Investigating the Advantages of Ultrasonic-assisted Welding Technique Applied in Underwater Wet Welding by in-situ X-ray Imaging Method

Abstract

1. Introduction

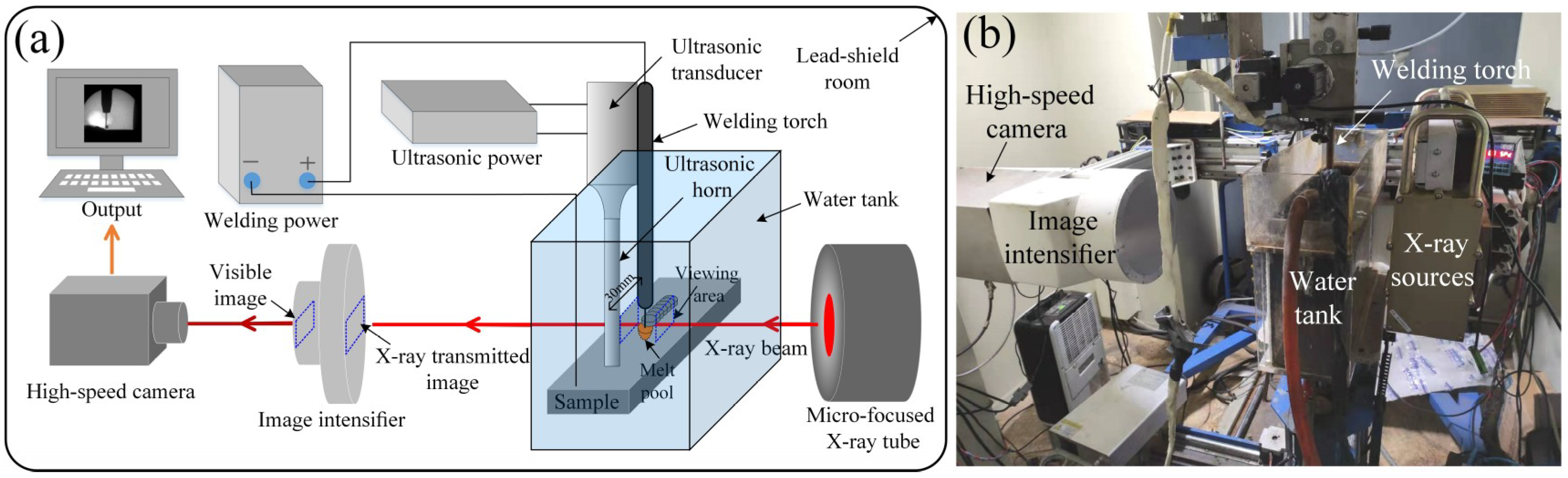

