Design an Epoxy Coating with TiO2/GO/PANI Nanocomposites for Enhancing Corrosion Resistance of Q235 Carbon Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

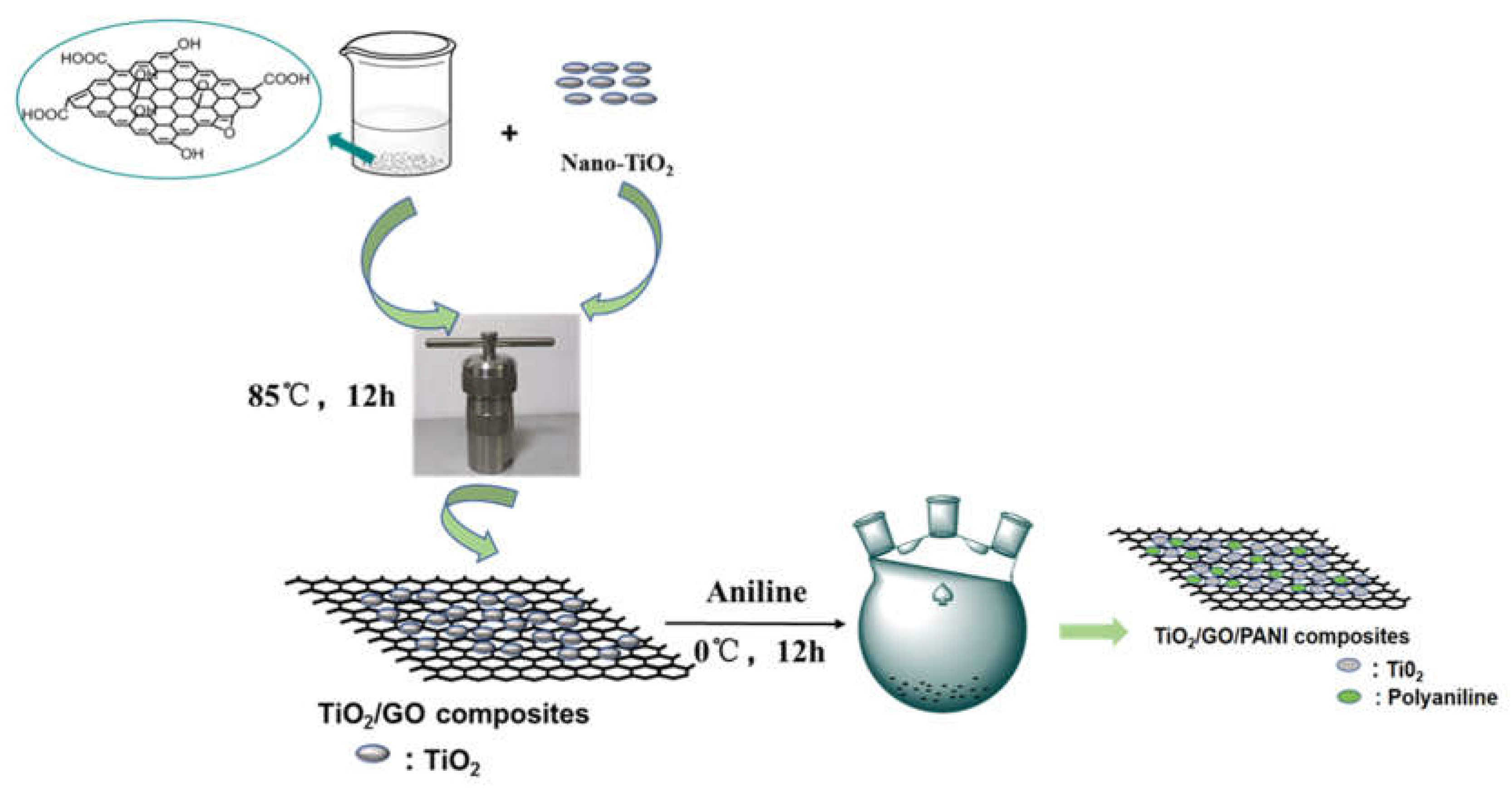

2.2. Preparation of Binary TiO2/GO Composite Materials

2.3. Preparation of Binary TiO2/PANI Composite Material

2.4. Preparation of Ternary TiO2/GO/PANI Composite Material

