Structural and Micromechanical Properties of Nd:YAG Laser Marking Stainless Steel (AISI 304 and AISI 316)

Abstract

:1. Introduction

2. Materials and Methods

Experimental

3. Results and Discussion

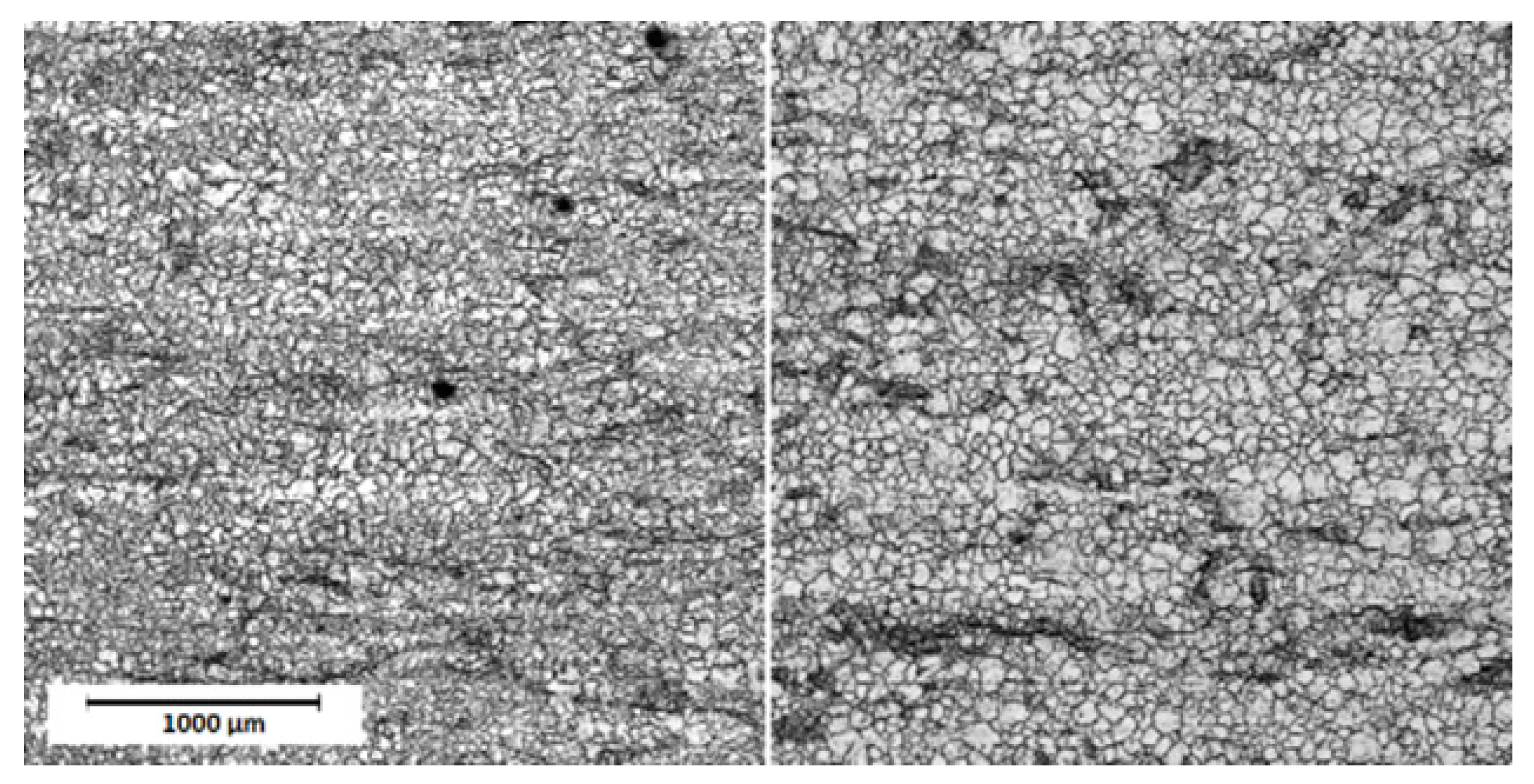

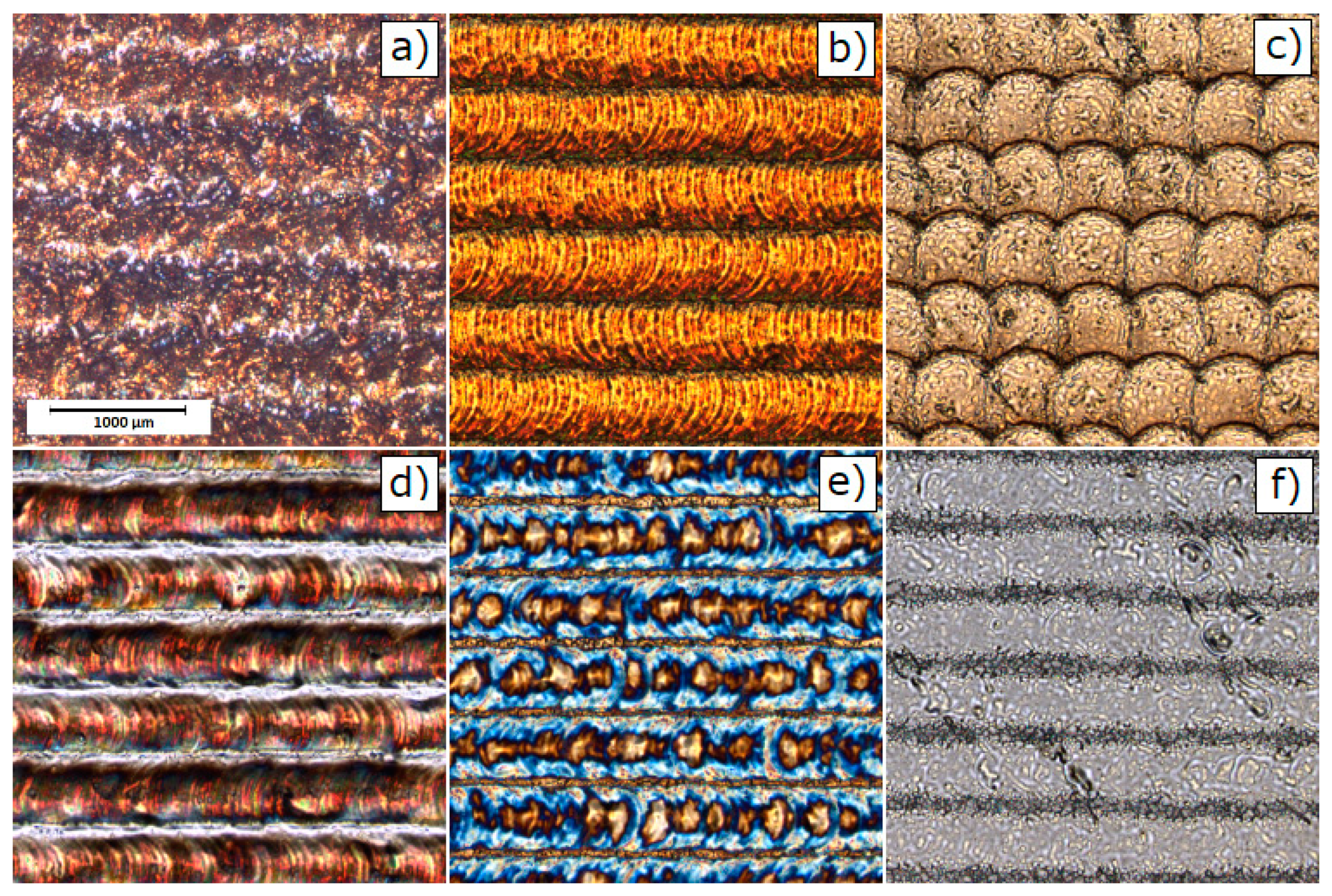

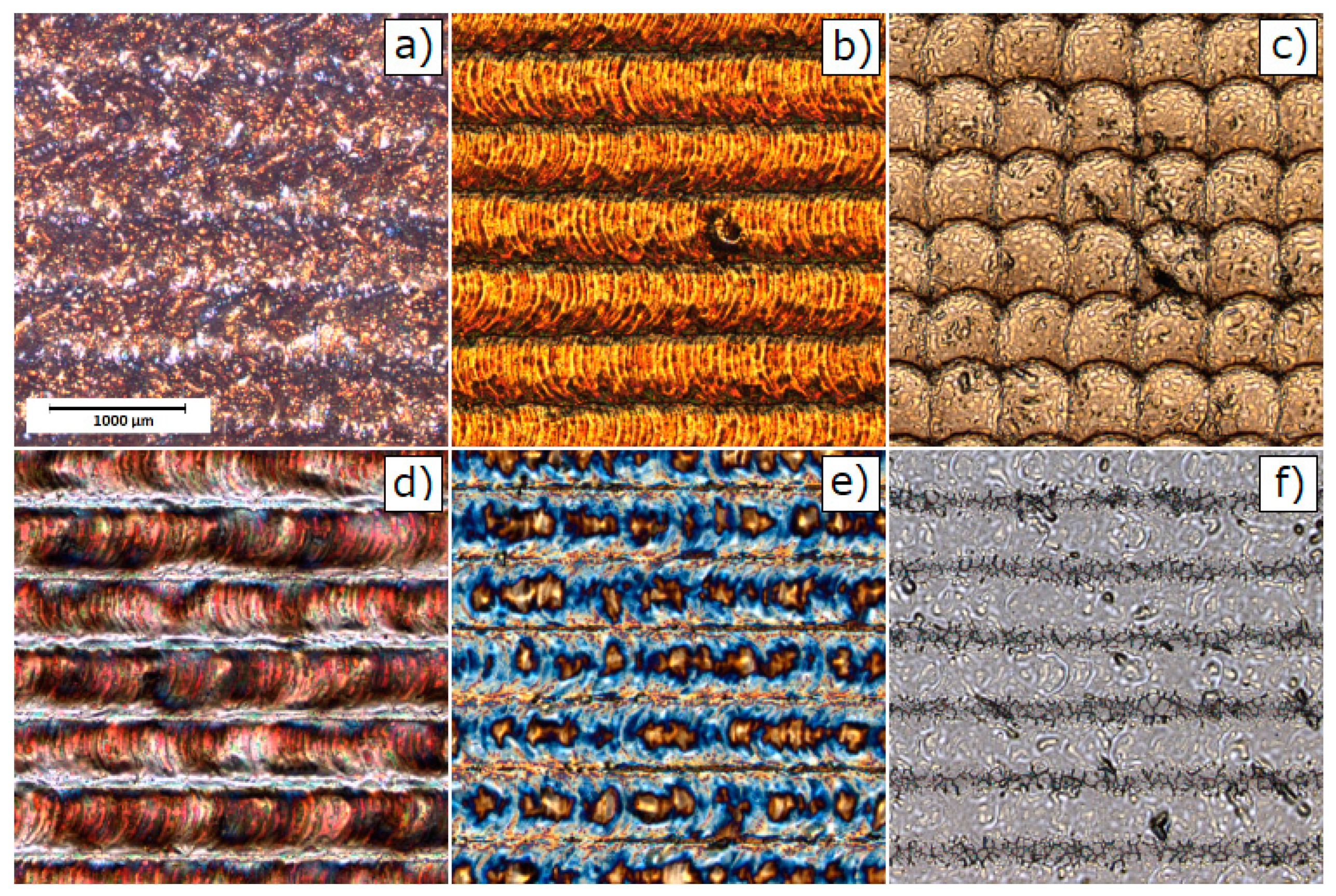

3.1. Topography

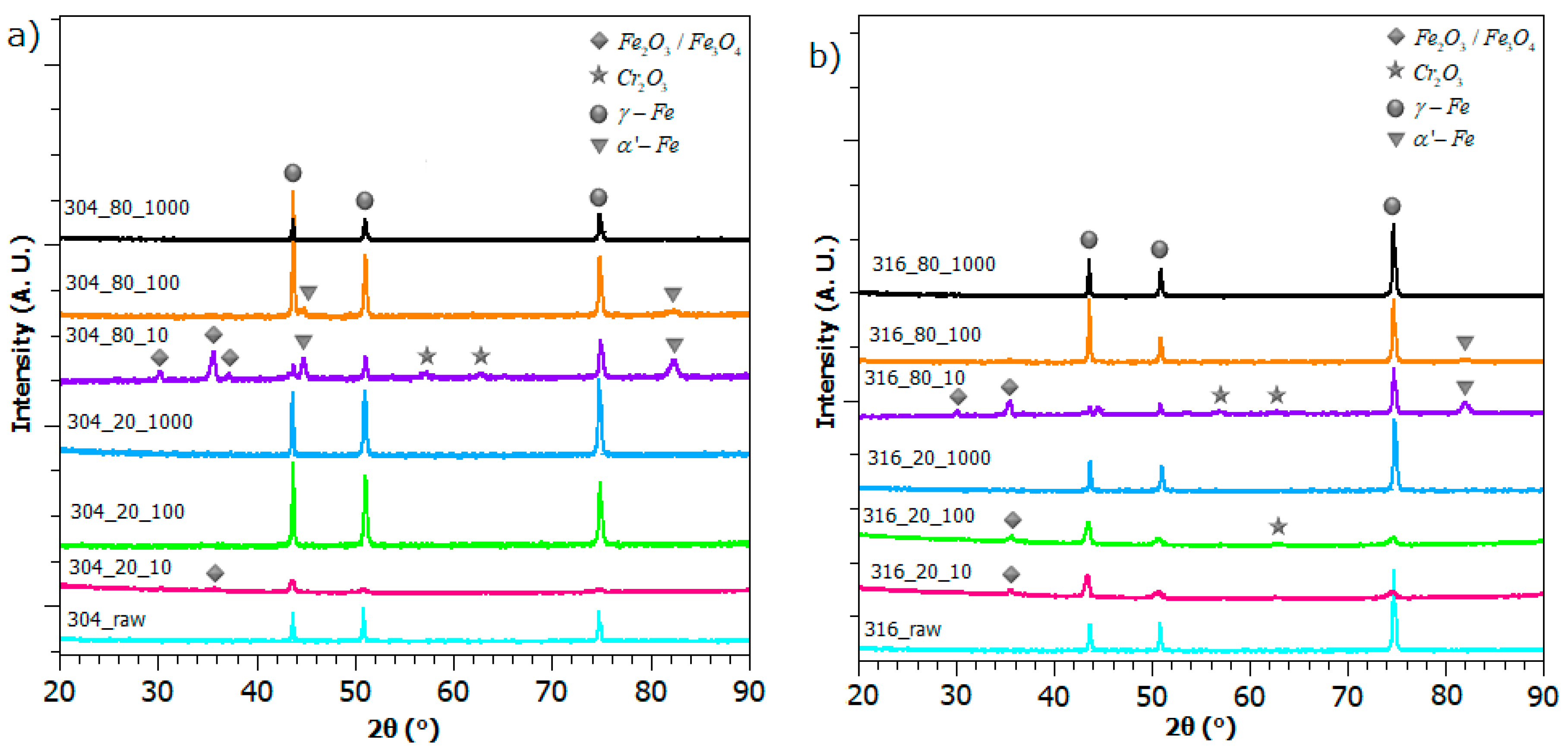

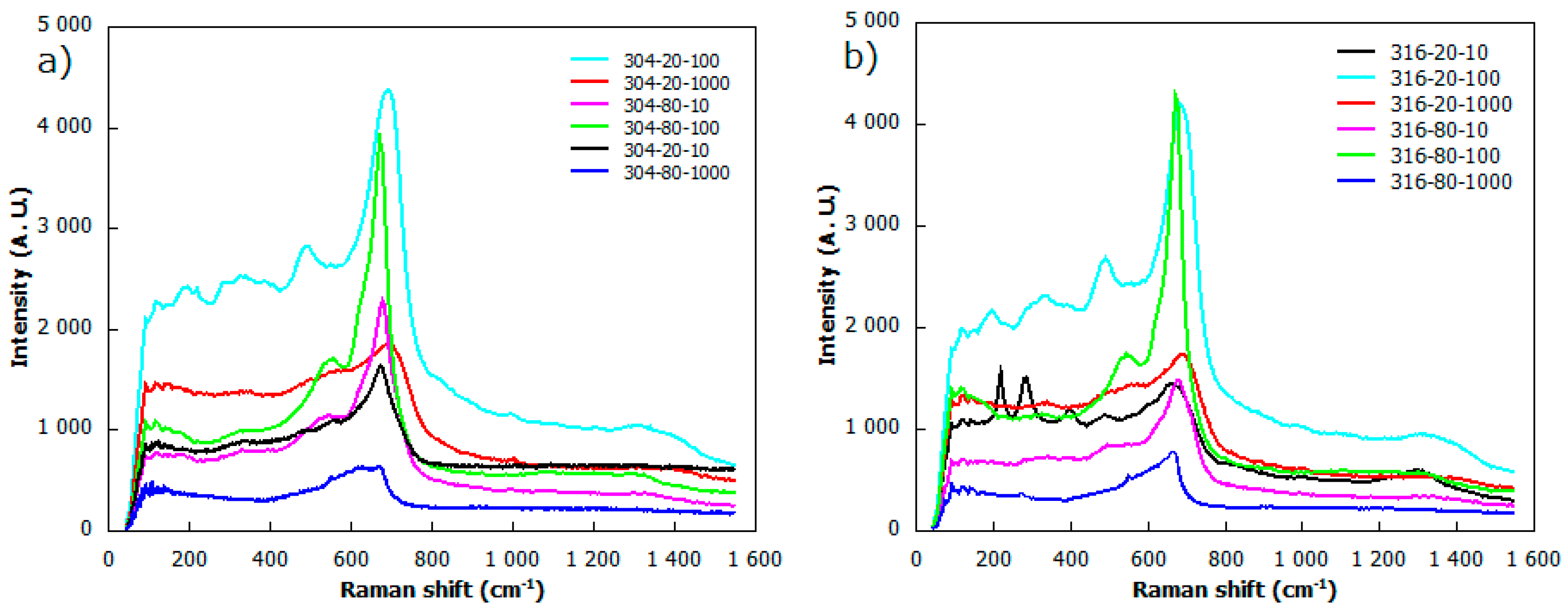

3.2. Phase Composition

