Hazardous Waste Management of Buffing Dust Collagen

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Rubber and Other Ingredients

2.1.2. Buffing Dust Collagen (BDC)

2.2. Preparation of Composites

3. Research Techniques

4. Results and Discussion

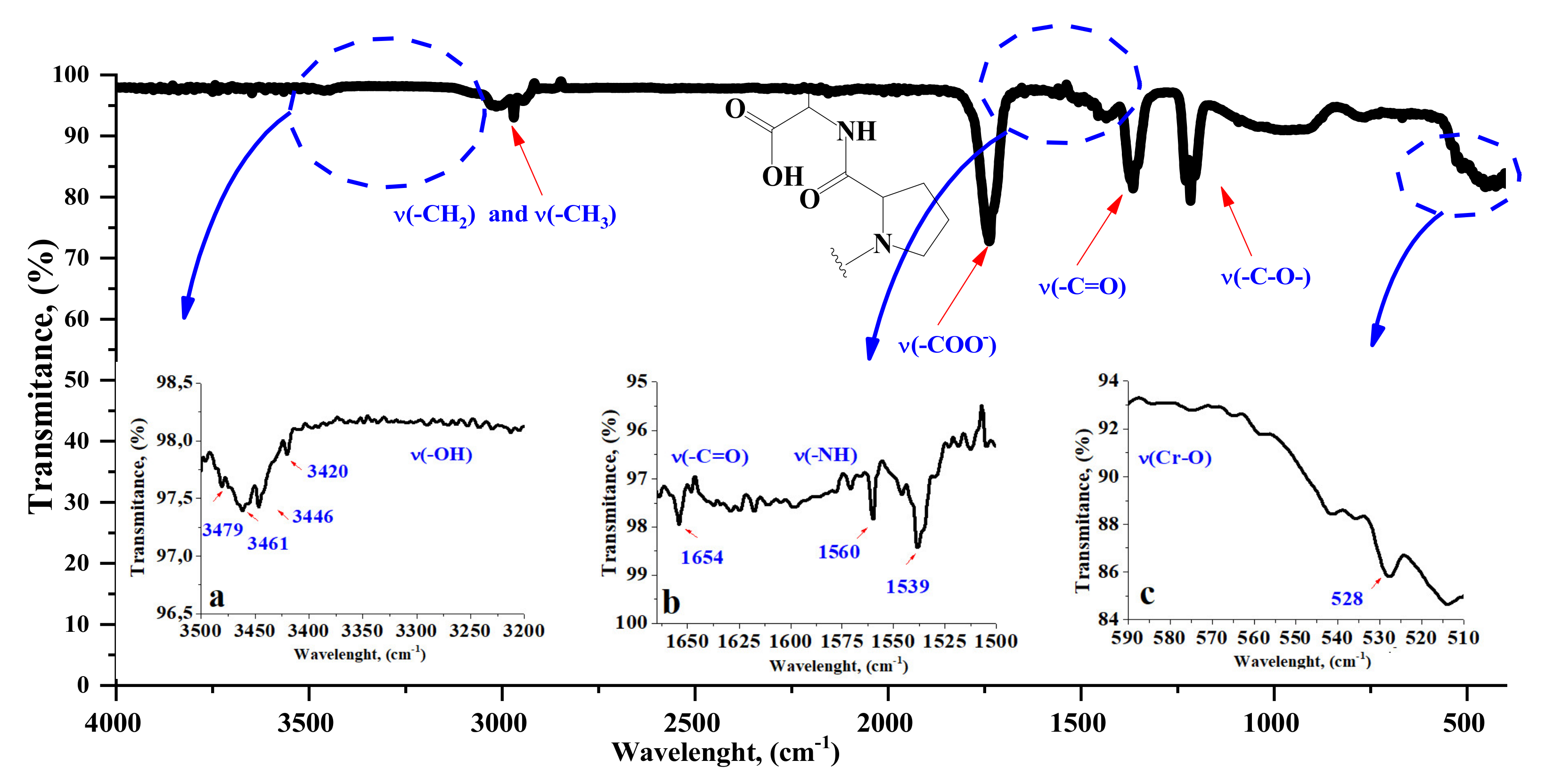

