Cracking Behavior of René 104 Nickel-Based Superalloy Prepared by Selective Laser Melting Using Different Scanning Strategies

Abstract

1. Introduction

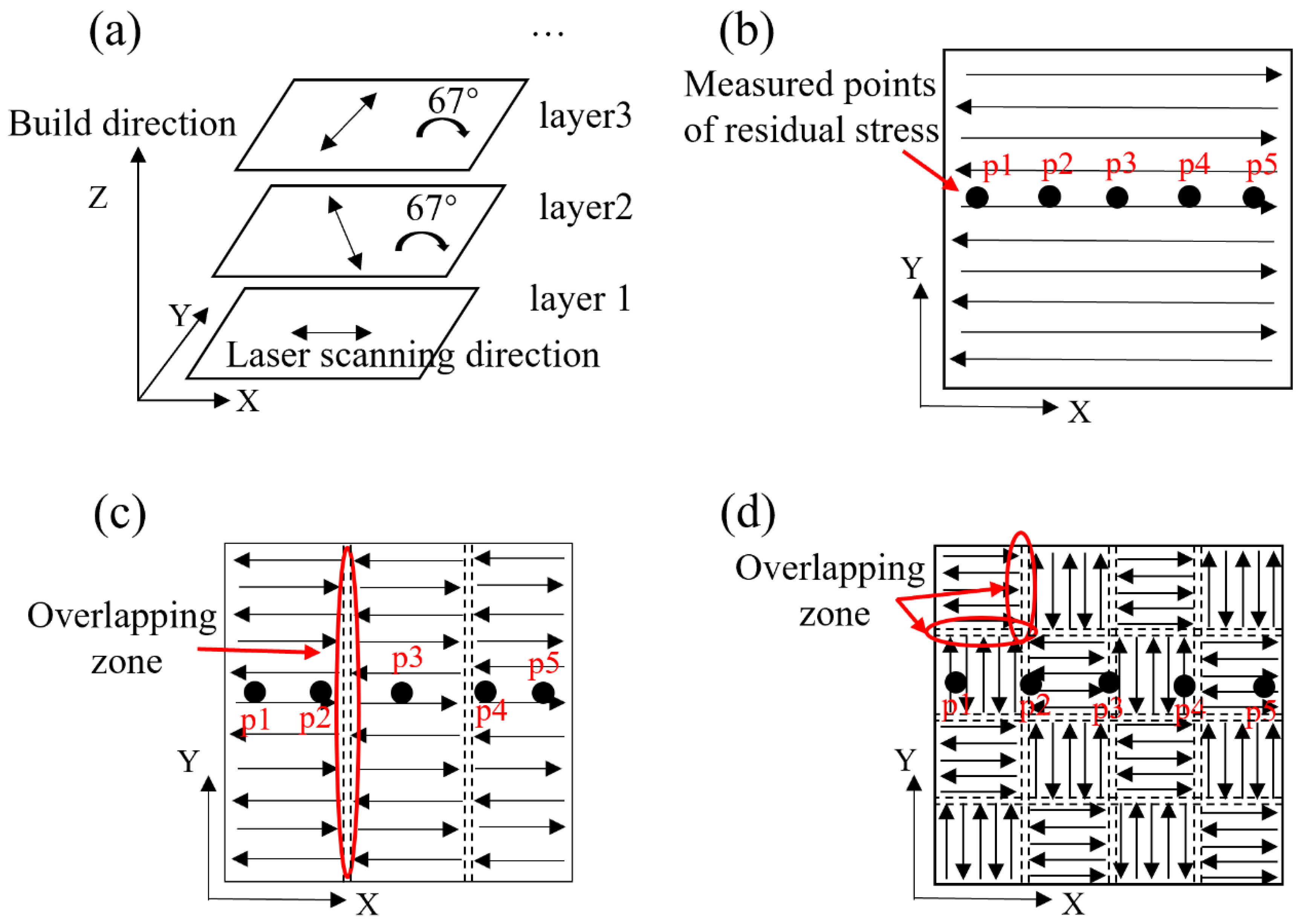

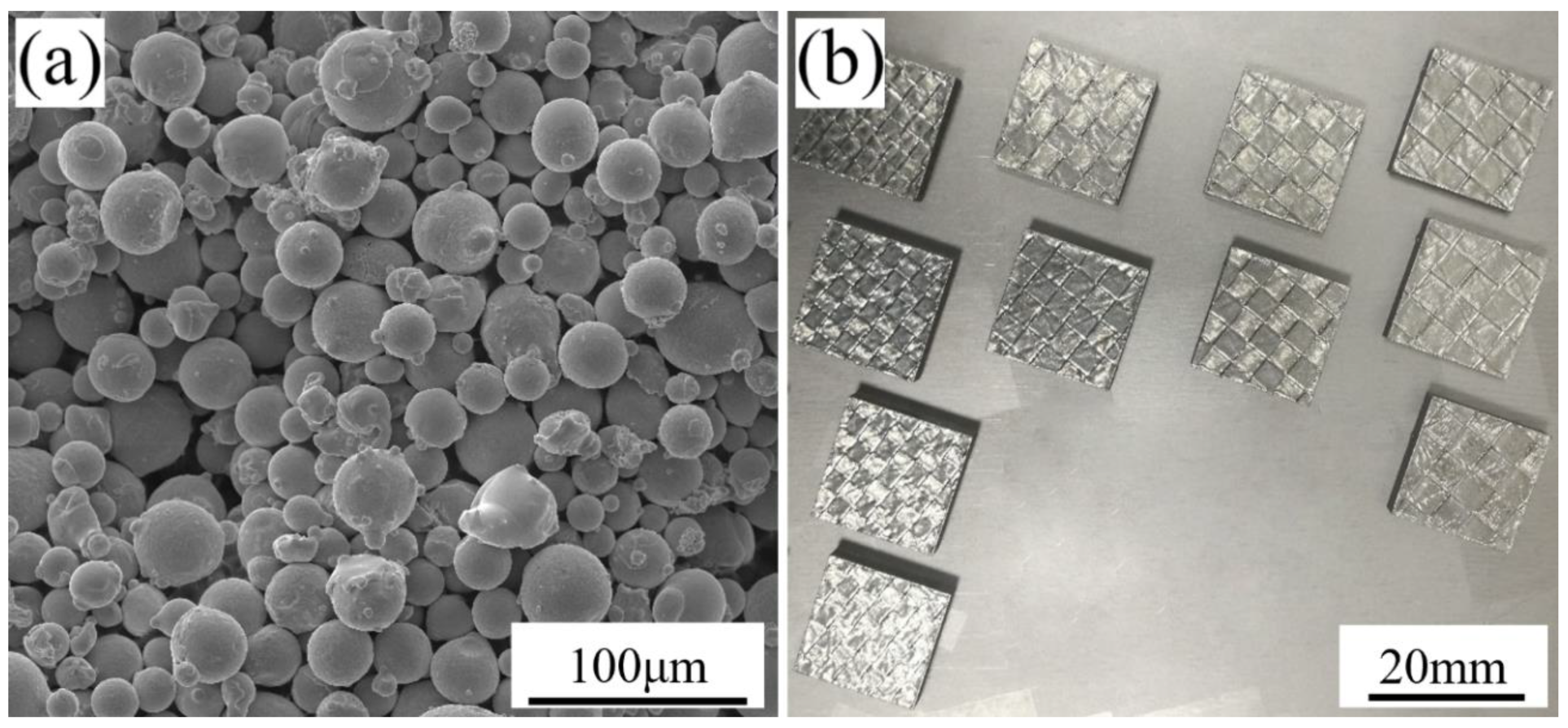

2. Materials and Methods

3. Results and Discussion

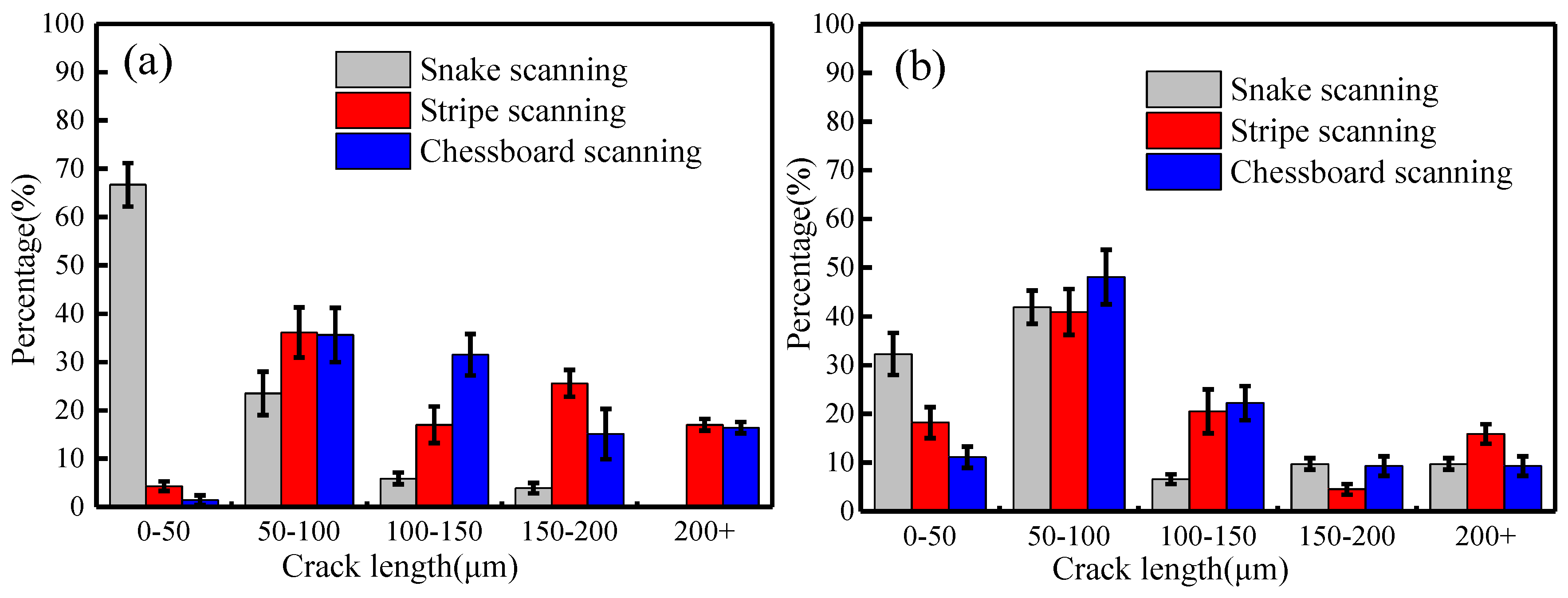

3.1. Cracks and Their Distribution

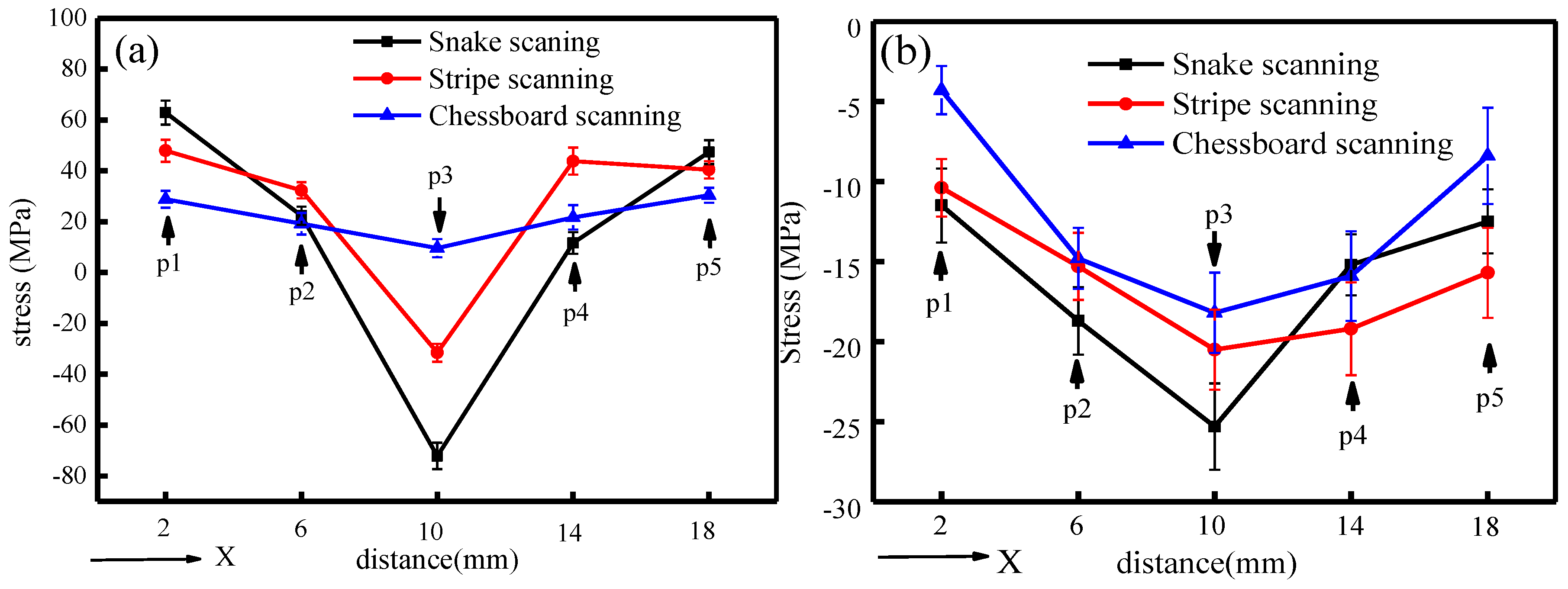

3.2. Residual Stress

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lu, B.; Li, D.; Tian, X. Development Trends in Additive Manufacturing and 3D Printing. Engineering 2015, 1, 85–89. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Tan, X.P.; Tan, Y.J.; Chow, C.S.L.; Tor, S.B.; Yeong, W.Y. Metallic powder-bed based 3D printing of