Characteristics of Newly Developed Extruded Products Supplemented with Plants in a Form of Microwave-Expanded Snacks

Abstract

1. Introduction

2. Materials and Methods

2.1. Pellet and Snack Preparation

2.2. Chemical Properties

2.2.1. Solvent Extraction Procedure

2.2.2. Total Phenolic Content (TPC)

2.2.3. Scavenging Activity on 1,1-Diphenyl-2-picrylhydrazyl (DPPH) Radical

2.3. Physical Properties

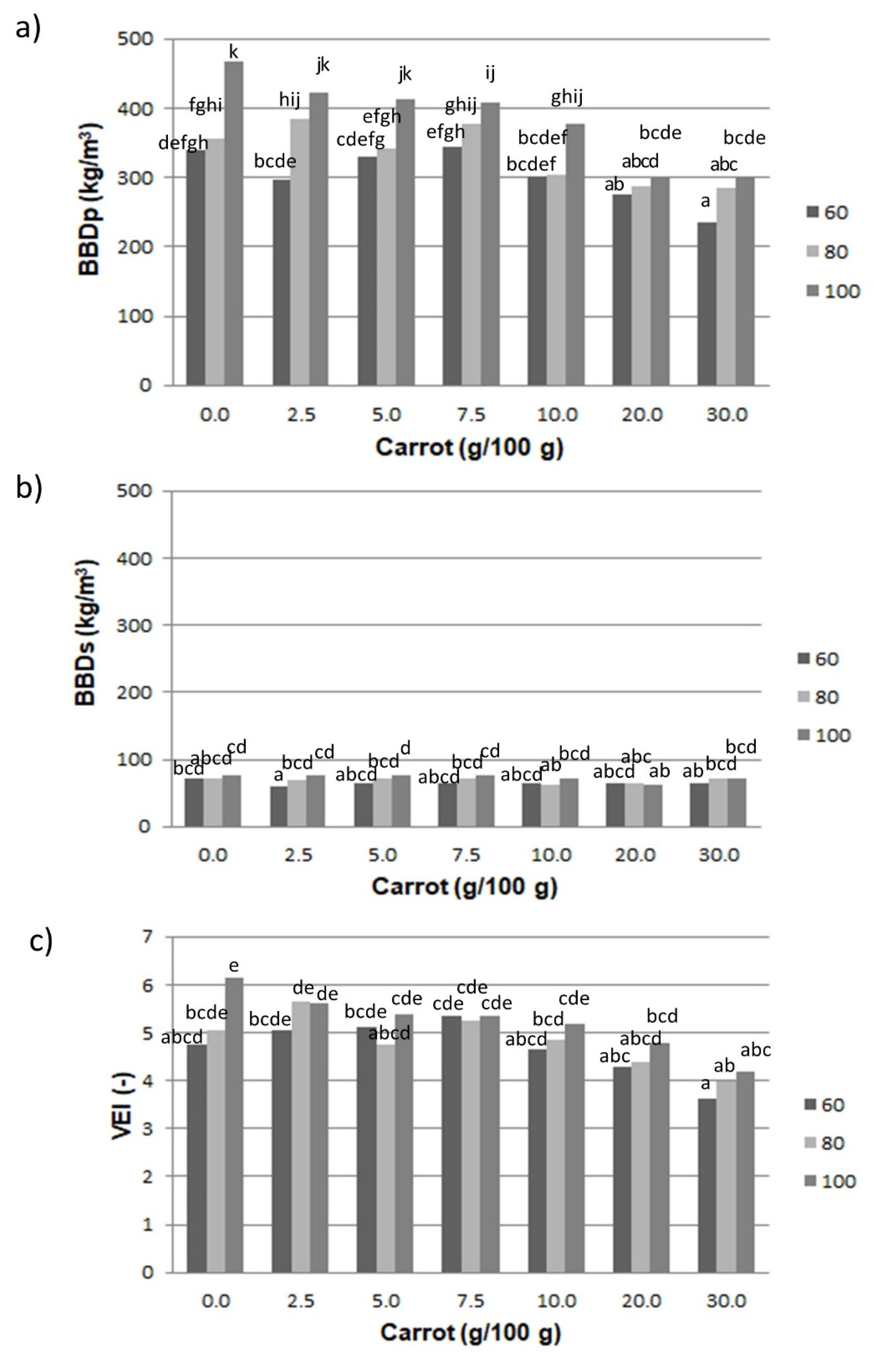

2.3.1. Bulk Density, Volumetric Expansion Index and Structure

2.3.2. Water Absorption Index (WAI) and Water Solubility Index (WSI)

2.3.3. Color Measurements

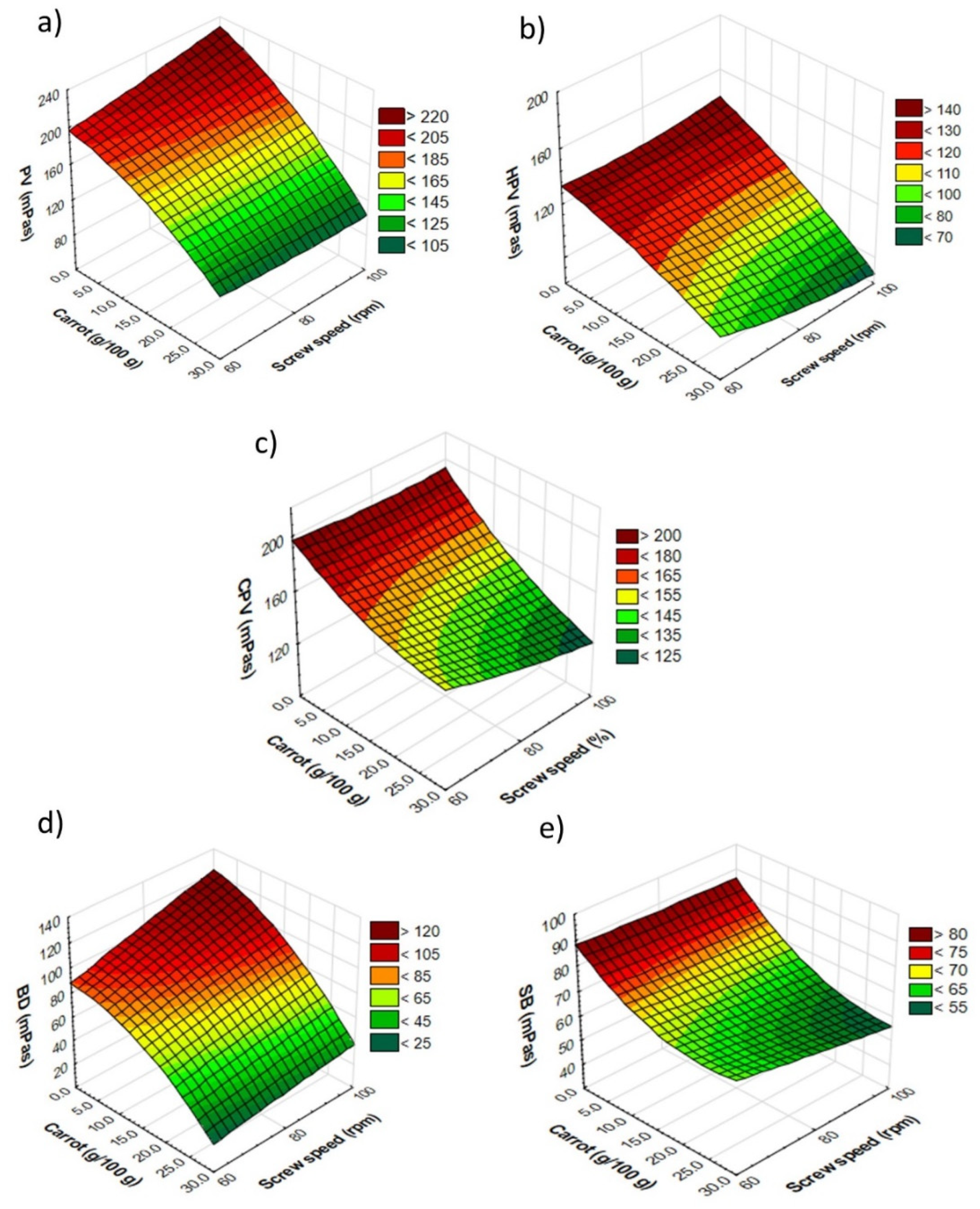

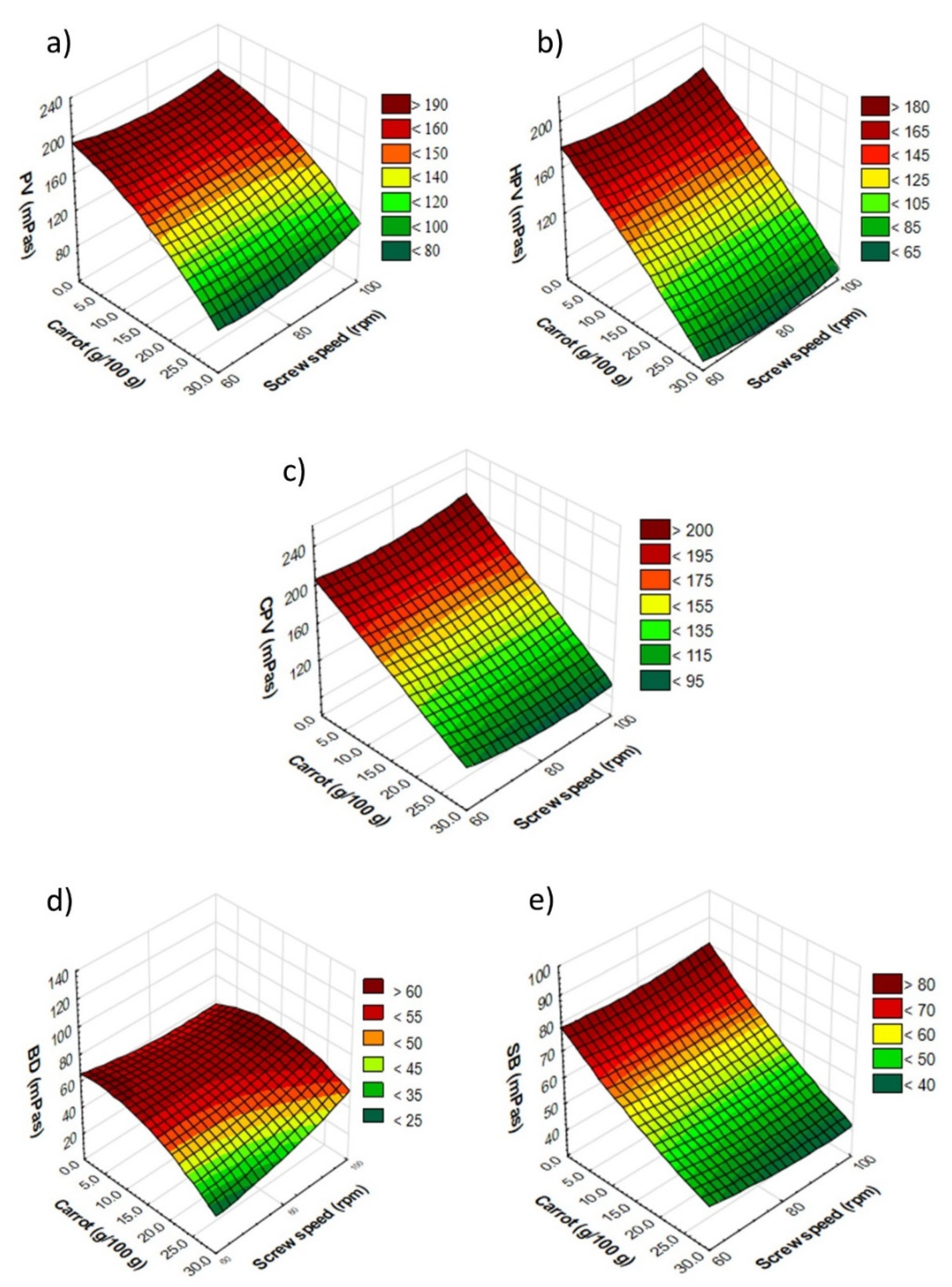

2.4. Pasting Properties

2.5. Texture Measurements

2.6. Statistical Analysis

3. Results and Discussion

3.1. Total Phenolic Content (TPC) and Antioxidant Activity of Snacks

