1. Introduction

The modern manufacturing industry needs to meet the growing demands of aerospace production, while adhering to increasingly strict environmental and sustainability constraints, which calls for the optimization of the machining methods used in the industry. This improvement in productivity, which is defined as the production output in a given time frame, requires increasing the cutting speeds and feeds, which adversely affects the cutting temperatures and causes them to reach temperatures above 900 °C in the case of titanium alloy Ti-6Al-4V [

1]. Titanium alloys are known for being difficult-to-machines alloys, specifically because of these high cutting temperatures which promote different types of tool wear and eventually lead to premature tool failure. The increased tool wear also compromises the surface integrity of the workpiece and the high cutting temperatures induce tensile residual stresses, as well as surface and subsurface cracks [

2]. Therefore, cryogenic machining has become an area of vast investigation for researchers with potential machinability benefits.

Previous work showed important improvements when cryogenically machining titanium alloys compared to dry cutting. Experiments by Jerold and Kumar showed a decrease in cutting temperatures by up to 50% when using liquid carbon dioxide to cut Ti-6Al-4V compared to dry machining [

3]. In cryogenic milling, Sadik and Isakson showed an increase in tool life by six times in cryogenic machining of Ti-6Al-4V compared to dry milling [

4]. In addition, Bordin et al. showed a decrease in adhesion on the tool rake face when turning Ti-6Al-4V cryogenically compared to dry turning [

5]. Cryogenic machining was also shown to have a positive effect on the surface roughness compared to flood machining, with a decrease of 19% in average surface roughness when using liquid nitrogen [

6]. These papers demonstrate the cryogenic effect on the machining process; however, the optimization of the nozzle position is not accounted for, which is an objective of this research paper.

Few papers study the optimization of the nozzle position in a cryogenic system, but they are mostly simulation based. Previous work used a computational fluid dynamic (CFD) model to vary the nozzle position but simplified the tool–chip geometry into a flat Ti-6Al-4V plate and ignored the heat generated due to plastic deformation of machining [

7]. Another research used a CFD model to simulate the correct tool–chip geometry but assumed a constant convection coefficient [

6]. More recent work used a finite difference model to vary the cryogenic nozzle’s position between rake and flank face, but this model assumed only 1D heat transfer on a flat plate [

8]. Thus, the literature lacks a model that accurately simulates the cryogenic environment and impingement of the cryogenic fluid on the tool–chip interface.

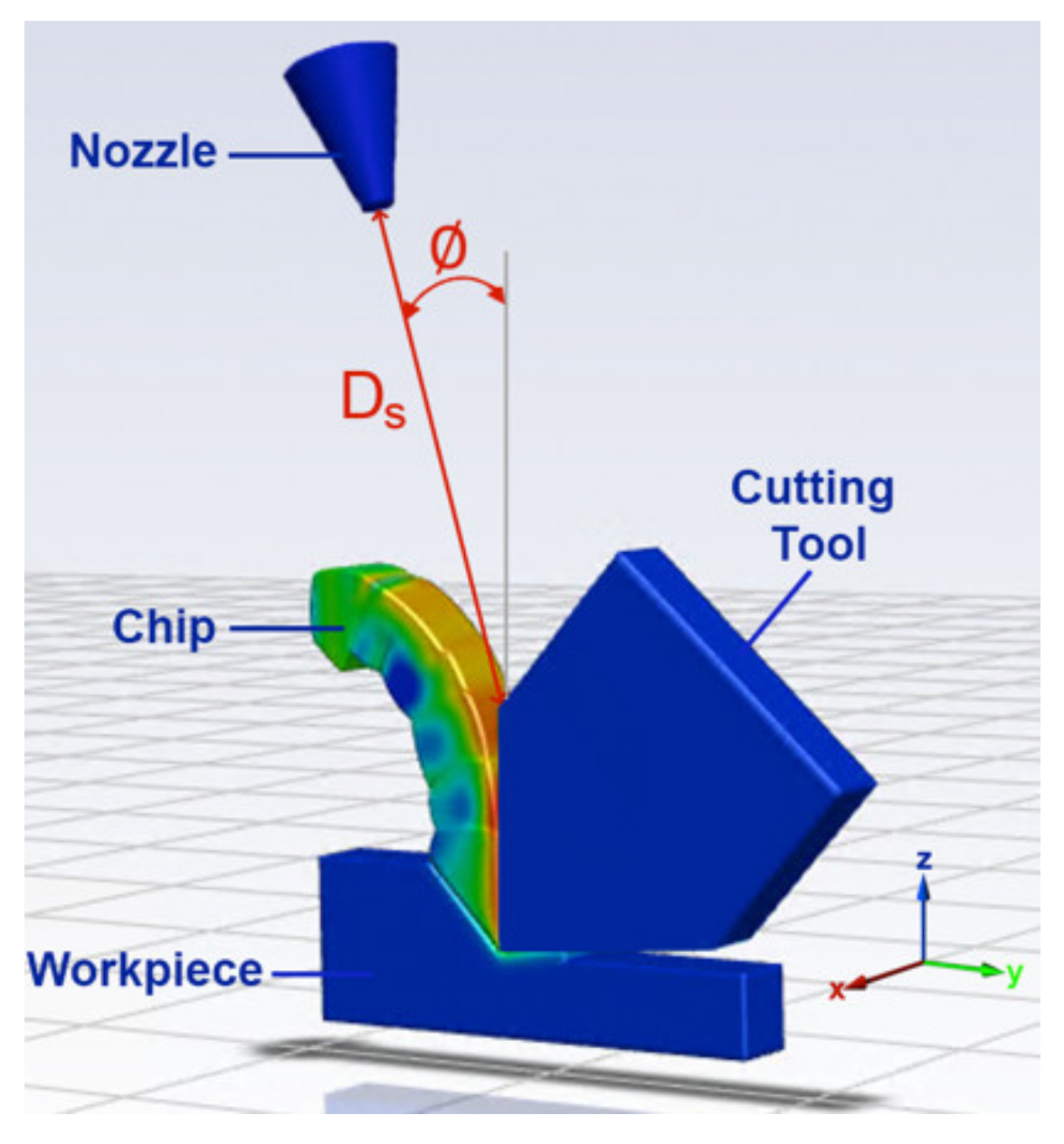

A cryogenic model that accurately simulates the impingement of the fluid on the tool–chip geometry is needed in order to better understand the effect of the nozzle location on the cryogenic machining process. To address this gap, this research uses a finite element model (FEM), CFD validated by experiments to determine the optimal nozzle position in the cryogenic setup, following the methodology illustrated in

Figure 1 The term ‘optimal nozzle position’ in this research paper is used to refer to the optimal among the nozzle positions that were studied, and not the absolute optimal nozzle position. It should be noted that the optimal nozzle position for each cryogenic setup may be different, however, the results and interpretations made in this paper should remain valid.