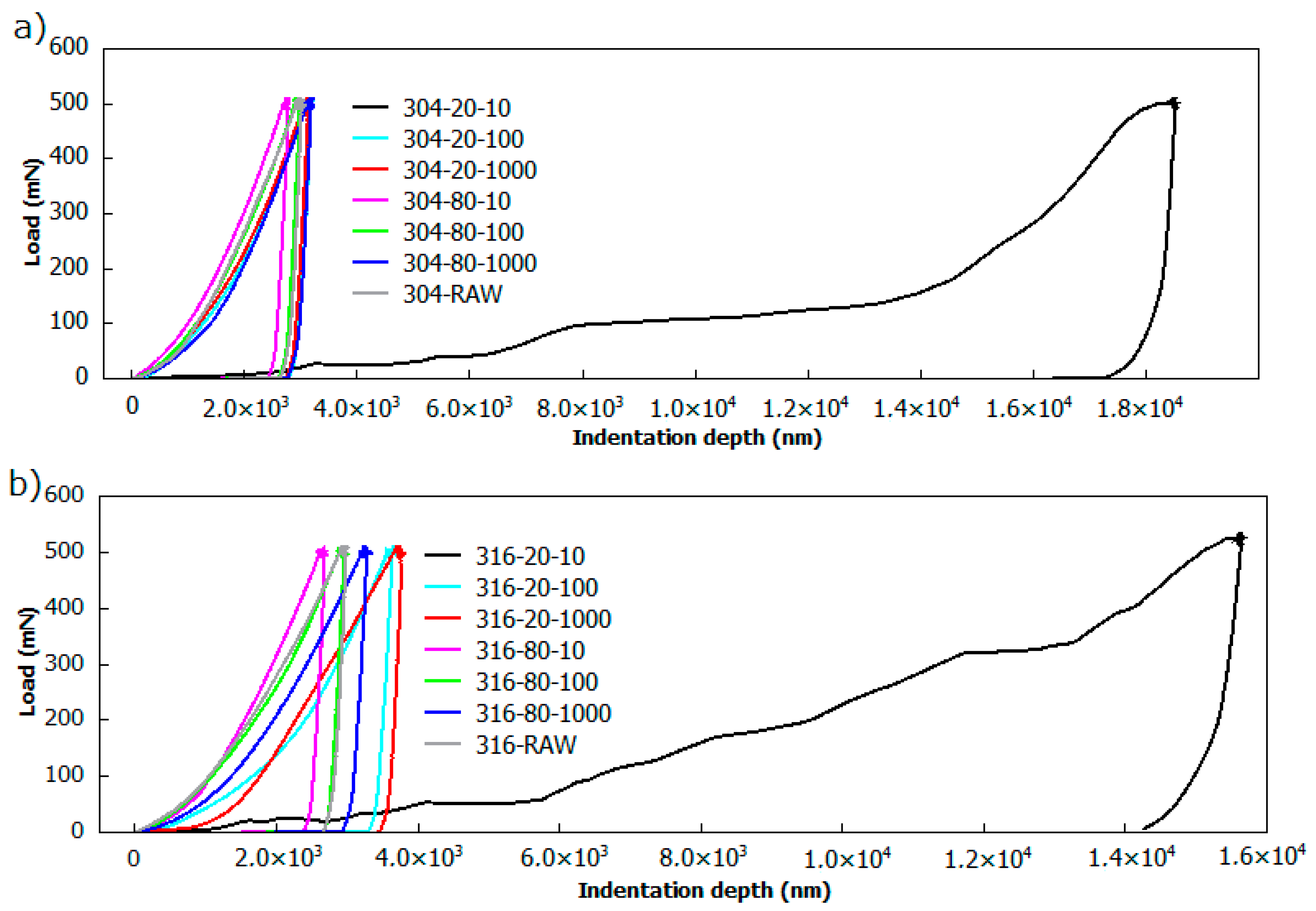

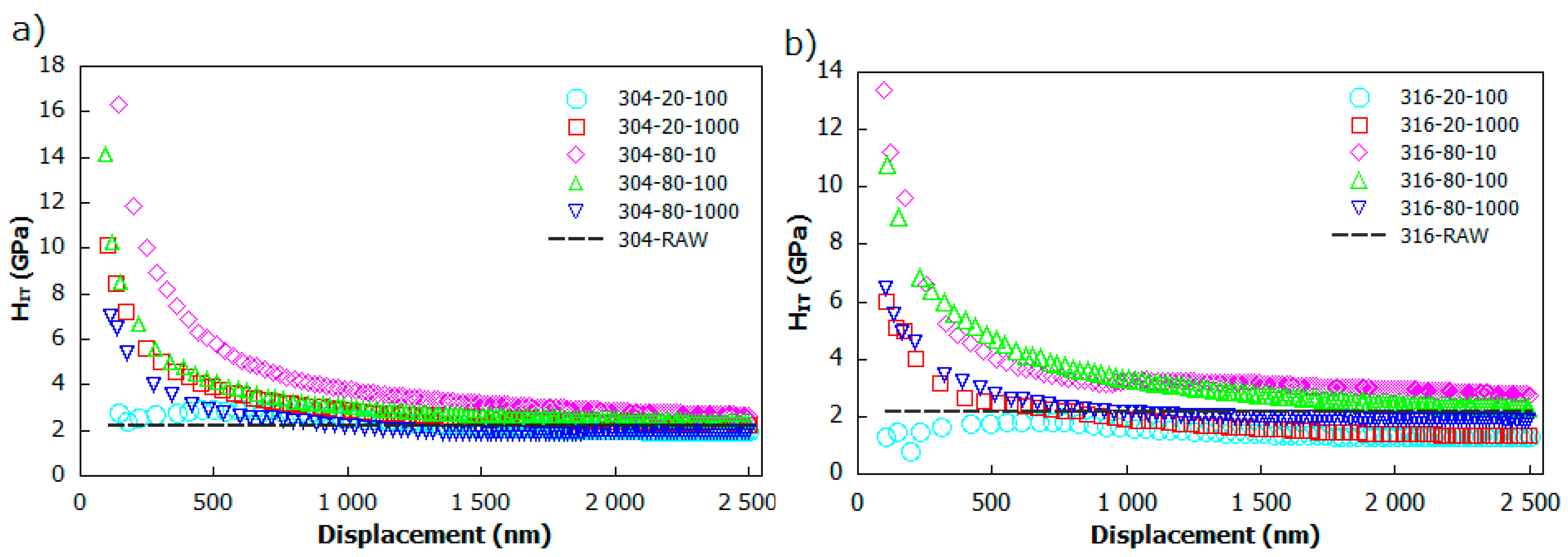

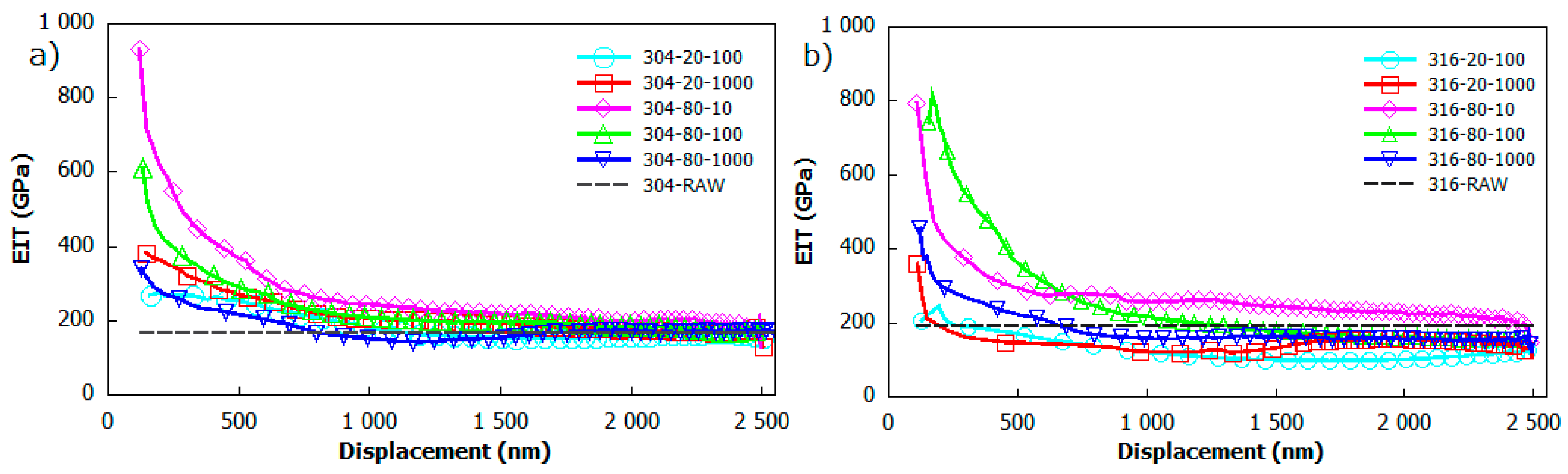

3.3. Microhardness Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dutta Majumdar, J.; Galun, R.; Mordike, B.L.; Manna, I. Effect of laser surface melting on corrosion and wear resistance of a commercial magnesium alloy. Mater. Sci. Eng. A 2003, 361, 119–129. [Google Scholar] [CrossRef]

