Energy Absorption Capacity of SBR Latex-Modified Ordinary Portland Cement by Charpy Impact Test

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Specimens

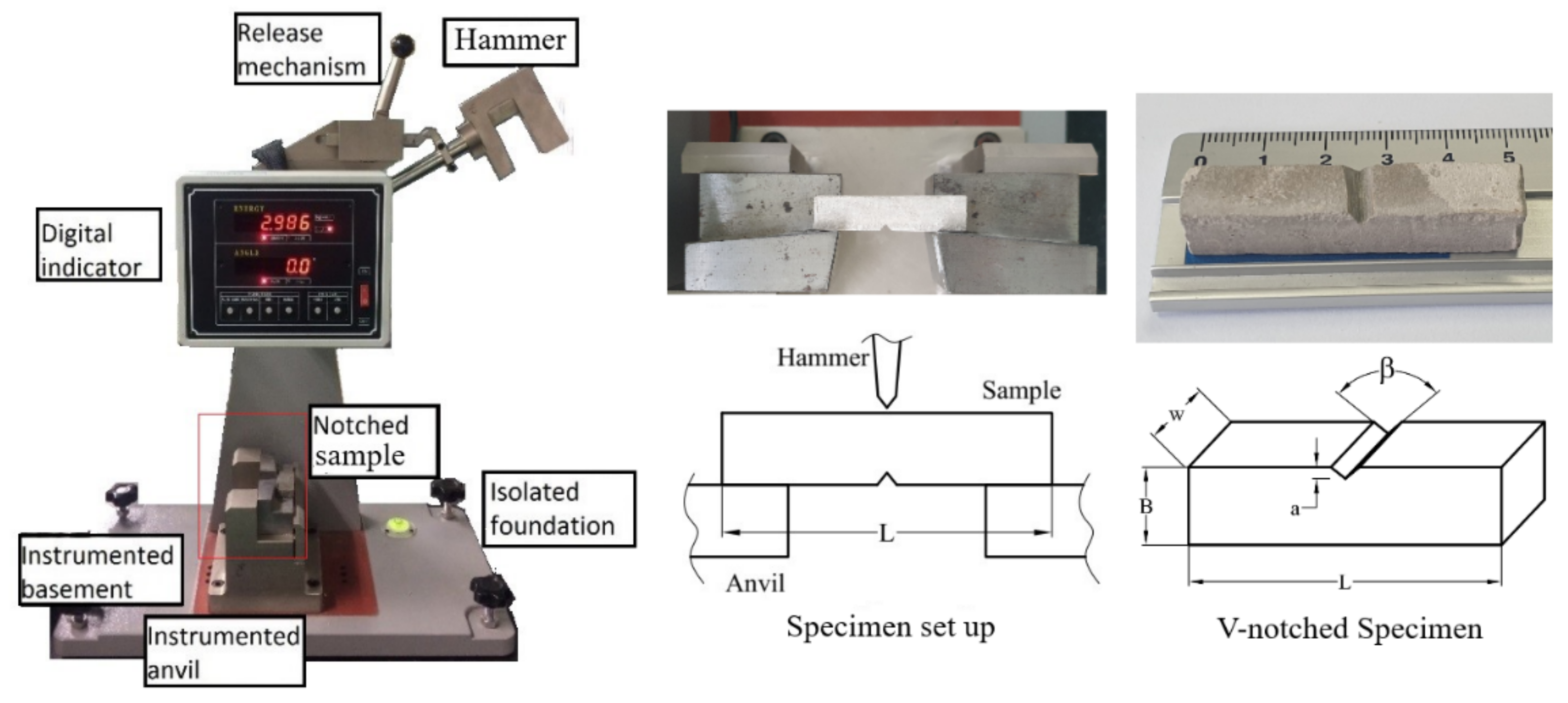

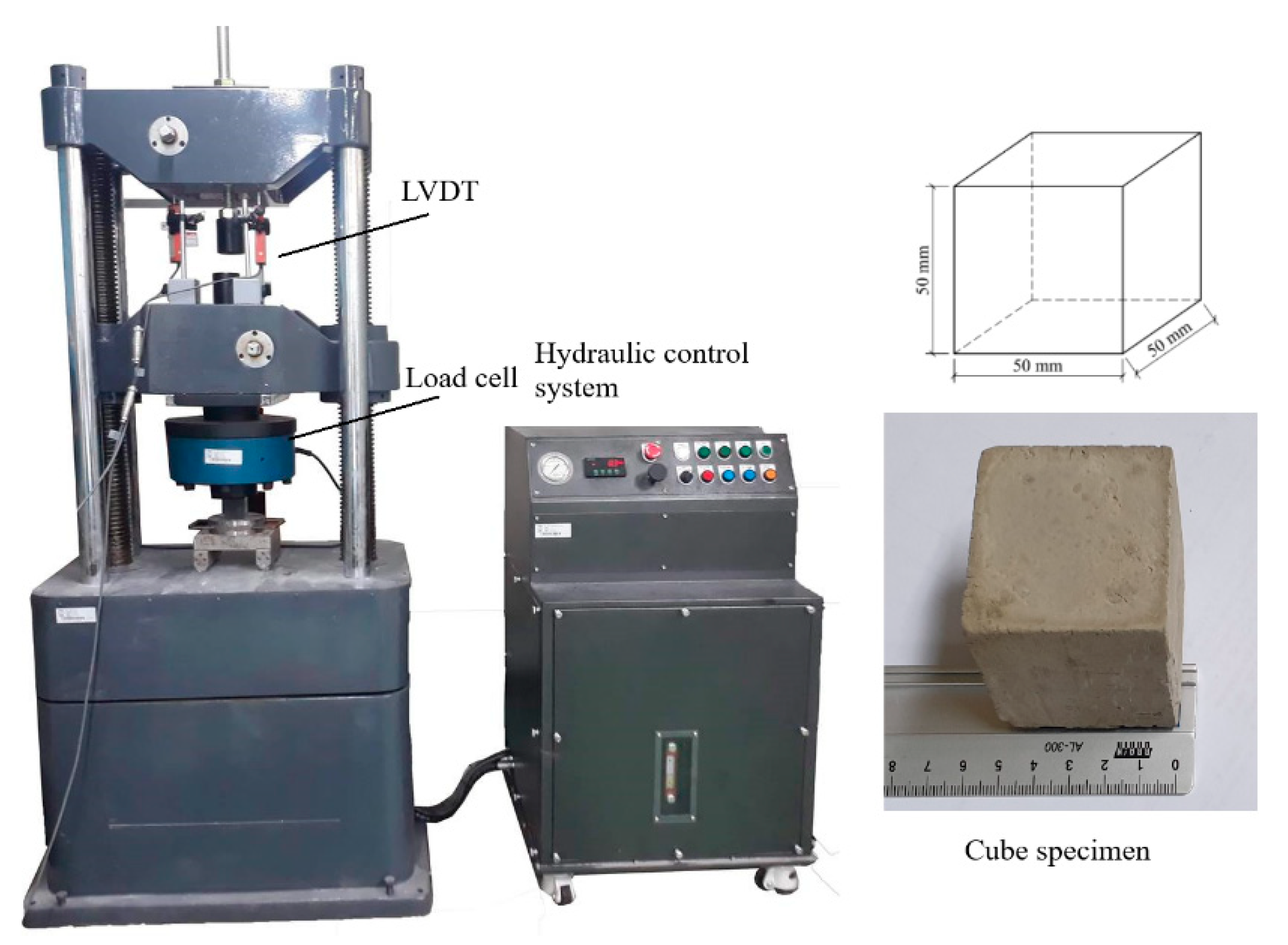

2.2. Testing Methods

3. Results and Discussion

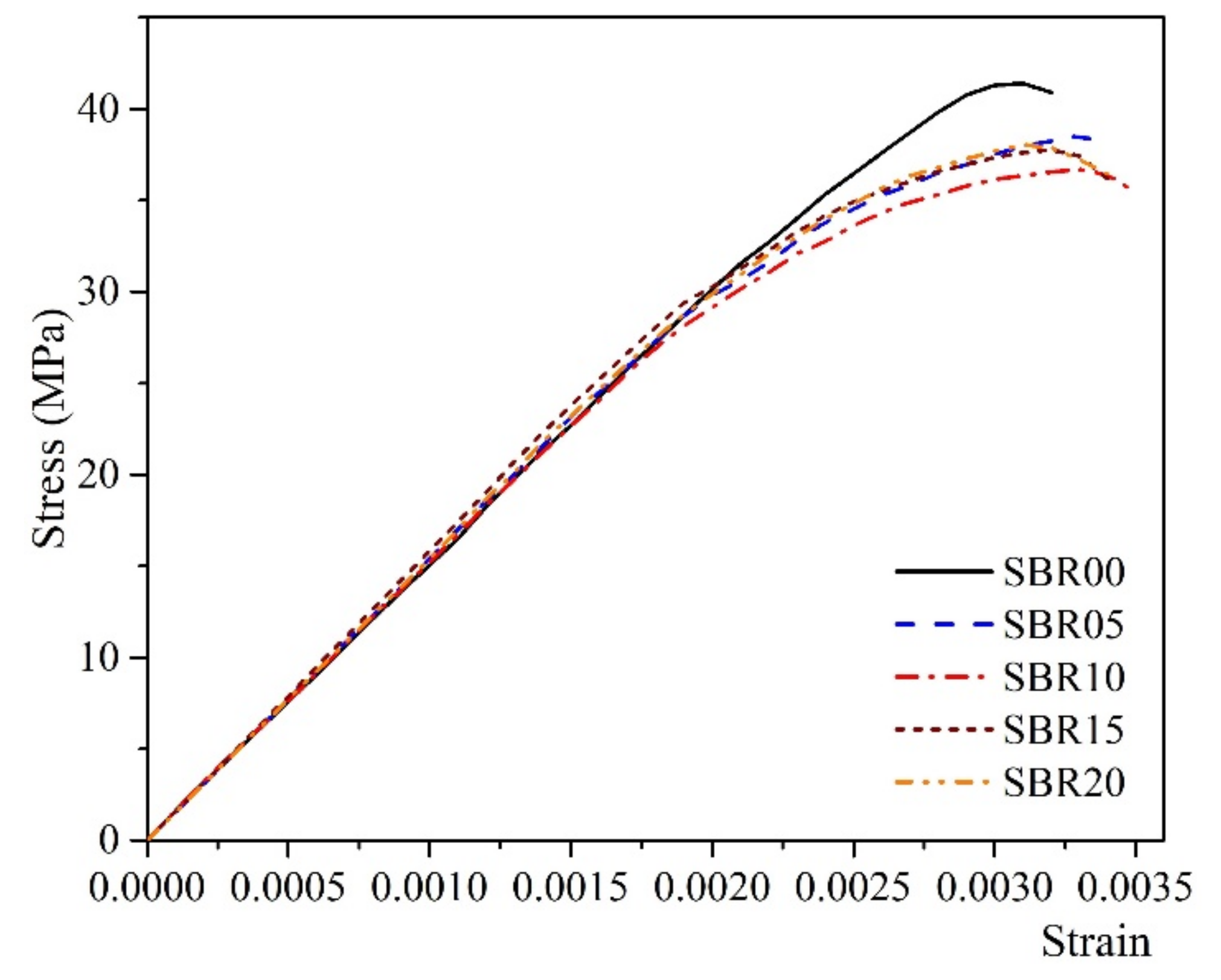

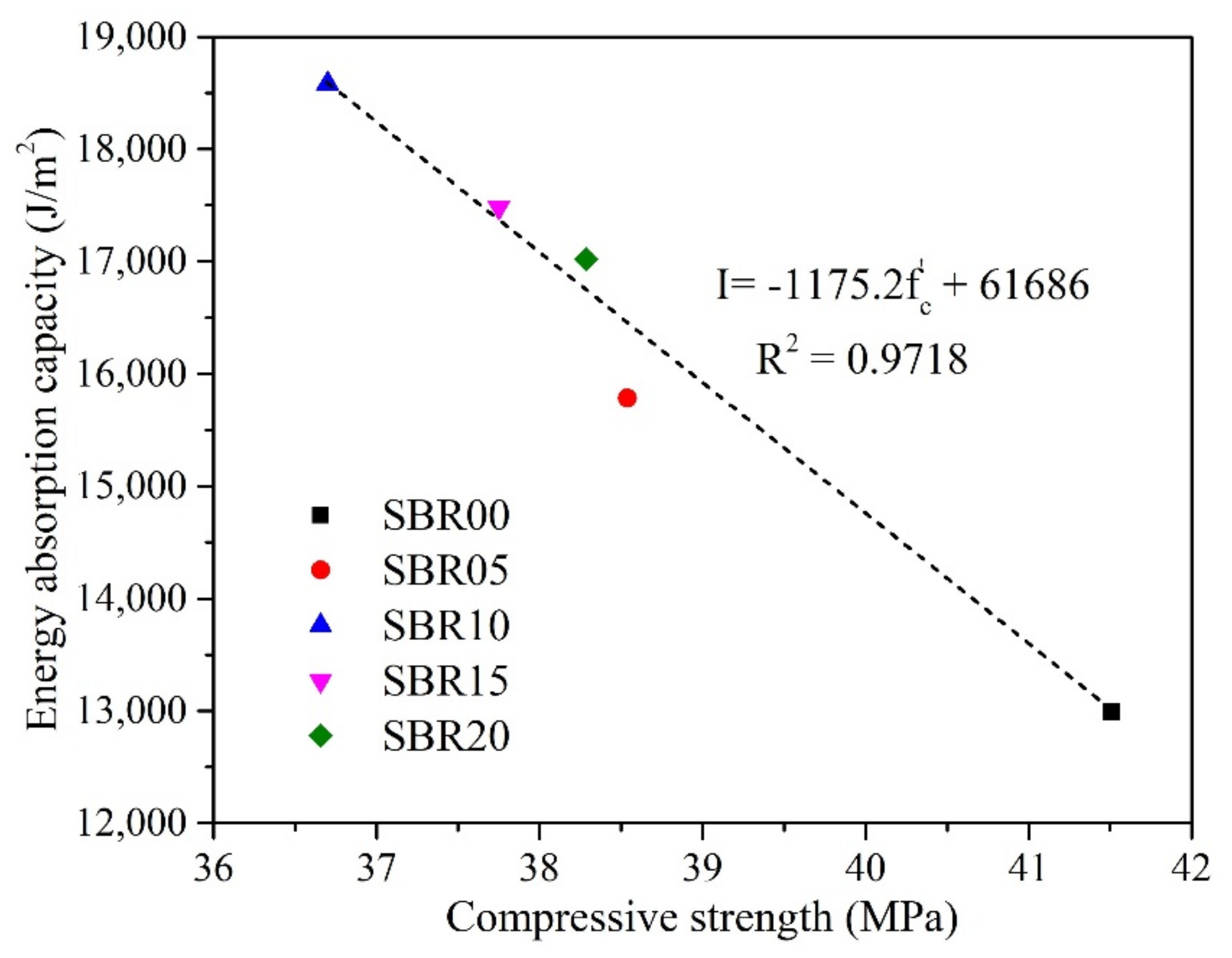