The nozzle position in this research is optimized using two parameters, the separation distance D

s and the inclination angle

from the rake face, shown in

Figure 2. The developed FEM model simulates the orthogonal cutting of Ti-6Al-4V and outputs the cutting geometry, temperature profile, heat generation rate and cutting forces. These are then fed to the CFD model, as shown in

Figure 1, where the cryogenic impingement on the tool–chip interface is simulated from different nozzle positions, varied in terms of D

s and

, to obtain the optimal temperature profile. By varying the same nozzle positions as the CFD model, the experimental section of the study aims to determine the nozzle position that yields the minimum cutting forces. As shown in

Figure 1, the experimental results are linked to the CFD results and a correlation between the cooling rates and the cutting forces is established to determine the optimal nozzle position for cryogenic machining. This optimal nozzle position is then applied during longitudinal turning of Ti-6Al-4V, referred to as an industrial practical application in

Figure 1, to determine the effect of using the optimized nozzle position on tool wear and surface integrity when applied on an industrial scale.

The research provides a better understanding of the cryogenic effect during machining of aerospace alloys, by linking the thermo-fluid properties of the cryogenic fluid to the heat transfer mechanisms at work during the cooling process. In addition, the work examines the effect of the cryogenic application on the tool wear mechanisms. Lastly, the research studies the effect of varying the nozzle position to provide an optimized industrial solution that reduces cutting forces, extends tool life and improves surface quality of the finished product.

4. Experimental Results and Discussion

The cutting forces were measured during the orthogonal and longitudinal experiments and compared to the dry turning. The measurements during the orthogonal cutting were used to determine the nozzle position that led to the minimum cutting forces. The tool wear was also assessed for the optimal cryogenic case and compared to dry turning. Lastly, the surface roughness parameter Ra was evaluated for the workpiece in longitudinal cryogenic and dry turning.

