Synthesis and Stability of Hydrogen Storage Material Aluminum Hydride

Abstract

1. Introduction

2. Physical and Chemical Properties

3. Synthesis Methods

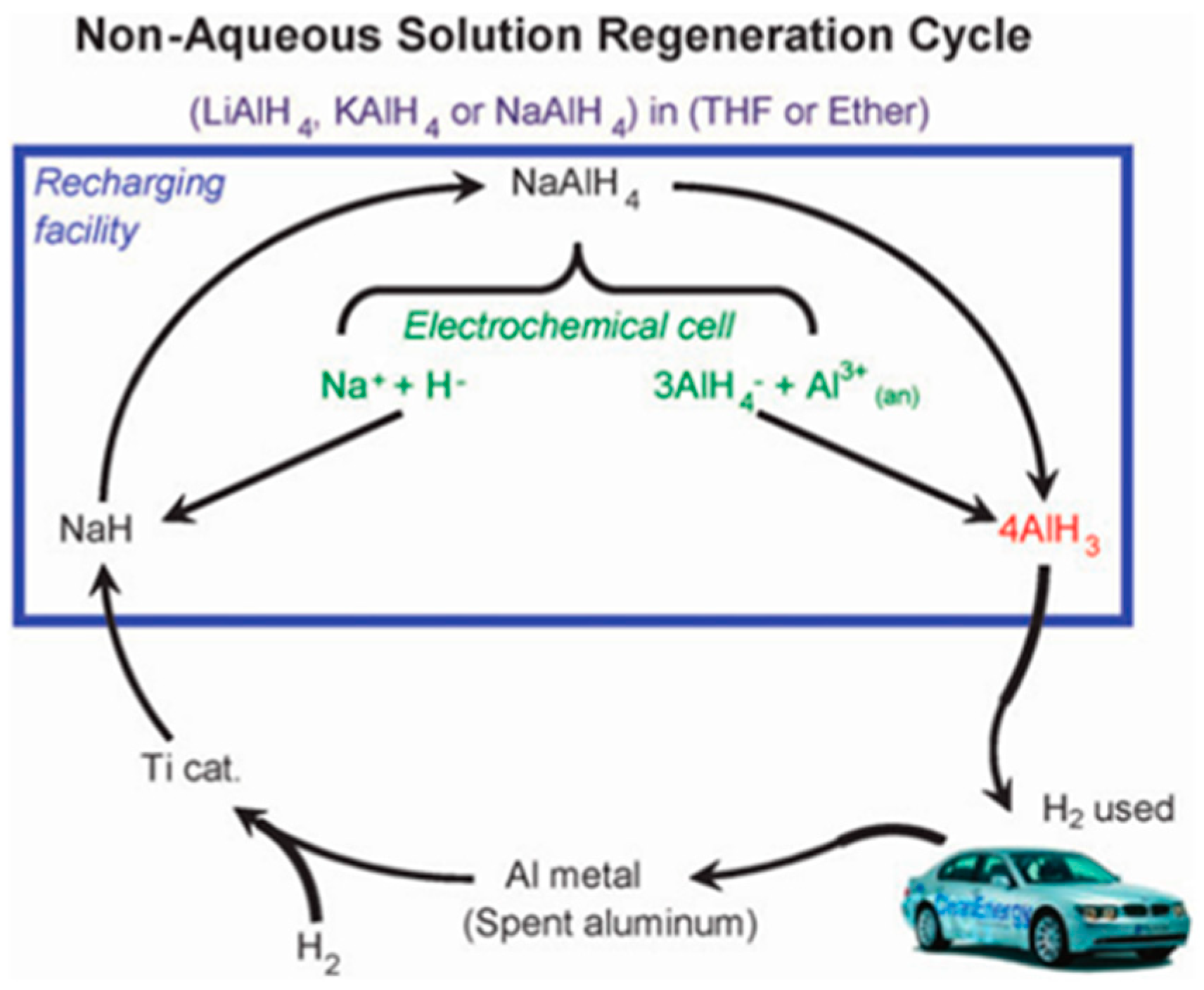

3.1. Liquid Phase Synthesis Methods

3.2. Dry Synthesis

3.3. Other Synthetic Methods

4. Stability

4.1. Surface Passivation Method

4.2. Doping Stabilization Method

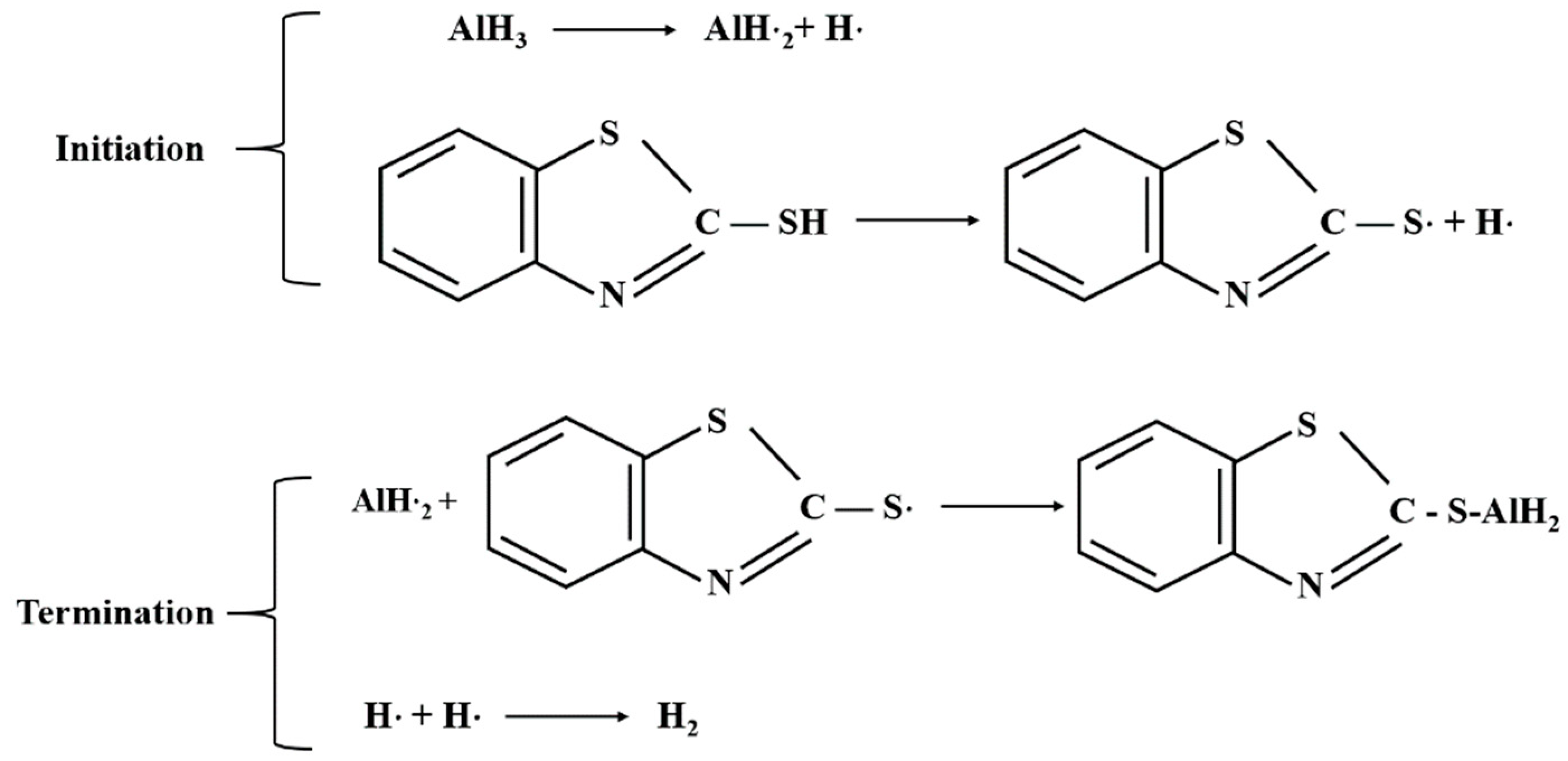

4.3. Surface Coating Method

5. Applications and Challenges

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Weiser, V.; Eisenreich, N.; Koleczko, A.; Roth, E. On the Oxidation and Combustion of AlH3 a Potential Fuel for Rocket Propellants and Gas Generators. Propellants Explos. Pyrotech. 2007, 32, 213–221. [Google Scholar] [CrossRef]

- Yang, J.; Beaumont, P.R.; Humphries, T.D.; Jensen, C.M.; Li, X. Efficient Synthesis of an Aluminum Amidoborane Ammoniate. Energies 2015, 8, 9107–9116. [Google Scholar] [CrossRef]