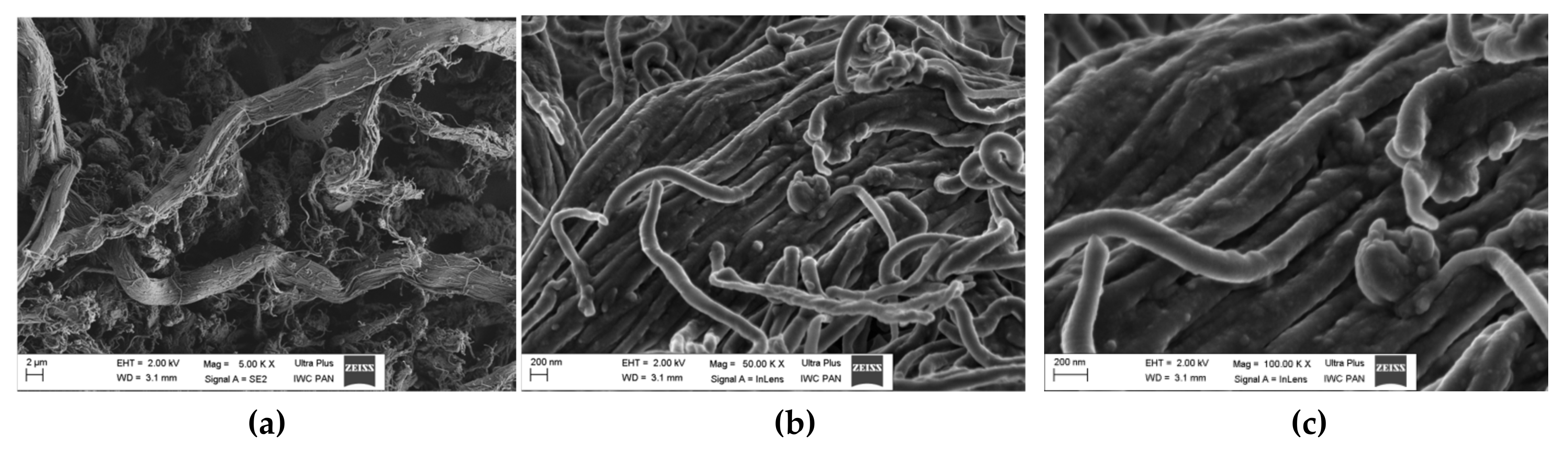

4.1. Characterization of BDC Powder

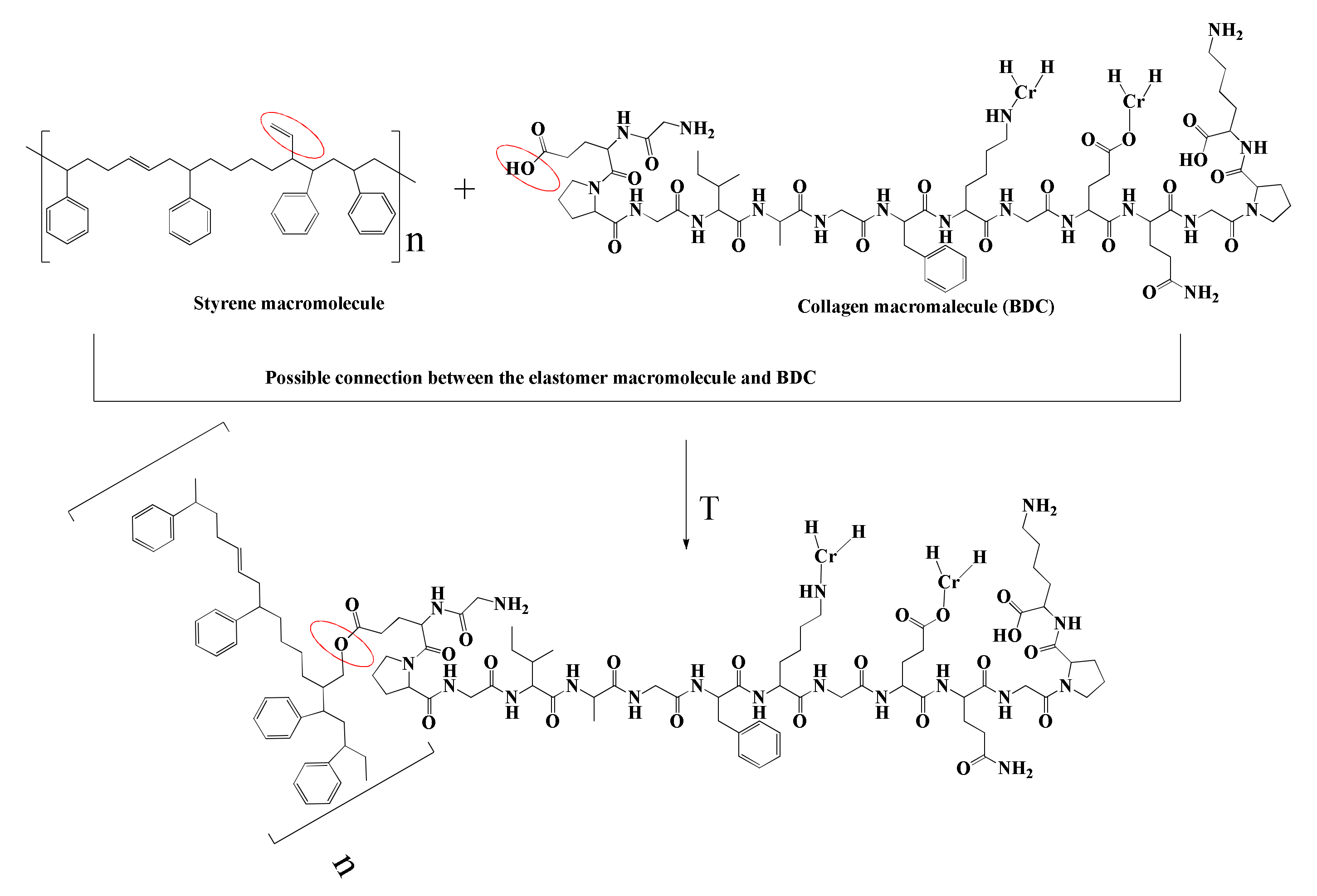

4.2. Characterization of SBR/BDC Composites

4.2.1. Rheometric Properties

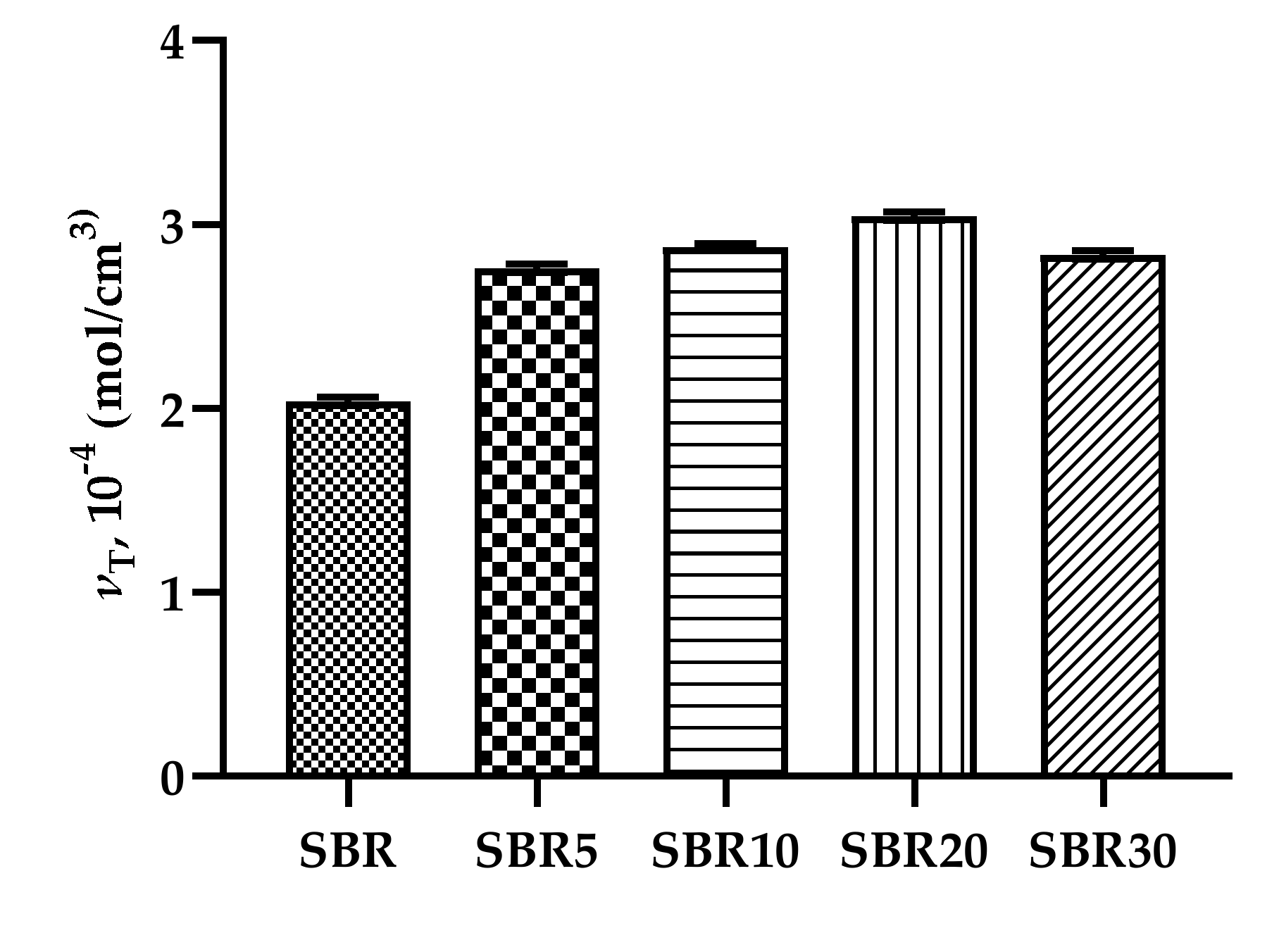

4.2.2. Cross-Linking Density

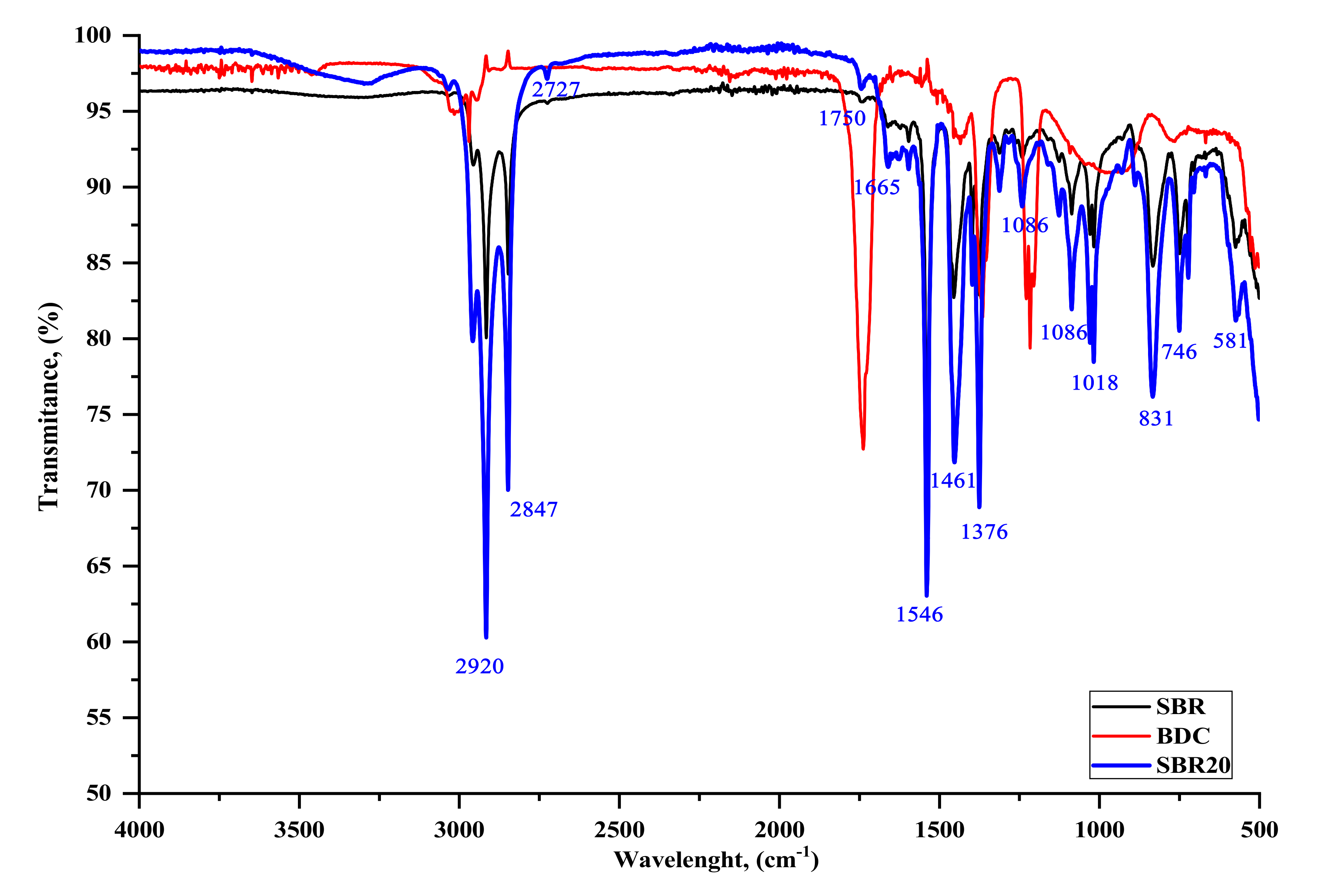

