Novel Low-Twist Bast Fibre Yarns from Flax Tow for High-Performance Composite Applications

Abstract

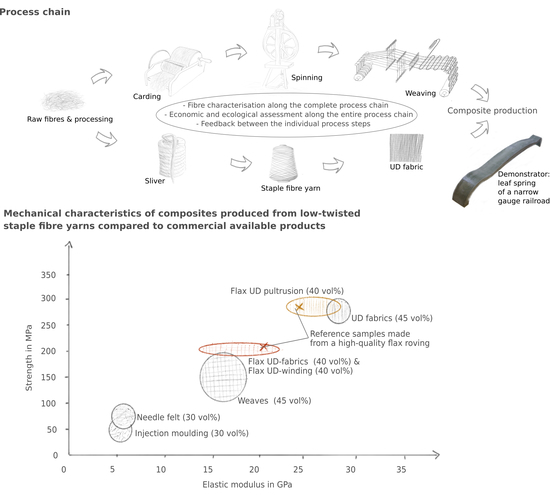

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fibre Analysis

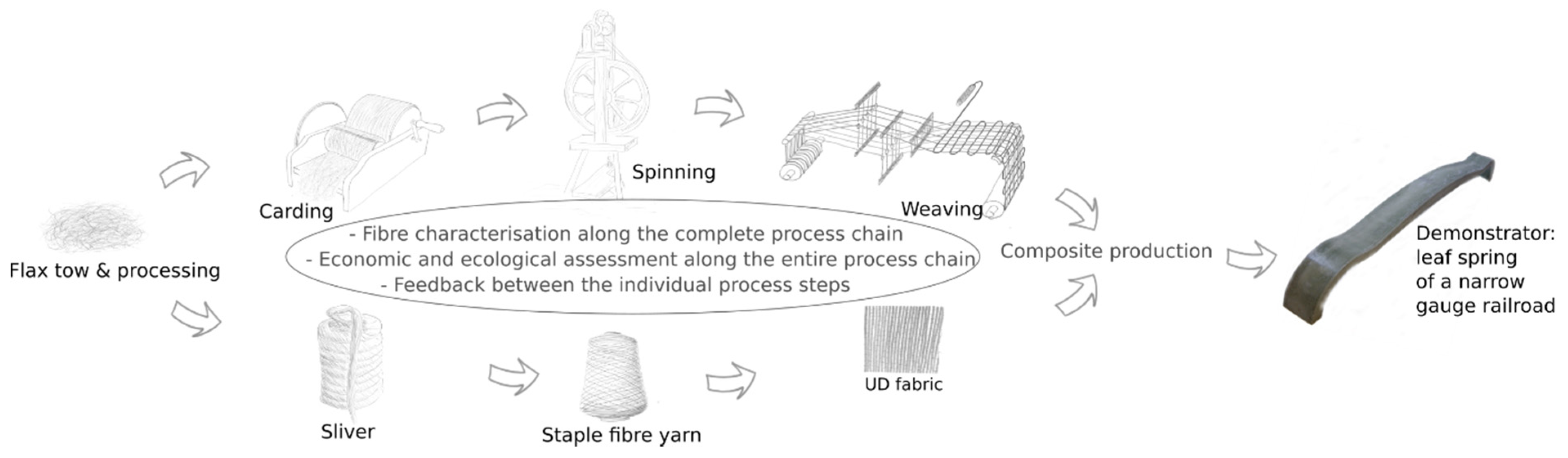

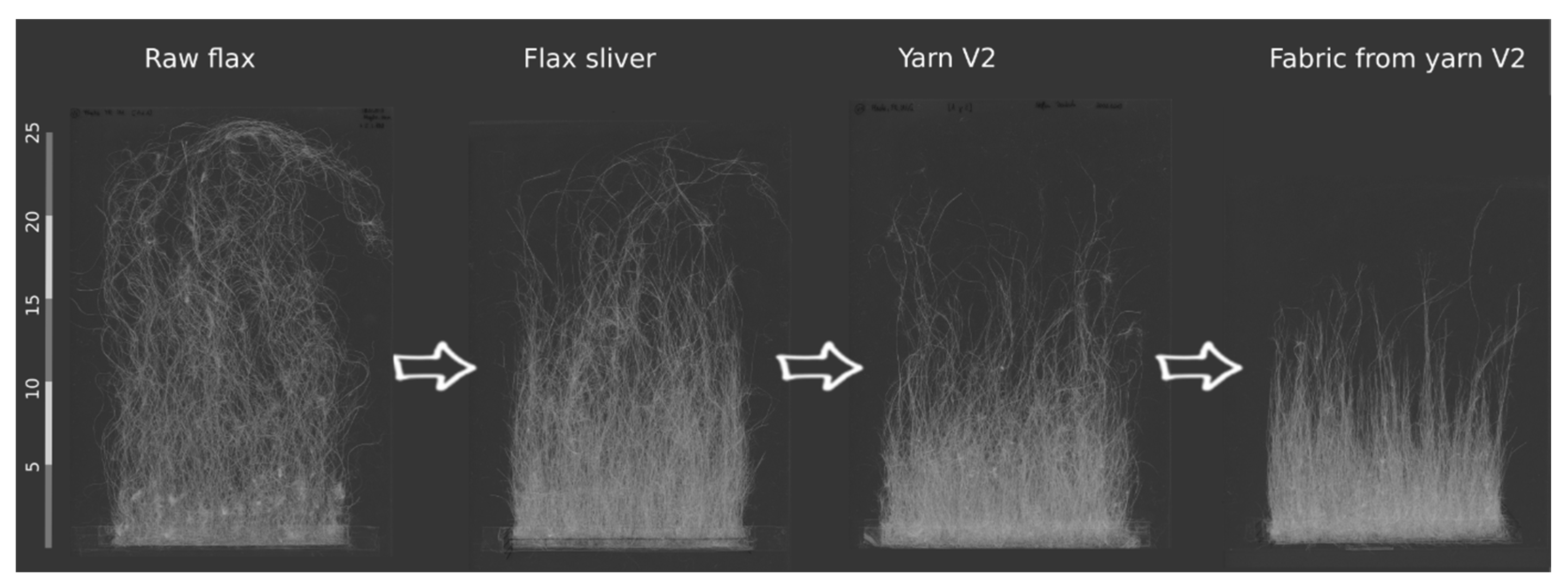

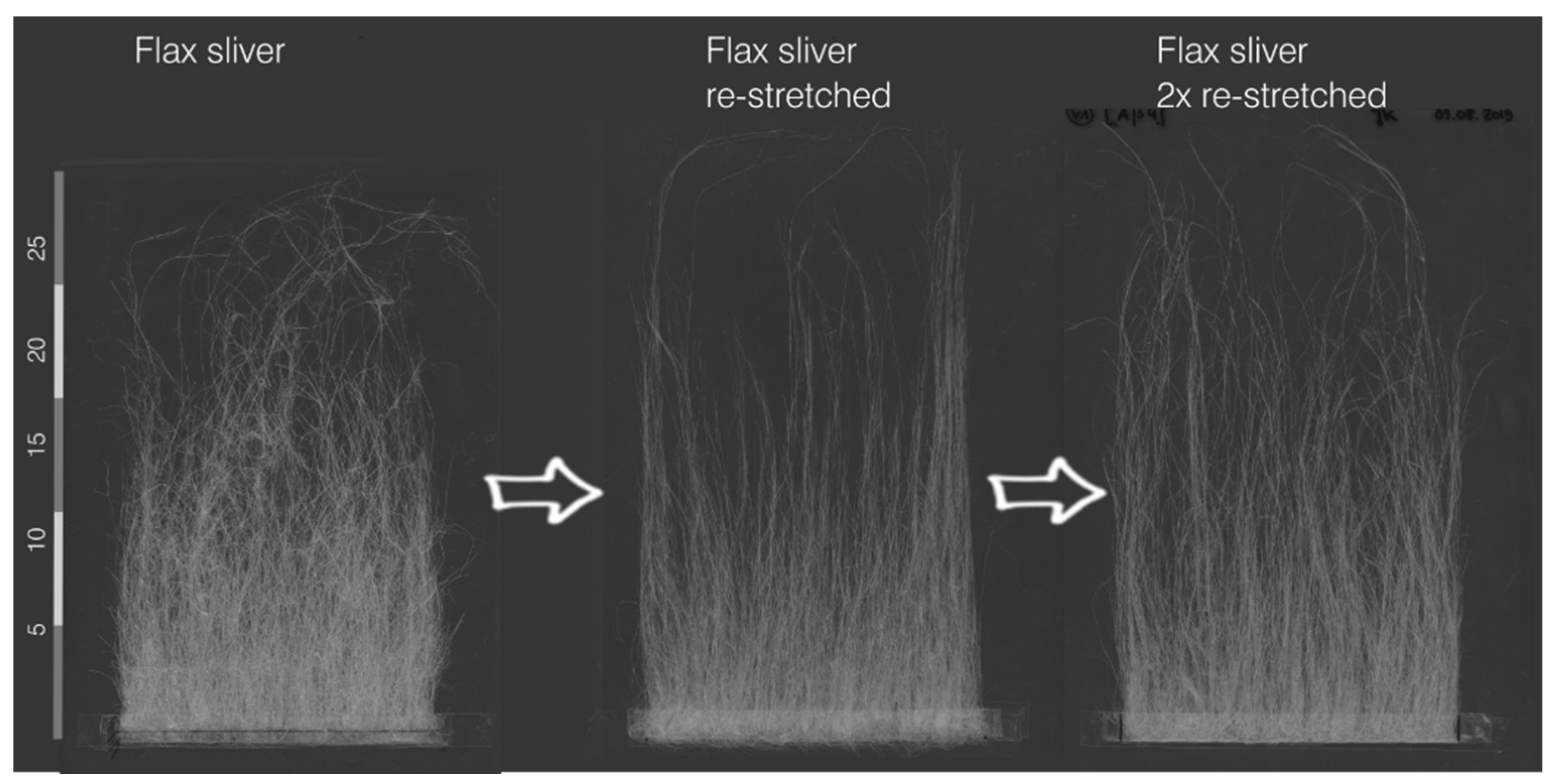

2.3. Fibre Processing, Yarn and Fabric Production

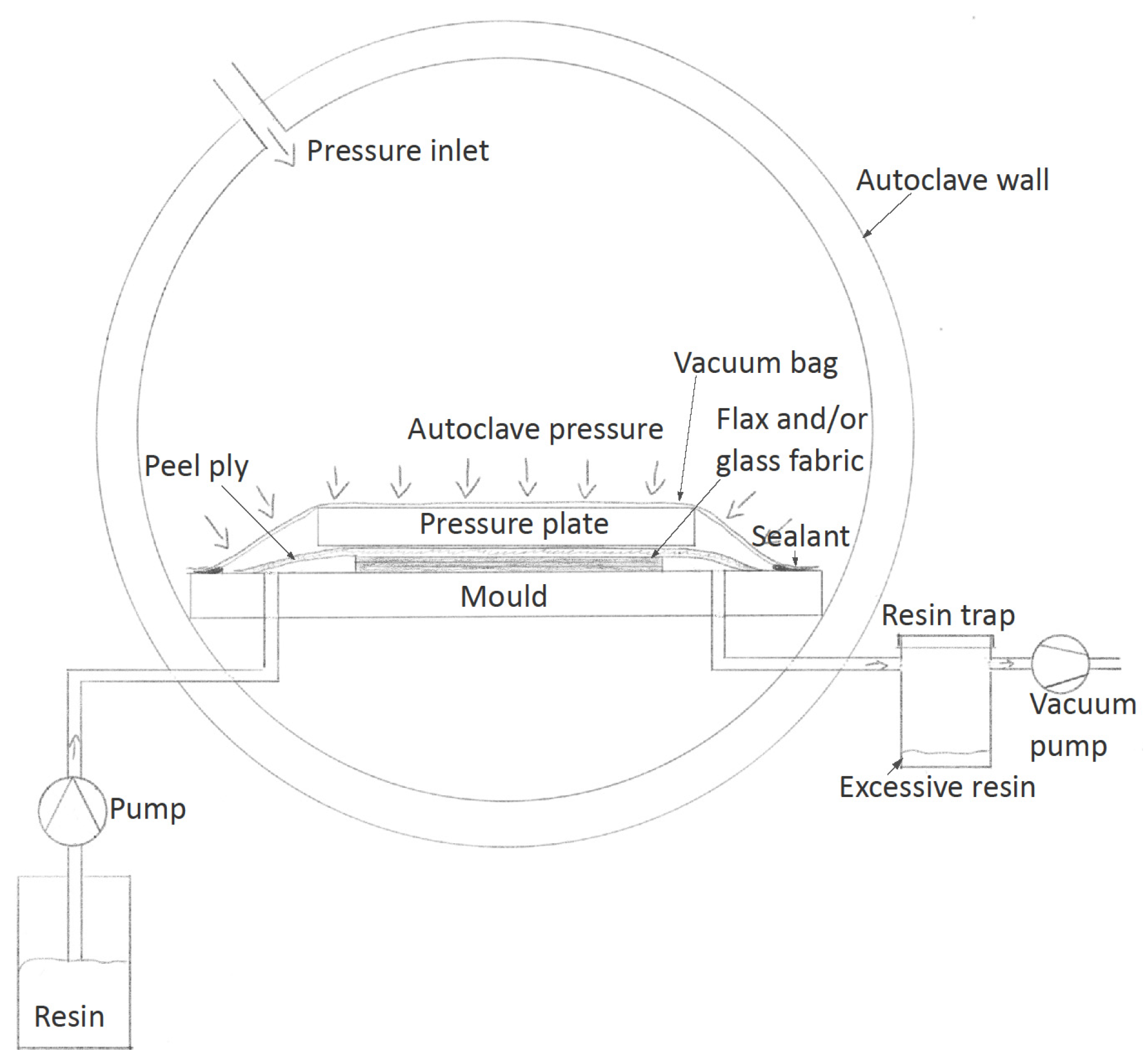

2.4. Composite Production

2.5. Composite Characterisation

3. Results and Discussion

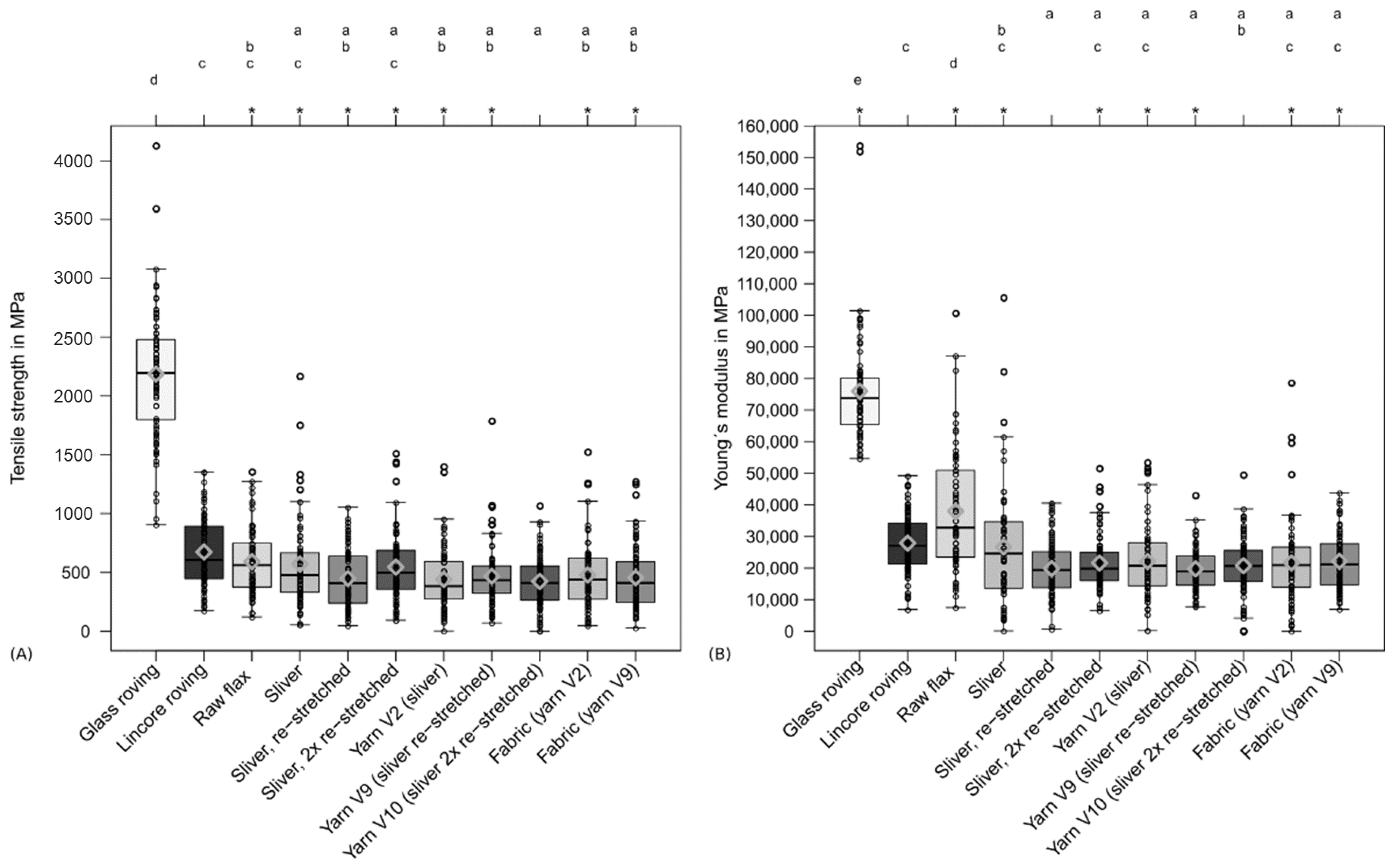

3.1. Fibre Characteristics

3.2. Composite Characteristics

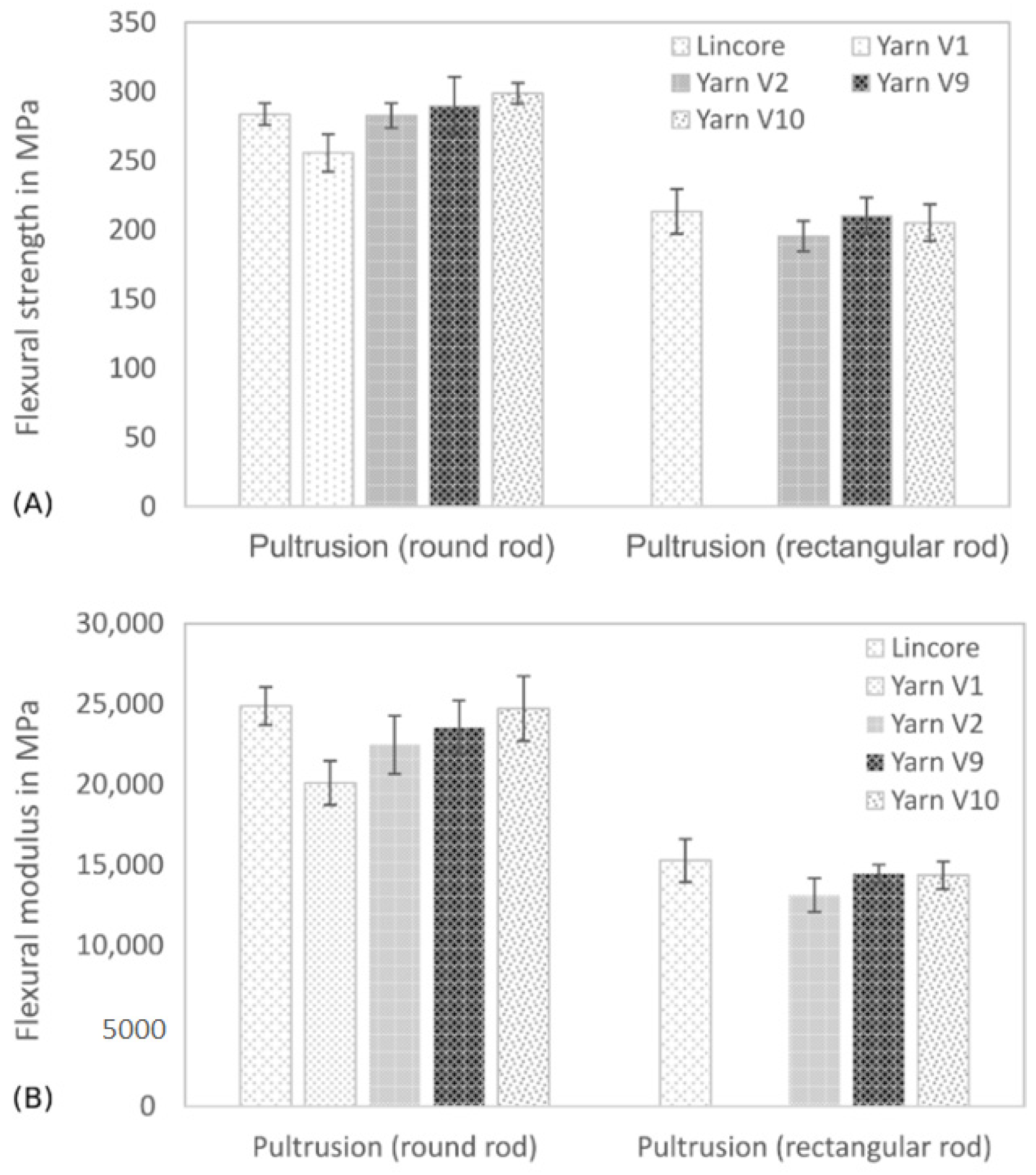

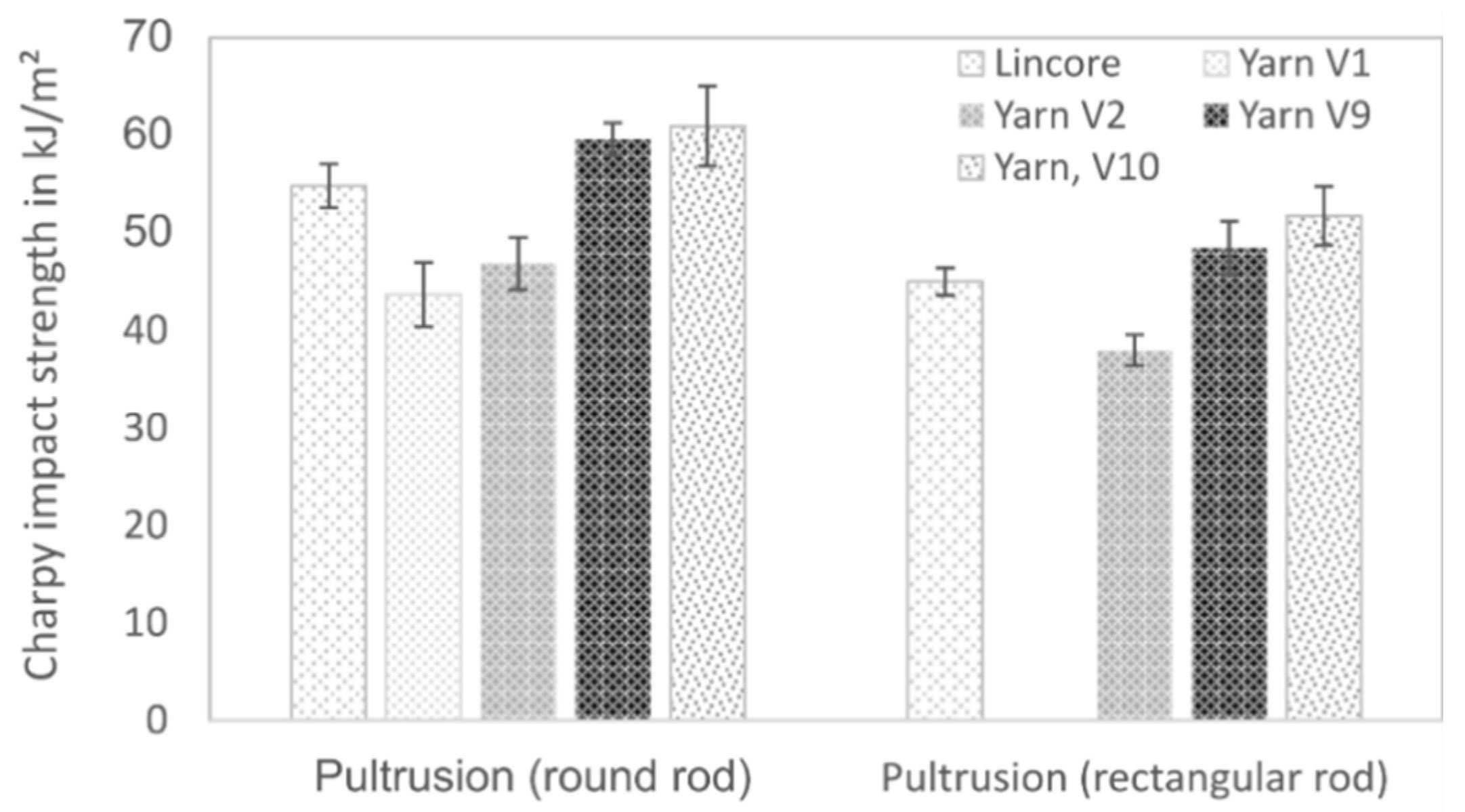

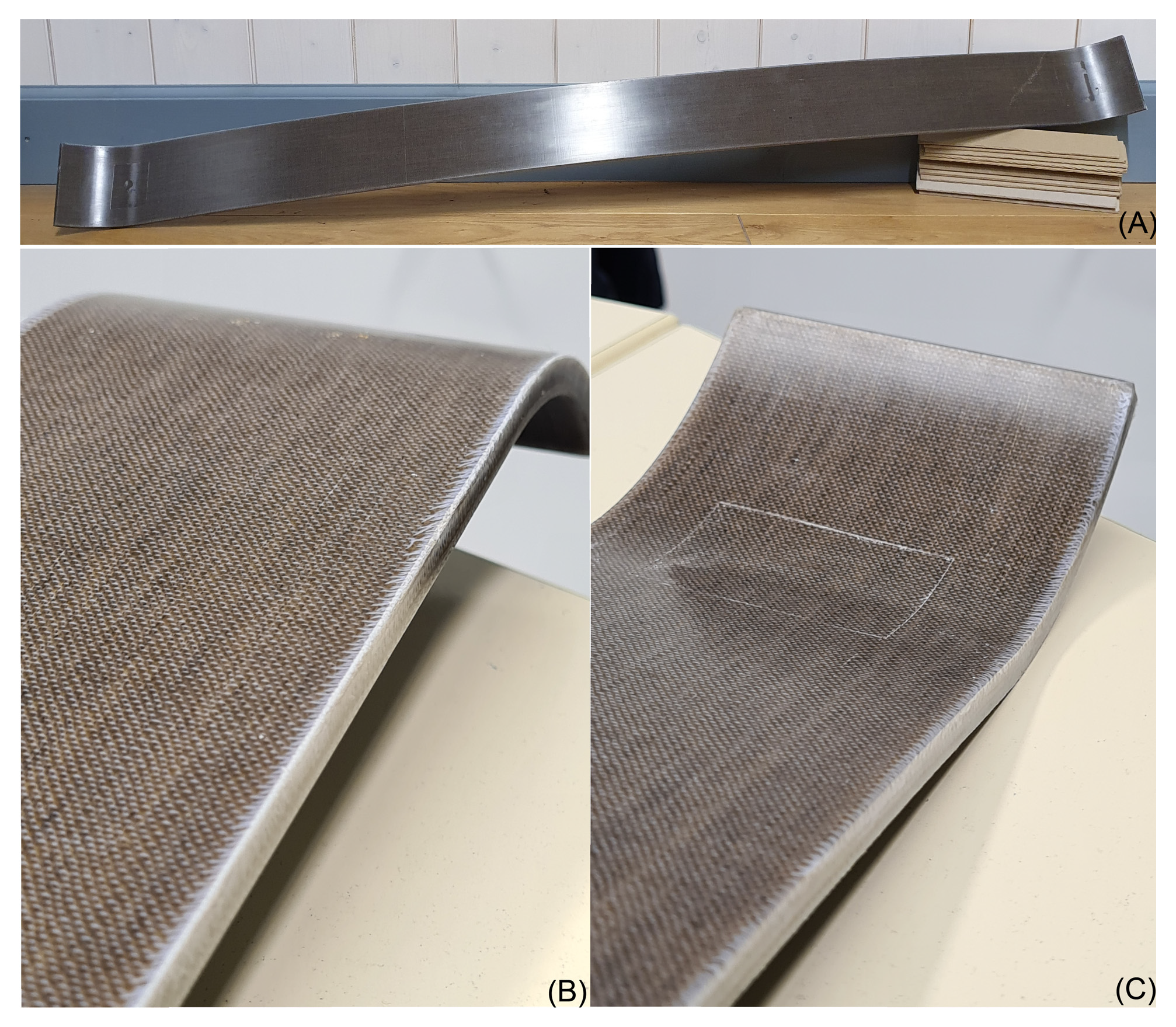

3.3. Pultruded Composites

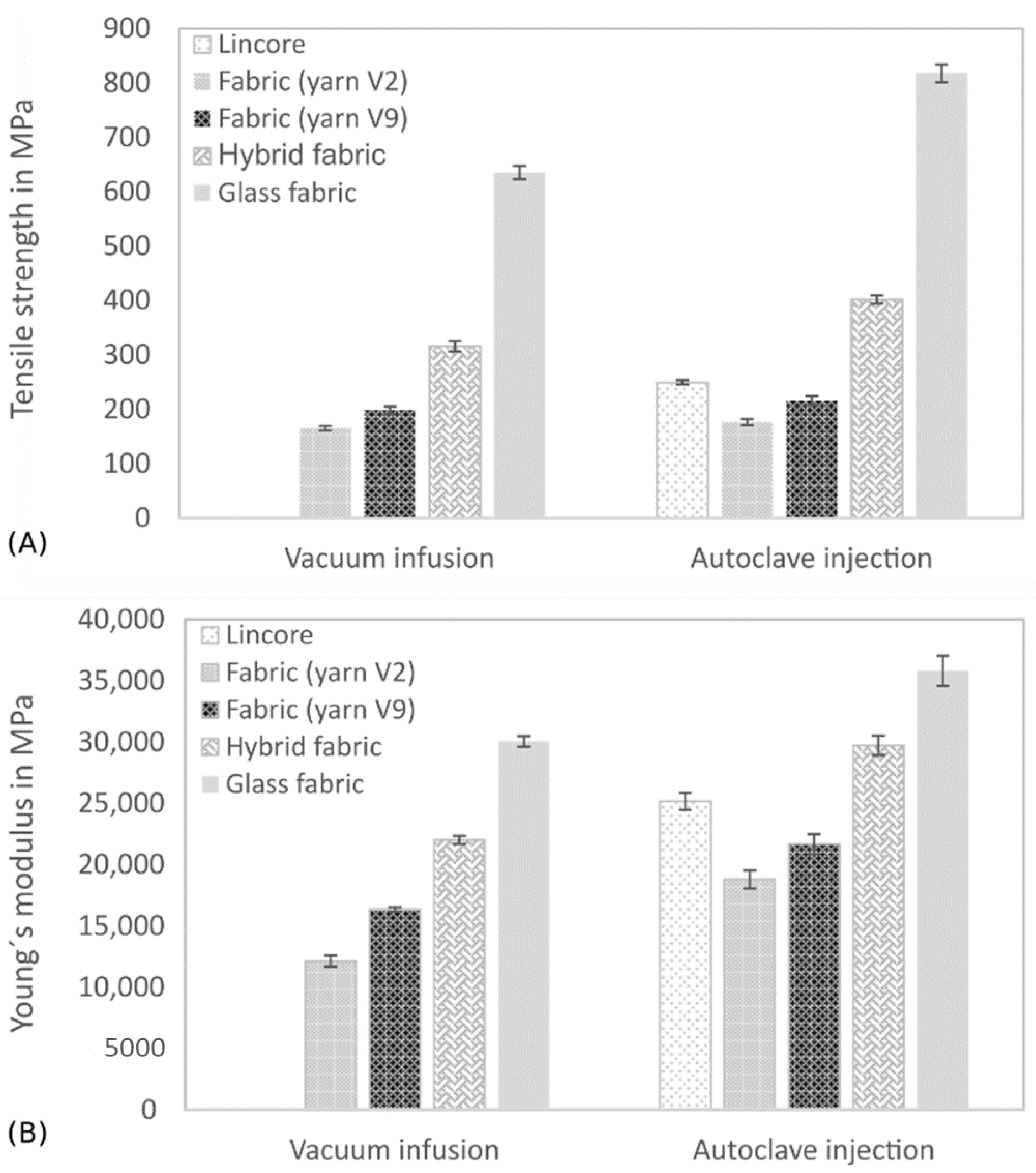

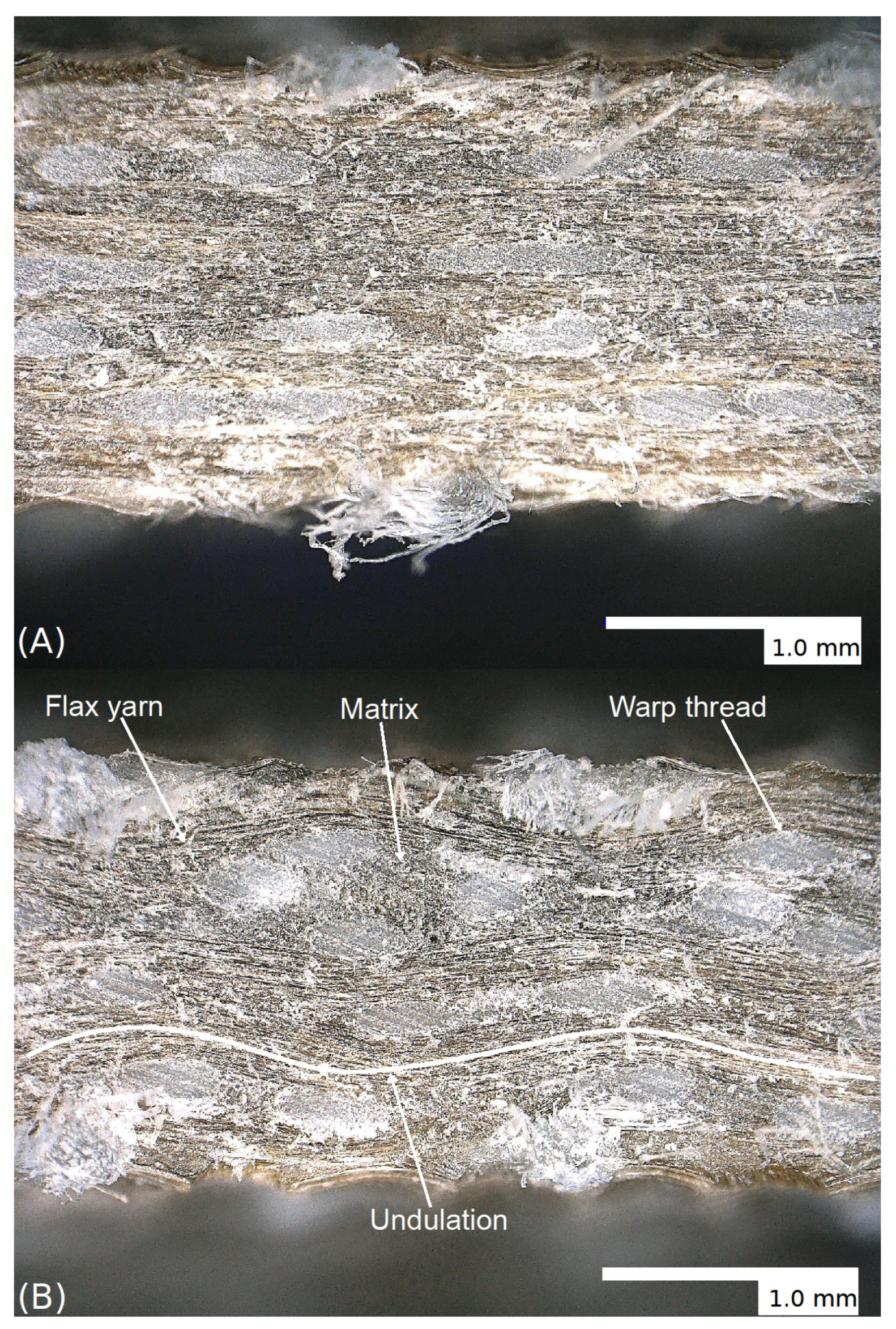

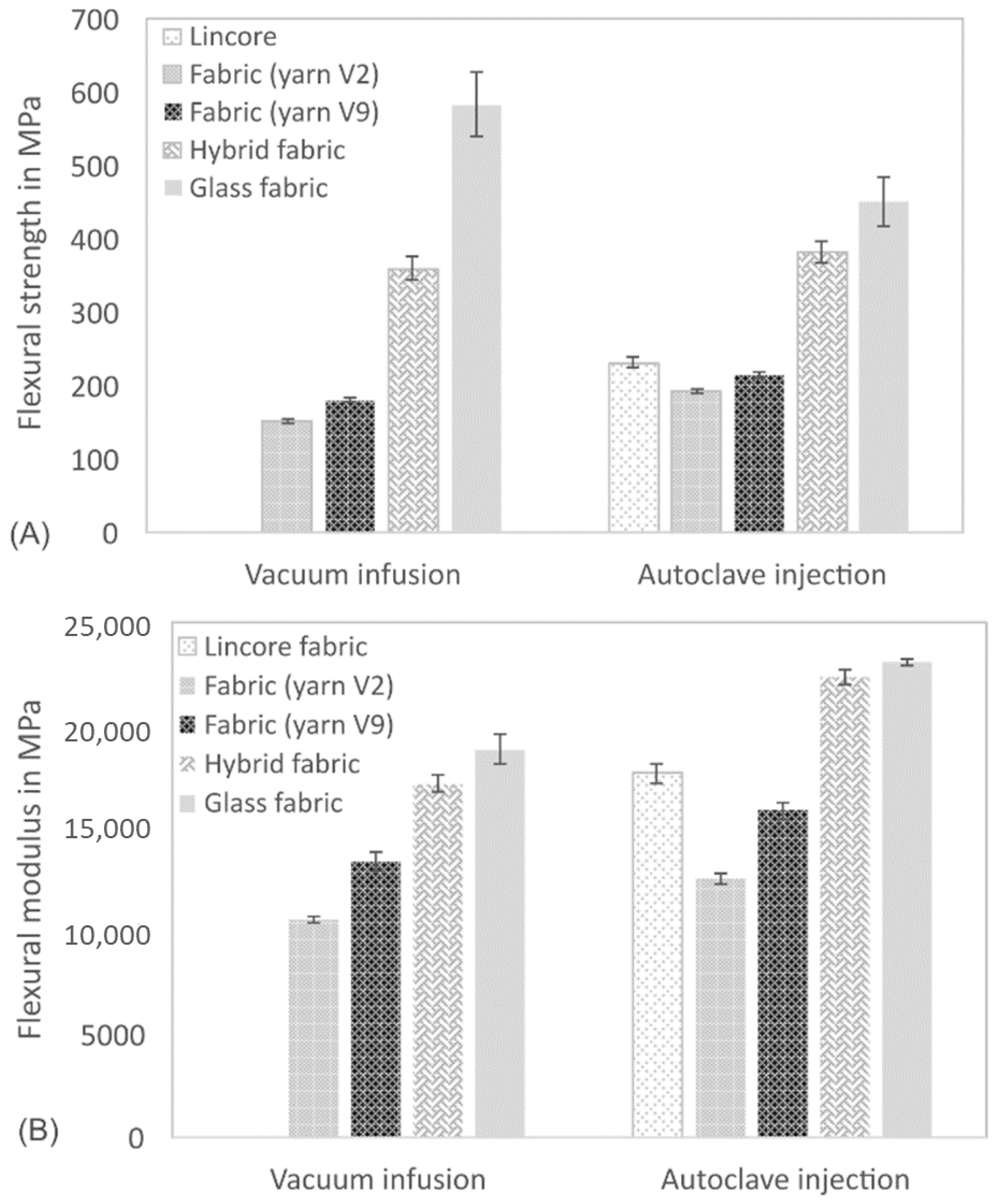

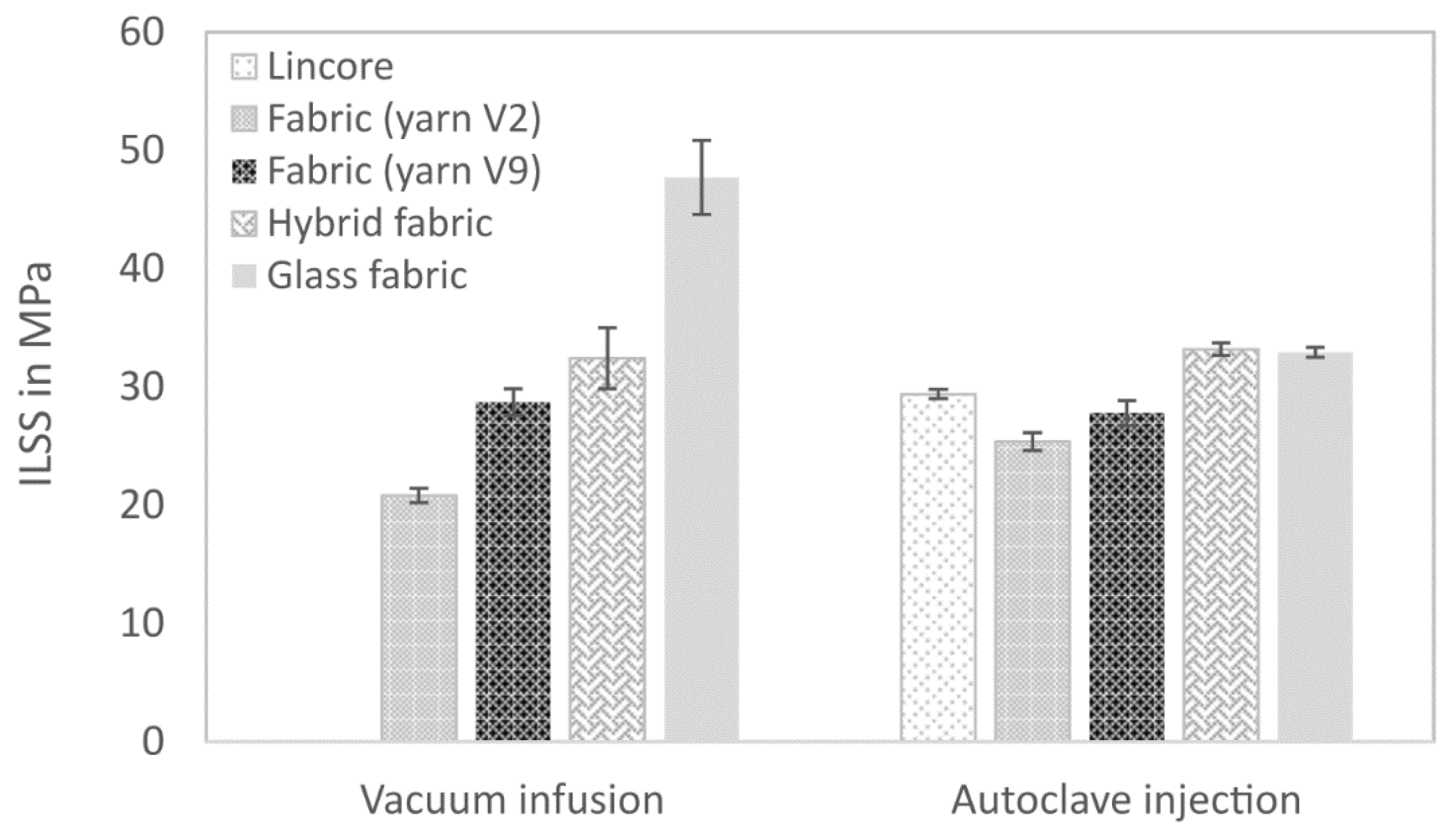

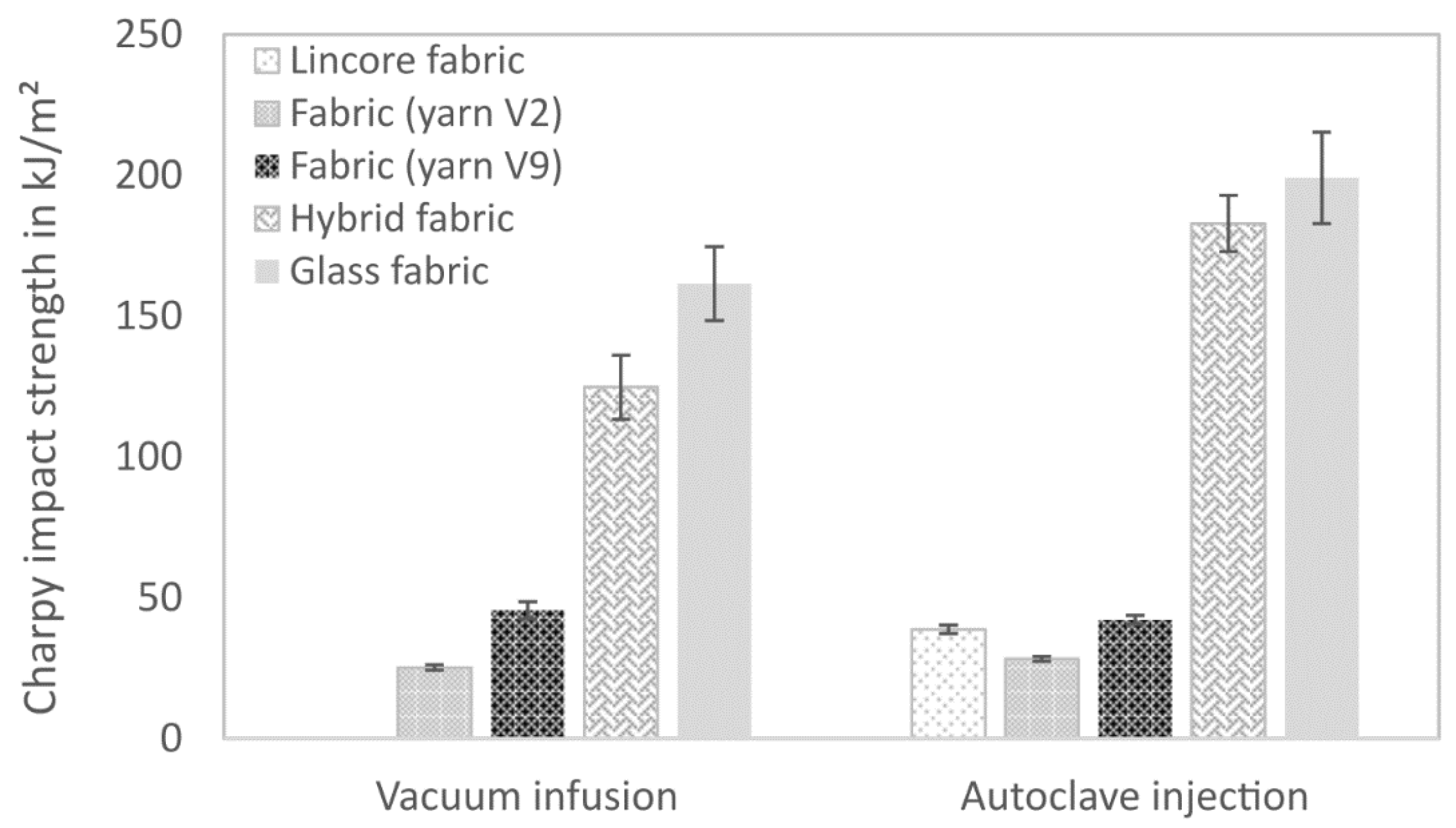

3.4. Composite Laminates from Fabrics

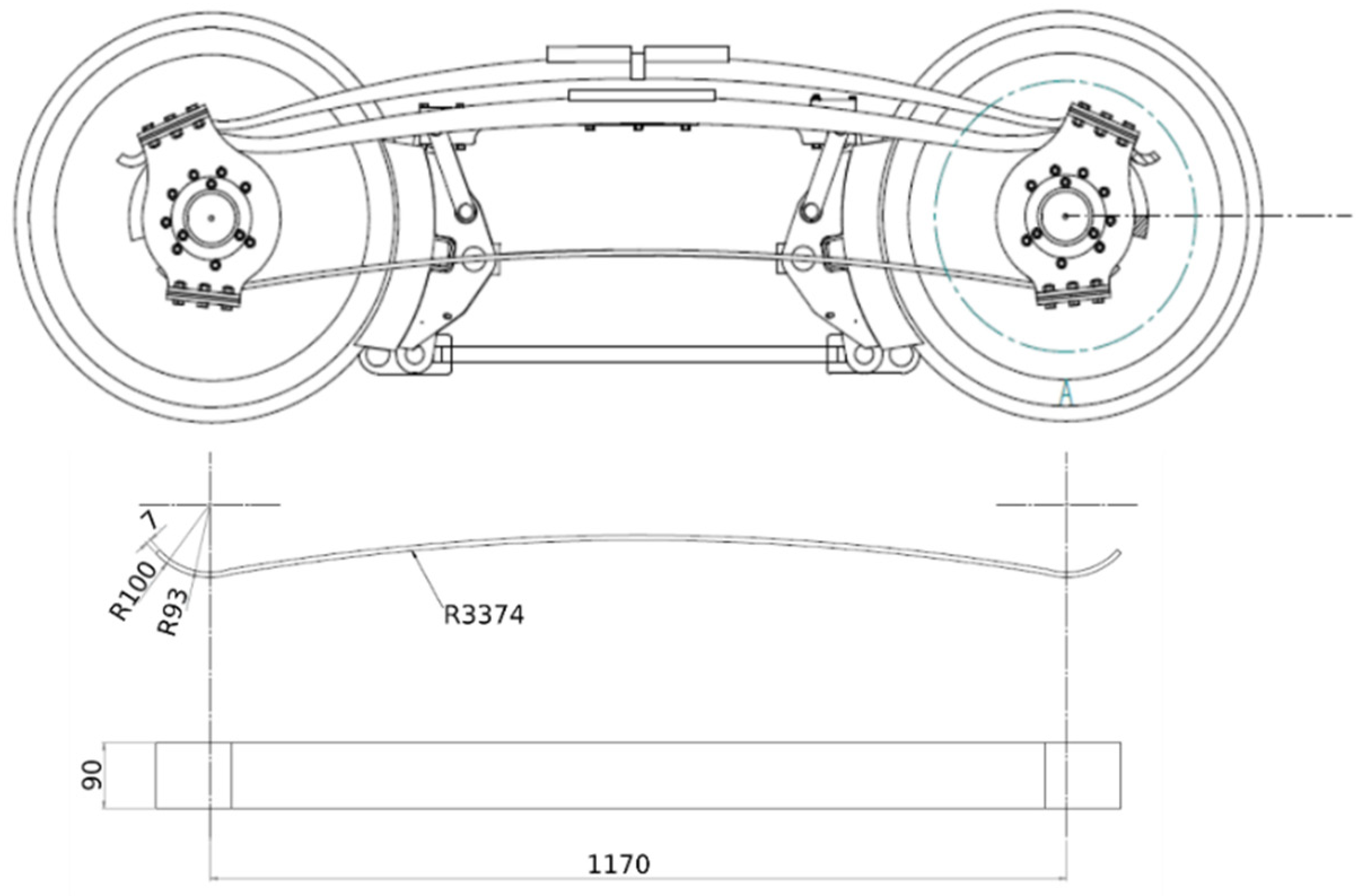

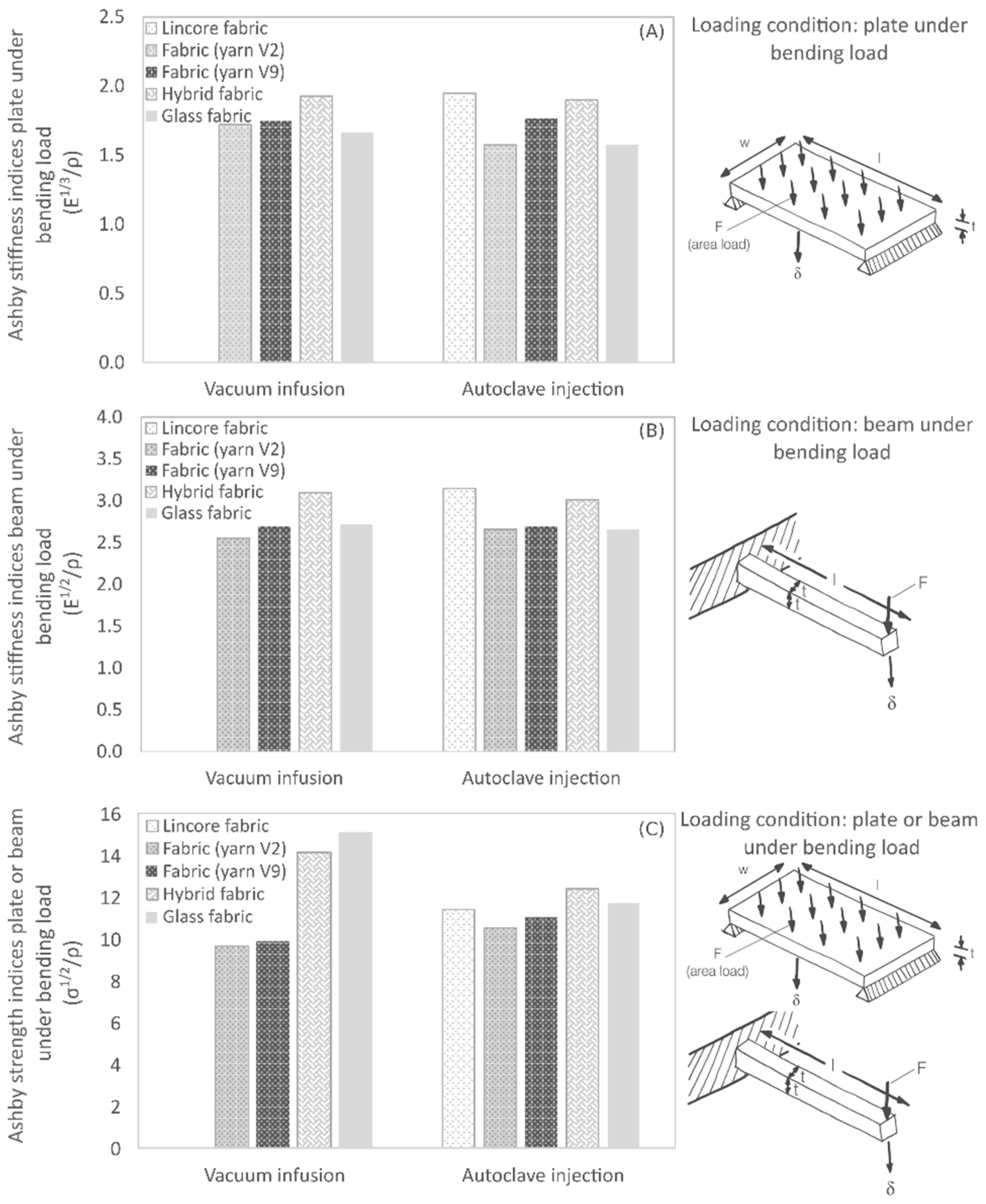

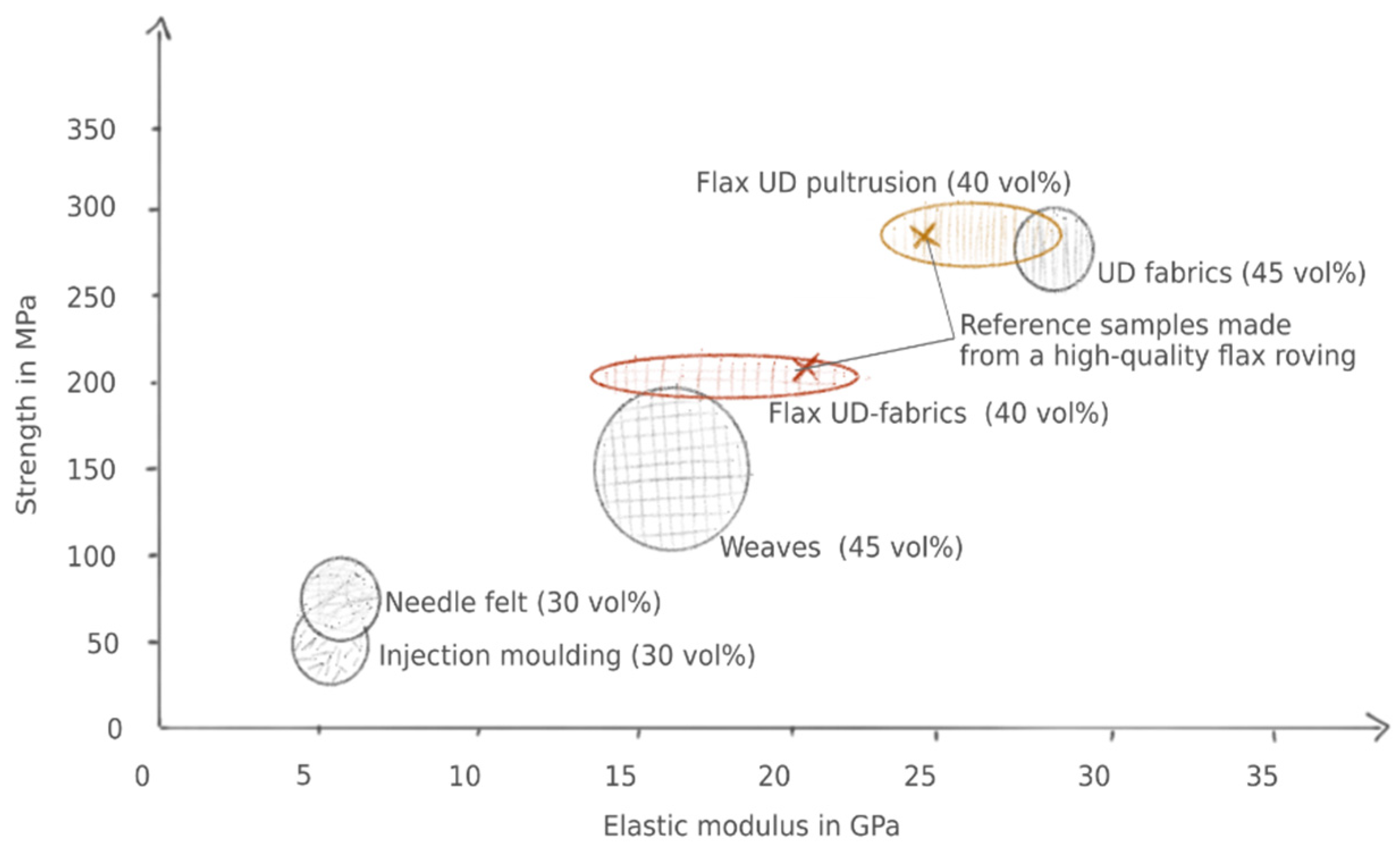

3.5. Lightweight Construction Potential

