Multi Ceramic Particles Inclusion in the Aluminium Matrix and Wear Characterization through Experimental and Response Surface-Artificial Neural Networks

Abstract

1. Introduction

2. Materials and Methods

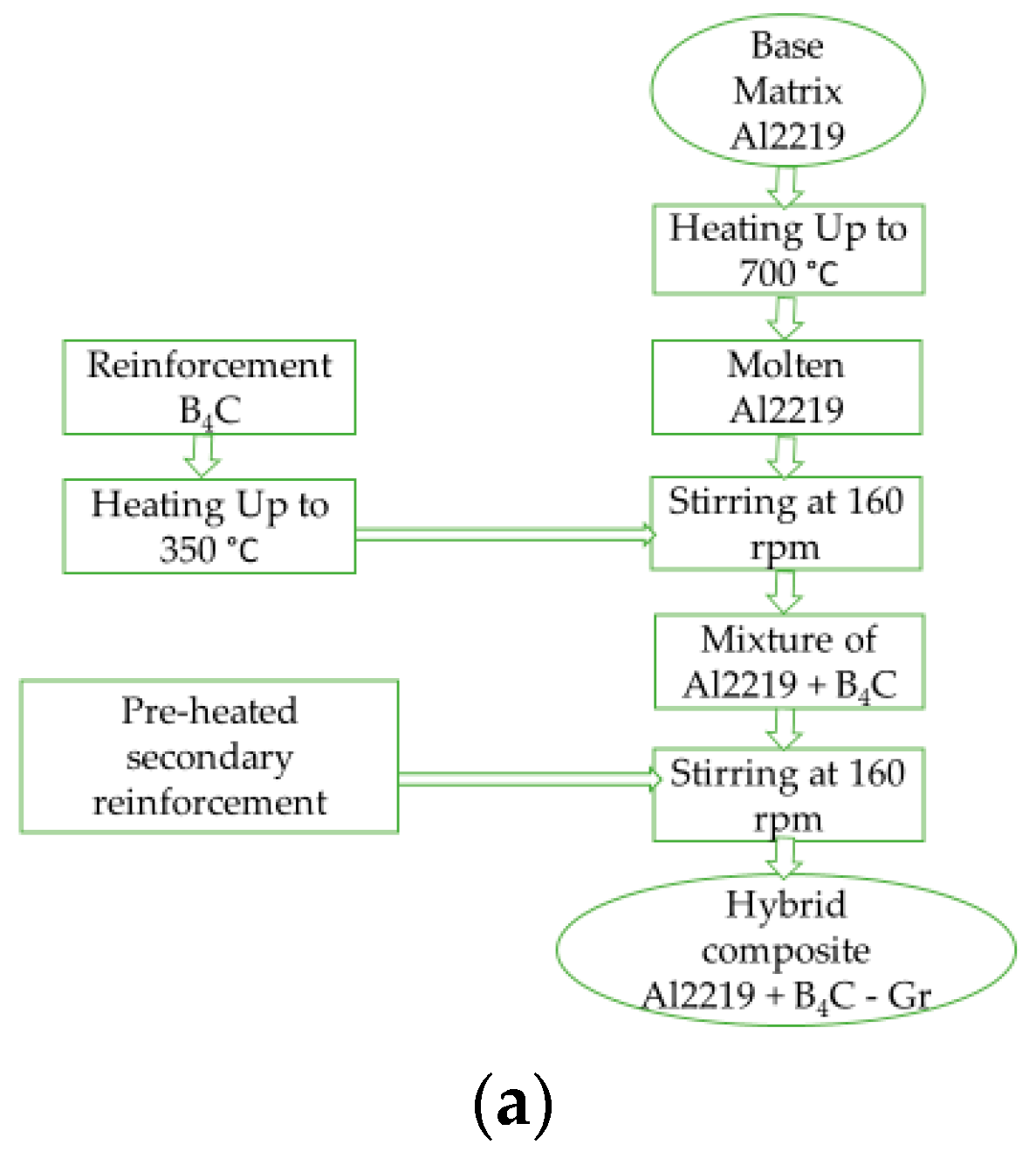

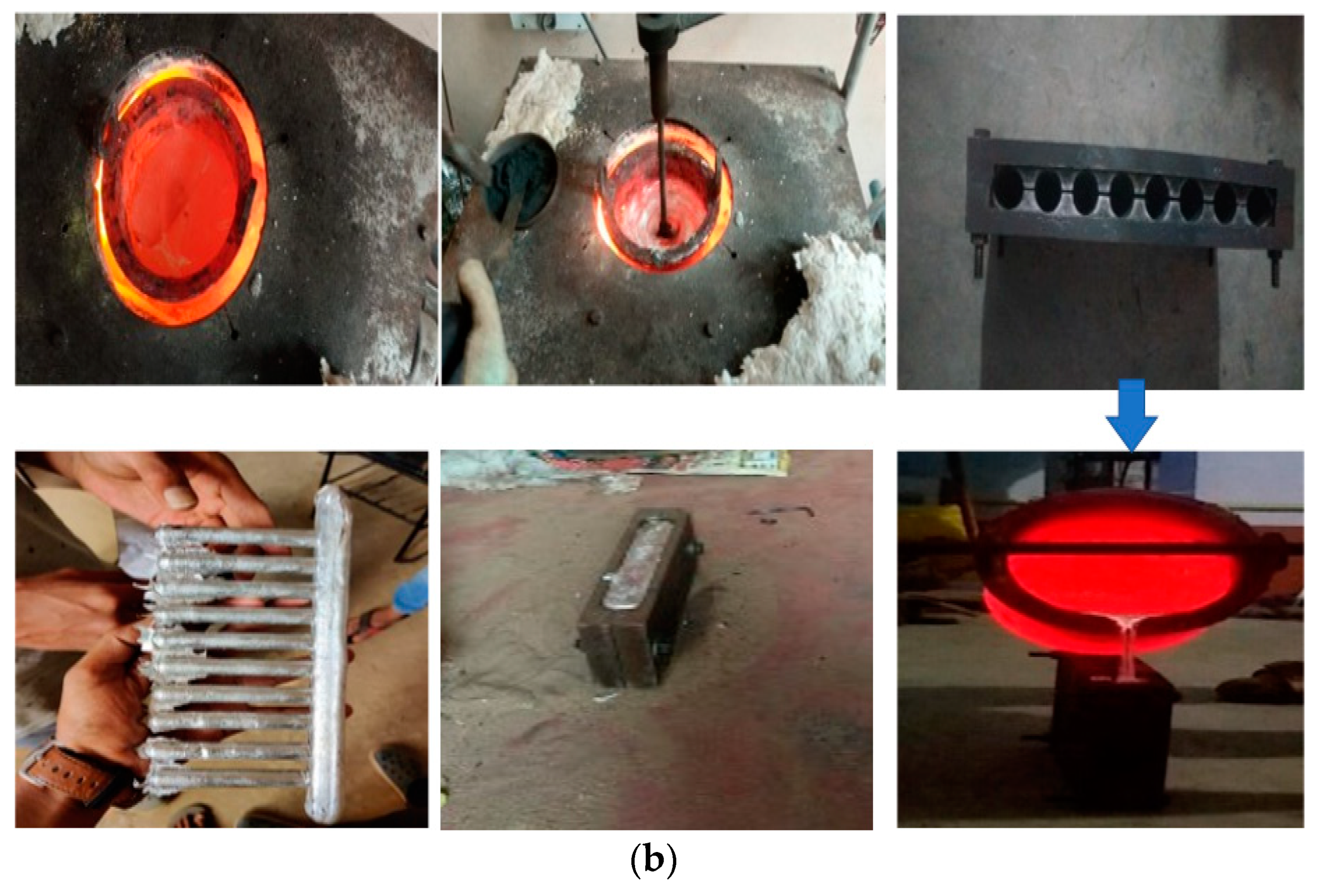

2.1. Fabrication of Composites by Using the Stir Casting Method

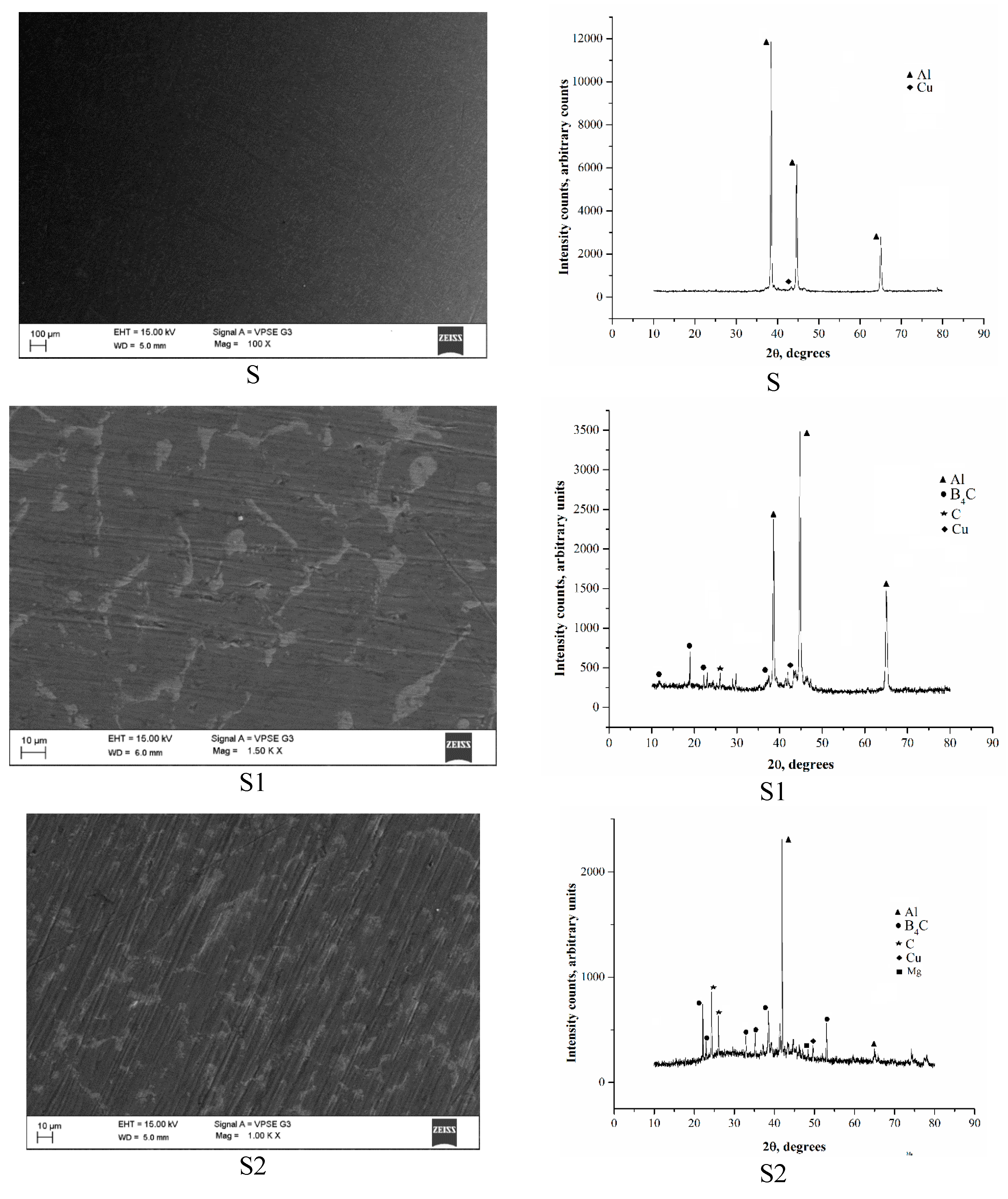

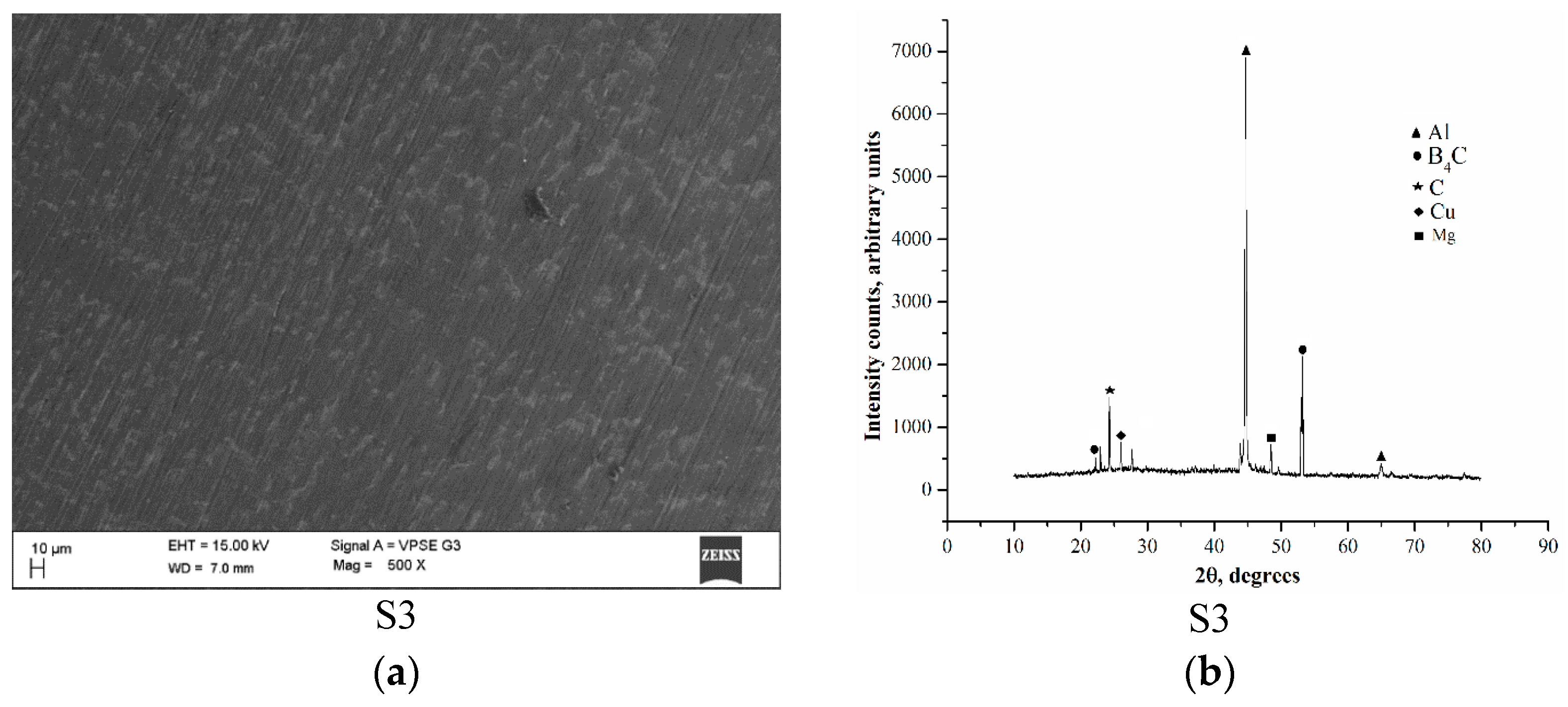

2.2. X-ray Diffraction and Microstructural Study

2.3. Hardness Test

2.4. Wear Test

3. Results and Discussion

3.1. X-ray Analysis and Microstructural Study

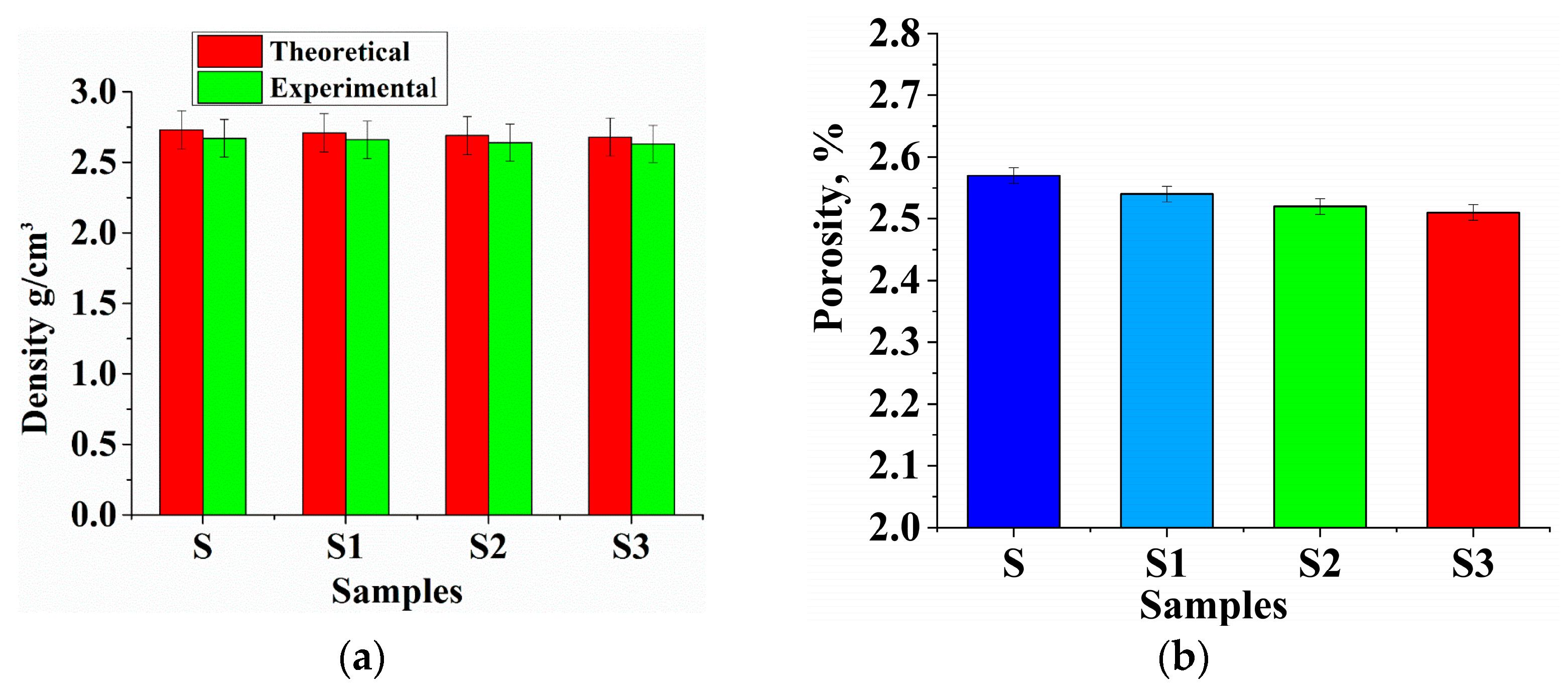

3.2. Density and Porosity

3.3. Hardness Test

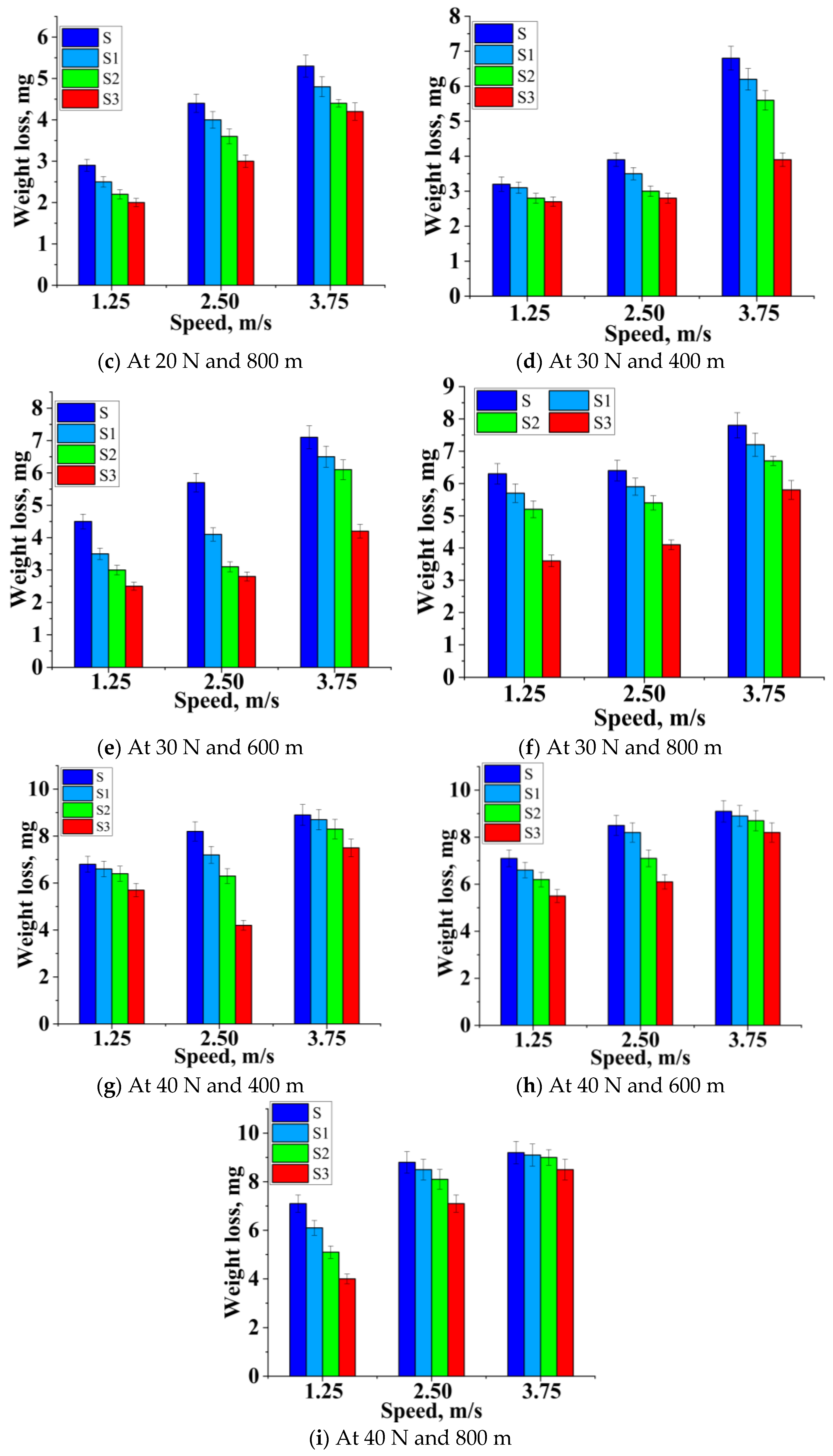

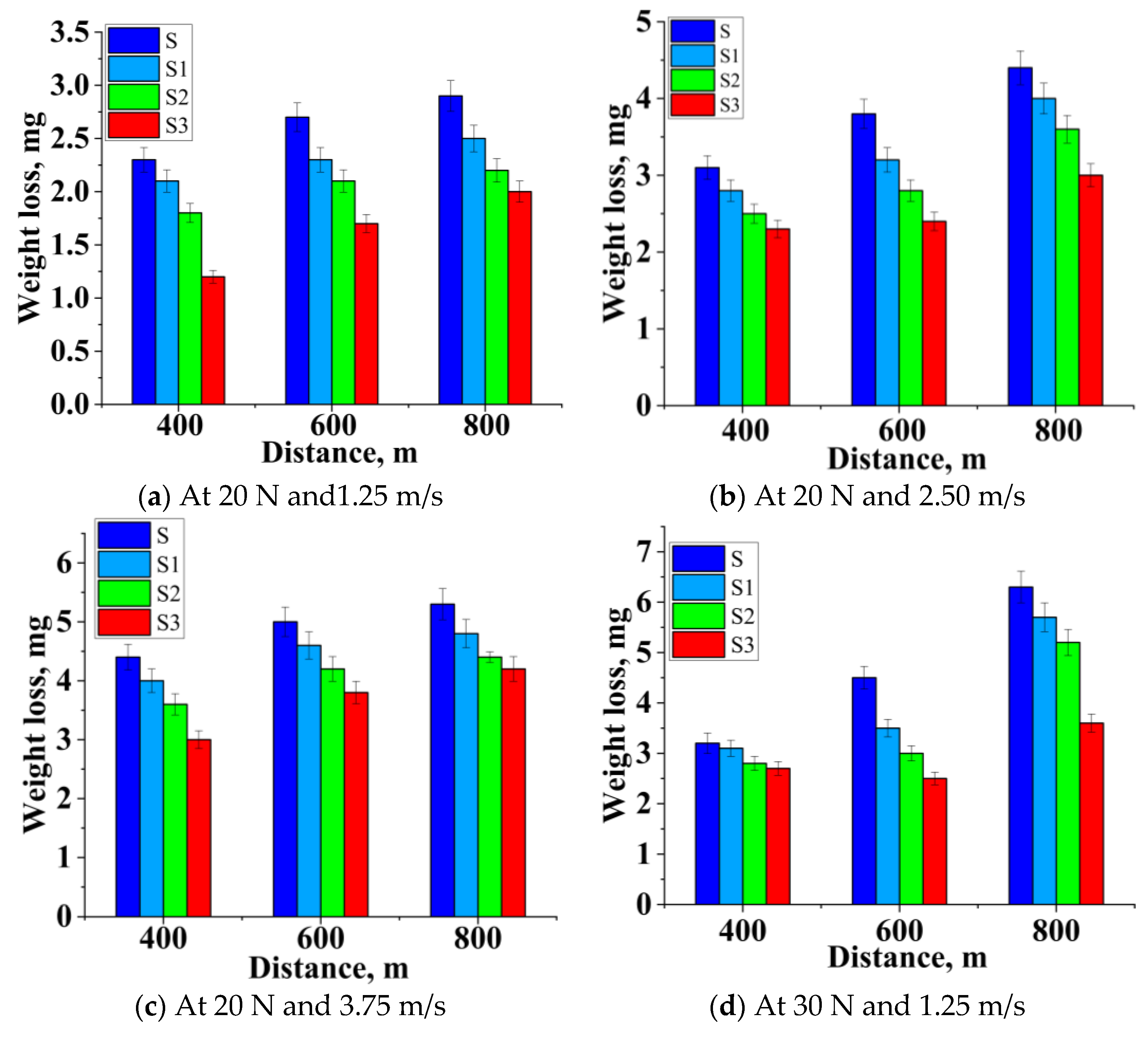

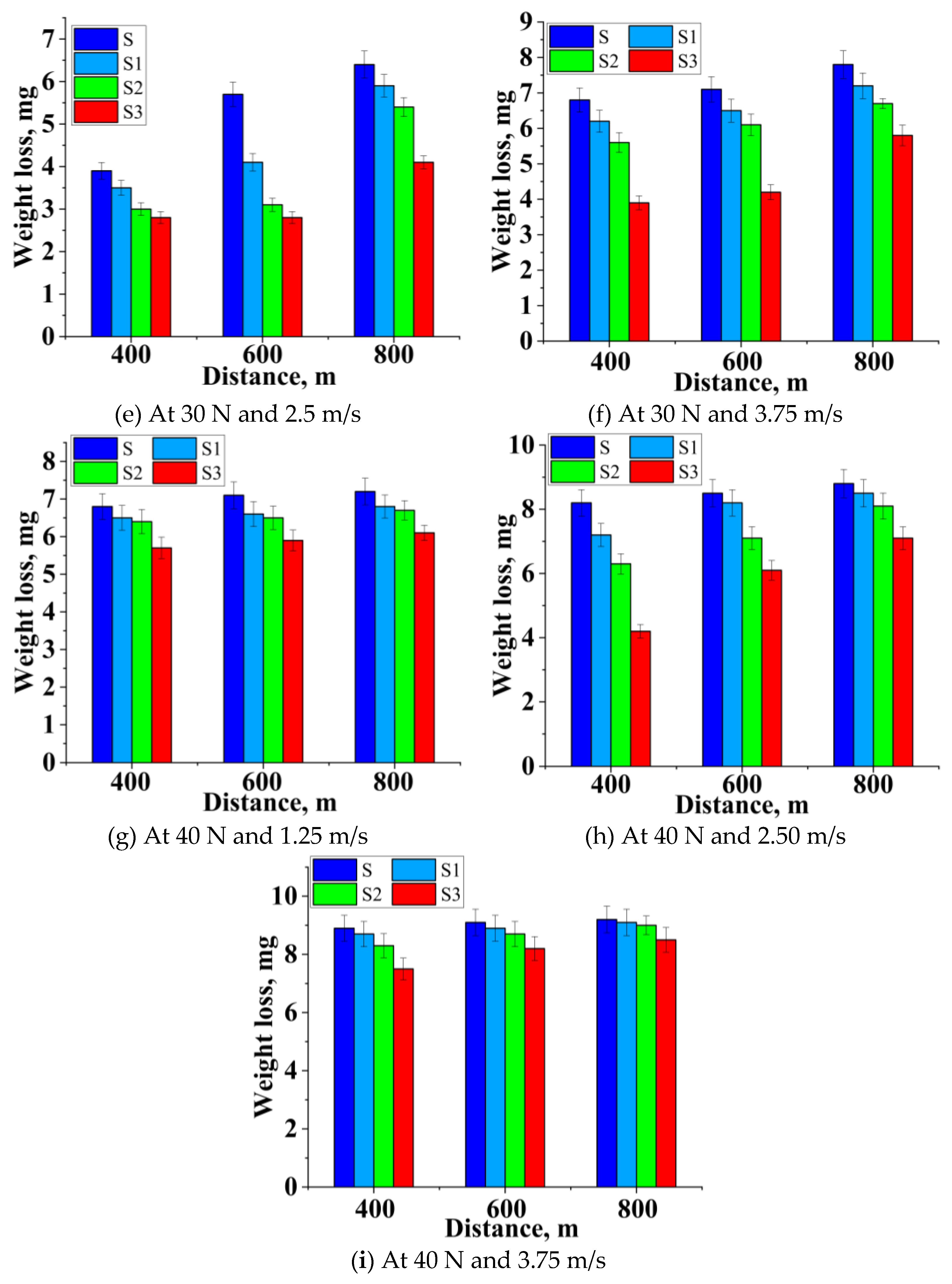

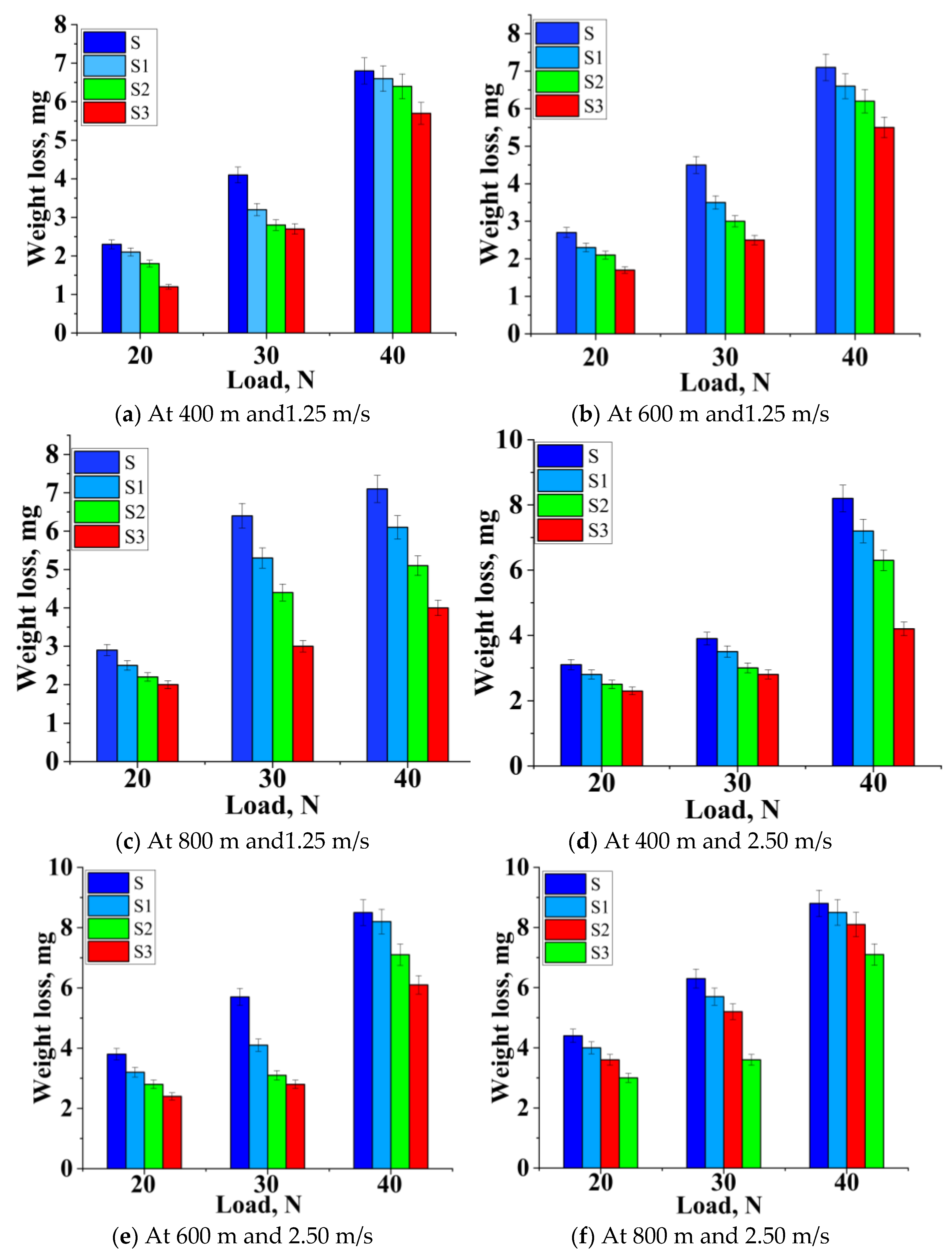

3.4. Wear Behavior

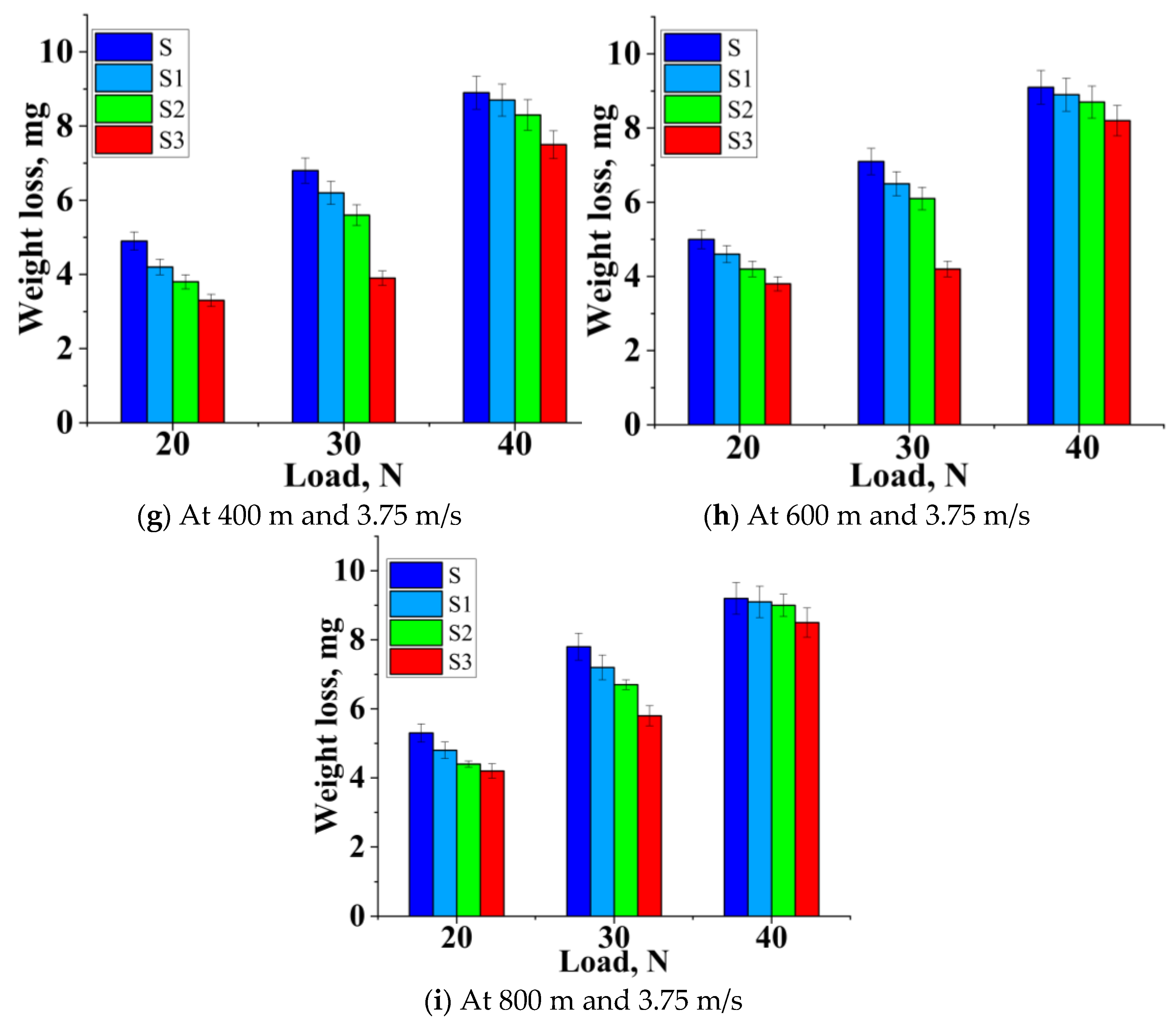

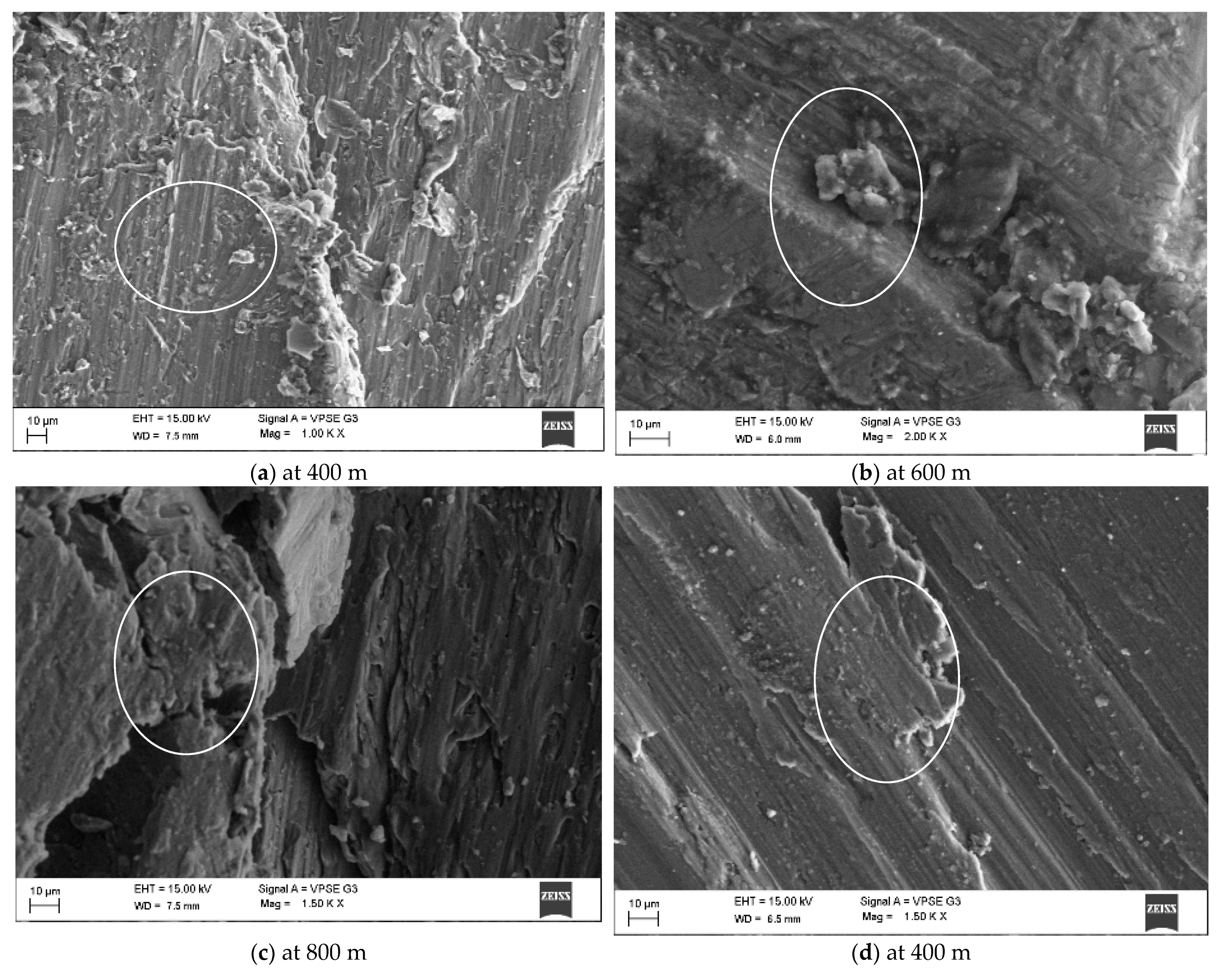

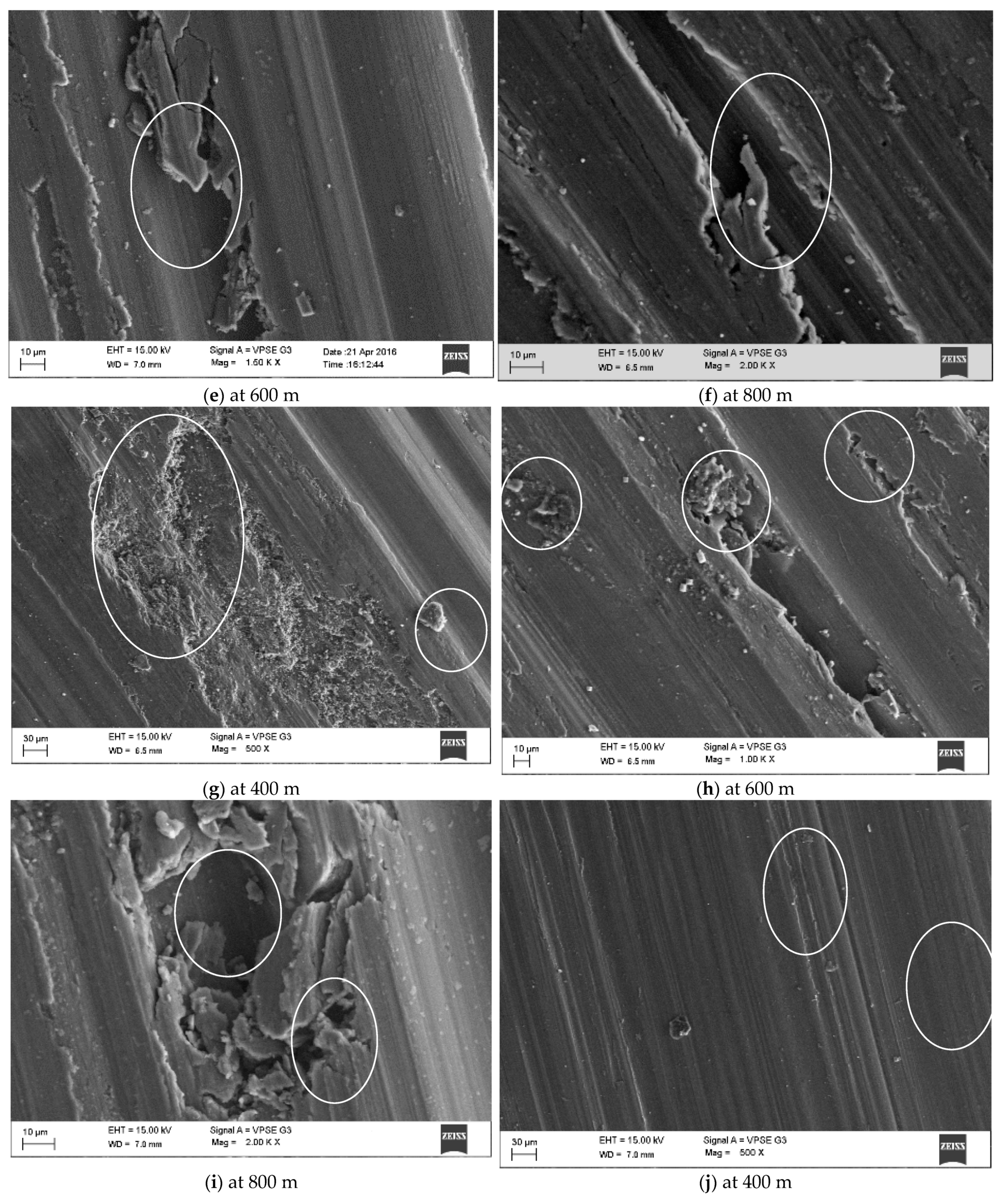

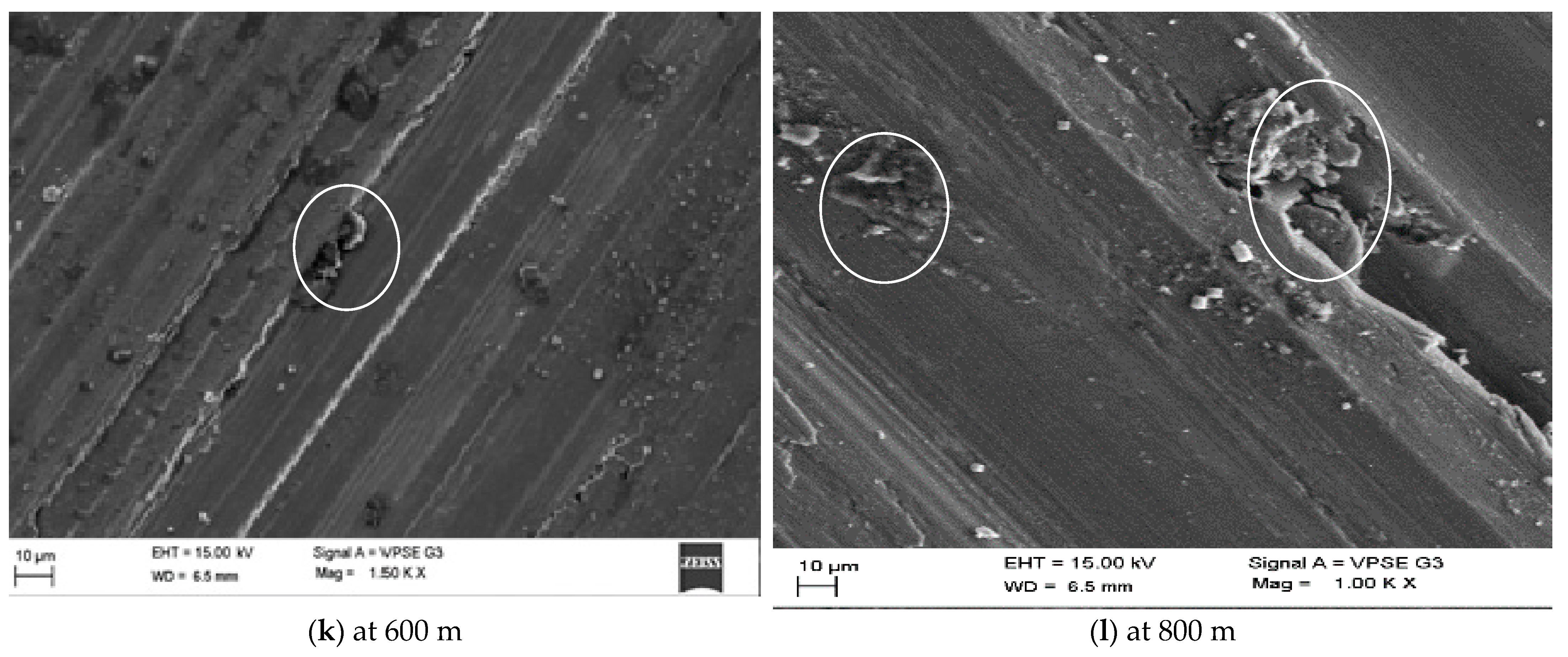