cellular scaffolds for orthopaedic implants: A state-of-the-art review on manufacturing, topological design, mechanical properties and biocompatibility. Mater. Sci. Eng. C 2017, 76, 1328–1343. [Google Scholar] [CrossRef] [PubMed]

- Mohd Yusuf, S.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive manufacturing of ultrafine-grained high-strength titanium alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef]

- Zebrowski, R.; Walczak, M.; Korga, A.; Iwan, M.; Szala, M. Effect of Shot Peening on the Mechanical Properties and Cytotoxicity Behaviour of Titanium Implants Produced by 3D Printing Technology. J. Healthc. Eng. 2019, 2019, 8169538. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.Q.; Wang, W.; Attallah, M.M.; Loretto, M.H. Microstructure and strength of selectively laser melted AlSi10Mg. Acta Mater. 2016, 117, 311–320. [Google Scholar] [CrossRef]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef]

- Riede, M.; Knoll, M.; Wilsnack, C.; Gruber, S.; Alegre Cubillo, A.; Melzer, C.; Brandão, A.; Pambaguian, L.; Seidel, A.; Lopez, E.; et al. Material Characterization of AISI 316L Flexure Pivot Bearings Fabricated by Additive Manufacturing. Materials 2019, 12, 2426. [Google Scholar] [CrossRef] [PubMed]

- Seede, R.; Shoukr, D.; Zhang, B.; Whitt, A.; Gibbons, S.; Flater, P.; Elwany, A.; Arroyave, R.; Karaman, I. An ultra-high strength martensitic steel fabricated using selective laser melting additive manufacturing: Densification, microstructure, and mechanical properties. Acta Mater. 2020, 186, 199–214. [Google Scholar] [CrossRef]

- Amato, K.N.; Gaytan, S.M.; Murr, L.E.; Martinez, E.; Shindo, P.W.; Hernandez, J.; Collins, S.; Medina, F. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 2012, 60, 2229–2239. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y.; Huang, S.; Zhu, S.; Wang, F.; Li, D. Manufacturing and Analysis of High-Performance Refractory High-Entropy Alloy via Selective Laser Melting (SLM). Materials 2019, 12, 720. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Deng, S.; Yang, Y.; Li, Y.; Wang, D.; Wang, A.; Song, C. Planning of area-partition scanning path and its effect on residual stress of SLM molding parts. Chin. J. Lasers 2016, 43, 67–75. [Google Scholar] [CrossRef]

