Improving the Properties of Laser-Welded Al–Zn–Mg–Cu Alloy Joints by Aging and Double-Sided Ultrasonic Impact Compound Treatment

Abstract

1. Introduction

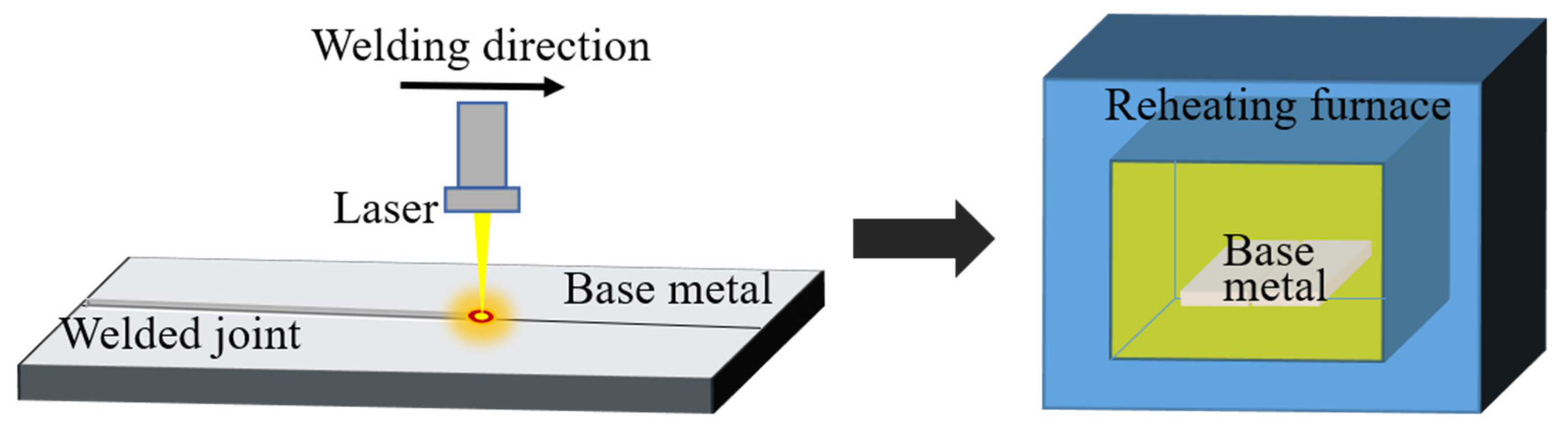

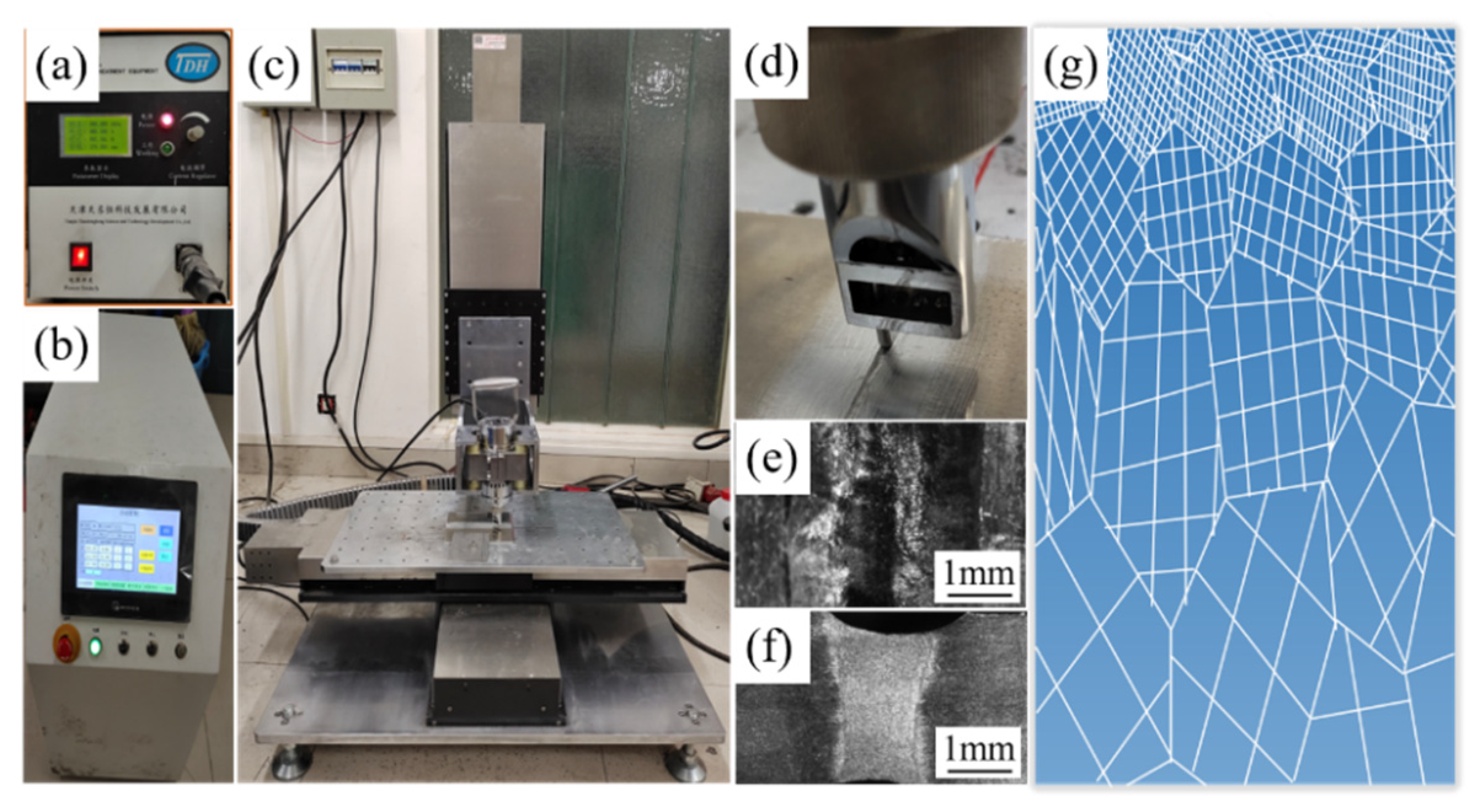