3.2. Physical Properties

3.3. Pasting Characteristics

3.4. Texture of Extrudates and Final RTE Products

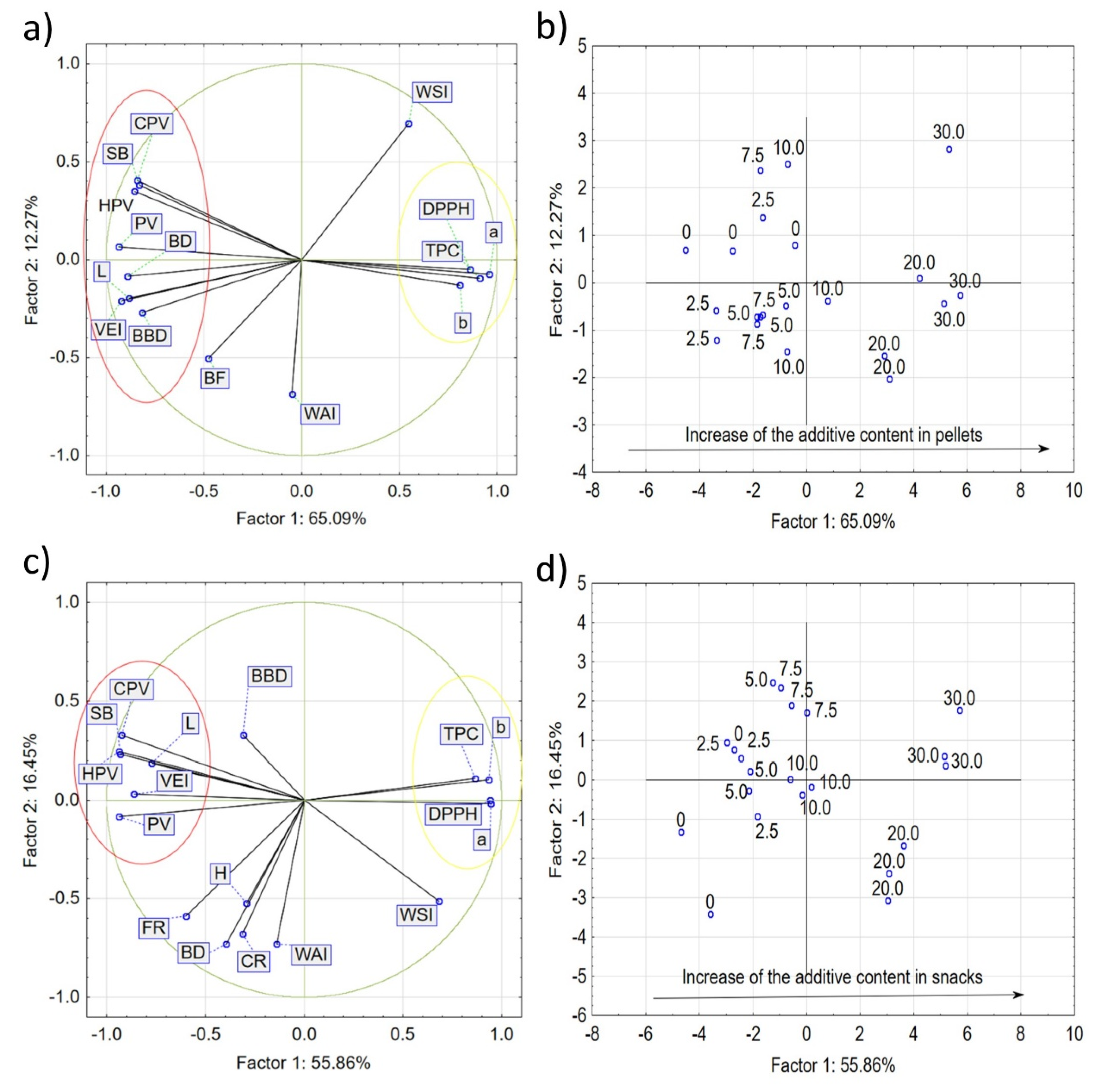

3.5. Principal Component Analysis (PCA)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ozturk, O.K.; Takhar, P.S. Physical and viscoelastic properties of carrots during drying. J. Texture Stud. 2019, 51, 532–541. [Google Scholar] [CrossRef] [PubMed]