4.1. Cutting Forces

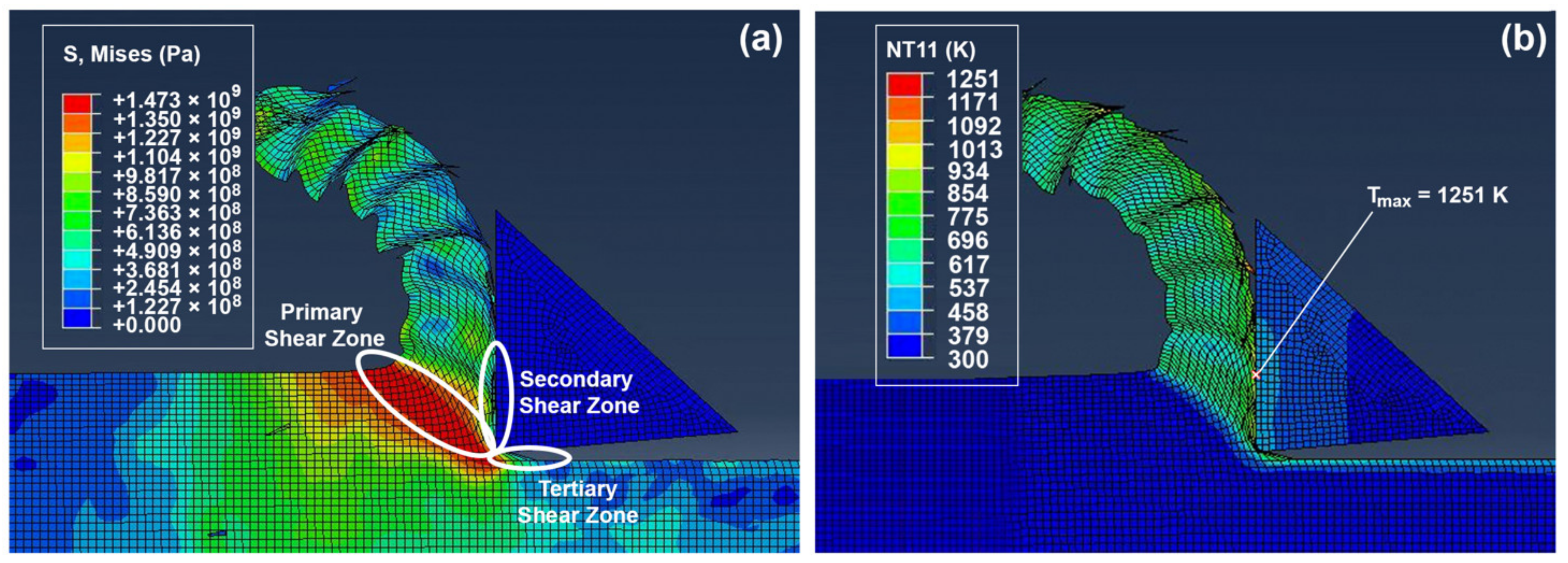

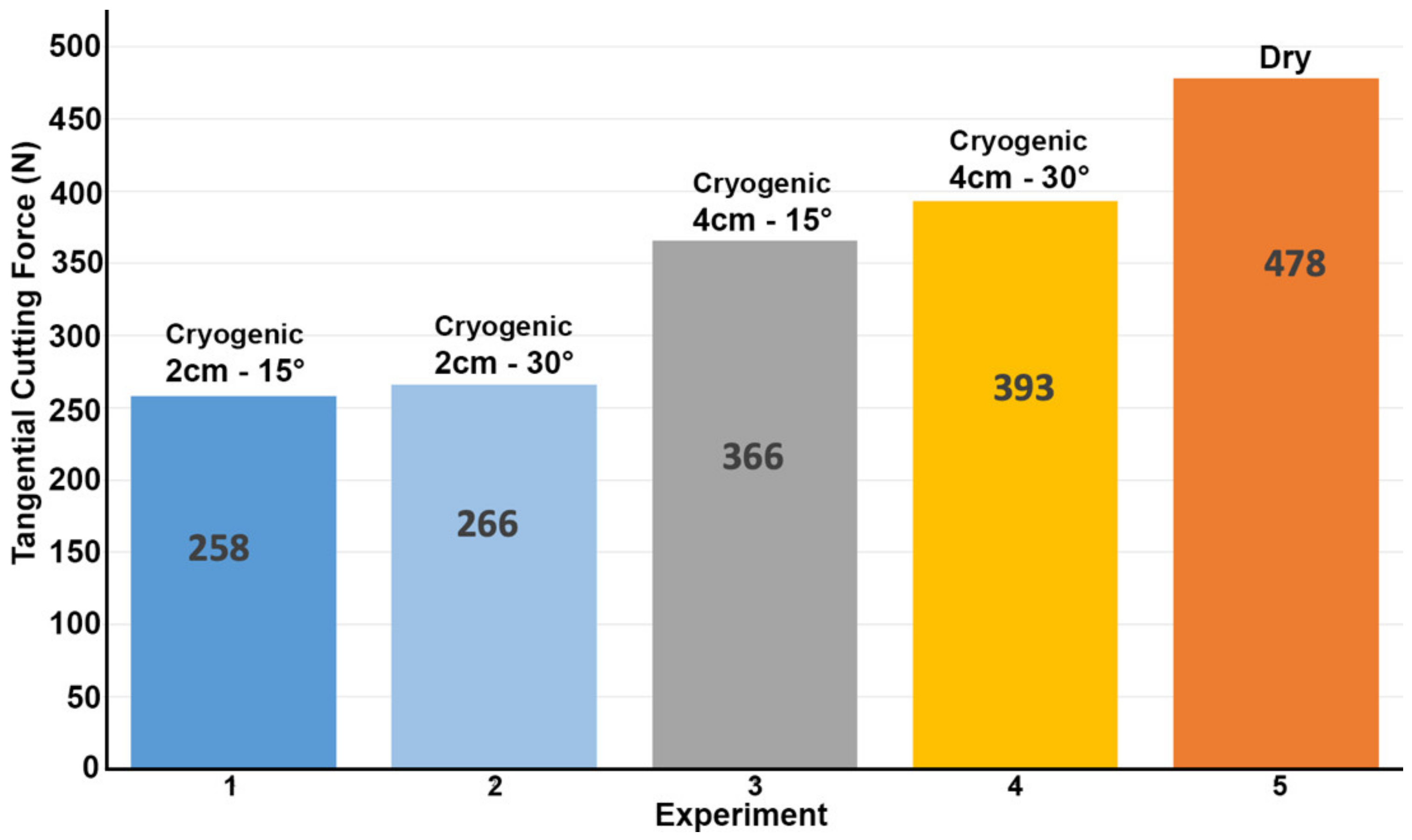

Figure 10 shows the measured tangential cutting forces for each experiment. Comparing the dry cutting measured tangential force and the FEM tangential force, the FEM forces are 2% less than the experimental one, which validates the FEM model.

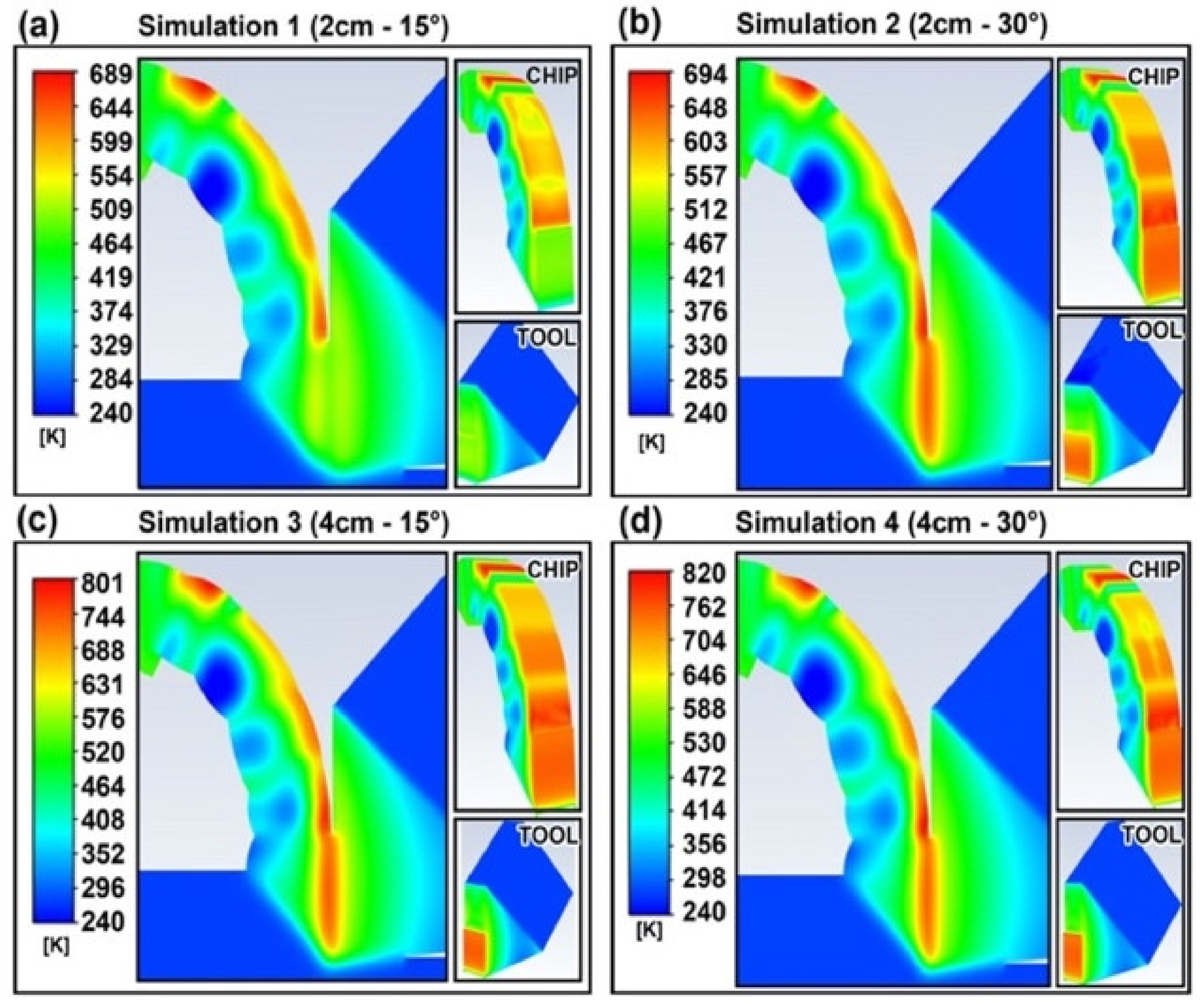

The largest decrease in cutting forces compared to dry turning was measured for experiment 1, where the tangential cutting force was reduced from 478N by 46% to 258N. In the cases of experiments 2, 3 and 4, the percentage reductions in force were 44%, 23% and 18%, respectively. Therefore, the optimal nozzle positions in the experiments and the CFD simulations are in agreement. The nozzle position that resulted in maximum cooling (2 cm/15) in the CFD simulation is the same position that showed the minimum cutting force during orthogonal cutting. In addition, as the cutting temperature decreased, the measured cutting force decreased as well, where TSim1 < TSim2 < TSim3 < TSim4 and FExp1 < FExp2 < FExp3 < FExp4. It is therefore possible to deduce that the cooling effect is in direct correlation with the cutting force.

