Effect of Reconstruction Algorithm on the Identification of 3D Printing Polymers Based on Hyperspectral CT Technology Combined with Artificial Neural Network

Abstract

1. Introduction

2. Materials and Methods

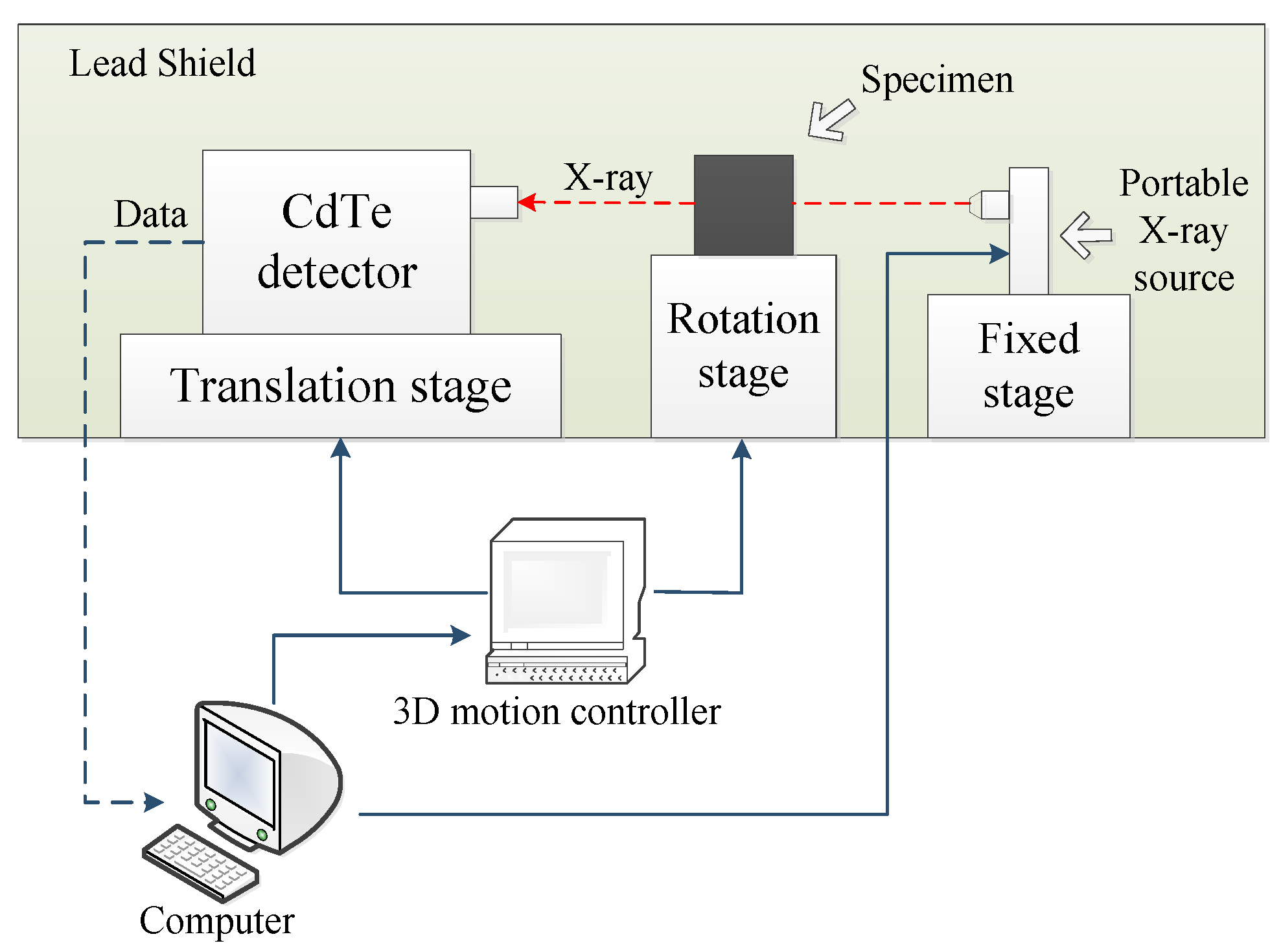

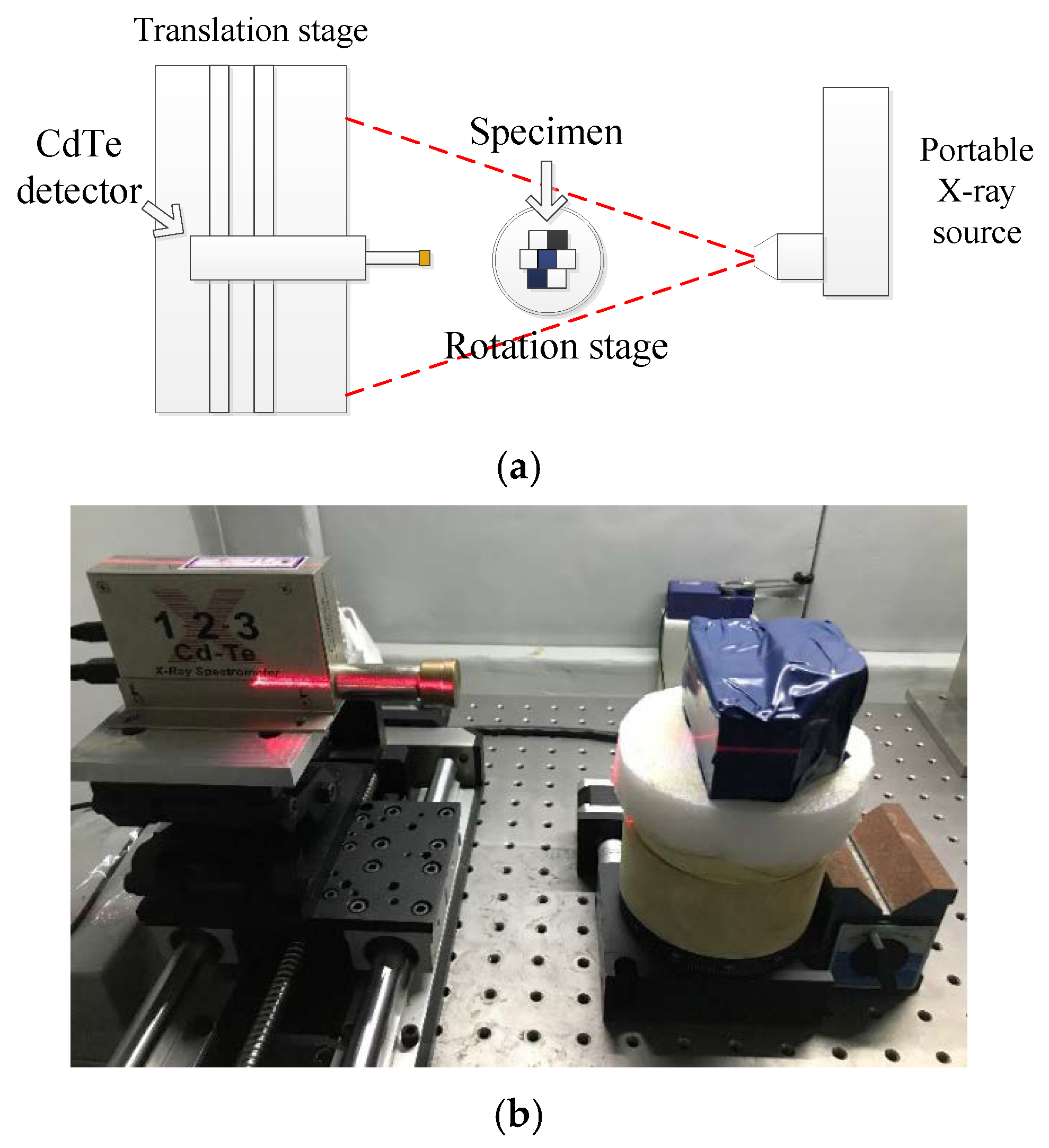

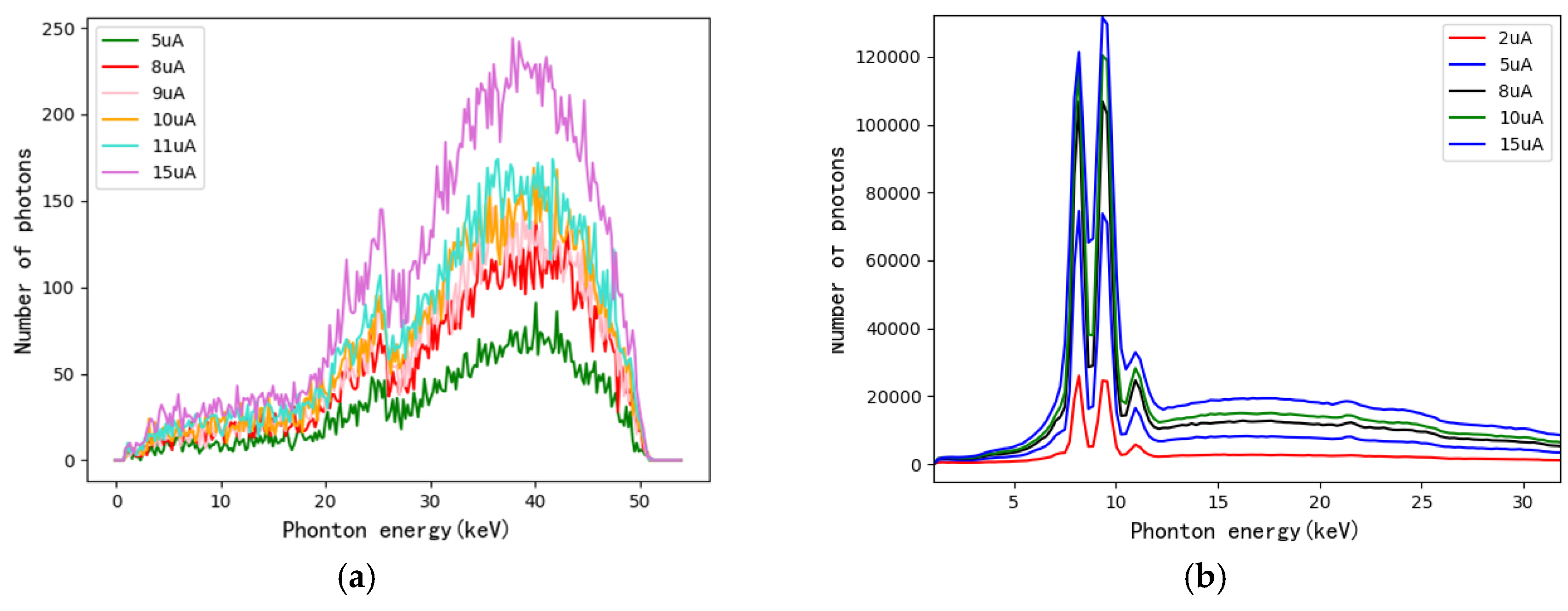

2.1. Instrumental Setup and Specimen

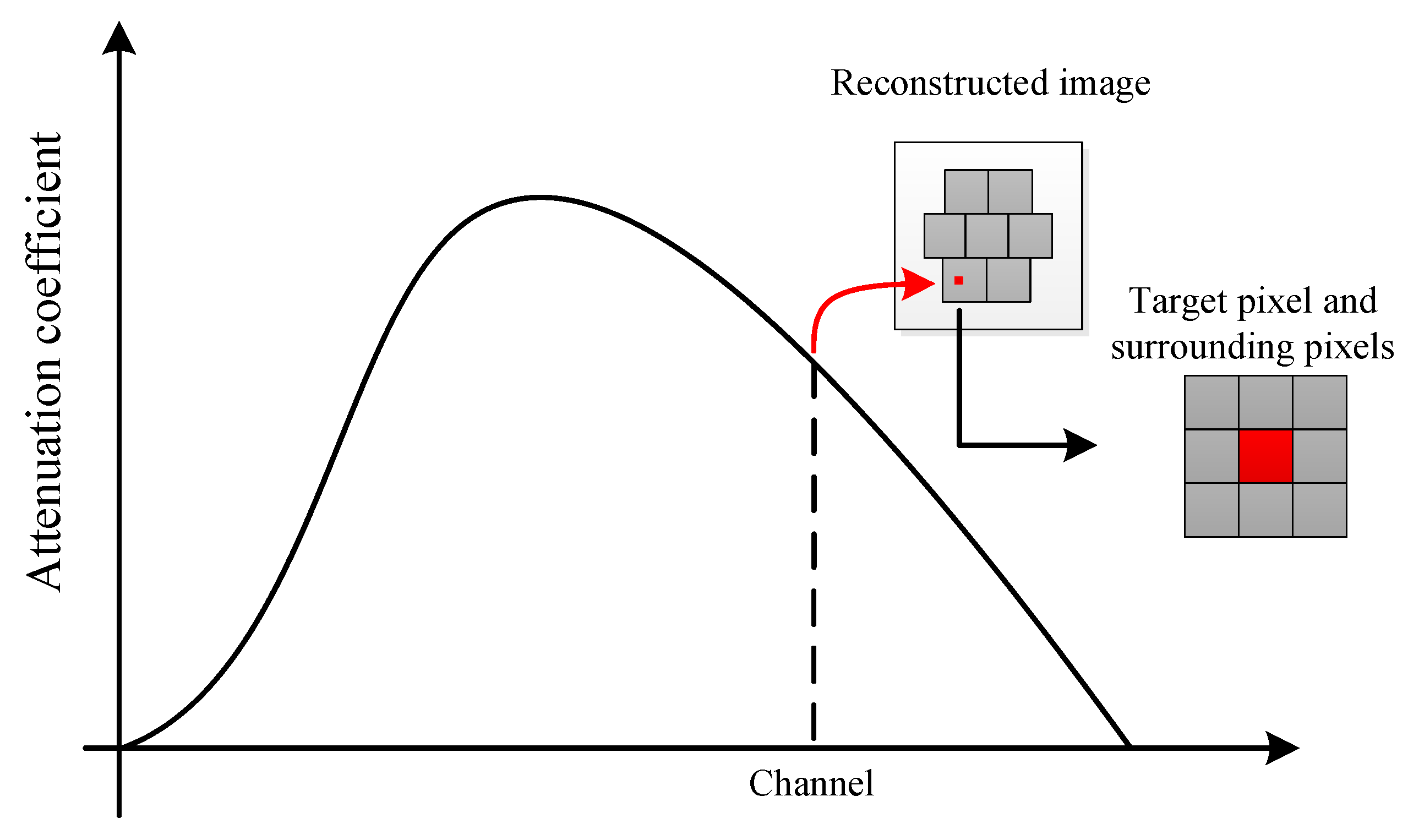

2.2. Reconstruction of CT Image and XAS

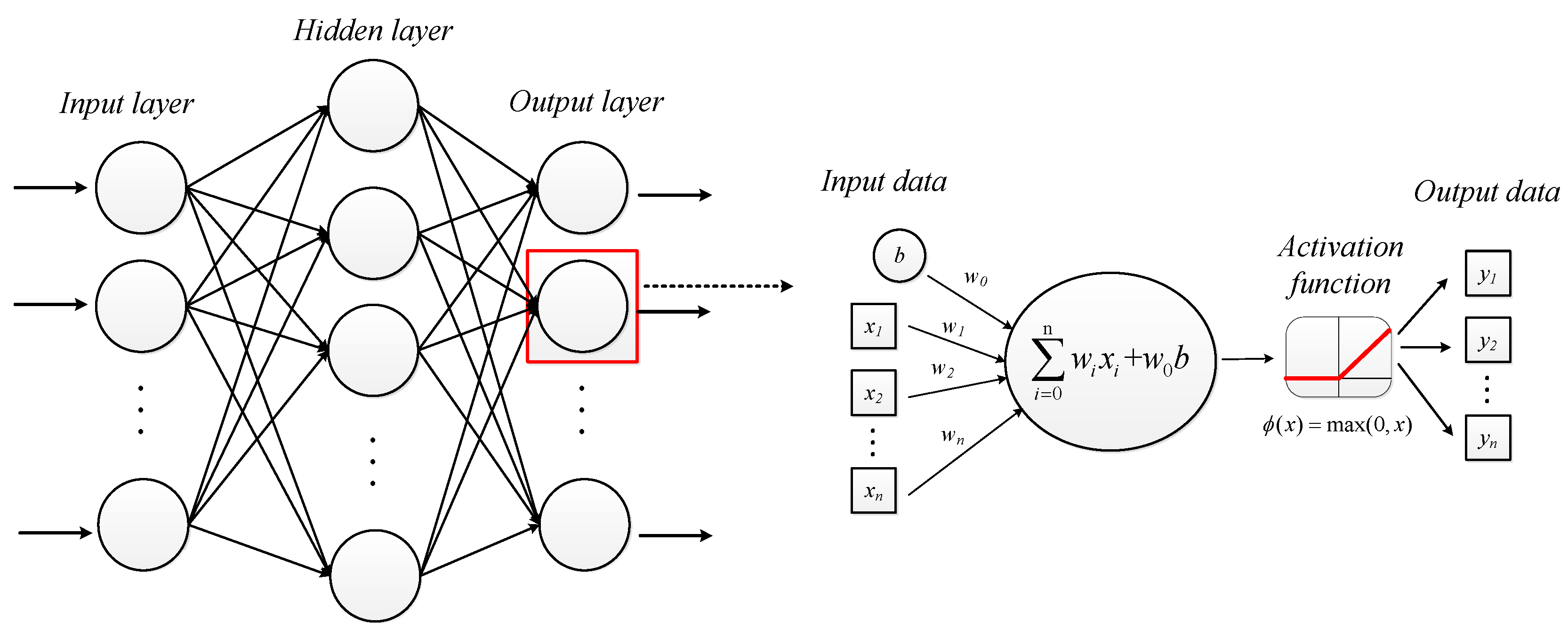

2.3. Classification of Reconstructed XAS

3. Results and Discussion

