Hot Deformation Behavior and Microstructure Evolution of Cu–Ni–Co–Si Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

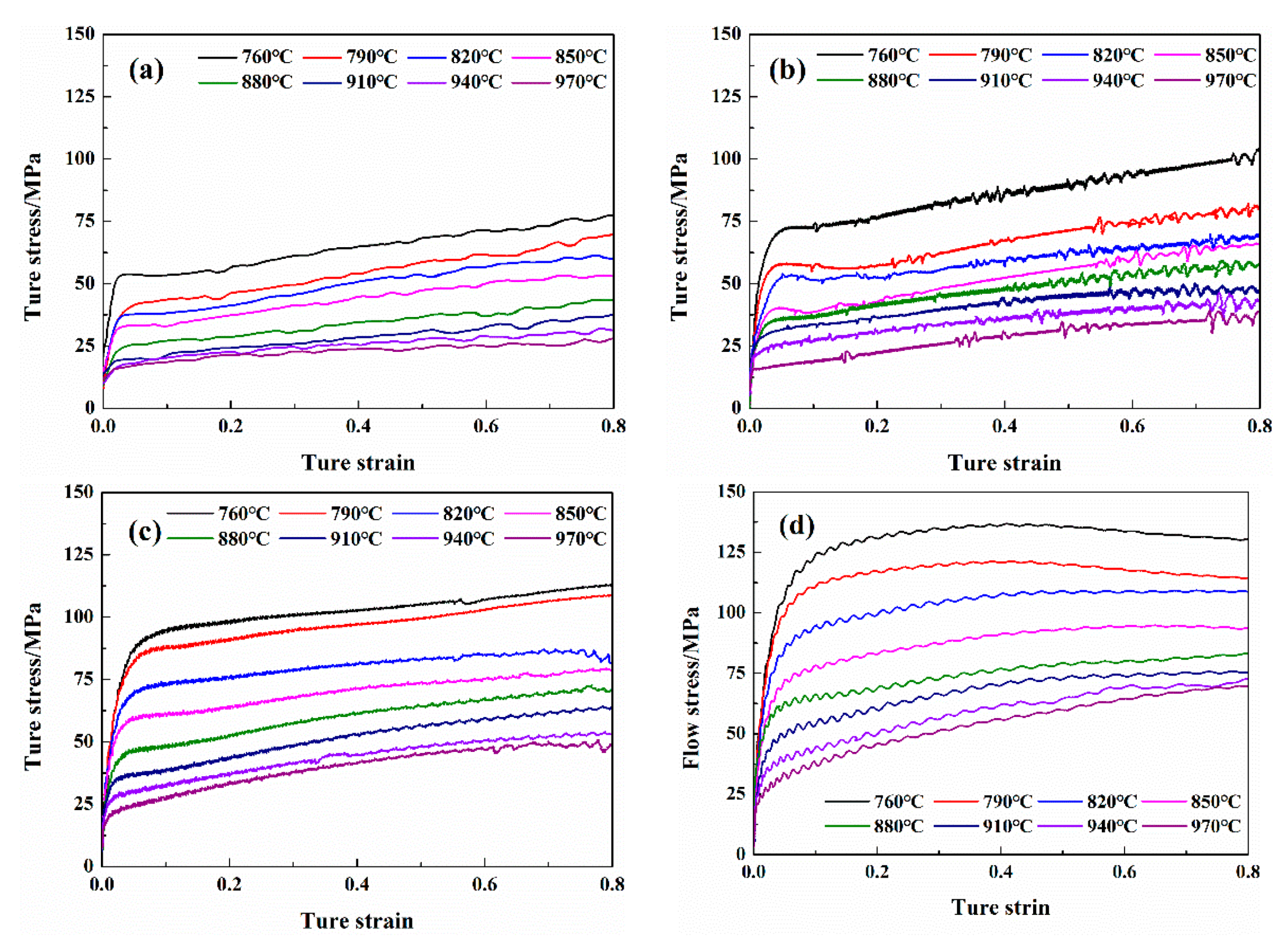

3.1. The True Stress–True Strain Curve