Compared to dry turning, the cutting forces were reduced for all the experiments with cryogenic application. The drop in cutting forces can be attributed to the cooling effect that the cryogenic fluid has on the cutting insert, which decreases the thermal-induced softening of the insert and helps retain a sharp cutting edge for a longer period of time. Tool wear analysis was conducted in

Section 4.2 and showed that cryogenic application does indeed preserve a sharp cutting edge for a longer time. This cooling effect is also enhanced by the significant difference in thermal conductivities between the workpiece and insert, indicating that the cryogenic fluid can absorb heat faster from the insert than the workpiece, thus cooling the insert at a faster rate and decreasing the thermal softening effect further.

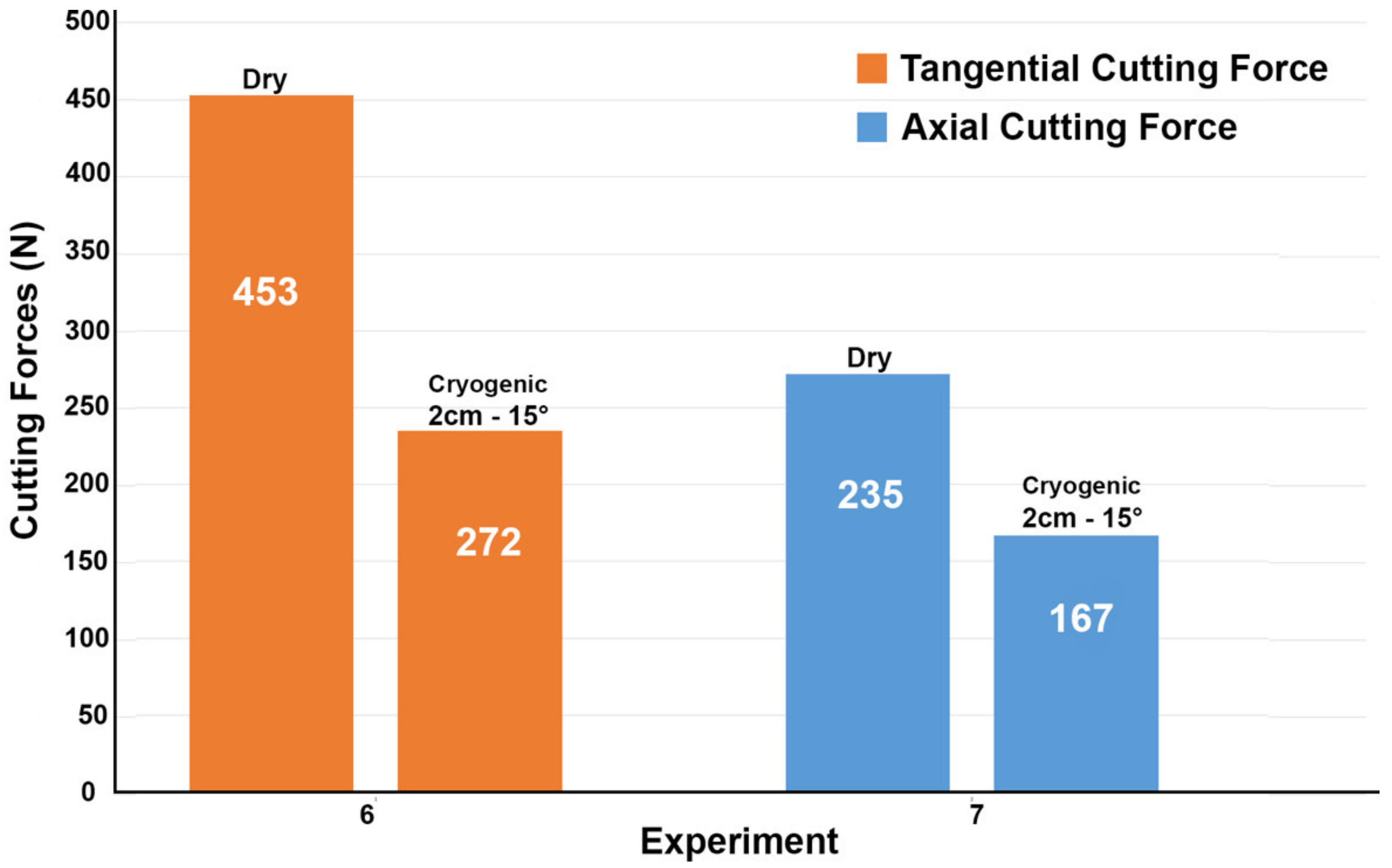

The optimal cryogenic nozzle position was then applied for longitudinal turning and the axial and longitudinal forces were measured and compared to dry longitudinal turning. The results are shown in

Figure 11, where the axial cutting force underwent a 38% drop to 167N and the tangential cutting force a 47% drop to 235N, a similar percentage drop compared to the orthogonal cutting case, confirming the benefits in force reduction found in orthogonal cutting.

4.2. Tool Wear

A qualitative study of the tool wear was completed for the case of dry turning and the optimal cryogenic case, in both the orthogonal cutting (experiments 1 and 5) and longitudinal turning (experiments 6 and 7). The wear was evaluated using optical microscopy, SEM and EDS analysis.

4.2.1. Tool Wear during Orthogonal Turning

When machining titanium alloys with uncoated tungsten carbide tools, adhesion and diffusion are the most dominant wear mechanisms that lead to tool failure [

19]. These wear mechanisms are influenced by the mechanical properties of titanium, which possesses low thermal conductivity, high hardness and high affinity to other elements at increased temperatures. Adhesion of workpiece material onto the tool is a common phenomenon observed during the machining of titanium alloys. Machining titanium produces thin chips, high cutting pressures at the tool–chip interface as well as high cutting temperatures. The low thermal conductivity of Ti-6Al-4V allows for high cutting temperatures, also accelerating the diffusion–dissolution phenomenon which is a thermally activated process and commonly observed during machining of titanium alloys [

5].