3.5. Worn Surface Morphology

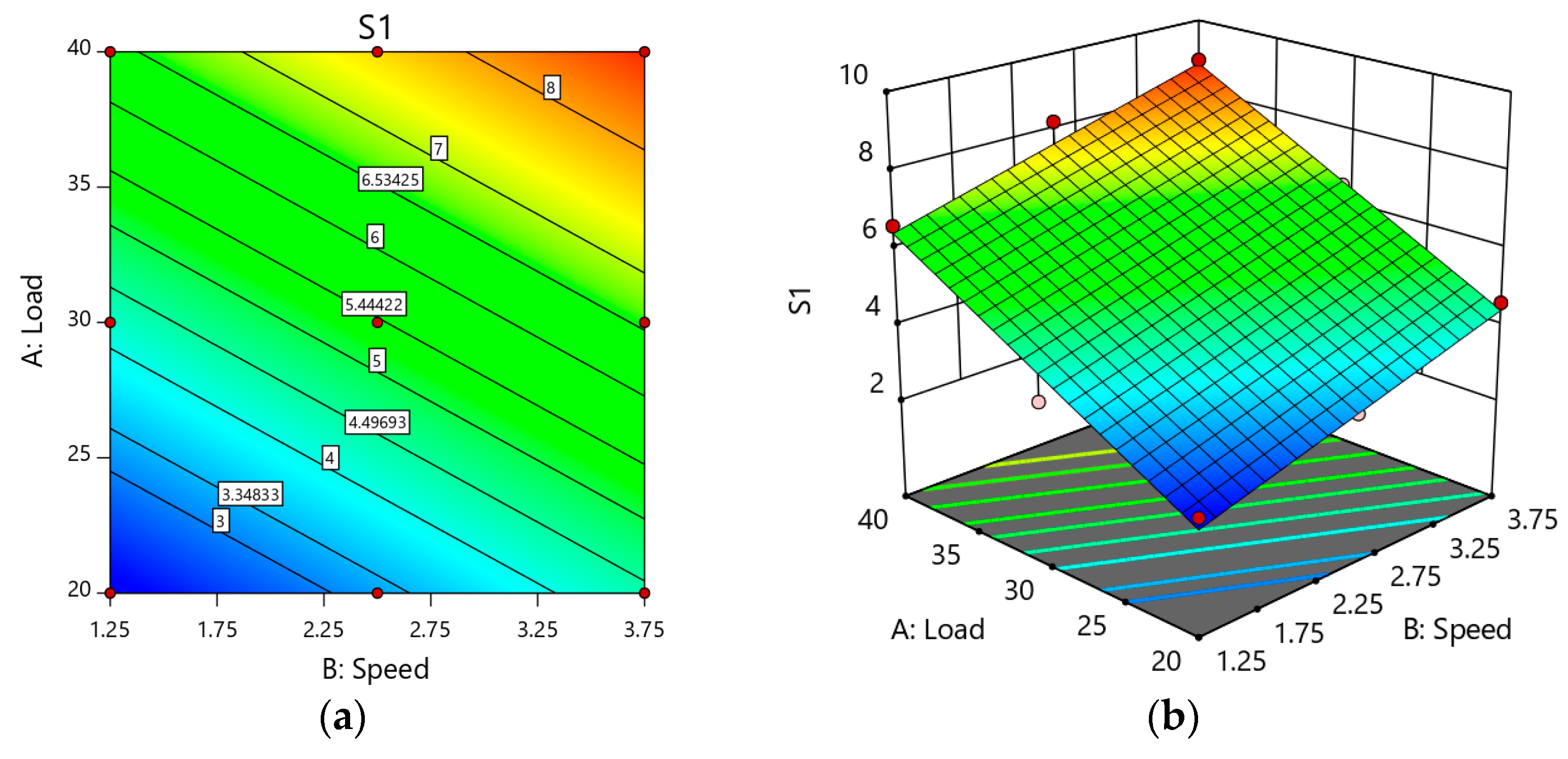

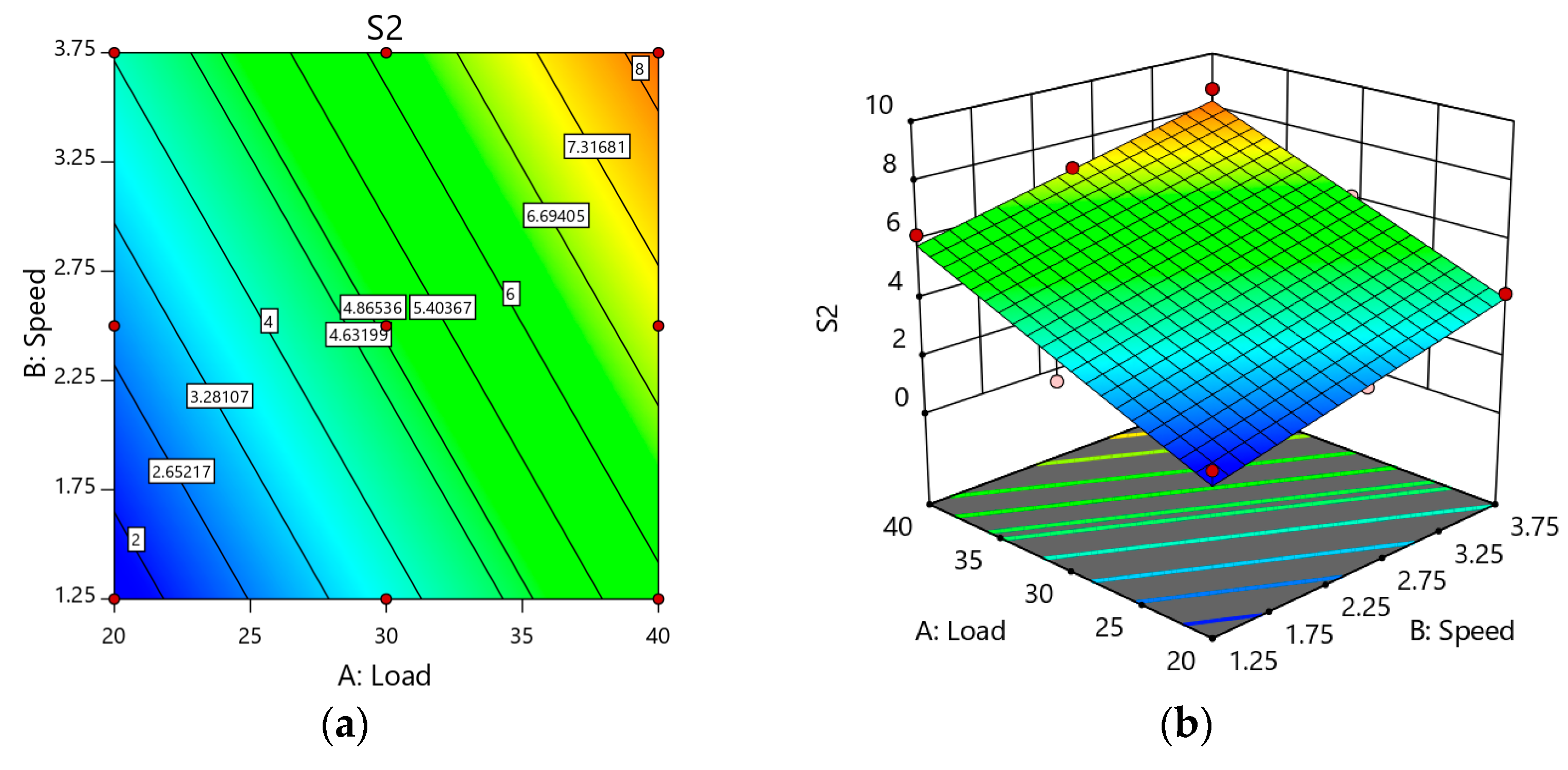

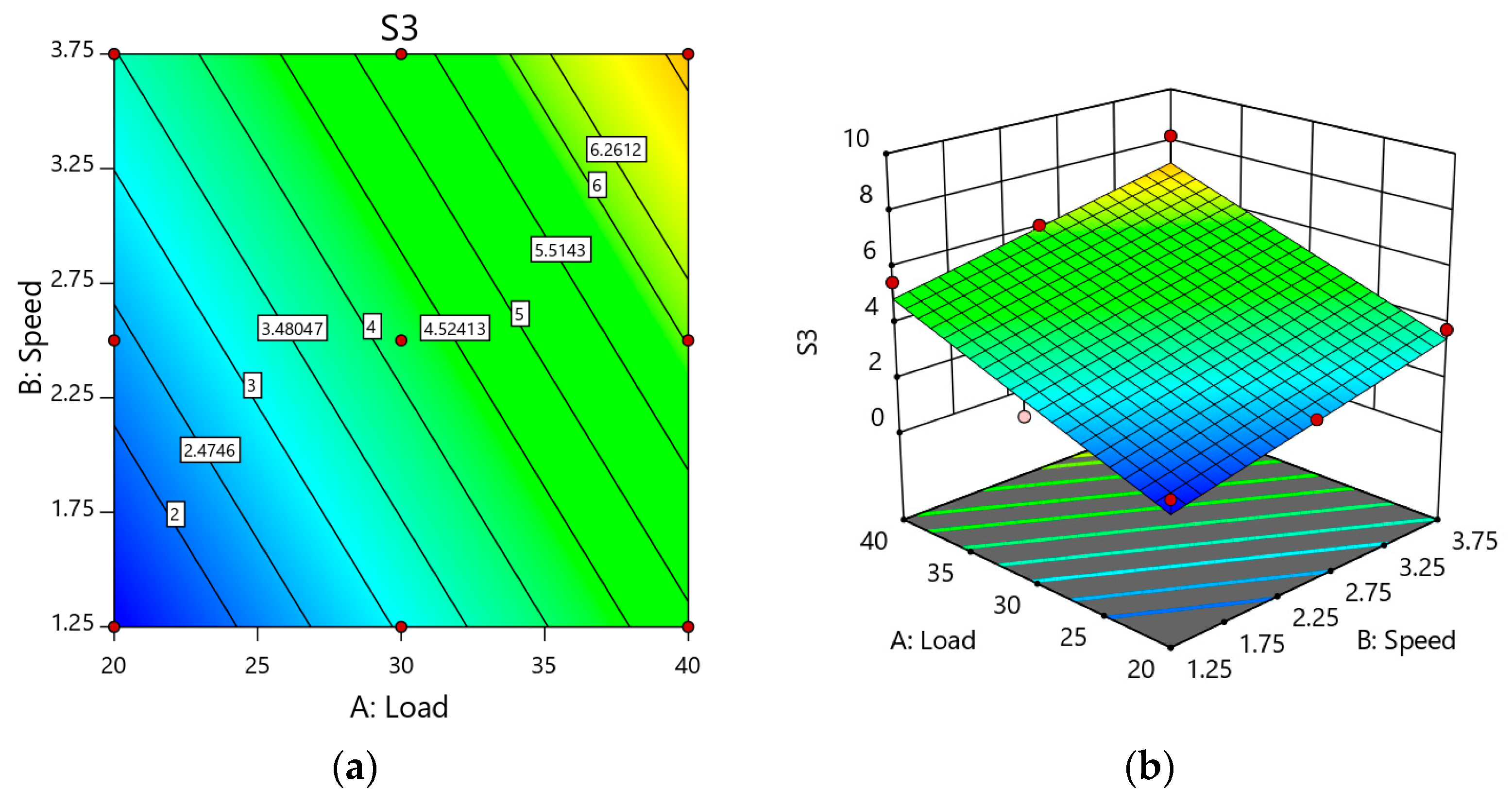

3.6. Response Surface Analysis

3.7. ANN (Artificial Neural Networks) Analysis

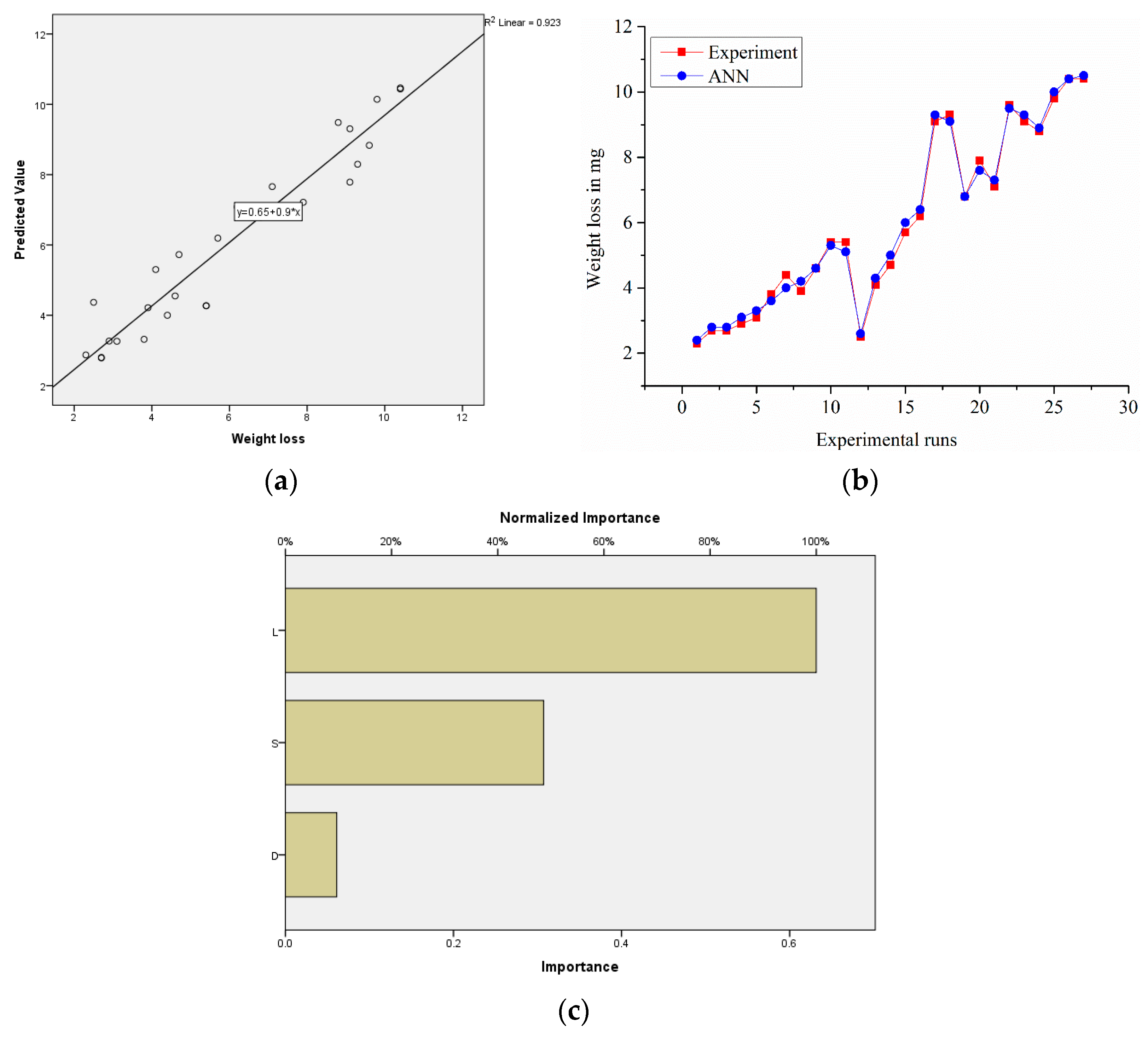

3.7.1. ANN Analysis for Sample S

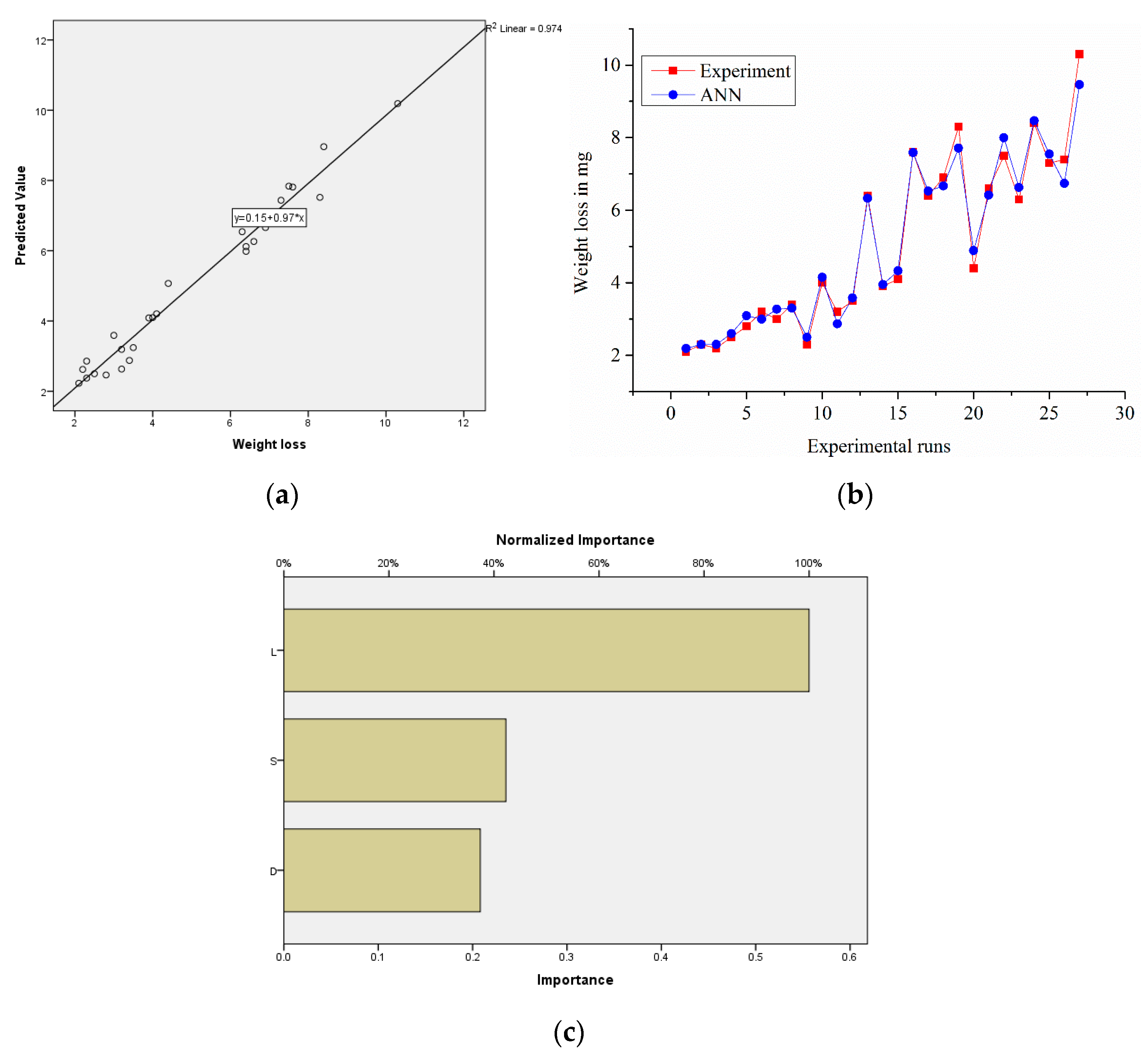

3.7.2. ANN Analysis for Sample S1

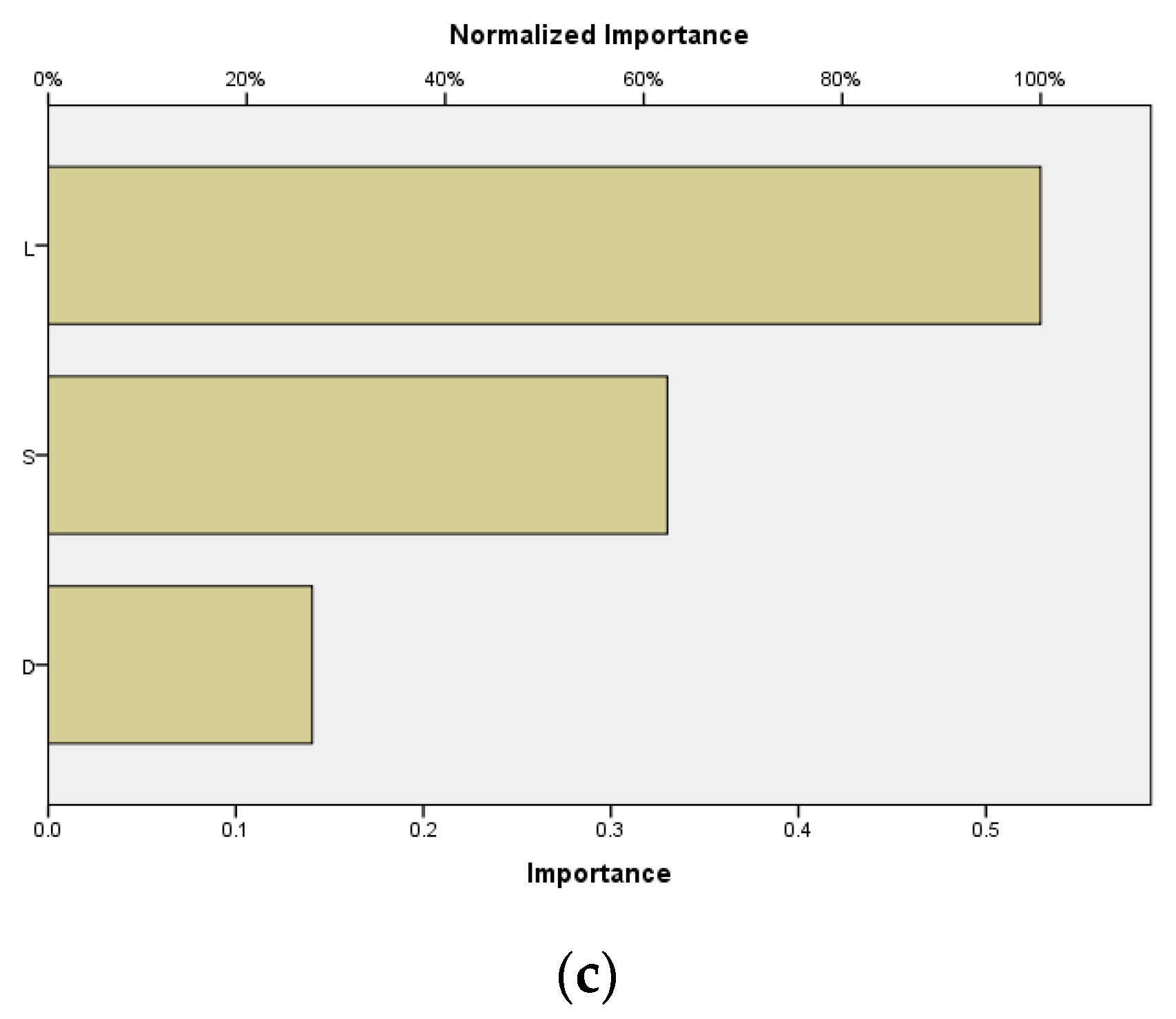

3.7.3. ANN Analysis for Sample S2

3.7.4. ANN Analysis for Sample S3

4. Conclusions

- Hybridized composites were successfully fabricated by the stir-casting process.

- The reinforced matrix was harder (37%) than the base alloy because of the increased ceramic phase in the Al2219 matrix.

- The inclusion of the B4C and Gr particles served as a barrier to dislocation and contributed to a greater hardness than the Al2219 matrix.

- It was found that hardness was directly proportional to wear resistance.

- The inclusion of B4C and Gr particles could be attributed to the induction of a greater strength to the matrix by providing greater wear resistance.