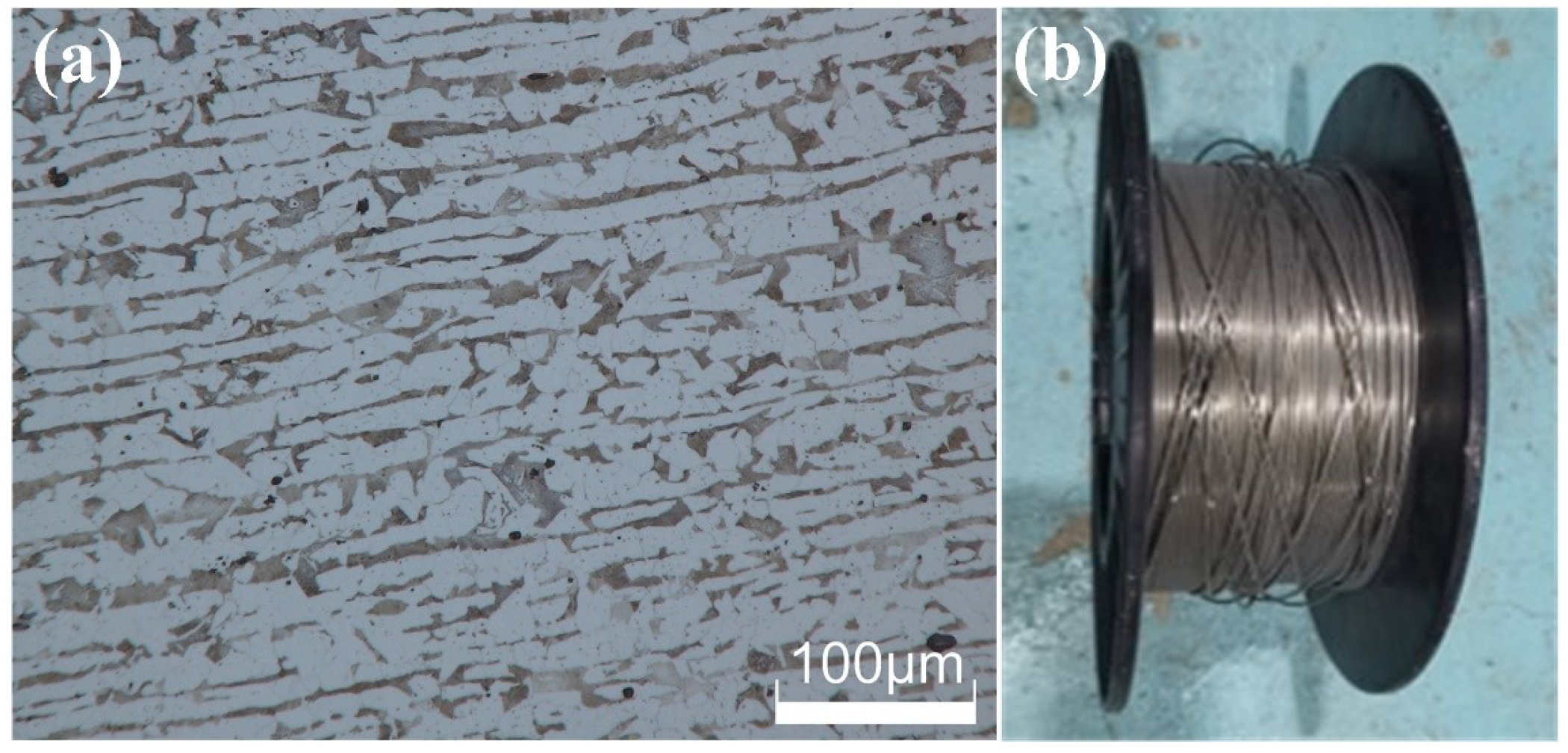

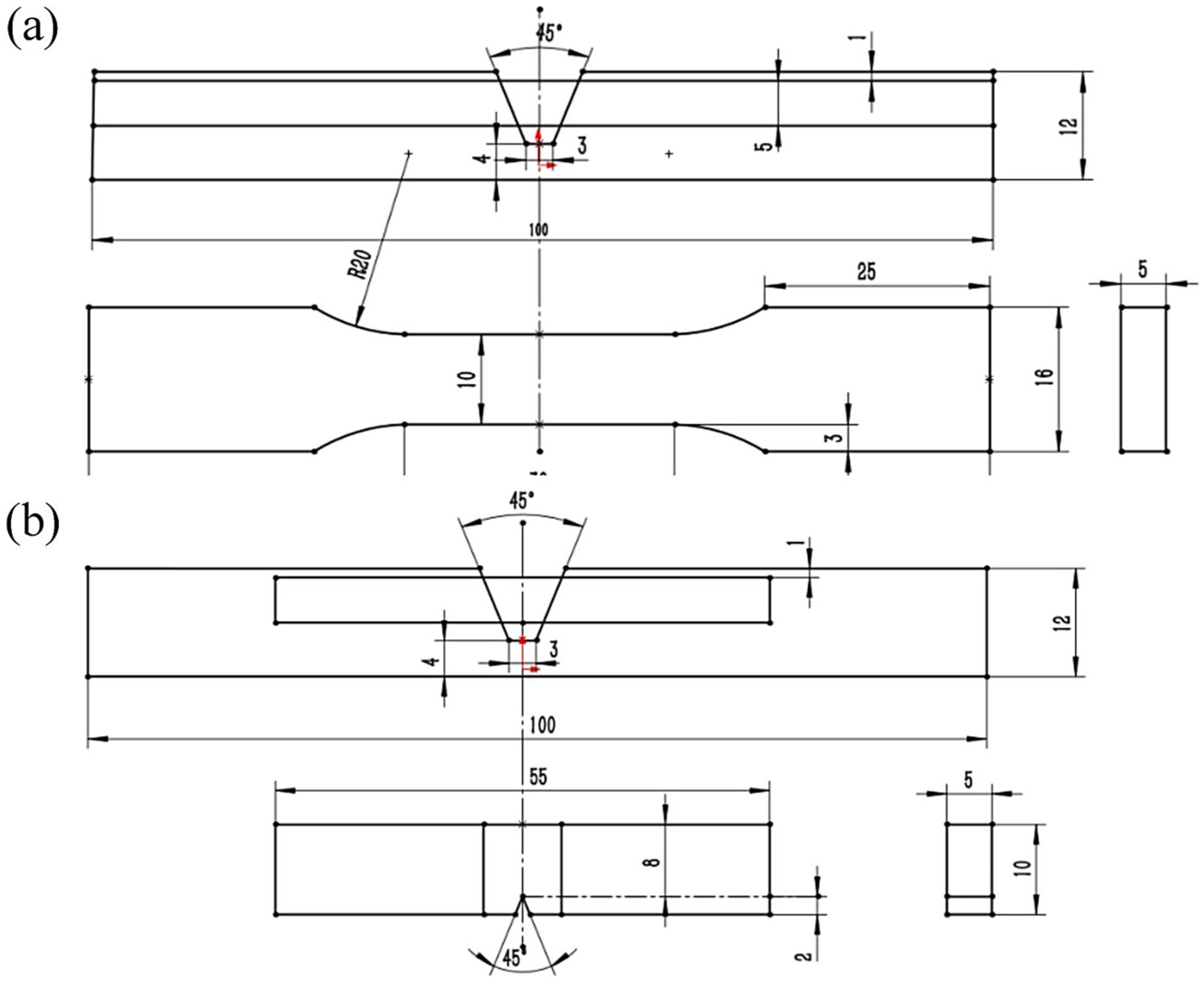

