Synthesis of Perovskite by Solid-Phase Method with Metatitanic Acid and Calcium Carbonate and Its Pigment Properties Investigation

Abstract

1. Introduction

2. Experiment Section

2.1. Materials

2.2. Synthesis of SPP and Preparing Architectural Coatings with SPP

2.3. Structure Characterization and Performance of SPP

3. Results and Discussion

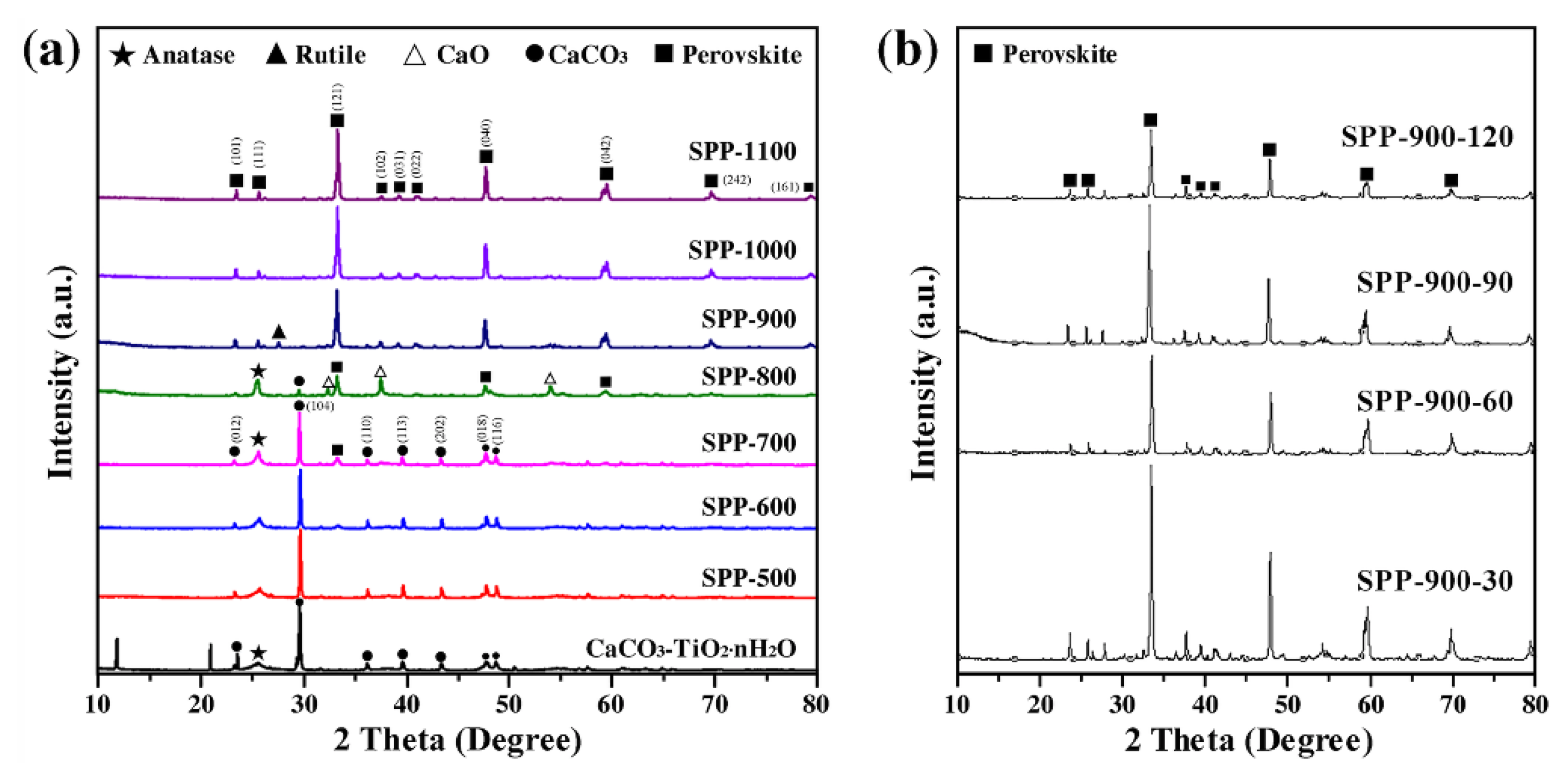

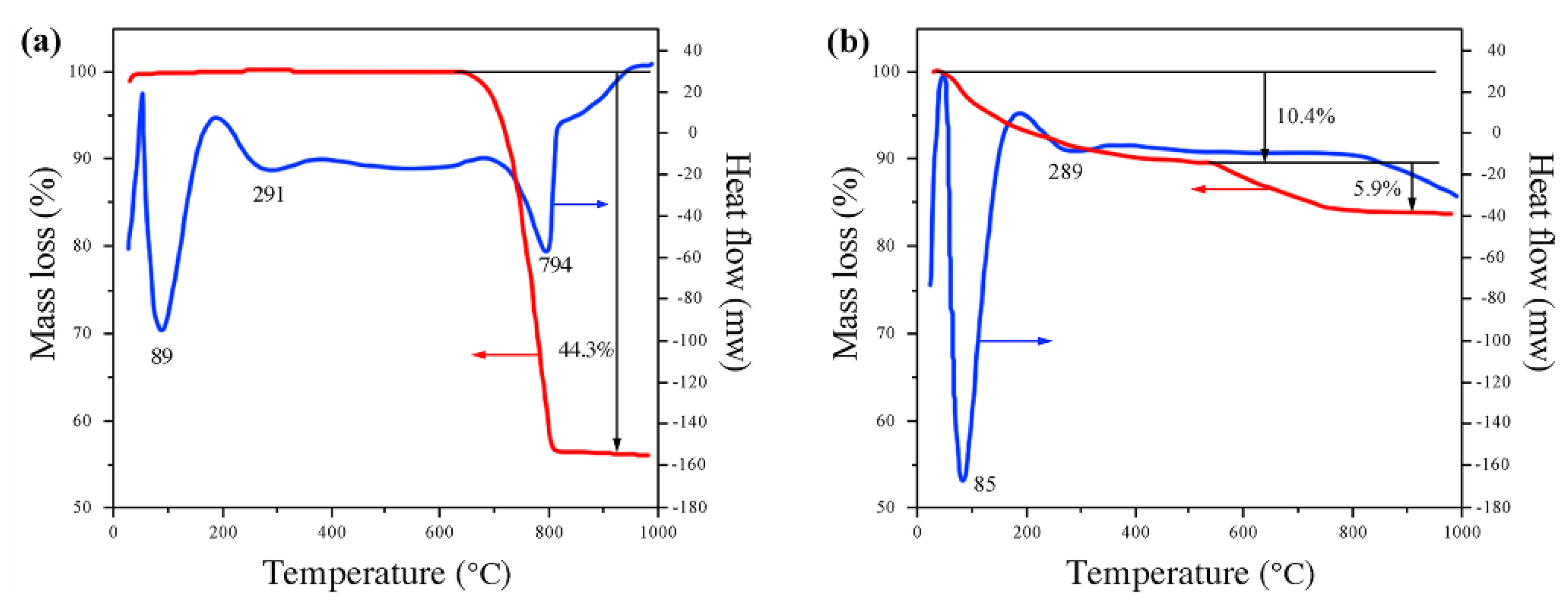

3.1. Effect of Calcination Temperature and Time on the Phase of SPP Particles

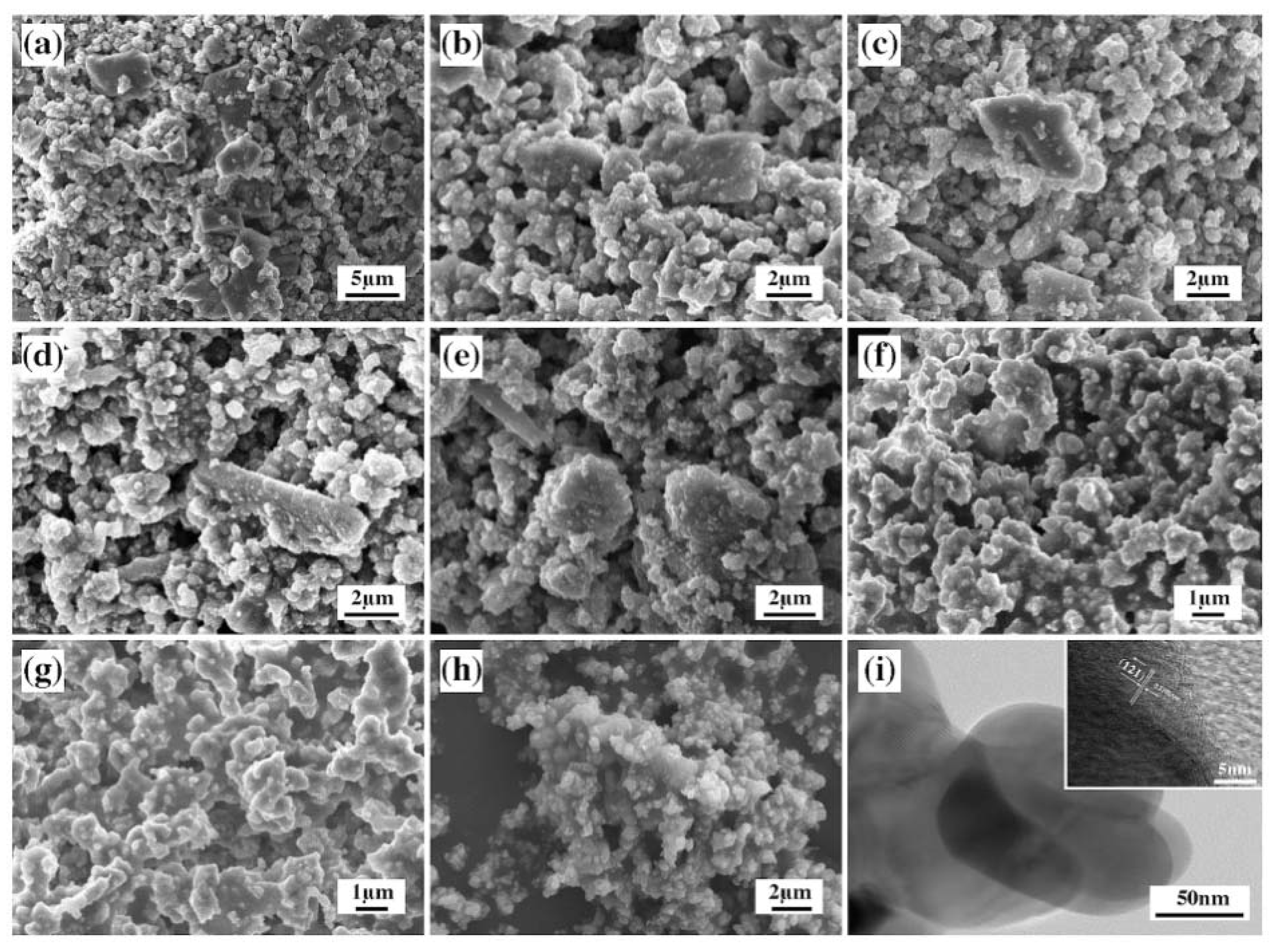

3.2. Effect of Calcination Temperature on the Morphology of SPP Particles

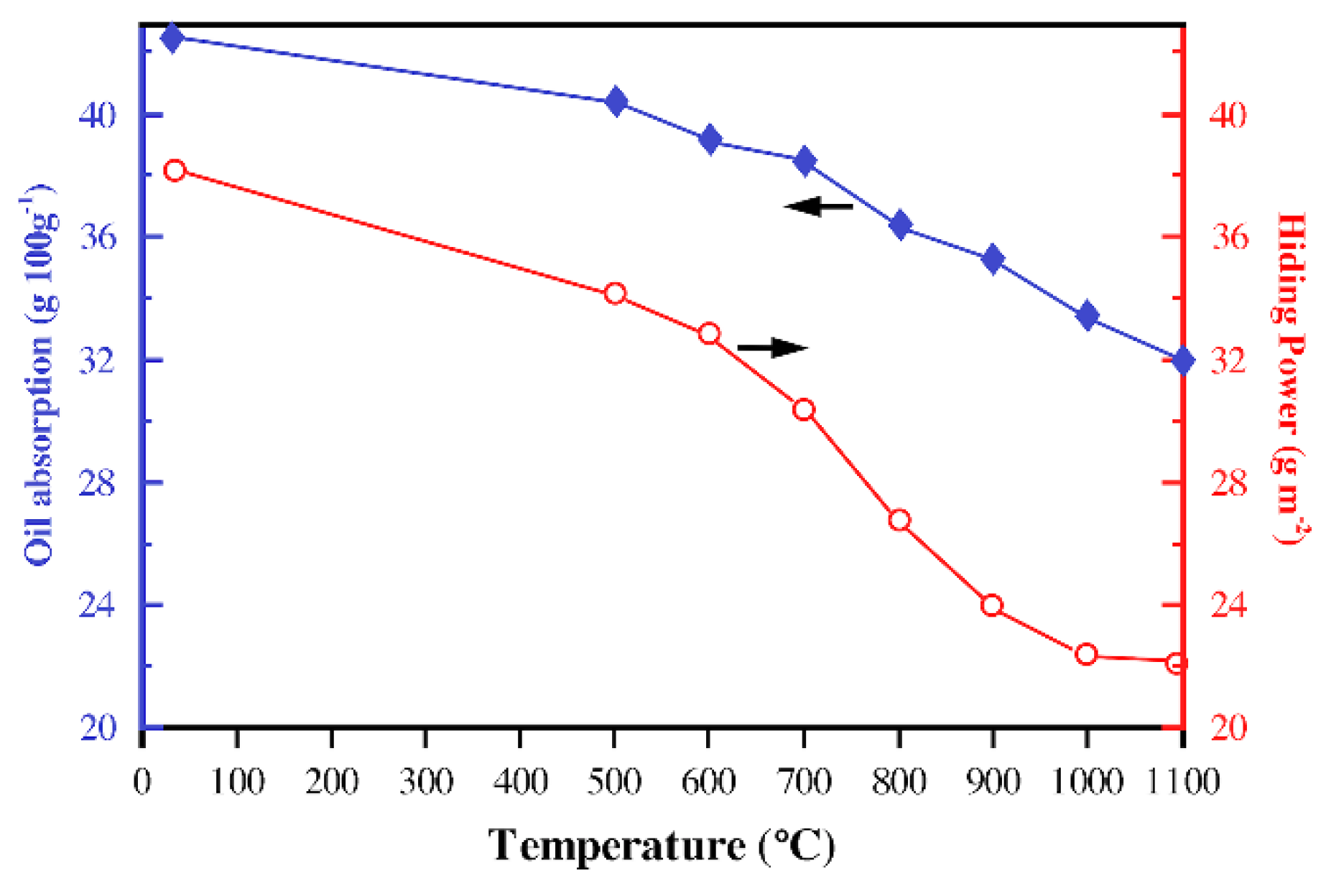

3.3. Pigment Properties of SPP Particles