2.5. Preparation of Quaternary TiO2/GO/PANI/EP Composite Coating

2.6. Characterizations

3. Results

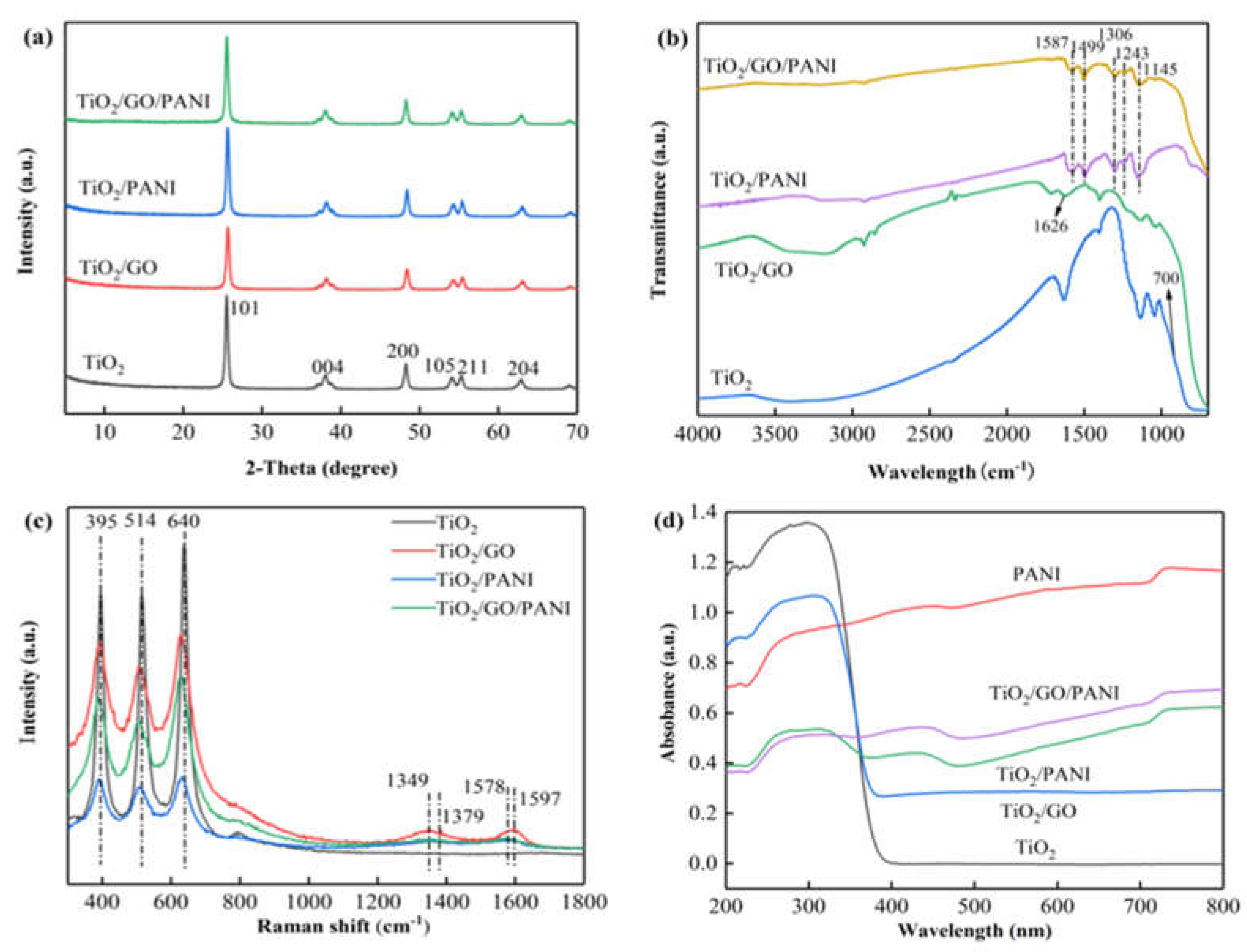

3.1. Structure Characterization

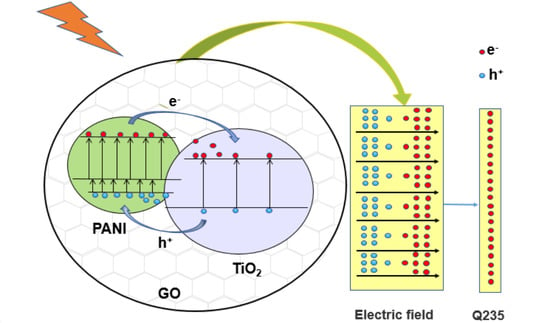

3.2. Photoelectrochemical Performance

3.3. Morphology of Coatings

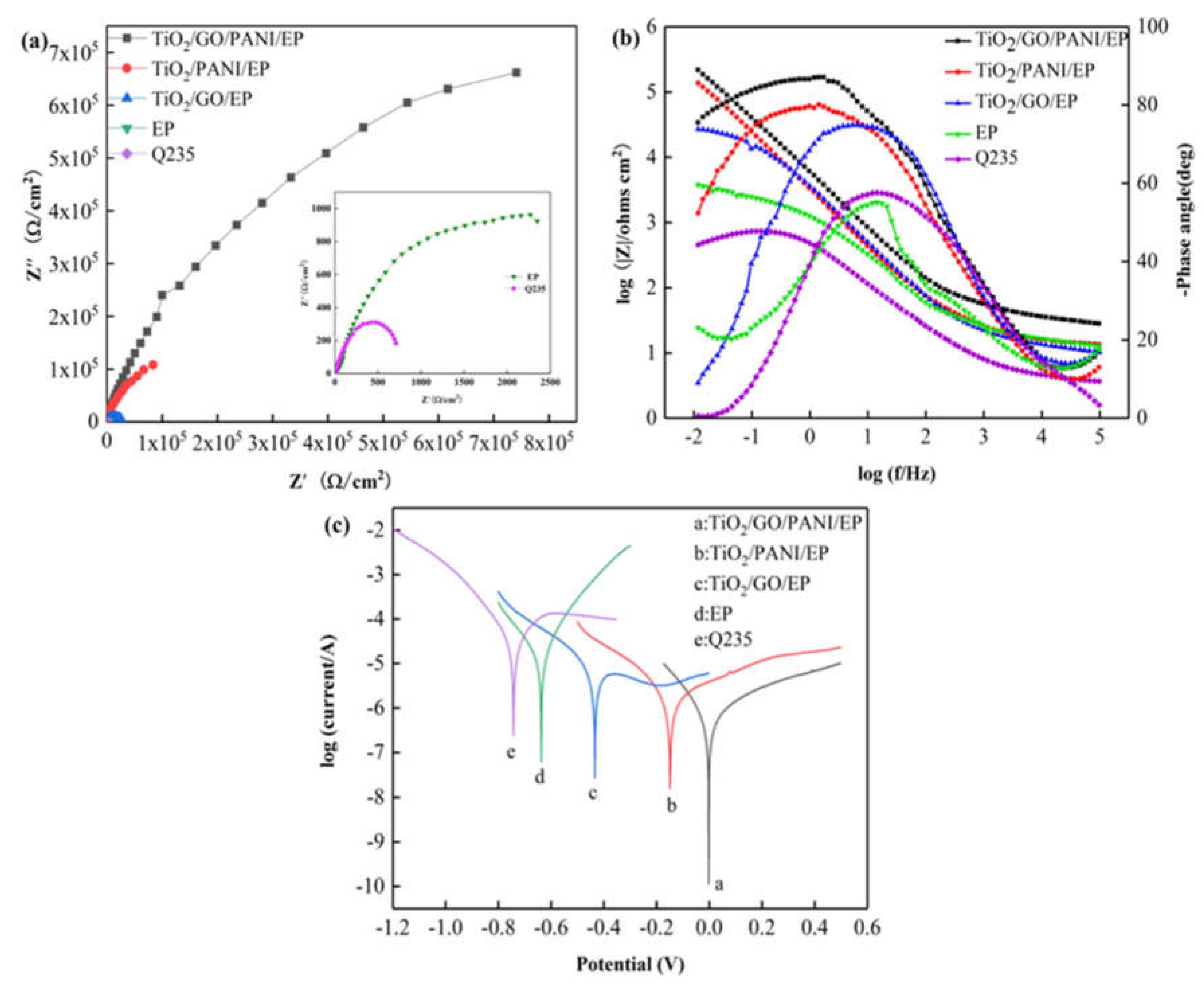

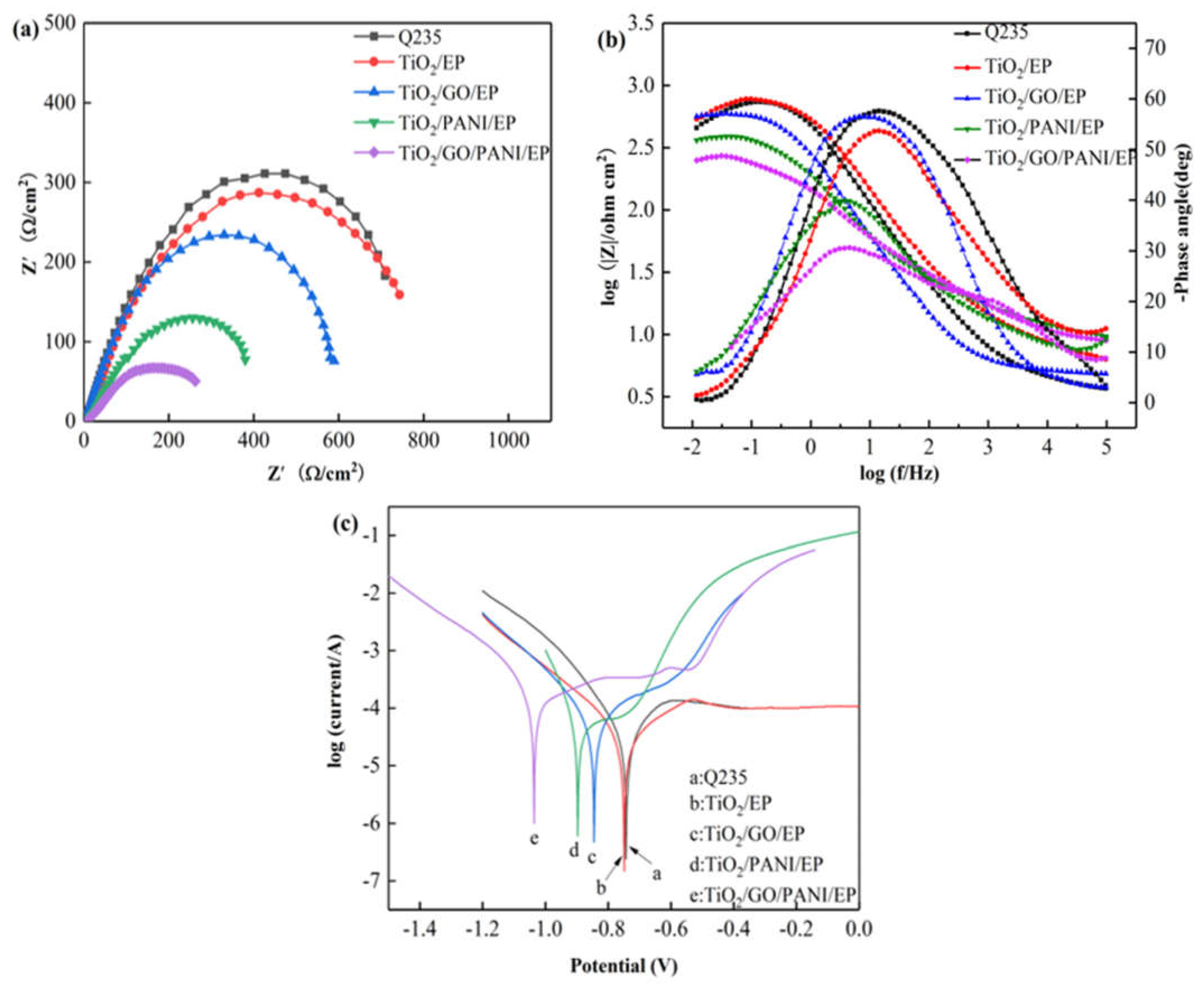

