Comparative Study of Steel-FRP, FRP and Steel-Reinforced Coral Concrete Beams in Their Flexural Performance

Abstract

1. Introduction

2. Test Program

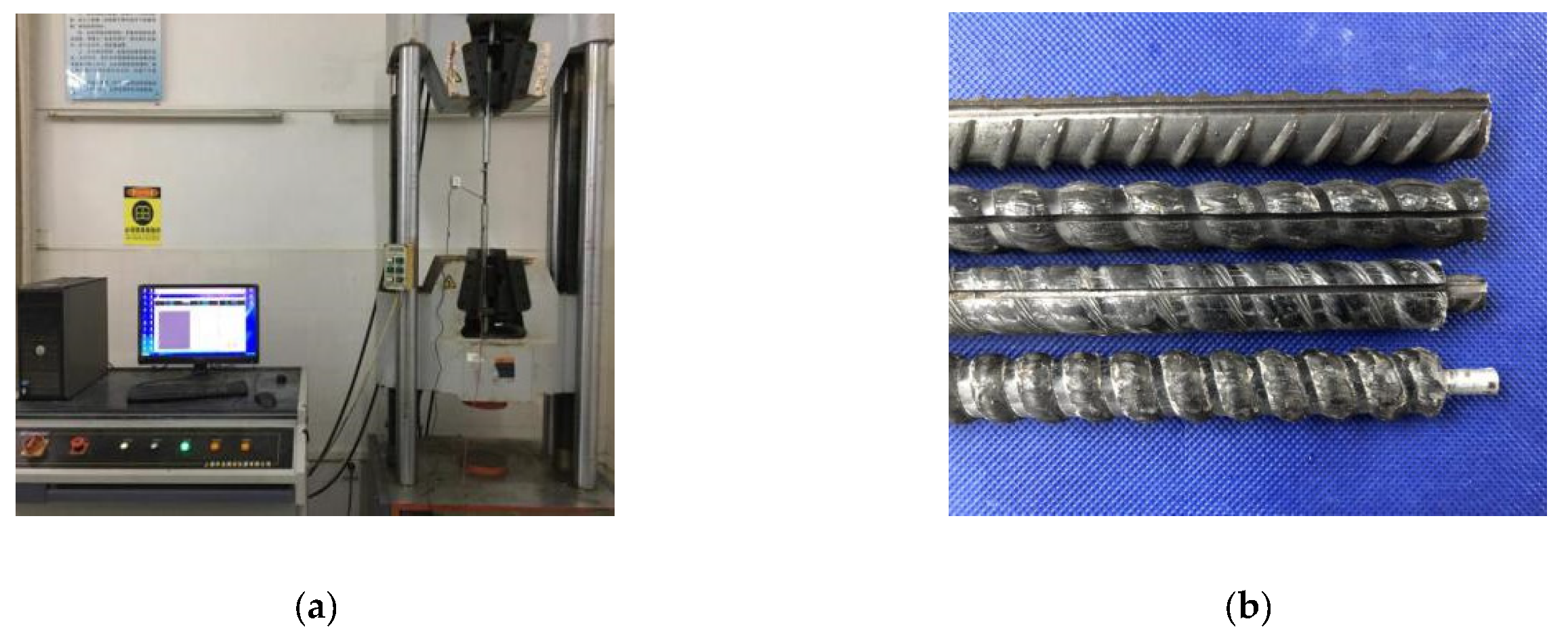

2.1. Test Materials

2.2. Test Specimens

2.3. Loading and Instrumentation

3. Test Results and Analysis