2. Materials and Methods

3. Results and Discussion

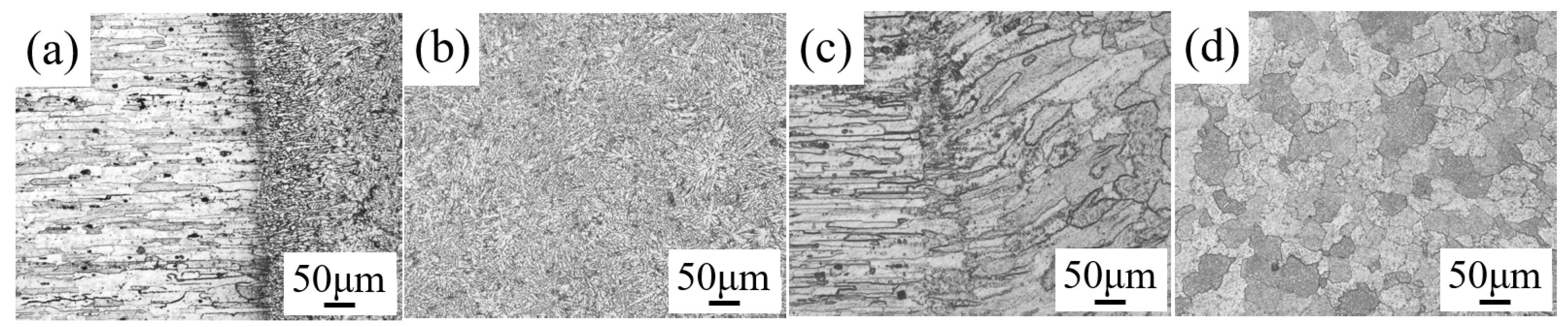

3.1. Effect of Aging Treatment on the Microstructure of the Welded Goints

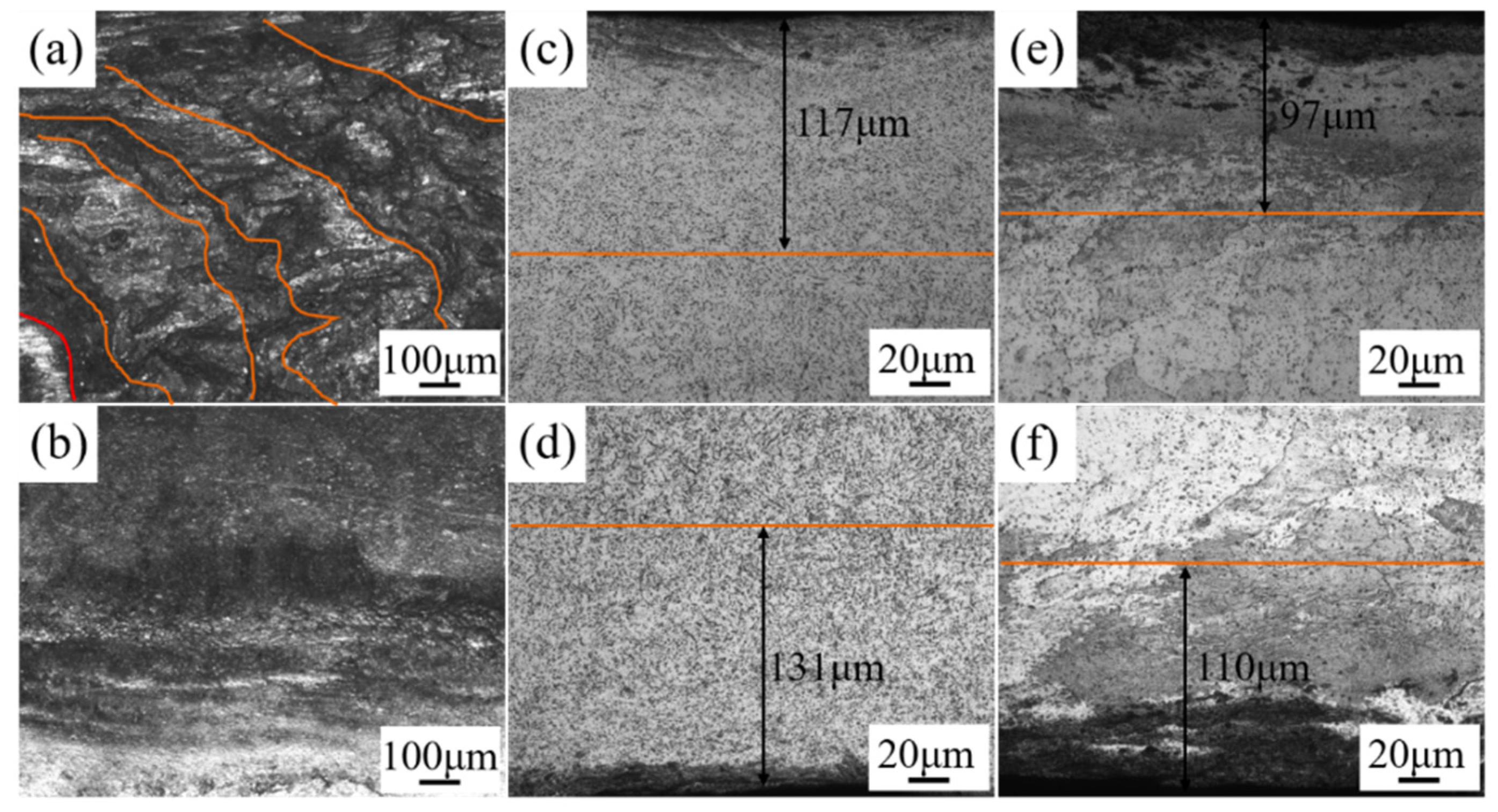