3.4. Corrosion Resistance Property of Coatings

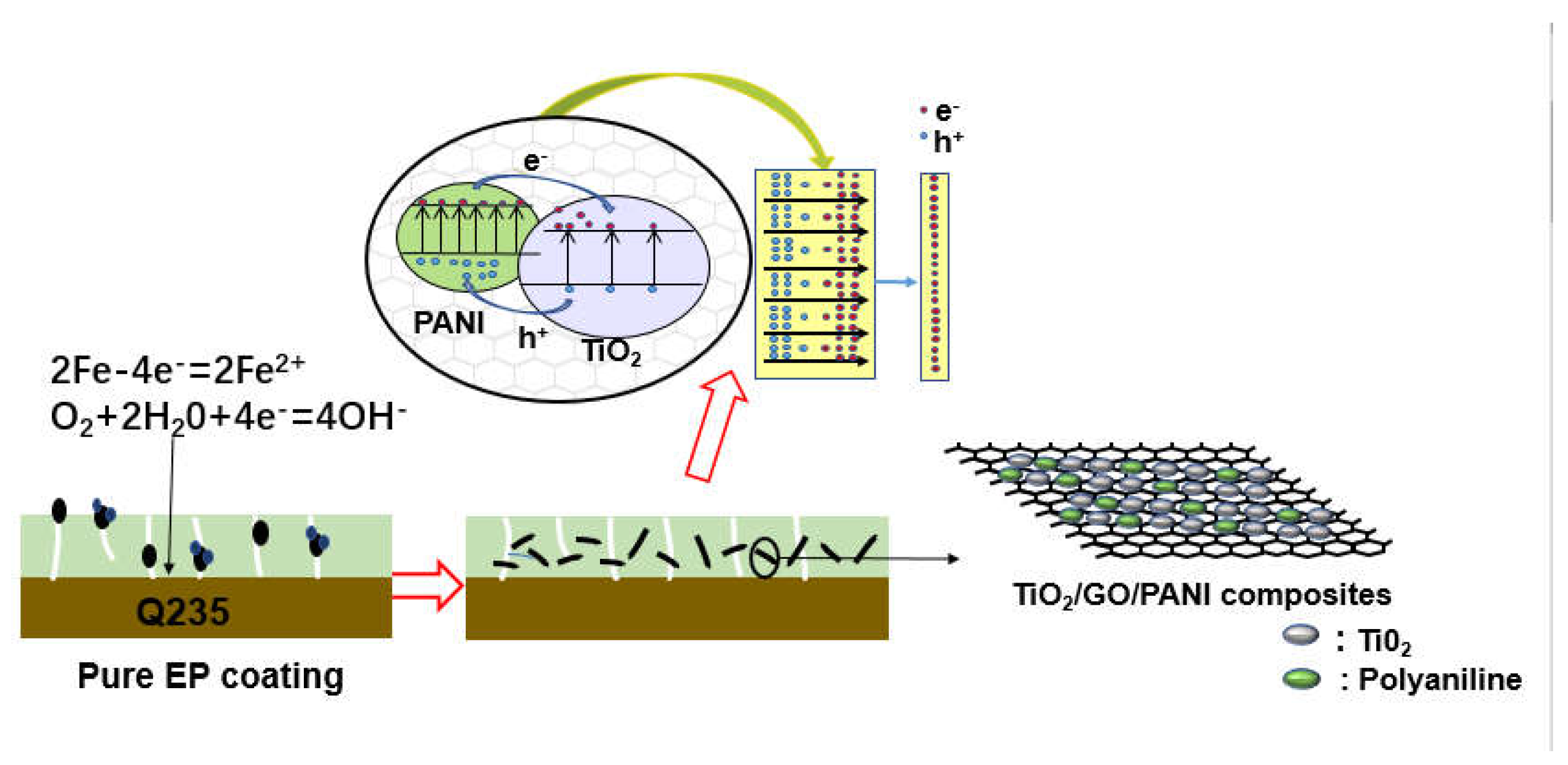

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, L.P.; Zhao, Y.; Vilbrandt, N.; Gallei, M.; Vimalanandan, A.; Rohwerder, M.; Landfester, K.; Crespy, D. Redox Responsive Release of Hydrophobic Self-Healing Agents from Polyaniline Capsules. J. Am. Chem. Soc. 2013, 135, 14198–14205. [Google Scholar] [CrossRef] [PubMed]

- Shen, L.; Zhao, W.; Miao, L. Designed a Novel EP + GO/ZRC + GO Coating with Bilayered Structure for Enhancing Corrosion Resistance of Steel Substrate. J. Hazard. Mater. 2021, 403, 123670. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Liu, Q.; Gao, R.; Wang, J.; Yang, W.; Liu, L. One-step method for the fabrication of superhydrophobic surface on magnesium alloy and its corrosion protection, antifouling performance. Corros. Sci. 2014, 80, 177–183. [Google Scholar] [CrossRef]

- Chen, T.; Fu, J. pH-responsive nanovalves based on hollow mesoporous silica spheres for controlled release of corrosion inhibitor. Nanotechnology 2012, 23, 235605. [Google Scholar] [CrossRef]