- Bazyn, T.; Eyer, R.; Krier, H.; Glumac, N. Combustion Characteristics of Aluminum Hydride at Elevated Pressure and Temperature. J. Propuls. Power 2004, 20, 427–431. [Google Scholar] [CrossRef]

- Graetz, J.; Reilly, J.J. Decomposition Kinetics of the AlH3Polymorphs. J. Phys. Chem. B 2005, 109, 22181–22185. [Google Scholar] [CrossRef]

- Nakagawa, Y.; Isobe, S.; Wang, Y.; Hashimoto, N.; Ohnuki, S.; Zeng, L.; Liu, S.; Ichikawa, T.; Kojima, Y. Dehydrogenation process of AlH3 observed by TEM. J. Alloys Compd. 2013, 580, S163–S166. [Google Scholar] [CrossRef]

- Wolverton, C.; Ozoliņš, V.; Asta, M. Hydrogen in aluminum: First-principles calculations of structure and thermodynamics. Phys. Rev. B 2004, 69, 144109. [Google Scholar] [CrossRef]

- Graetz, J. New approaches to hydrogen storage. Chem. Soc. Rev. 2009, 38, 73–82. [Google Scholar] [CrossRef] [PubMed]

- Gupta, S.; Kobayashi, T.; Hlova, I.Z.; Goldston, J.F.; Pruski, M.; Pecharsky, V.K. Solvent-free mechanochemical synthesis of alane, AlH3: Effect of pressure on the reaction pathway. Green Chem. 2014, 16, 4378–4388. [Google Scholar] [CrossRef]

- Sinke, G.C. Thermodynamic Properties of Aluminum Hydride. J. Chem. Phys. 1967, 47, 2759. [Google Scholar] [CrossRef]

- Graetz, J.; Reilly, J.; Yartys, V.; Maehlen, J.; Bulychev, B.; Antonov, V.; Tarasov, B.; Gabis, I. Aluminum hydride as a hydrogen and energy storage material: Past, present and future. J. Alloys Compd. 2011, 509, S517–S528. [Google Scholar] [CrossRef]

- Normatov, I.S. Catalytic Synthesis of Aluminum Hydride in the Presence of Palladium Black. Kinet. Catal. 2004, 45, 558–560. [Google Scholar] [CrossRef]

- Bulychev, B.M.; Burlakova, A.G.; Storozhenko, P.A. Complex compounds of aluminum hydride ethoxide with mixed aluminum and boron hydrides with lithium and magnesium: Compositions, physicochemical properties, and synthesis of unsolvated aluminum hydride. Zhurnal Neorg. Khimii 1998, 43, 829–836. [Google Scholar]

- Sato, T.; Ikeda, K.; Li, H.-W.; Yukawa, H.; Morinaga, M.; Orimo, S.-I. Direct Dry Syntheses and Thermal Analyses of a Series of Aluminum Complex Hydrides. Mater. Trans. 2009, 50, 182–186. [Google Scholar] [CrossRef]

- Bulychev, B.M.; Golubeva, A.V.; Storozhenko, P.A.; Semenenko, K.N. Synthesis of aluminum hydride compounds from sodium hydride and aluminum trichloride diethyl ether. Zhurnal Neorg. Khimii 1998, 43, 1242–1245. [Google Scholar] [CrossRef]

- Nakagawa, Y.; Lee, C.-H.; Matsui, K.; Kousaka, K.; Isobe, S.; Hashimoto, N.; Yamaguchi, S.; Miyaoka, H.; Ichikawa, T.; Kojima, Y. Doping effect of Nb species on hydrogen desorption properties of AlH3. J. Alloys Compd. 2018, 734, 55–59. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Zhou, H.; Gao, S.; Ge, H.; Li, S.; Yan, M. Improved hydrogen desorption properties of LiBH4 by AlH3 addition. Int. J. Hydrog. Energy 2016, 41, 22118–22127. [Google Scholar] [CrossRef]

- Yang, J.; Liang, F.; Cheng, Y.; Yin, D.; Wang, L. Improvement of dehydrogenation performance by adding CeO2 to α-AlH3. Int. J. Hydrog. Energy 2020, 45, 2119–2126. [Google Scholar] [CrossRef]

