Structural Characterization of Al65Cu20Fe15 Melt-Spun Alloy by X-ray, Neutron Diffraction, High-Resolution Electron Microscopy and Mössbauer Spectroscopy

Abstract

1. Introduction

2. Materials and Methods

3. Results

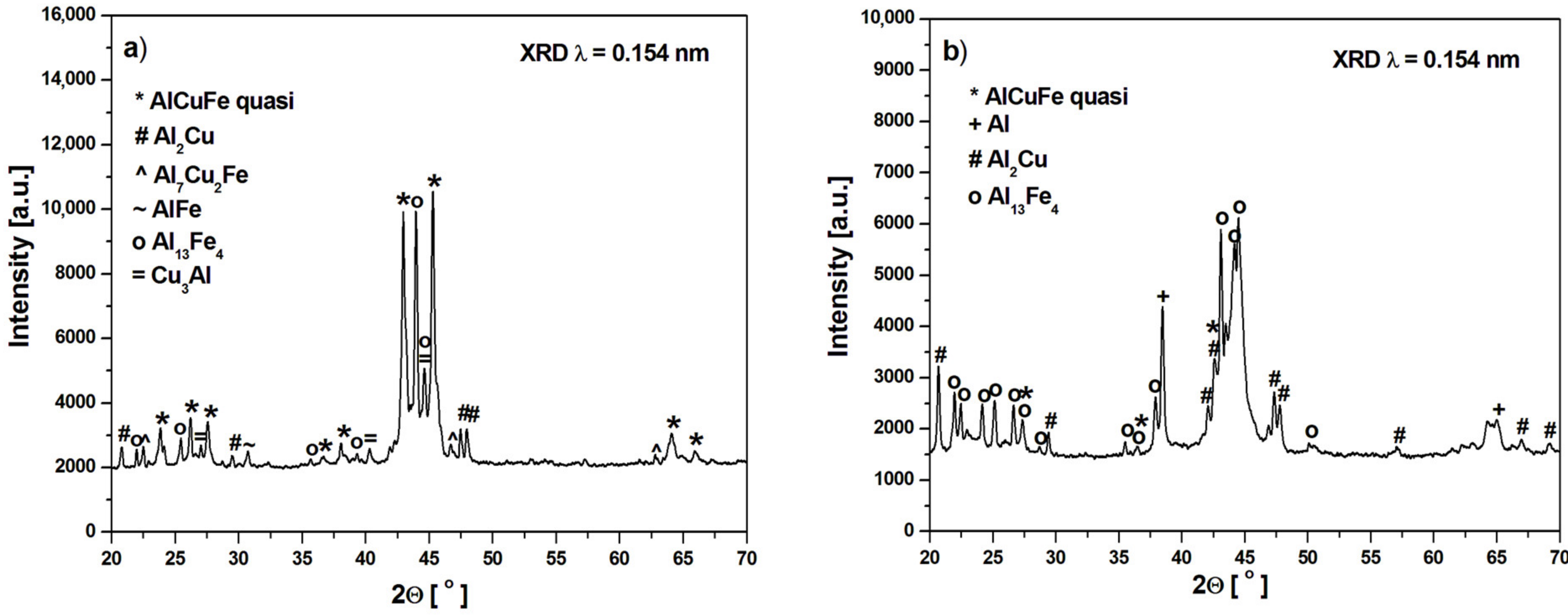

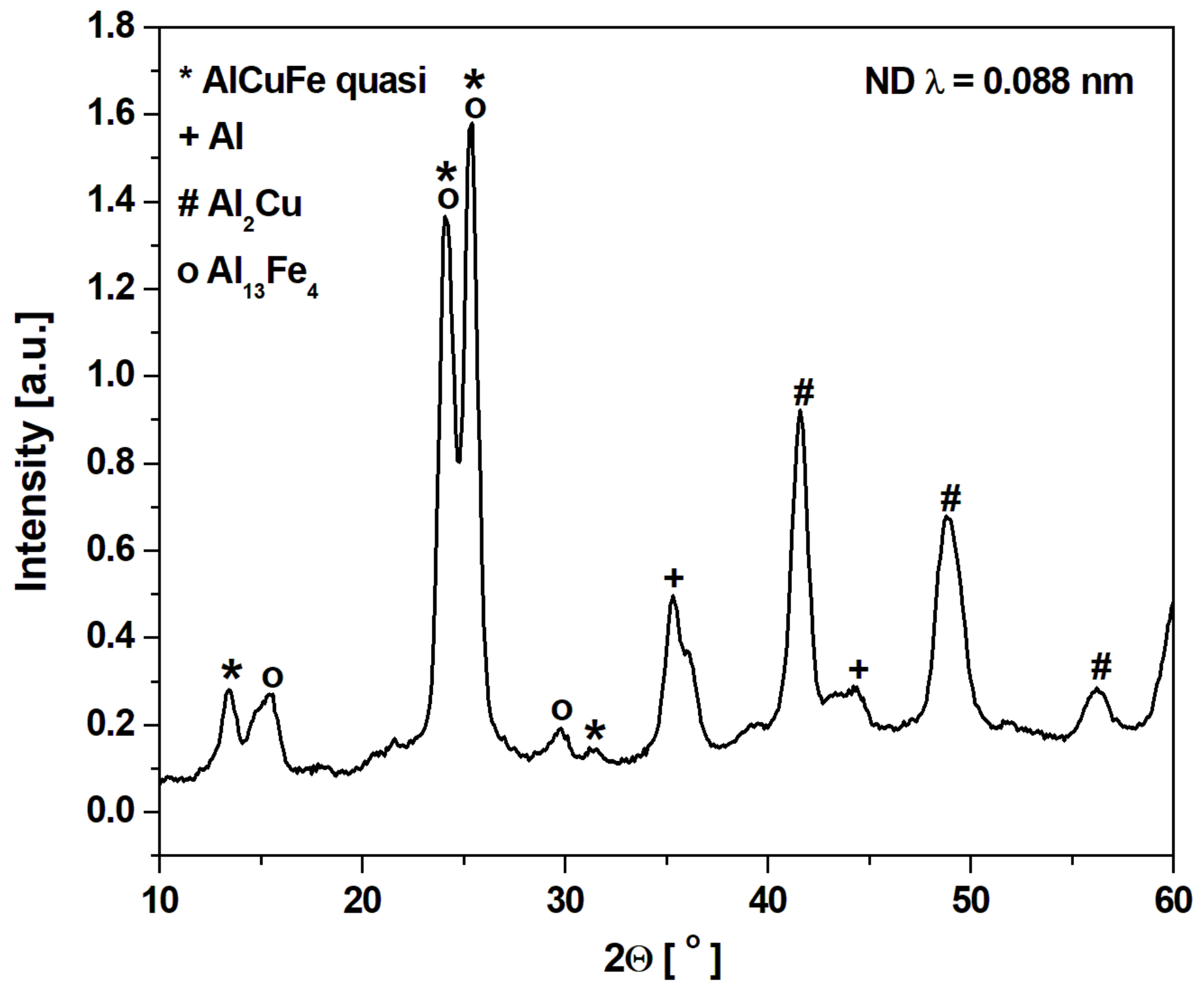

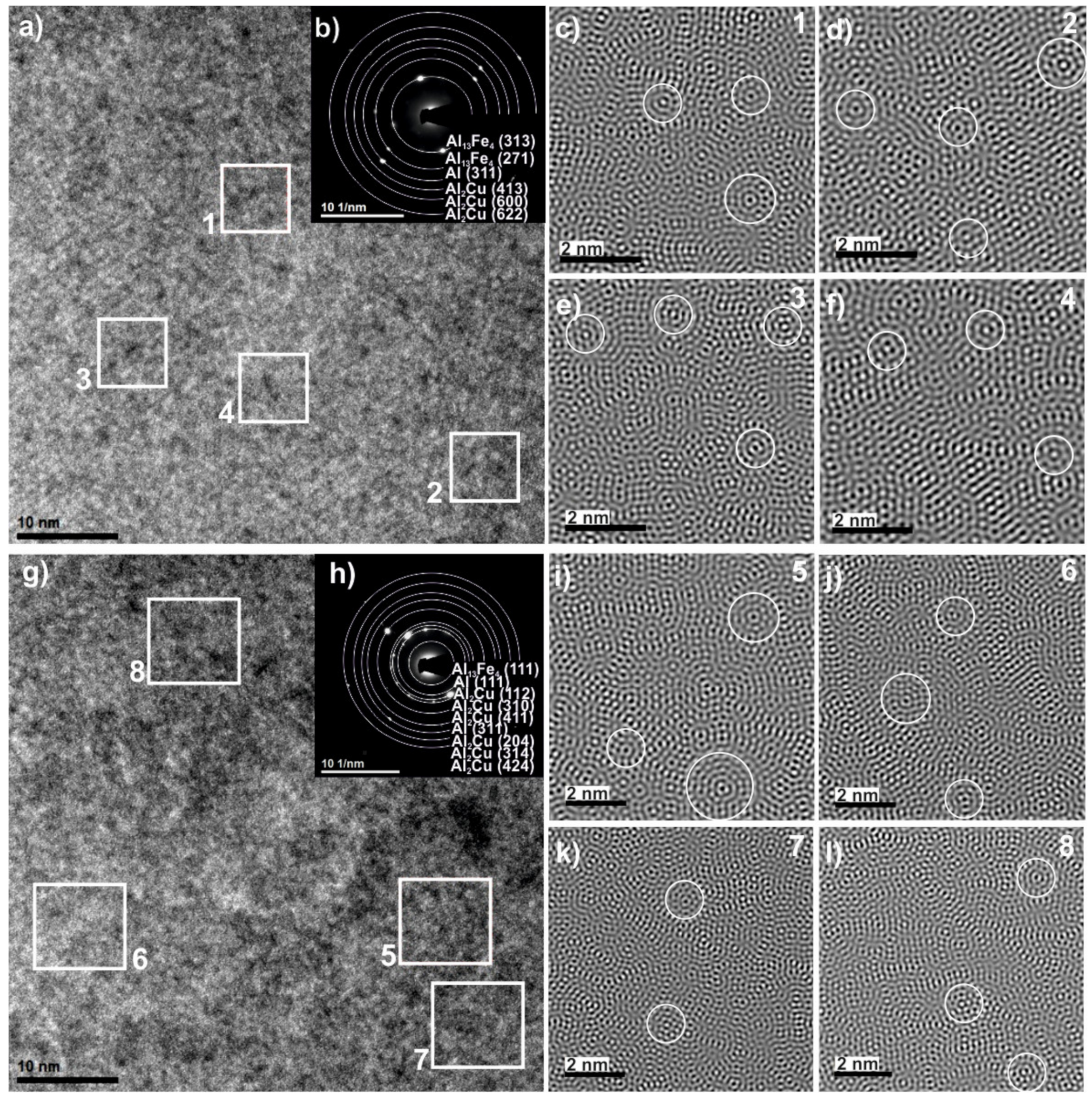

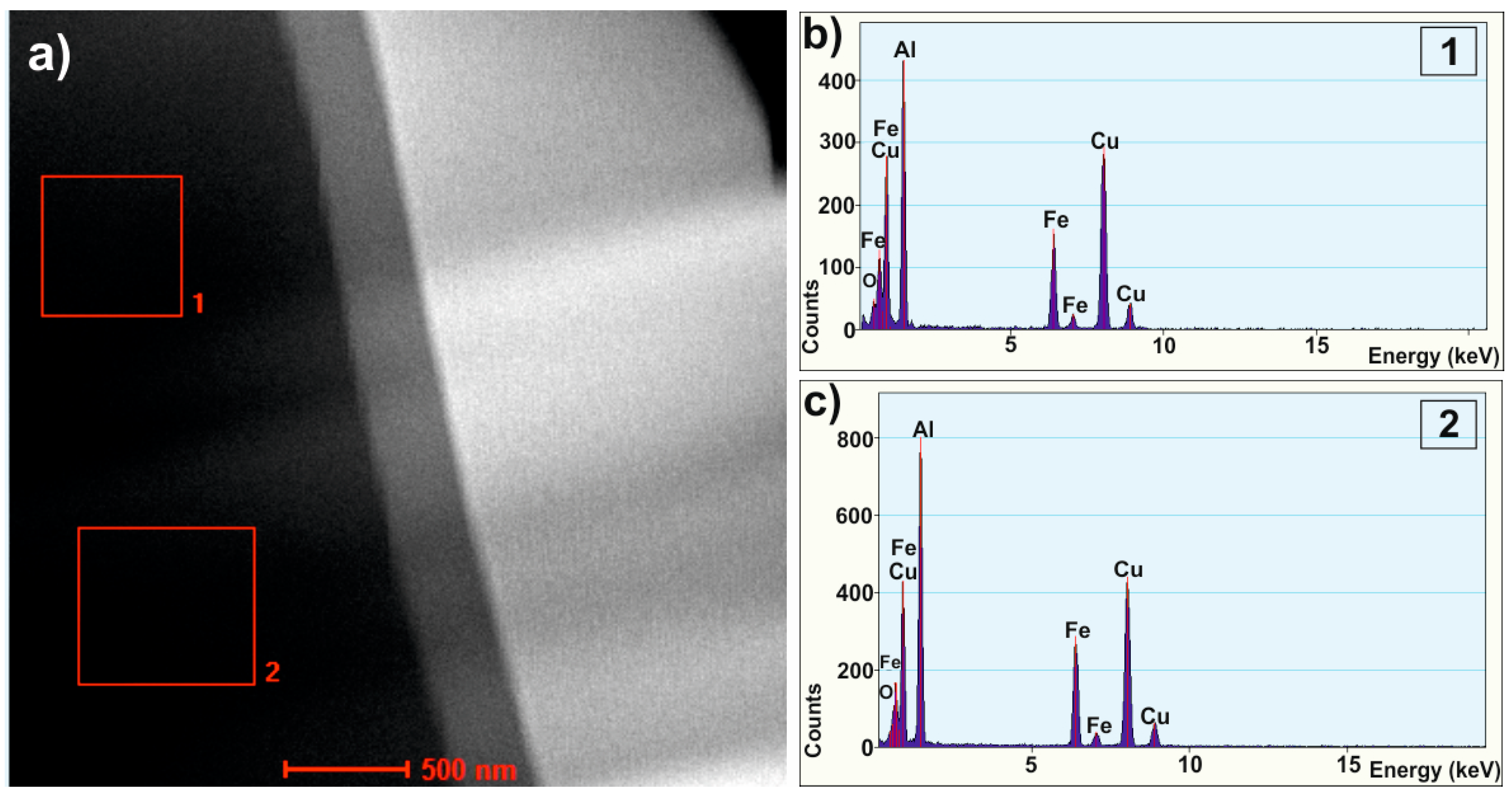

3.1. Structure Analysis

3.2. Corrosion Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- El-Eskandarany, M.S. Mechanical Alloying (Second Edition); William Andrew Publishing: Norwich, NY, USA, 2015; pp. 1–12. [Google Scholar] [CrossRef]

- Inoue, A.; Kimura, H. Fabrications and mechanical properties of bulk amorphous, nanocrystalline, nanoquasicrystalline alloys in aluminum-based system. J. Light Met. 2001, 1, 31–41. [Google Scholar] [CrossRef]

- Lavernia, E.J.; Srivatsan, T.S. The rapid solidification processing of materials: Science, principles, technology, advances, and applications. J. Mater. Sci. 2010, 45, 287–325. [Google Scholar] [CrossRef]

- Lavernia, E.J.; Ayers, J.D.; Srivatsan, T.S. Rapid solidification processing with specific application to aluminium alloys. Int. Mater. Rev. 1992, 37, 1–44. [Google Scholar] [CrossRef]