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Davies, P. Variability of mechanical properties of flax fibres for composite reinforcement. A review. Ind. Crop. Prod. 2020, 145, 111984. [Google Scholar] [CrossRef]

- Ramesh, M. Flax (Linum usitatissimum L.) fibre-reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mater. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites: A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Bourmaud, A.; Beaugrand, J.; Shah, D.U.; Placet, V.; Baley, C. Towards the design of high-performance plant fibre composites. Prog. Mater. Sci. 2018, 97, 347–408. [Google Scholar] [CrossRef]

- Scida, D.; Bourmaud, A.; Baley, C. Influence of the scattering of flax fibres properties on flax/epoxy woven ply stiffness. Mater. Des. 2017, 122, 136–145. [Google Scholar] [CrossRef]

- Poilane, C.; Cherif, Z.E.; Richard, F.; Vivet, A.; Doudou, B.; Chen, J. Polymer reinforced by flax fibres as a viscoelastoplastic material. Compos. Struct. 2014, 112, 100–112. [Google Scholar] [CrossRef]

- Santamala, H.; Livingston, R.; Sixta, H.; Hummel, M.; Skrifvars, M.; Saarela, O. Advantages of regenerated cellulose fibres as compared to flax fibres in the processability and mechanical performance of thermoset composites. Compos. Part A Appl. Sci. Manuf. 2016, 84, 377–385. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J.; Licence, P. Mechanical property characterisation of aligned plant yarn reinforced thermoset matrix composites manufactured via vacuum infusion. Polym.-Plast. Technol. Eng. 2014, 53, 239–253. [Google Scholar] [CrossRef]

- Baets, J.; Plastria, D.; Ivens, J.; Verpoest, I. Determination of the optimal flax fibre preparation for use in unidirectional flax/epoxy composites. J. Reinf. Plast. Compos. 2014, 33, 493–502. [Google Scholar] [CrossRef]

- Goutianos, S.; Peijs, T.; Nystrom, B.; Skrifvars, M. Development of flax fibre based textile reinforcements for composite applications. Appl. Compos. Mater. 2006, 13, 199–215. [Google Scholar] [CrossRef]

- Liu, Q.; Hughes, M. The fracture behaviour and toughness of woven flax fibre-reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1644–1652. [Google Scholar] [CrossRef]

- Li, Y.; Li, Q.; Ma, H. The voids formation mechanisms and their effects on the mechanical properties of flax fiber reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2015, 72, 40–48. [Google Scholar] [CrossRef]

- Madsen, B.; Lilholt, H. Physical and mechanical properties of unidirectional plant fibre composites–an evaluation of the influence of porosity. Compos. Sci. Technol. 2003, 63, 1265–1272. [Google Scholar] [CrossRef]

