Effect of Equal Channel Angular Pressing on the Dynamic Softening Behavior of Ti-6Al-4V Alloy in the Hot Deformation Process

Abstract

1. Introduction

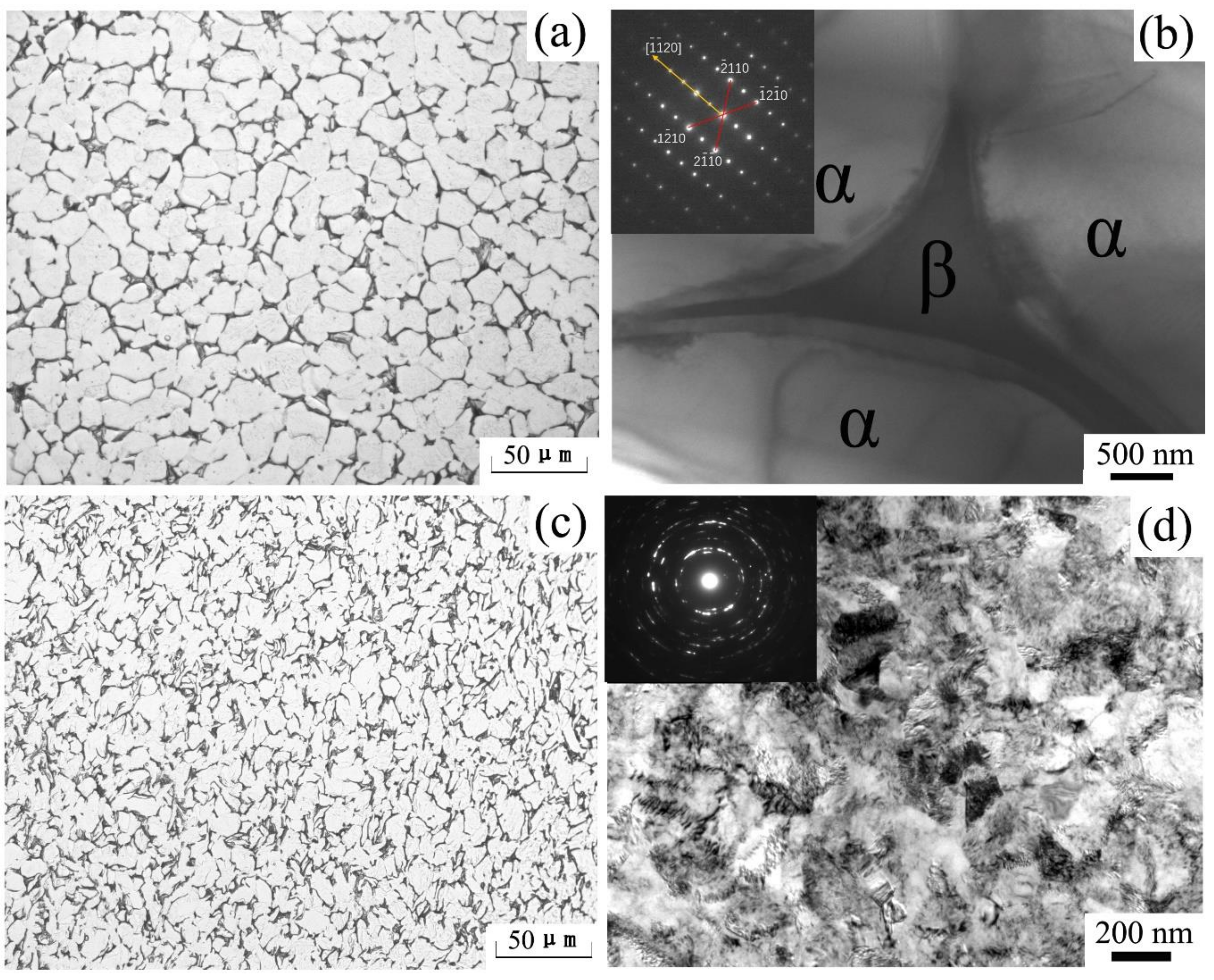

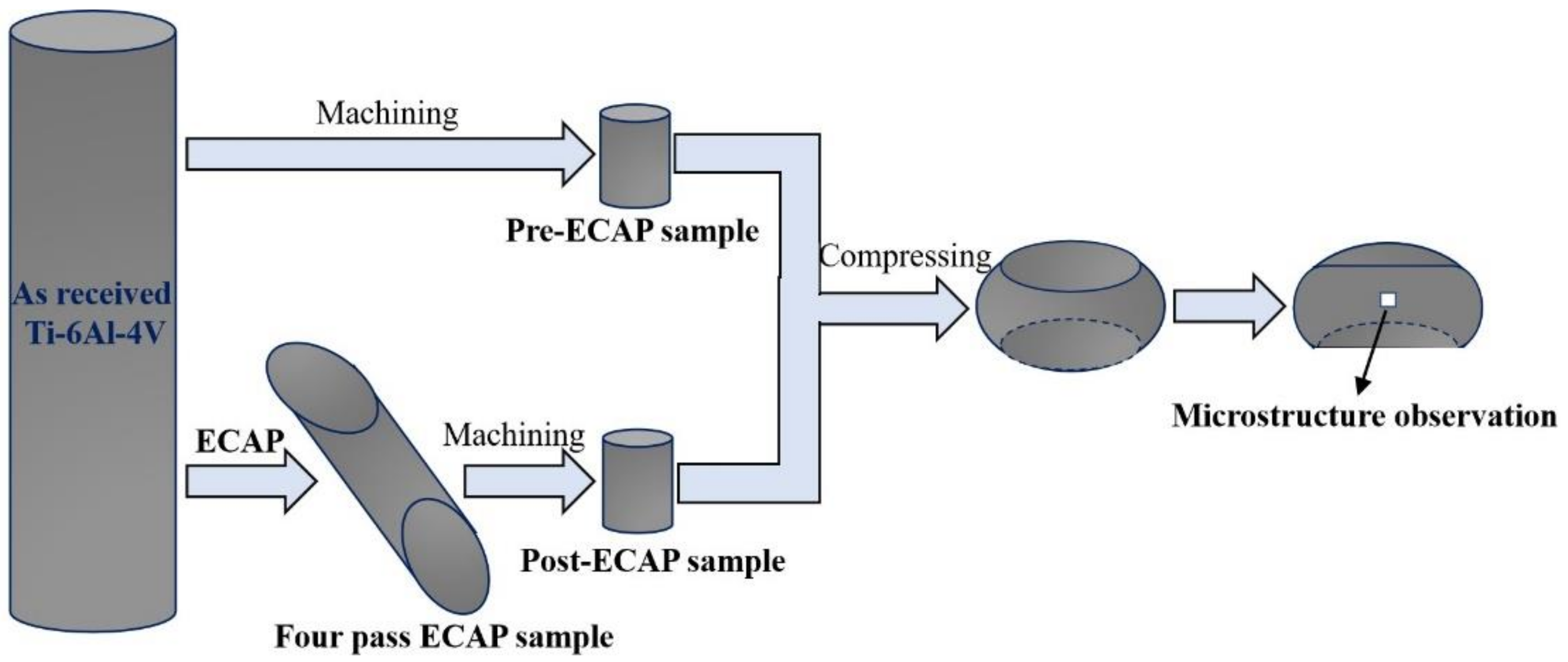

2. Experimental Procedure

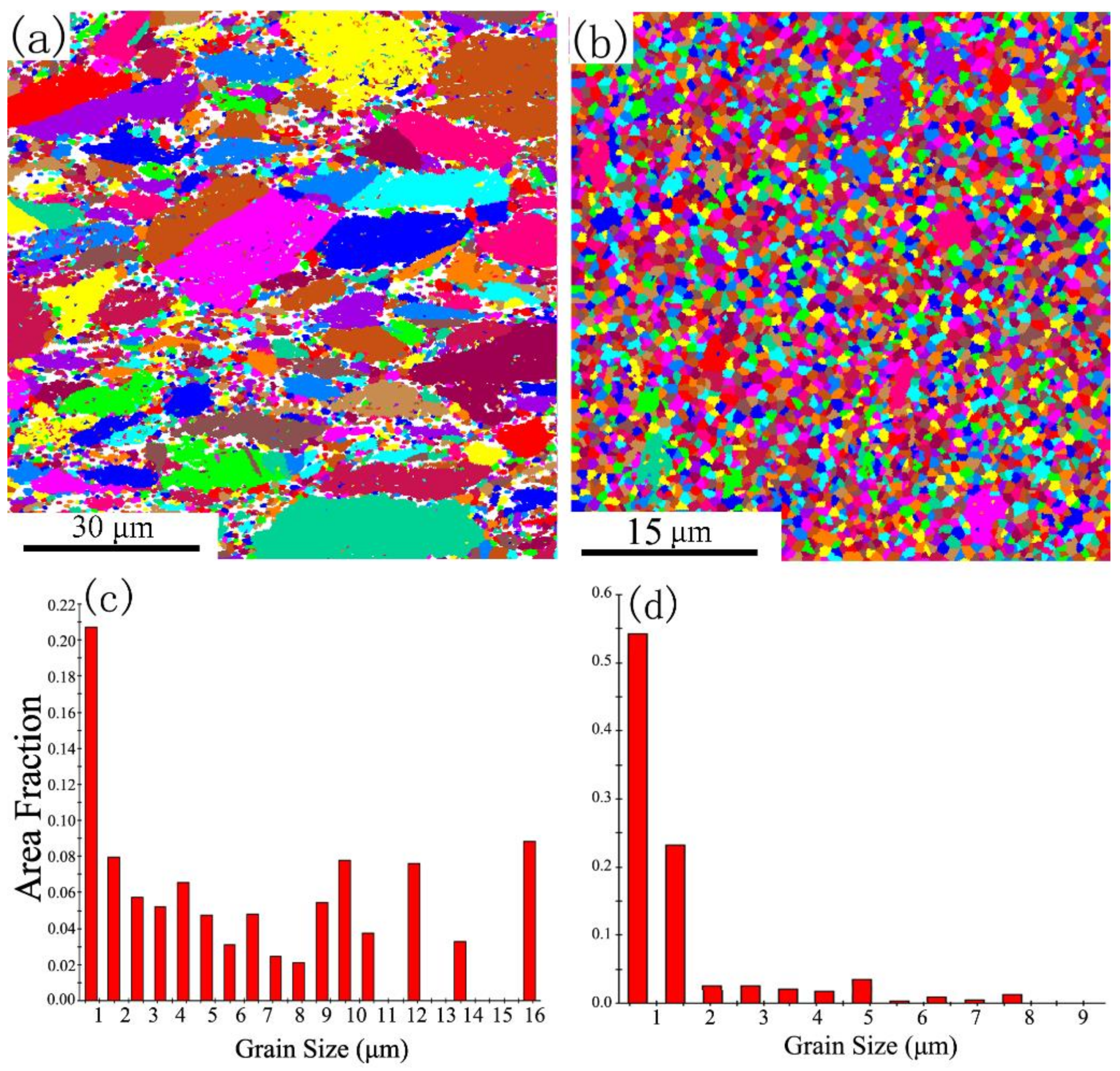

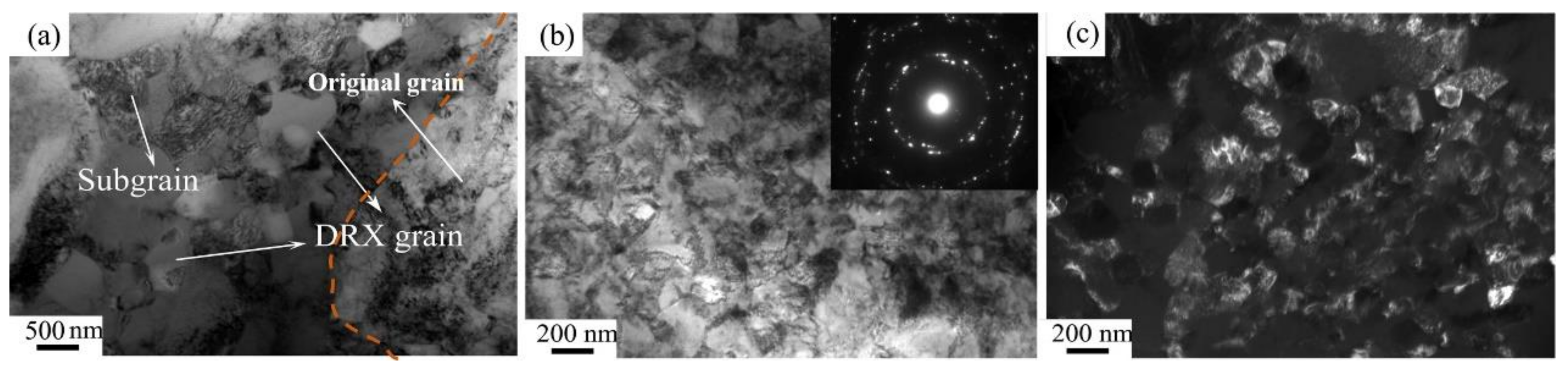

3. Results

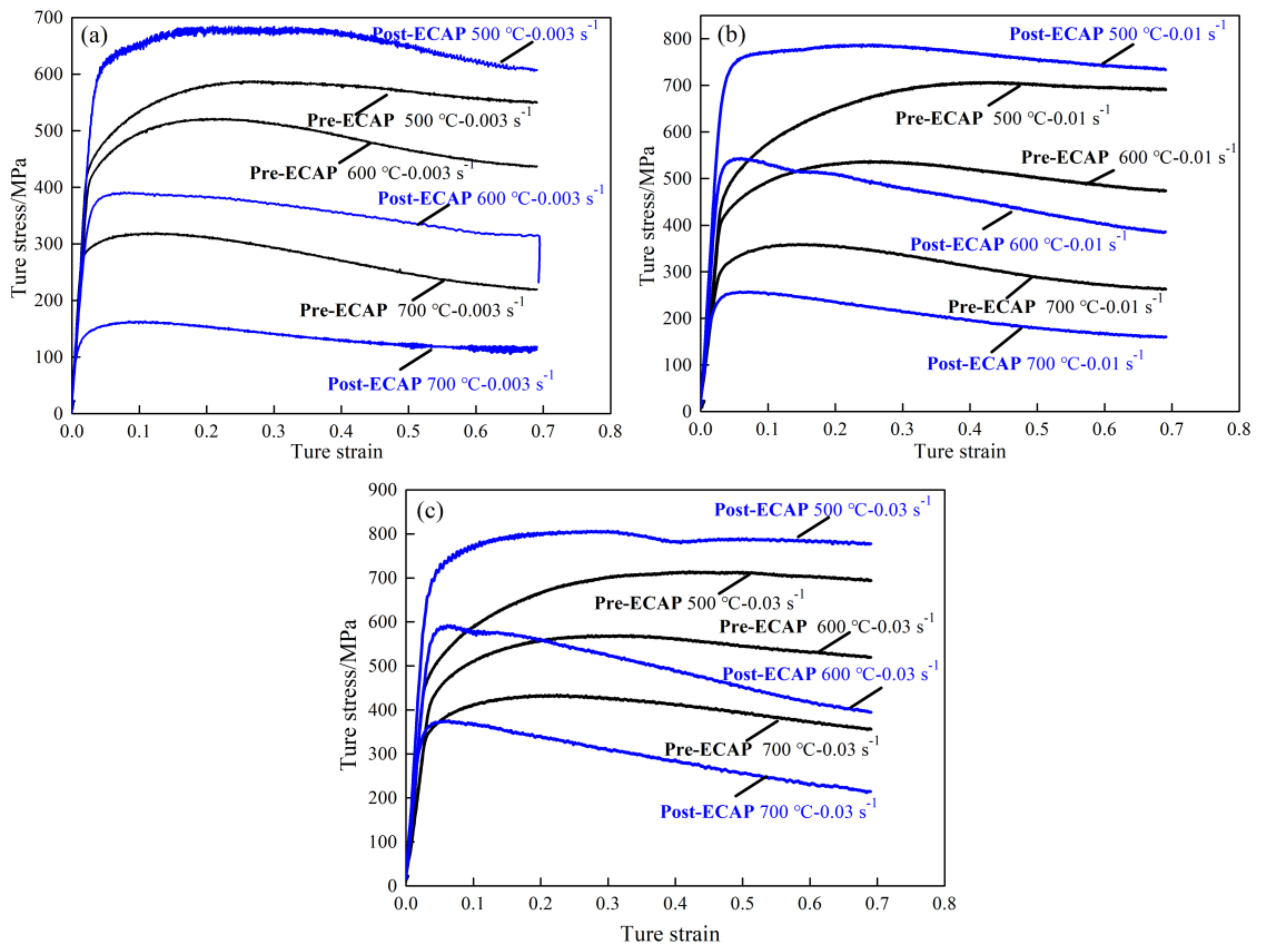

3.1. Stress–Strain Behavior

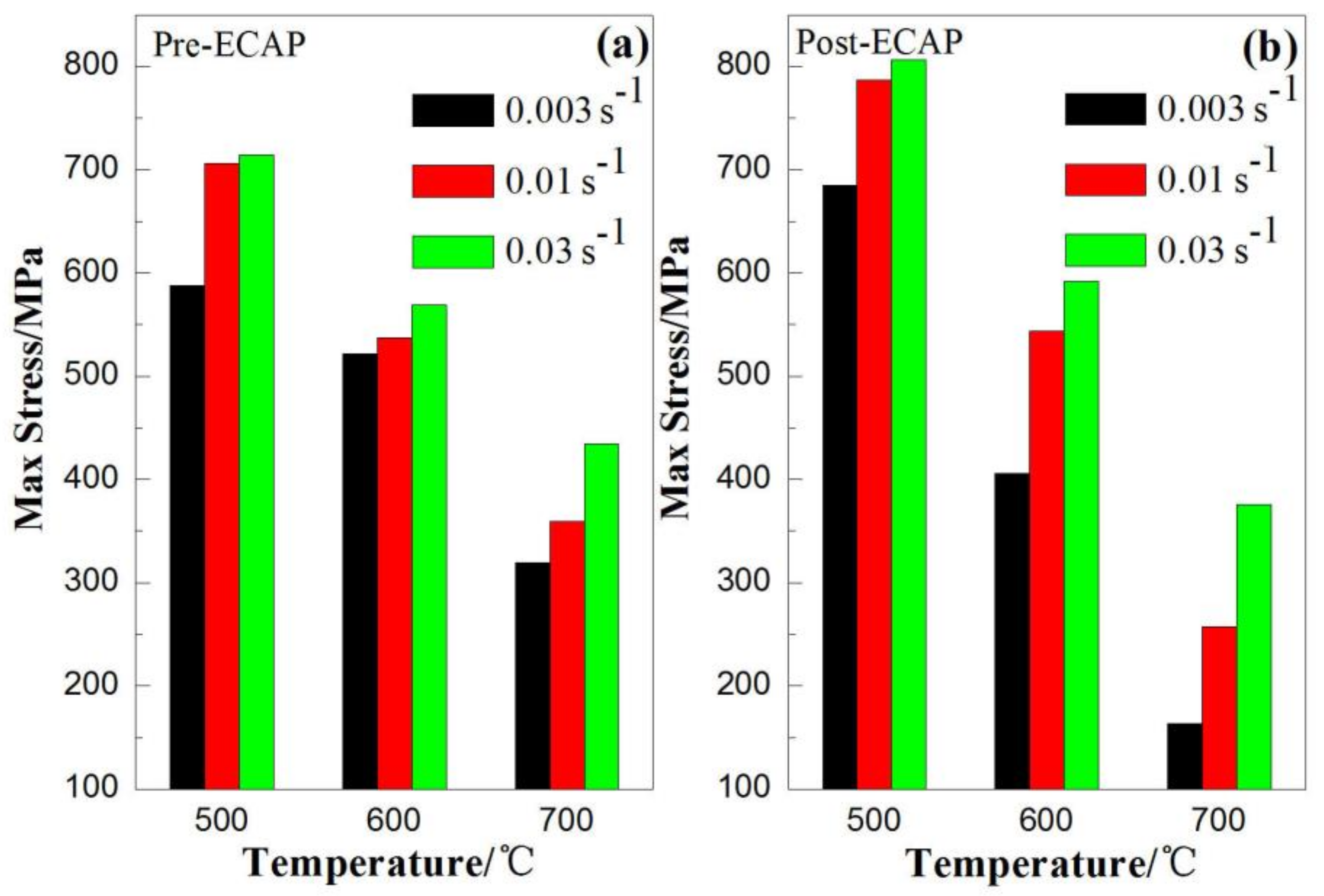

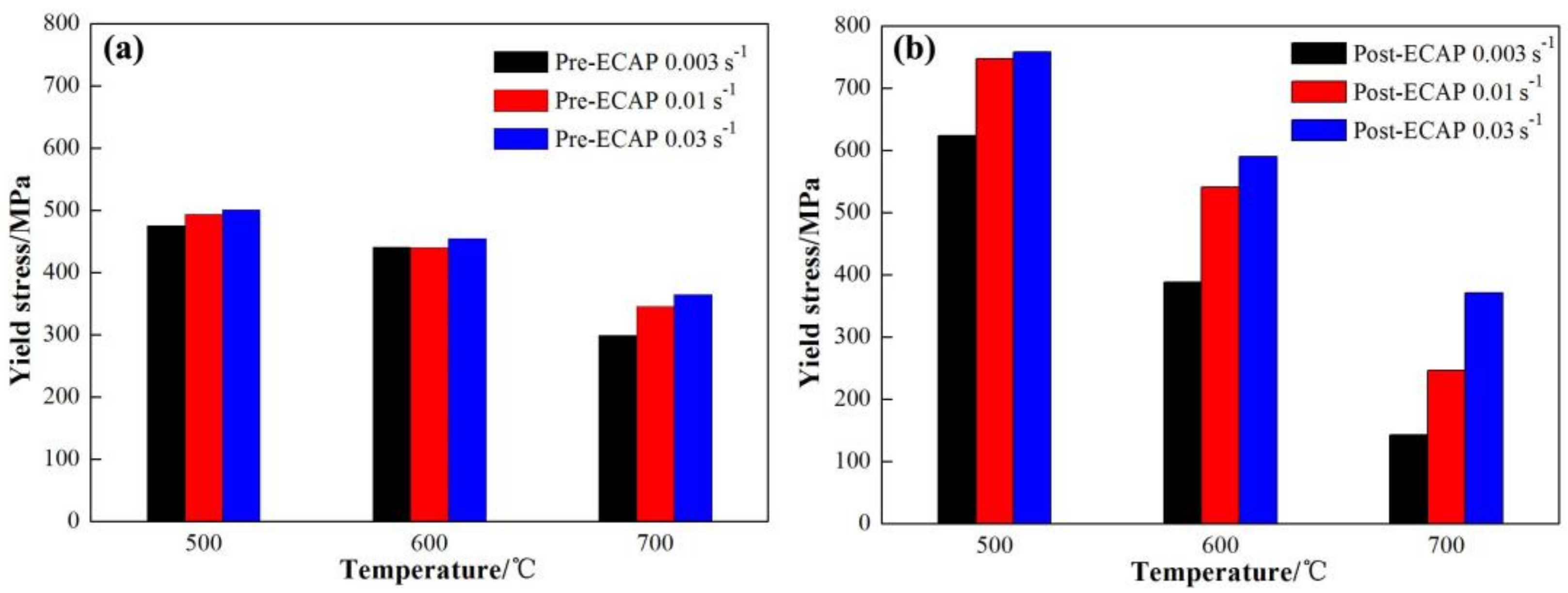

3.2. Effect of Temperature and Strain Rate on Deformation Behavior of Ti-6Al-4V Alloy