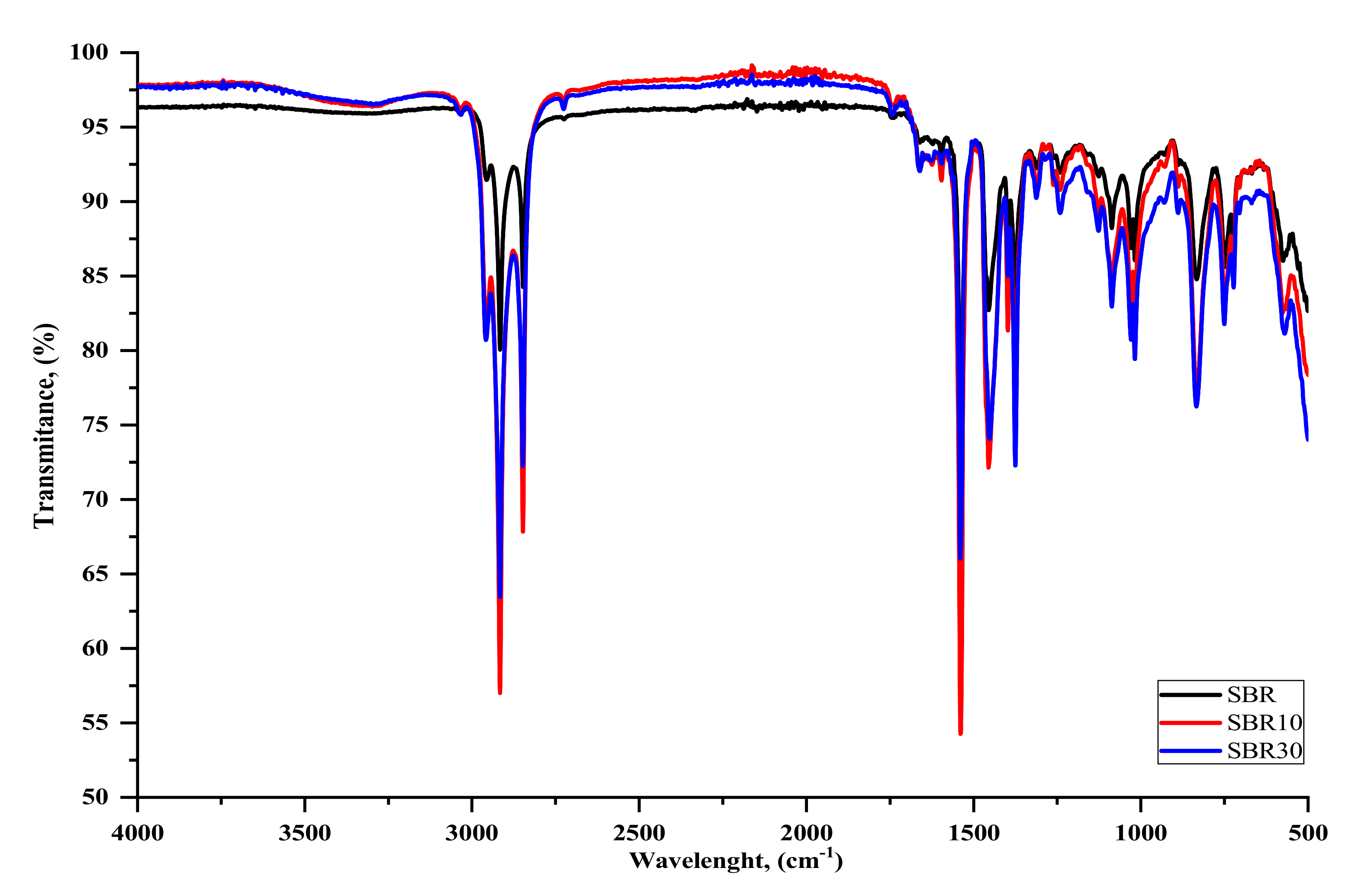

4.2.3. FTIR Analysis

4.2.4. Mechanical and Hardness Tests

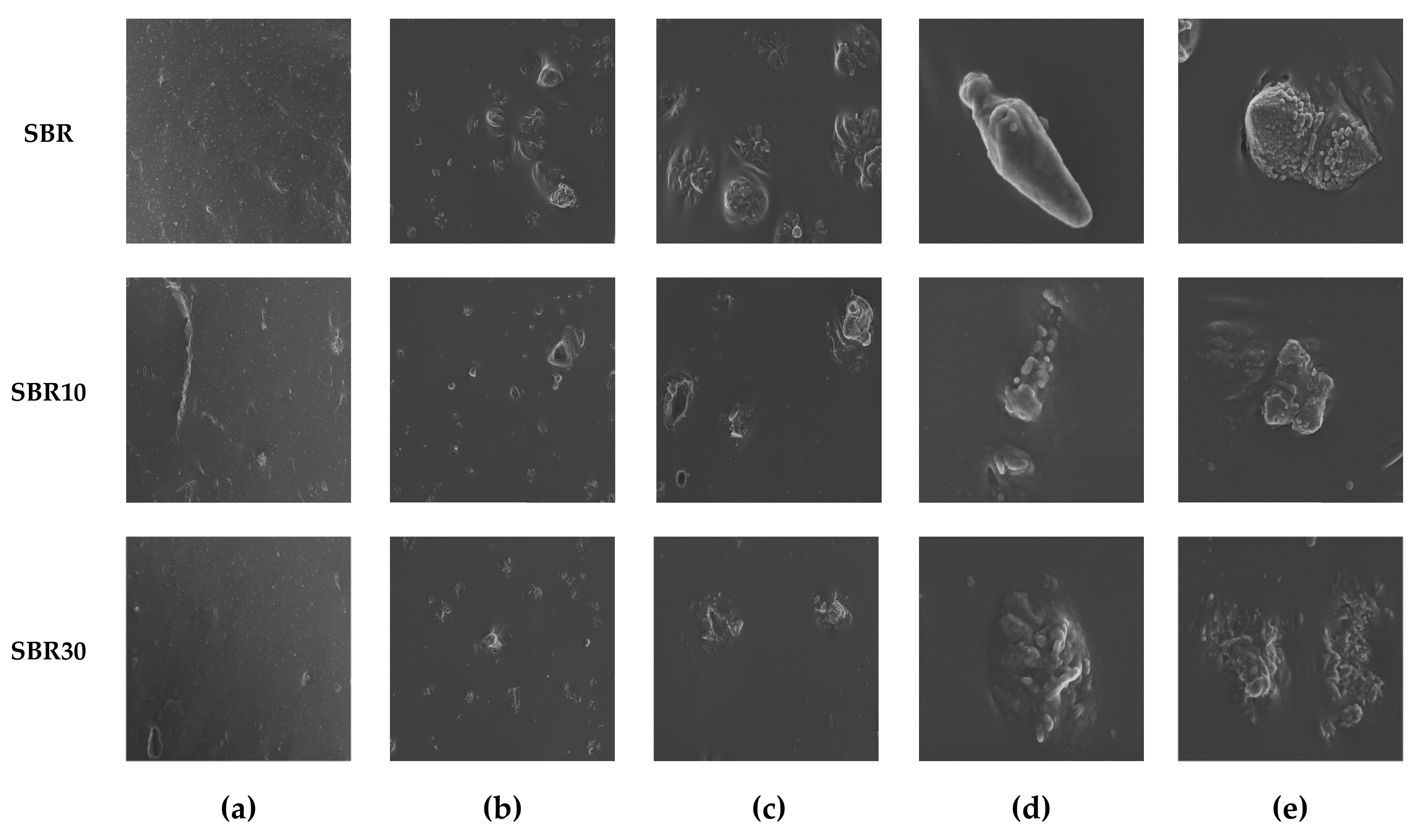

4.2.5. SEM Analysis

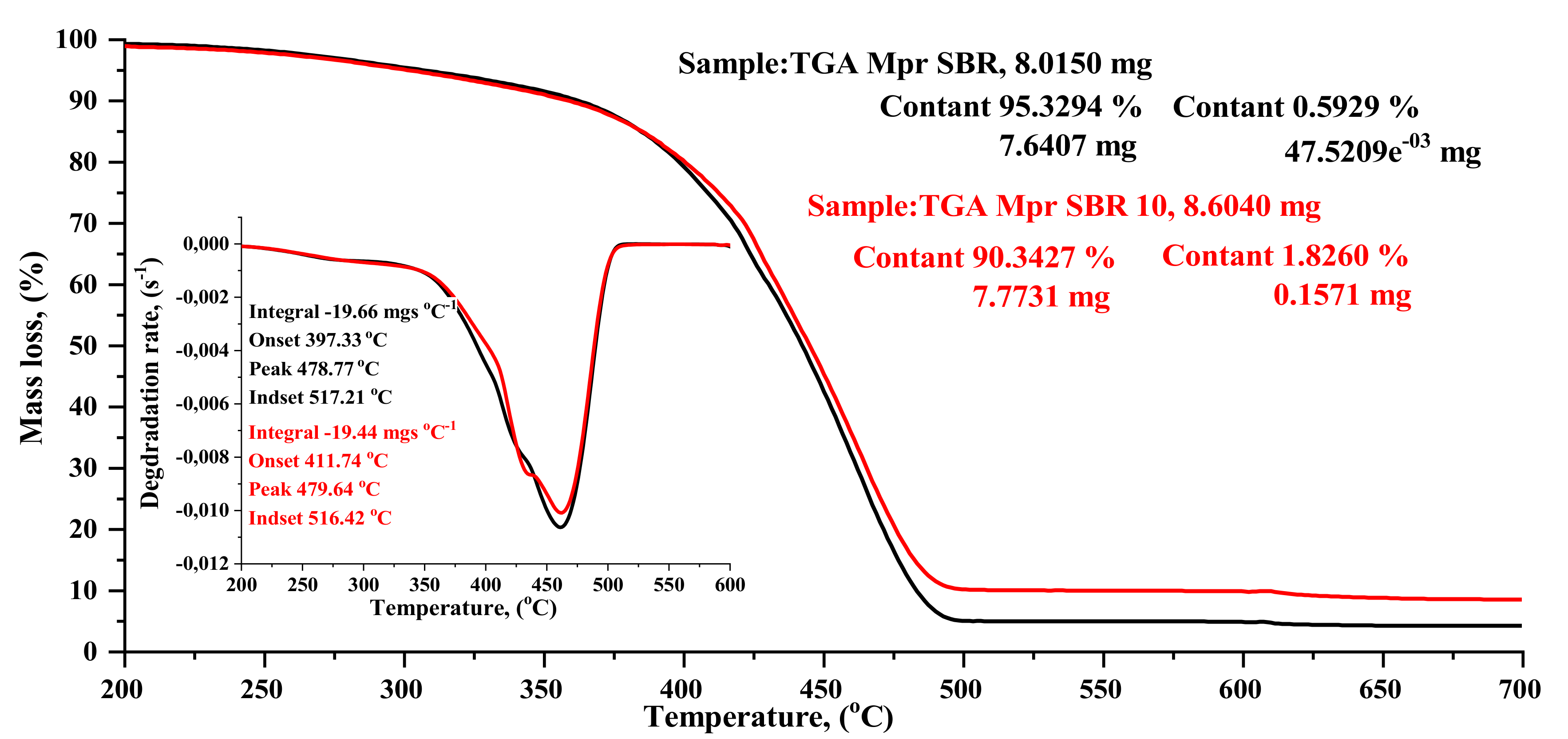

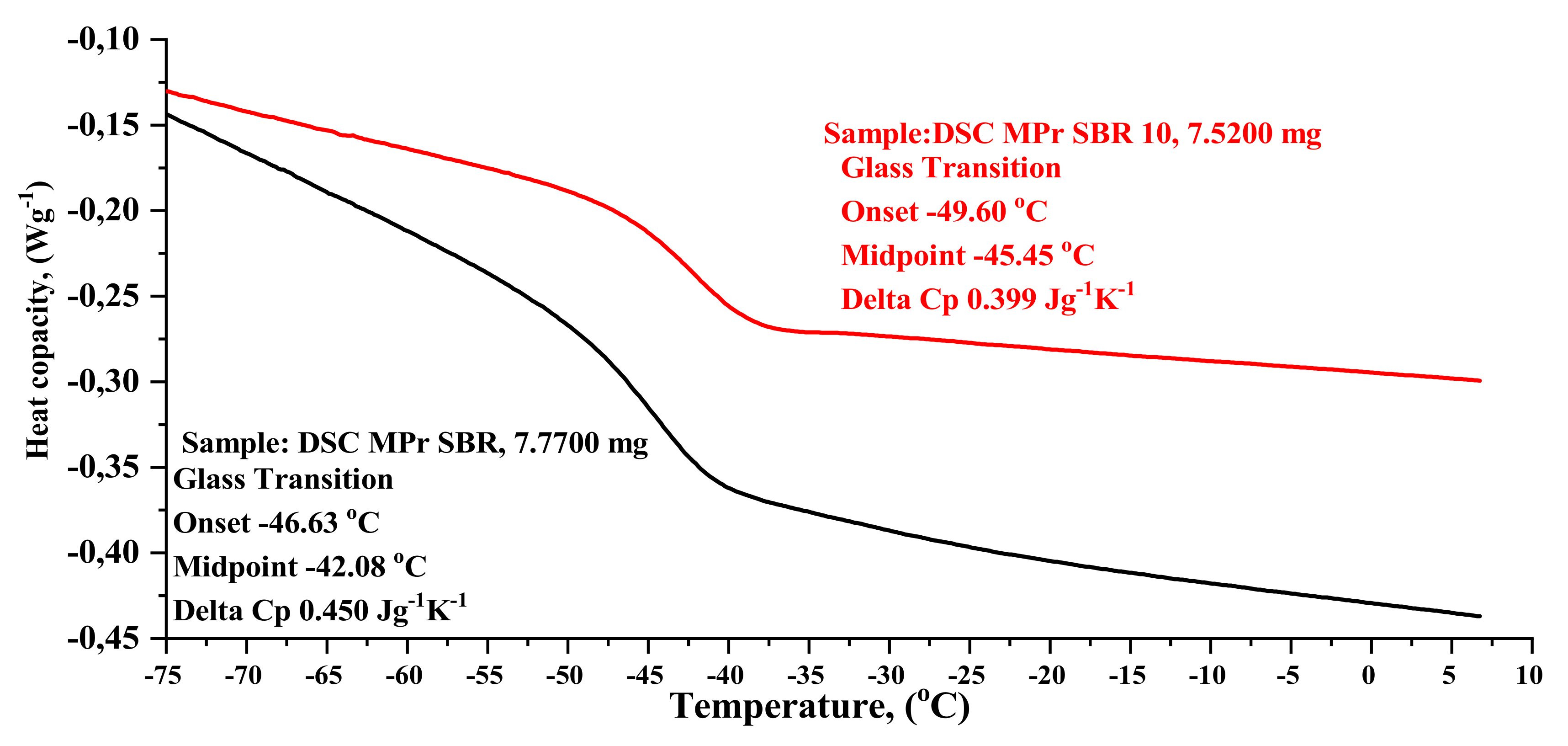

4.2.6. DSC & TGA analysis