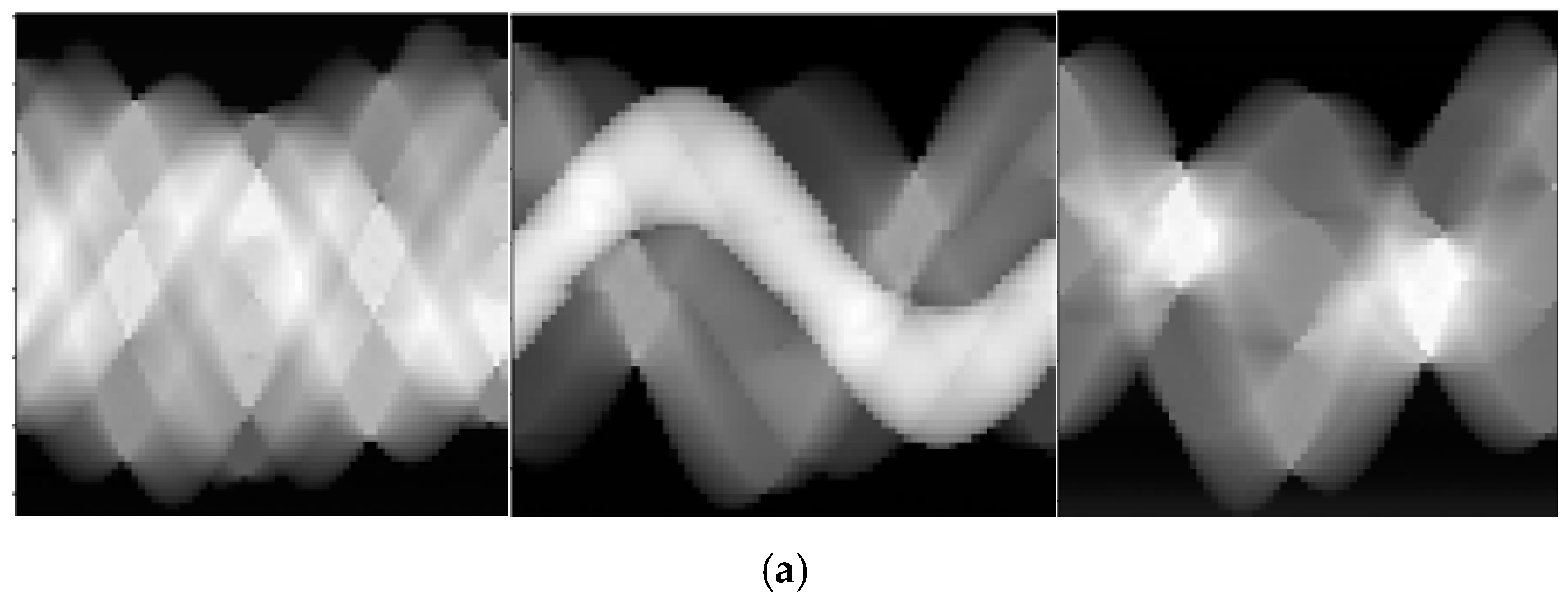

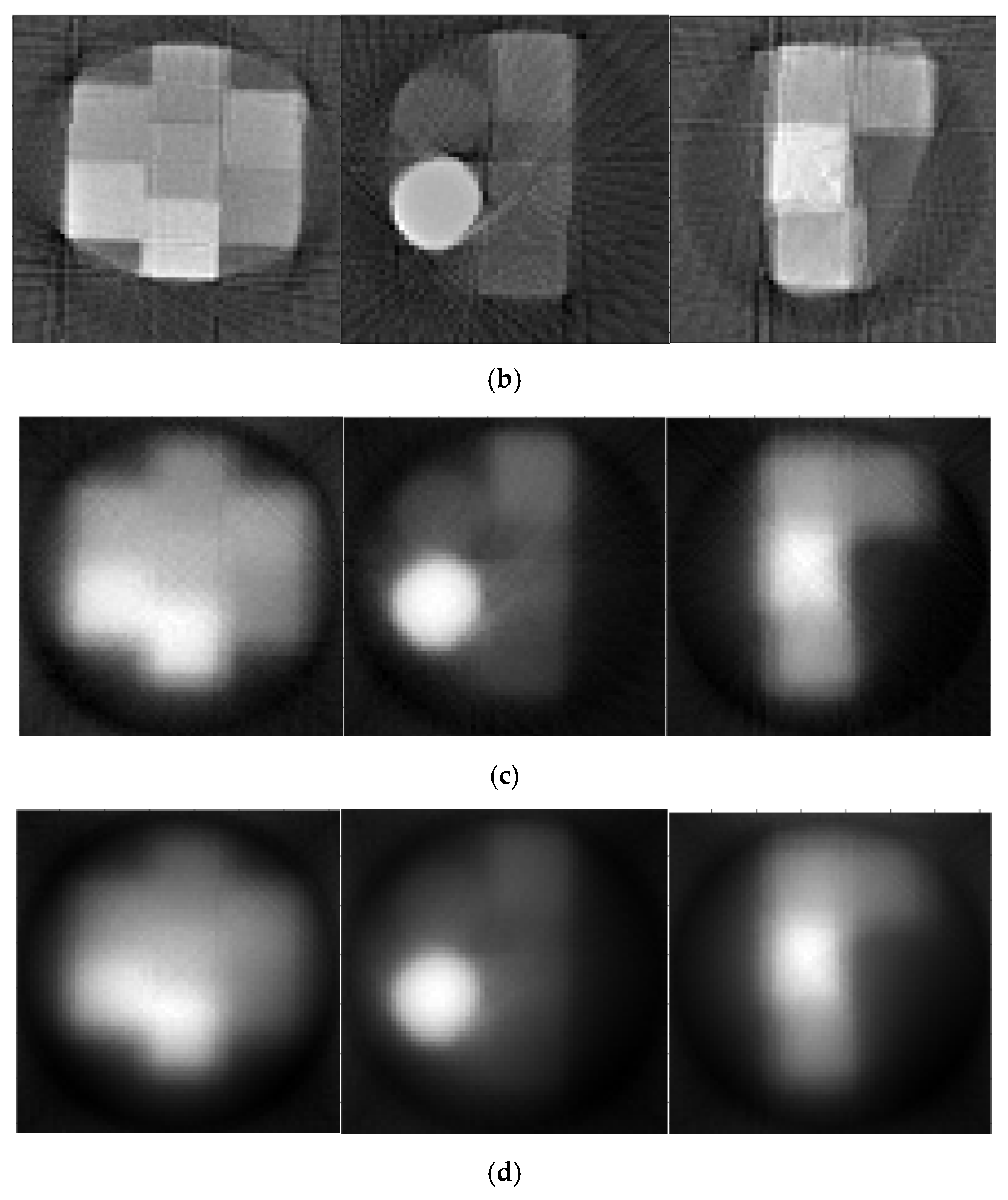

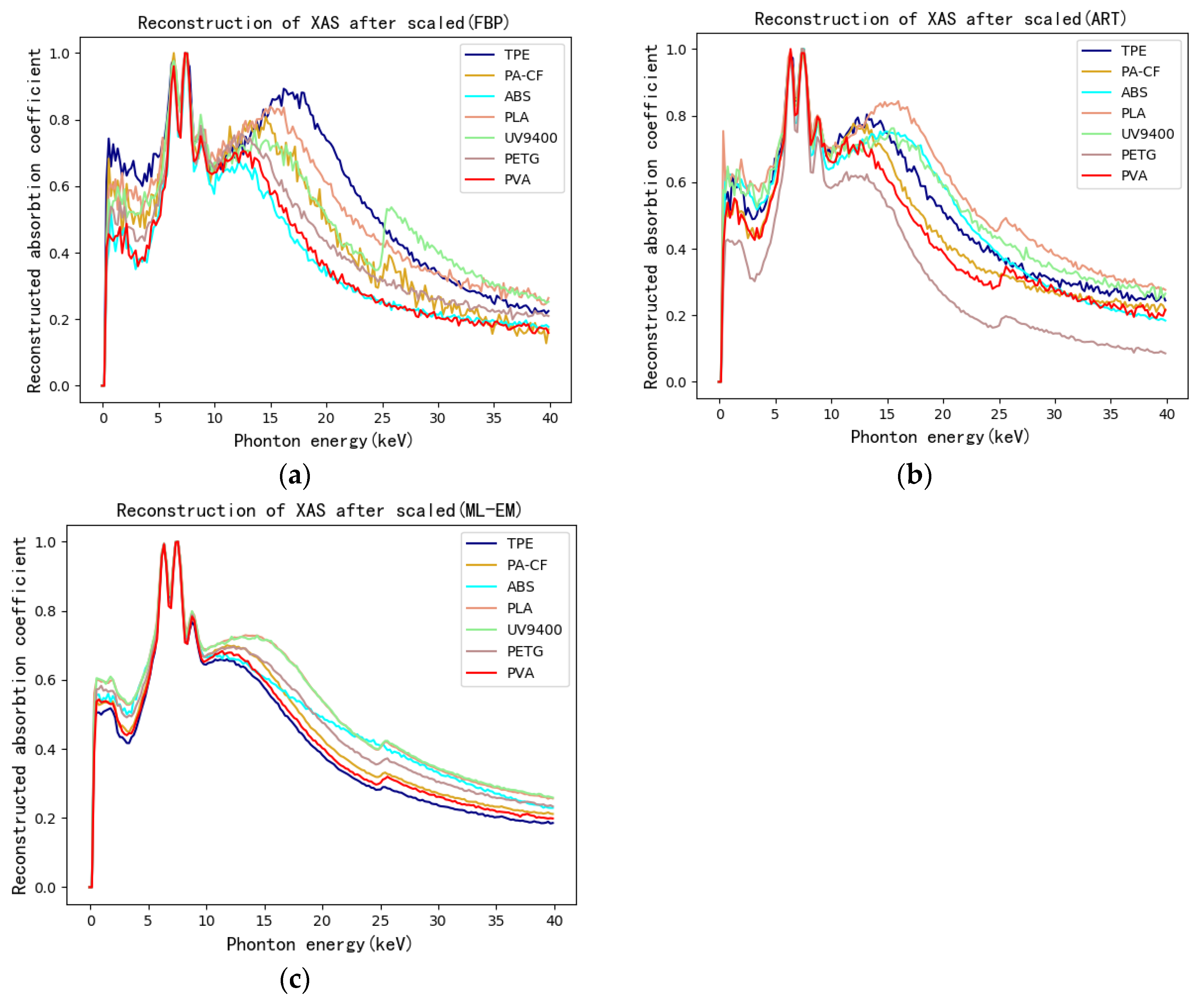

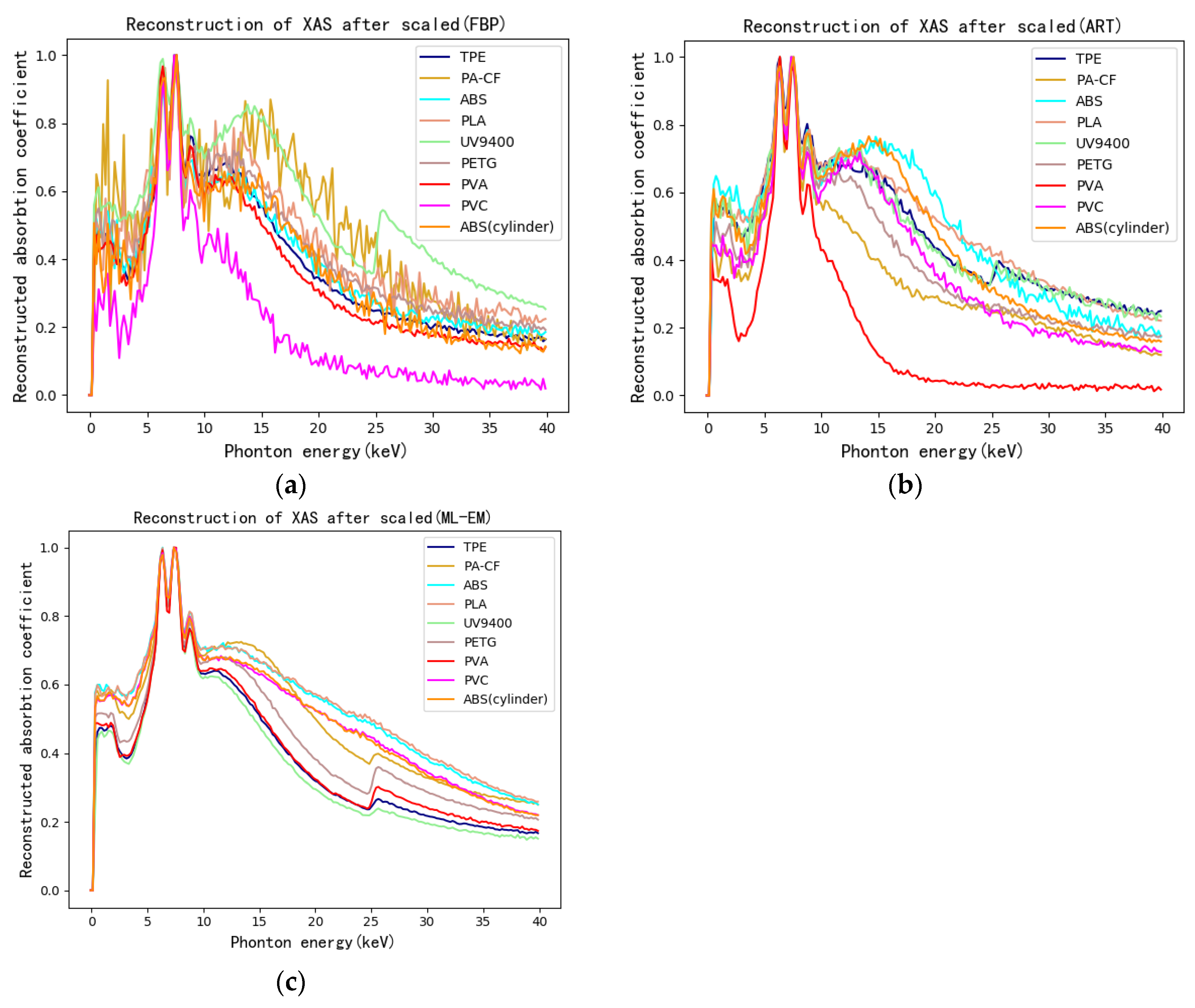

3.1. Reconstruction of CT Image and XAS in ROI

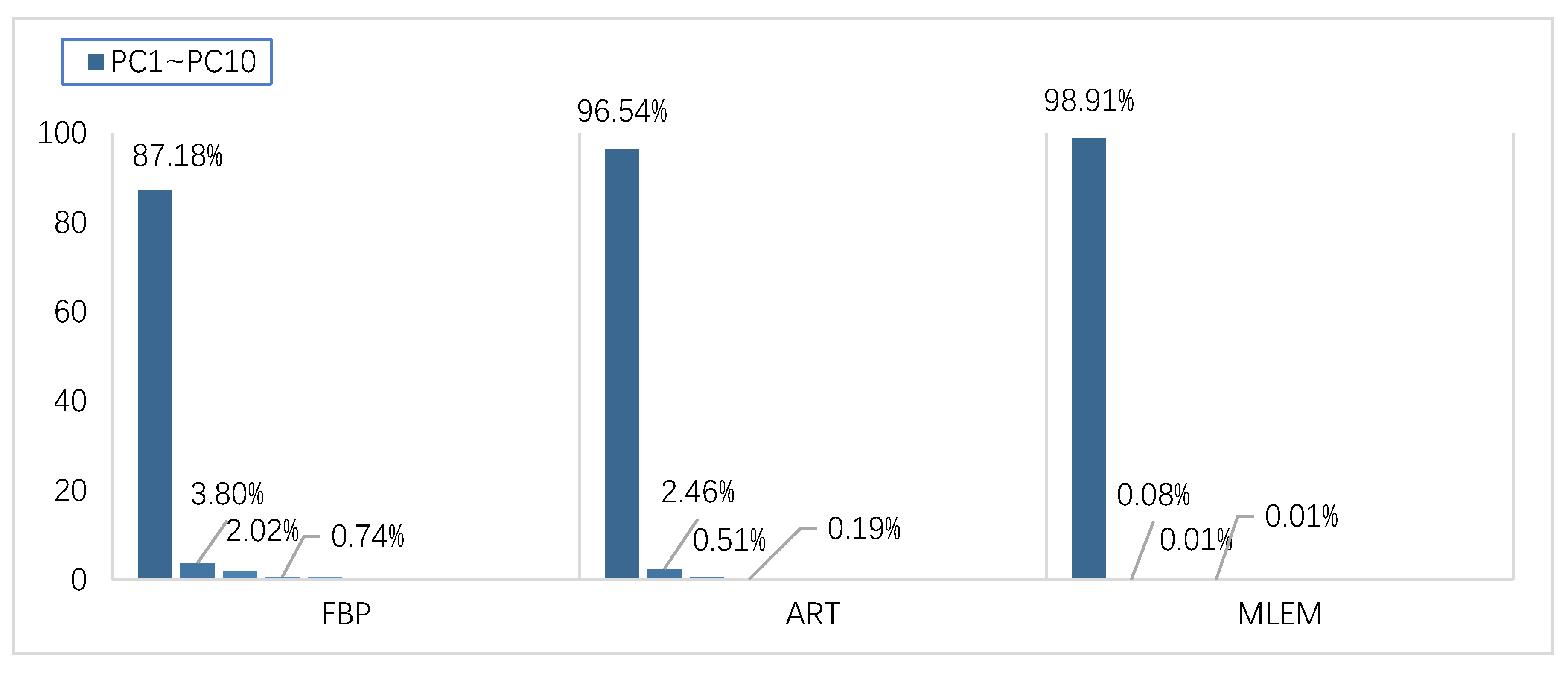

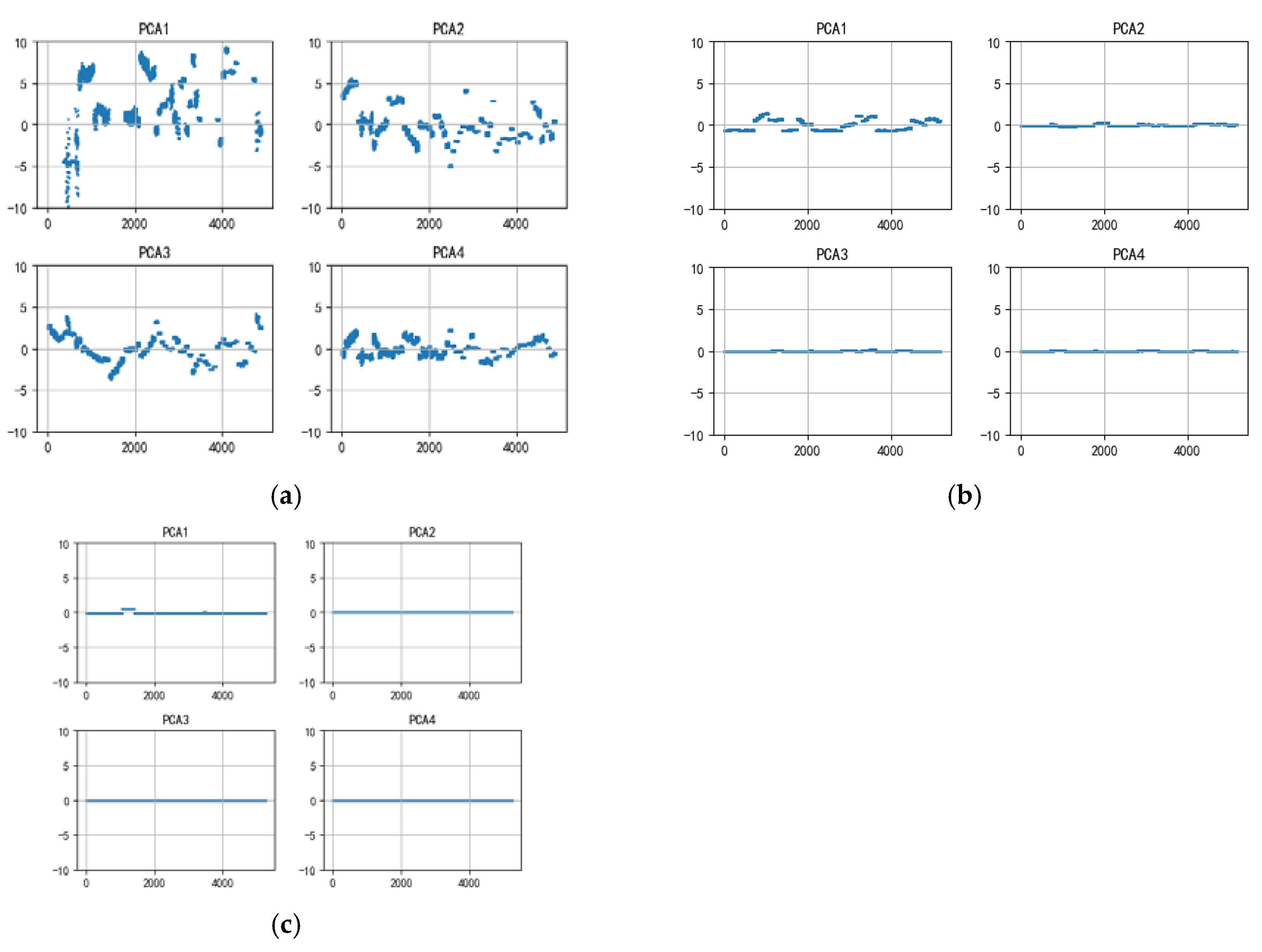

3.2. Reconstructed XAS Preprocessing and ANN

3.3. Evaluation of Classification Results Based on ANN

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pop, M.A.; Croitoru, C.; Bedo, T.; Geaman, V.; Radomir, I.; Cosnita, M.; Zaharia, S.M.; Chicos, L.A.; Milosan, I. Structural