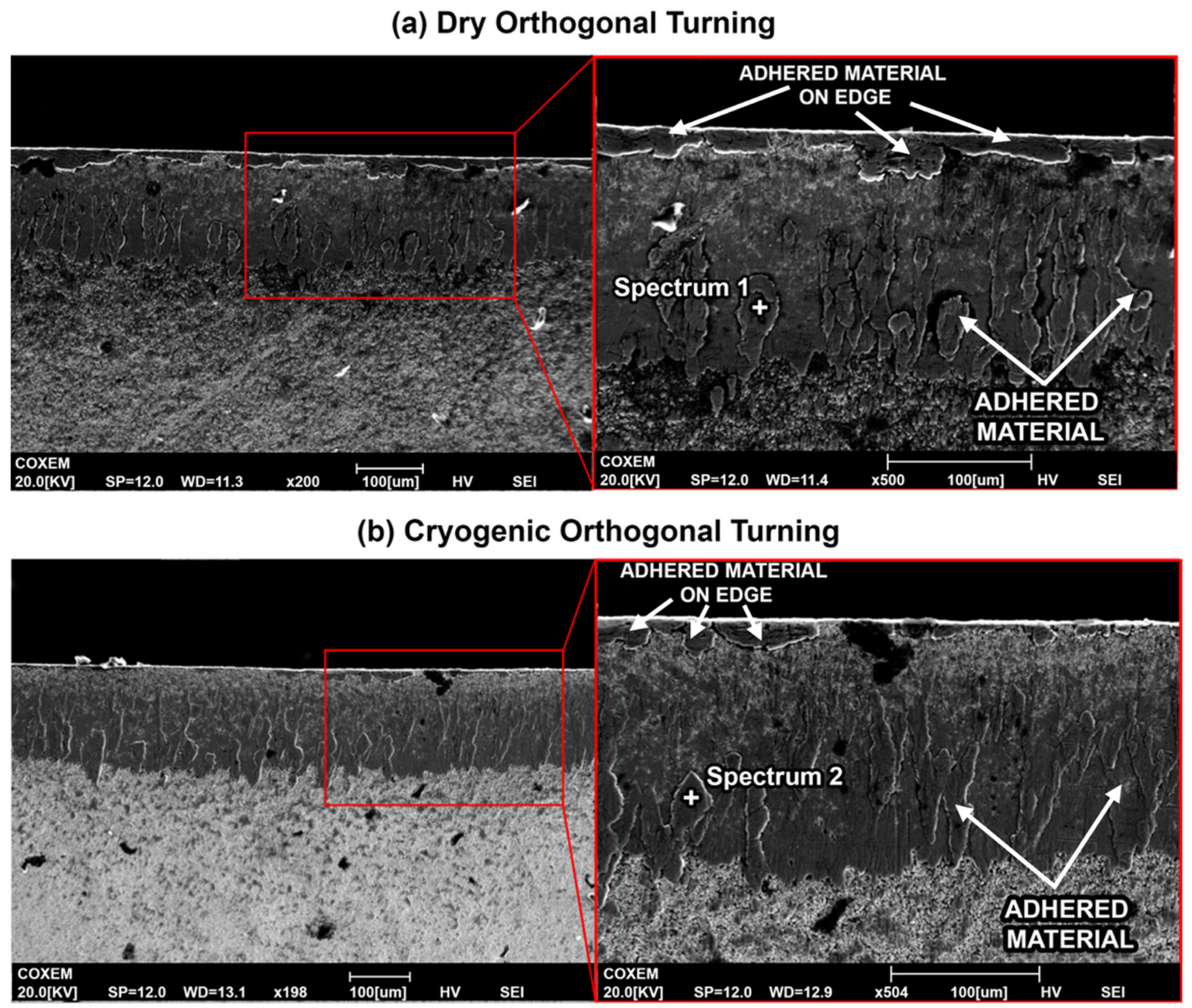

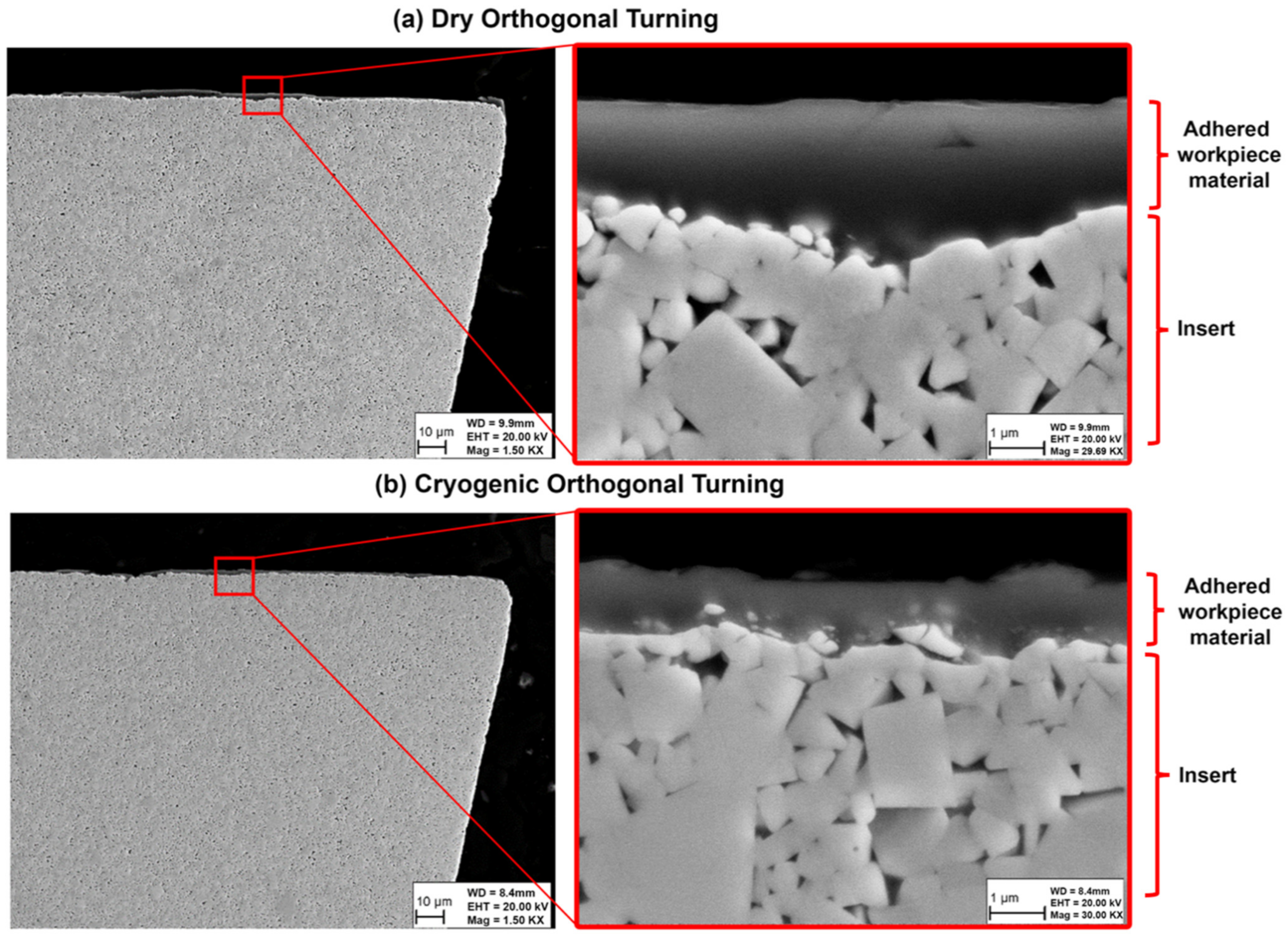

Figure 12 compares the inserts used in machining under dry and cryogenic conditions. It can be observed that more adhered workpiece material is present on the edge of the insert. Previous work when machining a similar workpiece indicated that small microchipping occurs on the edge very early on when machining Ti-6Al-4V [

20,

21]. The rough surface produced after the small chip provides additional anchoring for the workpiece material and promotes adhesion. This explains why more adhered material is present for the dry insert (

Figure 12a), whereas under cryogenic conditions, the edge is preserved for a longer time with reduced microchipping on the edge.