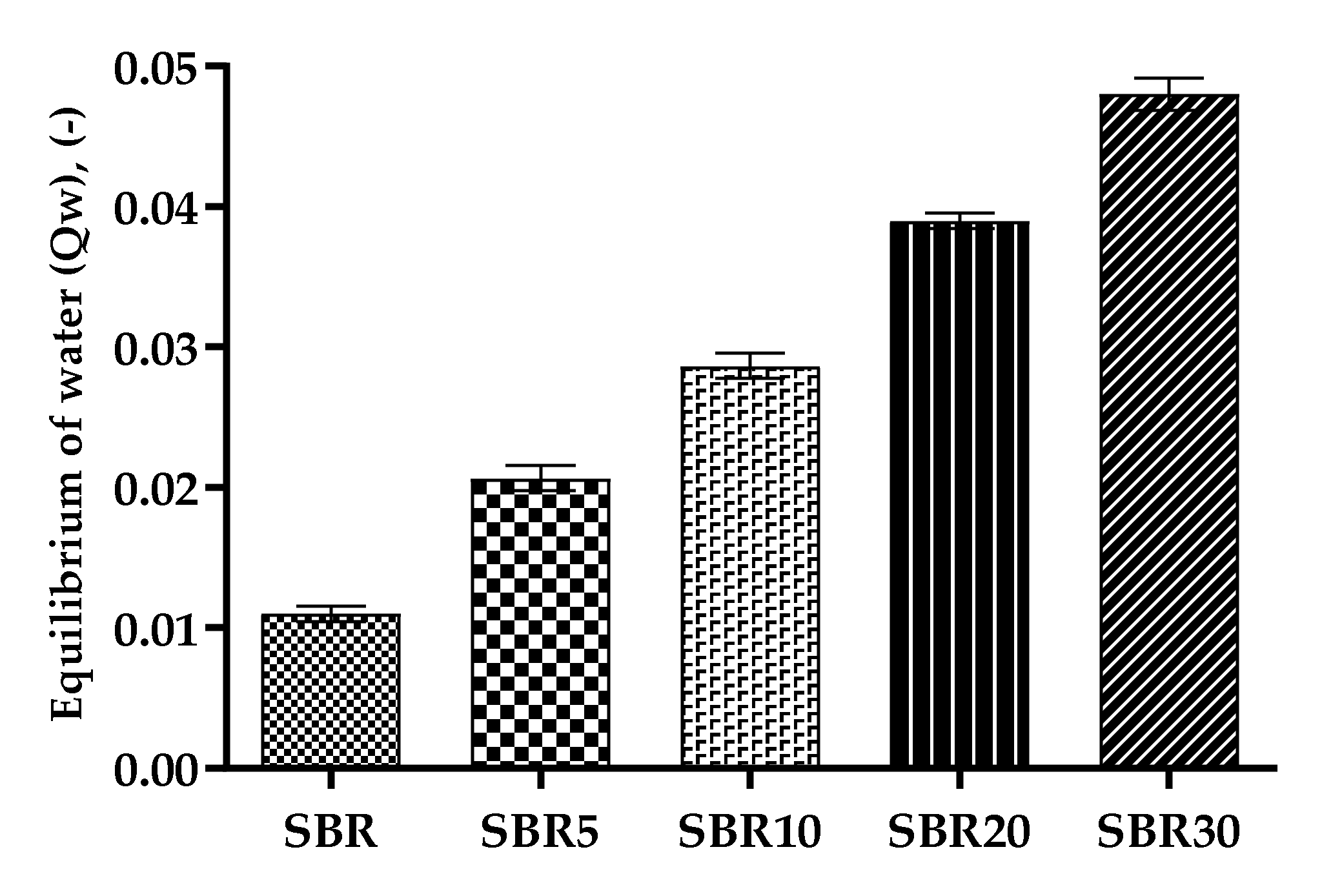

4.2.7. Swelling Balance in Water, Color Research, Soil Test, and Thermo-Oxidative Aging Process

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Ravindran, B.; Wong, J.W.; Selvam, A.; Thirunavukarasu, K.; Sekaran, G. Microbial biodegradation of proteinaceous tannery solid waste and production of a novel value added product–Metalloprotease. Bioresour. Technol. 2016, 217, 150–156. [Google Scholar] [CrossRef]

- Masilamani, D.; Madhan, B.; Saravanan, G.; Palanivel, S.; Narayan, B. Extraction of collagen from raw trimming wastes of tannery: A waste to wealth approach. J. Clean. Prod. 2016, 113, 338–344. [Google Scholar] [CrossRef]

- Duperriez, F.; Poncet, T.; Lety, R.; Kulińska, I.; Kosińska, K.; Mikulska, M.; Prygiel, H.; Sadowski, T. Przewodnik Wprowadzania Systemu Zarządzania środowiskowego w Garbarniach; AFNOR: Paris, France, 2010; pp. 11–13. [Google Scholar]