changes during 3D printing of bioderived and synthetic thermoplastic materials. J. Appl. Polym. Sci. 2019, 136. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Reinicke, T. 3D-printed sensors: Current progress and future challenges. Sens. Actuators A: Phys. 2020, 305, 111916. [Google Scholar] [CrossRef]

- Zolfagharian, A.; Khosravani, M.R.; Kaynak, A. Fracture Resistance Analysis of 3D-Printed Polymers. Polymers 2020, 12, 302. [Google Scholar] [CrossRef]

- Babilotte, J.; Guduric, V.; Le Nihouannen, D.; Naveau, A.; Fricain, J.-C.; Catros, S. 3D printed polymer-mineral composite biomaterials for bone tissue engineering: Fabrication and characterization. J. Biomed. Mater. Res. Part B-Appl. Biomater. 2019, 107, 2579–2595. [Google Scholar] [CrossRef] [PubMed]

- Jia, H.; Gu, S.Y.; Chang, K. 3D printed self-expandable vascular stents from biodegradable shape memory polymer. Adv. Polym. Technol. 2018, 37, 3222–3228. [Google Scholar] [CrossRef]

- Joshi, S.; Rawat, K.; Karunakaran, C.; Rajamohan, V.; Mathew, A.T.; Koziol, K.; Thakur, V.K.; Balan, A.S.S. 4D printing of materials for the future: Opportunities and challenges. Appl. Mater. Today 2020, 18, 100490. [Google Scholar] [CrossRef]

- Pyl, L.; Kalteremidou, K.A.; Van Hemelrijck, D. Exploration of the design freedom of 3D printed continuous fibre-reinforced polymers in open-hole tensile strength tests. Compos. Sci. Technol. 2019, 171, 135–151. [Google Scholar] [CrossRef]

- Khalil, Y.F. Eco-efficient lightweight carbon-fiber reinforced polymer for environmentally greener commercial aviation industry. Sustain. Prod. Consum. 2017, 12, 16–26. [Google Scholar] [CrossRef]

