaka, Y.; Maejima, T.; Morioka, H.; Minami, M. Generalized crack initiation and crack damage stress thresholds of brittle rock masses near underground excavations. Int. J. Rock Mech. Min. 2004, 41, 833–847. [Google Scholar] [CrossRef]

- Wang, B.; Li, X. Mesomechanics analysis of static compressive strength and dynamic compressive strength of water-saturated rock under uniaxial load. Explos. Shock Waves 2012, 32, 423–431. [Google Scholar]

- Yu, W.; Sun, T.C.; Liu, Z.Z.; Kou, J.; Cheng-yan, X. Study on the strength of cold-bonded high-phosphorus oolitic hematite-coal composite briquettes. Int. J. Miner. Metall. Mater. 2014, 21, 423–430. [Google Scholar] [CrossRef]

- Omran, M.; Fabritius, T. Effect of steelmaking dust characteristics on suitable recycling process determining: Ferrochrome converter (CRC) and electric arc furnace (EAF) dusts. Powder Technol. 2016, 308, 47–60. [Google Scholar] [CrossRef]

- Schwartz, J.B.; Zelinskie, J.A. The Binding and Disintegrant Properties of the Corn Starch Fractions: Amylose and Amylopectin. Drug Dev. Ind. Pharm. 1978, 4, 463–483. [Google Scholar] [CrossRef]

- Bie, Y.; Yang, J.; Nuli, Y.; Wanga, J. Oxidized starch as a superior binder for silicon anodes in lithium-ion batteries. RSC Adv. 2016, 6, 97084–97088. [Google Scholar] [CrossRef]

| Particle Size Range | <0.5 mm | 0.5–2 mm | 2–3.15 mm | 3.15–5 mm |

|---|---|---|---|---|

| Sample A | 19.56 | 38.42 | 15.24 | 26.68 |

| Sample B | 100 | 0 | 0 | 0 |

| Constituents | Sample A | Sample B |

|---|---|---|

| Fe (total) | 58.36 | 56.12 |

| FeO | 7.46 | 0.41 |

| SiO2 | 6.51 | 2.76 |

| CaO | 8.11 | 0.11 |

| Al2O3 | 1.19 | 1.36 |

| MgO | 1.27 | 0.07 |

| TiO2 | - | 15.28 |

| MnO | 0.31 | 0.26 |

| S | 0.05 | 0.02 |

| C | 2.39 | - |

| The Decrepitation Index | Sample AC | Sample BC |

|---|---|---|

| Mass of dry sample before treatment, g | 544.1 | 551.04 |

| Mass of sample after treatment at 700 °C for 30 min, g | 523.9 | 519.29 |

| Mass of sample pass 0.5 mm after treatment, g | 0.55 | 0.57 |

| Mass of sample pass 3.15 mm after treatment, g | 0.89 | 2.05 |

| Mass of sample pass 6.3 mm after treatment, g | 0.89 | 2.05 |

| Loss on ignition, % | 3.71 | 5.76 |

| Effective Volume of Blast Furnace (m3) | Weight Percentage of CBB (%) | Productivity (t/(m3·day)) | Coke Rate (kg/tHM) | Coal Rate (kg/tHM) | Fuel Rate (kg/tHM) |

|---|---|---|---|---|---|

| 450 | 0% | 3.32 | 424.32 | 143.21 | 538.89 |

| 3% | 3.36 | 417.93 | 145.69 | 534.48 | |

| 6% | 3.42 | 419.23 | 137.82 | 529.72 | |

| 9% | 3.45 | 417.46 | 149.39 | 536.97 | |

| 2800 | 0% | 2.26 | 443.73 | 102.38 | 525.63 |

| 1.5% | 2.37 | 437.58 | 106.00 | 522.38 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Chen, H.; Hammam, A.; Wei, H.; Nie, H.; Ding, W.; Omran, M.; Yan, L.; Yu, Y. Study of an Organic Binder of Cold-Bonded Briquettes with Two Different Iron Bearing Materials. Materials 2021, 14, 2952. https://doi.org/10.3390/ma14112952

Li Y, Chen H, Hammam A, Wei H, Nie H, Ding W, Omran M, Yan L, Yu Y. Study of an Organic Binder of Cold-Bonded Briquettes with Two Different Iron Bearing Materials. Materials. 2021; 14(11):2952. https://doi.org/10.3390/ma14112952

Chicago/Turabian StyleLi, Ying, Huiting Chen, Abourehab Hammam, Han Wei, Hao Nie, Weitian Ding, Mamdouh Omran, Lixiang Yan, and Yaowei Yu. 2021. "Study of an Organic Binder of Cold-Bonded Briquettes with Two Different Iron Bearing Materials" Materials 14, no. 11: 2952. https://doi.org/10.3390/ma14112952

APA StyleLi, Y., Chen, H., Hammam, A., Wei, H., Nie, H., Ding, W., Omran, M., Yan, L., & Yu, Y. (2021). Study of an Organic Binder of Cold-Bonded Briquettes with Two Different Iron Bearing Materials. Materials, 14(11), 2952. https://doi.org/10.3390/ma14112952