- Kinloch, A.J.; Taylor, A.C.; Techapaitoon, M.; Teo, W.S.; Sprenger, S. Tough, natural-fibre composites based upon epoxy matrices. J. Mater. Sci. 2015, 50, 6947–6960. [Google Scholar] [CrossRef]

- Coroller, G.; Lefeuvre, A.; Le Duigou, A.; Bourmaud, A.; Ausias, G.; Gaudry, T.; Baley, C. Effect of flax fibres individualisation on tensile failure of flax/epoxy unidirectional composite. Compos. Part A Appl. Sci. Manuf. 2013, 51, 62–70. [Google Scholar] [CrossRef]

- Martin, N.; Davies, P.; Baley, C. Comparison of the properties of scutched flax and flax tow for composite material reinforcement. Ind. Crop. Prod. 2014, 61, 284–292. [Google Scholar] [CrossRef]

- Deimann, F. (GREENBOATS GmbH, Bremen, Germany). Personal communication, 2020.

- Müssig, J.; Haag, K.; Musio, S.; Bjelková, M.; Albrecht, K.; Uhrlaub, B.; Wang, S.; Wieland, H.; Amaducci, S. Biobased’ mid-performance’ composites using losses from the hackling process of long hemp–A feasibility study as part of the development of a biorefinery concept–. Ind. Crop. Prod. 2020, 145, 111938. [Google Scholar] [CrossRef]

- Zhang, L.; Miao, M. Commingled natural fibre/polypropylene wrap spun yarns for structured thermoplastic composites. Compos. Sci. Technol. 2010, 70, 130–135. [Google Scholar] [CrossRef]