- Yang, S.; Wang, Z.; Kokawa, H.; Sato, Y.S. Reassesment of the effects of laser surface melting on IGC of SUS 304. Mater. Sci. Eng. A. 2008, 474, 112–119. [Google Scholar] [CrossRef]

- Chan, W.K. Laser Surface Melting (LSM) of Stainless Steels for Mitigating Intergranular Corrosion (IGC). Woodhead Publishing Series in Metals and Surface Engineering; Elsevier: Amsterdam, The Netherlands, 2012; pp. 79–108. [Google Scholar]

- Conde, A.; Colaco, R.; Vilar, R.; de Damborenea, J. Corrosion behaviour of steels after laser surface melting. Matter Des. 2000, 21, 441–445. [Google Scholar] [CrossRef]

- Hou, J.; Chen, W.; Chen, Z.; Zhang, K.; Huang, A. Microstructure, tensile properties and mechanical anisotropy of selective laser melted 304L stainless steel. J. Mater. Sci. Technol. 2020, 48, 63–71. [Google Scholar] [CrossRef]

- Yan, X.; Chen, C.; Chang, C.; Dong, D.; Zhao, R.; Jenkins, R.; Ren, Z.; Liu, M.; Liao, H.; Lupoi, R.; et al. Study of the microstructure and mechanical performance of C-X stainless steel processed by selective laser melting (SLM). Mater. Sci. Eng. A 2020, 781, 139227. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, Q.; Zhang, Z.; Su, H.; Fu, Y.; Xu, J. Surface micro-structuring of Sapphire by a Q-switched DPSS nanosecond pulsed laser. Mater. Sci. Semicond. Process. 2020, 107, 104864. [Google Scholar] [CrossRef]