3.1. Compressive Strength

3.2. Impact Resistance

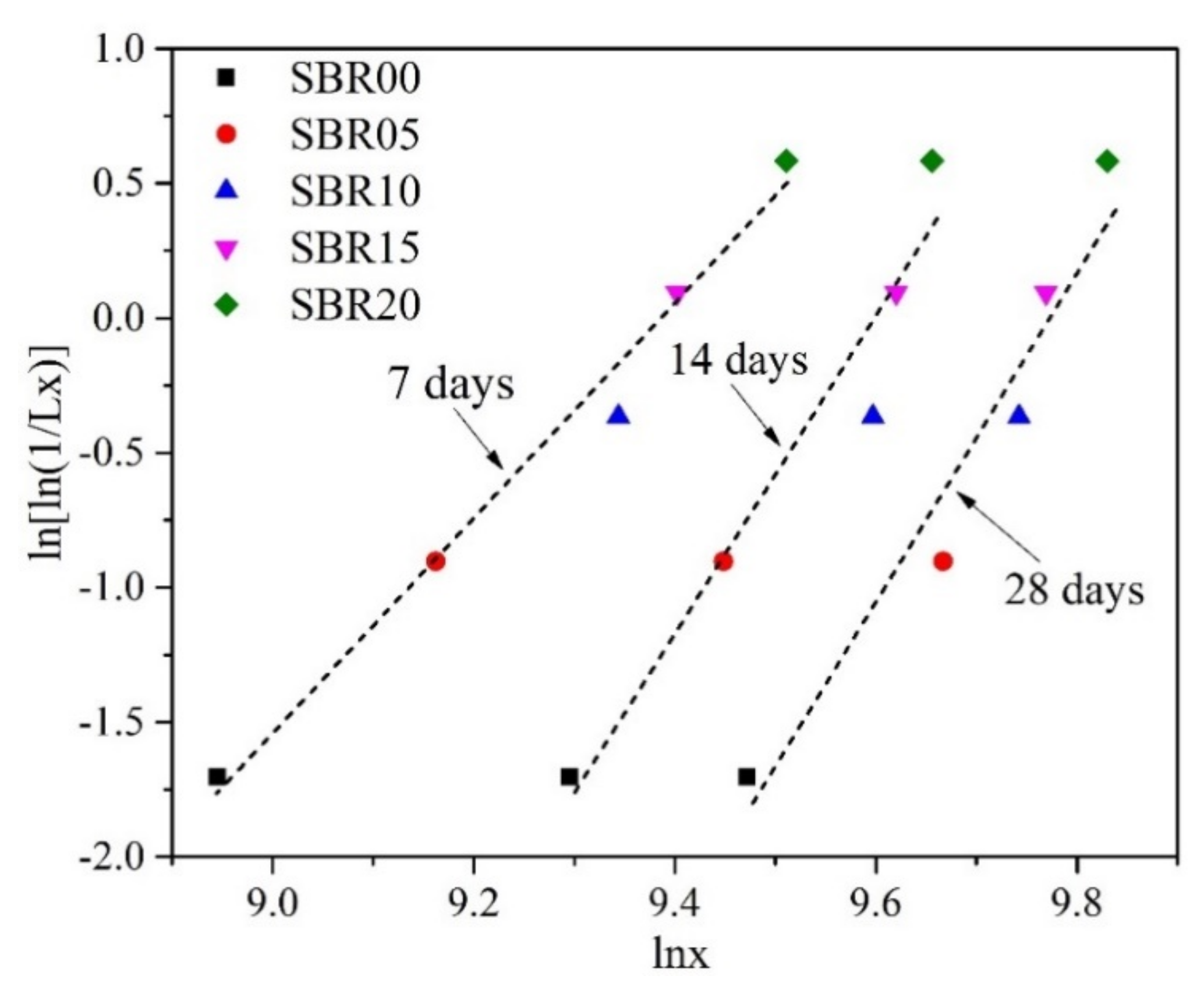

3.3. Weibull Distribution Analysis of the Charpy Impact Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Neville, A.M. Properties of Concrete, 5th ed.; Prentice Hall: Hoboken, NJ, USA, 2005. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw-Hill Education: New York, NY, USA, 2006. [Google Scholar]

- Yang, J.; Peng, G.-F.; Zhao, J.; Shui, G.-S. On the explosive spalling behavior of ultra-high performance concrete with and without coarse aggregate exposed to high temperature. Constr. Build. Mater. 2019, 226, 932–944. [Google Scholar] [CrossRef]

- Jamnam, S.; Maho, B.; Techaphatthanakon, A.; Sonoda, Y.; Yoo, D.-Y.; Sukontasukkul, P. Steel fiber reinforced concrete panels subjected to impact projectiles with different caliber sizes and muzzle energies. Case Stud. Constr. Mater. 2020, 13, e00360. [Google Scholar] [CrossRef]

- Nataraja, M.; Dhang, N.; Gupta, A. Statistical variations in impact resistance of steel fiber-reinforced concrete subjected to drop weight test. Cem. Concr. Res. 1999, 29, 989–995. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Weinberg, K. A review on split Hopkinson bar experiments on the dynamic characterisation of concrete. Constr. Build. Mater. 2018, 190, 1264–1283. [Google Scholar] [CrossRef]

- Francois, D.; Pineau, A. From Charpy to Present Impact Testing, 1st ed.; Elsevier Science: Amsterdam, The Netherlands, 2002; Volume 30. [Google Scholar]