- Park, S.Y.; Choi, C.H.; Choi, W.J.; Hwang, S.S. A comparison of the properties of carbon fiber epoxy composites produced by non-autoclave with vacuum bag only prepreg and autoclave process. Appl. Compos. Mater. 2019, 26, 187–204. [Google Scholar] [CrossRef]

- Sunilpete, M.A.; Cadambi, R.M. Development of cost effective out-of-autoclave technology-vacuum infusion process with tailored fibre volume fraction. Mater. Today Proc. 2020, 21, 1293–1297. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Krishnaraj, V.; Senthil Kumar, M.; Zitoune, R. Sound and vibration damping properties of flax fiber reinforced composites. Procedia Eng. 2014, 97, 573–581. [Google Scholar] [CrossRef]

- Duc, F.; Bourban, P.E.; Plummer, C.J.G.; Manson, J.-A.E. Damping of thermoset and thermoplastic flax fibre composites. Compos. Part A Appl. Sci. Manuf. 2014, 64, 115–123. [Google Scholar] [CrossRef]

- Pil, L.; Bensadoun, F.; Pariset, J.; Verpoest, I. Why are designers fascinated by flax and hemp fibre composites? Compos. Part A 2016, 83, 193–205. [Google Scholar] [CrossRef]

- Lee, H.P.; Ng, B.M.P.; Rammohan, A.V.; Tran, L.Q.N. An investigation of the sound absorption properties of flax/epoxy composites compared with glass/epoxy composites. J. Nat. Fibers 2017, 14, 71–77. [Google Scholar] [CrossRef]