3.1. Comparison of Flexural Capacity and Failure Modes

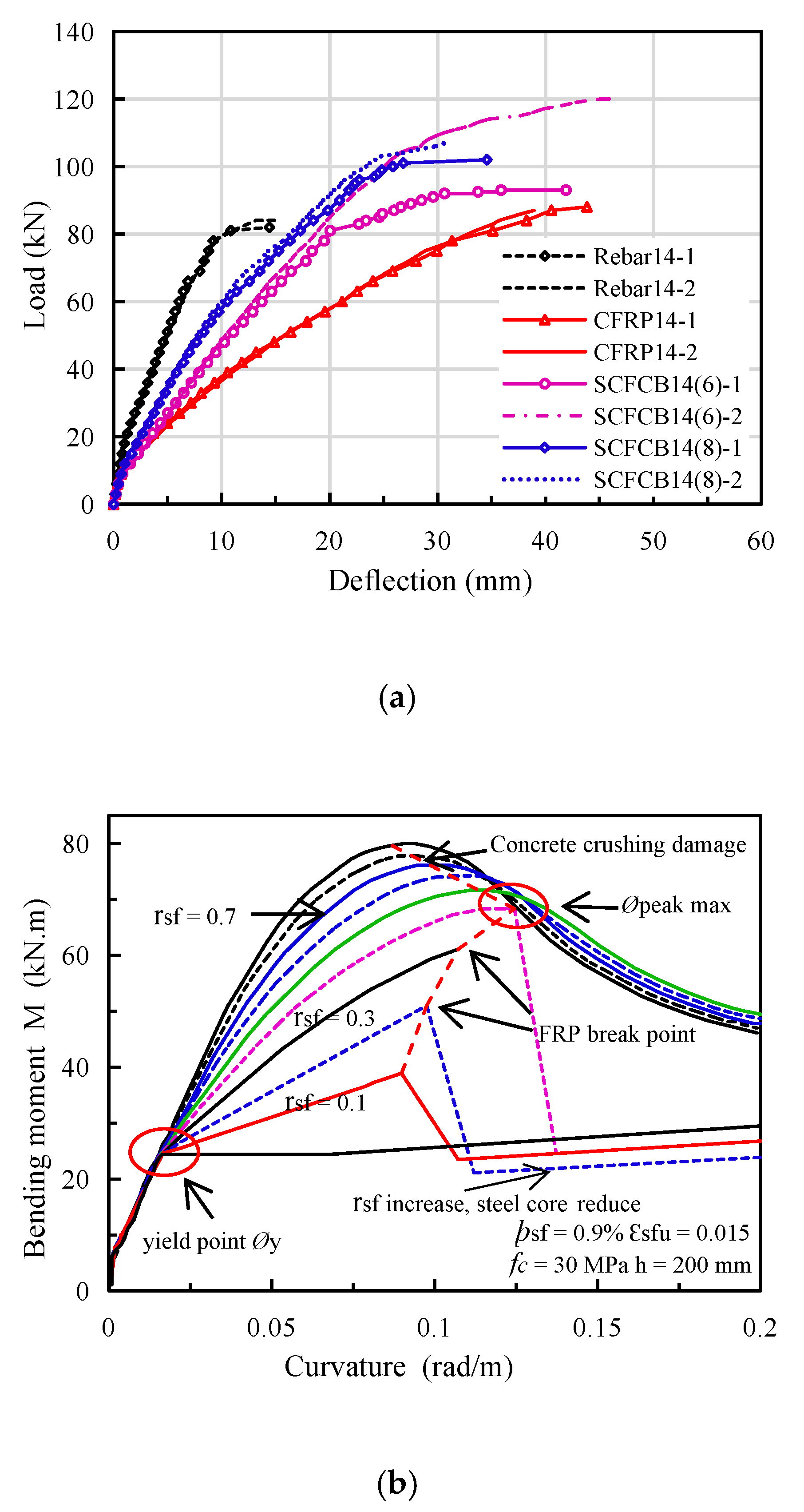

3.2. Comparison of Load-Span Deflection Curves

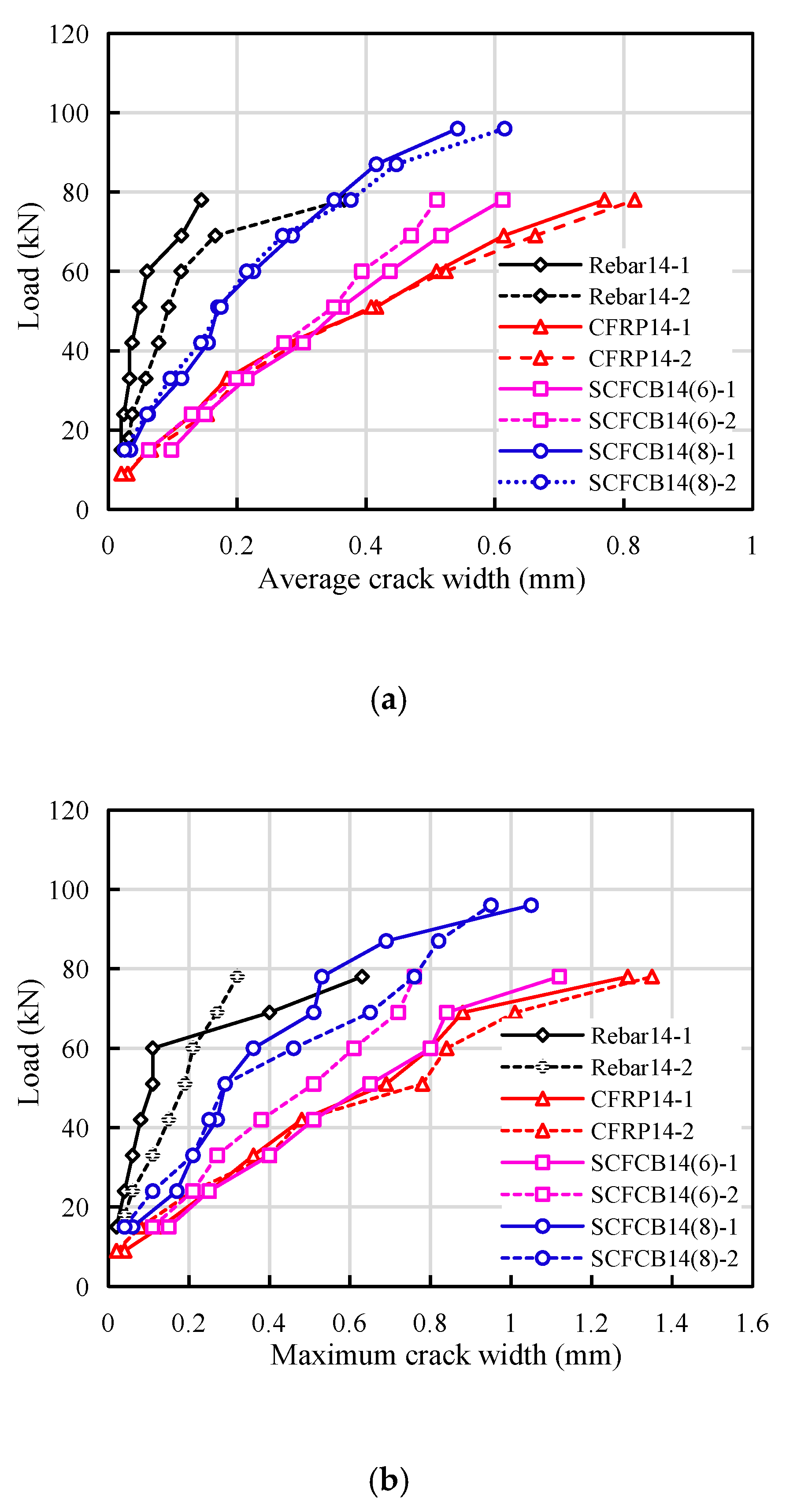

3.3. Comparison of Crack Patterns

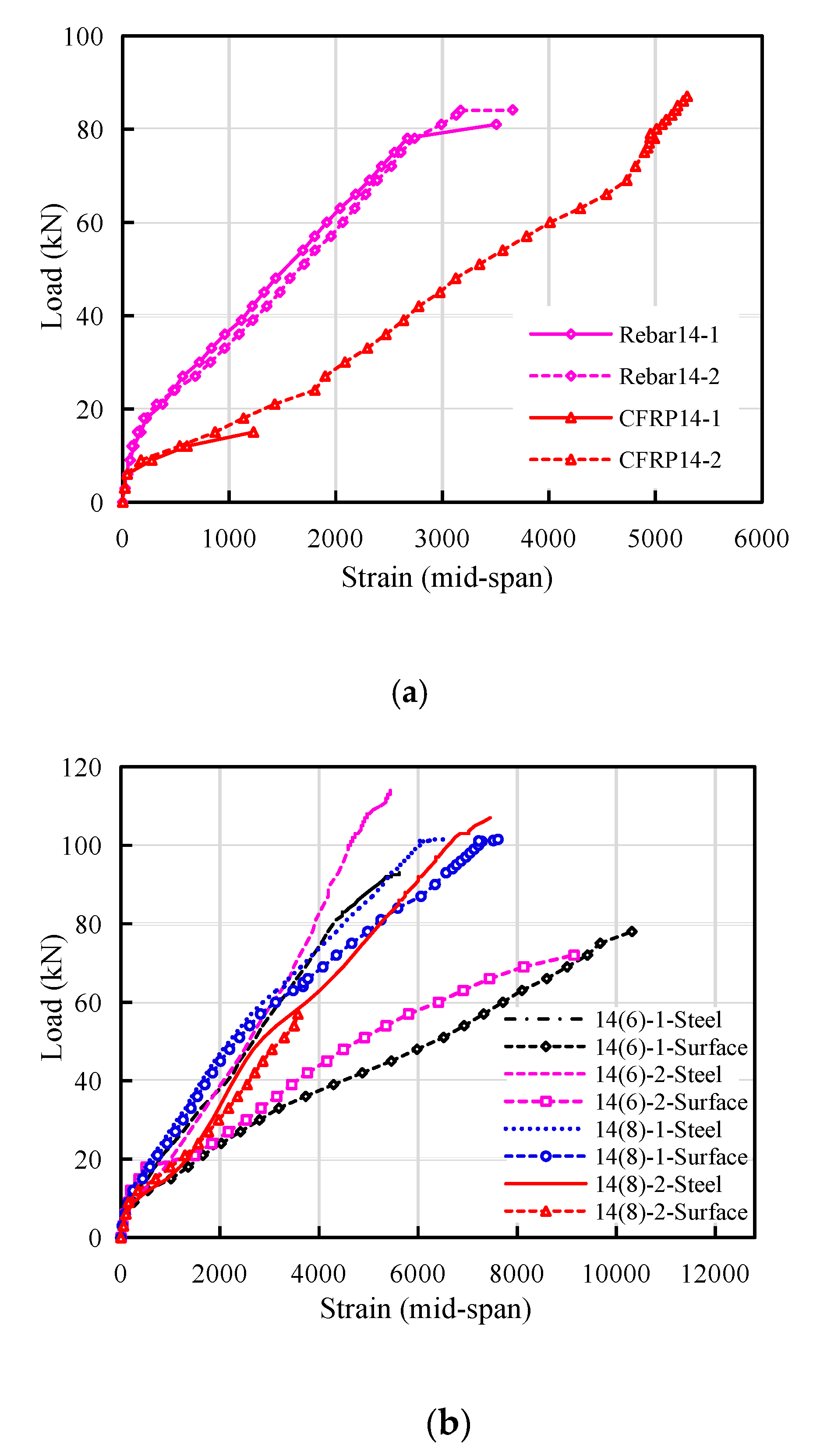

3.4. Comparison of the Strain Development in the Rebars