The adhesion of the workpiece material to the tool substrate promotes chemical transfer between the two materials in a process called diffusion. The void created by microchipping, under the effect of high cutting pressure from the flowing chips promotes adherence of workpiece material which are then plastically deformed onto the tool and appear as smearing, as observed in

Figure 12. The process can be repeated for different locations, and results in more signs of adherence on the insert due to the effect of flowing chips [

22]. Adhesion and diffusion work hand in hand to accelerate the wear, where diffusion can deplete the carbon from the tool matrix, making it easier for the flowing chips to pull out the tungsten particles that are no longer anchored [

23,

24].

Figure 12 shows adhesion on the dry cutting insert, where the workpiece material is bonded to the tool rake face. Since diffusion is a wear mechanism that highly depends on the temperature at the cutting zone, the high cutting temperatures in the case of dry turning titanium provide ideal conditions for the exchange of elements between the tool and workpiece.

EDS spectra were taken at the same distance from the cutting edge and the results are summarized in

Table 3, where spectrum 1 shows high concentrations of titanium, aluminum and vanadium on the cutting insert used for dry cutting. This shows the high level of adhesion that is a common characteristic of titanium machining. The insert used for cryogenic turning also shows the workpiece elements, but to a lesser extent than the dry insert. Concentrations of workpiece elements (Ti, Al and V) at spectrum 2 are considerably less, showing higher concentrations of tool elements W and Co instead. The decrease in Ti, Al and V concentrations using the EDS spectra is an indication of reduced adhesion when cryogenic fluid is applied.

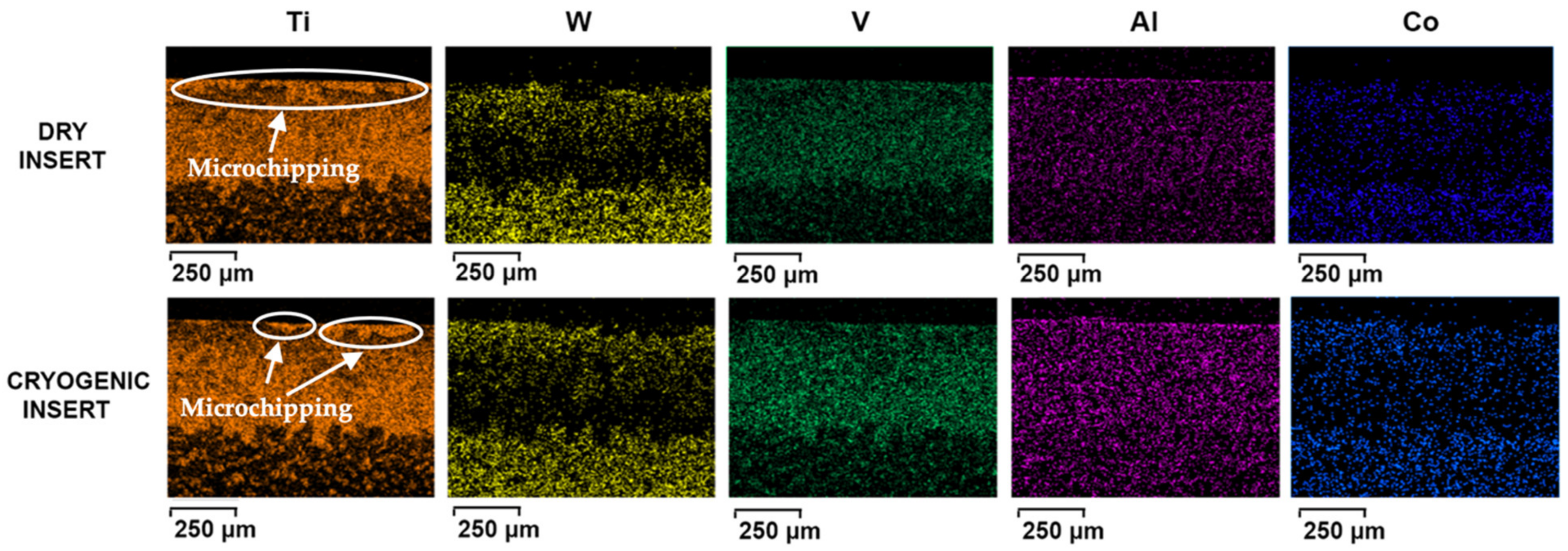

The EDS element maps in

Figure 13 show the high concentration of titanium present on the rake face of the tool, confirming the high amount of adhesion during the machining process. While this benefits the tool by forming a layer to protect the substrate from abrasive wear, it actually promotes wear on the crater side by activating the diffusion mechanism as described previously. Instead of being plastically deformed onto the rake face, an alternative scenario is for the built-up Ti-6Al-4V lumps to break off regularly due to the high pressure and cutting forces exerted on the tool from the rotating workpiece, causing microchipping of the cutting edge. The microchipping can be observed on the cutting edges in both the dry and cryogenic inserts in

Figure 13. Since adhesive wear is decreased in the case of cryogenic machining, then the frequency of microchipping is also reduced, as shown in

Figure 13. This may explain why chipping can be observed along the entire cutting edge in the case of dry cutting but less so in the case of cryogenic turning. The size of the chips along the edge is also larger in the case of the dry cutting and this could be justified by the higher cutting forces in dry cutting as demonstrated previously, which are likely promoting the pulling out of the adhered particles, thus creating larger chipped zones [

21]. This suggests that adhesion, combined with the higher cutting forces, can be the driving force behind the microchipping seen in

Figure 13.

From the SEM images for the cross sections of the cutting inserts, shown in

Figure 14, it is evident that the depth of wear and adhered workpiece material on the rake side of the tool for dry cutting is larger than that for cryogenic turning. Under dry conditions, the worn rake face surface has deeper pits. In both cutting conditions, WC fragments can be observed. Since the cryogenic insert is still in the early stages of the wear process, more fragments can be observed compared to the dry cutting condition.

4.2.2. Tool Wear during Longitudinal Turning

The experiments of longitudinal turning were used to compare the tool wear in dry turning versus the optimal cryogenic case. The tool wear observed using SEM for the cutting inserts used in the longitudinal experiments is shown in

Figure 15. Similar to the case of orthogonal cutting, there is significant adhesion observed, in addition to loss of insert material on the crater face of the tool. The EDS elemental maps show the high levels of adherence of the Ti-6Al-4V workpiece to the tool, while

Table 4 presents the elemental concentrations obtained at spectrum 3, showing the existence of workpiece material and high adhesion under dry cutting conditions.