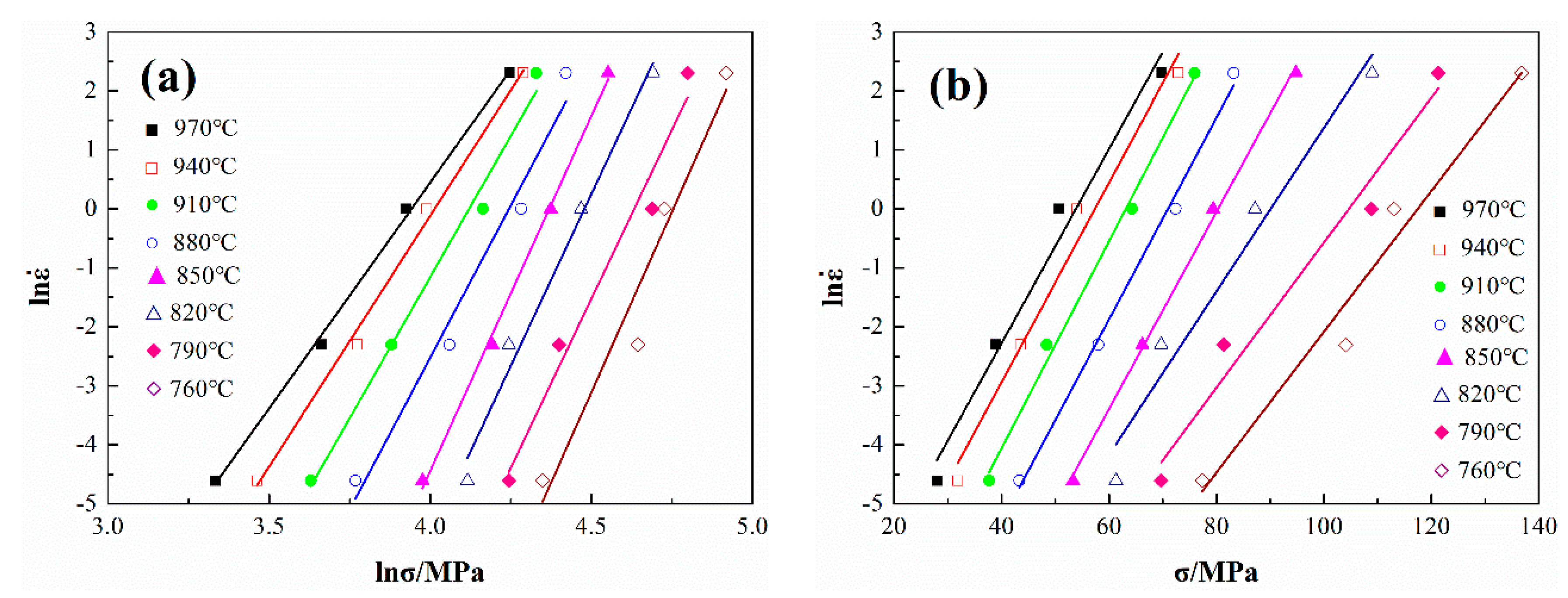

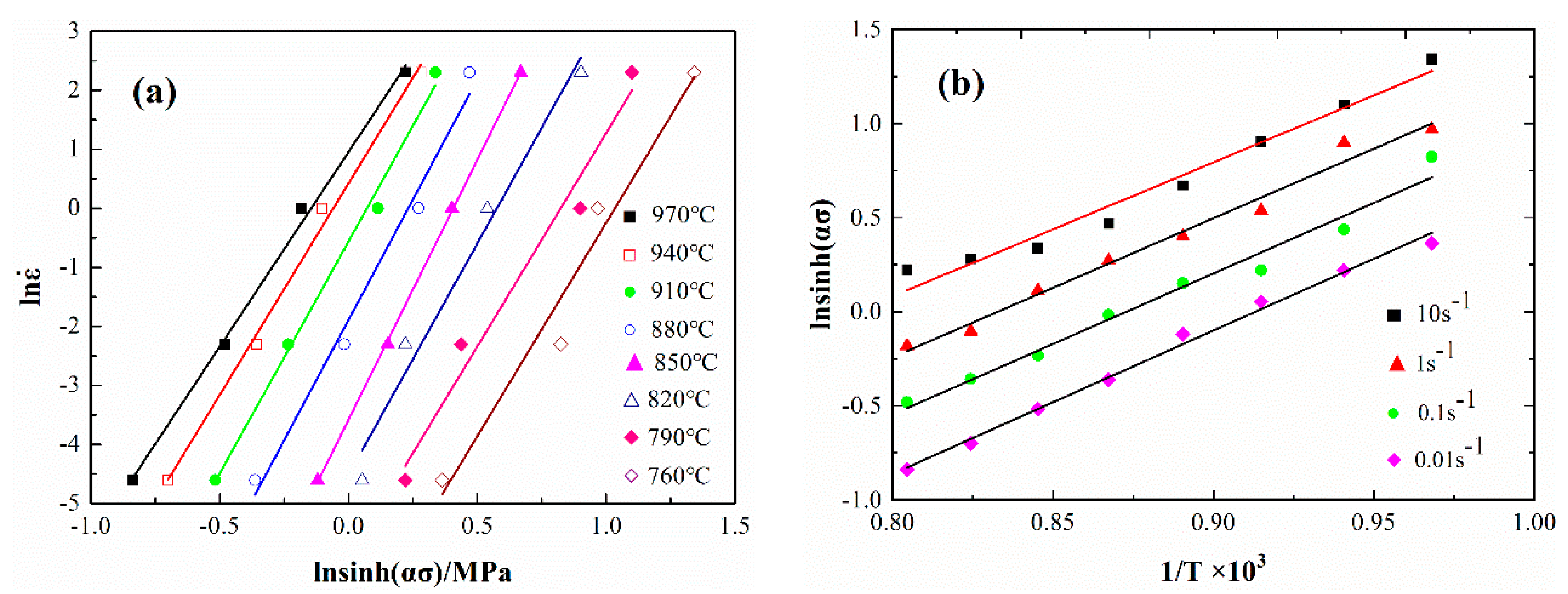

3.2. Constitutive Model of Flow Stress

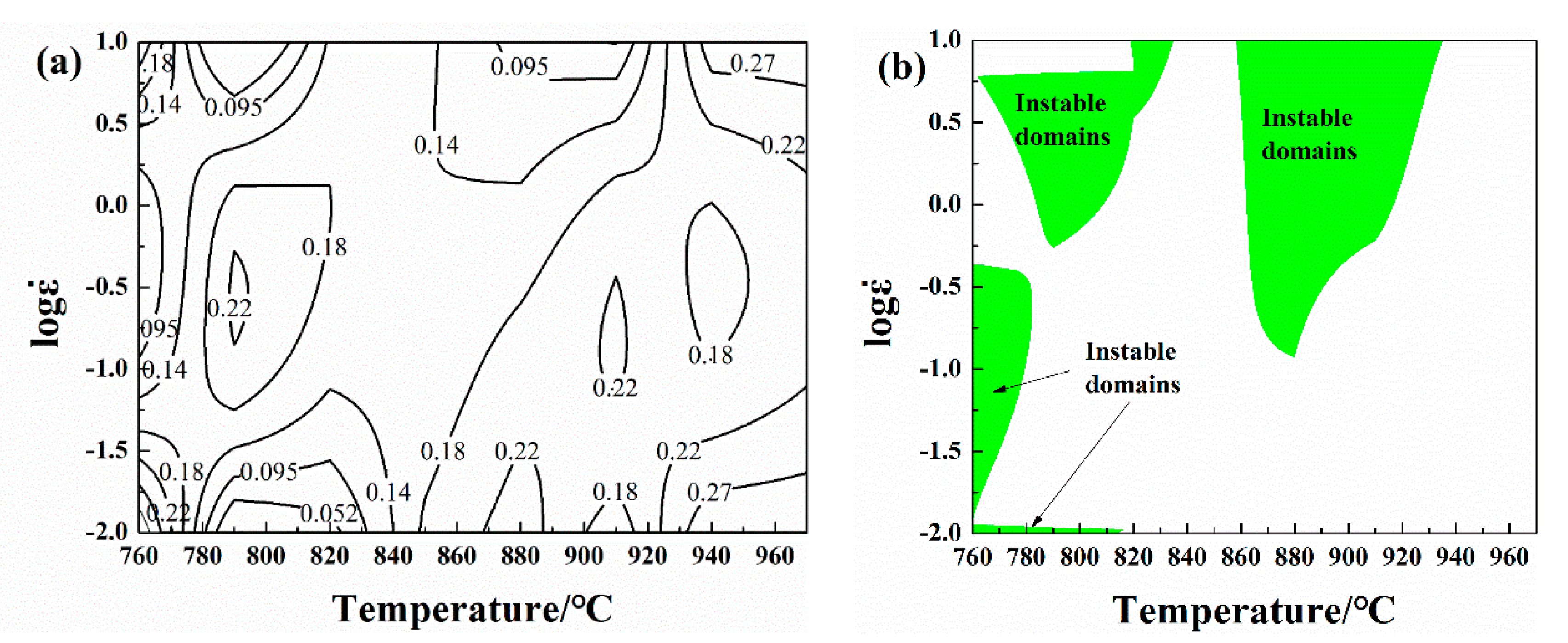

3.3. The Construction and Analysis of