3.2. Effect of DSUIT on the Microstructure of the Welded Joint

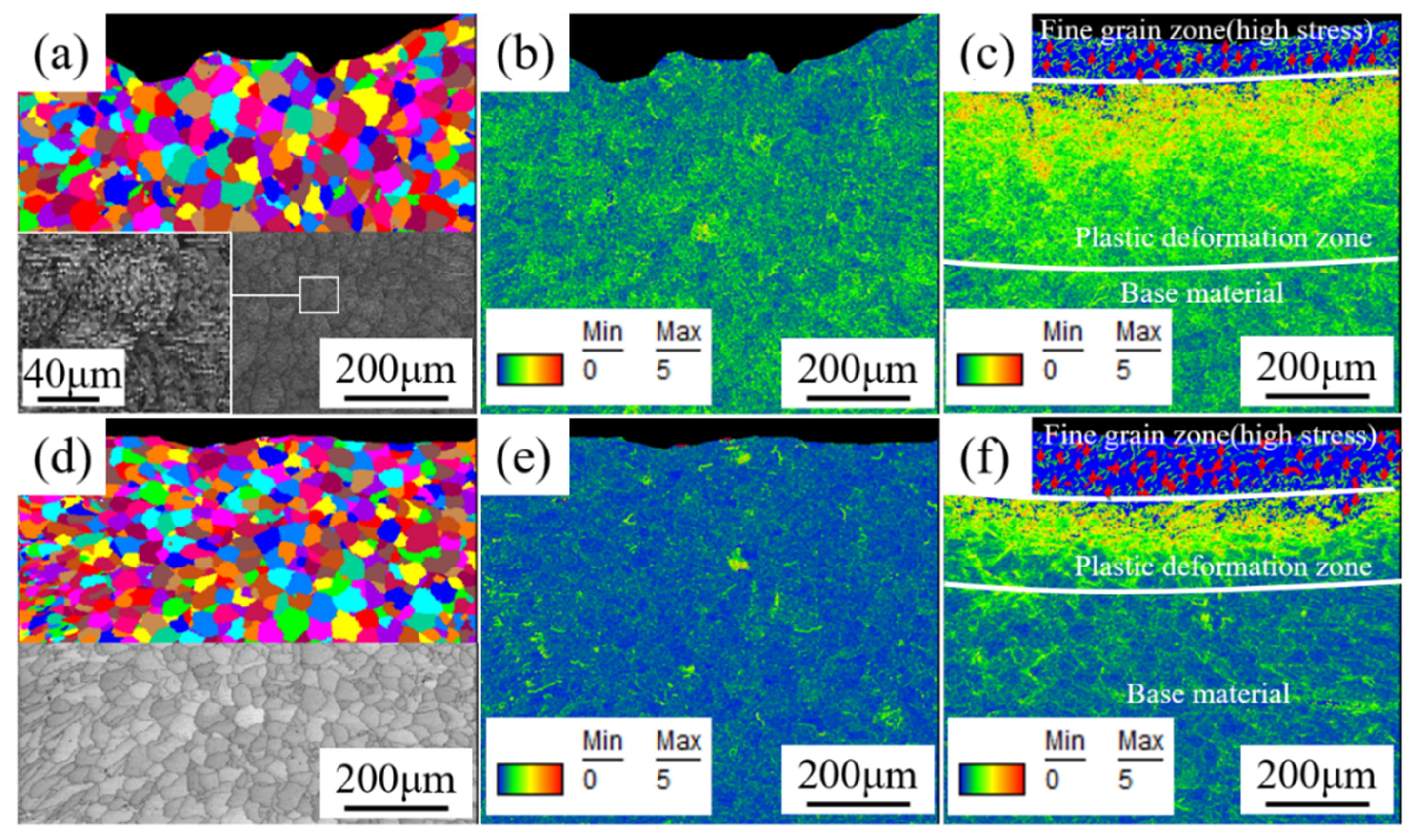

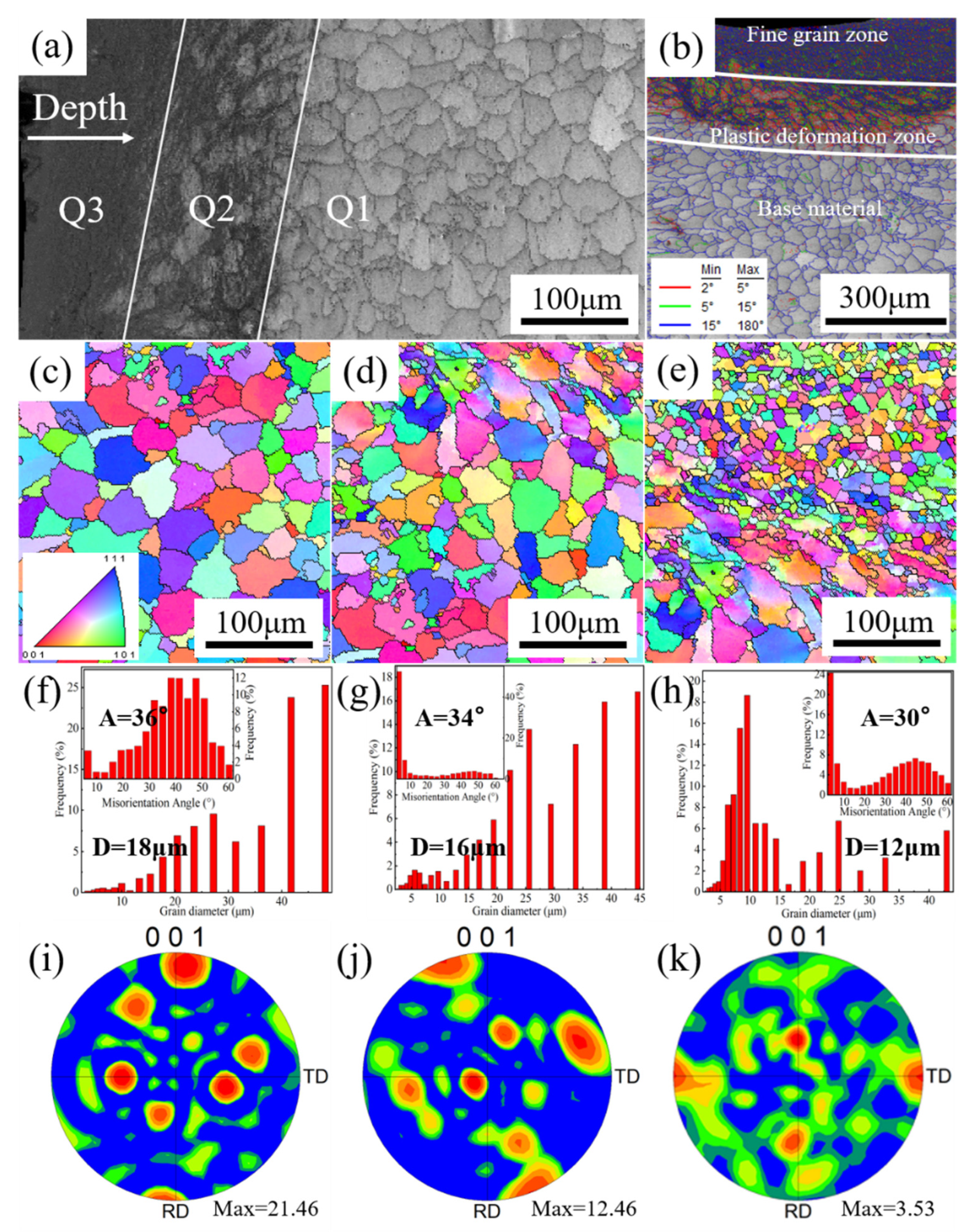

3.3. EBDS Analysis of Welded Joints under Different Processes

3.4. Microhardness Analysis of the Welded Joints