- The weight loss was significantly less for the 15 wt.% B4C and 5 wt.% Gr, because of the existence of a mechanically mixed layer that contained B4C and Gr.

- The weight loss of Sample S3 (47%) was significantly less than for Sample S.

- ANN results confirmed that the load and speed contributed to the weight loss of the composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Straffelini, G.; Pellizzari, M.; Molinari, A. Influence of load and temperature on the dry sliding behaviour of Al-based metal-matrix-composites against friction material. Wear 2004, 256, 754–763. [Google Scholar] [CrossRef]

- Kumar, A.; Lal, S.; Kumar, S. Fabrication, and characterization of A359/Al2O3 metal matrix composite using electro-magnetic stir casting method. JMRT 2013, 2, 250–254. [Google Scholar]

- Zhang, G.S.; Xing, J.D.; Gao, Y.M. Impact wear resistance of WC/Hadfield steel composite and its interfacial characteris-tics. Wear 2006, 260, 728–734. [Google Scholar] [CrossRef]

- Uyyuru, R.K.; Surappa, M.K.; Brusethaug, S. Effect of reinforcement volume fraction and size distribution on the tribo-logical behavior of Al-composite/brake pad tribo-couple. Wear 2006, 260, 1248–1255. [Google Scholar] [CrossRef]

- Rao, R.; Das, S. Effect of matrix alloy and influence of SiC particle on the sliding wear characteristics of aluminium alloy composites. Mater. Des. 2010, 31, 1200–1207. [Google Scholar] [CrossRef]

- Hamid, A.A.; Ghosh, P.; Jain, S.; Ray, S. Influence of particle content and porosity on the wear behaviour of cast in situ Al(Mn)–Al2O3(MnO2) composite. Wear 2006, 260, 368–378. [Google Scholar] [CrossRef]

- Klaffke, D.; Wäsche, R.; Janakiraman, N. Tribological characterization of silicon carbonitride ceramics derived from prece-ramic polymers. Wear 2006, 260, 711–719. [Google Scholar] [CrossRef]

- Kök, M.; Özdin, K. Wear resistance of aluminium alloy and its composites reinforced by Al2O3 particles. J. Mater. Process. Technol. 2007, 183, 301–309. [Google Scholar] [CrossRef]