- Drozd, V.; Garimella, S.; Saxena, S.; Chen, J.; Palasyuk, T. High-Pressure Raman and X-ray Diffraction Study of β- and γ-Polymorphs of Aluminum Hydride. J. Phys. Chem. C 2012, 116, 3808–3816. [Google Scholar] [CrossRef]

- Li, N.; Zhao, F.Q.; Luo, Y.; Hao, H.X.; Gao, H.X.; Yao, E.G.; Xiao, L.B.; Zu Hu, R.; Yi, J.H. Study on thermodynamics and kinetics for the reaction of aluminum hydride and water by microcalorimetry. J. Therm. Anal. Calorim. 2015, 120, 1847–1851. [Google Scholar] [CrossRef]

- Duan, C.; Cao, Y.; Hu, L.; Fu, D.; Ma, J. Synergistic effect of TiF3 on the dehydriding property of α-AlH3 nano-composite. Mater. Lett. 2019, 238, 254–257. [Google Scholar] [CrossRef]

- Yartys, V.A.; Denys, R.V.; Maehlen, J.P.; Frommen, C.; Fichtner, M.; Bulychev, B.M.; Emerich, H. Double-Bridge Bonding of Aluminium and Hydrogen in the Crystal Structure of γ-AlH3. Inorg. Chem. 2007, 46, 1051–1055. [Google Scholar] [CrossRef] [PubMed]

- Brinks, H.W.; Istad-Lem, A.A.; Hauback, B.C. Mechanochemical Synthesis and Crystal Structure of α‘-AlD3and α-AlD3. J. Phys. Chem. B 2006, 110, 25833–25837. [Google Scholar] [CrossRef]

- Brower, F.M.; Matzek, N.E.; Reigler, P.F.; Rinn, H.W.; Roberts, C.B.; Schmidt, D.L.; Snover, J.A.; Terada, K. Preparation and properties of aluminum hydride. J. Am. Chem. Soc. 1976, 98, 2450–2453. [Google Scholar] [CrossRef]

- Graetz, J.; Reilly, J.J. Thermodynamics of the α,β and γ polymorphs of AlH3. J. Alloys Compd. 2006, 424, 262–265. [Google Scholar] [CrossRef]

- Turley, J.W.; Rinn, H.W. Crystal structure of aluminum hydride. Inorg. Chem. 1969, 8, 18–22. [Google Scholar] [CrossRef]

- Brinks, H.; Langley, W.; Jensen, C.; Graetz, J.; Reilly, J.; Hauback, B. Synthesis and crystal structure of β-AlD3. J. Alloys Compd. 2007, 433, 180–183. [Google Scholar] [CrossRef]

- Sartori, S.; Opalka, S.M.; Løvvik, O.M.; Guzik, M.N.; Tang, X.; Hauback, B.C. Experimental studies of α-AlD3 and α′-AlD3versus first-principles modelling of the alane isomorphs. J. Mater. Chem. 2008, 18, 2361–2370. [Google Scholar] [CrossRef]

- Kempa, P.B.; Thome, V.; Herrmann, M. Structure, Chemical and Physical Behavior of Aluminum Hydride. Part. Part. Syst. Charact. 2009, 26, 132–137. [Google Scholar] [CrossRef]

- Ito, S.; Tanaka, K.; Chujo, Y. Characterization and Photophysical Properties of a Luminescent Aluminum Hydride Complex Supported by a β-Diketiminate Ligand. Inorganics 2019, 7, 100. [Google Scholar] [CrossRef]

- Liu, M.-X.; He, J.-X.; Cao, Y.-L. Study on synthesis and properties of aluminum hydride. J. Solid Rocket Technol. 2008, 31, 75–78. [Google Scholar]

- Bakum, S.I.; Kuznetsova, S.F.; Kuznetsov, N.T. Method for the preparation of aluminum hydride. Russ. J. Inorg. Chem. 2010, 55, 1830–1832. [Google Scholar] [CrossRef]

- Ichikawa, K.; Ikeda, Y.; Wagatsuma, A.; Watanabe, K.; Szarek, P.; Tachibana, A. Theoretical study of hydrogenated tetrahedral aluminum clusters. Int. J. Quantum Chem. 2010, 111, 3548–3555. [Google Scholar] [CrossRef]

- Wang, L.; Rawal, A.; Aguey-Zinsou, K.-F. Hydrogen storage properties of nanoconfined aluminium hydride (AlH3). Chem. Eng. Sci. 2019, 194, 64–70. [Google Scholar] [CrossRef]