- Bensadoun, F.; Vallons, K.A.M.; Lessard, L.B.; Verpoest, I.; Van Vuure, A.W. Fatigue behaviour assessment of flax-epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 82, 253–266. [Google Scholar] [CrossRef]

- Gassan, J. A study of fibre and interface parameters affecting the fatigue behaviour of natural fibre composites. Comosites Part A Appl. Sci. Manuf. 2002, 33, 369–374. [Google Scholar] [CrossRef]

- Asgarinia, S.; Viriyasuthee, C.; Phillips, S.; Dube, M.; Baets, J.; Van Vuure, A.; Verpoest, I.; Lessard, L. Tension-tension fatigue behaviour of woven flax/epoxy composites. J. Reinf. Plast. Compos. 2015, 34, 857–867. [Google Scholar] [CrossRef]

- Seghini, M.C.; Touchard, F.; Sarasini, F.; Chocinski-Arnault, L.; Ricciardi, M.R.; Antonucci, V.; Tirillo, J. Fatigue behaviour of flax-basalt/epoxy hybrid composites in comparison with non-hybrid composites. Int. J. Fatigue 2020, 139, 105800. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Guthrie, R.; MacMullen, J.; Bennett, N. Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Di Bella, G. Mechanical behavior of carbon/flax hybrid composites for structural applications. J. Compos. Mater. 2012, 46, 2089–2096. [Google Scholar] [CrossRef]