- Mudali, U.K.; Dayal, R.K. Improving intergranular corrosion resistance of sensitized type 316 austenitic stainless steel by laser surface melting. J. Mater. Eng. Perform. 1992, 1, 341–345. [Google Scholar] [CrossRef]

- Kim, J.S.; Chung, C.-M.; Baik, S.-H.; Lee, S.-B. Study on laser-surface melting to enhance intergranular corrosion resistance of SUS 304 weld. Met. Mater. Int. 2011, 17, 77–82. [Google Scholar] [CrossRef]

- Antonczak, A.J.; Kocon, D.; Nowak, M.; Koziol, P.; Abramski, K.M. Laser-induced colour marking–Sensitivity scaling for stainless steel. Appl. Surf. Sci. 2013, 264, 229–236. [Google Scholar] [CrossRef]

- Leone, C.; Genna, S.; Caprino, G.; de Iorio, I. AISI 304 stainless steel marking by a Q-switched diod pumped Nd:YAG laser. J. Mater. Process. Technol. 2010, 210, 1297–1303. [Google Scholar] [CrossRef]

- Cui, C.; Hu, J.; Liu, Y.; Guo, Z. Microstructure evolution on the surface of stainless steel by Nd:YAG pulsed laser irradiation. Appl. Surf. Sci. 2008, 254, 3442–3448. [Google Scholar] [CrossRef]

- Qi, J.; Wang, K.L.; Zhu, Y.M. A study on the laser marking process of stainless steel. J. Mater. Process. Technol. 2003, 139, 273–276. [Google Scholar] [CrossRef]

- Watanabe, N.; Takahashi, N.; Tsushima, K. Non-equilibrium garnet films grown by pulsed laser deposition. Mater. Chem. Phys. 1998, 54, 173–176. [Google Scholar] [CrossRef]

- Yang, J.; Lian, J.; Dong, Q.; Guo, Z. Nano-structured films formed on the AISI 329 stainless steel by Nd-YAG pulsed laser irradiation. Appl. Surf. Sci. 2004, 229, 2–8. [Google Scholar] [CrossRef]

- Hoppius, J.S.; Kukreja, L.M.; Knyazeva, M.; Pohl, F.; Walther, F.; Ostendorf, A.; Gurevih, E.L. On femtosecond laser shock peening of stainless steel AISI 316. Appl. Surf. Sci. 2018, 435, 1120–1124. [Google Scholar] [CrossRef] [Green Version]

- Ageev, E.I.; Kudryashov, S.I.; Nikonorov, N.V.; Nuryvey, R.K.; Petrov, A.A.; Samokhalov, A.A.; Veiko, V.P. Non-contact ultrasonic acquisition of femtosecond laser-driven ablative mbar-level shock waves on Ti alloy surface. Appl. Phys. Lett. 2016, 108, 084106. [Google Scholar] [CrossRef]

- Bai, T.; Guan, K. Evaluation of stress corrosion cracking susceptibility of nanocrystallized stainless steel 304L welded joint by small punch test. Matter. Des. 2013, 52, 849–860. [Google Scholar] [CrossRef]

- Pramatarova, L.; Pecheva, E.; Krastev, V.; Riesz, F. Ion implantation modified stainless steel as a substrate for hydroxyapatite deposition. Part I. Surface modification and characterization. J. Mater. Sci.-Mater. Med. 2007, 18, 435–440. [Google Scholar]

- Zhang, D.; Ren, L.; Zhang, Y.; Xue, N.; Yang, K.; Zhong, M. Antibacterial activity against Porphyromonas gingivalis and biological characteristics of antibacterial stainless steel. Colloids Surf. B 2013, 105, 51–57. [Google Scholar] [CrossRef]

- Hascalik, A.; Unal, E.; Ozdemir, N. Fatigue behaviour of AISI 304 steel to AISI 4340 steel welded by friction welding. J. Mater. Sci. 2006, 41, 3233–3239. [Google Scholar] [CrossRef]

- Valette, S.; Steyer, P.; Richard, L.; Forest, B.; Donnet, C.; Audouard, E. Influence of femtosecond laser marking on the corrosion resistance of stainless steel. Appl. Surf. Sci. 2006, 252, 4696–4701. [Google Scholar] [CrossRef]

- Barlow, B.C.; Guo, B.; Situm, A.; Grosvenor, A.P.; Burgess, I.J. Shell isolated nanoparticle enhanced Raman spectroscopy (SHINERS) studies of steel surface corrosion. J. Electroanal. Chem. 2019, 853, 113559. [Google Scholar] [CrossRef]

- Oblonsky, L.J.; Devine, T.M. A surface enhanced Raman spectroscopic study of the passive films formed in borate buffer on iron, nickel, chromium and stainless steel. Corros. Sci. 1995, 37, 17–41. [Google Scholar] [CrossRef]

- Wang, K.; Wang, J.; Hu, W. Evaluation of temperature effect on the corrosion process of 304 stainles steel in high temperature water with electrochemical noise. Matter Des. 2015, 82, 155–163. [Google Scholar] [CrossRef]

- Lehmuskero, A.; Kontturi, V.; Hiltunen, J.; Kuittinen, M. Modeling of laser- colored stainless steel surfaces by color pixels. Appl. Phys. 2009, 98, 497–500. [Google Scholar] [CrossRef]

- Dusser, B.; Sagan, Z.; Soder, H.; Faure, N.; Colombier, J.P.; Jourlin, M.; Audouard, E. Controlled nanostructures formation by ultra fast laser pulses for color mark- ing. Opt. Express. 2010, 18, 2913–2924. [Google Scholar] [CrossRef] [Green Version]