- Durazzo, A. Study approach of antioxidant properties: Updated and considerations. Foods 2017, 6, 17. [Google Scholar] [CrossRef] [PubMed]

- Santini, A.; Tenore, G.C.; Novellino, E. Nutraceuticals: A paradigm of proactive medicine. Eur. J. Pharm. Sci. 2017, 1, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.O.; Komarek, A.R. Dietary fibre basics: Health, nutrition, analysis, and applications. Food Qual. Saf. 2017, 1, 47–59. [Google Scholar] [CrossRef]

- Bozalan, N.K.; Karadeniz, F. Carotenoid profile, total phenolic content, and antioxidant activity of carrots. Int. J. Food Prop. 2011, 14, 1060–1068. [Google Scholar] [CrossRef]

- Hedrén, E.; Diaz, V.; Svanberg, U. Estimation of carotenoid accessibility from carrots determined by an in vitro digestion method. Eur. J. Clin. Nutr. 2002, 56, 425–430. [Google Scholar] [CrossRef]

- Klein, C.; Rodriguez-Concepcion, M. Carotenoids in Carrot. In Pigments in Fruits and Vegetables; Chen, C., Ed.; Springer: New York, NY, USA, 2015; pp. 217–228. [Google Scholar]

- Da Silva Dias, J.C. Nutritional and health benefits of carrots and their seed extracts. J. Food Nutr. 2014, 5, 2147–2156. [Google Scholar] [CrossRef]

- Conner, T.S.; Brookie, K.L.; Richardson, A.C.; Polak, M.A. On carrots and curiosity: Eating fruit and vegetables is associated with greater flourishing in daily life. Brit. J. Health Psychol. 2015, 20, 413–427. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Zalewska-Korona, M.; Jabłońska-Ryś, E.; Skalicka-Woźniak, K.; Oniszczuk, A. Chemical characteristics and physical properties of functional snacks enriched with powdered tomato. Polish J. Food Nutr. Sci. 2018, 68, 251–261. [Google Scholar] [CrossRef]

- Luo, S.; Chan, E.; Masatcioglu, M.T.; Erkinbaev, C.; Paliwal, J.; Koksel, F. Effects of extrusion conditions and nitrogen injection on physical, mechanical, and microstructural properties of red lentil puffed snacks. Food Bioprod. Process. 2020, 121, 143–153. [Google Scholar] [CrossRef]

- Krau, S.; Schuchmann, H.P.; Gaukel, V. Factors influencing the microwave-induced expansion of starch-based extruded pellets under vacuum. J. Food Process Eng. 2014, 37, 264–272. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A. Possibility to save water and energy by application of fresh vegetables to produce supplemented potato-based snack pellets. Processes 2020, 8, 153. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A.; Bouasla, A.; Kasprzak, K. Design of new gluten-free extruded rice snack products supplemented with fresh vegetable pulps: The effect on processing and functional properties. Int. Agrophys. 2021, 35, 41–60. [Google Scholar] [CrossRef]

- Singleton, V.; Orthofer, R.; Lamuela-Raventós, R.M. Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Method. Enzymol. 1999, 299C, 152–178. [Google Scholar]

- Lisiecka, K.; Wójtowicz, A.; Dziki, D.; Gawlik-Dziki, U. The influence of Cistus incanus L. leaves on wheat pasta quality. J. Food Sci. Technol. 2019, 56, 4311–4322. [Google Scholar] [CrossRef] [PubMed]

- Oniszczuk, A.; Olech, M.; Oniszczuk, T.; Wojtunik-Kulesza, K.; Wójtowicz, A. Extraction methods, LC-ESI-MS/MS analysis of phenolic compounds and antiradical properties of functional food enriched with elderberry flowers or fruits. Arab. J. Chem. 2016, 12, 4719–4730. [Google Scholar] [CrossRef]

- Blois, M.S. Antioxidant determinations by the use of a stable free radical. Nature 1958, 181, 1199–1200. [Google Scholar] [CrossRef]

- Lisiecka, K.; Wójtowicz, A. The influence of fresh kale addition on selected properties of corn snacks. Int. J. Food Eng. 2019, 15, 20180319. [Google Scholar] [CrossRef]

- Jozinović, A.; Ačkar, D.; Jokić, S.; Babić, J.; Balentić, J.P.; Banožić, M.; Šubarić, D. Optimisation of extrusion variables for the production of corn snack products enriched with defatted hemp cake. Czech J. Food Sci. 2017, 35, 507–516. [Google Scholar]

- Mitrus, M.; Wójtowicz, A.; Kocira, S.; Kasprzycka, A.; Szparaga, A.; Oniszczuk, T.; Combrzyński, M.; Kupryaniuk, K.; Matwijczuk, A. Effect of extrusion-cooking conditions on the pasting properties of extruded white and red bean seeds. Int. Agrophys. 2020, 34, 25–32. [Google Scholar] [CrossRef]

- Shah, F.U.H.; Sharif, M.K.; Butt, M.S.; Shahid, M. Development of protein, dietary fiber, and micronutrient enriched extruded corn snacks. J. Texture Stud. 2017, 48, 221–230. [Google Scholar] [CrossRef]

- Hayat, K.; Zhang, X.; Chen, H.; Xia, S.; Jia, C.; Zhong, F. Liberation and separation of phenolic compounds from citrus mandarin peels by microwave heating and its effect on antioxidant activity. Sep. Purif. Technol. 2010, 73, 371–376. [Google Scholar] [CrossRef]

- Wataniyakul, P.; Pavasant, P.; Goto, M.; Shotipruk, A. Microwave pretreatment of defatted rice bran for enhanced recovery of total phenolic compounds extracted by subcritical water. Bioresour. Technol. 2012, 124, 18–22. [Google Scholar] [CrossRef] [PubMed]