4. Suitability of Using Calculation Formulas of Different Specifications in SCFCB-Einforced Coral Concrete Structures

4.1. Calculation and Prediction of Cracking Moment, Ultimate Bending Moment and Failure Mode

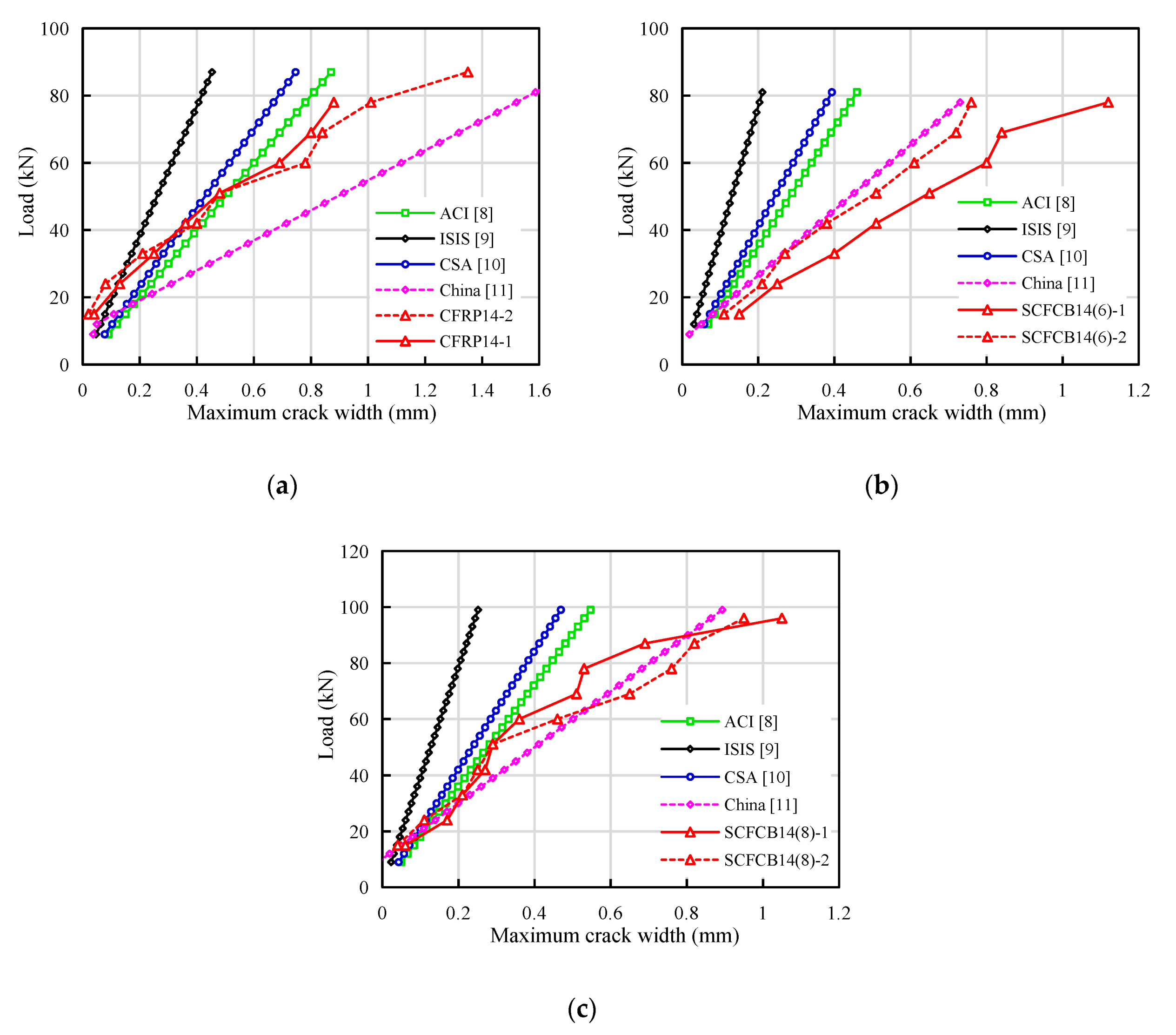

4.2. Application of Crack Width and Deflection Calculation Formulas

5. Discussion

6. Conclusions

- The flexural capacity of the test beam was obviously different, while the bearing capacity of the SCFCB test beam was higher than the other two. At failure, SCFCB beam achieved 70% to 85% of its ultimate strength, but CFRP beams only achieved less than 50%.