Hot Deformation Processing Maps

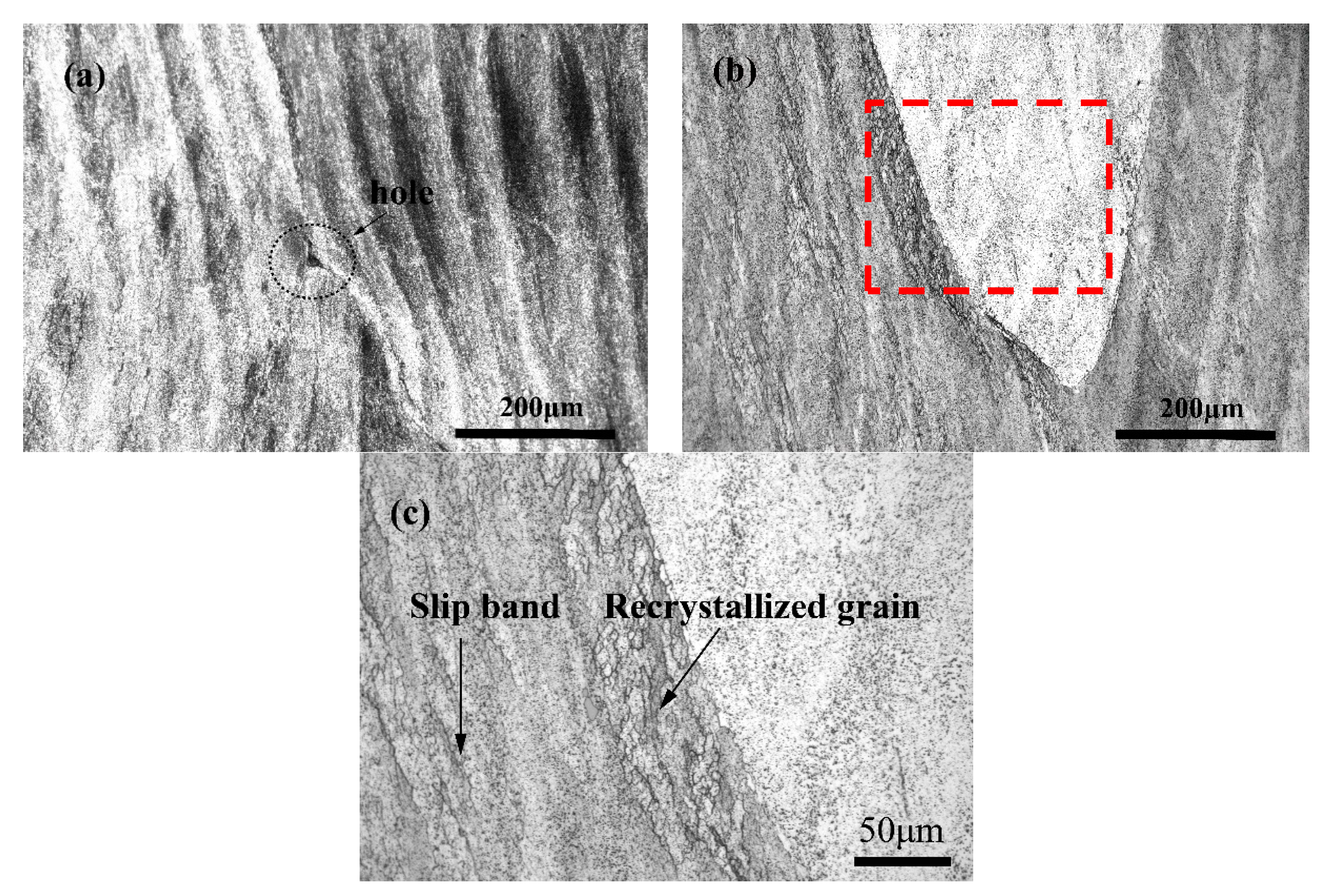

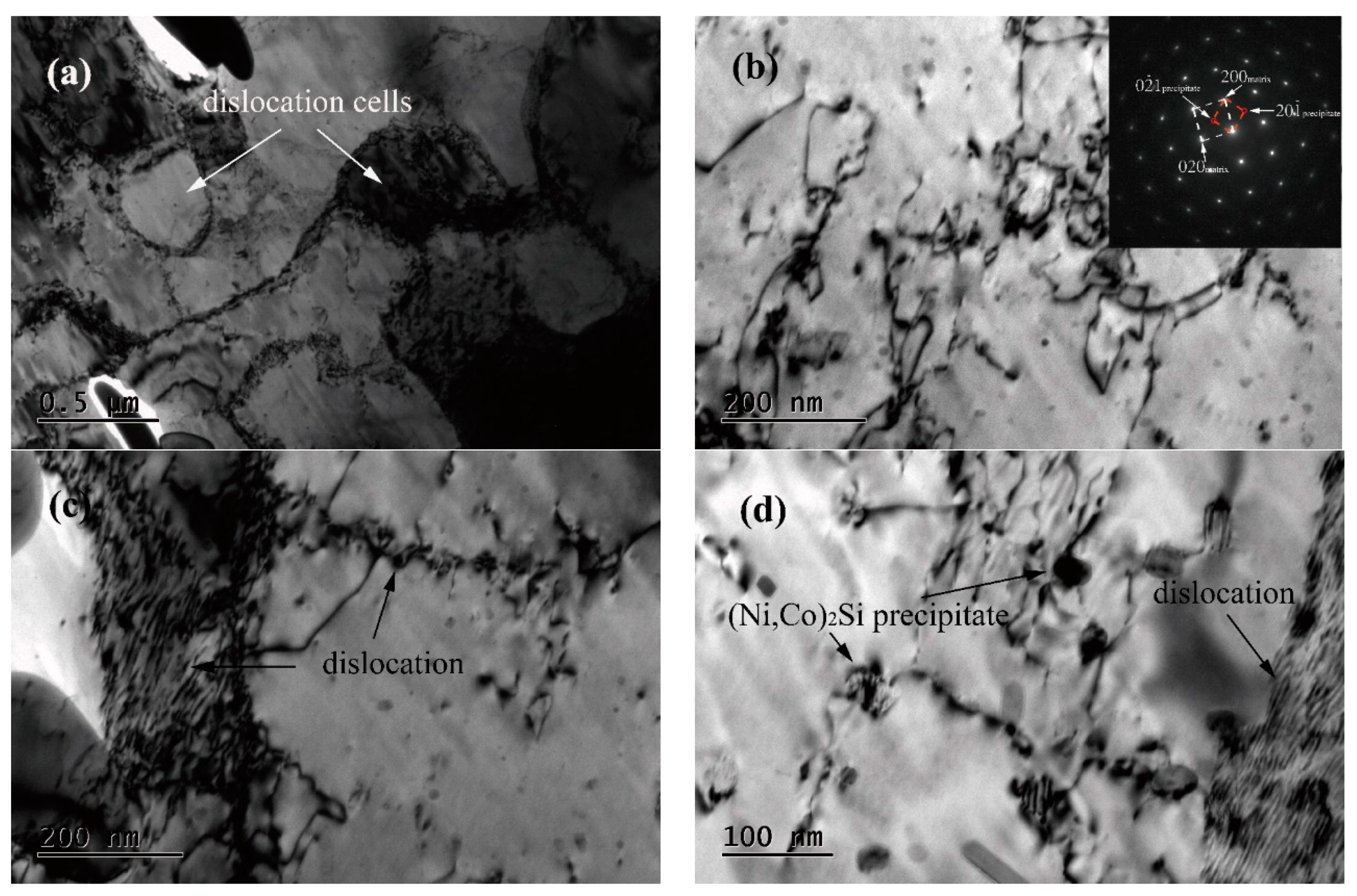

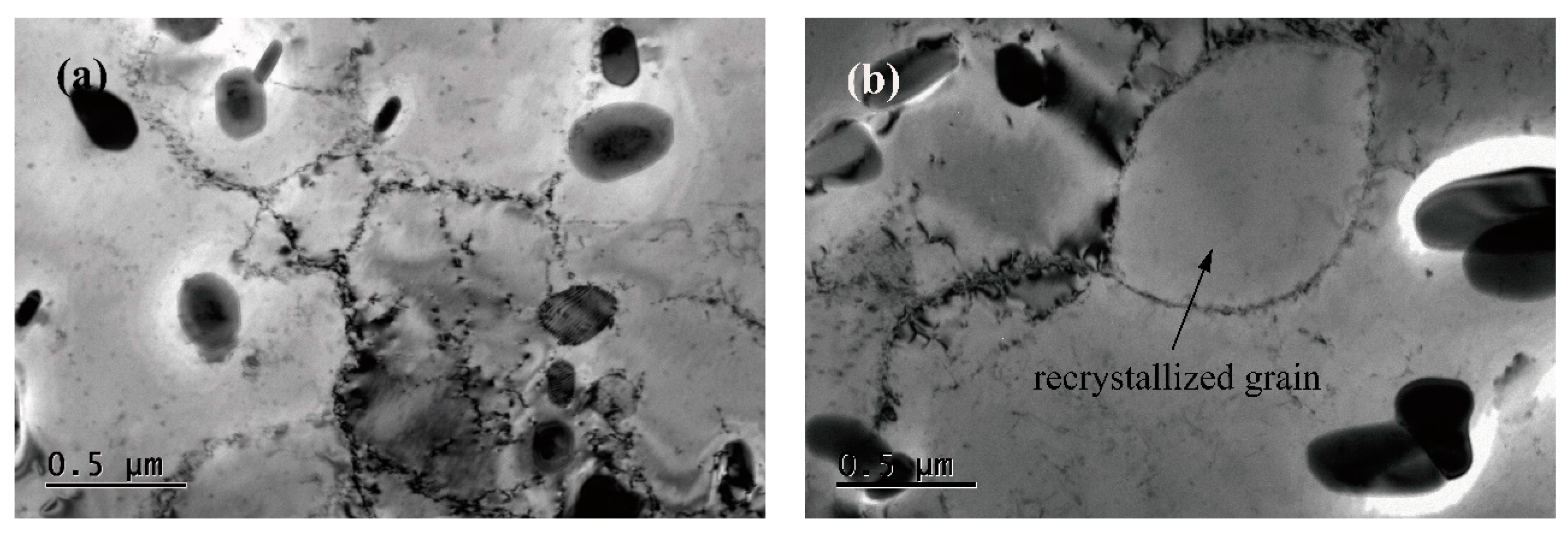

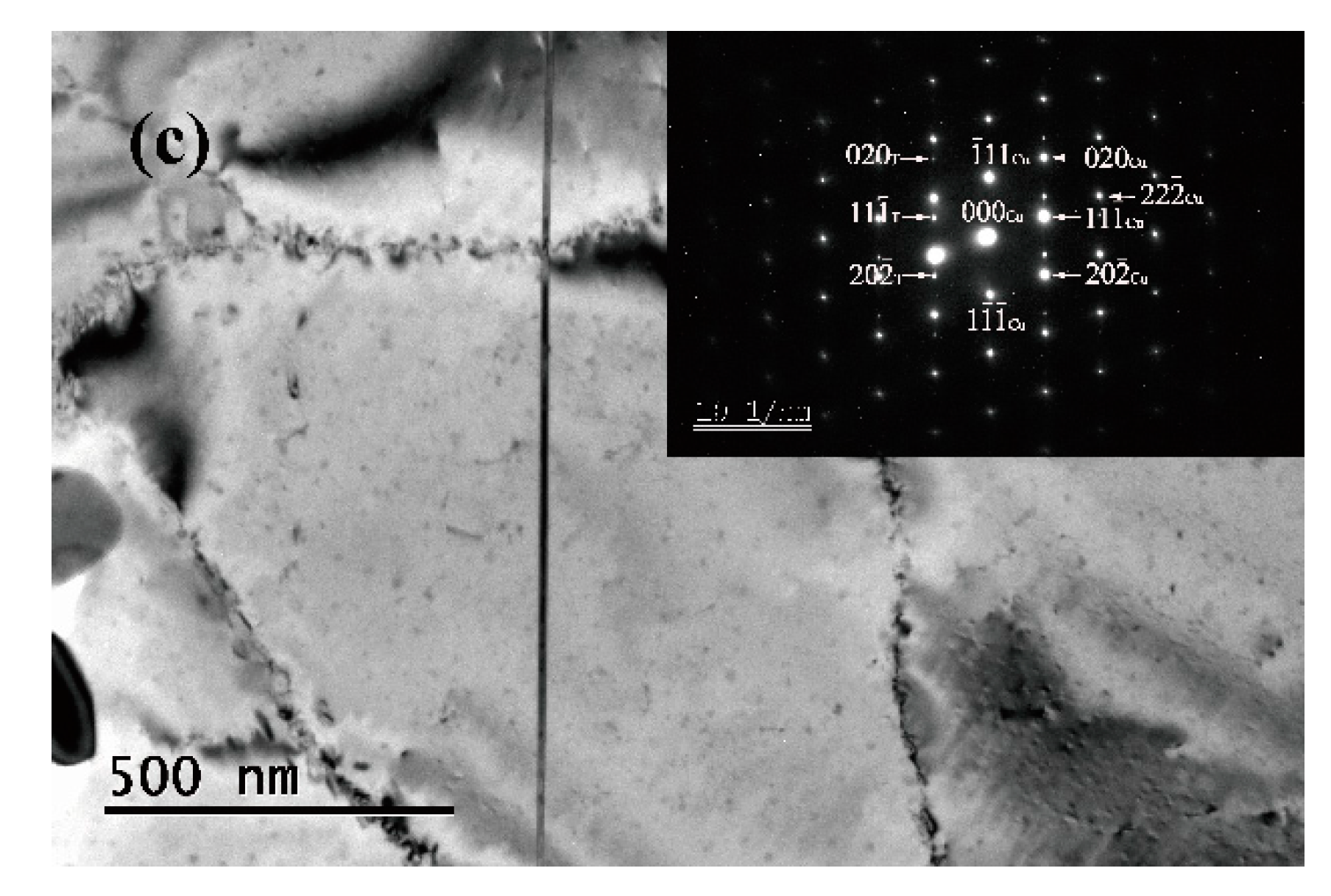