From the SEM images in

Figure 15, it is evident that the dry turning led to significant volume loss on the crater side compared to reduced loss in the case of cryogenic turning for the same machining parameters and duration. The loss of insert material can be related to brittle-like macro-chipping resulting in the formation of a vertical wall in the crater face surface, as shown in

Figure 15a for the dry cutting insert. In the case of cryogenic turning, the insert also shows signs of cracking; however, the cracks are normal to the surface and to the cutting edge and are less dangerous than the lateral cracks. The lateral cracks can be observed in

Figure 16, which shows the cross section of the cutting inserts for both dry and cryogenic machining. The reason for the observed lateral cracks and loss of cutting edge in the case of dry turning is possibly due to the micro-chipping and adhesion–diffusion mechanisms at work. The higher thermal load in the dry cutting is causing a higher thermal gradient in the insert. The resulting expansion of the insert material may then lead to higher stresses, which can lead to the dangerous lateral cracks that gradually cause the loss of the cutting edge.

The loss of material on the crater face may be aggravated by the synergy between diffusion and adhesion wear mechanisms. According to Saketi et al., when the Ti-6Al-4V adheres to the tool rake face, the tool substrate elements diffuse to the adhered layer, especially carbon, causing the embrittlement of the tool matrix [

23]. The carbon depletion and decrease in binder concentration in the insert makes it easier for the flowing chips to pull out the adhered Ti-6Al-4V layer and with it, pull out weakened tungsten carbide grains leading to considerable material loss in the cutting tool. The carbon-depleted layer can be seen in the SEM image for the rake face of the cryogenic insert in

Figure 16b. Other previous work showed a depleted carbon layer on the surface with high W content and was shown as a lighter shade in the SEM images [

25].

Figure 16b shows a similar pattern. A model by Saketi et al. describes the removal of the brittle depleted region where scattered pieces from the depleted surface are gradually removed by the flow of chips [

24].

Figure 16a shows similar scattered pieces of WC which are observed inside the workpiece material. Comparing

Figure 16a,b indicates that the cryogenic cooling reduces the micro-removal from the tool surface.

The EDS mapping for the dry cutting insert, shown in

Figure 17, shows the adhesion mechanism of Ti-6Al-4V elements on the crater. The substrate material is exposed in the crater, which indicates that the adhered layer was pulled off exposing the tungsten. This wear on the crater face is slowed down/eliminated in the case of cryogenic machining due to the reduction in temperature which considerably slows down both adhesion and diffusion, effectively reducing the main causes that trigger these wear mechanisms. The decrease in worn volume on the crater is shown by difference in the 3D topographic worn volume between the two inserts, as shown in

Figure 18.

On the flank side of the inserts, the dominant type of wear is typically abrasive wear due to the flowing chips and high friction between the workpiece and cutting insert [

4]. During the machining of titanium alloys, adhesion and diffusion act simultaneously in addition to abrasion wear and increase flank wear considerably. The adhesion of titanium on the insert is observed at the flank face of both inserts in the EDS element maps of

Figure 19. The SEM images in

Figure 19 also show that most of the edge is chipped in the case of dry turning, which is not apparent in the case of cryogenic turning. The chipping in the case of dry turning can be caused by the combination of high stresses and adhesion as described previously [

26]. The EDS maps in the case of cryogenic turning show that the bottom of the tungsten distribution is nearly a straight line, whereas the maps for dry turning show an oblique edge, indicating that the cutting edge has been lost in the case of dry turning. The oblique contour is what is left from the edge—below this line, the EDS will not detect signals arriving from a different plane. This may also explain why the EDS maps show a higher concentration of titanium in the case of cryogenic machining. The titanium elements in the dry insert are adhering to the broken cutting edge which is now in a different plane and are no longer being captured by the EDS imaging.

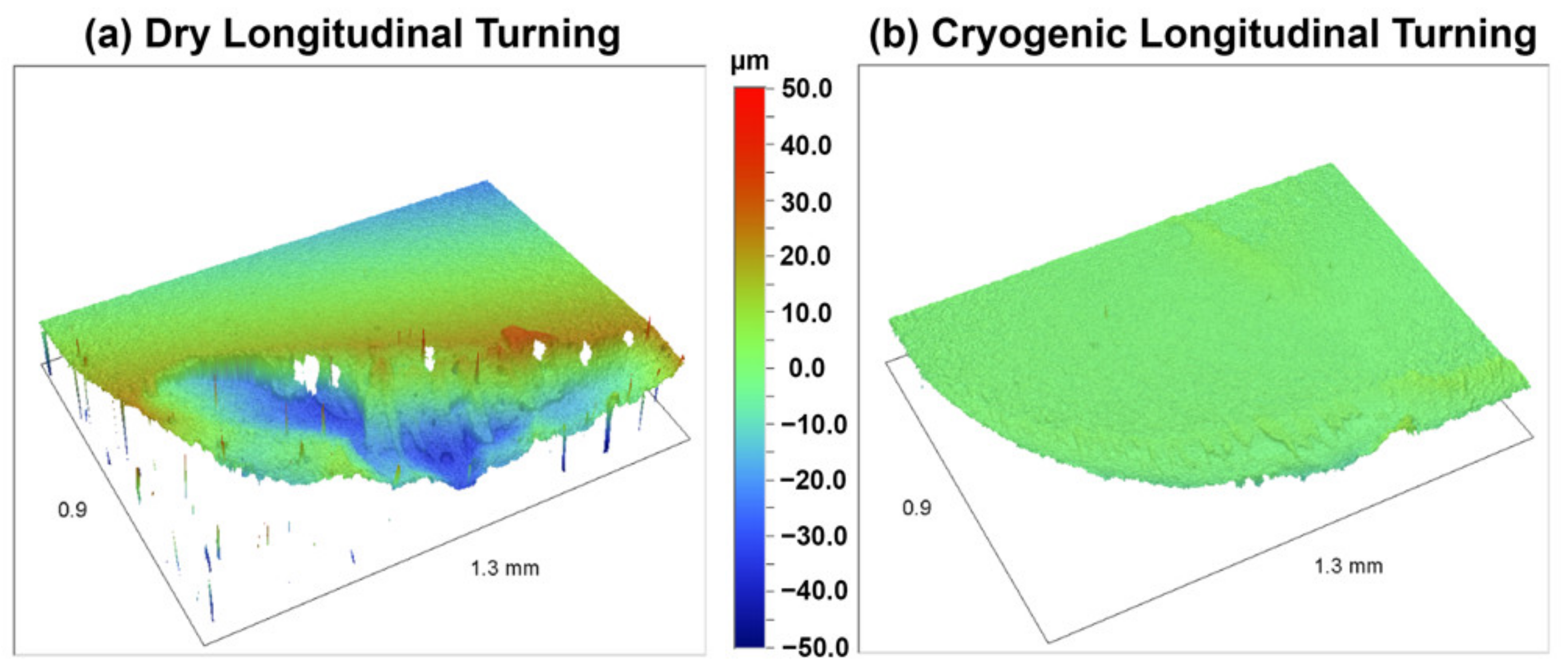

4.3. Surface Roughness of Workpieces

In industrial applications, one of the most important outcomes of a machining process is the quality of the finished workpiece. For this reason, surface integrity is evaluated and includes surface roughness, residual stresses and other parameters. In this research, the focus was on evaluating the average surface roughness parameter Ra of the turned titanium workpiece in both dry and cryogenic environments in order to determine the effect of cryogenic application on the average surface roughness parameter Ra.