- SCFCB coral concrete beams has good ductility, but the flexural stiffness was lower than that of ordinary steel-reinforced beams and higher than that of CFRP bars reinforced beams.

- The performance of SCFCB-reinforced beams was greatly affected by the steel core. a larger deflection can be achieved when the steel core yield.

- SCFCB exhibits a significant “stress lag” phenomenon, which was manifested by the small and unsynchronized stress growth of the steel core, and the strain of the fiber layer was about twice the steel core strain; The steel core was related to the bonding of the fiber, and its stress transfer mechanism should be further studied.

- When the existing FRP bar calculation specification was applied to the CFRP reinforcement coral concrete structure, there was a certain error. The bond performance between CFRP bar and coral concrete and the difference between different types of concrete should be fully considered.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Af | area of FRP tension reinforcement (mm2) | h1 | Distance from neutral axis to center of tensile reinforcement (mm) |

| h2 | distance from neutral axis to extreme tension fiber (mm) | ||

| a | shear span (mm) | Icr | moment of inertia of transformed cracked section (mm4) |

| BS | bending stiffness of beam | Ie | effective moment of inertia (mm4) |

| b | effective beam width (mm) | Ig | gross moment of inertia of uncracked section (mm4) |

| C | spacing or cover dimension. (mm) | kb | bond-dependent coefficient |

| d | distance from the extreme compression fiber to the centroid of tension force (mm) | Lg | length of the uncracked section (mm) |

| Mcr | cracking moment (kN·m) | ||

| db | bar diameter (mm) | Mn | nominal moment capacity (mm) |

| dc | Thickness of concrete cover measured from extreme tension fiber to center of bar or wire location closest thereto (mm) | p | applied load (kN) |

| pu | ultimate load (kN) | ||

| s | spacing between the longitudinal reinforcement bars (mm) | ||

| Ec | modulus of elasticity of longitudinal reinforcement (MPa) | w | maximum crack width (mm) |

| Ef | modulus of elasticity of longitudinal reinforcement (MPa) | wcr | Load of test beam when cracking (mm) |

| fc | cubic compression strength of concrete (MPa) | wmean | Average crack width (mm) |

| fck | cylindric compressive strength of concrete (MPa) | coefficient of strain inhomogeneity of longitudinal bar | |

| ft | tensile splitting strength of concrete (MPa) | stress in longitudinal reinforcement bar under specified loads (MPa) | |

| ffu | Design tensile strength of FRP (MPa) | ||

| hh | rib height of the bar (mm) | bonding strength of steel and carbon fiber | |

| hs | rib spacing of the bar (mm) | pcr | Load of test beam when cracking (kN) |

| mid-span deflection (mm) | ρ | Longitudinal reinforcement ratio |

References

- Kassem, C.; Farghaly, A.S.; Benmokrance, B. Evaluation of flexural behavior and service ability performance of concrete beams reinforced with FRP Bars. J. Compos. Constr. 2011, 15, 682–695. [Google Scholar] [CrossRef]

- Caro, M.; Jemaa, Y.; Dirar, S. Bond performance of deep embedment FRP bars epoxy-bonded intoconcrete. Eng. Struct. 2017, 147, 448–457. [Google Scholar] [CrossRef]

- Zaidi, A.; Brahim, M.M.; Mouattah, K.; Masmoudi, R. FRP properties effect on numerical deformations in FRP bars reinforced concrete elements in hot zone. Energy Procedia 2017, 139, 798–803. [Google Scholar] [CrossRef]

- Al-Sunna, R.; Pilakoutas, K.; Hajirasouliha, I.; Guadagnini, M. Deflection behavior of FRP reinforced concrete beams and slabs: An experimental investigation. Compos. Part B Eng. 2012, 43, 2125–2134. [Google Scholar] [CrossRef]

- Wu, G.; Wu, Z.S.; Luo, Y.B.; Sun, Z.Y.; Hu, X.Q. Mechanical properties of steel-FRP composite bar under uniaxial and cyclic tensile loads. J. Mater. Civ. Eng. ASCE 2010, 22, 1056–1066. [Google Scholar] [CrossRef]

- Sun, Z.Y.; Wu, G.; Wu, Z.S.; Zhang, M. Seismic Behavior of Concrete Columns Reinforced by Steel-FRP (Fiber-Reinforced Polymer) Composite Bar. J. Compos. Constr. ASCE 2011, 15, 696–706. [Google Scholar] [CrossRef]

- ACI Committee 440. Guide for the Design and Construction of Concrete Reinforced with FRP Bars (ACI 440.1R-06); American Concrete Institute: Farmington Hills, MI, USA, 2006; p. 44. [Google Scholar]

- ACI Committee 440. Guide for the Design and Construction of Concrete Reinforced with FRP Bars (ACI 440.1R-15); American Concrete Institute: Farmington Hills, MI, USA, 2015; p. 85. [Google Scholar]