3.4. Coating Performance with SPP as a Pigment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pena, M.A.; Fierro, J.L.G. Chemical Structures and Performance of Perovskite Oxides. Chem. Rev. 2001, 101, 1981–2017. [Google Scholar] [CrossRef] [PubMed]

- Wong, Y.J.; Hassan, J.; Hashim, M. Dielectric properties, impedance analysis and modulus behavior of CaTiO3 ceramic prepared by solid state reaction. J. Alloys Compd. 2013, 571, 138–144. [Google Scholar] [CrossRef]

- Schouwink, P.; Ley, M.B.; Tissot, A.; Hagemann, H.; Jensen, T.R.; Smrcok, L.; Cerny, R. Structure and properties of complex hydride perovskite materials. Nat. Commun. 2014, 5, 5706. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Paterson, A.R.; Wu, H.; Gao, P.; Ren, W.; Ye, Z.-G. Synthesis, structure and piezo-/ferroelectric properties of a novel bismuth-containing ternary complex perovskite solid solution. J. Mater. Chem. C 2017, 5, 3916–3923. [Google Scholar] [CrossRef]

- Xu, X.; Su, C.; Zhou, W.; Zhu, Y.; Chen, Y.; Shao, Z. Co-doping Strategy for Developing Perovskite Oxides as Highly Efficient Electrocatalysts for Oxygen Evolution Reaction. Adv. Sci. (Weinh) 2016, 3, 1500187. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Nie, Y.; Hu, C.; Qu, J. Enhanced Fenton degradation of Rhodamine B over nanoscaled Cu-doped LaTiO3 perovskite. Appl. Catal. B Environ. 2012, 125, 418–424. [Google Scholar] [CrossRef]

- Correa-Baena, J.P.; Saliba, M.; Buonassisi, T.; Grätzel, M.; Abate, A.; Tress, W.; Hagfeldt, A. Promises and challenges of perovskite solar cells. Science 2017, 358, 739–744. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.; Jain, A.C.P.; Pandya, S.; Dong, Y.; Yuan, Y.; Zhou, H.; Dedon, L.R.; Thoreton, V.; Saremi, S.; Xu, R.; et al. Designing Optimal Perovskite Structure for High Ionic Conduction. Adv. Mater. 2020, 32, e1905178. [Google Scholar] [CrossRef] [PubMed]

- Bin Adnan, M.A.; Arifin, K.; Minggu, L.J.; Kassim, M.B. Titanate-based perovskites for photochemical and photoelectrochemical water splitting applications: A review. Int. J. Hydrogen Energy 2018, 43, 23209–23220. [Google Scholar] [CrossRef]

- Grabowska, E. Selected perovskite oxides: Characterization, preparation and photocatalytic properties—A review. Appl. Catal. B Environ. 2016, 186, 97–126. [Google Scholar] [CrossRef]

- Dong, W.; Song, B.; Meng, W.; Zhao, G.; Han, G. A simple solvothermal process to synthesize CaTiO3 microspheres and its photocatalytic properties. Appl. Surf. Sci. 2015, 349, 272–278. [Google Scholar] [CrossRef]