under Different Treatment Processes

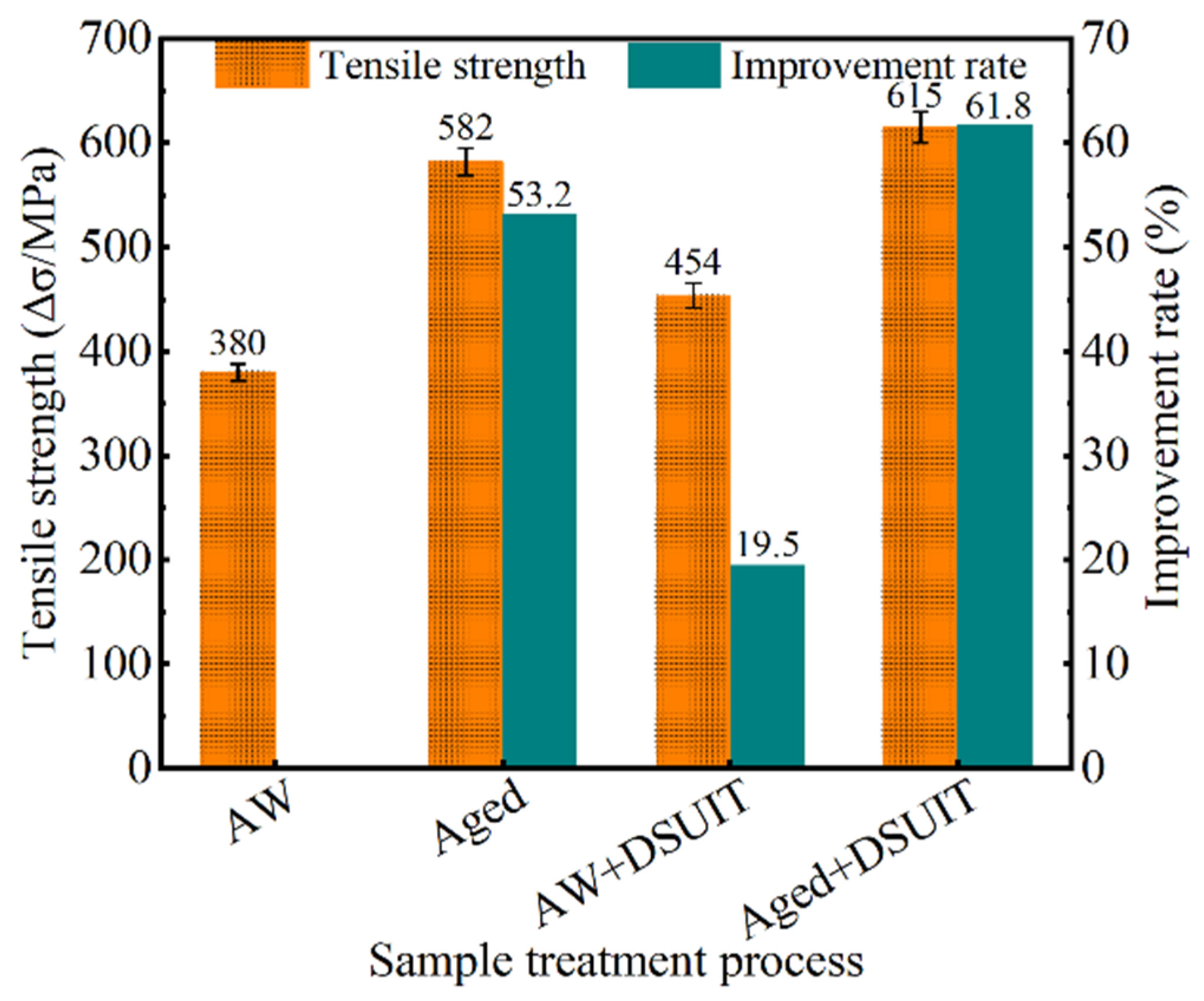

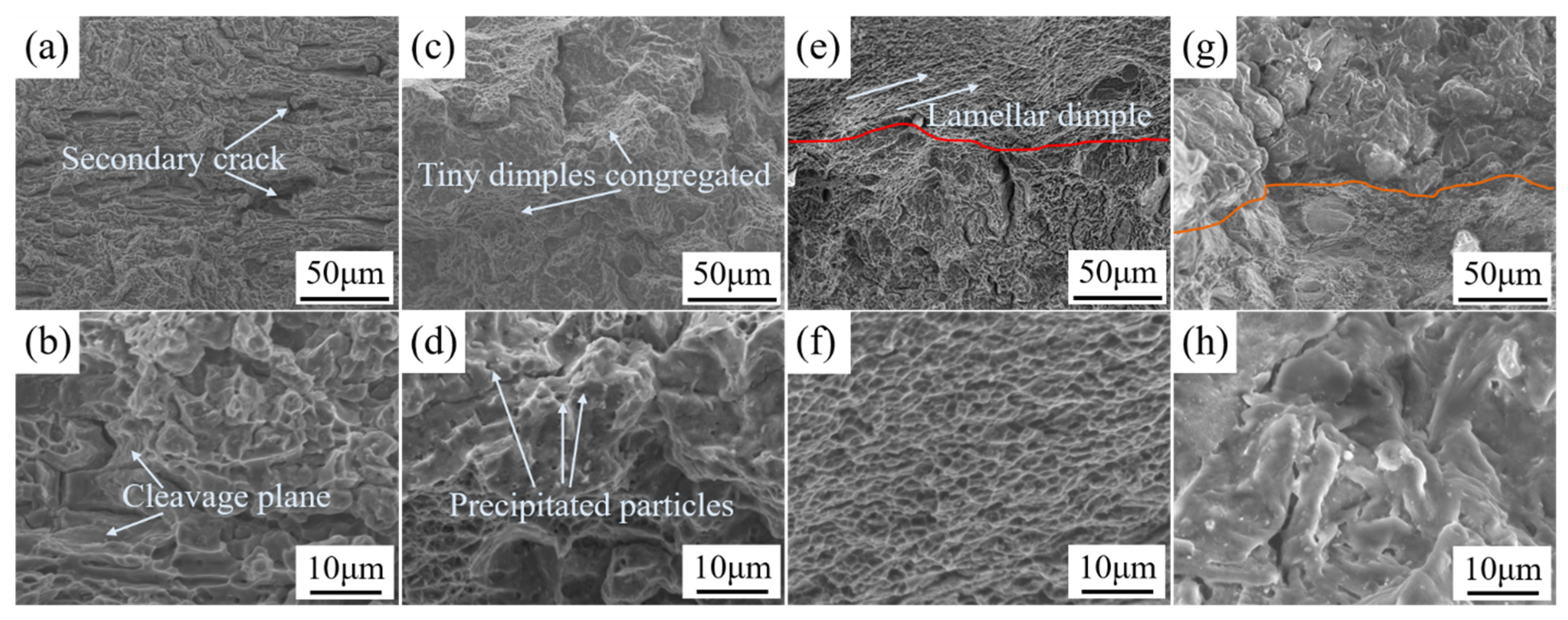

3.5. Tensile Properties and Fracture Morphology Analysis under the Different Processes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, J.-H.; Yoo, D.; Kwon, Y.N.; Kim, D. Pneumatic Experimental Design for Strain Rate Sensitive Forming Limit Evaluation of 7075 Aluminum Alloy Sheets under Biaxial Stretching Modes at Elevated Temperature. Metals 2020, 10, 1639. [Google Scholar] [CrossRef]

- Ma, Q.; Shao, F.; Bai, L.; Xu, Q.; Xie, X.; Shen, M. Corrosion Fatigue Fracture Characteristics of FSW 7075 Aluminum Alloy Joints. Materials 2020, 13, 4196. [Google Scholar] [CrossRef] [PubMed]