- ISO 148-1:2016. Metallic Materials—Charpy Pendulum Impact Test; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- ASTM E23-18. Standard Test Methods for Notched Bar Impact Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- ISO 179-1:2010. Plastics—Determination of Charpy Impact Properties; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- ASTM D6110-18. Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Pereira, A.C.; Monteiro, S.N.; de Assis, F.S.; Margem, F.M.; da Luz, F.S.; Braga, F.D.O. Charpy impact tenacity of epoxy matrix composites reinforced with aligned jute fibers. J. Mater. Res. Technol. 2017, 6, 312–316. [Google Scholar] [CrossRef]

- Macke, T.; Quenisset, J.; Neuilly, D.; Rocher, J.; Naslain, R. A comparative study of the impact behavior of ceramic matrix composites. Compos. Sci. Technol. 1990, 37, 267–278. [Google Scholar] [CrossRef]

- Tanks, J.; Sharp, S.; Harris, D. Charpy impact testing to assess the quality and durability of unidirectional CFRP rods. Polym. Test. 2016, 51, 63–68. [Google Scholar] [CrossRef]

- Thomas, R.J.; Sorensen, A.D. Charpy Impact Test Methods for Cementitious Composites: Review and Commentary. J. Test. Eval. 2018, 46, 2422–2430. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Thermal and mechanical properties of hemp fabric-reinforced nanoclay–cement nanocomposites. J. Mater. Sci. 2014, 49, 1684–1694. [Google Scholar] [CrossRef]

- Liu, Z.; Cui, Q.; Li, Q. Properties of GRC Modified by Emulsion. Presented at the GRCA 2015 Congress, Dubai, United Arab Emirates, 19–21 April 2015; International Glassfibre Reinforced Concrete Association: Hampton, UK, 2015; p. 14. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H. Static properties and impact resistance of a green Ultra-High Performance Hybrid Fibre Reinforced Concrete (UHPHFRC): Experiments and modeling. Constr. Build. Mater. 2014, 68, 158–171. [Google Scholar] [CrossRef]

- Cresson, L. Improved Manufacture of Ruber Road-Acting, Rubber-Flooring, Rubber-Tiling or Other Rubber-Lining. British Patent 191, 1923. [Google Scholar]

- Lefebure, V. Improvements in or Relatingto Concrete, Cements, Plasters and the Like. British Patent 217, 1924. [Google Scholar]

- Ohama, Y. Polymer-based admixtures. Cem. Concr. Compos. 1998, 20, 189–212. [Google Scholar] [CrossRef]

- Su, Z.; Bijen, J.; Larbi, J. Influence of polymer modification on the hydration of portland cement. Cem. Concr. Res. 1991, 21, 242–250. [Google Scholar] [CrossRef]

- Sakai, E.; Sugita, J. Composite mechanism of polymer modified cement. Cem. Concr. Res. 1995, 25, 127–135. [Google Scholar] [CrossRef]

- Cong-Sheng, J.; Tao, W.; Qing-Jun, D.; Shao-Long, H.; Fa-Zhou, W.; Jian, G.; Shu-Guang, H. Influence of polymer addition on performance and mechanical properties of lightweight aggregate concrete. Wuhan Univ. J. Nat. Sci. 2004, 9, 348–352. [Google Scholar] [CrossRef]

- Xu, F.; Zhou, M.; Chen, J.; Ruan, S. Mechanical performance evaluation of polyester fiber and SBR latex compound-modified cement concrete road overlay material. Constr. Build. Mater. 2014, 63, 142–149. [Google Scholar] [CrossRef]

- Wang, R.; Li, X.-G.; Wang, P.-M. Influence of polymer on cement hydration in SBR-modified cement pastes. Cem. Concr. Res. 2006, 36, 1744–1751. [Google Scholar] [CrossRef]

- Diab, A.M.; ElYamany, H.E.; Ali, A.H. Experimental investigation of the effect of latex solid/water ratio on latex modified co-matrix mechanical properties. Alex. Eng. J. 2013, 52, 83–98. [Google Scholar] [CrossRef]

- Qu, X.; Zhao, X. Influence of SBR latex and HPMC on the cement hydration at early age. Case Stud. Constr. Mater. 2017, 6, 213–218. [Google Scholar] [CrossRef]