4. Discussions

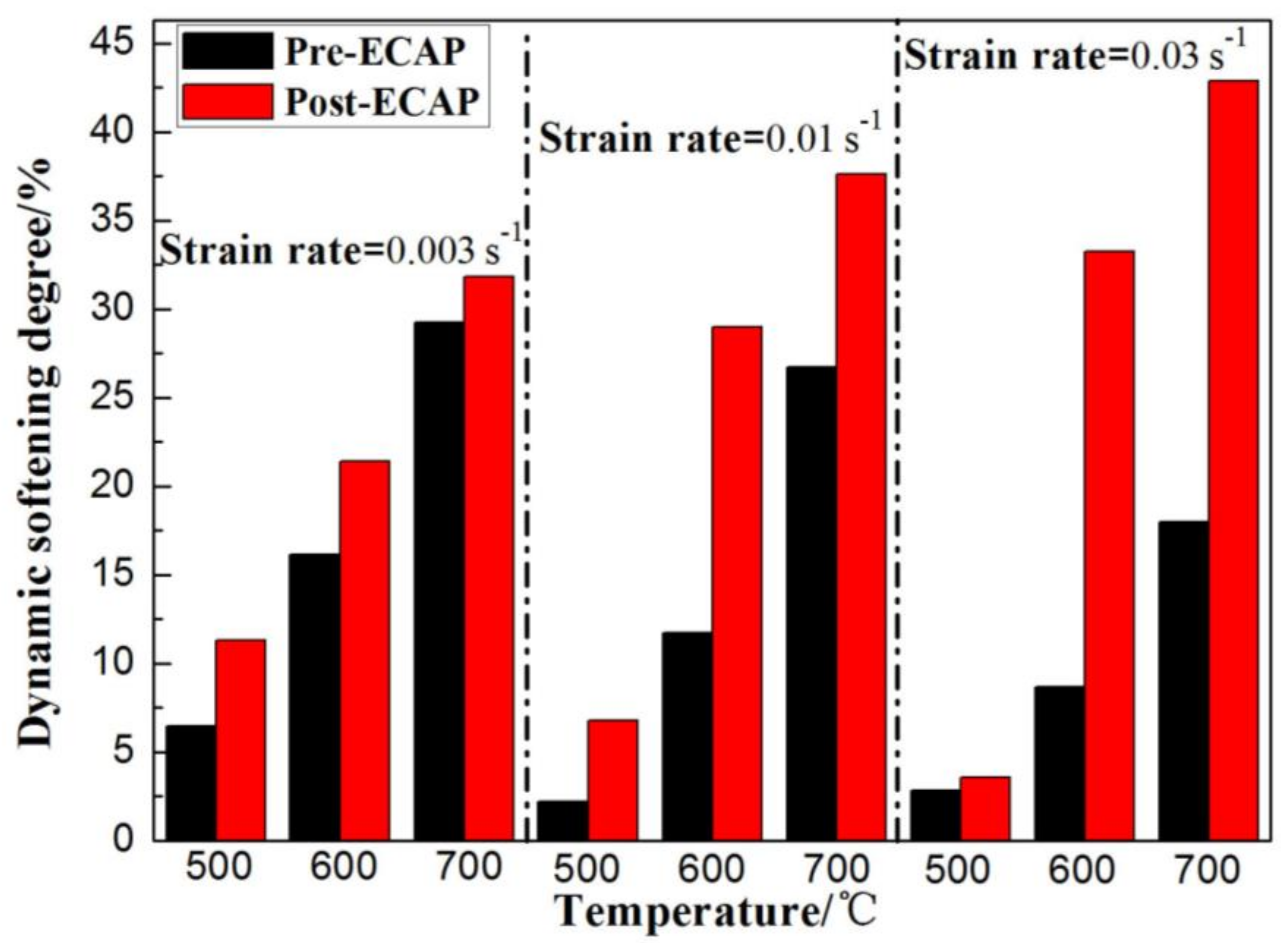

4.1. Dynamic Softening Coefficient

4.2. Effect of Strain Rate on the Dynamic Softening Mechanism

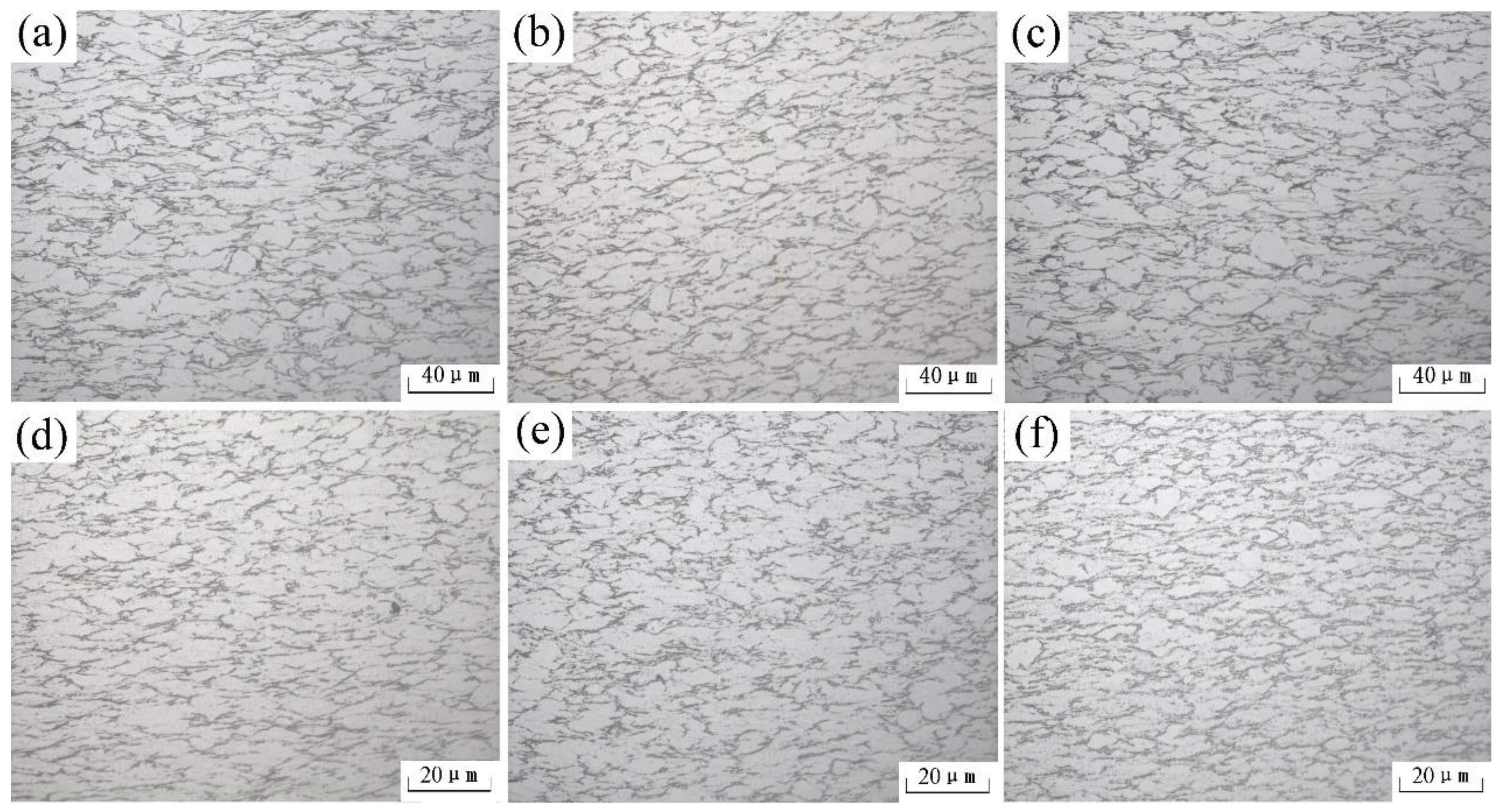

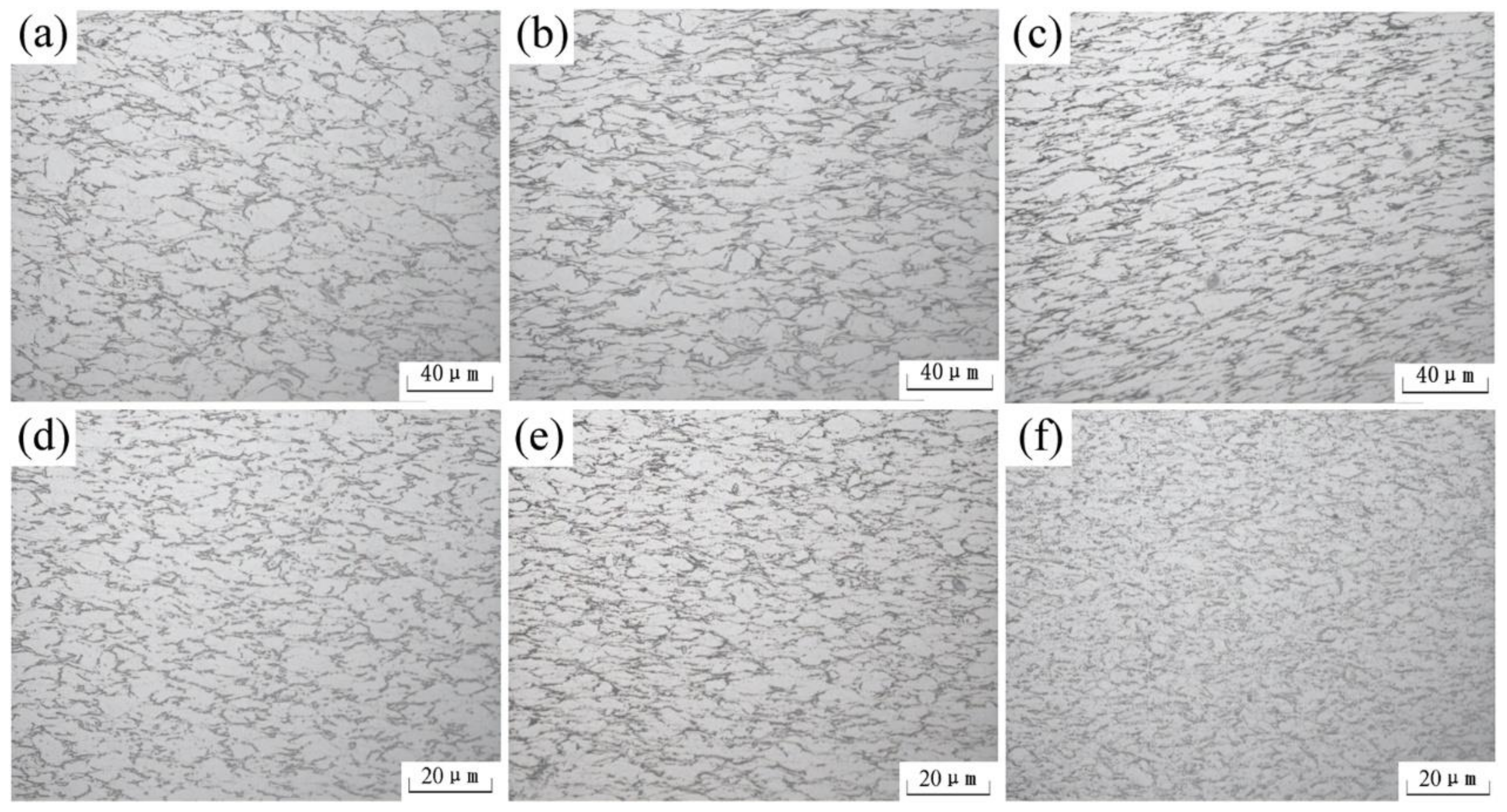

4.3. Effect of Temperature on the Dynamic Softening Mechanism

4.4. Effect of Initial Microstructure on the Dynamic Recrystallization Behavior

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Yu, H.; Yan, M.; Li, J.; Godbole, A.; Lu, C.; Tieu, K.; Li, H.; Kong, C. Mechanical properties and microstructure of a Ti-6Al-4V alloy subjected to