- Ravandi, M.; Kureemun, U.; Banu, M.; Teo, W.S.; Tong, L.; Tay, T.E.; Lee, H.P. Effect of interlayer carbon fiber dispersion on the low-velocity impact performance of woven flax-carbon hybrid composites. J. Compos. Mater. 2019, 53, 1717–1734. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillo, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D.; Lampani, L.; Gaudenzi, P. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. Part B Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Wang, A.; Wang, X.; Xian, G. Mechanical, low-velocity impact, and hydrothermal aging properties of flax/carbon hybrid composite plates. Polym. Test. 2020, 90, 106759. [Google Scholar] [CrossRef]

- Papa, I.; Ricciardi, M.R.; Antonucci, V.; Pagliarulo, V.; Lopresto, V. Impact behaviour of hybrid basalt/flax twill laminates. Compos. Part B Eng. 2018, 153, 17–25. [Google Scholar] [CrossRef]

- Petrucci, R.; Santulli, C.; Puglia, D.; Sarasini, F.; Torre, L.; Kenny, J.M. Mechanical characterisation of hybrid composite laminates based on basalt fibres in combination with flax, hemp and glass fibres manufactured by vacuum infusion. Mater. Des. 2013, 49, 728–735. [Google Scholar] [CrossRef]

- Savran, M.; Aydin, L. Stochastic optimisation of graphite-flax/epoxy hybrid laminated composite for maximum fundamental frequency and minimum cost. Eng. Struct. 2018, 174, 675–687. [Google Scholar] [CrossRef]

- Sarwar, A.; Mahboob, Z.; Zdero, R.; Bougherara, H. Mechanical characterisation of a new kevlar/flax/epoxy hybrid composite in a sandwich structure. Polym. Test. 2020, 90, 106680. [Google Scholar] [CrossRef]

- Barouni, A.K.; Dhakal, H.M. Damage investigation and assessment due to low-velocity impact on flax/glass hybrid composite plates. Compos. Struct. 2019, 226, 111224. [Google Scholar] [CrossRef]

- Calabrese, L.; Fiore, V.; Scalici, T.; Valenza, A. Experimental assessment of the improved properties during aging of flax/glass hybrid composite laminates for marine applications. J. Appl. Polym. Sci. 2019, 136, 47203. [Google Scholar] [CrossRef]

- Fiore, V.; Calabrese, L.; Scalici, T.; Bruzzaniti, P.; Valenza, A. Bearing strength and failure behavior of pinned hybrid glass-flax composite laminates. Polym. Test. 2018, 69, 310–319. [Google Scholar] [CrossRef]

- Jusoh, M.S.M.; Santulli, C.; Yahya, M.Y.; Hussein, N.S.; Ahmad, H. Effect of stacking sequence on the tensile and flexural properties of glass fibre epoxy composites hybridised with basalt, flax or jute fibres. Mater. Sci. Eng. Adv. Res. 2017, 1, 19–25. [Google Scholar]

- Meenakshi, C.M.; Krishnamoorthy, A. Study on the effect of surface modification on the mechanical and thermal behaviour of flax, sisal and glass fiber-reinforced epoxy hybrid composites. J. Renew. Mater. 2019, 7, 153–169. [Google Scholar] [CrossRef]

- Morye, S.S.; Wool, R.P. Mechanical properties of glass/flax hybrid composites based on a novel modified soybean oil matrix material. Polym. Compos. 2005, 26, 407–416. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Assarar, M.; Sabhi, H.; Ayad, R. Hybridisation effect on diffusion kinetic and tensile mechanical behaviour of epoxy based flax-glass composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 153–160. [Google Scholar] [CrossRef]

- Saidane, E.H.; Scida, D.; Assarar, M.; Ayad, R. Damage mechanisms assessment of hybrid flax-glass fibre composites using acoustic emission. Compos. Struct. 2017, 174, 1–11. [Google Scholar] [CrossRef]

- Santulli, C.; Janssen, M.; Jeronimidis, G. Partial replacement of e-glass fibers with flax fibers in composites and effect on falling weight impact performance. J. Mater. Sci. 2005, 40, 3581–3585. [Google Scholar] [CrossRef]

- Selver, E.; Ucar, N.; Gulmez, T. Effect of stacking sequence on tensile, flexural and thermomechanical properties of hybrid flax/glass and jute/glass thermoset composites. J. Ind. Text. 2018, 48, 494–520. [Google Scholar] [CrossRef]

- Sathish, S.; Kumaresan, K.; Prabhu, L.; Gokulkumar, S. Experimental investigation of mechanicaland ftir analysis of flax fiber/epoxy compositesincorporating sic, Al2O3 and graphite. Rom. J. Mater. 2018, 48, 476–482. [Google Scholar]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung. DIN EN ISO 139:2005–Textiles-Standard Atmospheres for Conditioning and Testing; DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2005. [Google Scholar]

- Graupner, N.; Sarasini, F.; Müssig, J. Ductile viscose fibres and stiff basalt fibres for composite applications-an overview and the potential of hybridisation. Compos. Part B Eng. 2020, 194, 108041. [Google Scholar] [CrossRef]

- Deutsches Institut für Normung. DIN EN ISO 291:2005–Plastics–Standard Atmospheres for Conditioning and Testing; DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2005. [Google Scholar]

- Deutsches Institut für Normung. DIN EN ISO 14125:2003–Fibre-Reinforced Plastic Composites–Determination of Flexural Properties; DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2003. [Google Scholar]

- International Organization for Standardization. ISO 3597-1:2003: Textile-Glass-Reinforced Plastics–Determination of Mechanical Properties on Rods Made of Roving-Reinforced Resin–Part 2: Determination of Flexural Strength; ISO International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

- Deutsches Institut für Normung. DIN EN 14130:1998–Fibre-Reinforced Plastic Composites–Determination of Apparent Interlaminar Shear Strength by Short-Beam Method; DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 1998. [Google Scholar]

- Deutsches Institut für Normung. DIN EN ISO 527-2:1996–Plastics–Determination of Tensile Properties–Part 2: Test Conditions for Moulding and Extrusion Plastics; DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 1996. [Google Scholar]

- Truong, M.; Zhong, W.; Boyko, S.; Alcock, M. A comparative study on natural fibre density measurement. J. Text. Inst. 2009, 100, 525–529. [Google Scholar] [CrossRef]

- Van de Weyenberg, I.; Ivens, J.; De Coster, A.; Kino, B.; Baetens, E.; Verpoest, I. Influence of processing and chemical treatment of flax fibres on their composites. Compos. Sci. Technol. 2003, 63, 1241–1246. [Google Scholar] [CrossRef]

- Heijenrath, R.; Peijs, T. Natural-fibre-mat-reinforced thermoplastic composites based on flax fibres and polypropylene. Adv. Compos. Lett. 1996, 5, 81–85. [Google Scholar] [CrossRef]

- Riedel, U.; Gassan, J.; Karus, M.; Müssig, J.; Prömper, E.; Schönberger, D.; Sperber, V. Technical and economical framework for parts based on natural fibre composites. In Proceedings of the 8th Internationale AVK-TV Tagung für verstärkte Kunststoffe und duroplastische Formmassen, Baden-Baden, Germany, 27–28 September 2005; Arbeitsgemeinschaft Verstärkte Kunststoffe: Frankfurt am Main, Germany, 2005; pp. A 3–1–A 3–11. [Google Scholar]

- Cerbu, C.; Botis, M. Numerical modeling of the flax/glass/epoxy hybrid composite materials in bending. Procedia Eng. 2017, 181, 308–315. [Google Scholar] [CrossRef]

- Groupe Depestele. Dry Flax Fabrics Range. 2020. Available online: https://www.groupedepestele.com/pro_ecomateriaux_licoreffang.html (accessed on 24 October 2020).

- Duc, F.; Bourban, P.E.; Manson, J.-A.E. The role of twist and crimp on the vibration behaviour of flax fibre composites. Compos. Sci. Technol. 2014, 102, 94–99. [Google Scholar] [CrossRef]

- Kersani, M.; Lomov, S.V.; Van Vuure, A.W.; Bouabdallah, A.; Verpoest, I. Damage in flax/epoxy quasi-unidirectional woven laminates under quasi-static tension. J. Compos. Mater. 2015, 49, 403–413. [Google Scholar] [CrossRef]

- Compston, P.; Jar, P.-Y.B. The influence of fibre volume fraction on the mode I interlaminar fracture toughness of a glass-fibre/vinyl ester composite. Appl. Compos. Mater. 1999, 6, 353–368. [Google Scholar] [CrossRef]

- Budan, A.D.; Basavarajappa, S.; Prasanna Kumar, M.; Joshi, A.G. Influence of fibre volume reinforcement in drilling GFRP laminates. J. Eng. Sci. Technol. 1999, 6, 733–744. [Google Scholar]

- Marrot, L.; Bourmaud, A.; Bono, P.; Baley, C. Multi-scale study of the adhesion between flax fibers and biobased thermoset matrices. Mater. Des. 2014, 62, 47–56. [Google Scholar] [CrossRef]

- Esnaola, A.; Tena, I.; Aurrekoetxea, J.; Gallego, I.; Ulacia, I. Effect of fibre volume fraction on energy absorption capabilities of e-glass/polyester automotive crash structures. Compos. Part B Eng. 2016, 85, 1–7. [Google Scholar] [CrossRef]

- Ashir, M.; Nocke, A.; Bulavinov, A.; Pinchuk, R.; Cherif, C. Influence of defined amount of voids on the mechanical properties of carbon fiber-reinforced plastics. Polym. Compos. 2019, 40, E1049–E1056. [Google Scholar] [CrossRef]

- Dong, C. Effects of process-induced voids on the properties of fibre reinforced composites. J. Mater. Sci. Technol. 2016, 32, 597–604. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, Z.-M.; Liu, L. Prediction of interfacial debonding in fiber-reinforced composite laminates. Polym. Compos. 2019, 40, 1828–1841. [Google Scholar] [CrossRef]

- Graupner, N.; Labonte, D.; Müssig, J. Rhubarb petioles inspire biodegradable cellulose fibre-reinforced PLA composites with increased impact strength. Compos. Part A Appl. Sci. Manuf. 2017, 98, 218–226. [Google Scholar] [CrossRef]

- Graupner, N.; Labonte, D.; Humburg, H.; Buzkan, T.; Dörgens, A.; Kelterer, W.; Müssig, J. Functional gradients in the pericarp of the green coconut inspire asymmetric fibre-composites with improved impact strength, and preserved flexural and tensile properties. Bioinspiration Biomim. 2017, 12, 026009. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene. 4. Impact properties. Compos. Part A Appl. Sci. Manuf. 1997, 28, 277–288. [Google Scholar] [CrossRef]

- Ashby, M.F.; Gibson, L.; Wegst, U.; Olive, R. The mechanical properties of natural materials. I. material property charts. Proc. R. Soc. Lond. A 1995, 450, 123–140. [Google Scholar]