- Cheng, B.; Shrestha, S.; Chou, K. Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit. Manuf. 2016, 12, 240–251. [Google Scholar] [CrossRef]

- Kaufmann, N.; Imran, M.; Wischeropp, T.M.; Emmelmann, C.; Siddique, S.; Walther, F. Influence of Process Parameters on the Quality of Aluminium Alloy EN AW 7075 Using Selective Laser Melting (SLM). Phys. Procedia 2016, 83, 918–926. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Chen, D.; Liu, T.; Liao, W.; Zhang, C.; Zhang, K. Temperature field during selective laser melting of metal powder under different scanning strategies. Chin. J. Lasers 2016, 43, 74–78. [Google Scholar] [CrossRef]

- Kontis, P.; Chauvet, E.; Peng, Z.; He, J.; da Silva, A.K.; Raabe, D.; Tassin, C.; Blandin, J.-J.; Abed, S.; Dendievel, R.; et al. Atomic-scale grain boundary engineering to overcome hot-cracking in additively-manufactured superalloys. Acta Mater. 2019, 177, 209–221. [Google Scholar] [CrossRef]

- Xu, J.; Lin, X.; Guo, P.; Dong, H.; Wen, X.; Li, Q.; Xue, L.; Huang, W. The initiation and propagation mechanism of the overlapping zone cracking during laser solid forming of IN-738LC superalloy. J. Alloy. Compd. 2018, 749, 859–870. [Google Scholar] [CrossRef]

- Tomus, D.; Rometsch, P.A.; Heilmaier, M.; Wu, X. Effect of minor alloying elements on crack-formation characteristics of Hastelloy-X manufactured by selective laser melting. Addit. Manuf. 2017, 16, 65–72. [Google Scholar] [CrossRef]

- Han, Q.; Gu, Y.; Soe, S.; Lacan, F.; Setchi, R. Effect of hot cracking on the mechanical properties of Hastelloy X superalloy fabricated by laser powder bed fusion additive manufacturing. Opt. Laser Technol. 2020, 124, 105984. [Google Scholar] [CrossRef]

- Harrison, N.J.; Todd, I.; Mumtaz, K. Reduction of micro-cracking in nickel superalloys processed by Selective Laser Melting: A fundamental alloy design approach. Acta Mater. 2015, 94, 59–68. [Google Scholar] [CrossRef]

- Han, Q.; Gu, Y.; Setchi, R.; Lacan, F.; Johnston, R.; Evans, S.L.; Yang, S. Additive manufacturing of high-strength crack-free Ni-based Hastelloy X superalloy. Addit. Manuf. 2019, 30, 100919. [Google Scholar] [CrossRef]

- Li, K.; Wang, D.; Xing, L.; Wang, Y.; Yu, C.; Chen, J.; Zhang, T.; Ma, J.; Liu, W.; Shen, Z. Crack suppression in additively manufactured tungsten by introducing secondary-phase nanoparticles into the matrix. Int. J. Refract. Met. Hard Mater. 2019, 79, 158–163. [Google Scholar] [CrossRef]

- Qiu, C.; Chen, H.; Liu, Q.; Yue, S.; Wang, H. On the solidification behaviour and cracking origin of a nickel-based superalloy during selective laser melting. Mater. Charact. 2019, 148, 330–344. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Wang, G.B.; Shen, J.; Zhang, G.Q.; Li, Y.P.; Yan, M. Selective laser melting of the hard-to-weld IN738LC superalloy: Efforts to mitigate defects and the resultant microstructural and mechanical properties. J. Alloy. Compd. 2019, 807, 151662. [Google Scholar] [CrossRef]

- Tin, S.; Pollock, T.M. Nickel-Based Superalloys. In Turbine Aerodynamics, Heat Transfer, Materials, and Mechanics; American Institute of Aeronautics and Astronautics, Inc.: Reston, VA, USA, 2014; Volume 243, pp. 423–466. [Google Scholar]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide, 2nd ed.; ASM International: Novelty, OH, USA, 2002. [Google Scholar]