- Canadian Standard Association (CSA). Design and Construction of Building Components with Fibre Reinforced Polymers; CAN/CSA S806-12: Rexdale, ON, USA, 2012; p. 187. [Google Scholar]

- ISIS Manual No. 3. Reinforced Concrete Structures with Fifibre-Reinforced Polymers; ISIS Canada Research Network; University of Manitoba: Winnipeg, MB, USA, 2007; p. 151. [Google Scholar]

- GB 50608-2010. Technical Code for Infrastructure Application of FRP Composites; Planning Press: Beijing, China, 2011. (In Chinese) [Google Scholar]

- Chen, Y.; Davalos, J.F.; Ray, I.; Kim, H.Y. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures. Compos. Struct. 2007, 78, 101–111. [Google Scholar] [CrossRef]

- Ashrafi, H.; Bazli, M.; Najafabadi, E.P.; Oskouei, A.V. The effect of mechanical and thermal properties of FRP bars on theirtensile performance under elevated temperatures. Constr. Build. Mater. 2017, 157, 1001–1010. [Google Scholar] [CrossRef]

- Kim, H.Y.; Park, Y.H.; You, Y.J.; Moon, C.K. Short-term durability test for GFRP rods under various environmental conditions. Compos. Struct. 2008, 83, 37–47. [Google Scholar] [CrossRef]

- Baena, M.; Torres, L.; Turon, A.; Barris, C. Experimental study of bond behavior between concrete and FRP bars using a pull-out test. Compos. Part B 2009, 40, 784–797. [Google Scholar] [CrossRef]

- Castel, A.; François, R.; Tourneur, C. Effect of surface preconditioning on bond of carbon fiber reinforced polymer rods to concrete. Cem. Concr. Compos. 2007, 29, 677–689. [Google Scholar]

- Wang, L.; Mao, Y.; Lv, H.; Chen, S.; Li, W. Bond properties between FRP bars and coral concrete under seawater conditions at 30, 60, and 80 °C. Constr. Build. Mater. 2018, 162, 442–449. [Google Scholar] [CrossRef]

- Rezazadeh, M.; Carvelli, V. A damage model for high-cycle fatigue behavior of bond between FRP barand concrete. Int. J. Fatigue 2018, 111, 101–111. [Google Scholar] [CrossRef]

- Mohamed, H.M.; Masmoudi, R. Flexural strength and behavior of steel and FRP-reinforced concrete-filled FRP tube beams. Eng. Struct. 2010, 32, 3789–3800. [Google Scholar] [CrossRef]

- Hamed, E.; Bradford, M.A. Flexural time-dependent cracking and post-cracking behavior of FRP strengthened concrete beams. Int. J. Solids Struct. 2012, 49, 1595–1607. [Google Scholar] [CrossRef]

- Zhu, H.; Cheng, S.; Gao, D.; Neaz, S.M.; Li, C. Flexural behavior of partially fiber- reinforced high-strength concretebeams reinforced with FRP bars. Constr. Build. Mater. 2018, 161, 587–597. [Google Scholar] [CrossRef]

- Wang, H.; Belarbi, A. Ductility characteristics of fiber-reinforcedconcrete beams reinforced with FRP rebars. Constr. Build. Mater. 2011, 25, 2391–2401. [Google Scholar] [CrossRef]

- Toutanji, H.; Deng, Y. Deflection and crack-width prediction of concrete beams reinforced with glass FRP rods. Constr. Build. Mater. 2003, 17, 69–74. [Google Scholar] [CrossRef]

- Zhishen, W.G.L.Y.W.; Min, H.X.Z. Experimental and theoretical studies on the mechanical properties of steel-FRP composite bars. Chin. J. Civ. Eng. 2010, 43, 53–61. (In Chinese) [Google Scholar]

- Dong, Z.; Wu, G.; Zhao, X.L.; Zhu, H.; Lian, J. Bond durability of steel-FRP composite bars embedded in seawater sea-sand concrete under constant bending and shearing stress. Constr. Build. Mater. 2018, 192, 808–817. [Google Scholar] [CrossRef]

- Ren, S. Study on the Flexural Behavior of Concrete Beams Reinforced by Steel-FRP Composite Bars. Master’s Thesis, Southeast University, Nanjing, Jiangsu, June 2011. [Google Scholar]

- Sun, Z.Y.; Yang, Y.; Qin, W.H.; Ren, S.T.; Wu, G. Experimental Study on Flexural Behavior of Concrete Beams Reinforced by Steel-Fiber Reinforced Polymer Composite Bars. J. Reinf. Plast. Compos. 2012, 31, 53–61. [Google Scholar] [CrossRef]

- Seo, D.W.; Park, K.T.; You, Y.J.; Lee, S.Y. Experimental Investigation for Tensile Performance of GFRP-Steel Hybridized Rebar. Adv. Mater. Sci. Eng. 2016, 12, 1–12. [Google Scholar] [CrossRef]