- Parcheta, M.; Świsłocka, R.; Orzechowska, S.; Akimowicz, M.; Choińska, R.; Lewandowski, W. Recent developments in effective antioxidants: The structure and antioxidant properties. Materials 2021, 14, 1984. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Armenta, X.A.; Zazueta-Morales, J.D.J.; Delgado-Nieblas, C.I.; Carrillo-López, A.; Aguilar-Palazuelos, E.; Camacho-Hernández, I.L. Effect of the extrusion process and expansion by microwave heating on physicochemical, phytochemical, and antioxidant properties during the production of indirectly expanded snack foods. J. Food Process. Preserv. 2019, 43, e14261. [Google Scholar] [CrossRef]

- Sun, Y.; Muthukumarappan, K. Changes in functionality of soy-based extrudates during single-screw extrusion processing. Int. J. Food Prop. 2002, 5, 379–389. [Google Scholar] [CrossRef]

- Pardhi, S.D.; Singh, B.; Nayik, G.A.; Dar, B.N. Evaluation of functional properties of extruded snacks developed from brown rice grits by using response surface methodology. J. Saudi Soc. Agric. Sci. 2019, 18, 7–16. [Google Scholar] [CrossRef]

- Oikonomou, N.A.; Krokida, M.K. Literature data compilation of WAI and WSI of extrudate food products. Int. J. Food Prop. 2011, 14, 199–240. [Google Scholar] [CrossRef]

- Da Silva, M.C.; De Carvalho, C.W.P.; Andrade, C.T. The effects of water and sucrose contents on the physicochemical properties of non-directly expanded rice flour extrudates. Ciênc. Tecnol. Aliment. 2009, 29, 661–666. [Google Scholar] [CrossRef]

- Emran, S.; Nawade, B.; Yahyaa, M.; Jackline, A.N.; Dorothea, T.; Eizenberg, H.; Mwafaq, I. Broomrape infestation in carrot (Daucus carota): Changes in carotenoid gene expression and carotenoid accumulation in the parasitic weed Phelipanche aegyptiaca and its host. Sci. Rep. 2020, 10, 1–10. [Google Scholar] [CrossRef]

- Sawant, A.A.; Thakor, N.J.; Swami, S.B.; Divate, A.D. Physical and sensory characteristics of Ready-to-Eat food prepared from finger millet based composite mixer by extrusion. E-J. CIGR 2013, 15, 100–105. [Google Scholar]

- Adepehin, J.O. Microbial diversity and pasting properties of finger millet (Eleusine coracana), pearl millet (Pennisetum glaucum) and sorghum (Sorghum bicolor) sourdoughs. Food Biosci. 2020, 37, 100684. [Google Scholar] [CrossRef]

- Lopes, L.C.M.; Batista, K.A.; Fernandes, K.F.; Santiago, R.A.C. Functional, biochemical and pasting properties of extruded bean (Phaseolus vulgaris L.) cotyledons. Int. J. Food Sci. Technol. 2012, 47, 1859–1865. [Google Scholar] [CrossRef]

- Valdez-Arana, J.C.; Steffolani, M.E.; Repo-Carrasco-Valencia, R.; Pérez, G.T.; Condezo-Hoyos, L. Physicochemical and functional properties of isolated starch and their correlation with flour from the Andean Peruvian quinoa varieties. Int. J. Biol. Macromol. 2020, 147, 997–1007. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Kolasa, A.; Mościcki, L. Influence of buckwheat addition on physical properties, texture and sensory characteristics of extruded corn snacks. Polish J. Food Nutr. Sci. 2013, 63, 239–244. [Google Scholar] [CrossRef]

- Karkle, E.; Alavi, S.; Dogan, H. Cellular architecture and its relationship with mechanical properties in expanded extrudates containing apple pomace. Food Res. Int. 2012, 46, 10–21. [Google Scholar] [CrossRef]

| Amount of Carrot (g/100 g) | Screw Speed (rpm) | TPC 1 (mg GAE/100 g) | DPPH 2 (%) | ||

|---|---|---|---|---|---|

| P | S | P | S | ||

| 0 | 60 | 58.88 ± 1.07 a | 127.52 ± 3.62 ab | 6.89 ± 0.56 a | 19.78 ± 0.34 a |

| 80 | 61.65 ± 1.71 abc | 127.09 ± 3.20 ab | 6.61 ± 0.70 a | 19.74 ± 1.39 a | |

| 100 | 59.73 ± 0.64 ab | 124.54 ± 0.64 a | 6.65 ± 0.74 a | 19.50 ± 0.26 a | |

| 2.5 | 60 | 61.86 ± 1.49 abcd | 128.37 ± 2.77 ab | 8.79 ± 0.91 ab | 23.31 ± 0.20 ab |

| 80 | 62.72 ± 0.64 abcd | 129.23 ± 2.77 ab | 9.70 ± 0.70 ab | 25.29 ± 1.65 ab | |

| 100 | 64.21 ± 2.13 abcd | 130.29 ± 2.56 ab | 8.02 ± 0.28 ab | 24.88 ± 1.09 ab | |

| 5.0 | 60 | 66.55 ± 0.21 abcdef | 130.72 ± 2.13 abc | 8.42 ± 0.72 ab | 23.72 ± 1.16 ab |

| 80 | 66.34 ± 2.13 abcde | 133.28 ± 2.55 abc | 6.82 ± 0.35 a | 24.30 ± 0.58 ab | |

| 100 | 67.19 ± 1.28 bcdef | 134.56 ± 2.13 abc | 7.14 ± 0.32 a | 24.01 ± 0.29 ab | |