- Barluenga, G.; Hernández-Olivares, F. SBR latex modified mortar rheology and mechanical behaviour. Cem. Concr. Res. 2004, 34, 527–535. [Google Scholar] [CrossRef]

- Sun, K.; Wang, S.; Zeng, L.; Peng, X. Effect of styrene-butadiene rubber latex on the rheological behavior and pore structure of cement paste. Compos. Part B Eng. 2019, 163, 282–289. [Google Scholar] [CrossRef]

- Wang, R.; Wang, P.-M.; Li, X.-G. Physical and mechanical properties of styrene–butadiene rubber emulsion modified cement mortars. Cem. Concr. Res. 2005, 35, 900–906. [Google Scholar] [CrossRef]

- Wang, R.; Lackner, R.; Wang, P.-M. Effect of Styrene-Butadiene Rubber Latex on Mechanical Properties of Cementitious Materials Highlighted by Means of Nanoindentation. Strain 2011, 47, 117–126. [Google Scholar] [CrossRef]

- ASTM C150/C150M-20. Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM C109/C109M-20b. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens); ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Timoshenko, S.P.; Gere, J.M. Mechanics of Materials; PWS-Kent Publishing: Boston, MA, USA, 1984. [Google Scholar]

- Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 2015, 83, 76–87. [Google Scholar] [CrossRef]

- Chen, X.-Y.; Ding, Y.-N.; Azevedo, C.M. Combined effect of steel fibres and steel rebars on impact resistance of high performance concrete. J. Central South Univ. 2011, 18, 1677–1684. [Google Scholar] [CrossRef]

- Nowak, A.S.; Collins, K.S. Reliability of Structure; Thomas Casson, McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

| TSC (%) | pH | Sp.gr (Kg/m2) | Viscosity (cps) | Average Particle Size (Å) | Tg (°C) | MFT (°C) |

|---|---|---|---|---|---|---|

| 47.0 | 9–11 | 1090 | <500 | 1500 | −1 | −1 |

| Name | SBR00 | SBR05 | SBR10 | SBR15 | SBR20 |

|---|---|---|---|---|---|

| Cement | 1 | 1 | 1 | 1 | 1 |

| SBR polymer (solid content) | 0 | 0.05 | 0.1 | 0.15 | 0.2 |

| Water | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Name | SBR00 | SBR05 | SBR10 | SBR15 | SBR20 |

|---|---|---|---|---|---|

| Compressive strength (MPa) | 41.51 | 38.54 | 36.7 | 37.75 | 38.29 |

| (3.191) | (3.077) | (1.801) | (1.005) | (1.743) | |

| Toughness (J/m3) | 74,725.0 | 79,970.2 | 81,586.6 | 80,797.6 | 80,138.7 |

| Energy absorption capacity (J/m2) | 12,991.5 | 14,848.1 | 18,582 | 17,483.1 | 17,021.5 |

| (778.1) | (982.1) | (792) | (956.7) | (816.3) |

| Curing Time (days) | Regression Coefficient (k) | Regression Coefficient (klnu) | Correlation Coefficient (R2) |

|---|---|---|---|

| 7 | 3.951 | 37.092 | 0.984 |

| 14 | 5.724 | 54.971 | 0.938 |

| 28 | 6.224 | 60.805 | 0.942 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, T.N.M.; Kim, J.J. Energy Absorption Capacity of SBR Latex-Modified Ordinary Portland Cement by Charpy Impact Test. Materials 2021, 14, 2544. https://doi.org/10.3390/ma14102544

Nguyen TNM, Kim JJ. Energy Absorption Capacity of SBR Latex-Modified Ordinary Portland Cement by Charpy Impact Test. Materials. 2021; 14(10):2544. https://doi.org/10.3390/ma14102544

Chicago/Turabian StyleNguyen, Tri N. M., and Jung J. Kim. 2021. "Energy Absorption Capacity of SBR Latex-Modified Ordinary Portland Cement by Charpy Impact Test" Materials 14, no. 10: 2544. https://doi.org/10.3390/ma14102544

APA StyleNguyen, T. N. M., & Kim, J. J. (2021). Energy Absorption Capacity of SBR Latex-Modified Ordinary Portland Cement by Charpy Impact Test. Materials, 14(10), 2544. https://doi.org/10.3390/ma14102544