- Singh, J. Fabrication characteristics and tribological behavior of Al/SiC/Gr hybrid aluminum matrix composites: A review. Friction 2016, 4, 191–207. [Google Scholar] [CrossRef]

- Surappa, M.; Prasad, S.; Rohatgi, P. Wear and abrasion of cast Al-Alumina particle composites. Wear 1982, 77, 295–302. [Google Scholar] [CrossRef]

- Liang, Y.N.; Ma, Z.Y.; Li, S.Z.; Bi, J. Effect of particle size on wear behaviour of SiC particulate-reinforced aluminum alloy composites. J. Mater. Sci. Lett. 1995, 14, 114–116. [Google Scholar] [CrossRef]

- Krakhmalev, P.; Bergström, J. Tribological behavior and wear mechanisms of MoSi2-base composites sliding against AA6063 alloy at elevated temperature. Wear 2006, 260, 450–457. [Google Scholar] [CrossRef]

- Yu, S.Y.; Ishii, H.; Tohgo, K.; Cho, Y.T.; Diao, D. Temperature dependence of sliding wear behavior in SiC whisker or SiC particulate reinforced 6061 aluminum alloy composite. Wear 1997, 213, 21–28. [Google Scholar] [CrossRef]

- Kok, M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J. Mater. Process. Technol. 2005, 161, 381–387. [Google Scholar] [CrossRef]