| 7.5 | 60 | 69.54 ± 0.64 def | 136.05 ± 4.05 abc | 6.75 ± 0.56 a | 29.73 ± 0.89 bc |

| 80 | 68.05 ± 0.85 cdef | 134.13 ± 2.56 abc | 6.47 ± 0.98 a | 30.17 ± 0.44 bcd | |

| 100 | 68.68 ± 0.21 cdef | 134.98 ± 2.13 abc | 7.63 ± 0.25 a | 30.06 ± 0.11 bcd | |

| 10.0 | 60 | 74.23 ± 1.49 fgh | 133.92 ± 3.62 abc | 7.17 ± 0.56 a | 37.44 ± 0.82 ef |

| 80 | 74.01 ± 0.85 efgh | 134.56 ± 2.12 abc | 7.67 ± 0.07 a | 36.83 ± 0.48 cde | |

| 100 | 72.95 ± 0.64 efg | 141.38 ± 1.71 abc | 7.07 ± 0.60 a | 36.95 ± 0.12 de | |

| 20.0 | 60 | 78.92 ± 1.92 gh | 141.80 ± 3.84 abc | 11.32 ± 0.77 b | 43.52 ± 2.12 efg |

| 80 | 79.34 ± 1.49 gh | 142.23 ± 2.98 bc | 19.67 ± 0.97 cd | 37.07 ± 0.24 de | |

| 100 | 80.41 ± 1.71 ghi | 140.31 ± 2.77 abc | 17.18 ± 0.67 c | 39.15 ± 2.20 ef | |

| 30.0 | 60 | 81.48 ± 2.34 hij | 147.56 ± 1.92 cd | 22.90 ± 0.53 d | 49.48 ± 2.71 g |

| 80 | 88.08 ± 0.43 ij | 160.56 ± 3.84 de | 20.17 ± 0.73 cd | 44.34 ± 1.02 fg | |

| 100 | 88.72 ± 1.07 j | 171.01 ± 4.05 e | 20.54 ± 0.37 dc | 47.27 ± 2.20 g | |

| Amount of Carrot (g/100 g) | Screw Speed (rpm) | WAI 1 (g/g) | WSI 1 (%) | ||

|---|---|---|---|---|---|

| P | S | P | S | ||

| 0 | 60 | 4.53 ± 0.05 cdefgh | 4.82 ± 0.26 abc | 3.56 ± 0.01 abcdef | 4.32 ± 0.69 abcd |

| 80 | 4.37 ± 0.06 cdef | 5.49 ± 0.14 cd | 2.76 ± 0.28 abcdef | 6.73 ± 0.35 defg | |

| 100 | 3.85 ± 0.04 ab | 5.00 ± 0.28 abcd | 2.78 ± 0.18 abcdef | 3.94 ± 0.32 abcd | |

| 2.5 | 60 | 4.51 ± 0.10 cdefgh | 4.85 ± 0.29 abcd | 4.56 ± 0.24 fg | 5.54 ± 1.31 bcde |

| 80 | 4.65 ± 0.02 defgh | 4.54 ± 0.16 a | 1.77 ± 0.34 ab | 3.27 ± 0.50 ab | |

| 100 | 4.29 ± 0.01 cde | 4.69 ± 0.23 ab | 1.99 ± 0.69 abc | 3.71 ± 0.23 abc | |

| 5.0 | 60 | 4.76 ± 0.03 fgh | 4.72 ± 0.09 ab | 1.42 ± 0.35 a | 4.79 ± 0.06 abcd |

| 80 | 4.90 ± 0.03 h | 4.53 ± 0.02 a | 1.91 ± 0.40 abc | 2.34 ± 0.05 a | |

| 100 | 4.67 ± 0.03 efgh | 5.43 ± 0.37 bcd | 1.85 ± 0.25 abc | 4.11 ± 0.10 abcd | |

| 7.5 | 60 | 3.71 ± 0.10 a | 4.49 ± 0.02 a | 3.76 ± 0.52 cdefg | 3.92 ± 1.23 abcd |

| 80 | 4.76 ± 0.33 fgh | 4.78 ± 0.21 abc | 2.83 ± 0.22 abcdef | 5.15 ± 0.90 abcde | |

| 100 | 4.66 ± 0.03 efgh | 4.98 ± 0.11 abcd | 2.55 ± 0.24 abcdef | 4.99 ± 0.20 abcd | |

| 10.0 | 60 | 3.87 ± 0.06 ab | 4.70 ± 0.30 ab | 3.92 ± 1.10 cdefg | 5.97 ± 0.10 bcde |

| 80 | 4.81 ± 0.01 gh | 4.79 ± 0.17 abc | 2.21 ± 0.06 abcd | 4.00 ± 0.82 abcd | |

| 100 | 4.85 ± 0.10 gh | 4.60 ± 0.04 a | 2.68 ± 0.34 abcdef | 4.10 ± 0.70 abcd | |

| 20.0 | 60 | 4.25 ± 0.08 bcd | 5.05 ± 0.04 abcd | 4.10 ± 0.46 defg | 6.19 ± 0.19 cdef |

| 80 | 4.34 ± 0.24 cde | 5.05 ± 0.14 abcd | 2.41 ± 0.69 abcde | 8.83 ± 0.24 fgh | |

| 100 | 4.55 ± 0.12 cdefgh | 5.61 ± 0.29 d | 2.70 ± 0.58 abcdef | 10.48 ± 1.57 h | |

| 30.0 | 60 | 4.15 ± 0.05 bc | 4.45 ± 0.27 a | 5.69 ± 0.91 g | 7.85 ± 1.29 efgh |