- Wang, L.; Shen, N.; Zhang, M.; Fu, F.; Qian, K. Bond performance of Steel-CFRP bar reinforced coral concrete beams. Constr. Build. Mater. 2020, 245, 118456. [Google Scholar] [CrossRef]

- Sun, Z.; Xiao, W.; Wu, G.; Yang, Y.; Wu, Z. Preliminary Study on Moment-curvature Behavior of Concrete Beams Reinforced by Steel-Fiber Reinforced Polymer Composite Bars. In Proceedings of the 9th National Construction Engineering FRP Application Academic Exchange, Chongqing, China, 16–18 May 2015; pp. 66–70. [Google Scholar]

- Zhang, L. Study on Bond Behavior between Steel-FRP Composite Bar (SCFCB) and Concrete under Cyclic Loading. Ph.D. Thesis, Southeast University, Nanjing, Jiangsu, June 2011. [Google Scholar]

- Sun, Z.Y.; Wu, G.; Wu, Z.S.; Zhang, J. Nonlinear Behavior and Simulation of Concrete Columns Reinforced by Steel-FRP Composite Bar. J. Bridge Eng. 2014, 19, 220–234. [Google Scholar] [CrossRef]

- Xiao, T.L.; Qiu, H.X.; Li, J.L. Seismic Behaviors of Concrete Beams Reinforced with Steel-FRP Composite Bars under Quasi-Static Loading. Appl. Sci. 2018, 8, 1913. [Google Scholar] [CrossRef]

- Harsha, S. Tension Stiffness Effect in GFRP Reinforced Concrete Elements. Ph.D. Thesis, The University of Sheffield, Sheffield, UK, 2006; pp. 66–68. [Google Scholar]

- Adam, M.A.; Said, M.; Mahmoud, A.A.; Shanour, A.S. Analytical and experimental flexural behavior of concrete beams reinforced with glass fiber reinforced polymers bars. Constr. Build. Mater. 2015, 84, 354–366. [Google Scholar] [CrossRef]

- Aielllo, M.A.; Ombres, L. Load-deflection analysis of FRP reinforced concrete flexural members. J. Compos. Constr. 2000, 4, 164–171. [Google Scholar] [CrossRef]

- El-Nemr, A.; Ahmed, E.A.; El-Safty, A.; Benmokrane, B. Evaluation of the flexural strength and serviceability of concrete beams reinforced with different types of GFRP bars. Eng. Struct. 2018, 173, 606–619. [Google Scholar] [CrossRef]

- Bischoff, P.H.; Gross, S.P. Equivalent Moment of Inertia Based on Integration of Curvature. J. Compos. Constr. 2011, 15, 263–273. [Google Scholar] [CrossRef]

- Guo, L.; Liu, Y.; Fu, F.; Huang, H. Behavior of axially loaded circular stainless steel tube confined concrete stub columns. Thin-Walled Struct. 2019, 139, 66–76. [Google Scholar] [CrossRef]

- Gao, S.; Guo, L.; Fu, F.; Zhang, S. Capacity of semi-rigid composite joints in accommodating column loss. J. Constr. Steel Res. 2017, 139, 288–301. [Google Scholar] [CrossRef]

- Deng, X.F.; Liang, S.L.; Fu, F.; Qian, K. Effects of High-Strength Concrete on Progressive Collapse Resistance of Reinforced Concrete Frame. J. Struct. Eng. 2020, 146, 04020078. [Google Scholar] [CrossRef]

- Qian, K.; Liang, S.L.; Xiong, X.Y.; Fu, F.; Fang, Q. Quasi-static and dynamic behavior of precast concrete frames with high performance dry connections subjected to loss of a penultimate column scenario. Eng. Struct. 2020, 205, 110115. [Google Scholar] [CrossRef]

- Weng, Y.H.; Qian, K.; Fu, F.; Fang, Q. Numerical investigation on load redistribution capacity of flat slab substructures to resist progressive collapse. J. Build. Eng. 2020, 29, 101109. [Google Scholar] [CrossRef]

| Bar Type | db (mm) | hh (mm) | hs (mm) | ffu (Mpa) | Ef (GPa) | Ultimate Strain (%) | ||

|---|---|---|---|---|---|---|---|---|

| Steel | Carbon Fiber | |||||||

| Rebar 14 | 14 | 1.15 | 9.00 | 608 | 200.4 | 0.32 ± 0.03 | - | - |

| CFRP 14 | 14 | 0.76 | 15.66 | 826 | 109.7 | - | 1.11 ± 0.03 | - |

| SCFCB 14(6) | 14 | 1.00 | 9.63 | 1073.8 | 132.6 | 0.31 ± 0.05 | 1.21 ± 0.04 | 3.08 |

| SCFCB 14(8) | 14 | 0.32 | 13.63 | 858.4 | 136.0 | 0.36 ± 0.02 | 1.23 ± 0.14 | 9.72 |

| Concrete Strength | Water–Cement Ratio | fc (MPa) | fck (MPa) | ft (MPa) | Ec (GPa) |