- Vieira, D.R.; Vieira, R.K.; Chain, M.C. Strategy and management for the recycling of carbon fiber-reinforced polymers (CFRPs) in the aircraft industry: A critical review. Int. J. Sustain. Dev. World Ecol. 2017, 24, 214–223. [Google Scholar] [CrossRef]

- Jain, A.; Bansal, K.K.; Tiwari, A.; Rosling, A.; Rosenholm, J.M. Role of Polymers in 3D Printing Technology for Drug Delivery—An Overview. Curr. Pharm. Des. 2018, 24, 4979–4990. [Google Scholar] [CrossRef]

- Duty, C.; Ajinjeru, C.; Kishore, V.; Compton, B.; Hmeidat, N.; Chen, X.; Liu, P.; Hassen, A.A.; Lindahl, J.; Kunc, V. What makes a material printable? A viscoelastic model for extrusion-based 3D printing of polymers. J. Manuf. Process. 2018, 35, 526–537. [Google Scholar] [CrossRef]

- Kastner, J.; Heinzl, C. X-ray Computed Tomography for Non-destructive Testing and Materials Characterization. In Integrated Imaging and Vision Techniques for Industrial Inspection: Advances and Applications; Liu, Z., Ukida, H., Ramuhalli, P., Niel, K., Eds.; Springer: London, UK, 2015; pp. 227–250. [Google Scholar]

- Withers, P.J.; Preuss, M. Fatigue and Damage in Structural Materials Studied by X-Ray Tomography. In Annual Review of Materials Research; Clarke, D.R., Ed.; Annual Reviews: Palo Alto, CA, USA, 2012; Volume 42, pp. 81–103. [Google Scholar]

- Buffiere, J.Y.; Maire, E.; Adrien, J.; Masse, J.P.; Boller, E. In Situ Experiments with X ray Tomography: An Attractive Tool for Experimental Mechanics. Exp. Mech. 2010, 50, 289–305. [Google Scholar] [CrossRef]

- Kowaluk, T.; Wozniak, A. Accuracy of X-ray computed tomography for dimensional metrology with employment of a new threshold selection method. J. X-Ray Sci. Technol. 2018, 26, 833–841. [Google Scholar] [CrossRef]

- Davis, G.R.; Evershed, A.N.Z.; Mills, D. Quantitative high contrast X-ray microtomography for dental research. J. Dent. 2013, 41, 475–482. [Google Scholar] [CrossRef]

- Jahrman, E.P.; Holden, W.M.; Ditter, A.S.; Mortensen, D.R.; Seidler, G.T.; Fister, T.T.; Kozimor, S.A.; Piper, L.F.J.; Rana, J.; Hyatt, N.C.; et al. An improved laboratory-based x-ray absorption fine structure and x-ray emission spectrometer for analytical applications in materials chemistry research. Rev. Sci. Instrum. 2019, 90. [Google Scholar] [CrossRef] [PubMed]

- Vishwakarma, P.; Gupta, M.; Phase, D.M.; Gupta, A. In situ soft x-ray absorption spectroscopic study of polycrystalline Fe/MgO interfaces. J. Phys. Condens. Matter 2019, 31. [Google Scholar] [CrossRef] [PubMed]

- Yu, P.F.; Long, X.H.; Zhang, N.; Feng, X.F.; Fu, J.M.; Zheng, S.; Ren, G.X.; Liu, Z.; Wang, C.; Liu, X.S. Charge Distribution on S and Intercluster Bond Evolution in Mo6S8 during the Electrochemical Insertion of Small Cations Studied by X-ray Absorption Spectroscopy. J. Phys. Chem. Lett. 2019, 10, 1159–1166. [Google Scholar] [CrossRef]

- Weber, F.; Ren, J.; Petit, T.; Bande, A. Theoretical X-ray absorption spectroscopy database analysis for oxidised 2D carbon nanomaterials. Phys. Chem. Chem. Phys. 2019, 21, 6999–7008. [Google Scholar] [CrossRef] [PubMed]

- Fehrenbach, U.; Kahn, J.; Boning, G.; Feldhaus, F.; Merz, K.; Frost, N.; Maurer, M.H.; Renz, D.; Hamm, B.; Streitparth, F. Spectral CT and its specific values in the staging of patients with non-small cell lung cancer: Technical possibilities and clinical impact. Clin. Radiol. 2019, 74, 456–466. [Google Scholar] [CrossRef] [PubMed]

- Schlomka, J.P.; Roessl, E.; Dorscheid, R.; Dill, S.; Martens, G.; Istel, T.; Baeumer, C.; Herrmann, C.; Steadman, R.; Zeitler, G.; et al. Experimental feasibility of multi-energy photon-counting K-edge imaging in pre-clinical computed tomography. Phys. Med. Biol. 2008, 53, 4031–4047. [Google Scholar] [CrossRef] [PubMed]

- Si-Mohamed, S.; Bar-Ness, D.; Sigovan, M.; Tatard-Leitman, V.; Cormode, D.P.; Naha, P.C.; Coulon, P.; Rascle, L.; Roessl, E.; Rokni, M.; et al. Multicolour imaging with spectral photon-counting CT: A phantom study. Eur. Radiol. Exp. 2018, 2, 34. [Google Scholar] [CrossRef]

- Raja, A.Y.; Moghiseh, M.; Bateman, C.J.; de Ruiter, N.; Schon, B.; Schleich, N.; Woodfield, T.B.F.; Butler, A.P.H.; Anderson, N.G. Measuring Identification and Quantification Errors in Spectral CT Material Decomposition. Appl. Sci. Basel 2018, 8, 467. [Google Scholar] [CrossRef]

- Egan, C.K.; Jacques, S.D.M.; Wilson, M.D.; Veale, M.C.; Seller, P.; Beale, A.M.; Pattrick, R.A.D.; Withers, P.J.; Cernik, R.J. 3D chemical imaging in the laboratory by hyperspectral X-ray computed tomography. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef]

- Hu, B.; Zhang, X.; Ouyang, Q.; Wu, X.; Fang, Z. A prototype system to measure X-ray absorption spectra for diagnosis in vivo. Measurement 2016, 93, 252–257. [Google Scholar] [CrossRef]

- Singh, L.; Rani, P.; Ghumman, S.S. Variation of energy absorption build-up factor with penetration depth for some titanium compounds. In 4th International Conference on Advancements in Engineering & Technology; Srivastava, T., Rani, S., Kakkar, S., Eds.; EDP Sciences: Les Ulis, France, 2016; Volume 57. [Google Scholar]

- Tozakidou, M.; Apine, I.; Petersen, K.U.; Weinrich, J.M.; Schindera, S.; Jopp-van Well, E.; Puschel, K.; Herrmann, J. Comparison of different iterative CT reconstruction techniques and filtered back projection for assessment of the medial clavicular epiphysis in forensic age estimation. Int. J. Leg. Med. 2020, 134, 355–361. [Google Scholar] [CrossRef] [PubMed]

- Greffier, J.; Frandon, J.; Larbi, A.; Beregi, J.P.; Pereira, F. CT iterative reconstruction algorithms: A task-based image quality assessment. Eur. Radiol. 2020, 30, 487–500. [Google Scholar] [CrossRef]

- Zheng, H.; Tuo, X.; Peng, S.; Shi, R.; Li, H.; He, A.; Li, Z.; Han, Q. An improved algebraic reconstruction technique for reconstructing tomographic gamma scanning image. Nucl. Instrum. Methods Phys. Res. Sect. Accel. Spectrometers Detect. Assoc. Equip. 2018, 906, 77–82. [Google Scholar] [CrossRef]

- Oehler, M.; Buzug, T.M. Two step MLEM algorithm for artifact reduction in CT images. Int. J. Comput. Assist. Radiol. Surg. 2007, 2, S38–S41. [Google Scholar]

- Hu, Y.; Nagy, J.G.; Zhang, J.; Andersen, M.S. Nonlinear optimization for mixed attenuation polyenergetic image reconstruction. Inverse Probl. 2019, 35. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Q.; Ma, J.; Zhang, W.; Li, P.; Fang, Z. A hyperspectral X-ray computed tomography system for enhanced material identification. Rev. Sci. Instrum. 2017, 88. [Google Scholar] [CrossRef]

- Chakravarthi, K.K.; Shyamala, L.; Vaidehi, V. Budget aware scheduling algorithm for workflow applications in IaaS clouds. Clust. Comput. J. Netw. Softw. Tools Appl. 2020. [Google Scholar] [CrossRef]

