Assessment of AlN/Mg–8Al Composites Reinforced with In Situ and/or Ex Situ AlN Particles

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, J.; Zhe, C.; Zhang, F.; Gang, J.; Wang, M.; Yu, M. Simultaneously increasing strength and ductility of nanoparticles reinforced Al composites via accumulative orthogonal extrusion process. Mater. Res. Lett. 2018, 6, 406–412. [Google Scholar] [CrossRef]

- Berndt, N.; Frint, P.; Bohme, M.; Wagner, M.F.X. Microstructure and mechanical properties of an AA6060 aluminum alloy after cold and warm extrusion. Mater. Sci. Eng. A 2017, 707, 717–724. [Google Scholar] [CrossRef]

- Sokoluk, M.; Cao, C.Z.; Pan, S.H.; Li, X.C. Nanoparticle–enabled phase control for arc welding of unweldable aluminum alloy 7075. Nat. Commun. 2019, 10, 98. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Zhao, N.; Shi, C.; Liu, E.; Fang, H.; Ma, L. In–situ synthesis of graphene decorated with nickel nanoparticles for fabricating reinforced 6061Al matrix composites. Mater. Sci. Eng. A 2017, 699, 185–193. [Google Scholar] [CrossRef]

- Bian, Y.H.; Gao, T.; Li, Z.Q.; Sun, Q.Q.; Ma, X.; Liu, X.F. In–situ synthesis of an Al composite reinforced with multi–scale Al12Mo, (Al,Zr,Si) and Al2O3 particles through a multi–stage reaction. Mater. Sci. Eng. A 2019, 762, 138069. [Google Scholar] [CrossRef]

- Wu, Z.; Curtin, W.A. The origins of high hardening and low ductility in magnesium. Nature 2015, 526, 62–67. [Google Scholar] [CrossRef]

- Hirsch, J.; Al–Samman, T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Mater. 2013, 61, 818–843. [Google Scholar] [CrossRef]

- Shen, M.J.; Ying, T.; Chen, F.Y.; Hou, J.M. Effects of hybrid SiCp on the microstructures and mechanical properties of AZ31B alloy. Int. J. Met. 2017, 11, 266–273. [Google Scholar] [CrossRef]

- Jiang, Q.C.; Li, X.L.; Wang, H.Y. Fabrication of TiC particulate reinforced magnesium matrix composites. Scr. Mater. 2003, 48, 713–717. [Google Scholar] [CrossRef]

- Meenashisundaram, G.K.; Seetharaman, S.; Gupta, M. Enhancing overall tensile and compressive response of pure Mg using nano–TiB2 particulates. Mater. Charact. 2014, 94, 178–188. [Google Scholar] [CrossRef]

- Gao, T.; Bian, Y.H.; Li, Z.Q.; Xu, Q.F.; Yang, H.B.; Zhao, K. Synthesis of a (ZrAl3+AlN)/Al composite and the influence of particles content and element Cu on the microstructure and mechanical properties. J. Alloys Compd. 2019, 791, 730–738. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, Y.F.; Zhao, X.J.; Gao, T.; Chen, H.W.; Liu, X.F. Influence mechanisms of Cu or Fe on the microstructures and tensile properties at 350 °C of network AlNp reinforced Al composites. J. Alloys Compd. 2018, 740, 452–460. [Google Scholar] [CrossRef]

- Cao, G.; Choi, H.; Oportus, J.; Konishi, H.; Li, X. Study on tensile properties and microstructure of cast AZ91D/AlN nanocomposites. Mater. Sci. Eng. A 2008, 494, 127–131. [Google Scholar] [CrossRef]

- Chen, J.; Bao, C.G.; Chen, W.H.; Zhang, L.; Liu, J.L. Mechanical properties and fracture behavior of Mg–Al/AlN composite with different particle contents. J. Mater. Sci. Technol. 2017, 33, 668–674. [Google Scholar] [CrossRef]

- Ye, H.Z.; Liu, X.Y.; Luan, B. In situ synthesis of AlN in Mg–Al alloys by liquid nitridation. Mater. Process. Technol. 2005, 166, 79–85. [Google Scholar] [CrossRef]

- Yang, C.L.; Zhang, B.; Zhao, D.C.; Lu, H.B.; Zhai, T.G.; Liu, F. Microstructure and mechanical properties of AlN particles in situ reinforced Mg matrix composites. Mater. Sci. Eng. A 2016, 674, 158–163. [Google Scholar] [CrossRef]