cold rolling, asymmetric rolling and asymmetric cryorolling. Mater. Sci. Eng. A 2018, 710, 10–16. [Google Scholar] [CrossRef]

- Liu, J.; Qin, Y.; Zheng, J.; Chen, C.; Xiao, P. New approach to achieve high strength powder metallurgy Ti-6Al-4V alloy through a simplified hydrogenation-dehydrogenation treatment. J. Alloys Compd. 2018, 763, 111–119. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, G.; Hou, H.; Han, B.; Zhang, Y.; Zhang, N. Influence of High-Energy Pulse Current on the Mechanical Properties and Microstructures of Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2017, 26, 5146–5153. [Google Scholar] [CrossRef]

- Zhao, Z.; Hou, H.; Zhang, N.; Zhang, Y.; Wang, Y.; Wang, G. Effect of high-energy electro-pulses on the compression deformation behavior of Ti-6Al-4V alloy. Met. Mater. Int. 2016, 22, 585–593. [Google Scholar] [CrossRef]

- Chong, Y.; Bhattacharjee, T.; Gholizadeh, R.; Yi, J.; Tsuji, N. Investigation on the hot deformation behaviors and globularization mechanisms of lamellar Ti–6Al–4V alloy within a wide range of deformation temperatures. Materialia 2019, 8, 100480. [Google Scholar] [CrossRef]