- Doel, T.J.A.; Bowen, P. Tensile properties of particulate-reinforced metal matrix composites. Compos. Part A Appl. Sci. Manuf. 1996, 27, 655–665. [Google Scholar] [CrossRef]

- Sharif, E.M.; Karimzadeh, F.; Enayati, M.H. Fabrication and evaluation of mechanical and tribological properties of boron car-bide reinforced aluminum matrix nanocomposites. Mater. Des. 2011, 32, 3263–3271. [Google Scholar] [CrossRef]

- Tang, F.; Wu, X.; Ge, S.; Ye, J.; Zhu, H. Dry sliding friction and wear properties of B4C particulate-reinforced Al-5083 matrix composites. Wear 2008, 264, 555–561. [Google Scholar] [CrossRef]

- Alizadeh, A.; Abdollahi, A.; Biukani, H. Creep behavior and wear resistance of Al 5083 based hybrid composites reinforced with carbon nanotubes (CNTs) and boron carbide (B4C). J. Alloys Compd. 2015, 650, 783–793. [Google Scholar] [CrossRef]

- Saraswat, R.; Yadav, A.; Tyagi, R. Sliding Wear Behaviour of Al-B4C Cast Composites under Dry Contact. Mater. Today Proc. 2018, 5, 16963–16972. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Laoui, T.; Haseeb, A.S.M.A. Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: A comparative study. J. Mat. Proc. Technol. 2003, 142, 738–743. [Google Scholar] [CrossRef]

- Ipek, R. Adhesive wear behaviour of B4C and SiC reinforced 4147 Al matrix composites (Al/B4C–Al/SiC). J. Mater. Process. Technol. 2005, 162–163, 71–75. [Google Scholar] [CrossRef]

- Auradi, V.; Rajesh, G.; Kori, S. Processing of B 4 C Particulate Reinforced 6061Aluminum Matrix Composites by Melt Stirring Involving Two-step Addition. Procedia Mater. Sci. 2014, 6, 1068–1076. [Google Scholar] [CrossRef]

- Kala, H.; Mer, K.K.S.; Kumar, S. A review on mechanical and tribological behaviors of stir cast aluminum matrix compo-sites. Proc. Mat. Sci. 2014, 6, 1951–1960. [Google Scholar]

- Cho, M.H.; Ju, J.; Kim, S.J.; Jang, H. Tribological properties of solid lubricants (graphite, Sb2S3, MoS2) for automotive brake friction materials. Wear 2006, 260, 855–860. [Google Scholar] [CrossRef]