- Dubey, A.K.; Tripathi, G.; Basu, B. Characterization of hydroxyapatite-perovskite (CaTiO3) composites: Phase evaluation and cellular response. J. Biomed. Mater. Res. B Appl. Biomater. 2010, 95, 320–329. [Google Scholar] [CrossRef] [PubMed]

- Holliday, S.; Stanishevsky, A. Crystallization of CaTiO3 by sol–gel synthesis and rapid thermal processing. Surf. Coat. Technol. 2004, 188–189, 741–744. [Google Scholar] [CrossRef]

- Orihashi, T.; Adachi, S. Synthesis condition and structural/luminescent properties of CaTiO3:Eu3+ red phosphor. J. Alloys Compd. 2015, 646, 1116–1123. [Google Scholar] [CrossRef]

- Evans, I.R.; Howard, J.A.K.; Sreckovic, T.; Ristic, M.M. Variable temperature in situ X-ray diffraction study of mechanically activated synthesis of calcium titanate, CaTiO3. Mater. Res. Bull. 2003, 38, 1203–1213. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Wang, L.; Xue, T.; Qi, T. Preparation of Rutile Titanium Dioxide White Pigment via Doping and Calcination of Metatitanic Acid Obtained by the NaOH Molten Salt Method. Ind. Eng. Chem. Res. 2010, 49, 7693–7696. [Google Scholar] [CrossRef]

- Gesenhues, U. Calcination of Metatitanic Acid to Titanium Dioxide White Pigments. Chem. Eng. Technol. 2001, 24, 685–694. [Google Scholar] [CrossRef]

- Yahui, L.; Fancheng, M.; Fuqiang, F.; Weijing, W.; Jinglong, C.; Tao, Q. Preparation of rutile titanium dioxide pigment from low-grade titanium slag pretreated by the NaOH molten salt method. Dyes Pigment. 2016, 125, 384–391. [Google Scholar] [CrossRef]

- Sun, S.; Ding, H.; Hou, X. Preparation of CaCO3-TiO2 Composite Particles and Their Pigment Properties. Materials 2018, 11, 1131. [Google Scholar] [CrossRef] [PubMed]

- HG/T 3851-2006. Covering Power Determination of Dyestuff; National Development and Reform Commission: Beijing, China, 2006. [Google Scholar]

- Huang, Y.-J.; Tsai, M.-C.; Chiu, H.-T.; Sheu, H.-S.; Lee, C.-Y. Artificial Synthesis of Platelet-Like Kassite and Its Transformation to CaTiO3. Cryst. Growth Des. 2010, 10, 1221–1225. [Google Scholar] [CrossRef]

- GB/T 9755-2014. Synthetic Resin Emulsion Coatings for Exterior Wall; Standards Press of China: Beijing, China, 2014. [Google Scholar]

| Samples | Oil Absorption/g·100 g−1 | Whiteness/% | Hiding Power/g·m−2 | Relative Hiding Power (R)/% | (R = R − 58.8)/% |

|---|---|---|---|---|---|

| SPP | 35.03 | 90.5 | 24.02 | 81.60 | 22.80 |

| Pure TiO2 | 33.26 | 87.8 | 19.60 | 100 | -- |

| Raw GCC | 14.21 | 96.2 | 165.00 | 11.88 | -- |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Sun, S.; Liu, W.; Ding, H.; Zhang, J. Synthesis of Perovskite by Solid-Phase Method with Metatitanic Acid and Calcium Carbonate and Its Pigment Properties Investigation. Materials 2020, 13, 1508. https://doi.org/10.3390/ma13071508

Zhang H, Sun S, Liu W, Ding H, Zhang J. Synthesis of Perovskite by Solid-Phase Method with Metatitanic Acid and Calcium Carbonate and Its Pigment Properties Investigation. Materials. 2020; 13(7):1508. https://doi.org/10.3390/ma13071508

Chicago/Turabian StyleZhang, Han, Sijia Sun, Wei Liu, Hao Ding, and Jianmeng Zhang. 2020. "Synthesis of Perovskite by Solid-Phase Method with Metatitanic Acid and Calcium Carbonate and Its Pigment Properties Investigation" Materials 13, no. 7: 1508. https://doi.org/10.3390/ma13071508

APA StyleZhang, H., Sun, S., Liu, W., Ding, H., & Zhang, J. (2020). Synthesis of Perovskite by Solid-Phase Method with Metatitanic Acid and Calcium Carbonate and Its Pigment Properties Investigation. Materials, 13(7), 1508. https://doi.org/10.3390/ma13071508