- Sreeja Kumari, S.S.; Pillai, U.T.S.; Pai, B.C. Synthesis and characterization of in situ Al–AlN composite by nitrogen gas bubbling method. J. Alloys Compd. 2011, 509, 2503–2509. [Google Scholar] [CrossRef]

- Gao, T.; Li, Z.Q.; Bian, Y.H.; Xu, Q.F.; Hu, K.Q.; Han, M.X. Dispersing nano–AlN particles cluster by designing Al–Si–AlN/Mg diffusion couples and the preparation of AlN/Mg–Al composite. Mater. Sci. Eng. A 2019, 766, 138347. [Google Scholar] [CrossRef]

- Li, Z.Q.; Gao, T.; Xu, Q.F.; Yang, H.B.; Han, M.X.; Liu, X.F. Microstructure and mechanical properties of an AlN/Mg–Al composite synthesized by Al–AlN master alloy. Int. J. Met. 2019, 13, 384–391. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, Y.F.; Tian, W.J.; Qian, Z.; Chen, H.W.; Wu, Y.Y. A novel Al matrix composite reinforced by nano–AlNp network. Sci. Rep. 2016, 6, 34919. [Google Scholar] [CrossRef]

- Cheng, L.Z.; Zhang, Y.H.; Ren, S.Z.; Wang, X.Z.; Shi, W. Physical Chemistry, 2nd ed.; Shanghai Science and Technology Press: Shanghai, China, 2005. [Google Scholar]

- Bian, Y.H.; Gao, T.; Liu, L.Y.; Liu, G.L.; Liu, X.F. Liquid–solid reaction mechanism in Al–ZrO2(–B2O3) system and the preparation of (α–Al2O3+ZrB2/ZrAl3)/Al composites. J. Alloys Compd. 2020, 842, 155926. [Google Scholar] [CrossRef]

- Zhao, Y.F.; Qian, Z.; Ma, X.; Chen, H.W.; Gao, T.; Wu, Y.Y. Unveiling the semi–coherent interface with definite orientation relationships between reinforcements and matrix in novel Al3BC/Al composites. ACS Appl. Mater. Inter. 2016, 8, 28194–28201. [Google Scholar] [CrossRef] [PubMed]

- Dalen, M.E.V.; Dunand, D.C.; Seidman, D.N. Effects of Ti additions on the nanostructure and creep properties of precipitation–strengthened Al–Sc alloys. Acta Mater. 2005, 53, 4225–4235. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids 1963, 11, 127–140. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Peng, H.X. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog. Mater. Sci. 2015, 71, 93–168. [Google Scholar] [CrossRef]

- Zhang, X.M.; Peng, Z.K.; Chen, J.M.; Deng, Y.L. Heat–resistant magnesium alloys and their development. Chin. J. Nonferrous Met. 2004, 14, 1443–1450. [Google Scholar]

- Mordike, B.L.; Stulíková, I.; Smola, B. Mechanisms of creep deformation in Mg–Sc–based alloys. Metall. Mater. Trans. A 2005, 36, 1729–1736. [Google Scholar] [CrossRef]