|---|---|---|---|---|---|

| C35 | 0.33 | 37.7 | 32.5 | 2.10 | 28.8 |

| Coefficient of variation (%) | — | 0.019 | 0.021 | 0.027 | 0.024 |

| Beam | ρ (%) | Steel Ratio (%) | Crack | Failure | Yield Load a (kN) | Pu (Kn) | Failure Mode b | ||

|---|---|---|---|---|---|---|---|---|---|

| Pcr (kN) | wcr (mm) | w (mm) | wmean (mm) | ||||||

| CFRP14-1 | 1.18 | - | 9 | 0.02 | 1.29 | 0.77 | - | 88.7 | CC |

| CFRP14-2 | 1.18 | - | 9 | 0.02 | 1.35 | 0.83 | - | 87 | CC |

| SCFCB14(6)-1 | 1.18 | 18.39 | 6 | 0.02 | 1.12 | 0.61 | 45 | 93 | SSC |

| SCFCB14(6)-2 | 1.18 | 18.39 | 6 | 0.02 | 1.85 | 0.9 | 45 | 120.6 | SSS |

| SCFCB14(8)-1 | 1.18 | 32.68 | 6 | 0.02 | 1.05 | 0.54 | 53 | 102 | CC |

| SCFCB14(8)-2 | 1.18 | 32.68 | 9 | 0.02 | 1.24 | 0.76 | 56 | 107 | CC |

| Rebar 14-1 | 1.18 | 100 | 10 | 0.01 | 0.63 | 0.48 | 78 | 82 | YCC |

| Rebar 14-2 | 1.18 | 100 | 15 | 0.02 | 0.67 | 0.52 | 78 | 85 | YCC |

| Beam | Experimental Results | ACI [8] | CSA [9] | ISIS [10] | GB 50608-2010 [11] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mcr kN·m | Mn kN·m | Failure Mode 1 | Mcr Exp | Mn Exp | Failure Mode 1 | Mcr Exp | Mn Exp | Failure Mode 1 | Mcr Exp | Mn Exp | Failure Mode 1 | Mcrb Exp | Mn Exp | Failure Mode 1 | |

| 14-1 | 3.15 | 31.05 | CC | 1.2 | 0.71 | CC | 1.2 | 0.64 | CC | 1.2 | 0.75 | CC | - | 0.84 | CC |

| 14-2 | 3.15 | 30.45 | CC | 1.2 | 0.69 | CC | 1.2 | 0.63 | CC | 1.2 | 0.74 | CC | - | 0.82 | CC |

| 14(6)-1 | 2.10 | 32.55 | SSa | 0.8 | 0.61 | CC | 0.8 | 0.56 | CC | 0.8 | 0.65 | CC | - | 0.56 | CC |

| 14(6)-2 | 2.10 | 42.21 | SSa | 0.8 | 0.79 | CC | 0.8 | 0.73 | CC | 0.8 | 0.84 | CC | - | 0.73 | CC |

| 14(8)-1 | 2.10 | 35.70 | CC | 0.8 | 0.79 | CC | 0.8 | 0.74 | CC | 0.8 | 0.84 | CC | - | 0.75 | CC |

| 14(8)-2 | 3.15 | 37.45 | CC | 1.2 | 0.83 | CC | 1.2 | 0.78 | CC | 1.2 | 0.88 | CC | - | 0.78 | CC |

| Average | 1.0 | 0.74 | - | 1.0 | 0.68 | - | 1.0 | 0.78 | - | - | 0.75 | - | |||

| Standard deviation | 0.2 | 0.19 | - | 0.2 | 0.23 | - | 0.2 | 0.17 | - | - | 0.19 | - | |||

| Coefficient of variation (%) | 20% | 26% | - | 20% | 34% | - | 20% | 22% | - | 25% | - | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Zhang, J.; Huang, C.; Fu, F. Comparative Study of Steel-FRP, FRP and Steel-Reinforced Coral Concrete Beams in Their Flexural Performance. Materials 2020, 13, 2097. https://doi.org/10.3390/ma13092097

Wang L, Zhang J, Huang C, Fu F. Comparative Study of Steel-FRP, FRP and Steel-Reinforced Coral Concrete Beams in Their Flexural Performance. Materials. 2020; 13(9):2097. https://doi.org/10.3390/ma13092097

Chicago/Turabian StyleWang, Lei, Jiwang Zhang, Changshi Huang, and Feng Fu. 2020. "Comparative Study of Steel-FRP, FRP and Steel-Reinforced Coral Concrete Beams in Their Flexural Performance" Materials 13, no. 9: 2097. https://doi.org/10.3390/ma13092097

APA StyleWang, L., Zhang, J., Huang, C., & Fu, F. (2020). Comparative Study of Steel-FRP, FRP and Steel-Reinforced Coral Concrete Beams in Their Flexural Performance. Materials, 13(9), 2097. https://doi.org/10.3390/ma13092097