Influence of Scanning Strategy Parameters on Residual Stress in the SLM Process According to the Bridge Curvature Method for AISI 316L Stainless Steel

Abstract

1. Introduction

2. Materials and Methods

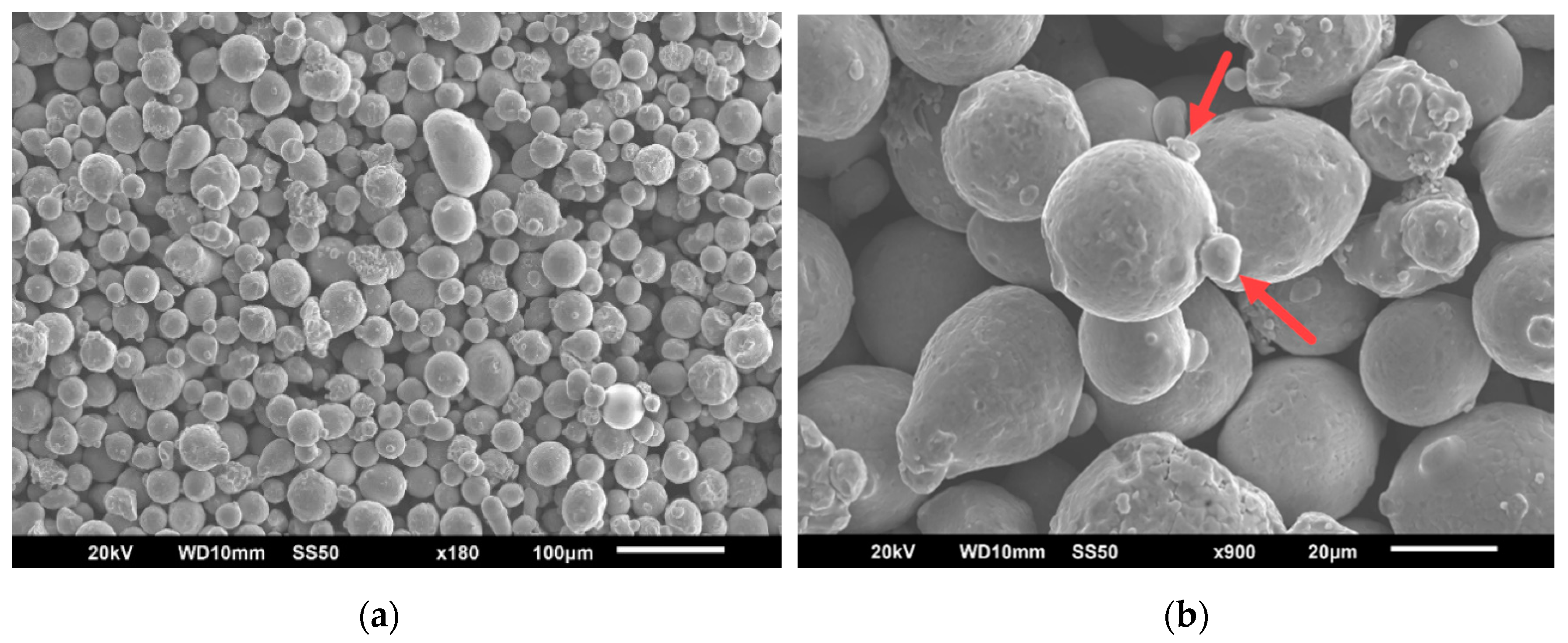

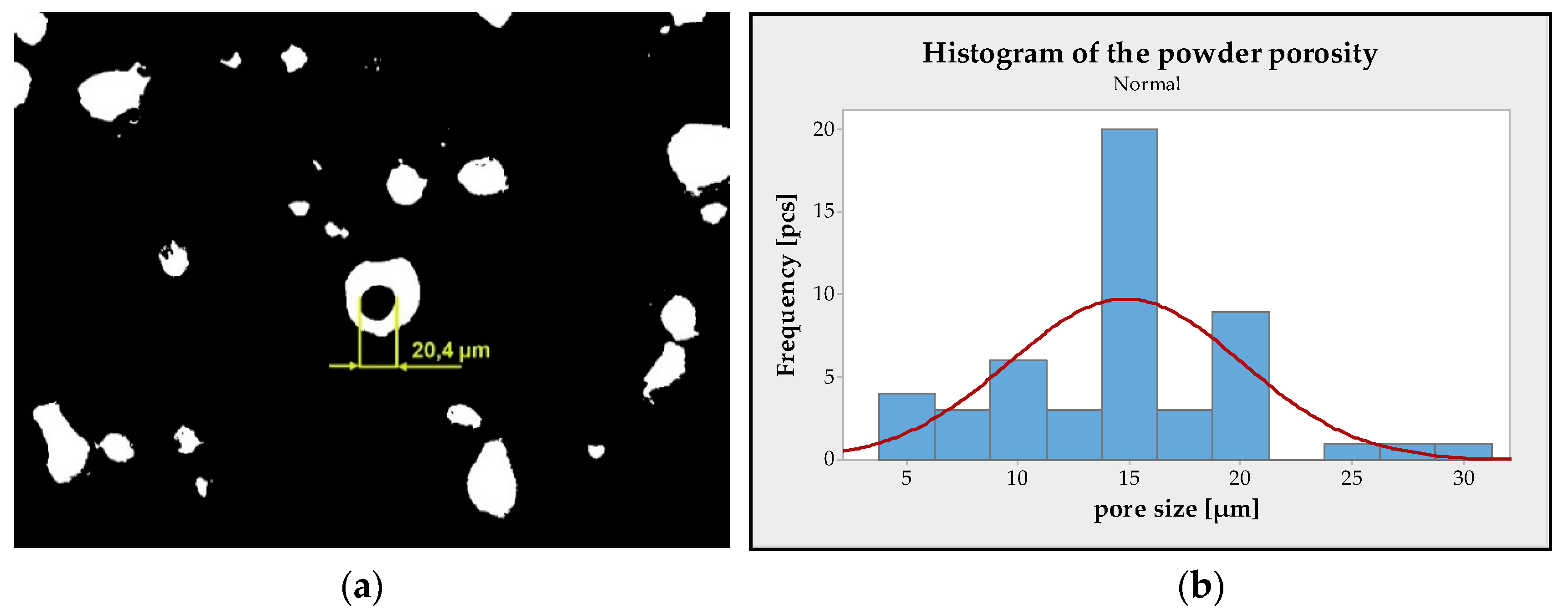

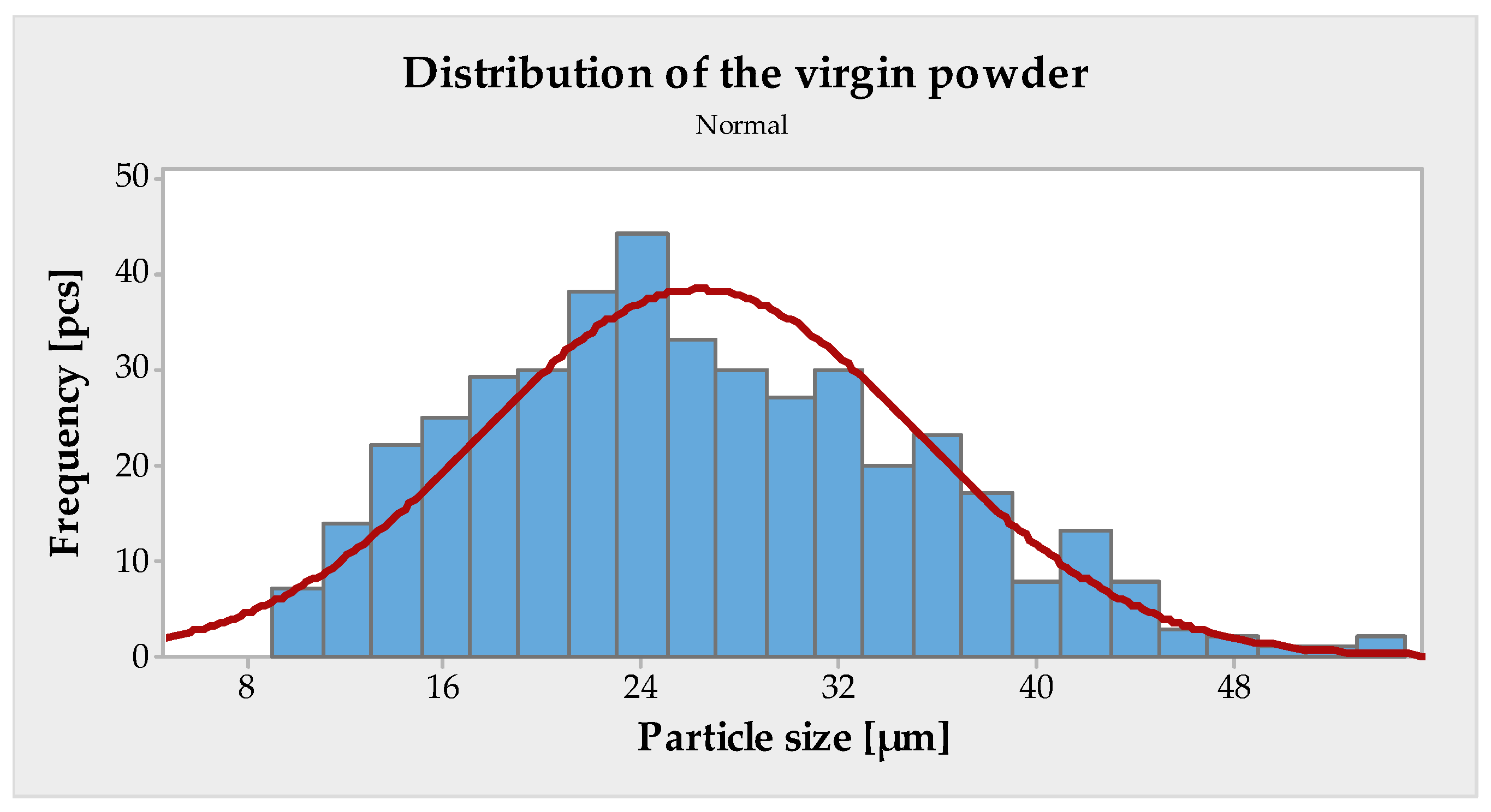

2.1. Powder Characterisation

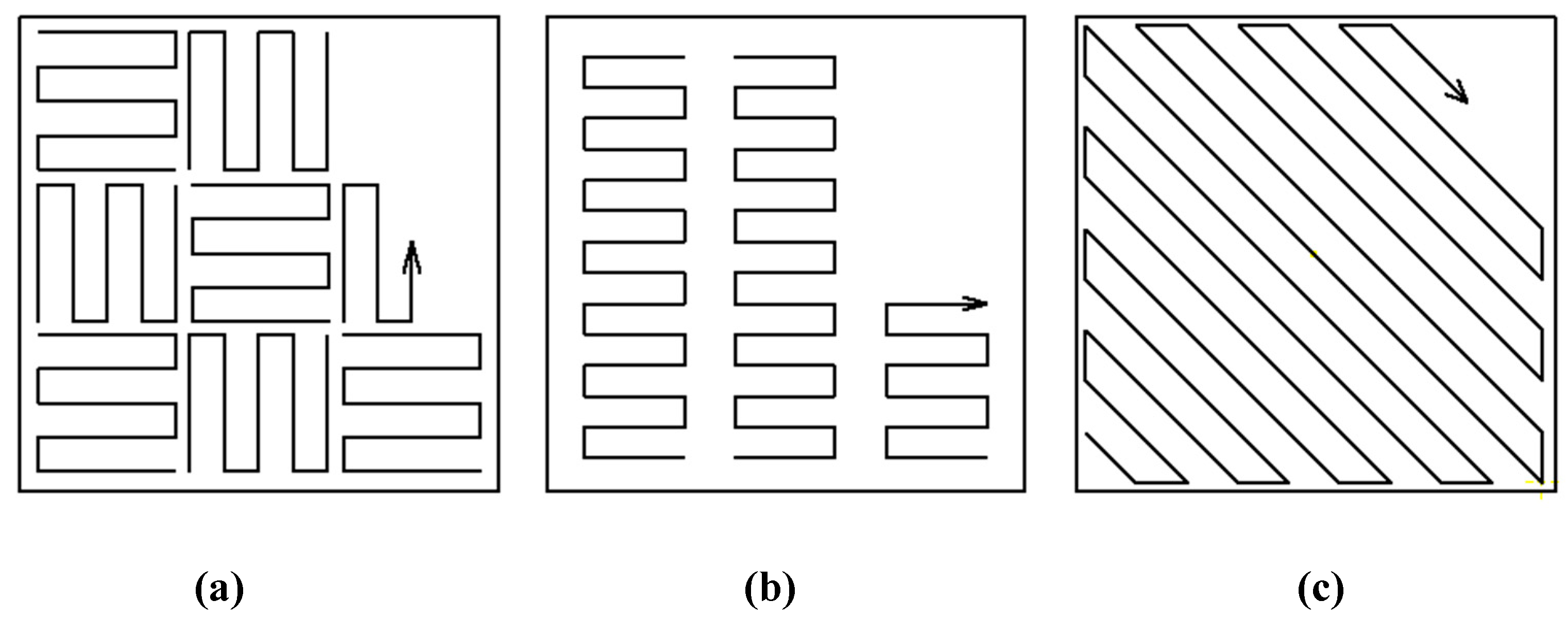

2.2. Settings and Sample Fabrication

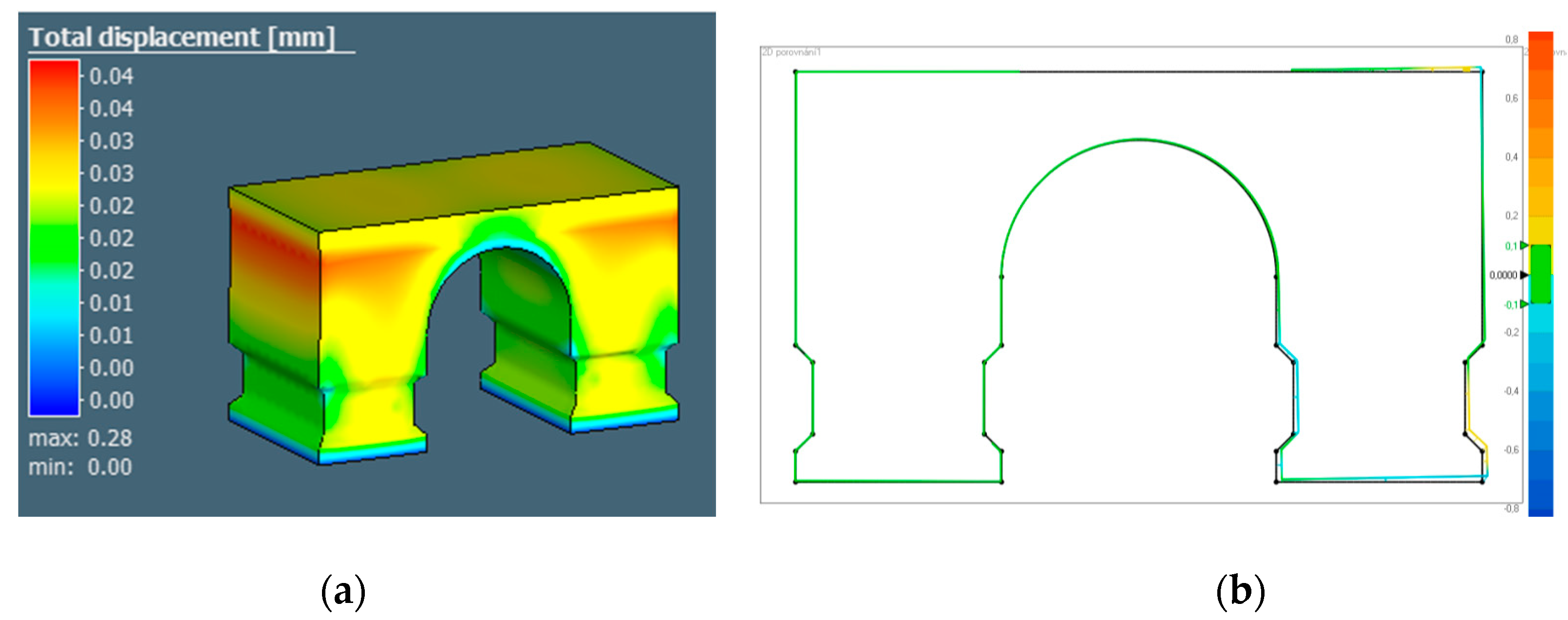

2.3. Simulation of Chosen Samples

2.4. Design of Experiment

3. Results

3.1. Evaluation of Powder Characteristics

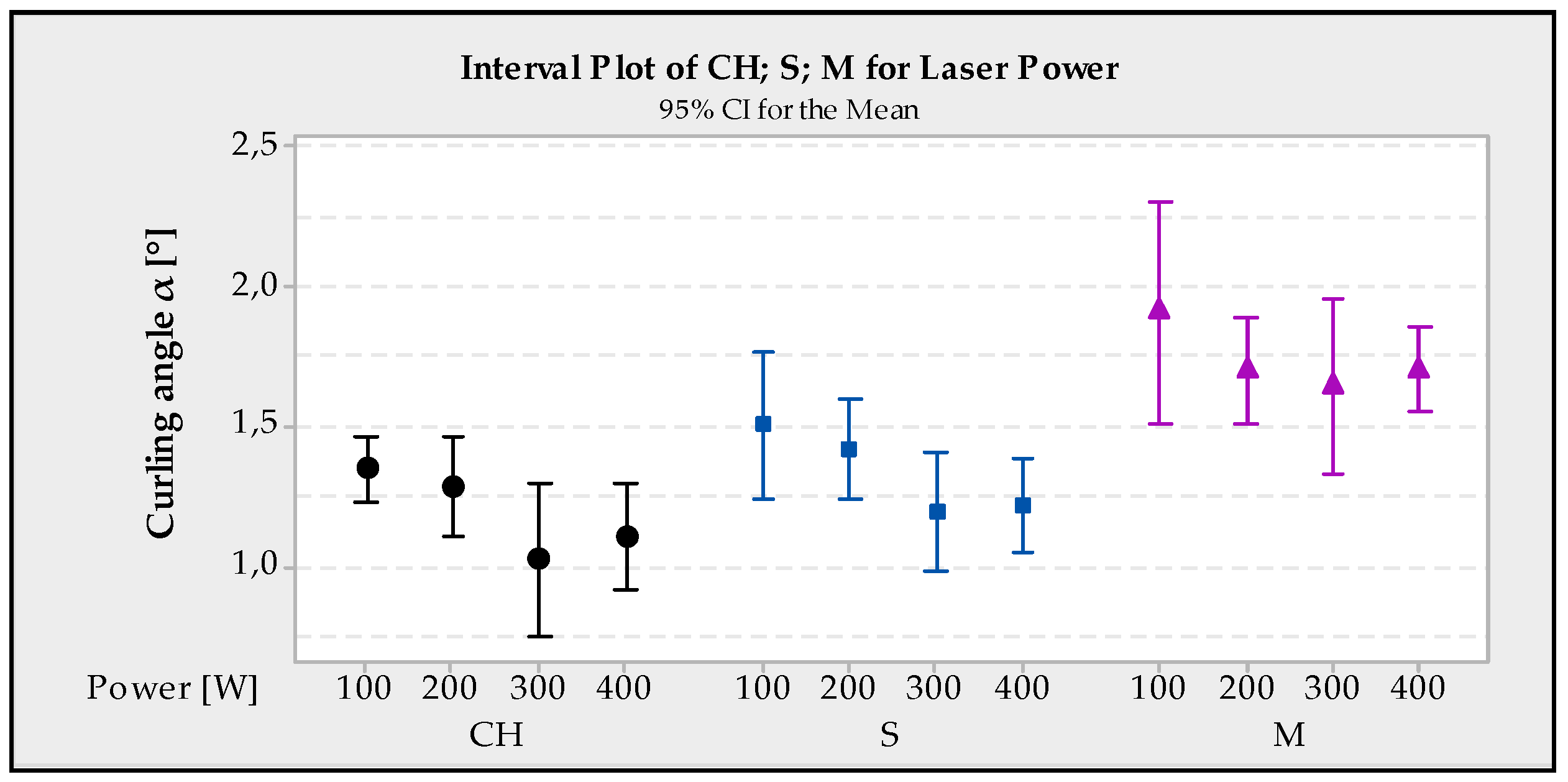

3.2. Evaluation of Curling Angle

3.3. Analysis of Taguchi Design