- Ma, X.; Nie, X.; Zhao, J.; Shrotriyya, P.; Zhang, Y.; Cui, Y.; Wang, J. Effect of nanosecond pulsed laser parameters on the color making of 304 stainless steel. Opt. Laser. Technol. 2020, 126, 106104. [Google Scholar] [CrossRef]

- Birnbaum, M. Semiconductor surface damage produced by ruby lasers. J. Appl. Phys. 1965, 36, 3688–3689. [Google Scholar] [CrossRef]

- Bonse, J.; Krüger, J.; Höhm, S.; Rosenfeld, A. Femtosecond laser-induced periodic surface structures. J. Laser Appl. 2012, 24, 042006. [Google Scholar] [CrossRef]

- Cui, C.Y.; Cui, X.G.; Zhang, Y.K.; Luo, K.Y.; Zhao, Q.; Hu, J.D.; Liu, Z.; Wang, Y.M. Microstructure and microhardness analysis of the hexagonal oxides formed on the surface of the AISI 304 stainless steel after Nd:YAG pulsed laser surface melting. Appl. Surf. Sci. 2010, 256, 6782–6786. [Google Scholar] [CrossRef]

- Steel Products Manual: Stainless and Heat Resisting Steels; Iron and Steel Society: Warrendale, PA, USA, 1990; ISBN 9780932897565.

- Hosemann, P.; Frazer, D.; Vasudevamurthy, G.; Byun, T.S.; Hunn, J.D.; Jolly, B.C.; Terrani, K.; Okuniewski, M.; Matros, J.N. Mechanical characteristics of SiC coating layer in TRISO fuel particles. J. Nucl. Mater. 2013, 442, 133–142. [Google Scholar] [CrossRef]

- Xing, Y.M.; Lu, J. An experimental study of residual stress induced by ultrasonic shot peening. J. Mater. Process. Technol. 2004, 152, 56–61. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Ducheyne, P. Comprehensive Biomaterials; Elsevier: Amsterdam, The Netherlands, 2011; ISBN 9780080553023. [Google Scholar]

- Pluta, Z.; Hryniewicz, T. Quantitative Determination of Material Hardness. J. Quantum. Inf. Sci. 2011, 1, 127–134. [Google Scholar] [CrossRef] [Green Version]

- Wen, T.; Gong, J.; Peng, Z.; Jiang, D.; Wang, C.; Fu, Z.; Miao, H. Analysis of continuous stiffness data measured during nanoindentation of titanium films on glass substrate. Mater. Chem. Phys. 2011, 125, 500–504. [Google Scholar] [CrossRef]

- Antonczak, A.; Skowronski, L.; Trzcinski, M.; Kinzhybalo, V.; Lazarek, L.; Abramski, K. Laser-induced oidation of titanium substrate: Analysis of the physochemical structure of the surface and sub-surface layers. App. Surf. Sci. 2015, 325, 217–226. [Google Scholar] [CrossRef]

- Raciukaitis, G.; Brikas, M.; Gecys, P.; Gedvilas, M. Accumulation effects in aser ablation of metals with high-repetition-rate lasers. Proc. SPIE 2008, 70052L. [Google Scholar] [CrossRef]

- Kucera, M.; Svantner, M.; Smazalova, E. Influence of laser marking stainless steel surface and corrosion resistance. In Proceedings of the METAL 2014-23rd International Conference on Metallurgy and Materials. Conference Proceedings, Brno, Czech Republic, 21–23 May 2015. [Google Scholar]

- Singh, R.; Sachan, D.; Verma, R.; Goel, S.; Jayaganthan, R.; Kumar, A. Mechanical behaviour of 304 stainless steel processed by cryogenic rolling. Mater. Today Proc. 2018, 5, 16880–16886. [Google Scholar] [CrossRef]

- Karimi, N.; Riffard, F.; Rabaste, F.; Perrier, S.; Cueff, R.; Issartel, C.; Buscail, H. Characterization of the oxides formed at 1000 °C on the AISI 304 stainless steel by X-ray diffraction and infrared spectroscopy. Appl. Surf. Sci. 2008, 254, 2292–2299. [Google Scholar] [CrossRef]

- AI-Sayed, S.R.; Hussein, A.A.; Nofal, A.A.; Hassab Elnaby, S.I.; Elgazzar, H. Characterization of a Laser Surface-Treated Martensitic Stainless Steel. Materials 2017, 10, 595. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ferreira, M.G.S.; Moura e Silva, T.; Catrarino, A.; Pankuch, M.; Melendres, C.A. Electrochemical and Laser Raman Spectroscopy Studies of Stainless Steel in 0.15 M NaCl Solution. J. Electrochem. Soc. 1992, 139, 3146–3151. [Google Scholar] [CrossRef]

- Ramya, S.; Nanda Gopla Krishna, D.; Kamachi Mudali, U. In-situ Raman and X-ray photoelectron spectroscopic studies on the pitting corrosion of modified 9Cr-1Mo steel in neutral chloride solution. Appl. Surf. Sci. 2018, 428, 1106–1118. [Google Scholar]

- Sahay, S.; Kumar Pandey, M.; Kumar Kar, A. Metal concentration dependent mechanical properties of electrodeposited nickel incorporated diamond like carbon (Ni-DLC) thin films studied by nanoindentation. Appl. Surf. Sci. 2019, 489, 73–79. [Google Scholar] [CrossRef]

- Lee, E.H.; Lee, Y.; Oliver, W.C.; Mansur, L.K. Hardness measurements of Ar+-beam treated polyimide by depth-sensing ultra low load indentation. J. Mater. Res. 2011, 8, 377–387. [Google Scholar] [CrossRef]

- Ye, C.; Telang, A.; Gill, A.S.; Suslov, S.; Idell, Y.; Zweiacker, K.; Wiezorek, J.M.K.; Zhou, Z.; Qian, D.; Mannava, S.R.; et al. Gradient nanostructure and residual stresses induced by Ultrasonic Nano-crystal Surface Modification in 304 austenitic stainless steel for high strength and high ductility. Mater. Sci. Eng. A 2014, 613, 274–288. [Google Scholar] [CrossRef] [Green Version]