| 80 | 4.44 ± 0.14 cdefg | 4.70 ± 0.05 ab | 3.46 ± 1.27 abcdef | 9.28 ± 0.10 gf | |

| 100 | 4.32 ± 0.09 cde | 4.53 ± 0.15 a | 4.48 ± 0.27 efg | 5.34 ± 0.86 bcde | |

| Amount of Carrot (g/100 g) | Screw Speed (rpm) | L*1 | a* 1 | b* 1 | ΔE | ||||

|---|---|---|---|---|---|---|---|---|---|

| P | S | P | S | P | S | P | S | ||

| 0 | 60 | 78.21 ± 1.09 defg | 84.03 ± 0.63 cdefg | 5.74 ± 0.29 abc | 8.43 ± 0.25 a | 26.51 ± 0.58 cd | 22.30 ± 0.41 ab | ref | ref |

| 80 | 81.98 ± 1.78 ghijk | 85.50 ± 1.95 fg | 5.49 ± 0.25 abc | 8.17 ± 0.20 a | 24.40 ± 0.52 abc | 21.52 ± 0.50 a | ref | ref | |

| 100 | 85.06 ± 2.52 k | 86.03 ± 1.00 fg | 5.07 ± 0.38 ab | 8.36 ± 0.10 a | 22.22 ± 0.76 a | 21.95 ± 0.19 ab | ref | ref | |

| 2.5 | 60 | 81.67 ± 0.75 ghijk | 85.93 ± 1.45 fg | 5.64 ± 0.18 abc | 8.44 ± 0.11 a | 25.79 ± 0.60 bcd | 22.93 ± 0.35 bc | 0.36 | 2.01 |

| 80 | 84.33 ± 1.25 jk | 85.13 ± 1.16 efg | 4.81 ± 0.18 a | 8.62 ± 0.19 ab | 23.61 ± 0.41 ab | 22.90 ± 0.31 bc | 0.54 | 1.50 | |

| 100 | 80.81 ± 1.37 fghij | 86.84 ± 1.34 g | 6.20 ± 0.43 bcd | 8.72 ± 0.25 ab | 26.27 ± 0.93 bcd | 23.12 ± 0.68 bcd | 1.17 | 1.46 | |

| 5.0 | 60 | 80.31 ± 0.53 efghi | 84.81 ± 0.89 defg | 6.54 ± 0.17 cd | 9.10 ± 0.21 bc | 27.28 ± 1.02 d | 23.79 ± 0.42 cde | 0.72 | 1.81 |

| 80 | 77.27 ± 0.54 cdef | 84.44 ± 1.71 defg | 8.47 ± 0.18 ef | 9.51 ± 0.25 cde | 33.04 ± 1.38 fgh | 24.45 ± 0.39 ef | 1.52 | 3.39 | |

| 100 | 78.80 ± 0.51 defg | 85.67 ± 0.73 fg | 8.11 ± 0.25 ef | 9.37 ± 0.21 cd | 30.64 ± 0.29 ef | 24.24 ± 0.34 de | 2.06 | 2.52 | |

| 7.5 | 60 | 80.23 ± 1.36 efghi | 85.09 ± 0.32 efg | 7.42 ± 0.32 de | 9.16 ± 0.09 bc | 26.28 ± 0.80 bcd | 24.20 ± 0.16 de | 0.35 | 2.30 |

| 80 | 83.06 ± 0.75 ijk | 83.98 ± 1.38 bcdef | 7.29 ± 0.35 de | 10.53 ± 0.19 fg | 27.90 ± 1.00 de | 26.11 ± 0.49 gh | 1.14 | 5.75 | |

| 100 | 82.74 ± 2.77 hijk | 82.97 ± 0.84 bcdef | 7.43 ± 0.55 de | 9.42 ± 0.19 cd | 27.48 ± 0.80 d | 23.82 ± 0.51 cde | 0.30 | 3.74 | |

| 10.0 | 60 | 77.57 ± 0.36 cdef | 82.16 ± 0.76 abcde | 8.88 ± 0.16 fg | 9.84 ± 0.07 de | 31.35 ± 0.84 fg | 24.09 ± 0.10 cde | 0.78 | 2.94 |

| 80 | 76.13 ± 0.97 cd | 83.64 ± 1.11 cdef | 10.04 ± 0.62 g | 10.02 ± 0.19 ef | 31.27 ± 0.74 fg | 24.88 ± 0.43 efg | 0.92 | 4.26 | |

| 100 | 81.00 ± 1.40 fghij | 81.72 ± 0.96 abcd | 8.21 ± 0.70 ef | 9.93 ± 0.29 de | 25.79 ± 2.57 bcd | 23.88 ± 0.58 cde | 2.16 | 4.97 | |

| 20.0 | 60 | 76.59 ± 1.96 cde | 79.41 ± 0.52 a | 12.43 ± 1.30 hi | 10.99 ± 0.26 gh | 33.43 ± 1.77 fg | 25.64 ± 0.67 fg | 1.79 | 6.25 |

| 80 | 78.89 ± 0.56 defgh | 79.98 ± 1.37 ab | 11.74 ± 0.53 h | 11.05 ± 0.14 ghi | 31.97 ± 0.70 fgh | 26.14 ± 0.39 gh | 1.27 | 7.76 | |

| 100 | 76.85 ± 1.64 cde | 82.08 ± 0.68 abcde | 12.58 ± 0.46 hi | 11.45 ± 0.13 hij | 32.93 ± 0.74 fgh | 27.18 ± 0.42 hi | 0.88 | 7.24 | |