- Stecher, O.; Wiberg, E. Über einen nichtflüchtigen, polymeren Aluminiumwasserstoff (AlH3)xund einige flüchtige Verbindungen des monomeren AlH3. Berichte Dtsch. Chem. Ges. 1942, 75, 2003–2012. [Google Scholar] [CrossRef]

- Finholt, A.E.; Bond, A.C.; Schlesinger, H.I. Lithium Aluminum Hydride, Aluminum Hydride and Lithium Gallium Hydride, and Some of their Applications in Organic and Inorganic Chemistry1. J. Am. Chem. Soc. 1947, 69, 1199–1203. [Google Scholar] [CrossRef]

- Chizinsky, G.; Evans, G.G.; Gibb, T.R.P.; Rice, M.J. NON-SOLVATED ALUMINUM HYDRIDE1. J. Am. Chem. Soc. 1955, 77, 3164–3165. [Google Scholar] [CrossRef]

- Ashby, E.C.; Sanders, J.R.; Claudy, P.; Schwartz, R. Diethyl ether soluble aluminum hydride. J. Am. Chem. Soc. 1973, 95, 6485–6486. [Google Scholar] [CrossRef]

- Bulychev, B.M.; Verbetskii, V.N.; Storozhenko, P.A. “Direct” synthesis of unsolvated aluminum hydride involving Lewis and Bronsted acids. Russ. J. Inorg. Chem. 2008, 53, 1000–1005. [Google Scholar] [CrossRef]

- Lacina, D.; Reilly, J.; Johnson, J.; Wegrzyn, J.; Graetz, J. The reversible synthesis of bis(quinuclidine) alane. J. Alloy. Compd. 2011, 509, S654–S657. [Google Scholar] [CrossRef]

- Graetz, J.; Chaudhuri, S.; Wegrzyn, J.; Celebi, Y.; Johnson, J.R.; Zhou, W.; Reilly, J.J. Direct and Reversible Synthesis of AlH3−Triethylenediamine from Al and H2. J. Phys. Chem. C 2007, 111, 19148–19152. [Google Scholar] [CrossRef]

- Baranowski, B.; Tkacz, M. The Equilibrium Between Solid Aluminium Hydride and Gaseous Hydrogen. Z. Phys. Chem. 1983, 135, 27–38. [Google Scholar] [CrossRef]

- Appel, M.; Frankel, J.P. Production of Aluminum Hydride by Hydrogen-Ion Bombardment. J. Chem. Phys. 1965, 42, 3984. [Google Scholar] [CrossRef]

- Saitoh, H.; Machida, A.; Katayama, Y.; Aoki, K. Formation and decomposition of AlH3 in the aluminum-hydrogen system. Appl. Phys. Lett. 2008, 93, 151918. [Google Scholar] [CrossRef]

- Saitoh, H.; Okajima, Y.; Yoneda, Y.; Machida, A.; Kawana, D.; Watanuki, T.; Katayama, Y.; Aoki, K. Formation and crystal growth process of AlH3 in Al–H system. J. Alloys Compd. 2010, 496, L25–L28. [Google Scholar] [CrossRef]

- Baranowski, B.; Tkacz, M.; Filipek, S. High pressure investigations of the Al-H system. Mater. Res. Soc. Symp. Proc. 1984, 22, 53–56. [Google Scholar]

- Dymova, T.N.; Mal’Tseva, N.N.; Konoplev, V.N.; Golovanova, A.I.; Aleksandrov, D.P.; Sizareva, A.S. Solid-Phase Solvate-Free Formation of Magnesium Hydroaluminates Mg(AlH4)2 and MgAlH5 upon Mechanochemical Activation or Heating of Magnesium Hydride and Aluminum Chloride Mixtures. Russ. J. Co-ord. Chem. 2003, 29, 385–389. [Google Scholar] [CrossRef]

- Dymova, T.N.; Konoplev, V.N.; Sizareva, A.S.; Aleksandrov, D.P. Magnesium tetrahydroaluminate: Solid-phase formation with mechanochemical activation of a mixture of aluminum and magnesium hydrides. Russ. J. Coord. Chem./Koord. Khimiya 1999, 25, 312–315. [Google Scholar]

- Fichtner, M.; Frommen, C.; Fuhr, O. Synthesis and Properties of Calcium Alanate and Two Solvent Adducts. Inorg. Chem. 2005, 44, 3479–3484. [Google Scholar] [CrossRef] [PubMed]