- Poorganji, B.; Yamaguchi, M.; Itsumi, Y.; Matsumoto, K.; Tanaka, T.; Asa, Y.; Miyamoto, G.; Furuhara, T. Microstructure evolution during deformation of a near-α titanium alloy with different initial structures in the two-phase region. Scr. Mater. 2009, 61, 419–422. [Google Scholar] [CrossRef]

- Niu, Y.; Hou, H.; Li, M.; Li, Z. High temperature deformation behavior of a near alpha Ti600 titanium alloy. Mater. Sci. Eng. A 2008, 492, 24–28. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, P.; Liang, X.; Cao, Y.; Ouyang, S.; Liu, Y.; Wu, Z. Strength-ductility trade-off deviation in a pre-deformed metastable β titanium alloy. J. Alloys Compd. 2020, 835, 155332. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. The thermomechanical processing of alpha/beta titanium alloys. JOM 1997, 49, 33–39. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and Issues in the Application of Titanium Alloys for Aerospace Components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Semiatin, S.L. An Overview of the Thermomechanical Processing of α/β Titanium Alloys: Current Status and Future Research Opportunities. Met. Mater. Trans. A 2020, 51, 2593–2625. [Google Scholar] [CrossRef]

- Zhang, Z.; Fan, J.; Tang, B.; Kou, H.; Wang, J.; Chen, Z.; Li, J. Microstructure/texture evolution maps to optimize hot deformation process of near-α titanium alloy. Prog. Nat. Sci. 2020, 30, 86–93. [Google Scholar] [CrossRef]

- Zhang, Z.; Qu, S.; Feng, A.H.; Shen, J.; Chen, D. Hot deformation behavior of Ti-6Al-4V alloy: Effect of initial microstructure. J. Alloys Compd. 2017, 718, 170–181. [Google Scholar] [CrossRef]

- Luo, J.; Ye, P.; Li, M.; Liu, L. Effect of the alpha grain size on the deformation behavior during isothermal compression of Ti–6Al–4V alloy. Mater. Des. 2015, 88, 32–40. [Google Scholar] [CrossRef]