- Bacardit, A.; Baquero, G.; Sorolla, S.; Ollé, L. Evaluation of a new sustainable continuous system for processing bovine leather. J. Clean. Prod. 2015, 101, 197–204. [Google Scholar] [CrossRef][Green Version]

- Bacardit, A.; van der Burgh, S.; Armengol, J.; Ollé, L. Evaluation of a new environment friendly tanning process. J. Clean. Prod. 2014, 65, 568–573. [Google Scholar] [CrossRef]

- Nashy, E.H.A.; Osman, O.; Mahmoud, A.A.; Ibrahim, M. Molecular spectroscopic study for suggested mechanism of chrome tanned leather. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2012, 88, 171–176. [Google Scholar] [CrossRef]

- Ma, H.; Zhou, J.; Hua, L.; Cheng, F.; Zhou, L.; Qiao, X. Chromium recovery from tannery sludge by bioleaching and its reuse in tanning process. J. Clean. Prod. 2017, 142, 2752–2760. [Google Scholar] [CrossRef]

- Dong, H.; Xuguang, J.; Lv, G.; Yong, C.; Jianhua, Y. Co-combustion of tannery sludge in a commercial circulating fluidized bed boiler. Waste Manag. 2015, 46, 227–233. [Google Scholar] [CrossRef]

- Abbas, N.; Jamil, N.; Hussain, N. Assessment of key parameters in tannery sludge management: A prerequisite for energy recovery. Energy Sources Part A Recover. Util. Environ. Eff. 2016, 38, 2656–2663. [Google Scholar] [CrossRef]

- Skierka, E.; Sadowska, M. The influence of different acids and pepsin on the extractability of collagen from the skin of Baltic cod (Gadus morhua). Food Chem. 2007, 105, 1302–1306. [Google Scholar] [CrossRef]

- Ferreira, M.; Almeida, M.; Pinho, S.; Santos, I. Finished leather waste chromium acid extraction and anaerobic biodegradation of the products. Waste Manag. 2010, 30, 1091–1100. [Google Scholar] [CrossRef]

- Chronska, K.; Przepiorkowska, A. Buffing dust as a filler of carboxylated butadiene-acrylonitrile rubber and butadiene-acrylonitrile rubber. J. Hazard. Mater. 2007, 151, 348–355. [Google Scholar] [CrossRef]

- Chrońska-Olszewska, K.; Przepiórkowska, A. A Mixture of Buffing Dust and Chrome Shavings as a Filler for Nitrile Rubbers. J. Appl. Polym. Sci. 2011, 122, 2899–2906. [Google Scholar] [CrossRef]

- Przepiórkowska, A.; Chjrońska, K.; Zaborski, M. Chrome-tanned leather shavings as a filler of butadiene–acrylonitrile rubber. J. Hazard. Mater. 2007, 141, 252–257. [Google Scholar] [CrossRef] [PubMed]

- Tadeusiak, A.; Przepiórkowska, A. Próba wykorzystania odpadów skór garbowanych do uzyskania biorozkładalnych materiałów białkowo-elastomerowych. Przetwórstwo tworzyw. 2011, 5, 393–396. [Google Scholar]

- Przepiórkowska, A.; Prochoń, M.; Zaborski, M.; Żakowska, Z.; Piotrowska, M. Biodegradable protein-containing elastomeric vulcanizates. Rubber Chem. Technol. 2005, 75, 868–878. [Google Scholar] [CrossRef]

- Ravichandran, K.; Natchimuthu, N. Vulcanization characteristics and mechanical properties of natural rubber-scrap rubber compositions filled with leather particles. Polym. Int. 2005, 54, 553–559. [Google Scholar] [CrossRef]

- Rethinam Senthil, R.; Hemalatha, T.; Manikandan, R.; Nath Das, B. Leather boards from buffing dust: A novel perspective. Clean. Technol. Environ. Policy 2015, 17, 571–576. [Google Scholar] [CrossRef]

- Rajaram, J.; Rajnikanth, B.; Gnanamani, A. Preparation characterization and application of leather particulate-polymer composites (LPPCs). J. Polym. Environ. 2009, 17, 181–186. [Google Scholar] [CrossRef]

- Kowalska, E.; Żubrowiska, M. Termoplastyczne kompozyty napełniane odpadami poprodukcyjnymi z garbowania skóry. Recykling. Przegląd Komunal. 2004, 2, 14–15. [Google Scholar]

- Zhou, J.; Yu, J.; Liao, H.; Zhang, Y.; Luo, X. Facile fabrication of bimetallic collagen fiber particles via immobilizing zirconium on chrome-tanned leather as adsorbent for fluoride removal from ground water near hot spring. Sep. Sci. Technol. 2020, 4, 658–671. [Google Scholar] [CrossRef]

- Arcibar-Orozco, J.A.; Barajas-Elias, B.S.; Caballero-Briones, F.; Nielsen, L.; Rangel-Mendez, J.R. Hybrid Carbon Nanochromium Composites Prepared from Chrome-Tanned Leather Shavings for Dye Adsorption. Water Air Soil Pollut. 2019, 230, 1–13. [Google Scholar] [CrossRef]

- Kamaraj, C.; Lakshmi, S.; Rose, C.; Muralidharan, C. Wet Blue Fiber and Lime from Leather Industry Solid Waste as Stabilizing Additive and Filler in Design of Stone Matrix Asphalt. Asian J. Res. Soc. Sci. Humanit. 2017, 7, 240–257. [Google Scholar] [CrossRef]

- Ma, F.; Dinga, S.; Renb, H.; Penga, P. Preparation of chrome-tanned leather shaving-based hierarchical porous carbon and its capacitance properties. RSC Adv. 2019, 9, 18333–18343. [Google Scholar] [CrossRef]

- Liu, y.; Wang, Q.; Li, L. Reuse of leather shavings as a reinforcing filler for poly (vinyl alcohol). J. Thermoplast. Compos. Mater. 2014, 29, 1–15. [Google Scholar]

- Şaşmaz, S.L.; Karaağaç, B.; Uyanık, N. Utilization of chrome-tanned leather wastes in natural rubber and styrene-butadiene rubber blends. J. Mater. Cycles Waste Manag. 2019, 21, 166–175. [Google Scholar] [CrossRef]

- Polgar, L.M.; Kingma, A.; Roelfs, M.; van Essen, M.; van Duin, M.; Picchioni, F. Kinetics of cross-linking and de-cross-linking of EPM rubber with thermoreversible. Diels-Alder Chem. Eur. Polym. J. 2017, 90, 150–161. [Google Scholar]