- Jeong, H.T.; Kim, W.J. Comparison of Hot Deformation Behavior Characteristics between As-Cast and Extruded Al-Zn-Mg-Cu (7075) Aluminum Alloys with a Similar Grain Size. Materials 2019, 12, 3807. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Guan, Y.; Wang, Z.; Zheng, H.; Lin, J.; Zhai, J.; Xie, Z. Influence of Surface Nanocrystallization and Partial Amorphization Induced by Ultrasonic Shot Peening on Surface Properties of 7075 Aluminum Alloy. J. Mater. Eng. Perorform. 2020, 29, 7693–7709. [Google Scholar] [CrossRef]

- Chen, F.; Yang, Y.; Feng, H. Regional Control and Optimization of Heat Input during CMT by Wire Arc Additive Manufacturing: Modeling and Microstructure Effects. Materials 2021, 14, 1061. [Google Scholar] [CrossRef]

- He, H.; Forouzan, F.; Volpp, J.; Robertson, S.M.; Vuorinen, E. Microstructure and Mechanical Properties of Laser-Welded DP Steels Used in the Automotive Industry. Materials 2021, 14, 456. [Google Scholar] [CrossRef]

- Čapek, J.; Trojan, K.; Kec, J.; Černý, I.; Ganev, N.; Němeček, S. On the Weldability of Thick P355NL1 Pressure Vessel Steel Plates Using Laser Welding. Materials 2021, 14, 131. [Google Scholar] [CrossRef]

- Chen, L.; Wang, C.; Zhang, X.; Mi, G. Effect of parameters on microstructure and mechanical property of dissimilar joints between 316L stainless steel and GH909 alloy by laser welding. J. Manuf. Process. 2021, 65. [Google Scholar] [CrossRef]

- Kumar, B.; Bag, S.; Mahadevan, S.; Paul, C.P.; Das, C.R.; Bindra, K.S. On the interaction of microstructural morphology with residual stress in fiber laser welding of austenitic stainless steel. CIRP J. Manuf. Sci. Technol. 2021, 33. [Google Scholar] [CrossRef]

- Guzanová, A.; Džupon, M.; Draganovská, D.; Brezinová, J.; Viňáš, J.; Cmorej, D.; Janoško, E.; Maruschak, P. The corrosion and wear resistance of laser and mag weld deposits. Acta Metall. Slovaca 2020, 26, 37–41. [Google Scholar] [CrossRef]

- Li, H.C.; Xu, W.; Xiao, G.; Chen, B. Weld Formation in Laser Hot-Wire Welding of 7075 Aluminum Alloy. Metals 2018, 8, 909. [Google Scholar] [CrossRef]

- Hu, Z.L.; Wang, X.S.; Pang, Q.; Huang, F.; Qin, X.P.; Hua, L. The effect of postprocessing on tensile property and microstructure evolution of friction stir welding aluminum alloy joint. Mater. Charact. 2015, 99. [Google Scholar] [CrossRef]

- Dhakal, B.; Swaroop, S. Review: Laser shock peening as post welding treatment technique. J. Manuf. Process. 2018, 32. [Google Scholar] [CrossRef]

- Jörn, B.; Natalie, S.H. Fatigue behaviour of high frequency hammer peened ultra high strength steels. Int. J. Fatigue 2016, 82. [Google Scholar] [CrossRef]

- Ivanov, Y.F.; Gromov, V.E.; Konovalov, S.V.; Zagulyaev, D.V.; Petrikova, E.A.; Semin, A.P. Modification of structure and surface properties of hypoeutectic silumin by intense pulse electron beams. A-DSUIT demonstrated Prog. Phys. Met. 2018, 19, 195–222. [Google Scholar] [CrossRef]

- Valkov, S.; Parshorov, S.; Andreeva, A.; Bezdushnyi, R.; Nikolova, M.; Dechev, D.; Ivanov, N.; Petrov, P. Influence of electron beam treatment of Co-Cr alloy on the growing mechanism, surface topography, and mechanical properties of deposited TiN/TiO2 coatings. Coatings 2019, 9, 513. [Google Scholar] [CrossRef]

- Eisazadeh, H.; Aidun, D.K. Residual stress reduction in dissimilar metals weld. J. Manuf. Process. 2021, 64. [Google Scholar] [CrossRef]

- Bala Parandhma Raju, M.; Sankaranarayanasamy, K.; Latha, S.; Prabhu, T.V.; Prasad Reddy, G.V. Tensile Properties of Modified 9Cr–1Mo Steel Clad Tube to End Plug Weld Joint. J. Mater. Eng. Perform. 2021. [Google Scholar] [CrossRef]

- Liang, H.; Kan, Y.; Chen, H.N.; Zhan, R.; Liu, X.G.; Wang, D.P. Effect of cutting process on the residual stress and fatigue life of the welded joint treated by ultrasonic impact treatment. Int. J. Fatigue 2021, 143. [Google Scholar] [CrossRef]