- Ashby, M.F.; Jones, D.R.H. Werkstoffe 2: Metalle, Keramik und Gläser, Kunststoffe und Verbundwerkstoffe, 3rd ed.; Spektrum Akademischer Verlag-Elsevier GmbH: Munich, Germany, 2005. (In Germany) [Google Scholar]

| Reinforcement | Mass per Unit Area in g/m2 | Per Cent by Mass of Reinforcing Fibres in % | Per Cent by Mass of Warp Threads (PES) in % |

|---|---|---|---|

| Lincore fabric (Rε3) | 275.2 | 84.0 | 16.0 |

| Glass fabric (Rε4) | 296.6 | 83.6 | 16.4 |

| Flax fabric 006 (Aε1 and Aε3) | 300.5 | 84.3 | 15.7 |

| Flax fabric 013 (Aε4 and Aε5) | 287.5 | 83.9 | 16.1 |

| Pultrusion (Yarn)—Round Rods | Pultrusion (Yarn)—Rectangular Rods | Vacuum-Infusion—UD Fabric Laminates | Autoclave-Injection—UD Fabric Laminates |

|---|---|---|---|

| Lincore roving, 40% (Rγ1) | Lincore roving, 30% (Rγ1) | - | Lincore fabric (Rε3), 5 layers |

| Glass roving, 40% (Rγ2) | - | Glass fabric (Rε8), 6 layers | Glass fabric (Rε4), 9 layers |

| Flax yarn V1, 945 tex, 40% (Aγ1) | - | - | - |

| Flax yarn V2, 213 tex, sliver 40% (Aγ2) | Flax yarn V2, 213 tex, sliver 30% (Aγ2) | Flax fabric, yarn V2 (006, Aε3), 4 layers | Flax fabric, yarn V2 (006, Aε1), 5 layers |

| Flax yarn V9, 200 tex, re-stretched sliver, 40% (Aγ9) | Flax yarn V9, 200 tex, re-stretched sliver, 30% (Aγ9) | Flax fabric, yarn V9 (014, Aε5), 4 layers | Flax fabric, yarn V9 (013, Aε4), 5 layers |

| Flax yarn V10, 200 tex, 2x re-stretched sliver, 40% (Aγ10) | Flax yarn V10, 200 tex, 2x re-stretched sliver, 30% (Aγ10) | - | - |

| - | - | Flax/glass hybrid, 2 × 1 glass outer layers, 3 flax (V9) inner layers (Rε6) | Flax/glass hybrid, 2 × 2 glass outer layers, 3 flax (V9) inner layers) (Rε5) |

| Flax yarn, 200 tex, re-stretched sliver, 55% (Aγ9) | - | - | - |

| Sample | Density in g/cm3 | Fibre Volume in % | Voids in % |

|---|---|---|---|

| Round rods | |||

| Lincore roving, 40% (Rγ1) | 1.265 ± 0.005 | 45.3 | 2.7 |

| Glass roving, 40% (Rγ2) | 1.747 ± 0.016 | 46.5 | 1.0 |

| Flax yarn V1, 945 tex, 40% (Aγ1) | 1.228 ± 0.022 | 43.9 | 1.6 |

| Flax yarn V2, 213 tex, sliver 40% (Aγ2) | 1.270 ± 0.014 | 42.2 | 1.1 |

| Flax yarn V9, 200 tex, re-stretched sliver, 40% (Aγ9) | 1.295 ± 0.008 | 44.6 | 0.3 |

| Flax yarn V10, 200 tex, 2x re-stretched sliver, 40% (Aγ10) | 1.275 ± 0.006 | 43.2 | 1.3 |

| Flax yarn V9, 200 tex, re-stretched sliver, 55% (Aγ9) | 1.319 ± 0.005 | 55.5 | 1.1 |

| Rectangular rods | |||

| Lincore roving, 30% (Rγ1) | 1.174 ± 0.004 | 30.4 | 6.9 |

| Flax yarn V2, 213 tex, sliver 30% (Aγ2) | 1.186 ± 0.017 | 31.5 | 5.4 |

| Flax yarn V9, 200 tex, re-stretched sliver, 30% (Aγ9) | 1.161 ± 0.030 | 32.0 | 7.5 |

| Flax yarn V10, 200 tex, 2x re-stretched sliver, 30% (Aγ10) | 1.152 ± 0.040 | 31.3 | 8.1 |

| Manufacturing Process/Composite | Layers | Density in g/cm3 | Volume Fraction PES in % | Volume Fraction Reinforcing Fibre in % |

|---|---|---|---|---|

| Vacuum infusion | ||||

| Glass fabric (Rε8) | 6 | 1.60 | 11.2 | 30.5 |

| Flax fabric, yarn V2 (006, Aε3) | 4 | 1.28 | 6.6 | 33.6 |

| Flax fabric, yarn V9 (014, Aε5) | 4 | 1.46 | 7.4 | 36.5 |

| Flax/glass hybrid, 2 × 1 glass outer layers, 3 flax (V9) inner layers (Rε6) | - | - | - | - |

| Glass | 3 | - | 3.5 | 9.6 |

| Flax | 2 | - | 5.0 | 24.8 |

| Ʃ | 5 | 1.34 | 8.5 | 34.4 |

| Flax/glass hybrid, 2 × 1 flax (V9) outer layers, 3 Glass inner layers (Rε7) | - | - | - | - |

| Glass | 2 | - | 6.9 | 18.7 |

| Flax | 3 | - | 4.3 | 21.3 |

| Ʃ | 5 | 1.45 | 11.2 | 40.0 |

| Autoclave injection | ||||

| Lincore fabric (Rε3) | 5 | 1.34 | 9.6 | 48.0 |

| Glass fabric (Rε4) | 9 | 1.81 | 15.7 | 42.7 * |

| Flax fabric, yarn V2 (006, Aε1) | 5 | 1.32 | 10.5 | 52.9 |

| Flax fabric, yarn V9 (013, Aε4) | 5 | 1.32 | 10.4 | 50.7 |

| Flax/glass hybrid, 2 × 2 glass outer layers, 3 flax (V9) inner layers) (Rε5) | - | - | - | - |

| Glass | 4 | - | 7.6 | 20.8 |

| Flax | 3 | - | 5.4 | 26.6 |

| Ʃ | 7 | 1.57 | 13.0 | 47.4 |

| Sample Mechanical Characteristics | Tensile Strength | Young’s Modulus | Flexural Strength | Flexural Modulus | Charpy impact Strength | ILSS |

|---|---|---|---|---|---|---|

| in MPa | in GPa | in MPa | in GPa | in kJ/m2 | in MPa | |

| Vacuum-infusion process | ||||||

| Glass fabric (Rε8), 6 layers | 635.0 ± 12.3 | 30.1 ± 0.4 | 584.5 ± 43.9 | 18.9 ± 0.7 | 161.5 ± 13.1 | 47.7 ± 3.1 |

| Flax fabric, yarn V2 (006, Aε3), 4 layers | 165.3 ± 4.1 | 12.1 ± 0.5 | 153.9 ± 3.2 | 10.7 ± 0.2 | 25.2 ± 0.9 | 20.8 ± 0.6 |

| Flax fabric, yarn V9 (014, Aε5), 4 layers | 198.2 ± 6.6 | 16.3 ± 0.2 | 181.8 ± 3.6 | 13.4 ± 0.4 | 45.6 ± 3.1 | 28.7 ± 1.1 |

| Flax/glass hybrid, 2 × 1 glass outer layers, 3 flax (V9) inner layers (Rε6) | 315.8 ± 9.9 | 22.0 ± 0.3 | 360.9 ± 15.5 | 17.2 ± 0.4 | 124.7 ± 11.4 | 32.4 ± 2.6 |

| Autoclave-injection process | ||||||

| Lincore fabric (Rε3), 5 layers | 249.4 ± 4.1 | 25.2 ± 0.7 | 232.6 ± 6.6 | 17.7 ± 0.5 | 38.8 ± 1.5 | 29.4 ± 0.4 |

| Glass fabric (Rε4), 9 layers | 817.3 ± 16.1 | 35.8 ± 1.2 | 452.2 ± 32.8 | 23.1 ± 0.2 | 199.0 ± 16.2 | 32.9 ± 0.4 |

| Flax fabric, yarn V2 (006, Aε1), 5 layers | 175.8 ± 5.7 | 18.8 ± 0.7 | 193.2 ± 3.8 | 12.6 ± 0.3 | 23.8 ± 0.9 | 25.4 ± 0.8 |

| Flax fabric, yarn V9 (013, Aε4), 5 layers | 215.7 ± 8.2 | 21.7 ± 0.8 | 215.1 ± 4.7 | 15.9 ± 0.4 | 42.2 ± 1.5 | 27.8 ± 1.1 |

| Flax/glass hybrid, 2 × 2 glass outer layers, 3 flax (V9) inner layers) (Rε5) | 401.5 ± 7.6 | 29.7 ± 0.8 | 383.9 ± 14.2 | 22.4 ± 0.4 | 182.8 ± 10.0 | 33.2 ± 0.5 |

| Reinforcement | Fibre Volume Fraction in % | Tensile Strength in MPa | Tensile Modulus in GPa | Reference |

|---|---|---|---|---|

| Quasi-UD flax fabric | 36 | 153 | n.s. | [14] |

| Quasi-UD flax fabric (yarn V9) | 37 | 198 | 16 | This study |

| Quasi-UD Lincore fabric | 40 | 270 | 28 | [63] |

| Quasi-UD flax fabric | 40 | 252 | 20 | [64] |

| Quasi-UD flax fabric | 44 | 163 | n.s. | [14] |

| Quasi-UD flax fabric | 45 | 218 | 23.5 | [12] |

| Quasi-UD flax fabric | 46 | 235 | 23 | [6] |

| Quasi-UD flax fabric | 47 | 296 | 27 | [65] |

| Quasi-UD Lincore fabric | 48 | 249 | 25 | This study |

| Quasi-UD flax fabric (yarn V9) | 51 | 216 | 22 | This study |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Graupner, N.; Lehmann, K.-H.; Weber, D.E.; Hilgers, H.-W.; Bell, E.G.; Walenta, I.; Berger, L.; Brückner, T.; Kölzig, K.; Randerath, H.; et al. Novel Low-Twist Bast Fibre Yarns from Flax Tow for High-Performance Composite Applications. Materials 2021, 14, 105. https://doi.org/10.3390/ma14010105

Graupner N, Lehmann K-H, Weber DE, Hilgers H-W, Bell EG, Walenta I, Berger L, Brückner T, Kölzig K, Randerath H, et al. Novel Low-Twist Bast Fibre Yarns from Flax Tow for High-Performance Composite Applications. Materials. 2021; 14(1):105. https://doi.org/10.3390/ma14010105

Chicago/Turabian StyleGraupner, Nina, Karl-Heinz Lehmann, David E. Weber, Hans-Willi Hilgers, Erik G. Bell, Isabel Walenta, Luisa Berger, Torsten Brückner, Kay Kölzig, Herbert Randerath, and et al. 2021. "Novel Low-Twist Bast Fibre Yarns from Flax Tow for High-Performance Composite Applications" Materials 14, no. 1: 105. https://doi.org/10.3390/ma14010105

APA StyleGraupner, N., Lehmann, K.-H., Weber, D. E., Hilgers, H.-W., Bell, E. G., Walenta, I., Berger, L., Brückner, T., Kölzig, K., Randerath, H., Bruns, A., Frank, B., Wonneberger, M., Joulian, M., Bruns, L., von Dungern, F., Janßen, A., Gries, T., Kunst, S., & Müssig, J. (2021). Novel Low-Twist Bast Fibre Yarns from Flax Tow for High-Performance Composite Applications. Materials, 14(1), 105. https://doi.org/10.3390/ma14010105