- Suresha, S.; Sridhara, B.K. Effect of silicon carbide particulates on wear resistance of graphitic aluminium matrix compo-sites. Mat. Des. 2010, 31, 4470–4477. [Google Scholar] [CrossRef]

- Hu, Q.; McColl, I.R.; Harris, S.J. The role of debris in the fretting wear of a SiC reinforced aluminium alloy matrix compo-site. Wear 2000, 245, 10–21. [Google Scholar] [CrossRef]

- Llorca, J. High temperature fatigue of discontinuously-reinforced metal—Matrix composites. Int. J. Fatigue 2002, 24, 233–240. [Google Scholar] [CrossRef]

- Bahrami, A.; Soltani, N.; Pech-Canul, M. Effect of sintering temperature on tribological behavior of Ce-TZP/Al2O3-aluminum nanocomposite. J. Compos. Mater. 2015, 49, 3507–3514. [Google Scholar] [CrossRef]

- Bahrami, A.; Soltani, N.; Pech-Canul, M.I.; Soltani, S.; González, L.A.; Gutiérrez, C.A.; Tapp, J.; Möller, A.; Gurlo, A. Bilayer graded Al/B4C/rice husk ash composite: Wettability behavior, thermo-mechanical, and electrical properties. J. Compos. Mater. 2018, 52, 3745–3758. [Google Scholar] [CrossRef]

- Bahrami, A.; Pech-Canul, M.; Soltani, N.; Gutiérrez, C.; Kamm, P.; Gurlo, A. Tailoring microstructure and properties of bilayer-graded Al/B4C/MgAl2O4 composites by single-stage pressureless infiltration. J. Alloys Compd. 2017, 694, 408–418. [Google Scholar] [CrossRef]

- Rao, P.S.; Sivadasan, K.G.; Balasubramanian, P.K. Structure-property correlation on AA 2219 aluminium alloy weldments. Bull. Mater. Sci. 1996, 19, 549–557. [Google Scholar] [CrossRef]

- NG, S.K.; Ravindranath, V.M.; GS, S.S. Dry sliding wear behavior of hybrid metal matrix composites. Int. J. Res. Eng. Technol. 2014, 3, 554–558. [Google Scholar]

- Hayajneh, M.; Hassan, A.M.; Mayyas, A.T. Artificial neural network modeling of the drilling process of self-lubricated aluminum/alumina/graphite hybrid composites synthesized by powder metallurgy technique. J. Alloys Compd. 2009, 478, 559–565. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, D. Artificial Neural Network-Based Wear Loss Prediction for A390 Aluminium Alloy. J. Theor. Appl. Infor. Technol. 2008, 4, 10. [Google Scholar]

- Şimşek, İ. The effect of B4C amount on wear behaviors of Al-Graphite/B4C hybrid composites produced by mechanical al-loying. Bor Derg. 2019, 4, 100–106. [Google Scholar]

- Mohanty, R.M.; Balasubramanian, K.; Seshadri, S.K. Boron carbide-reinforced alumnium 1100 matrix composites: Fabrication and properties. Mat. Sci. Eng. A 2008, 498, 42–52. [Google Scholar] [CrossRef]

- Muthazhagan, C.; Rajkumar, K.; Gnanavelbabu, A. Effect of Cooling Rate on Distribution of Boron Carbide and Graphite in Al 6061 Composites During Solidification. Int. J. Appl. Eng. Res. 2015, 10, 1429–1433. [Google Scholar]

- Thirumalai, T.; Subramanian, R.; Kumaran, S. Production and characterization of hybrid aluminum matrix composites reinforced with boron carbide (B4C) and graphite. J. Sci. Ind. Res. 2014, 73, 667–670. [Google Scholar]

- Baradeswaran, A.; Perumal, A.E. Influence of B4C on the tribological and mechanical properties of Al 7075–B4C composites. Compos. Part B Eng. 2013, 54, 146–152. [Google Scholar] [CrossRef]

- Sharath, B.; Madhu, K.; Venkatesh, C. Experimental Study on Dry Sliding Wear Behaviour of Al-B4C-Gr Metal Matrix Composite at Different Temperatures. Appl. Mech. Mater. 2019, 895, 96–101. [Google Scholar] [CrossRef]

- Ahmed, A.; Wahab, M.S.; Raus, A.A.; Kamarudin, K.; Bakhsh, Q.; Ali, D. Mechanical Properties, Material and Design of the Automobile Piston: An Ample Review. Indian J. Sci. Technol. 2016, 9. [Google Scholar] [CrossRef]

- Engel, L.; Klingele, H. Rasterelektronenmikroskopische Untersuchungen von Metallschäden (Scanning Electron Microscopy Used for the Inspection of Damage to Metal); Gerling: Köln, Germany, 1982. [Google Scholar]

- Alam, M.T.; Ansari, A.H. X-ray diffraction analysis and microstructural examination of al-sic composite fabricated by stir casting. Int. J. Sci. Technol. Manag. 2015, 4, 941–956. [Google Scholar]

- Narayan, S.; Rajeshkannan, A. Hardness, tensile and impact behaviour of hot forged aluminium metal matrix composites. J. Mater. Res. Technol. 2017, 6, 213–219. [Google Scholar] [CrossRef]

- Shorowordi, K.; Haseeb, A.; Celis, J. Velocity effects on the wear, friction and tribochemistry of aluminum MMC sliding against phenolic brake pad. Wear 2004, 256, 1176–1181. [Google Scholar] [CrossRef]

- Suresha, S.; Sridhara, B. Friction characteristics of aluminium silicon carbide graphite hybrid composites. Mater. Des. 2012, 34, 576–583. [Google Scholar] [CrossRef]

- Guo, M.; Tsao, C.-Y. Tribological behavior of self-lubricating aluminium/SiC/graphite hybrid composites synthesized by the semi-solid powder-densification method. Compos. Sci. Technol. 2000, 60, 65–74. [Google Scholar] [CrossRef]

- Riahi, A.; Alpas, A. The role of tribo-layers on the sliding wear behavior of graphitic aluminum matrix composites. Wear 2001, 251, 1396–1407. [Google Scholar] [CrossRef]

- Basavarajappa, S.; Chandramohan, G.; Davim, J.P. Application of Taguchi techniques to study dry sliding wear behaviour of metal matrix composites. Mater. Des. 2007, 28, 1393–1398. [Google Scholar] [CrossRef]

- Prasad, D.S.; Shoba, C. Hybrid composites—A better choice for high wear resistant materials. J. Mater. Res. Technol. 2014, 3, 172–178. [Google Scholar] [CrossRef]

- Kumar, V.; Gupta, R.D.; Batra, N. Comparison of Mechanical Properties and Effect of Sliding Velocity on Wear Properties of Al 6061, Mg 4%, Fly Ash and Al 6061, Mg 4%, Graphite 4%, Fly Ash Hybrid Metal Matrix Composite. Procedia Mater. Sci. 2014, 6, 1365–1375. [Google Scholar] [CrossRef]

- Mahdavi, S.; Akhlaghi, F. Effect of the Graphite Content on the Tribological Behavior of Al/Gr and Al/30SiC/Gr Composites Processed by In Situ Powder Metallurgy (IPM) Method. Tribol. Lett. 2011, 44, 1–12. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, P.; Sharma, A. Optimization of wear and friction characteristics of Phyllanthus Emblica seed oil based lubri-cant using response surface methodology. Egypt. J. Pet. 2018, 27, 1145–1155. [Google Scholar] [CrossRef]

- Afzal, A.; Yashawantha, K.M.; Aslfattahi, N.; Saidur, R.; Razak, R.K.A.; Subbiah, R. Back propagation modeling of shear stress and viscosity of aqueous Ionic-MXene nanofluids. J. Therm. Anal. Calorim. 2021, 1–21. [Google Scholar] [CrossRef]

- Mokashi, I.; Afzal, A.; Khan, S.A.; Abdullah, N.A.; Bin Azami, M.H.; Jilte, R.; Samuel, O.D. Nusselt number analysis from a battery pack cooled by different fluids and multiple back-propagation modelling using feed-forward networks. Int. J. Therm. Sci. 2021, 161, 106738. [Google Scholar] [CrossRef]

- Afzal, A.; Aabid, A.; Khan, A.; Khan, S.A.; Rajak, U.; Verma, T.N.; Kumar, R. Response surface analysis, clustering, and random forest regression of pressure in suddenly expanded high-speed aerodynamic flows. Aerosp. Sci. Technol. 2020, 107, 106318. [Google Scholar] [CrossRef]

- Afzal, A.; Khan, S.A.; Islam, T.; Jilte, R.D.; Khan, A.; Soudagar, M.E.M. Investigation and back-propagation modeling of base pressure at sonic and supersonic Mach numbers. Phys. Fluids 2020, 32, 096109. [Google Scholar] [CrossRef]

| Constituents | Si | Mg | Zr | Cu | Fe | Mn | Ti | V | Zn |

|---|---|---|---|---|---|---|---|---|---|

| Weight % | 0.2 | 0.02 | 0.1–0.25 | 5.8–6.8 | 0.3 | 0.02 | 0.02 | 0.05 | 0.1 |

| Sample Designations | Composition | Al2219, % | B4C, % | Gr, % | Total Particulate B4C and Gr Reinforcement, % |

|---|---|---|---|---|---|

| S | Al 2219 | 100 | 0 | 0 | 0 |

| S1 | Al2219 + 5% B4C − 5% Gr | 90 | 5 | 5 | 10 |

| S2 | Al2219 + 10% B4C − 5% Gr | 85 | 10 | 5 | 15 |

| S3 | Al2219 + 15% B4C − 5% Gr | 80 | 15 | 5 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sharath, B.N.; Venkatesh, C.V.; Afzal, A.; Aslfattahi, N.; Aabid, A.; Baig, M.; Saleh, B. Multi Ceramic Particles Inclusion in the Aluminium Matrix and Wear Characterization through Experimental and Response Surface-Artificial Neural Networks. Materials 2021, 14, 2895. https://doi.org/10.3390/ma14112895

Sharath BN, Venkatesh CV, Afzal A, Aslfattahi N, Aabid A, Baig M, Saleh B. Multi Ceramic Particles Inclusion in the Aluminium Matrix and Wear Characterization through Experimental and Response Surface-Artificial Neural Networks. Materials. 2021; 14(11):2895. https://doi.org/10.3390/ma14112895

Chicago/Turabian StyleSharath, Ballupete Nagaraju, Channarayapattana Venkataramaiah Venkatesh, Asif Afzal, Navid Aslfattahi, Abdul Aabid, Muneer Baig, and Bahaa Saleh. 2021. "Multi Ceramic Particles Inclusion in the Aluminium Matrix and Wear Characterization through Experimental and Response Surface-Artificial Neural Networks" Materials 14, no. 11: 2895. https://doi.org/10.3390/ma14112895

APA StyleSharath, B. N., Venkatesh, C. V., Afzal, A., Aslfattahi, N., Aabid, A., Baig, M., & Saleh, B. (2021). Multi Ceramic Particles Inclusion in the Aluminium Matrix and Wear Characterization through Experimental and Response Surface-Artificial Neural Networks. Materials, 14(11), 2895. https://doi.org/10.3390/ma14112895