- Mal’tseva, N.N.; Golovanova, A.I.; Dymova, T.N.; Aleksandrov, D.P. Solid-phase formation of calcium hydridoaluminates Ca(AlH4)2 and CaHAlH4 upon mechanochemical activation or heating of mixtures of calcium hydride with aluminum chloride. Russ. J. Inorg. Chem. 2001, 46, 1793–1797. [Google Scholar]

- Mamatha, M.; Bogdanovic, B.; Felderhoff, M.; Pommerin, A.; Schmidt, W.; Schueth, F.; Weidenthaler, C. Mechanochemical Preparation and Investigation of Properties of Magnesium, Calcium and Lithium—Magnesium Alanates. ChemInform 2006, 37. [Google Scholar] [CrossRef]

- Sartori, S.; Istad-Lem, A.; Brinks, H.W.; Hauback, B.C. Mechanochemical synthesis of alane. Int. J. Hydrogen Energy 2009, 34, 6350–6356. [Google Scholar] [CrossRef]

- Paskevicius, M.; Sheppard, D.; Buckley, C. Characterisation of mechanochemically synthesised alane (AlH3) nanoparticles. J. Alloys Compd. 2009, 487, 370–376. [Google Scholar] [CrossRef]

- Duan, C.W.; Hu, L.X.; Xue, D. Solid state synthesis of nano-sized AlH3 and its dehydriding behaviour. Green Chem. 2015, 17, 3466–3474. [Google Scholar] [CrossRef]

- Duan, C.W.; Hu, L.X.; Sun, Y.; Zhou, H.P.; Yu, H. Reaction kinetics for the solid state synthesis of the AlH3/MgCl2 nano-composite by mechanical milling. Phys. Chem. Chem. Phys. 2015, 17, 22152–22159. [Google Scholar] [CrossRef]

- Duan, C.; Hu, L.; Sun, Y.; Zhou, H.; Yu, H. An insight into the process and mechanism of a mechanically activated reaction for synthesizing AlH 3 nano-composites. Dalton Trans. 2015, 44, 16251–16255. [Google Scholar] [CrossRef] [PubMed]

- Hlova, I.Z.; Gupta, S.; Goldston, J.F.; Kobayashi, T.; Pruski, M.; Pecharsky, V.K. Dry mechanochemical synthesis of alane from LiH and AlCl3. Faraday Discuss. 2014, 170, 137–153. [Google Scholar] [CrossRef] [PubMed]

- Mcgrady, G.S. Hydrogenation of Aluminium using a Supercritical Fluid Medium. U.S. Patent 7931887B2, 2 October 2008. [Google Scholar]

- Zidan, R.; Garcia-Diaz, B.L.; Fewox, C.S.; Stowe, A.C.; Gray, J.R.; Harter, A.G. Aluminium hydride: A reversible material for hydrogen storage. Chem. Commun. 2009, 25, 3717–3719. [Google Scholar] [CrossRef] [PubMed]

- Sandrock, G.; Reilly, J.; Graetz, J.; Zhou, W.-M.; Johnson, J.; Wegrzyn, J. Accelerated thermal decomposition of AlH3 for hydrogen-fueled vehicles. Appl. Phys. A 2005, 80, 687–690. [Google Scholar] [CrossRef]

- Maehlen, J.; Yartys, V.; Denys, R.; Fichtner, M.; Frommen, C.; Bulychev, B.; Pattison, P.; Emerich, H.; Filinchuk, Y.; Chernyshov, D. Thermal decomposition of AlH3 studied by in situ synchrotron X-ray diffraction and thermal desorption spectroscopy. J. Alloys Compd. 2007, 446-447, 280–289. [Google Scholar] [CrossRef]

- Gao, S.; Liu, H.; Wang, X.; Xu, L.; Liu, S.; Sheng, P.; Zhao, G.; Wang, B.; Li, H.; Yan, M. Hydrogen desorption behaviors of γ-AlH 3: Diverse decomposition mechanisms for the outer layer and the inner part of γ-AlH 3 particle. Int. J. Hydrogen Energy 2017, 42, 25310–25315. [Google Scholar] [CrossRef]

- Graetz, J.; Reilly, J.; Kulleck, J.; Bowman, R. Kinetics and thermodynamics of the aluminum hydride polymorphs. J. Alloys Compd. 2007, 446-447, 271–275. [Google Scholar] [CrossRef]