- Avar, B.; Gogebakan, M.; Yılmaz, F. Characterization of the icosahedral quasicrystalline phase in rapidly solidified Al-Cu-Fe alloys. Z. Krist. 2008, 223, 731–734. [Google Scholar] [CrossRef]

- Ishimasa, T. Mysteries of icosahedral quasicrystals: How are the atoms arranged? IUCrJ 2016, 3, 230–231. [Google Scholar] [CrossRef]

- Pedrazzini, S.; Galano, M.; Audebert, F.; Siegkas, P.; Gerlach, R.; Tagarielli, V.L.; Smith, G.D.W. High strain rate behaviour of nano-quasicrystalline Al93Fe3Cr2Ti2 alloy and composites. Mater. Sci. Eng. A 2019, 764, 138201. [Google Scholar] [CrossRef]

- Shadangi, Y.; Shivam, V.; Singh, M.K.; Chattopadhyay, K.; Basu, J.; Mukhopadhyay, N.K. Synthesis and characterization of Sn reinforced Al-Cu-Fe quasicrystalline matrix nanocomposite by mechanical milling. J. Alloys Compd. 2019, 797, 1280–1287. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Q.; Wang, Y.; Qiang, J.; Dong, C. Composition rule for Al-transition metal binary quasicrystals. Philos. Mag. 2010, 90, 3935–3946. [Google Scholar] [CrossRef]

- Leskovar, B.; Šturm, S.; Samardžija, Z.; Ambrožič, B.; Markoli, B.; Naglič, I. Epitaxial growth of a metastable icosahedral quasicrystal on a stable icosahedral quasicrystal substrate. Scr. Mater. 2018, 150, 92–95. [Google Scholar] [CrossRef]

- Salimon, A.I.; Shevchukov, A.P.; Stepashkin, A.A.; Tcherdyntsev, V.V.; Olifirov, L.K.; Kaloshkin, S.C. Mechanical alloying as a solid state route for fabrication of Al-Cu-M(=Fe, Cr) quasicrystalline phases. J. Alloys Compd. 2017, 707, 315–320. [Google Scholar] [CrossRef]

- Gogebakan, M.; Avar, B.; Tarakci, M. Microstructures and mechanical properties of conventionally solidified Al63Cu25Fe12 alloy. J. Alloys Compd. 2011, 509, 316–319. [Google Scholar] [CrossRef]

- Stan-Głowińska, K.; Rogal, Ł.; Góral, A.; Wierzbicka-Miernik, A.; Wojewoda-Budka, J.; Schell, N.; Lityńska-Dobrzyńska, L. Formation of a quasicrystalline phase in Al-Mn base alloys cast at intermediate cooling rates. J. Mater. Sci. 2017, 52, 7794–7807. [Google Scholar] [CrossRef]

- Téllez-Vázquez, J.O.; Patiño-Carachure, C.; Bedolla-Jacuinde, A.; García-De León, E.; Pérez, R.; Rosas, G. Phase Stability of the Al-Cu-Co Decagonal Phase Under Conventional Solidification. Mater. Res. Soc. Symp. Proc. 2010, 1242, 29–34. [Google Scholar] [CrossRef]

- Lityńska-Dobrzyńska, L.; Dutkiewicz, J.; Stan-Głowińska, K.; Dembinski, L.; Coddet, C.; Ochin, P. Characterization of Rapidly Solidified Al65Cu20Fe15 Alloy in Form of Powder or Ribbon. Acta Phys. Pol. A 2014, 126, 512–515. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E. Microstructure, fabrication and properties of quasicrystalline Al-Cu-Fe alloys: A review. J. Alloys Compd. 2004, 363, 154–178. [Google Scholar] [CrossRef]

- Lityńska-Dobrzyńska, L.; Stan-Głowińska, K.; Wójcik, A.; Duraczyńska, D.; Serwicka, E.M. Microstructure and Catalytic Activity of Melt Spun Al-Cu-Fe Ribbons. Mater. Sci. Forum 2020, 985, 109–114. [Google Scholar] [CrossRef]

- Calvayrac, Y.; Quivy, A.; Bessiere, M.; Lefebvre, S.; Cornier-Quiquandon, M.; Gratias, D. Icosahedral AlCuFe alloys: Towards ideal quasicrystals. J. Phys. Paris 1990, 51, 417–431. [Google Scholar] [CrossRef]

- Tan, C.W.; Djuansjah, J.R.P.; Idris, M.H.; Ali, W.F.F. Characterisation of Al65Cu20Fe15 Quasicrystal Alloy Synthesised via In-situ Casting under Standard Room Ambient and Argon Enriched Atmosphere. Int. J. Curr. Res. Sci. Eng. Technol. 2018, 1, 280. [Google Scholar] [CrossRef]

- Li, C.; Carey, C.; Li, D.; Caputo, M.; Bouch, R.; Hampikian, H. A study on spherical particles in Al65Cu20Fe15 alloy prepared by arc melting. Mater. Charact. 2018, 140, 162–171. [Google Scholar] [CrossRef]

- Cheung, Y.L.; Chan, K.C.; Zhu, Y.H. Characterization of the icosahedral phase in as-cast quasicrystalline Al65Cu20Fe15 alloy. Mater. Charact. 2001, 47, 299–305. [Google Scholar] [CrossRef]