- Valiev, R.Z. Structure and mechanical properties of ultrafine-grained metals. Mater. Sci. Eng. A 1997, 59–66. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Despax, L.; Vidal, V.; Delagnes, D.; Dehmas, M.; Matsumoto, H.; Velay, V. Influence of strain rate and temperature on the deformation mechanisms of a fine-grained Ti-6Al-4V alloy. Mater. Sci. Eng. A 2020, 790, 139718. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Extreme grain refinement by severe plastic deformation: A wealth of challenging science. Acta Mater. 2013, 61, 782–817. [Google Scholar] [CrossRef]

- Yoshimura, H.; Nakahigashi, J. Ultra-Fine Grain Refinement, Superplasticity and its Application of Titanium Alloys Obtained through Protium Treatment. Mater. Sci. Forum 2003, 426–432, 673–680. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.; Zehetbauer, M.; Zhu, Y. Fundamentals of Superior Properties in Bulk NanoSPD Materials. Mater. Res. Lett. 2016, 4, 1–21. [Google Scholar] [CrossRef]

- Azushima, A.; Kopp, R.; Korhonen, A.; Yang, D.Y.; Micari, F.; Lahoti, G.D.; Groche, P.; Yanagimoto, J.; Tsuji, N.; Rosochowski, A.; et al. Severe plastic deformation (SPD) processes for metals. CIRP Ann. 2008, 57, 716–735. [Google Scholar] [CrossRef]

- Rosochowski, A. Processing Metals by Severe Plastic Deformation. Solid State Phenom. 2005, 101–102, 13–22. [Google Scholar] [CrossRef]

- Kulagin, R.; Beygelzimer, Y.; Bachmaier, A.; Pippan, R.; Estrin, Y. Benefits of pattern formation by severe plastic deformation. Appl. Mater. Today 2019, 15, 236–241. [Google Scholar] [CrossRef]

- Segal, V. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Semenova, I.P.; Modina, J.M.; Polyakov, A.V.; Klevtsov, G.V.; Klevtsova, N.A.; Pigaleva, I.N.; Valiev, R.Z.; Langdon, T.G. Fracture toughness at cryogenic temperatures of ultrafine-grained Ti-6Al-4V alloy processed by ECAP. Mater. Sci. Eng. A 2018, 716, 260–267. [Google Scholar] [CrossRef]

- Harsha, R.; Kulkarni, V.M.; Boppana, S.B. Severe Plastic Deformation—A Review. Mater. Today Proc. 2018, 5, 22340–22349. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, G.; Zhang, Y.; Gao, J.; Hou, H. Microstructure Evolution and Mechanical Properties of Ti-6Al-4V Alloy Prepared by Multipass Equal Channel Angular Pressing. J. Mater. Eng. Perform. 2020, 29, 905–913. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, G.; Zhang, Y.; Wang, Y.; Hou, H. Fast recrystallization and phase transformation in ECAP deformed Ti–6Al–4V alloy induced by pulsed electric current. J. Alloys Compd. 2019, 786, 733–741. [Google Scholar] [CrossRef]

- Bae, D.; Kim, S.; Kim, D.; Kim, W. Deformation behavior of Mg–Zn–Y alloys reinforced by icosahedral quasicrystalline particles. Acta Mater. 2002, 50, 2343–2356. [Google Scholar] [CrossRef]

- Verlinden, B.; Suhadi, A.; Delaey, L. A generalized constitutive equation for an AA6060 aluminium alloy. Scr. Met. Mater. 1993, 28, 1441–1446. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, G.; Hou, H.; Zhang, Y.; Wang, Y. The effect of pulsed current on the shear deformation behavior of Ti-6Al-4V alloy. Sci. Rep. 2018, 8, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Žitňanský, M.; Čaplovič, L. Effect of the thermomechanical treatment on the structure of titanium alloy Ti6Al4V. J. Mater. Process. Technol. 2004, 157, 643–649. [Google Scholar] [CrossRef]

- Arabi, H.; Ketabchi, M. Improved properties of Ti-6Al-4V by combining isothermal equal-channel angular processing and hot-extrusion. Mater. Sci. Technol. 2019, 35, 1735–1741. [Google Scholar] [CrossRef]

| Materials | Conditions | |

|---|---|---|

| Pre-ECAP | Temperature | 500 °C, 600 °C, 700 °C |

| Strain rate | 0.003 s−1, 0.01 s−1, 0.03 s−1 | |

| Post-ECAP | Temperature | 500 °C, 600 °C, 700 °C |

| Strain rate | 0.003 s−1, 0.01 s−1, 0.03 s−1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Gao, J.; Wang, Y.; Zhang, Y.; Hou, H. Effect of Equal Channel Angular Pressing on the Dynamic Softening Behavior of Ti-6Al-4V Alloy in the Hot Deformation Process. Materials 2021, 14, 232. https://doi.org/10.3390/ma14010232

Zhao Z, Gao J, Wang Y, Zhang Y, Hou H. Effect of Equal Channel Angular Pressing on the Dynamic Softening Behavior of Ti-6Al-4V Alloy in the Hot Deformation Process. Materials. 2021; 14(1):232. https://doi.org/10.3390/ma14010232

Chicago/Turabian StyleZhao, Zhiyong, Jun Gao, Yaoqi Wang, Yanling Zhang, and Hongliang Hou. 2021. "Effect of Equal Channel Angular Pressing on the Dynamic Softening Behavior of Ti-6Al-4V Alloy in the Hot Deformation Process" Materials 14, no. 1: 232. https://doi.org/10.3390/ma14010232

APA StyleZhao, Z., Gao, J., Wang, Y., Zhang, Y., & Hou, H. (2021). Effect of Equal Channel Angular Pressing on the Dynamic Softening Behavior of Ti-6Al-4V Alloy in the Hot Deformation Process. Materials, 14(1), 232. https://doi.org/10.3390/ma14010232