- Zhang, D.; Dey, R.; Lee, S. Fast and Robust ancestry prediction using principal component analysis. Bioinformatics 2020. [Google Scholar] [CrossRef] [PubMed]

- Banguero, E.; Correcher, A.; Perez-Navarro, A.; Garcia, E.; Aristizabal, A. Diagnosis of a battery energy storage system based on principal component analysis. Renew. Energy 2020, 146, 2438–2449. [Google Scholar] [CrossRef]

- Jafarian, A.; Nia, S.M.; Golmankaneh, A.K.; Baleanu, D. On artificial neural networks approach with new cost functions. Appl. Math. Comput. 2018, 339, 546–555. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Yan, S.; Yu, X.; Ma, Y.; Ma, L. Modifying the microstructure of algae-based active carbon and modelling supercapacitors using artificial neural networks. RSC Adv. 2019, 9, 14797–14808. [Google Scholar] [CrossRef]

- Liu, B.W.; Jin, W.T.; Lu, A.J.; Liu, K.; Wang, C.M.; Mi, G.Y. Optimal design for dual laser beam butt welding process parameter using artificial neural networks and genetic algorithm for SUS316L austenitic stainless steel. Opt. Laser Technol. 2020, 125. [Google Scholar] [CrossRef]

- Jo, H.-S.; Park, C.; Lee, E.; Choi, H.K.; Park, J. Path Loss Prediction based on Machine Learning Techniques: Principal Component Analysis, Artificial Neural Network and Gaussian Process. Sensors 2020, 20, 1927. [Google Scholar] [CrossRef]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef] [PubMed]

- Baldo, N.; Manthos, E.; Miani, M. Stiffness Modulus and Marshall Parameters of Hot Mix Asphalts: Laboratory Data Modeling by Artificial Neural Networks Characterized by Cross-Validation. Appl. Sci. Basel 2019, 9, 3502. [Google Scholar] [CrossRef]

- Sangeetha, M.; Kumaran, M.S. Deep learning-based data imputation on time-variant data using recurrent neural network. Soft Comput. 2020. [Google Scholar] [CrossRef]

- Ma, X.; Zeng, H.; Zhang, J.; Chen, L.; Jia, H. New practical methods to obtain crucial data in performing diagnostic meta-analysis of the published literature. J. Evid. Based Med. 2018, 11, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Bruyant, P.P. Analytic and iterative reconstruction algorithms in SPECT. J. Nucl. Med. 2002, 43, 1343–1358. [Google Scholar] [PubMed]

- Rodriguez-Alvarez, M.J.; Soriano, A.; Iborra, A.; Sanchez, F.; Gonzalez, A.J.; Conde, P.; Hernandez, L.; Moliner, L.; Orero, A.; Vidal, L.F.; et al. Expectation maximization (EM) algorithms using polar symmetries for computed tomography (CT) image reconstruction. Comput. Biol. Med. 2013, 43, 1053–1061. [Google Scholar] [CrossRef] [PubMed]

| Ingredients of Sample | Abbreviations | Density (g/cm3) | Trade Name | Manufacturer |

|---|---|---|---|---|

| 99% ABS resin 0.5% N,N’-Ethylene distearylamide 0.5% Tris-(2,4-di-tert-butylphenyl) phosphite | ABS | 1.080 | ABS filament | eSUN |

| 1,4-Benzenedicarboxylic acid, polymer with 1,4-cyclohexanedimethanol and 1,2-ethanediol | PETG | 1.380 | PETG filament | eSUN |

| 55% Polylactide resin 35% Poly (DL- lactide) 5% DL-Lactide 5% L-Lactide | PLA | 1.430 | PLA filament | eSUN |

| Polyvinyl alcohol | PVA | 1.310 | PVA filament | eSUN |

| Thermoplastic elastomer | TPE | 0.98 | TPE filament | eSUN |

| UV Photosensitive Resin | UV9400 | 1.13 | C-UV9400 | Online personal supplier |

| 74% Nylon-66 25% Carbon Fiber 1% Additives | PA-CF | 1.24 | ePA-CF filament | eSUN |

| Tube Voltage (kV) | Tube Current (μA) | |||||

|---|---|---|---|---|---|---|

| 60 | 2 | 5 | 8 | 10 | 11 | 15 |

| Predict | Real | |

|---|---|---|

| True | False | |

| Positive | True Positive (TP) | False Positive (FP) |

| Negative | False Negative (FN) | True Negative (TN) |

| Mark | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| Material | TPE | PA-CF | ABS | PLA | UV9400 | PETG | PVA |

| Row(X) | 16–26 | 15–25 | 34–44 | 33–43 | 32–42 | 51–61 | 50–60 |

| Column(Y) | 18–28 | 36–46 | 10–20 | 27–37 | 45–55 | 19–29 | 37–47 |

| Reconstruction Algorithms | Parameters of Hidden Layer | Average Accuracy of kCV | Confidence Interval |