- Prochoń, M.; Marzec, A.; Szadkowski, B. Preparation and Characterization of New Environmentally Friendly Starch-Cellulose Materials Modified with Casein or Gelatin for Agricultural Applications. Materials 2019, 12, 1–19. [Google Scholar]

- Baeta, D.A.; Zattera, J.A.; Oliveira, M.G.; Oliveira, P.J. The use of styrene-butadiene rubber waste as a potential filler in nitrile rubber: Order of addition and size of waste particles. J. Chem. Eng. 2009, 26, 23–31. [Google Scholar] [CrossRef]

- Kium, K.-H.; Lee, J.-Y.; Choi, J.-M.; Kim, H.J.; Seo, B.; Kim, B.-S.; Kwag, G.; Paik, H.-J.; Kim, W. Synthesis of Ionic Elastomer Based on Styrene-Butadiene Rubber Containing Methacrylic Acid. Elastomer Compos. 2013, 48, 46–54. [Google Scholar] [CrossRef]

- Brandt, H.-D.; Nentwig, W.; Rooney, N.; LaFlair, R.T.; Wolf, U.U.; Duffy, J.; Puskas, J.E.; Kaszas, G.; Drewitt, M.; Glander, S. Rubber, 5. Solution Rubbers; Encyclopedia of Industrial Chemistry Wiley-VCH: Hoboken, NJ, USA, 2012. [Google Scholar]

- Prochoń, M.; Przepiórkowska, A. Innovative application of biopolymer keratin as a filler of synthetic acrylonitrile-tadiene rubber NBR. J. Chem. 2013, 2013, 1–8. [Google Scholar] [CrossRef]

| Symbol | SBR | SBR5 | SBR10 | SBR20 | SBR30 |

|---|---|---|---|---|---|

| SBR (phr) | 100 | 100 | 100 | 100 | 100 |

| BDC (phr) | 0 | 5 | 10 | 20 | 30 |

| ZnO (phr) | 5 | 5 | 5 | 5 | 5 |

| Sulphur (phr) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| MBTS (phr) | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| Stearic acid (phr) | 2 | 2 | 2 | 2 | 2 |

| Symbol | LL (dNm) | ∆L (dNm) | τ02 (min) | τ90 (min) |

|---|---|---|---|---|

| SBR | 11.0 ± 0.3 | 39.9 ± 1.1 | 1.2 ± 0.1 | 24.5 ± 1.3 |

| SBR5 | 13.9 ± 0.1 | 54.8 ± 1.9 | 2.9 ± 0.1 | 30.0 ± 1.4 |

| SBR10 | 12.0 ± 0.2 | 61.6 ± 2.2 | 2.0 ± 0.1 | 33.0 ± 1.1 |

| SBR20 | 13.0 ± 0.1 | 51.7 ± 1.9 | 2.9 ± 0.2 | 37.0 ± 1.0 |

| SBR30 | 14.0 ± 0.1 | 47.5 ± 1.4 | 3.5 ± 0.2 | 38.5 ± 1.2 |

| Parameter | SBR | SBR5 | SBR10 | SBR20 | SBR30 |

|---|---|---|---|---|---|

| TS (MPa) | 3.34 ± 0.1 | 3.73 ± 0.2 | 4.78 ± 0.3 | 4.91 ± 0.3 | 3.94 ± 0.2 |

| SE300 (%) | 2.15 ± 0.5 | 2.41 ± 0.1 | 2.60 ± 0.2 | 3.07 ± 0.6 | 3.70 ± 0.1 |

| Eb (%) | 541 ± 4.2 | 228 ± 6.1 | 254 ± 5.5 | 322 ± 7.8 | 267 ± 4.9 |

| H (°Sh) | 44.08 ± 0.9 | 48.22 ± 1.2 | 49.20 ± 1.1 | 50.85 ± 0.8 | 53.88 ± 0.7 |

| Symbol | T5% (°C) | T peak (DTG) (°C) | Δm total (%) | Tg (°C) |

|---|---|---|---|---|

| SBR | 305 | 478.77 | 95.32 | −42.08 |

| SBR10 | 299 | 479.64 | 90.34 | −45.45 |

| Composite Symbol | SBR | SBR5 | SBR10 | SBR20 | SBR30 |

|---|---|---|---|---|---|

| BEFORE BIODEGRADATION |  |  |  |  |  |

| dL × ab | 3.84 | 0.99 | 0.20 | 0.26 | 0.46 |

| AFTER BIODEGRADATION |  |  |  |  |  |

| dL × ab | 7.35 | 2.63 | 1.34 | 4.52 | 3.18 |

| Effects of Aging and Biological on the Properties of SBR Composites | |||||

|---|---|---|---|---|---|

| Composite symbol | SBR | SBR5 | SBR10 | SBR20 | SBR30 |

| Aging coefficient ∆T(-) | |||||

| Thermal aging | 0.93 ± 0.04 | 1.42 ± 0.02 | 0.84 ± 0.03 | 1.14 ± 0.01 | 0.92 ± 0.03 |

| Soil test | 0.94 ± 0.01 | 0.83 ± 0.01 | 0.67 ± 0.02 | 0.56 ± 0.01 | 0.51 ± 0.02 |

| Hardness of obtained composites H (°Sh) | |||||

| Thermal aging | 45.17 ± 0.12 | 51.95 ± 0.08 | 53.33 ± 0.14 | 54.25 ± 0.23 | 58.15 ± 0.18 |

| Soil test | 45.00 ± 0.20 | 46.90 ± 0.13 | 48.07 ± 0.21 | 49.27 ± 0.10 | 53.03 ± 0.09 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prochon, M.; Marzec, A.; Dzeikala, O. Hazardous Waste Management of Buffing Dust Collagen. Materials 2020, 13, 1498. https://doi.org/10.3390/ma13071498

Prochon M, Marzec A, Dzeikala O. Hazardous Waste Management of Buffing Dust Collagen. Materials. 2020; 13(7):1498. https://doi.org/10.3390/ma13071498

Chicago/Turabian StyleProchon, Miroslawa, Anna Marzec, and Oleksandra Dzeikala. 2020. "Hazardous Waste Management of Buffing Dust Collagen" Materials 13, no. 7: 1498. https://doi.org/10.3390/ma13071498

APA StyleProchon, M., Marzec, A., & Dzeikala, O. (2020). Hazardous Waste Management of Buffing Dust Collagen. Materials, 13(7), 1498. https://doi.org/10.3390/ma13071498