4. Discussion

4.1. The Influence of Laser Power on Curling Angle

4.2. The Influence of Field Size on Curling Angle

5. Conclusions

- The internal porosity of the powder particles was measured at 99.695%

- Laser power has the biggest influence on RS regardless of the type of scanning strategy. The ideal setting is a 300 W laser power, which effectively reduces the curling angle.

- To reduce RS it is ideal to set the field size of the scan vectors to 5 mm2 or hatch distance to 0.111 mm.

- For AISI316L steel, the least influence on RS is a substrate preheating, which in the DoE shows the least significant value.

- The simulations performed on the selected samples show the same dependence as the samples actually printed, so it is possible to work with them further.

Author Contributions

Funding

Conflicts of Interest

References

- Baitimerov, R.M.; Lykov, P.A.; Radionova, L.V.; Safonov, E.V. Parameter optimization for selective laser melting of TiAl6V4 alloy by CO2 laser. IOP Conf. Ser. Mater. Sci. Eng. 2017, 17, 36–40. [Google Scholar]

- Williams, R.; Catrin, J.; Davies, M.; Hooper, P.A. A pragmatic part scale model for residual stress and distortion prediction in powder bed fusion. Addit. Manuf. 2018, 22, 416–425. [Google Scholar] [CrossRef]

- Li, C.; Liu, J.F.; Guo, Y.B. Prediction of Residual Stress and Part Distortion in Selective Laser Melting. Procedia CIRP 2016, 45, 171–174. [Google Scholar] [CrossRef]