- Aghzzaf, A.A.; Rhouta, B.; Rocca, E.; Khalil, A.; Steinmetz, J. Corrosion inhibition of zinc by calcium exchanged beidellite clay mineral: A new smart corrosion inhibitor. Corros. Sci. 2014, 80, 46–52. [Google Scholar] [CrossRef]

- Malucelli, G.; Di Gianni, A.; Deflorian, F.; Fedel, M.; Bongiovanni, R. Preparation of ultraviolet-cured nanocomposite coatings for protecting against corrosion of metal substrates. Corros. Sci. 2009, 51, 1762–1771. [Google Scholar] [CrossRef]

- Weng, C.J.; Huang, J.Y.; Huang, K.Y.; Jhuo, Y.S.; Tsai, M.H.; Yeh, J.M. Advanced anticorrosive coatings prepared from electroactive polyimide–TiO2 hybrid nanocomposite materials. Electrochim. Acta 2010, 55, 8430–8438. [Google Scholar] [CrossRef]

- Christodoulou, C.; Glass, G.; Webb, J.; Austin, S.; Goodier, C. Assessing the long term benefits of Impressed Current Cathodic Protection. Corros. Sci. 2010, 52, 2671–2679. [Google Scholar] [CrossRef]

- Parthiban, G.; Parthiban, T.; Ravi, R.; Saraswathy, V.; Palaniswamy, N.; Sivan, V. Cathodic protection of steel in concrete using magnesium alloy anode. Corros. Sci. 2008, 50, 3329–3335. [Google Scholar] [CrossRef]

- Kear, G.; Barker, B.; Stokes, K.; Walsh, F. Corrosion and impressed current cathodic protection of copper-based materials using a bimetallic rotating cylinder electrode (BRCE). Corros. Sci. 2005, 47, 1694–1705. [Google Scholar] [CrossRef]

- Pistofidis, N.; Vourlias, G.; Konidaris, S.; Pavlidou, E.; Stergiou, A.; Stergioudis, G. Microstructure of zinc hot-dip galvanized coatings used for corrosion protection. Mater. Lett. 2006, 60, 786–789. [Google Scholar] [CrossRef]

- Zheng, H.; Liu, Y.; Zhou, Y.; Zhao, D.; Wang, D.; Yun, L.; Zhang, D.; Zhang, L. Improved photocathodic protection performance of g-C3N4/rGO/ZnS for 304 stainless steel. J. Phys. Chem. Solids 2021, 148. [Google Scholar] [CrossRef]

- Xu, D.; Liu, Y.; Liu, Y.; Chen, F.; Zhang, C.; Liu, B. A review on recent progress in the development of photoelectrodes for photocathodic protection: Design, properties, and prospects. Mater. Des. 2021, 197. [Google Scholar] [CrossRef]

- Cui, M.; Ren, S.; Zhao, H.; Xue, Q.; Wang, L. Polydopamine coated graphene oxide for anticorrosive reinforcement of water-borne epoxy coating. Chem. Eng. J. 2018, 335, 255–266. [Google Scholar] [CrossRef]

- Cui, M.; Ren, S.; Qiu, S.; Zhao, H.; Wang, L.; Xue, Q. Non-covalent functionalized multi-wall carbon nanotubes filled epoxy composites: Effect on corrosion protection and tribological performance. Surf. Coat. Technol. 2018, 340, 74–85. [Google Scholar] [CrossRef]

- Ge, T.; Zhao, W.; Wu, X.; Wu, Y.; Shen, L.; Ci, X.; He, Y. Design alternate epoxy-reduced graphene oxide/epoxy-zinc multilayer coatings for achieving long-term corrosion resistance for Cu. Mater. Des. 2020, 186. [Google Scholar] [CrossRef]

- Cui, S.; Yin, X.; Yu, Q.; Liu, Y.; Wang, D.; Zhou, F. Polypyrrole nanowire/TiO2 nanotube nanocomposites as photoanodes for photocathodic protection of Ti substrate and 304 stainless steel under visible light. Corros. Sci. 2015, 98, 471–477. [Google Scholar] [CrossRef]

- Roy, P.; Berger, S.; Schmuki, P. TiO2 Nanotubes: Synthesis and Applications. Angew. Chem. Int. Ed. 2011, 50, 2904–2939. [Google Scholar] [CrossRef]