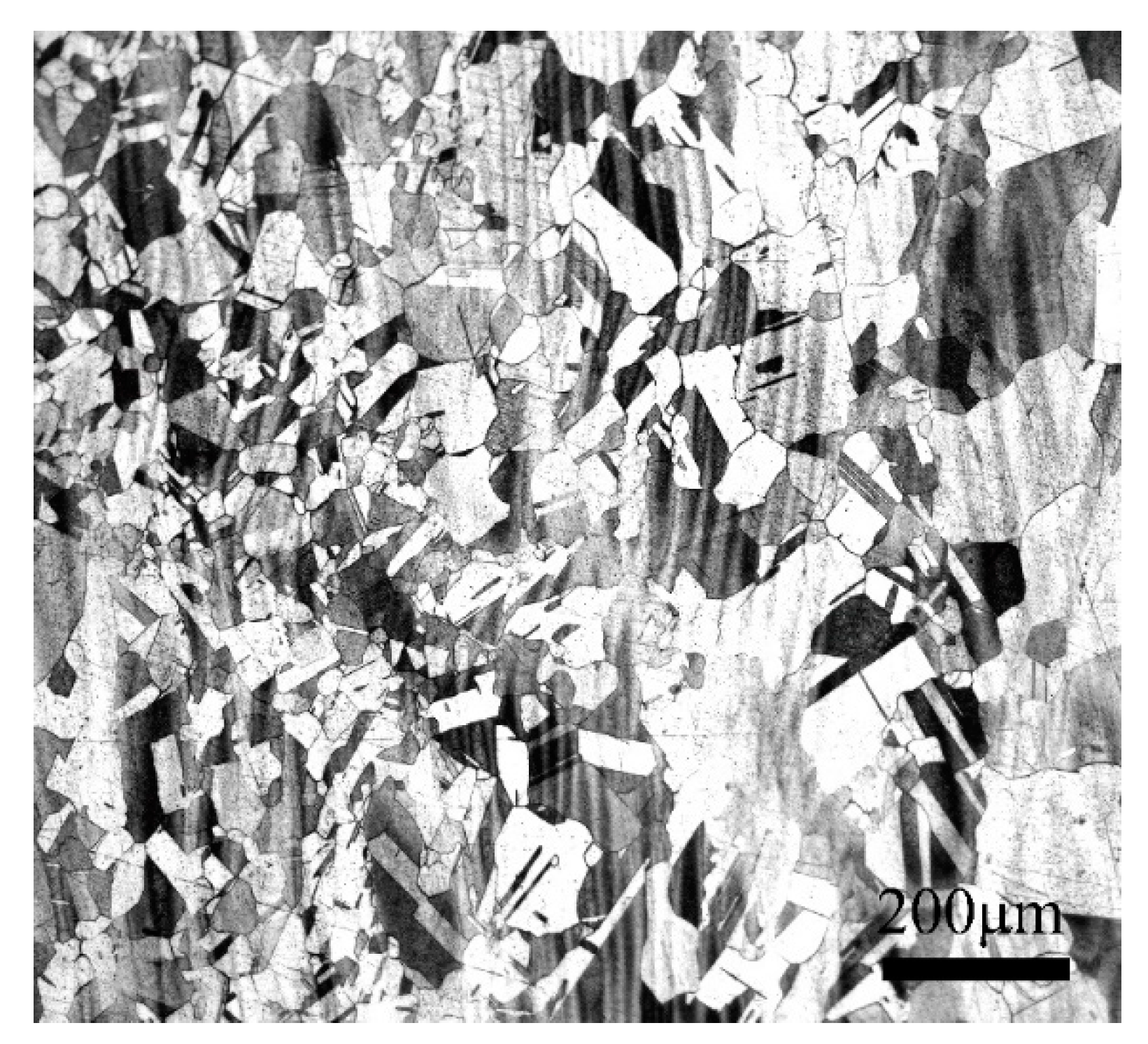

3.4. Microstructure Analysis

4. Conclusions

- (1)

- Deformation temperature and strain rate have significant effects on the flow stress of the Cu-1.7Ni-1.4Co-0.65Si alloy. The flow stress increases with the extension of strain rate and decreases with the increase in deformation temperature. The dynamic recovery, recrystallization and work hardening coexist during the hot compression deformation process. The precipitates of the (Ni,Co)2Si phase are observed and have a strong effect on dislocation movement, which is a response to the increase in strain and stress.