- Hardes, C.; Pöhl, F.; Röttger, A.; Thiele, M.; Theisen, W.; Esen, C. Cavitation erosion resistance of 316L austenitic steel processed by selective laser melting (SLM). Addit. Manuf. 2019, 29, 100786. [Google Scholar] [CrossRef]

- Kovalev, O.B.; Gurin, A.M. Multivortex convection of metal in molten pool with dispersed impurity induced by laser radiation. Int. J. Heat Mass Transf. 2014, 68, 269–277. [Google Scholar] [CrossRef]

- Qiu, Y.; Wu, J.; Chen, A.; Chen, P.; Yang, Y.; Liu, R.; Chen, G.; Chen, S.; Shi, Y.; Li, C. Balling phenomenon and cracks in alumina ceramics prepared by direct selective laser melting assisted with pressure treatment. Ceram. Int. 2020. [Google Scholar] [CrossRef]

- Alimardani, M.; Toyserkani, E.; Huissoon, J.; Paul, C.P. On the Delamination and Crack Formation in a Thin Wall Fabricated Using Laser Solid Freeform Fabrication Process: An Experimental–Numerical Investigation. Opt. Lasers Eng. 2009, 47, 1160–1168. [Google Scholar] [CrossRef]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An Experimental Investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Vasinonta, A.; Beuth, J.L.; Griffith, M. Process Maps for Predicting Residual Stress and Melt Pool Size in the Laser-Based Fabrication of Thin-Walled Structures. J. Manuf. Sci. Eng. 2007, 129, 101–109. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.-P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Zou, S.; Xiao, H.; Ye, F.; Li, Z.; Tang, W.; Zhu, F.; Chen, C.; Zhu, C. Numerical analysis of the effect of the scan strategy on the residual stress in the multi-laser selective laser melting. Results Phys. 2020, 16, 103005. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective laser melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Borralleras, P.; Segura, I.; Aranda, M.; Aguado, A. Influence of experimental procedure on d-spacing measurement by XRD of montmorillonite clay pastes containing PCE-based superplasticizer. Cem. Concr. Res. 2019, 116, 266–272. [Google Scholar] [CrossRef]