- Sun, X.; Lin, J.; Guan, H.; Li, L.; Sun, L.; Wang, Y.; Miao, S.; Su, Y.; Wang, X. Complete oxidation of formaldehyde over TiO2 supported subnanometer Rh catalyst at ambient temperature. Appl. Catal. B Environ. 2018, 226, 575–584. [Google Scholar] [CrossRef]

- Zhao, Z.; Kou, T.; Zhang, L.; Zhai, S.; Wang, W.; Wang, Y. Dealloying induced N-doping in spindle-like porous rutile TiO2 for enhanced visible light photocatalytic activity. Corros. Sci. 2018, 137, 204–211. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, X.T.; Liu, F.G.; Sun, H.F.; Li, H.; Wei, Q.Y.; Hou, B.R. Photogenerated cathodic protection of 304ss by ZnSe/TiO2 NTs under visible light. Mater. Lett. 2015, 143, 116–119. [Google Scholar] [CrossRef]

- Kalanur, S.S.; Hwang, Y.J.; Joo, O.S. Construction of efficient CdS–TiO2 heterojunction for enhanced photocurrent, photostability, and photoelectron lifetimes. J. Colloid Interface Sci. 2013, 402, 94–99. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wang, X.; Liu, Y.; Hou, B. Ag and SnO2 co-sensitized TiO2 photoanodes for protection of 304SS under visible light. Corros. Sci. 2014, 82, 145–153. [Google Scholar] [CrossRef]

- Alam Khan, M.; Han, D.H.; Yang, O.B. Enhanced photoresponse towards visible light in Ru doped titania nanotube. Appl. Surf. Sci. 2009, 255, 3687–3690. [Google Scholar] [CrossRef]

- Xu, D.; Liu, B.; Zou, W.; Wang, H.; Zhang, C. In situ synthesis of TiO2 nanosheets@CdSe nanocomposites and the improved photocatalytic performance on removal of methylene blue. Appl. Surf. Sci. 2019, 487, 91–100. [Google Scholar] [CrossRef]

- Yang, C.; Dong, W.; Cui, G.; Zhao, Y.; Shi, X.; Xia, X.; Tang, B.; Wang, W. Enhanced photocatalytic activity of PANI/TiO2 due to their photosensitization-synergetic effect. Electrochim. Acta 2017, 247, 486–495. [Google Scholar] [CrossRef]

- Sengupta, R.; Bhattacharya, M.; Bandyopadhyay, S.; Bhowmick, A.K. A review on the mechanical and electrical properties of graphite and modified graphite reinforced polymer composites. Prog. Polym. Sci. 2011, 36, 638–670. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef]

- Zuo, F.; Angelopoulos, M.; MacDiarmid, A.G.; Epstein, A.J. Transport studies of protonated emeraldine polymer: A granular polymeric metal system. Phys. Rev. B 1987, 36, 3475–3478. [Google Scholar] [CrossRef]

- De Farias, R.F. Synthesis, characterization and thermogravimetric study of zinc and cadmium acetates–polyaniline hybrids. Thermochim. Acta 2004, 409, 121–126. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, C.; Li, J. Photocatalysis and wave-absorbing properties of polyaniline/TiO2 microbelts composite by in situ polymerization method. Appl. Surf. Sci. 2010, 257, 944–948. [Google Scholar] [CrossRef]

- Xia, Y.; Cheng, H.; Duo, L.; Zhang, D.; Chen, X.; Shi, S.; Lei, L. Anticorrosion reinforcement of waterborne polyacrylate coating with nano-TiO2 loaded graphene. J. Appl. Polym. Sci. 2019, 137. [Google Scholar] [CrossRef]

- Zhang, W.; Guo, H.; Sun, H.; Zeng, R. Constructing ternary polyaniline-graphene-TiO hybrids with enhanced photoelectrochemical performance in photo-generated cathodic protection. Appl. Surf. Sci. 2017, 410, 547–556. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Zhang, L.; Hou, B. CdTe and graphene co-sensitized TiO2 nanotube array photoanodes for protection of 304SS under visible light. Nanotechnology 2015, 26, 155704. [Google Scholar] [CrossRef]

- Guan, Z.C.; Wang, H.P.; Wang, X.; Hu, J.; Du, R.G. Fabrication of heterostructured β-Bi2O3-TiO2 nanotube array composite film for photoelectrochemical cathodic protection applications. Corros. Sci. 2018, 136, 60–69. [Google Scholar] [CrossRef]