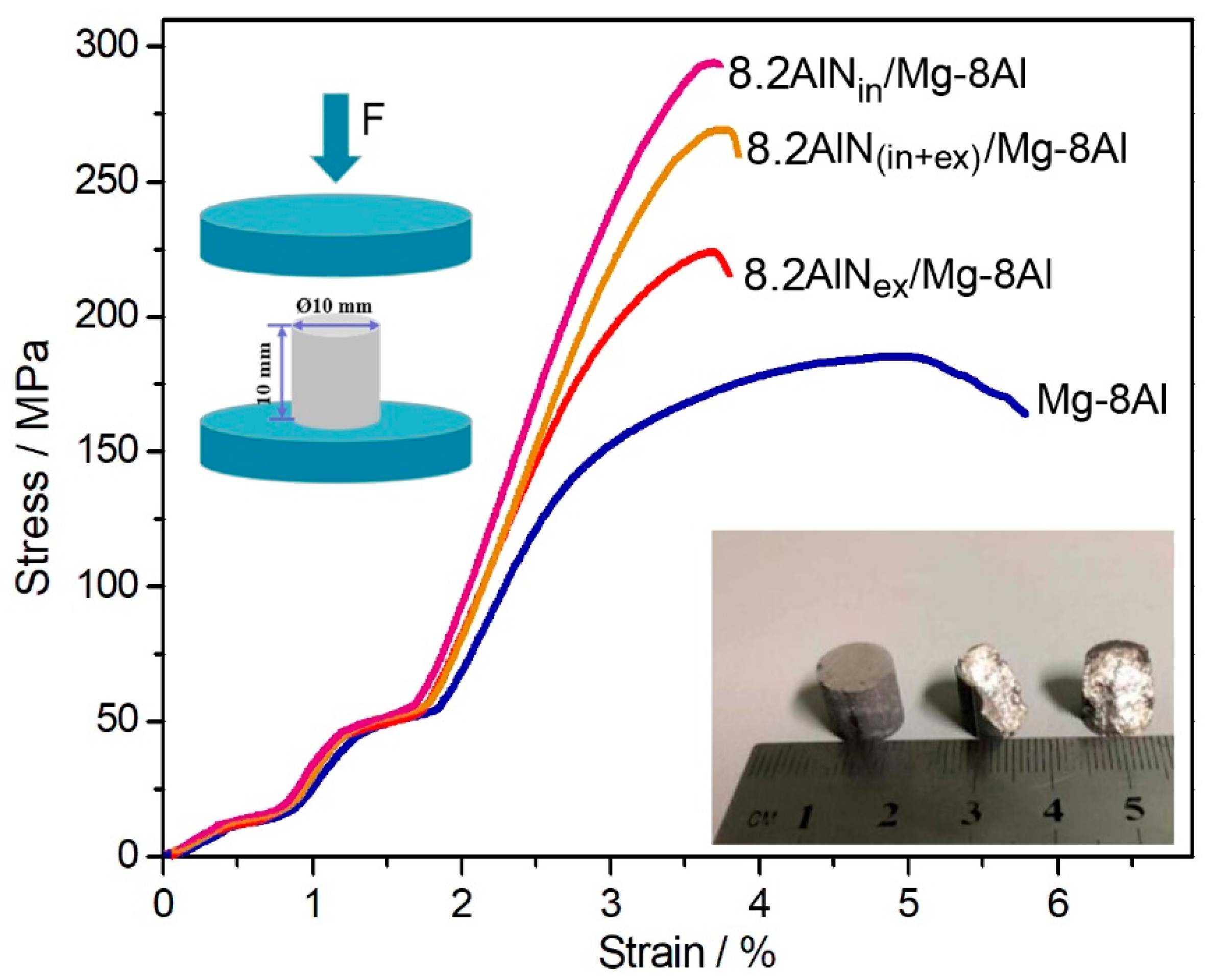

| Alloys | Density (g/cm3) | Hardness (HBW) | Compressive Strength (MPa) |

|---|---|---|---|

| Mg–8Al | 1.747 | 58.1 ± 2.1 | 181 ± 3 |

| 8.2AlNin/Mg–8Al | 1.746 | 89.5 ±2.3 | 295 ± 5 |

| 8.2AlN(in+ex)/Mg–8Al | 1.743 | 80.3 ± 3.8 | 280 ± 7 |

| 8.2AlNex/Mg–8Al | 1.734 | 70.6 ± 1.5 | 225 ± 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, T.; Li, Z.; Hu, K.; Bian, Y.; Liu, X. Assessment of AlN/Mg–8Al Composites Reinforced with In Situ and/or Ex Situ AlN Particles. Materials 2021, 14, 52. https://doi.org/10.3390/ma14010052

Gao T, Li Z, Hu K, Bian Y, Liu X. Assessment of AlN/Mg–8Al Composites Reinforced with In Situ and/or Ex Situ AlN Particles. Materials. 2021; 14(1):52. https://doi.org/10.3390/ma14010052

Chicago/Turabian StyleGao, Tong, Zengqiang Li, Kaiqi Hu, Yihan Bian, and Xiangfa Liu. 2021. "Assessment of AlN/Mg–8Al Composites Reinforced with In Situ and/or Ex Situ AlN Particles" Materials 14, no. 1: 52. https://doi.org/10.3390/ma14010052

APA StyleGao, T., Li, Z., Hu, K., Bian, Y., & Liu, X. (2021). Assessment of AlN/Mg–8Al Composites Reinforced with In Situ and/or Ex Situ AlN Particles. Materials, 14(1), 52. https://doi.org/10.3390/ma14010052