- Gabis, I.; Dobrotvorskiy, M.; Evard, E.; Voyt, A. Kinetics of dehydrogenation of MgH2 and AlH3. J. Alloys Compd. 2011, 509, S671–S674. [Google Scholar] [CrossRef]

- Herley, P.J.; Christofferson, O.; Irwin, R. Decomposition of.alpha.-aluminum hydride powder. 1. Thermal decomposition. J. Phys. Chem. 1981, 85, 1874–1881. [Google Scholar] [CrossRef]

- Claudy, P.; Bonnetot, B.; Letoffe, J.M. Preparation et proprietes physico-chimiques de l’alanate de magnesium Mg(AlH4)2. J. Therm. Anal. Calorim. 1979, 15, 119–128. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, L.; Ma, H.; Lu, C.; Luo, H.; Wang, X.; Huang, X.; Lan, Z.; Guo, J. Aluminum hydride for solid-state hydrogen storage: Structure, synthesis, thermodynamics, kinetics, and regeneration. J. Energy Chem. 2021, 52, 428–440. [Google Scholar] [CrossRef]

- Suárez-Alcántara, K.; Tena-Garcia, J.R.; Guerrero-Ortiz, R.; Alcántara, S.-; Garcia, T.-; Ortiz, G.-. Alanates, a Comprehensive Review. Materials 2019, 12, 2724. [Google Scholar] [CrossRef]

- Chen, R.; Duan, C.-L.; Liu, X.; Qu, K.; Tang, G.; Xu, X.-X.; Shan, B. Surface passivation of aluminum hydride particles via atomic layer deposition. J. Vac. Sci. Technol. A 2017, 35, 03E111. [Google Scholar] [CrossRef]

- Bulychev, B.M.; Storozhenko, P.A.; Fokin, V.N. “One-step” synthesis of nonsolvated aluminum hydride. Russ. Chem. Bull. 2009, 58, 1817–1823. [Google Scholar] [CrossRef]

- Ardis, A.; Natoli, F.J.U. Thermal Stability of Aluminium Hydride Through Use of Stabilizers. U.S. Patent 3801707A, 2 April 1974. [Google Scholar]

- Matzek, N.E.; Roehrs, H.C.J.U. Stabilization of Light Metal Hydride. U.S. Patent 3844854A, 29 October 1974. [Google Scholar]

- Flynn, J. Particulate Aluminum Hydride with Nitrocellulose Coating Suitable for Use in Solid Propellants. U.S. Patent 3855022A, 17 December 1974. [Google Scholar]

- Cai, X.W.; Yang, J.H.; Zhang, J.L.; Ma, D.X.; Wang, Y.P. Liquid Carbon Dioxide as Anti-Solvent Coating Aluminum Hydride. Propellants, Explos. Pyrotech. 2015, 40, 914–919. [Google Scholar] [CrossRef]

- Gaur, B.; Lochab, B.; Choudhary, V.; Varma, I.K. Azido Polymers—Energetic Binders for Solid Rocket Propellants. J. Macromol. Sci. Part C 2003, 43, 505–545. [Google Scholar] [CrossRef]

- Trache, D.; Klapötke, T.M.; Maiz, L.; Abd-ElGhany, M.; DeLuca, L.T. Recent advances in new oxidizers for solid rocket propulsion. Green Chem. 2017, 19, 4711–4736. [Google Scholar] [CrossRef]

- Pang, W.; Luigi, D.T.; Fan, X.; Wang, K.; Li, J.; Zhao, F. Progress on modification of high active aluminum powder and combustion agglomeration in chemical propellants. J. Solid Rocket Technol. 2019, 42, 42–53. [Google Scholar] [CrossRef]

- Cheng, Z.-P.; He, X.-X. Research progress of nano aluminum fuel. J. Solid Rocket Technol. 2017, 40, 437–447. [Google Scholar] [CrossRef]

- De Luca, L.T.; Galfetti, L.; Severini, F.; Meda, L.; Marra, G.; Vorozhtsov, A.B.; Sedoi, V.S.; Babuk, V.A. Burning of Nano-Aluminized Composite Rocket Propellants. Combust. Explos. Shock. Waves 2005, 41, 680–692. [Google Scholar] [CrossRef]

- Meda, L.; Marra, G.; Galfetti, L.; Severini, F.; De Luca, L. Nano-aluminum as energetic material for rocket propellants. Mater. Sci. Eng. C 2007, 27, 1393–1396. [Google Scholar] [CrossRef]