- (2)

- The hot deformation activation energy Q of the Cu-1.7Ni-1.4Co-0.65Si alloy can be calculated as 468.5 kJ/mol, and the high temperature deformation constitutive equation is confirmed as:

- (3)

- The hot processing map of the Cu-1.7Ni-1.4Co-0.65Si alloy is established on the basis of hot deformation behavior and hot working characteristics. With optimal hot deformation conditions of 940 to 970 °C and 0.01 to 10 s−1, the fine equiaxed grain and no holes are found in the matrix.

Author Contributions

Funding

Conflicts of Interest

References

- Lei, Q.; Li, Z.; Xiao, T.; Pang, Y.; Xiang, Z.Q.; Qiu, W.T.; Xiao, Z. A new ultrahigh strength Cu–Ni–Si alloy. Intermetallics 2013, 42, 77–84. [Google Scholar] [CrossRef]

- Lei, Q.; Li, Z.; Wang, M.P.; Zhang, L.; Xiao, Z.; Jia, Y.L. The evolution of microstructure in Cu–8.0 Ni–1.8 Si–0.15 Mg alloy during aging. Mater. Sci. Eng. A 2010, 527, 6728–6733. [Google Scholar] [CrossRef]

- Cheng, J.; Tang, B.; Yu, F.; Shen, B. Evaluation of nanoscaled precipitates in a Cu–Ni–Si–Cr alloy during aging. J. Alloy Compd. 2014, 614, 189–195. [Google Scholar] [CrossRef]

- Liu, F.; Mi, X.J.; Ma, J.M. Microstructure and properties of low concentration Cu-Ni-Si alloys. Chin. J. Nonferrous Met. 2019, 29, 286–294. [Google Scholar]

- Cheng, Z.X. A brief analysis on the lead frame design of high power integrated circuit. China Integr. Circuit 2019, 7, 73–77. [Google Scholar]

- Peng, L.J.; Ma, J.M.; Liu, X.Y.; Liu, F.; Huang, G.J.; Hong, S.B.; Xie, H.F.; Liu, D.M. Effects of different treatment processes on the microstructure and properties of Cu-Ni-Co-Si alloys. Rare Met. Mater. Eng. 2019, 48, 1969–1975. [Google Scholar]

- Peng, L.J.; Ma, J.M.; Liu, X.Y.; Liu, F.; Huang, G.J.; Hong, S.B.; Xie, H.F.; Yang, Z. Effect of heat treatment on microstructure and properties of Cu-Ni-Co-Si alloy. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; p. 012030. [Google Scholar]

- Lei, Q.; Li, Z.; Wang, J.; Li, S.; Zhang, L.; Dong, Q. High-temperature deformation behavior of Cu–6.0Ni–1.0Si–0.5Al–0.15. J. Mater. Sci. 2012, 47, 6034–6042. [Google Scholar] [CrossRef]

- Chalon, J.; Guerin, J.D.; Dubar, L.; Dubois, A.; Puchi-Cabrera, E.S. Characterization of the hot-working behavior of a Cu-Ni-Si alloy. Mater. Sci. Eng. A 2016, 667, 77–86. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Z.; Pan, D.Q.; Li, X.D.; Luo, Z.Q.; Zhang, T.D.; Yang, C.; Zhang, W.W. Effect of Si and Ti on dynamic recrystallization of high-performance Cu-15Ni-8Sn alloy during hot deformation. Trans. Nonferrous Met. Soc. China 2019, 29, 2556–2565. [Google Scholar] [CrossRef]

- Bahador, A.; Umeda, J.; Hamzah, E.; Yusof, F.; Li, X.C.; Kondoh, K. Synergistic strengthening mechanisms of copper matrix composites with TiO2 nanoparticles. Mater. Sci. Eng. A 2020, 772, 138797. [Google Scholar] [CrossRef]

- Xiao, X.P. Research on Fabrication, Microstructure and Properties of Cu-Ni-Co-Si Alloy with High Performance; General Research Institute for Nonferrous Metals: Beijing, China, 2013. [Google Scholar]

- Sun, H.L.; Zhang, T.; Volinsky, A.A.; Wang, B.J.; Tian, B.J.; Song, K.X.; Chai, Z.; Liu, Y. Effects of Ag addition on hot deformation behavior of Cu-Ni-Si alloy. Adv. Eng. Mater. 2017, 19, 1600607. [Google Scholar] [CrossRef]

- Hu, G.X.; Cai, X.; Rong, Y.H. Fundamentals of Materials Science; Shanghai Jiao Tong University Press: Shanghai, China, 2000. [Google Scholar]

- Wang, W.; Yuan, S.; Jiang, B.; Jie, W. Solidification pattern and microstructures of AZ91D magnesium alloy through rheoforming. Chin. Sci. Bull. 2005, 50, 1799–1804. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, L.T.; Fu, Y.X.; Jiang, Y.Q. Hot compressive deformation behavior of 7075 Al alloy under elevated temperature. J. Mater. Sci. 2012, 47, 1306–1318. [Google Scholar] [CrossRef]