|---|---|---|---|

| FBP | (256) | 0.99 | (±0.02) |

| (128 × 64) | 0.99 | (±0.03) | |

| (128 × 128) | 0.99 | (±0.02) | |

| (256 × 128 × 64) | 0.99 | (±0.02) | |

| (256 × 128 × 128) | 0.98 | (±0.02) | |

| ART | (256) | 0.67 | (±0.17) |

| (128 × 64) | 0.68 | (±0.20) | |

| (128 × 128) | 0.63 | (±0.20) | |

| (256 × 128 × 64) | 0.48 | (±0.26) | |

| (256 × 128 × 128) | 0.58 | (±0.25) | |

| ML-EM | (256) | 0.42 | (±0.24) |

| (128 × 64) | 0.38 | (±0.18) | |

| (128 × 128) | 0.44 | (±0.19) | |

| (256 × 128 × 64) | 0.43 | (±0.19) | |

| (256 × 128 × 128) | 0.43 | (±0.18) |

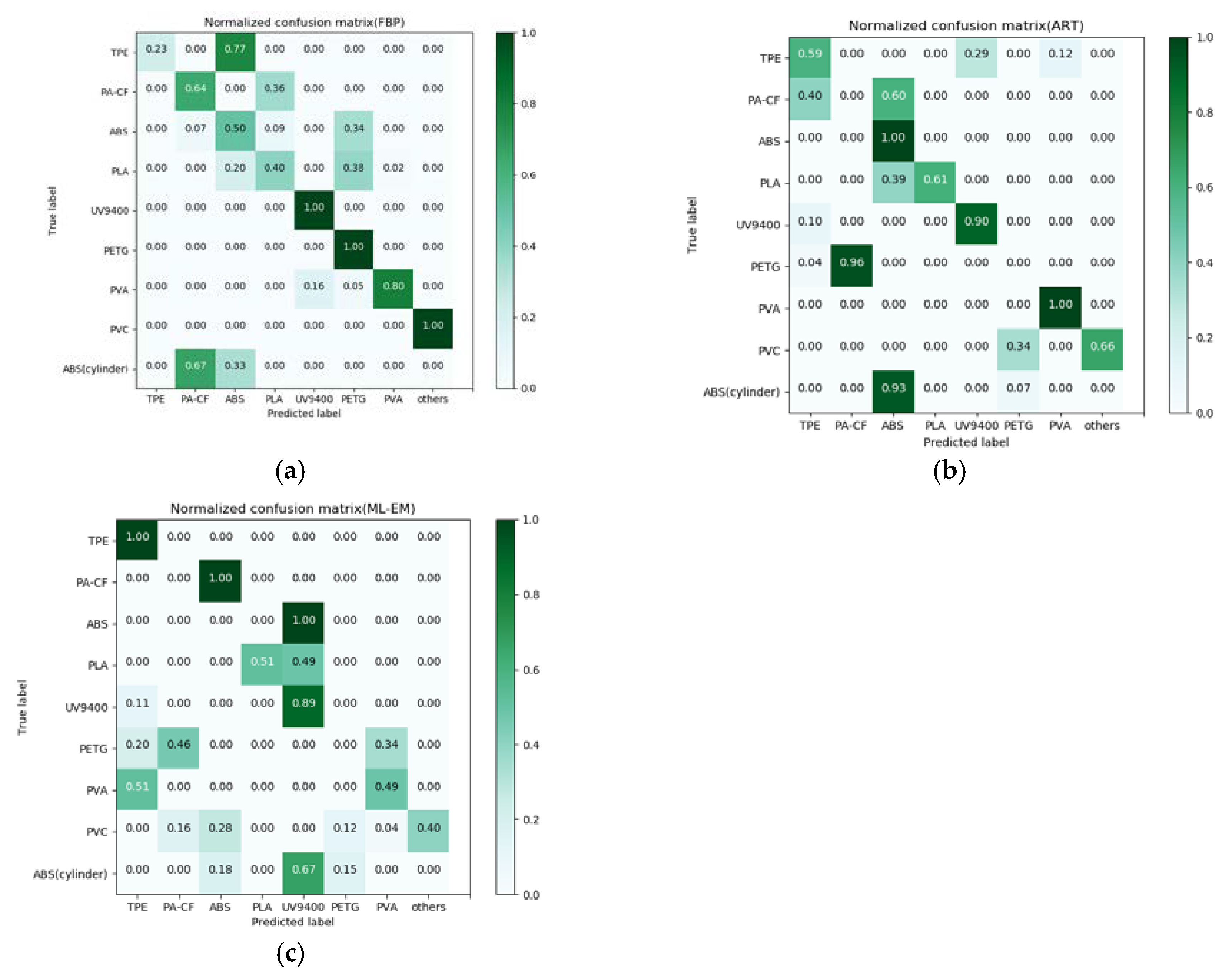

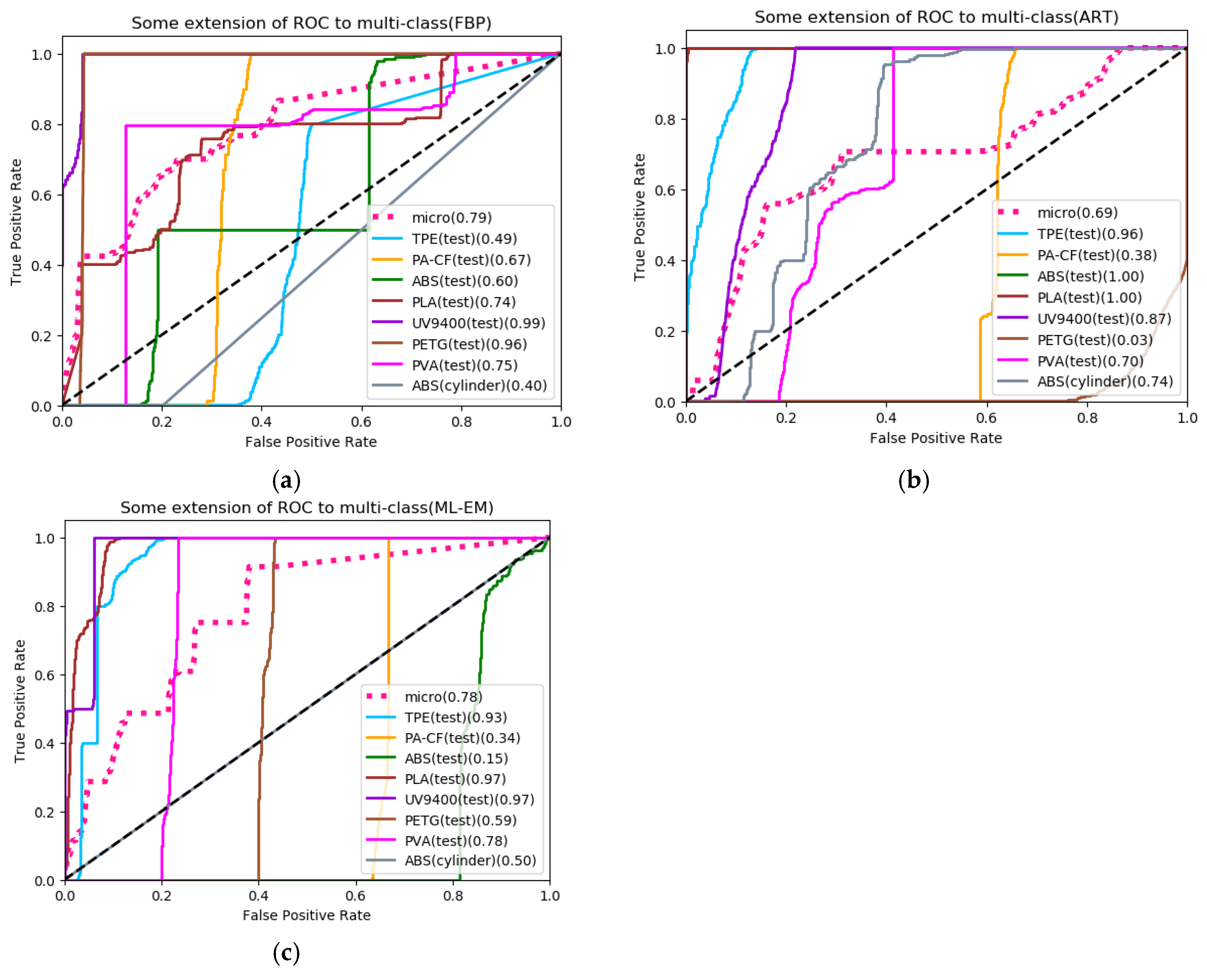

| Algorithm | Evaluation | TPE | PA-CF | ABS | PLA | UV9400 | PETG | PVA | PVC | ABS (Cylinder) | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FBP | Sensitivity | 0.23 | 0.64 | 0.50 | 0.40 | 1.00 | 1.00 | 0.80 | 1.00 | 0.33 | 0.66 |

| Specificity | 0.89 | 0.93 | 0.77 | 0.97 | 0.96 | 0.90 | 0.99 | 1.00 | 0.78 | 0.91 | |

| Precision | 1.00 | 0.22 | 0.26 | 0.74 | 0.83 | 0.13 | 1.00 | 1.00 | 0.13 | 0.59 | |

| Accuracy | 0.89 | 0.92 | 0.76 | 0.89 | 0.97 | 0.86 | 0.96 | 1.00 | 0.75 | 0.89 | |

| ART | Sensitivity | 0.59 | 0.00 | 1.00 | 0.61 | 0.90 | 0.00 | 1.00 | 0.66 | 0.93 | 0.63 |

| Specificity | 0.93 | 0.86 | 0.74 | 1.00 | 0.96 | 0.94 | 0.98 | 1.00 | 0.80 | 0.91 | |

| Precision | 0.55 | 1.00 | 0.17 | 1.00 | 0.56 | 0.00 | 0.89 | 1.00 | 0.40 | 0.62 | |

| Accuracy | 0.89 | 0.74 | 0.75 | 0.95 | 0.96 | 0.82 | 0.98 | 0.96 | 0.81 | 0.87 | |

| ML-EM | Sensitivity | 1.00 | 0.00 | 0.00 | 0.51 | 0.89 | 0.00 | 0.49 | 0.40 | 0.18 | 0.39 |

| Specificity | 0.90 | 0.91 | 0.81 | 1.00 | 0.76 | 0.97 | 0.95 | 1.00 | 0.83 | 0.90 | |

| Precision | 0.57 | 0.00 | 0.00 | 1.00 | 0.16 | 0.00 | 0.56 | 1.00 | 0.08 | 0.37 | |

| Accuracy | 0.91 | 0.80 | 0.70 | 0.94 | 0.76 | 0.85 | 0.89 | 0.93 | 0.79 | 0.84 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, Z.; Wang, R.; Wang, M.; Zhong, S.; Ding, L.; Chen, S. Effect of Reconstruction Algorithm on the Identification of 3D Printing Polymers Based on Hyperspectral CT Technology Combined with Artificial Neural Network. Materials 2020, 13, 1963. https://doi.org/10.3390/ma13081963

Fang Z, Wang R, Wang M, Zhong S, Ding L, Chen S. Effect of Reconstruction Algorithm on the Identification of 3D Printing Polymers Based on Hyperspectral CT Technology Combined with Artificial Neural Network. Materials. 2020; 13(8):1963. https://doi.org/10.3390/ma13081963

Chicago/Turabian StyleFang, Zheng, Renbin Wang, Mengyi Wang, Shuo Zhong, Liquan Ding, and Siyuan Chen. 2020. "Effect of Reconstruction Algorithm on the Identification of 3D Printing Polymers Based on Hyperspectral CT Technology Combined with Artificial Neural Network" Materials 13, no. 8: 1963. https://doi.org/10.3390/ma13081963

APA StyleFang, Z., Wang, R., Wang, M., Zhong, S., Ding, L., & Chen, S. (2020). Effect of Reconstruction Algorithm on the Identification of 3D Printing Polymers Based on Hyperspectral CT Technology Combined with Artificial Neural Network. Materials, 13(8), 1963. https://doi.org/10.3390/ma13081963