- Meda, L.; Marra, G.; Galfetti, L.; Inchingalo, S.; Severini, F.; De Luca, L. Nano-composites for rocket solid propellants. Compos. Sci. Technol. 2005, 65, 769–773. [Google Scholar] [CrossRef]

- Galfetti, L.; De Luca, L.T.; Severini, F.; Meda, L.; Marra, G.; Marchetti, M.; Regi, M.; Bellucci, S. Nanoparticles for solid rocket propulsion. J. Phys. Condens. Matter 2006, 18, S1991–S2005. [Google Scholar] [CrossRef]

- Shark, S.C.; Pourpoint, T.L.; Son, S.F.; Heister, S.D. Performance of Dicyclopentadiene/H2O2-Based Hybrid Rocket Motors with Metal Hydride Additives. J. Propuls. Power 2013, 29, 1122–1129. [Google Scholar] [CrossRef]

- DeLuca, L.; Galfetti, L.; Severini, F.; Rossettini, L.; Meda, L.; Marra, G.L.; Dandrea, B.; Weiser, V.; Calabro, M.; Vorozhtsov, A.; et al. Physical and ballistic characterization of AlH3-based space propellants. Aerosp. Sci. Technol. 2007, 11, 18–25. [Google Scholar] [CrossRef]

- Graetz, J.; Hauback, B.C. Recent developments in aluminum-based hydrides for hydrogen storage. MRS Bull. 2013, 38, 473–479. [Google Scholar] [CrossRef]

- Young, G.; Risha, G.A., Jr.; Yetter, R.A. Combustion of HTPB Based Solid Fuels Containing Metals and Metal Hydrides with Nitrous Oxide. Propellants, Explos. Pyrotech. 2019, 44, 744–750. [Google Scholar] [CrossRef]

- Shark, S.C.; Zaseck, C.R.; Pourpoint, T.L.; Son, S.F.; Heister, S.D. Performance and Flame Visualization of Dicyclopentadiene Rocket Propellants with Metal Hydride Additives. J. Propuls. Power 2016, 32, 869–881. [Google Scholar] [CrossRef]

- Maggi, F.; Gariani, G.; Galfetti, L.; DeLuca, L.T. Theoretical analysis of hydrides in solid and hybrid rocket propulsion. Int. J. Hydrogen Energy 2012, 37, 1760–1769. [Google Scholar] [CrossRef]

- Il’In, A.P.; Bychin, N.V.; Gromov, A.A. Products of Combustion of Aluminum Hydride in Air. Combust. Explos. Shock. Waves 2001, 37, 490–491. [Google Scholar] [CrossRef]

- Bazyn, T.; Krier, H.; Glumac, N.; Shankar, N.; Wang, X.; Jackson, T.L. Decomposition of Aluminum Hydride Under Solid Rocket Motor Conditions. J. Propuls. Power 2007, 23, 457–464. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, W.; Zhao, F.; Ma, L.; Tang, R.; Dong, Y.; Kong, G.; Zhang, Y.; Niu, S.; Tang, G.; Wang, Y.; et al. Synthesis and Stability of Hydrogen Storage Material Aluminum Hydride. Materials 2021, 14, 2898. https://doi.org/10.3390/ma14112898

Su W, Zhao F, Ma L, Tang R, Dong Y, Kong G, Zhang Y, Niu S, Tang G, Wang Y, et al. Synthesis and Stability of Hydrogen Storage Material Aluminum Hydride. Materials. 2021; 14(11):2898. https://doi.org/10.3390/ma14112898

Chicago/Turabian StyleSu, Wenda, Fangfang Zhao, Lei Ma, Ruixian Tang, Yanru Dong, Guolong Kong, Yu Zhang, Sulin Niu, Gen Tang, Yue Wang, and et al. 2021. "Synthesis and Stability of Hydrogen Storage Material Aluminum Hydride" Materials 14, no. 11: 2898. https://doi.org/10.3390/ma14112898

APA StyleSu, W., Zhao, F., Ma, L., Tang, R., Dong, Y., Kong, G., Zhang, Y., Niu, S., Tang, G., Wang, Y., Pang, A., Li, W., & Wei, L. (2021). Synthesis and Stability of Hydrogen Storage Material Aluminum Hydride. Materials, 14(11), 2898. https://doi.org/10.3390/ma14112898