- Huttunen-Saarivirta, E.; Vuorinen, J. Preparation and characterisation of melt-spun Al-Cu-Fe quasicrystals. Intermetallics 2005, 13, 885–895. [Google Scholar] [CrossRef]

- Tiwari, R.S.; Yadav, T.P.; Mukhopadhyay, N.K.; Shaz, M.A.; Srivastava, O.N. Nanocrystallization and structural correlation in quasicrystalline and crystalline phases during mechanical milling. Z. Krist. 2009, 224, 26–30. [Google Scholar] [CrossRef]

- Zhou, X.Y.; He, L.; Liu, Y.H. Formation and Characterization of the Quasicrystal Films. Mater. Sci. Forum 2007, 546–549, 1699–1702. [Google Scholar] [CrossRef]

- Chien, C.L.; Lu, M. Three states of Al65Cu20Fe15: Amorphous, crystalline, and quasicrystalline. Phys. Rev. B 1992, 45, 12793–12796. [Google Scholar] [CrossRef] [PubMed]

- Sadoc, A. Local order description of an icosahedral Al-Cu-Fe quasicrystal. Philos. Mag. Lett. 1989, 60, 195–200. [Google Scholar] [CrossRef]

- Mukhopadhyay, N.K.; Ali, F.; Srivastava, V.C.; Yadav, T.P.; Sakaliyska, M.; Surreddi, K.B.; Scudino, S.; Uhlenwinkel, V.; Eckert, J. Strain-induced structural transformation of single-phase Al-Cu-Fe icosahedral quasicrystal during mechanical milling. Philos. Mag. 2011, 91, 2482–2490. [Google Scholar] [CrossRef]

- Shadangi, Y.; Sharma, S.; Shivam, V.; Basu, J.; Chattopadhyay, K.; Majumdar, B.; Mukhopadhyay, N.K. Fabrication of Al-Cu-Fe quasicrystal reinforced 6082 aluminium matrix nanocomposites through mechanical milling and spark plasma sintering. J. Alloys Compd. 2020, 828, 1–12. [Google Scholar] [CrossRef]

- Yong, X.; Chang, I.T.; Jones, I.P. Formation of a quasicrystalline phase in mechanically alloyed Al65Cu25Fe15. J. Alloys Compd. 2005, 387, 128–133. [Google Scholar] [CrossRef]

- Kaloshkin, S.D.; Tcherdyntsev, V.V.; Tomilin, I.A.; Gunderov, D.V.; Stolyarov, V.V.; Baldokhin, Y.V.; Brodova, I.G.; Shelekhov, E.V. Composed Phases and Microhardness of Aluminium-Rich Aluminium-Iron Alloys Obtained by Rapid Quenching, Mechanical Alloying and High Pressure Torsion Deformation. Mater. Trans. 2002, 43, 2031–2038. [Google Scholar] [CrossRef][Green Version]

- Shulyatev, D.A.; Chernikov, M.A.; Korovushkin, V.V.; Kozlovskaya, N.A.; Klyueva, M.V. Synthesis, X-Ray analysis, and Mössbauer investigation of Al-Cu-Fe quasicrystals. J. Surf. Investig. 2013, 7, 434–436. [Google Scholar] [CrossRef]

- Faudot, F.; Quivy, A.; Calvayrac, Y.; Gratias, D.; Harmelin, M. About the Al-Cu-Fe icosahedral phase formation. Mater. Sci. Eng. A 1991, 133, 383–387. [Google Scholar] [CrossRef]

- Biswas, K.; Chattopadhyay, K. Formation of ω-Al7Cu2Fe phase during laser processing of quasicrystal-forming Al-Cu-Fe alloy. Philos. Mag. Lett. 2008, 88, 219–230. [Google Scholar] [CrossRef]

- Nguyen, H.H.; Nguyen, M.-T.; Kim, W.J.; Kim, J.-C. Synthesis and analysis of nanocrystalline β1-Cu3Al and β2-NiAl intermetallic-reinforced aluminum matrix composite by high energy ball milling. Met. Mater. Int. 2017, 23, 202–206. [Google Scholar] [CrossRef]

- Kirtay, S. Improvement of Oxidation Resistance of Mild Steel by SiO2-Al2O3 Sol Gel Coating. Acta Phys. Pol. A 2015, 128, 90–92. [Google Scholar] [CrossRef]

- Pi, J.; Ye, P.; Wu, J.; He, X. Influence of Minor Addition of in on Corrosion Resistance of Cu-Based Bulk Metallic Glasses in 3.5% NaCl Solution. Rare Met. Mater. Eng. 2014, 43, 32–35. [Google Scholar] [CrossRef]

- Froes, F.H.; Kim, Y.W.; Krishnamurthy, S. Rapid solidification of lightweight metal alloys. Mater. Sci. Eng. A 1989, 117, 19–32. [Google Scholar] [CrossRef]

- Babilas, R.; Bajorek, A.; Spilka, M.; Radoń, A.; Łoński, W. Structure and corrosion resistance of Al–Cu–Fe alloys. Prog. Nat. Sci. Mater. Int. 2020, 30, 393–401. [Google Scholar] [CrossRef]