- Zuo, J.; Wu, H.; Chen, A.; Zhu, J.; Ye, M.; Ma, J.; Qi, Z. Shape-dependent photogenerated cathodic protection by hierarchically nanostructured TiO2 films. Appl. Surf. Sci. 2018, 462, 142–148. [Google Scholar] [CrossRef]

- Peiró, A.M.; Peral, J.; Domingo, C.; Domènech, X.; Ayllón, J.A. Low-Temperature Deposition of TiO2 Thin Films with Photocatalytic Activity from Colloidal Anatase Aqueous Solutions. Chem. Mater. 2001, 13, 2567–2573. [Google Scholar] [CrossRef]

- Bissessur, R.; Scully, S. Intercalation of solid polymer electrolytes into graphite oxide. Solid State Ionics 2007, 178, 877–882. [Google Scholar] [CrossRef]

- Zujovic, Z.D.; Wang, Y.; Bowmaker, G.A.; Kaner, R.B. Structure of Ultralong Polyaniline Nanofibers Using Initiators. Macromolecules 2011, 44, 2735–2742. [Google Scholar] [CrossRef]

- Bledowski, M.; Wang, L.; Ramakrishnan, A.; Khavryuchenko, O.V.; Khavryuchenko, V.D.; Ricci, P.C.; Strunk, J.; Cremer, T.; Kolbeck, C.; Beranek, R. Visible-light photocurrent response of TiO2–polyheptazine hybrids: Evidence for interfacial charge-transfer absorption. Phys. Chem. Chem. Phys. 2011, 13, 21511–21519. [Google Scholar] [CrossRef]

- Karim, M.R.; Yeum, J.H.; Lee, M.S.; Lim, K.T. Preparation of conducting polyaniline/TiO2 composite submicron-rods by the γ-radiolysis oxidative polymerization method. React. Funct. Polym. 2008, 68, 1371–1376. [Google Scholar] [CrossRef]

- Yang, M.Q.; Zhang, N.; Xu, Y.J. Synthesis of Fullerene–, Carbon Nanotube–, and Graphene–TiO2Nanocomposite Photocatalysts for Selective Oxidation: A Comparative Study. ACS Appl. Mater. Interfaces 2013, 5, 1156–1164. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.F.; Zhang, H.; Liu, Q.; Liu, Y.; Stanciu, L.; Xie, J. Covalently-grafted polyaniline on graphene oxide sheets for high performance electrochemical supercapacitors. Carbon 2014, 71, 257–267. [Google Scholar] [CrossRef]

- Zhang, L.; Reisner, E.; Baumberg, J.J. Al-doped ZnO inverse opal networks as efficient electron collectors in BiVO4 photoanodes for solar water oxidation. Energy Environ. Sci. 2014, 7, 1402–1408. [Google Scholar] [CrossRef]

- Bu, Y.; Ao, J.P. A review on photoelectrochemical cathodic protection semiconductor thin films for metals. Green Energy Environ. 2017, 2, 331–362. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Li, B.; Xiao, R.; Luo, H.; Yu, S.; He, J.; Liao, X. Design an Epoxy Coating with TiO2/GO/PANI Nanocomposites for Enhancing Corrosion Resistance of Q235 Carbon Steel. Materials 2021, 14, 2629. https://doi.org/10.3390/ma14102629

Chen S, Li B, Xiao R, Luo H, Yu S, He J, Liao X. Design an Epoxy Coating with TiO2/GO/PANI Nanocomposites for Enhancing Corrosion Resistance of Q235 Carbon Steel. Materials. 2021; 14(10):2629. https://doi.org/10.3390/ma14102629

Chicago/Turabian StyleChen, Shimin, Bo Li, Rengui Xiao, Huanhu Luo, Siwu Yu, Jinghang He, and Xia Liao. 2021. "Design an Epoxy Coating with TiO2/GO/PANI Nanocomposites for Enhancing Corrosion Resistance of Q235 Carbon Steel" Materials 14, no. 10: 2629. https://doi.org/10.3390/ma14102629

APA StyleChen, S., Li, B., Xiao, R., Luo, H., Yu, S., He, J., & Liao, X. (2021). Design an Epoxy Coating with TiO2/GO/PANI Nanocomposites for Enhancing Corrosion Resistance of Q235 Carbon Steel. Materials, 14(10), 2629. https://doi.org/10.3390/ma14102629