2. Materials and Methods

3. Results and Discussion

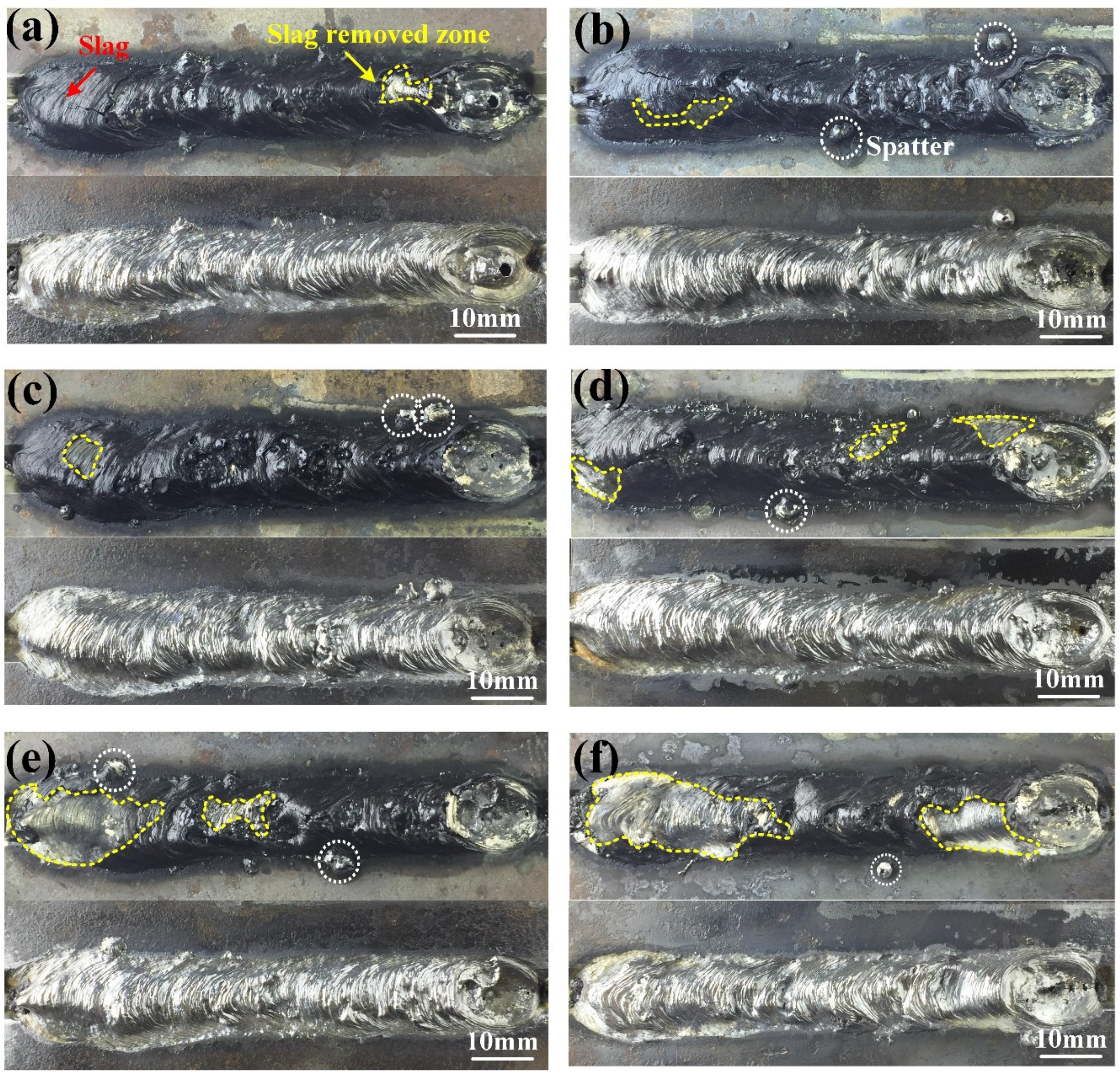