- Wang, K.X.; Zeng, W.D.; Zhao, Y.Q.; Lai, Y.; Zhou, Y. Hot working of Ti-17 titanium alloy with lamellar starting structure using 3-D processing maps. J. Mater. Sci. 2010, 45, 5883–5891. [Google Scholar] [CrossRef]

- Rajput, S.K.; Chaudhari, G.P.; Nath, S.K. Characterization of hot deformation behavior of a low carbon steel using processing maps, constitutive equations and Zener-Hollomon parameter. J. Mater. Process. Technol. 2016, 237, 113–125. [Google Scholar] [CrossRef]

- Padmavardhani, D.; Prasad, Y. Processing maps for hot working of Cu-Ni-Zn alloys. J. Mater. Sci. 1993, 28, 5269–5274. [Google Scholar] [CrossRef]

- Li, P.W.; Li, H.Z.; Huang, L.; Liang, X.P.; Zhu, Z.X. Characterization of hot deformation behavior of AA2014 forging aluminum alloy using processing map. Trans. Nonferrous Met. Soc. China 2017, 27, 1677–1688. [Google Scholar] [CrossRef]

- Banerjee, S.J.; Robi, P.S.; Srinivasan, A. Prediction of hot deformation behavior of Al–5.9% Cu–0.5% Mg alloys with trace additions of Sn. J. Mater. Sci. 2012, 47, 929–948. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, Z.; Jiang, Y.B. Composition design, phase transformation and preparation of high strength conductive copper alloys. Chin. J. Nonferrous Met. 2019, 29, 2009–2049. [Google Scholar]

- Prasad, Y. Processing maps: A status report. J. Mater. Eng. Perform. 2003, 12, 638–645. [Google Scholar] [CrossRef]

- Prasad, Y.; Gegel, H.L.; Doraivelu, S.M.; Malas, J.C.; Morgan, J.T.; Lark, K.A.; Barker, D.R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242. Metall. Trans. A 1984, 15, 1883–1892. [Google Scholar] [CrossRef]

- Prasad, Y.; Seshacharyulu, T. Modelling of hot deformation for microstructural control. Int. Mater. Rev. 1998, 43, 243–258. [Google Scholar] [CrossRef]

- Li, J.; Huang, G.J.; Mi, X.L.; Peng, L.J.; Xie, H.F.; Kang, Y.L. Microstructure evolution and properties of a quaternary Cu–Ni–Co–Si alloy with high strength and conductivity. Mater. Sci. Eng. A 2019, 766, 138390. [Google Scholar] [CrossRef]

- Li, J.; Huang, G.J.; Mi, X.J.; Peng, L.J.; Xie, H.F.; Kang, Y.L. Influence of the Ni/Co Mass Ratio on the Microstructure and Properties of Quaternary Cu-Ni-Co-Si Alloys. Materials 2019, 12, 2855. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Huang, G.J.; Mi, X.J.; Peng, L.J.; Xie, H.F.; Kang, Y.L. Relationship between the microstructure and properties of a peak aged Cu–Ni–Co–Si alloy. Mater. Sci. Technol. 2019, 35, 606–614. [Google Scholar] [CrossRef]

- Liu, P.; Fan, L.; Jia, S.G.; Tian, B.H. Study on dynamic recrystallization behavior and microstructure evolution of Cu-Ni-Si-Cr alloy. J. Univ. Shanghai Sci. Technol. 2009, 6, 10. [Google Scholar]

- Fan, L.; Liu, P.; Jia, S.G. Dynamic recrystallization of Cu-Ni-Si alloys for integrated circuits. Mech. Eng. Mater. 2009, 33, 25–28. [Google Scholar]

- Wang, J.Y. Study on Thermal Deformation Behavior of High-Strength and High-Conductivity Cu-Cr-Zr Alloy; Xi’an University of Architecture and Technology: Xi’an, China, 2013. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, F.; Ma, J.; Peng, L.; Huang, G.; Zhang, W.; Xie, H.; Mi, X. Hot Deformation Behavior and Microstructure Evolution of Cu–Ni–Co–Si Alloys. Materials 2020, 13, 2042. https://doi.org/10.3390/ma13092042

Liu F, Ma J, Peng L, Huang G, Zhang W, Xie H, Mi X. Hot Deformation Behavior and Microstructure Evolution of Cu–Ni–Co–Si Alloys. Materials. 2020; 13(9):2042. https://doi.org/10.3390/ma13092042

Chicago/Turabian StyleLiu, Feng, Jimiao Ma, Lijun Peng, Guojie Huang, Wenjing Zhang, Haofeng Xie, and Xujun Mi. 2020. "Hot Deformation Behavior and Microstructure Evolution of Cu–Ni–Co–Si Alloys" Materials 13, no. 9: 2042. https://doi.org/10.3390/ma13092042

APA StyleLiu, F., Ma, J., Peng, L., Huang, G., Zhang, W., Xie, H., & Mi, X. (2020). Hot Deformation Behavior and Microstructure Evolution of Cu–Ni–Co–Si Alloys. Materials, 13(9), 2042. https://doi.org/10.3390/ma13092042