- Chenakin, S.P.; Filatova, V.S.; Makeeva, I.N.; Vasylyev, M.A. Ultrasonic impact treatment of CoCrMo alloy: Surface composition and properties. Appl. Surf. Sci. 2017, 408. [Google Scholar] [CrossRef]

- Safarbali, B.; Shamanian, M.; Eslami, A. Effect of post-weld heat treatment on joint properties of dissimilar friction stir welded 2024-T4 and 7075-T6 aluminum alloys. Trans. Nonferrous Met. Soc. 2018, 28, 1287–1297. [Google Scholar] [CrossRef]

- Mohammad, M.M.; Hamed, J.A.; Roohollah, J. Effect of pre and post welding heat treatment in SiC-fortified dissimilar AA6061-AA2024 FSW butt joint. J. Manuf. Process. 2017. [Google Scholar] [CrossRef]

- Li, L.; Miru, K.; Seungjun, L.; Munki, B.; Deugwoo, L. Influence of multiple ultrasonic impact treatments on surface roughness and wear performance of SUS301 steel. Surf. Coat. Technol. 2016, 307. [Google Scholar] [CrossRef]

- Li, M.Y.; Zhang, Q.; Han, B.; Song, L.X.; Li, J.L.; Yang, J. Investigation on microstructure and properties of Al x CoCrFeMnNi high entropy alloys by ultrasonic impact treatment. J Alloys Compd. 2020, 816. [Google Scholar] [CrossRef]

- Enz, J.; Riekehr, S.; Ventzke, V.; Huber, N.; Kashaev, N. Fibre laser welding of high-alloyed Al–Zn–Mg–Cu alloys. J. Mater. Process. Technol. 2016, 237. [Google Scholar] [CrossRef]

- Kahraman, F. Surface layer properties of ultrasonic impact–treated AA7075 aluminum alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2018, 232, 2218–2225. [Google Scholar] [CrossRef]

- Chen, J.F.; Chu, J.Y.; Jiang, W.C.; Yao, B.; Zhou, F.; Wang, Z.B.; Zhao, P.C. Experimental and Numerical Simulation to Study the Reduction of Welding Residual Stress by Ultrasonic Impact Treatment. Materials 2020, 13, 837. [Google Scholar] [CrossRef]

| Element | Mg | Zn | Cu | Cr | Fe | Mn | Ti | Si | Al |

|---|---|---|---|---|---|---|---|---|---|

| GB/T3190 | 2.1–2.9 | 5.1–6.1 | 1.2–2.0 | 0.18–0.28 | ≤0.5 | ≤0.3 | ≤0.2 | ≤0.4 | balance |

| Reinspection | 2.23 | 5.54 | 1.41 | 0.19 | 0.43 | 0.22 | 0.14 | 0.31 | balance |

| Laser Welding Parameters | Power/W | Welding Speed v/m·s−1 | Defocusing Distance/mm | Upper/Lower Shielding Flow L/min | T6 Heat Treatment Process Parameters | Solution Temperature × Solution Time /°C × h | Quench | Aging Temperature × Aging Time/°C × h |

|---|---|---|---|---|---|---|---|---|

| 2700 | 0.054 | +4 | 15/15 | 470 × 2 | Water | 120 × 24 |

| Working Frequency f/KHz | Working Current I/A | Diameter of Impact Needle d/mm | Velocity of Impact Needle Movement v/mm·s−1 | Impact Times /N |

|---|---|---|---|---|

| 25 | 2.0 | 3 | 30 | 150 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Liu, C. Improving the Properties of Laser-Welded Al–Zn–Mg–Cu Alloy Joints by Aging and Double-Sided Ultrasonic Impact Compound Treatment. Materials 2021, 14, 2742. https://doi.org/10.3390/ma14112742

Chen F, Liu C. Improving the Properties of Laser-Welded Al–Zn–Mg–Cu Alloy Joints by Aging and Double-Sided Ultrasonic Impact Compound Treatment. Materials. 2021; 14(11):2742. https://doi.org/10.3390/ma14112742

Chicago/Turabian StyleChen, Furong, and Chenghao Liu. 2021. "Improving the Properties of Laser-Welded Al–Zn–Mg–Cu Alloy Joints by Aging and Double-Sided Ultrasonic Impact Compound Treatment" Materials 14, no. 11: 2742. https://doi.org/10.3390/ma14112742

APA StyleChen, F., & Liu, C. (2021). Improving the Properties of Laser-Welded Al–Zn–Mg–Cu Alloy Joints by Aging and Double-Sided Ultrasonic Impact Compound Treatment. Materials, 14(11), 2742. https://doi.org/10.3390/ma14112742