| 30.0 | 60 | 70.46 ± 2.25 ab | 82.08 ± 1.09 abcde | 13.39 ± 0.76 ij | 11.75 ± 0.43 j | 30.75 ± 1.20 fg | 27.48 ± 1.15 i | 1.40 | 6.45 |

| 80 | 69.23 ± 1.29 a | 83.45 ± 1.82 cdef | 16.09 ± 0.39 g | 10.88 ± 0.04 gh | 34.26 ± 0.71 h | 26.93 ± 0.22 hi | 0.55 | 6.39 | |

| 100 | 73.95 ± 2.33 bc | 81.06 ± 1.97 abc | 14.62 ± 0.69 j | 11.59 ± 0.45 ij | 32.42 ± 1.52 fgh | 27.29 ± 0.52 hi | 0.85 | 7.97 | |

| Amount of Carrot (g/100 g) | Screw Speed (rpm) | CF of Pellets 1 (N) | Texture of Expanded Snacks | ||

|---|---|---|---|---|---|

| H 2 (N) | CR 2 (N) | FR 2 (N) | |||

| 0 | 60 | 43.70 ± 7.57 bcd | 170.40 ± 15.96 abc | 10.47 ± 1.50 a | 26.07 ± 4.96 ab |

| 80 | 55.22 ± 7.72 de | 158.00 ± 14.06 abc | 34.97 ± 5.62 b | 37.58 ± 6.76 b | |

| 100 | 66.38 ± 7.96 efg | 195.40 ± 19.17 c | 29.52 ± 5.45 ab | 36.30 ± 6.12 b | |

| 2.5 | 60 | 75.64 ± 5.95 gh | 197.00 ± 20.97 bc | 20.88 ± 3.69 ab | 23.88 ± 5.66 ab |

| 80 | 88.92 ± 6.50 h | 149.60 ± 14.84 abc | 18.34 ± 3.81 ab | 25.76 ± 5.97 ab | |

| 100 | 83.28 ± 8.46 gh | 162.20 ± 18.41 abc | 16.13 ± 3.29 ab | 26.34 ± 3.90 ab | |

| 5.0 | 60 | 56.06 ± 6.40 def | 150.40 ± 14.39 abc | 18.51 ± 4.93 ab | 26.52 ± 4.81 ab |

| 80 | 43.64 ± 6.61 bcd | 136.16 ± 17.41 ab | 13.81 ± 2.66 ab | 19.61 ± 2.37 ab | |

| 100 | 45.56 ± 3.88 bcd | 109.40 ± 4.45 a | 21.38 ± 5.24 ab | 25.56 ± 4.94 ab | |

| 7.5 | 60 | 35.00 ± 5.18 bc | 109.98 ± 16.38 a | 16.26 ± 2.02 ab | 19.00 ± 3.46 ab |

| 80 | 53.18 ± 5.69 de | 107.38 ± 15.85 a | 18.82 ± 2.47 ab | 23.62 ± 4.45 ab | |

| 100 | 53.64 ± 7.16 de | 126.82 ± 12.90 ab | 13.57 ± 2.75 ab | 14.67 ± 2.95 a | |

| 10.0 | 60 | 45.74 ± 5.57 bcd | 192.00 ± 28.01 abc | 17.55 ± 4.10 ab | 22.77 ± 2.26 ab |

| 80 | 29.42 ± 4.22 ab | 164.60 ± 19.21 abc | 18.67 ± 4.59 ab | 25.43 ± 6.69 ab | |

| 100 | 55.48 ± 6.16 de | 157.58 ± 20.47 abc | 21.50 ± 5.48 ab | 28.72 ± 5.91 ab | |

| 20.0 | 60 | 32.64 ± 5.82 bc | 168.20 ± 23.68 abc | 24.50 ± 3.5 ab | 25.48 ± 4.46 ab |

| 80 | 73.12 ± 6.94 fgh | 151.20 ± 37.98 abc | 18.49 ± 2.45 ab | 18.94 ± 2.28 ab | |

| 100 | 81.24 ± 9.28 gh | 143.40 ± 32.32 abc | 17.17 ± 5.9 ab | 24.25 ± 4.23 ab | |

| 30.0 | 60 | 15.26 ± 3.20 a | 99.92 ± 20.42 a | 15.88 ± 4.73 ab | 16.23 ± 4.48 ab |

| 80 | 33.56 ± 6.33 bc | 161.40 ± 30.76 abc | 16.26 ± 4.9 ab | 18.45 ± 4.09 ab | |

| 100 | 47.16 ± 7.19 cd | 141.20 ± 32.93 abc | 16.64 ± 5.99 ab | 23.42 ± 4.14 ab | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lisiecka, K.; Wójtowicz, A.; Gancarz, M. Characteristics of Newly Developed Extruded Products Supplemented with Plants in a Form of Microwave-Expanded Snacks. Materials 2021, 14, 2791. https://doi.org/10.3390/ma14112791

Lisiecka K, Wójtowicz A, Gancarz M. Characteristics of Newly Developed Extruded Products Supplemented with Plants in a Form of Microwave-Expanded Snacks. Materials. 2021; 14(11):2791. https://doi.org/10.3390/ma14112791

Chicago/Turabian StyleLisiecka, Katarzyna, Agnieszka Wójtowicz, and Marek Gancarz. 2021. "Characteristics of Newly Developed Extruded Products Supplemented with Plants in a Form of Microwave-Expanded Snacks" Materials 14, no. 11: 2791. https://doi.org/10.3390/ma14112791

APA StyleLisiecka, K., Wójtowicz, A., & Gancarz, M. (2021). Characteristics of Newly Developed Extruded Products Supplemented with Plants in a Form of Microwave-Expanded Snacks. Materials, 14(11), 2791. https://doi.org/10.3390/ma14112791