The average surface roughness Ra for the cryogenic workpiece was measured to be 0.568 , which was 44% less than that of the dry workpiece, 1.016 . This decrease can be attributed to the lower cutting forces aided by a sharper tool edge in the cryogenic case. This also leads to reduced vibration while cutting and allows for a smoother surface to be formed. The lower surface roughness Ra is also due to the decreased tool wear, which was observed in the case of cryogenic machining. Less tool wear helps to maintain a sharp cutting edge for a longer time and thus yields a better surface finish of the workpiece.

5. Conclusions

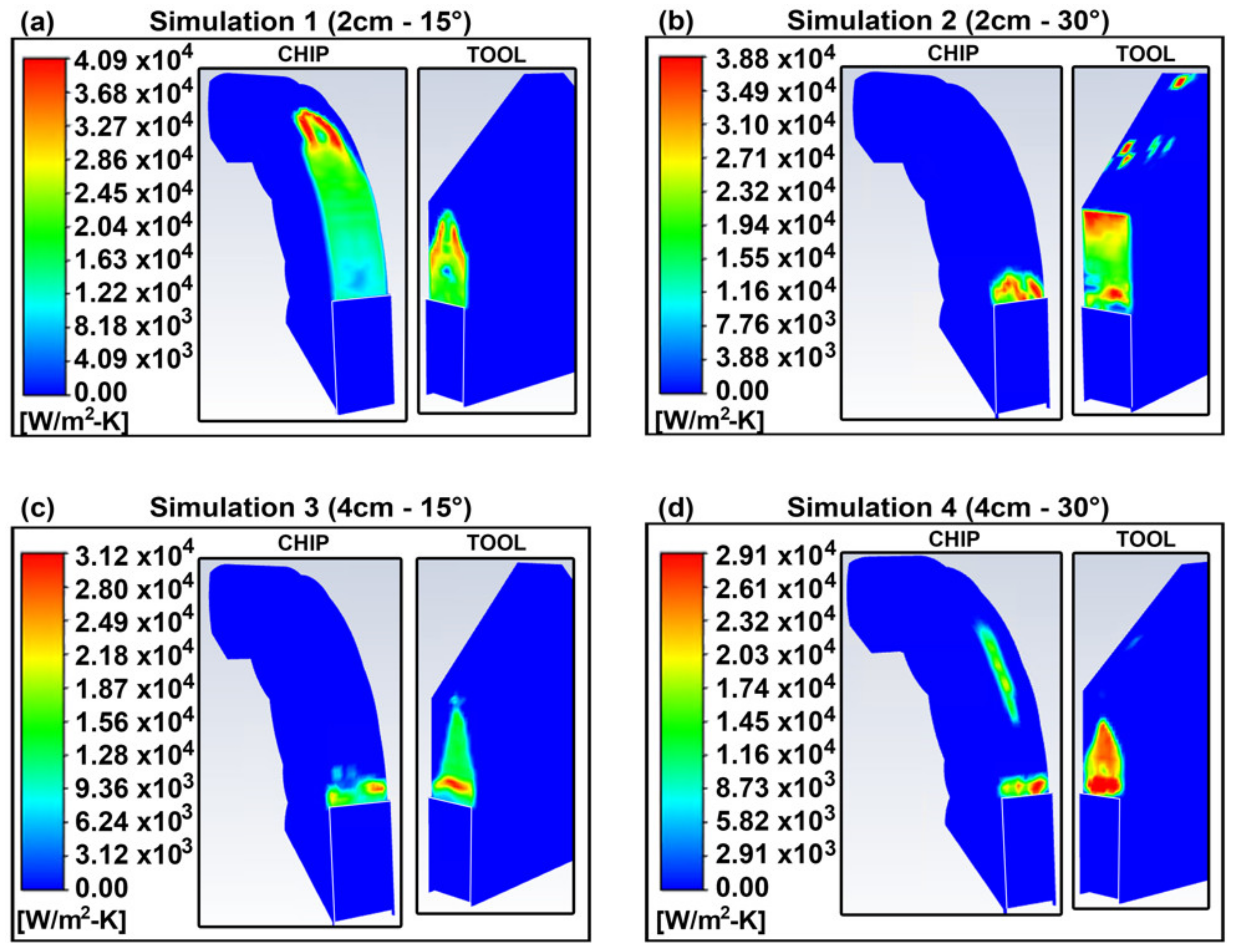

This research studied the effect of varying the nozzle’s position on the cryogenic machining process using FEM, CFD and experimentation. This research provided a better understanding of the cryogenic effect by linking the different thermo-fluid properties of the cryogenic flow to the machining outcomes. The gaps in literature regarding the lack of optimization of the cryogenic delivery system were addressed, where the optimal nozzle position for cooling was determined using FEM, CFD and validated experimentally. The variation in nozzle distance was found to have a more significant effect than the inclination angle on the cooling of the tool–chip interface. It was shown that a smaller separation distance and inclination angle from the rake face led to an enhanced cooling effect, mainly due to the increase in velocity and turbulence near the tool–chip interface. It was also shown that a higher static pressure near the tool–chip interface led to a better cooling effect mainly due to the thin thermal boundary layer found in that region of the flow.

Experimentally, the cutting force measurements showed that the nozzle with the smallest separation distance and orientation angle led to the biggest reduction in cutting forces. The optimal case resulted in a decrease of up to 48% in the case of cryogenic machining compared to dry conditions. This was explained by the decrease in the thermal-induced softening effect which led to a decrease in tool wear and allowed the cutting tool to retain a sharp cutting edge, thus facilitating the cutting of the workpiece. Adhesion and diffusion, which highly depend on the temperature at the cutting zone, were reduced in the case of cryogenic application because of the lower cutting temperatures. Wear on the crater face due to macroscopical chipping was observed in the dry turning case, but less in the cryogenic case and this was justified by the decrease in thermal gradients and diffusion of the binder and carbon material between the adhered layer and the tool, making the insert weaker. Finally, cryogenic application led to a 44% decrease in surface roughness, due to the decrease in cutting forces and tool wear which preserved a sharp cutting edge for a prolonged period of time. Building on this work, future research can further investigate the effects of varying other nozzle parameters such as the angle from the cutting plane in order to further enhance the understanding of the cryogenic effect during machining.