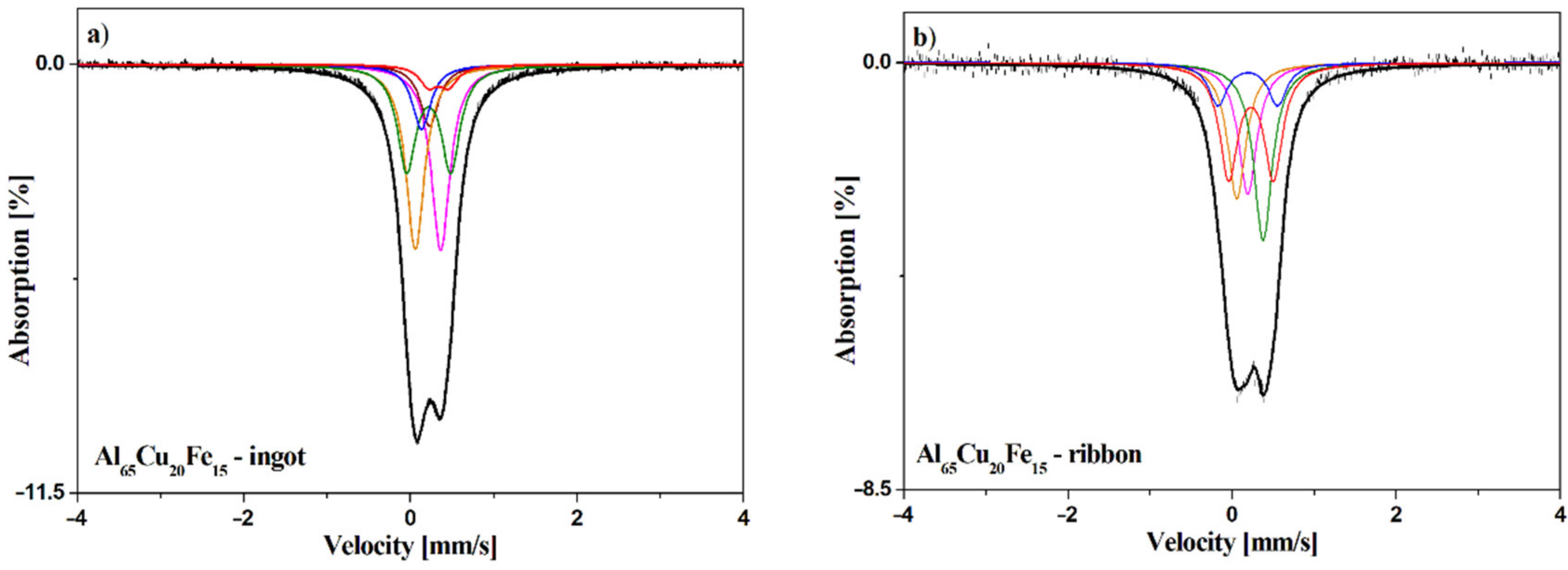

| Component | Is [mm/s] | Qs [mm/s] | FWHM [mm/s] | A [%] | Compound |

|---|---|---|---|---|---|

| Al65Cu20Fe15—Ingot | |||||

| L1 | 0.05 | - | 0.27 | 24 | Al13Fe4 |

| L2 | 0.23 | - | 9 | ||

| L3 | 0.36 | - | 24 | ||

| L4 | 0.14 | - | 10 | Al7Cu2Fe | |

| D1 | 0.34 | 0.24 | 5 | AlFe | |

| D2 | 0.21 | 0.53 | 29 | AlCuFe quasi | |

| Al65Cu20Fe15—Ribbon | |||||