- Lang, F.C.; Xing, Y.M.; Zhu, J.; Zhao, Y.R. Study of the Mechanical Properties of a Nanostructured Surface Layer on 316L Stainless Steel. Adv. Mater. Sci. Eng. 2016, 7517616. [Google Scholar] [CrossRef] [Green Version]

- Sinha, A.; Samanta, A.; Manna, I.; Lojkowski, W.; Chattopadhya, P.P. Micromechanical characterization of bulk composite prepared by sintering of mechanically alloyed aluminum-316 stainless steel (35 wt%) powder blend. Mater. Sci. Eng. A 2011, 528, 6034–6038. [Google Scholar] [CrossRef]

- Balijepalli, S.K.; Donnini, R.; Kaciulis, S.; Montanari, R.; Varone, A. Young’s Modulus Profile in Kolsterized AISI 316L Steel. Mater. Sci. Forum 2013, 762, 183–188. [Google Scholar] [CrossRef]

| Elements (wt. %) | C | Mn | Si | P | S | Cr | Ni | N | Mo |

|---|---|---|---|---|---|---|---|---|---|

| AISI 304 | 0.08 | 2.0 | 0.75 | 0.045 | 0.03 | 20.0 | 10.5 | 0.1 | – |

| AISI 316 | 0.08 | 2.0 | 1.0 | 0.045 | 0.03 | 18.0 | 14.0 | 0.1 | 3.0 |

| Sample | v (mm/s) | f (kHz) |

|---|---|---|

| 304_20_10 | 20 | 10 |

| 304_20_100 | 20 | 100 |

| 304_20_1000 | 20 | 1000 |

| 304_80_10 | 80 | 10 |

| 304_80_100 | 80 | 100 |

| 304_80_1000 | 80 | 1000 |

| 316_20_10 | 20 | 10 |

| 316_20_100 | 20 | 100 |

| 316_20_1000 | 20 | 1000 |

| 316_80_10 | 80 | 10 |

| 316_80_100 | 80 | 100 |

| 316_80_1000 | 80 | 1000 |

| Sample | Sa (µm) | Sq(µm) |

|---|---|---|

| 304_20_10 | 6.977 | 9.018 |

| 304_20_100 | 0.825 | 1.014 |

| 304_20_1000 | 0.241 | 0.368 |

| 304_80_10 | 0.792 | 0.900 |

| 304_80_100 | 0.357 | 0.471 |

| 304_80_1000 | 0.162 | 0.255 |

| 304_RAW | 0.209 | 0.372 |

| 316_20_10 | 7.587 | 9.776 |

| 316_20_100 | 0.858 | 1.056 |

| 316_20_1000 | 0.284 | 0.424 |

| 316_80_10 | 0.727 | 0.884 |

| 316_80_100 | 0.353 | 0.463 |

| 316_80_1000 | 0.160 | 0.278 |

| 316_RAW | 0.166 | 0.325 |

| Sample | HITMAX (GPa) | EITMAX (GPa) | HITAVG (GPa) | EITAVG (GPa) |

|---|---|---|---|---|

| 304_20_100 | 2.95 ± 0.6 | 296 ± 32 | 2.11 ± 0.2 | 159 ± 23 |

| 304_20_1000 | 10.15 ± 1.2 | 384 ± 41 | 2.48 ± 0.2 | 183 ± 31 |

| 304_80_10 | 16.32 ± 2.4 | 931 ± 111 | 3.01 ± 0.3 | 209 ± 40 |

| 304_80_100 | 14.13 ± 2.1 | 610 ± 74 | 2.54 ± 0.2 | 187 ± 33 |

| 304_80_1000 | 7.05 ± 1.0 | 340 ± 48 | 1.96 ± 0.2 | 165 ± 27 |

| 304_RAW | – | – | 2.63 ± 0.2 | 167 ± 9 |

| 316_20_100 | 1.84 ± 0.2 | 287 ± 32 | 1.35 ± 0.1 | 106 ± 15 |

| 316_20_1000 | 6.02 ± 0.9 | 359 ± 43 | 1.51 ± 0.1 | 144 ± 28 |

| 316_80_10 | 13.36 ± 1.9 | 794 ± 84 | 3.01 ± 0.2 | 235 ± 47 |

| 316_80_100 | 10.72 ± 2.1 | 823 ± 101 | 2.59 ± 0.3 | 165 ± 27 |

| 316_80_1000 | 6.47 ± 1.3 | 454 ± 69 | 1.98 ± 0.1 | 158 ± 27 |

| 316_RAW | – | – | 2.21 ± 0.2 | 258 ± 28 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dywel, P.; Szczesny, R.; Domanowski, P.; Skowronski, L. Structural and Micromechanical Properties of Nd:YAG Laser Marking Stainless Steel (AISI 304 and AISI 316). Materials 2020, 13, 2168. https://doi.org/10.3390/ma13092168

Dywel P, Szczesny R, Domanowski P, Skowronski L. Structural and Micromechanical Properties of Nd:YAG Laser Marking Stainless Steel (AISI 304 and AISI 316). Materials. 2020; 13(9):2168. https://doi.org/10.3390/ma13092168

Chicago/Turabian StyleDywel, Piotr, Robert Szczesny, Piotr Domanowski, and Lukasz Skowronski. 2020. "Structural and Micromechanical Properties of Nd:YAG Laser Marking Stainless Steel (AISI 304 and AISI 316)" Materials 13, no. 9: 2168. https://doi.org/10.3390/ma13092168

APA StyleDywel, P., Szczesny, R., Domanowski, P., & Skowronski, L. (2020). Structural and Micromechanical Properties of Nd:YAG Laser Marking Stainless Steel (AISI 304 and AISI 316). Materials, 13(9), 2168. https://doi.org/10.3390/ma13092168