- Prime, M.B. Cross-sectional mapping of residual stresses by measuring the surface contour after a cut. J. Eng. Mater. Technol. Trans. ASME 2001, 123, 162–168. [Google Scholar] [CrossRef]

- Kruth, J.P.; Deckers, J.; Evren, Y.; Wauthle, R. Assessing and comparing influencing factors of residual stresses in selective laser melting using a novel analysis method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 980–991. [Google Scholar] [CrossRef]

- Zhong, C.; Biermann, T.; Gasser, A.; Poprawe, G. Experimental study of effects of main process parameters on porosity, track geometry, deposition rate, and powder efficiency for high deposition rate laser metal deposition. J. Laser Appl. 2015, 27, 042003-1–042003-8. [Google Scholar] [CrossRef]

- Markusson, L. Powder Characterization for Additive Manufacturing Processes. Master’s Thesis, Luleå University of Technology, Luleå, Sweden, 2017. [Google Scholar]

- Hajnys, J. Research into the Effect of Finishing Operations on Modification of Utility Properties of Components Produced by Additive. Ph.D. Thesis, VSB - Technical University of Ostrava, Faculty of Mechanical Engineering, Ostrava, Czech Republic, 2019. [Google Scholar]

- Maly, M.; Höller, C.; Skalon, M.; Meier, B.; Koutny, D.; Pichler, R.; Sommitsch, C.; Paloušek, D. Effect of Process Parameters and High-Temperature Preheating on Residual Stress and Relative Density of Ti6Al4V Processed by Selective Laser Melting. Materials 2019, 12, 930. [Google Scholar] [CrossRef] [PubMed]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Processing Parameter effects on residual stress and mechanical properties of selective laser melted Ti6Al4V. J. Mater. Eng. Perform. 2018, 27, 4059–4068. [Google Scholar] [CrossRef] [PubMed]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Effect of scanning strategies on residual stress and mechanical properties of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2018, 712, 175–187. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Badrossamay, M.; Yasa, E.; Deckers, J.; Thijs, L.; Humbeeck, J. Part and material properties in selective laser melting of metals. In Proceedings of the 16th International Symposium on Electromachining, ISEM 2010, Shanghai, China, 19–23 April 2010. [Google Scholar]

| Fe | Cr | Ni | Mo | Mn | Si | N | O | P | C | S |

|---|---|---|---|---|---|---|---|---|---|---|

| Balance | 18 | 14 | 3 | < 2 | < 1 | < 0.1 | < 0.1 | < 0.045 | < 0.03 | < 0.03 |

| Parameters | Range of Variables | |||

|---|---|---|---|---|

| P [W] | 100 | 200 | 300 | 400 |

| FS/HD [mm] | 3 | 5 | 7 | 10 |

| T [°C] | 0 | 170 | 0 | 170 |

| Statistics [μm] | |

|---|---|

| Mean. | 26.33 |

| St. Dev. | 8.902 |

| d10 | 19.37 |

| d50 | 25.09 |

| d90 | 32.53 |

| Span | 0.525 |

| Sample No. | P [W] | T [°C] | FS/HD [mm] | α CH [°] | α S [°] | α M [°] | α Simulation[°] |