| L1 | 0.06 | - | 0.27 | 18 | Al13Fe4 |

| L2 | 0.19 | - | 18 | ||

| L3 | 0.38 | - | 23 | ||

| D1 | 0.19 | 0.73 | 12 | Al(Fe,Cu) | |

| D2 | 0.23 | 0.54 | 29 | AlCuFe quasi | |

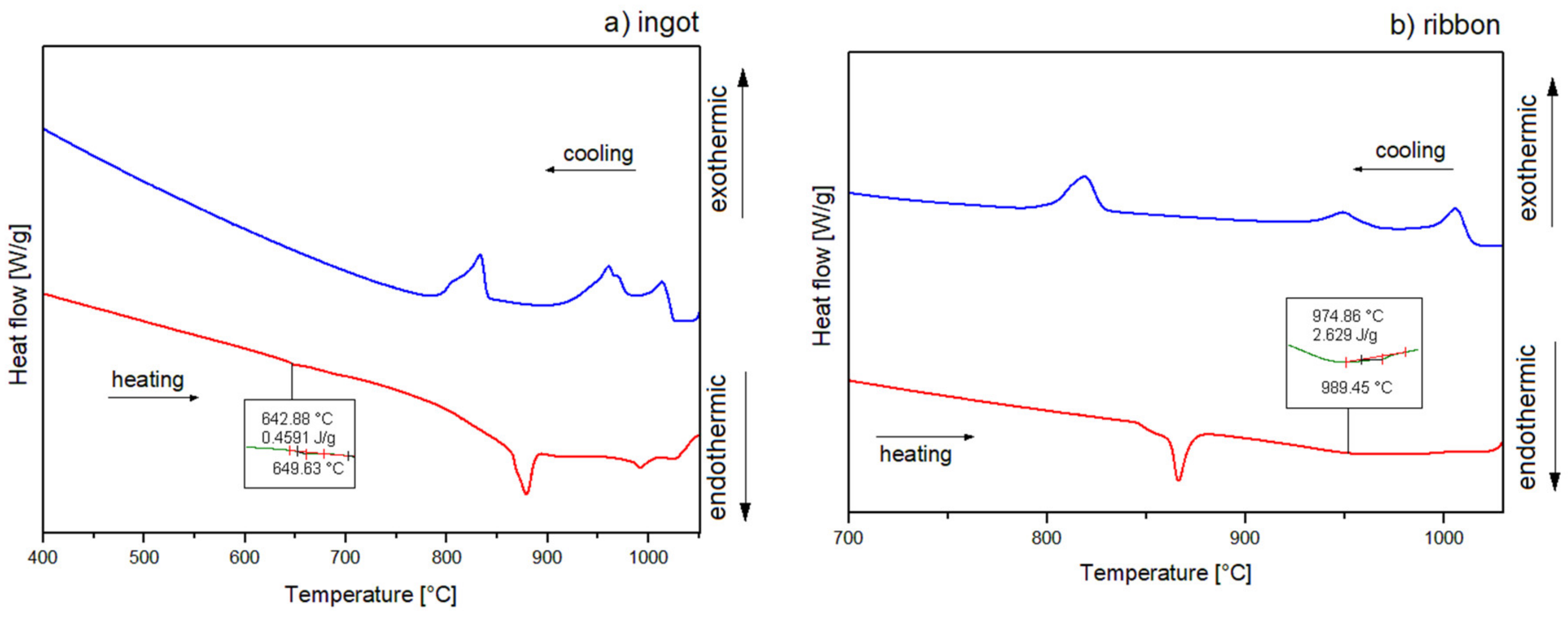

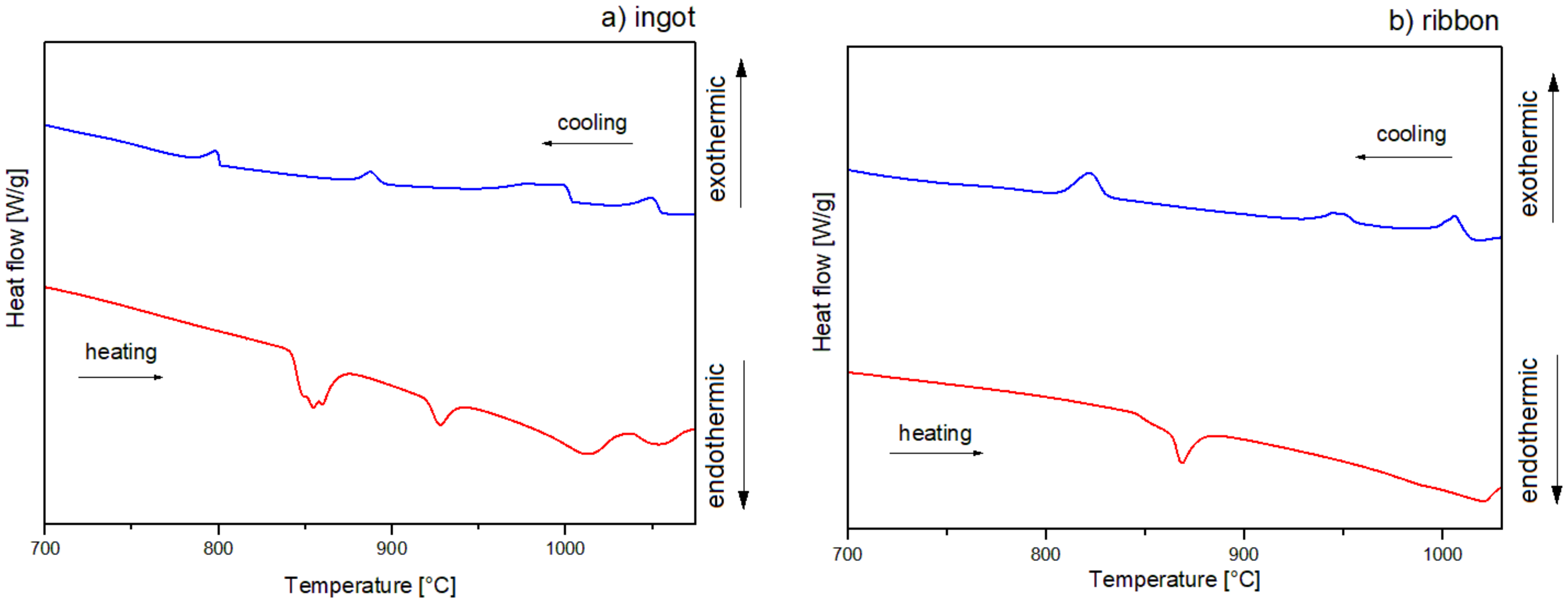

| Alloy | Identified Phases | Heating 10 °/min [°C] | Cooling 10 °/min [°C] | Heating 20 °/min [°C] | Cooling 20 °/min [°C] | |