- Duan, R.-X.; Huang, B.-Y.; Liu, Z.-M.; Peng, K.; Lu, X.-Q. Selective laser melting fabrication and cracking behavior of Renè 104 nickel-based superalloy. Chin. J. Nonferrous Met. 2018, 28, 1568–1578. [Google Scholar] [CrossRef]

- Yang, J.; Li, F.; Wang, Z.; Zeng, X. Cracking behavior and control of Rene 104 superalloy produced by direct laser fabrication. J. Mater. Process. Technol. 2015, 225, 229–239. [Google Scholar] [CrossRef]

- Ying, W.; Han, F.; Wang, J. Effects of preheating and cooling on the crack defects of laser solid formed Rene 104 superalloy parts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020. [Google Scholar] [CrossRef]

- Su, P.; Liu, Z.; Guo, Y.; Ma, M.; Duan, R.; Chen, S. Microstructure and solidification defect of Rene104 nickel-base superalloy powder atomized by argon gas atomization. J. Cent. South Univ. (Sci. Technol.) 2018, 49, 64–71. [Google Scholar] [CrossRef]

- Non-Destructive Testing-Test Method for Residual Stress Analysis by X-Ray Diffraction; BS EN 15305: 2008; British Standards Institution: London, UK, 2008.

- Impermeable Sintered Metal Materials and Hardmetals—Determination of Density; ISO 3369:2006; International Organization for Standardization: Geneva, Switzerland, 2006.

- Kruth, J.P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Mercelis, P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Easton, M. Powder bed fusion processes: An overview. In Laser Additive Manufacturing; Brandt, M., Ed.; Woodhead Publishing: Shaston, UK, 2017; pp. 55–77. [Google Scholar] [CrossRef]

- Knowles, C.; Becker, T.; Tait, R. Residual stress measurements and structural integrity implications for selective laser melted Ti-6Al-4V. S. Afr. J. Ind. Eng. 2012, 23, 119–129. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Yang, Y.; Dou, W.; Deng, S.; Wang, Z.; Li, S. The Effect of a Scanning Strategy on the Residual Stress of 316L Steel Parts Fabricated by Selective Laser Melting (SLM). Materials 2018, 11, 1821. [Google Scholar] [CrossRef]

| Element | Co | Cr | Al | Ti | Mo | W | Nb | Ta | Zr | B | C | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Normal | 20.6 | 13 | 3.4 | 3.9 | 3.8 | 2.1 | 0.9 | 2.4 | 0.05 | 0.03 | 0.04 | Bal |

| Measured | 20.0 | 12.6 | 3.78 | 2.14 | 3.24 | 3.66 | 2.05 | 0.82 | 0.057 | 0.045 | 0.05 | Bal |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, K.; Duan, R.; Liu, Z.; Lv, X.; Li, Q.; Zhao, F.; Wei, B.; Nong, B.; Wei, S. Cracking Behavior of René 104 Nickel-Based Superalloy Prepared by Selective Laser Melting Using Different Scanning Strategies. Materials 2020, 13, 2149. https://doi.org/10.3390/ma13092149

Peng K, Duan R, Liu Z, Lv X, Li Q, Zhao F, Wei B, Nong B, Wei S. Cracking Behavior of René 104 Nickel-Based Superalloy Prepared by Selective Laser Melting Using Different Scanning Strategies. Materials. 2020; 13(9):2149. https://doi.org/10.3390/ma13092149

Chicago/Turabian StylePeng, Kai, Ranxi Duan, Zuming Liu, Xueqian Lv, Quan Li, Fan Zhao, Bing Wei, Bizhong Nong, and Shizhong Wei. 2020. "Cracking Behavior of René 104 Nickel-Based Superalloy Prepared by Selective Laser Melting Using Different Scanning Strategies" Materials 13, no. 9: 2149. https://doi.org/10.3390/ma13092149

APA StylePeng, K., Duan, R., Liu, Z., Lv, X., Li, Q., Zhao, F., Wei, B., Nong, B., & Wei, S. (2020). Cracking Behavior of René 104 Nickel-Based Superalloy Prepared by Selective Laser Melting Using Different Scanning Strategies. Materials, 13(9), 2149. https://doi.org/10.3390/ma13092149