|---|---|---|---|---|---|---|---|

| 1 | 100 | 0 | 3 | 1.443 ± 0.011 | 1.744 ± 0.024 | 2.198 ± 0.036 | - |

| 2 | 100 | 0 | 5 | 1.293 ± 0.028 | 1.363 ± 0.037 | 1.703 ± 0.040 | 1.568 |

| 3 | 100 | 170 | 7 | 1.295 ± 0.015 | 1.444 ± 0.031 | 2.051 ± 0.019 | - |

| 4 | 100 | 170 | 10 | 1.382 ± 0.029 | 1.479 ± 0.042 | 1.703 ± 0.023 | - |

| 5 | 200 | 0 | 3 | 1.375 ± 0.025 | 1.511 ± 0.023 | 1.603 ± 0.046 | - |

| 6 | 200 | 0 | 5 | 1.316 ± 0.036 | 1.448 ± 0.024 | 1.587 ± 0.038 | 1.215 |

| 7 | 200 | 170 | 7 | 1.342 ± 0.041 | 1.465 ± 0.041 | 1.801 ± 0.017 | - |

| 8 | 200 | 170 | 10 | 1.121 ± 0.027 | 1.258 ± 0.049 | 1.805 ± 0.038 | - |

| 9 | 300 | 170 | 3 | 0.931 ± 0.038 | 1.183 ± 0.038 | 1.859 ± 0.036 | - |

| 10 | 300 | 170 | 5 | 0.835 ± 0.032 | 1.013 ± 0.012 | 1.744 ± 0.042 | 1.180 |

| 11 | 300 | 0 | 7 | 1.182 ± 0.031 | 1.293 ± 0.047 | 1.408 ± 0.034 | - |

| 12 | 300 | 0 | 10 | 1.157 ± 0.038 | 1.296 ± 0.035 | 1.571 ± 0.047 | - |

| 13 | 400 | 170 | 3 | 1.215 ± 0.046 | 1.292 ± 0.048 | 1.806 ± 0.023 | - |

| 14 | 400 | 170 | 5 | 1.088 ± 0.015 | 1.224 ± 0.030 | 1.648 ± 0.063 | 1.123 |

| 15 | 400 | 0 | 7 | 1.182 ± 0.040 | 1.298 ± 0.046 | 1.608 ± 0.042 | - |

| 16 | 400 | 0 | 10 | 0.948 ± 0.051 | 1.068 ± 0.055 | 1.767 ± 0.034 | - |

| Level | P | FS/HD | T |

|---|---|---|---|

| Chessboard Strategy | |||

| 1 | 1.353 | 1.241 | 1.237 |

| 2 | 1.289 | 1.133 | 1.151 |

| 3 | 1.026 | 1.250 | - |

| 4 | 1.108 | 1.152 | - |

| Delta | 0.327 | 0.117 | 0.086 |

| Rank | 1 | 2 | 3 |

| Stripe Strategy | |||

| 1 | 1.508 | 1.432 | 1.378 |

| 2 | 1.420 | 1.262 | 1.295 |

| 3 | 1.196 | 1.375 | - |

| 4 | 1.220 | 1.275 | - |

| Delta | 0.311 | 0.170 | 0.083 |

| Rank | 1 | 2 | 3 |

| Meander Strategy | |||

| 1 | 1.914 | 1.867 | 1.681 |

| 2 | 1.699 | 1.670 | 1.802 |

| 3 | 1.645 | 1.717 | - |

| 4 | 1.707 | 1.712 | - |

| Delta | 0.268 | 0.196 | 0.122 |

| Rank | 1 | 2 | 3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hajnys, J.; Pagáč, M.; Měsíček, J.; Petru, J.; Król, M. Influence of Scanning Strategy Parameters on Residual Stress in the SLM Process According to the Bridge Curvature Method for AISI 316L Stainless Steel. Materials 2020, 13, 1659. https://doi.org/10.3390/ma13071659

Hajnys J, Pagáč M, Měsíček J, Petru J, Król M. Influence of Scanning Strategy Parameters on Residual Stress in the SLM Process According to the Bridge Curvature Method for AISI 316L Stainless Steel. Materials. 2020; 13(7):1659. https://doi.org/10.3390/ma13071659

Chicago/Turabian StyleHajnys, Jiri, Marek Pagáč, Jakub Měsíček, Jana Petru, and Mariusz Król. 2020. "Influence of Scanning Strategy Parameters on Residual Stress in the SLM Process According to the Bridge Curvature Method for AISI 316L Stainless Steel" Materials 13, no. 7: 1659. https://doi.org/10.3390/ma13071659

APA StyleHajnys, J., Pagáč, M., Měsíček, J., Petru, J., & Król, M. (2020). Influence of Scanning Strategy Parameters on Residual Stress in the SLM Process According to the Bridge Curvature Method for AISI 316L Stainless Steel. Materials, 13(7), 1659. https://doi.org/10.3390/ma13071659