|---|---|---|---|---|---|---|

| Al65Cu20Fe15 | ingot | Al2Cu | 643 | - | - | - |

| I-AlCuFe | 863 | 840 | 843 | 801 | ||

| AlFe | - | - | 920 | 895 | ||

| Al13Fe4 | 982 | 1024 | 977 | 1004 | ||

| Cu3Al | 1010 | 1024 | 1039 | 1055 | ||

| ribbon | I-AlCuFe | 862 | 823 | 863 | 831 | |

| Al13Fe4 | 975 | 963 | - | 957 | ||

| Cu3Al | - | 1014 | - | 1016 | ||

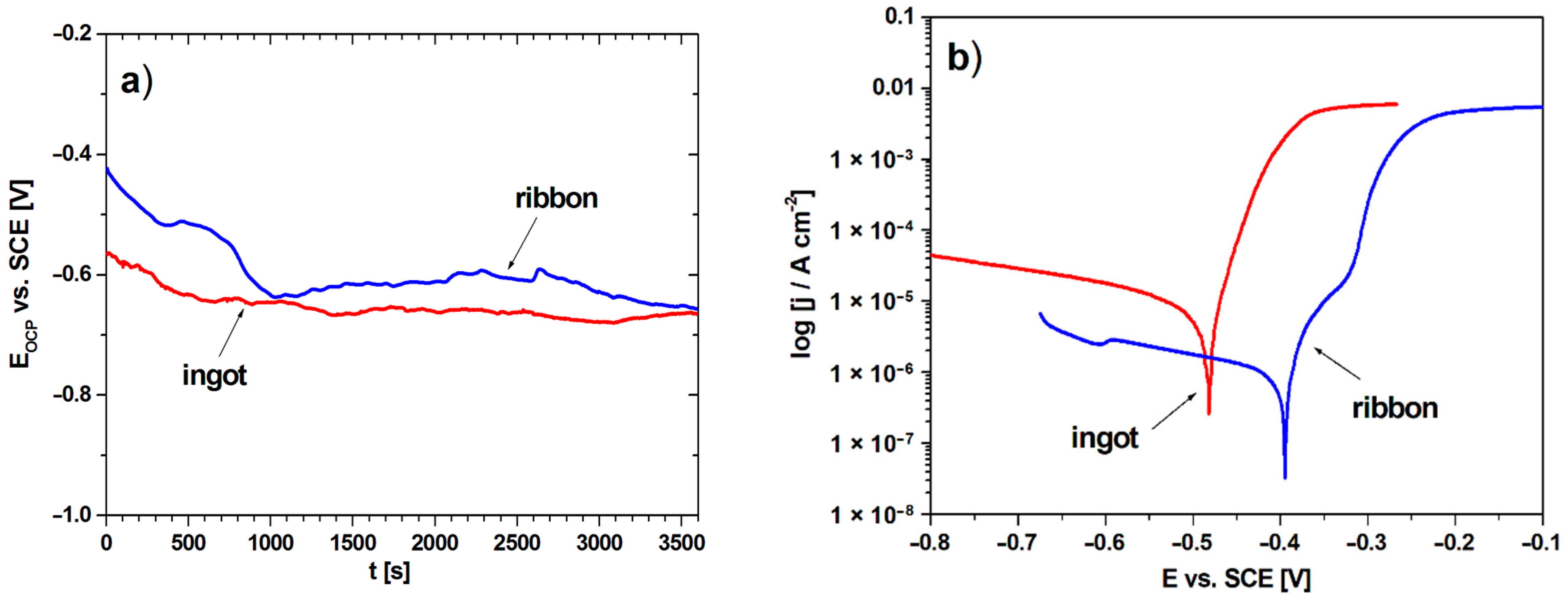

| Sample | EOCP [mV] | Ecorr [mV] | |βa| [mV/dec] | |βc| [mV/dec] | Rp [kΩ∙cm2] | jcorr [µA/cm2] |

|---|---|---|---|---|---|---|

| ingot | −665 | −482 | 90.8 | 23.2 | 2.23 | 3.59 |

| ribbon | −657 | −396 | 86.1 | 33.8 | 8.74 | 2.42 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Babilas, R.; Młynarek, K.; Łoński, W.; Łukowiec, D.; Kądziołka-Gaweł, M.; Czeppe, T.; Temleitner, L. Structural Characterization of Al65Cu20Fe15 Melt-Spun Alloy by X-ray, Neutron Diffraction, High-Resolution Electron Microscopy and Mössbauer Spectroscopy. Materials 2021, 14, 54. https://doi.org/10.3390/ma14010054

Babilas R, Młynarek K, Łoński W, Łukowiec D, Kądziołka-Gaweł M, Czeppe T, Temleitner L. Structural Characterization of Al65Cu20Fe15 Melt-Spun Alloy by X-ray, Neutron Diffraction, High-Resolution Electron Microscopy and Mössbauer Spectroscopy. Materials. 2021; 14(1):54. https://doi.org/10.3390/ma14010054

Chicago/Turabian StyleBabilas, Rafał, Katarzyna Młynarek, Wojciech Łoński, Dariusz Łukowiec, Mariola Kądziołka-Gaweł, Tomasz Czeppe, and László Temleitner. 2021. "Structural Characterization of Al65Cu20Fe15 Melt-Spun Alloy by X-ray, Neutron Diffraction, High-Resolution Electron Microscopy and Mössbauer Spectroscopy" Materials 14, no. 1: 54. https://doi.org/10.3390/ma14010054

APA StyleBabilas, R., Młynarek, K., Łoński, W., Łukowiec, D., Kądziołka-Gaweł, M., Czeppe, T., & Temleitner, L. (2021). Structural Characterization of Al65Cu20Fe15 Melt-Spun Alloy by X-ray, Neutron Diffraction, High-Resolution Electron Microscopy and Mössbauer Spectroscopy. Materials, 14(1), 54. https://doi.org/10.3390/ma14010054