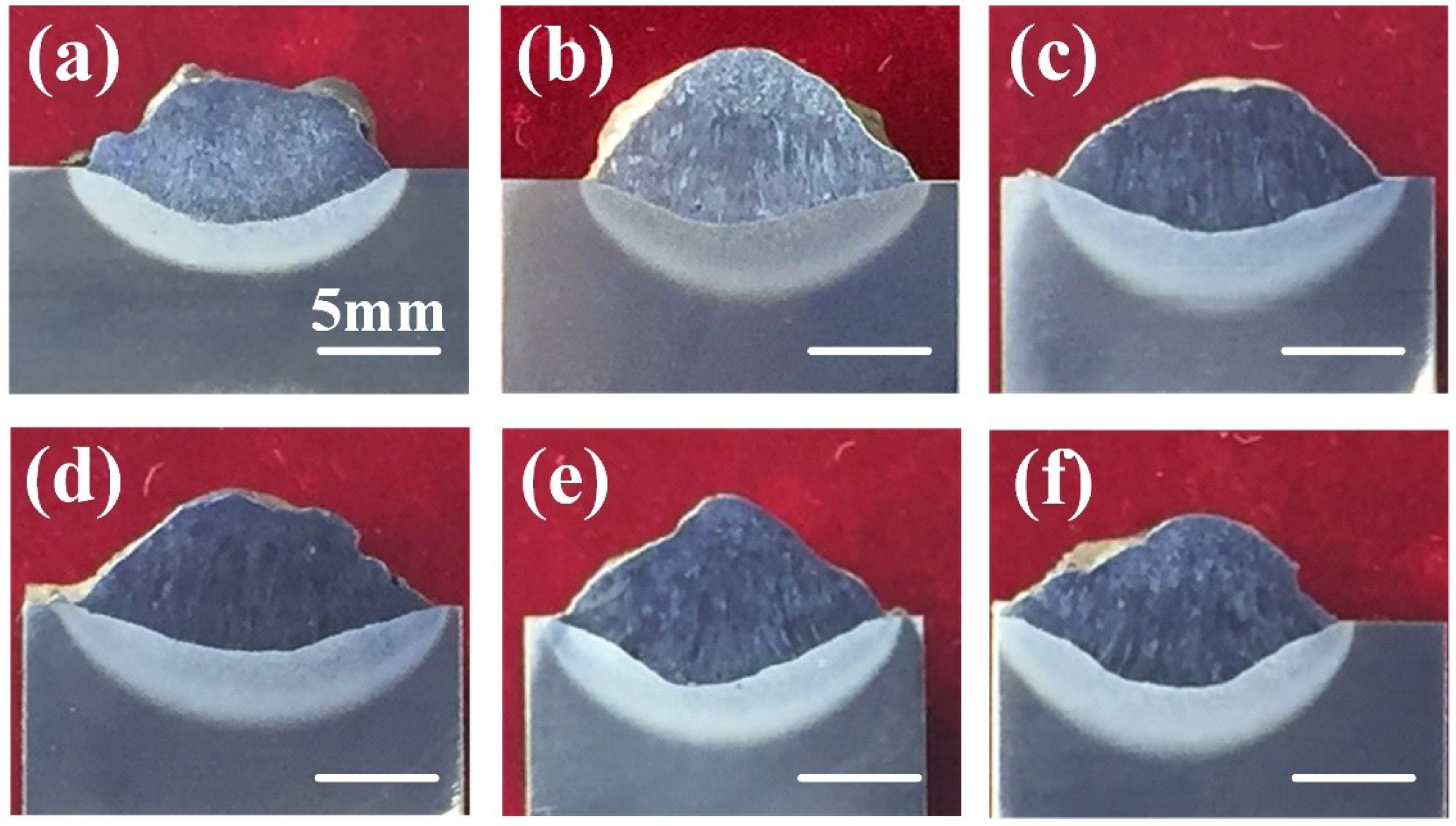

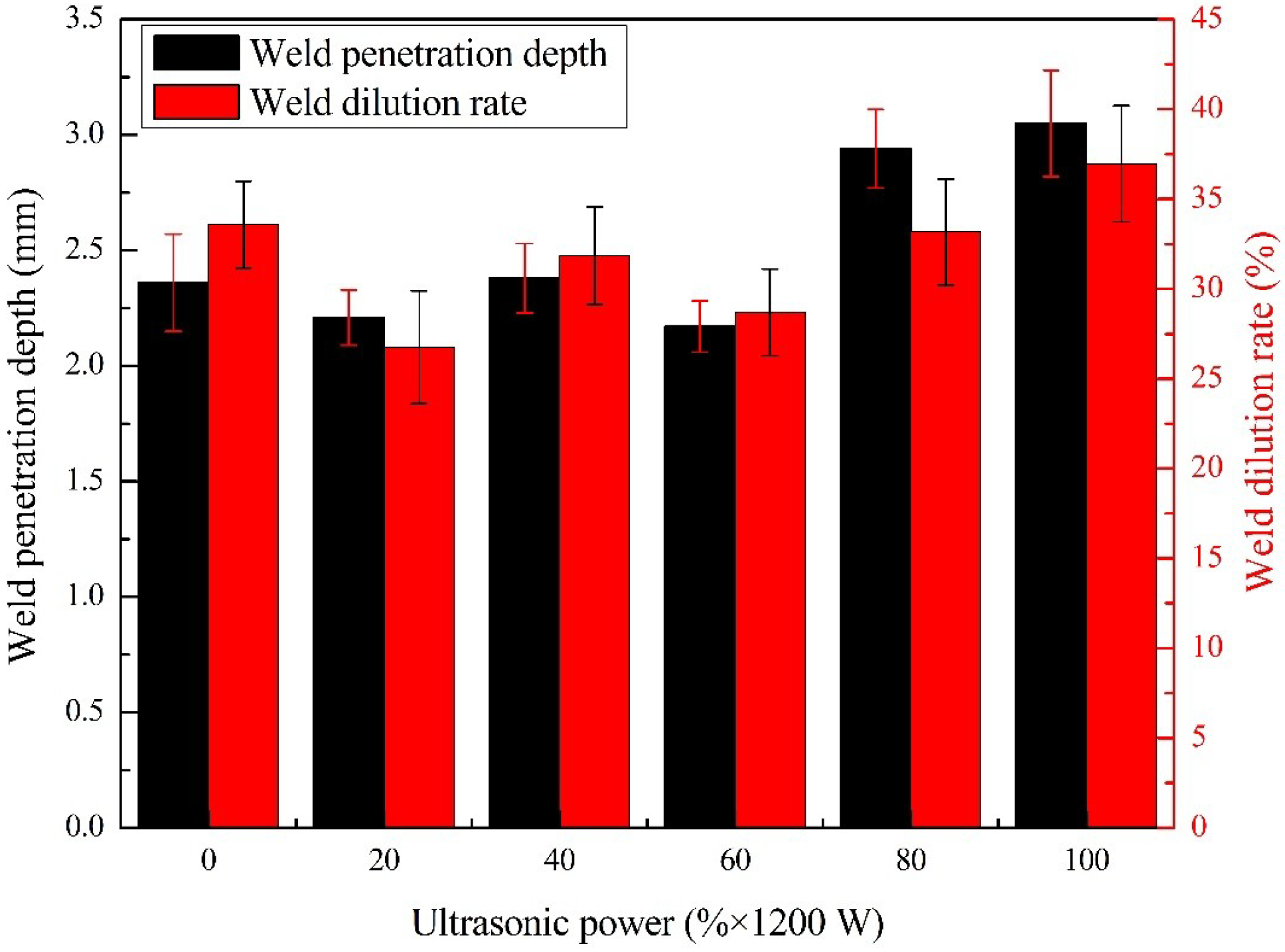

3.1. Weld Geometry

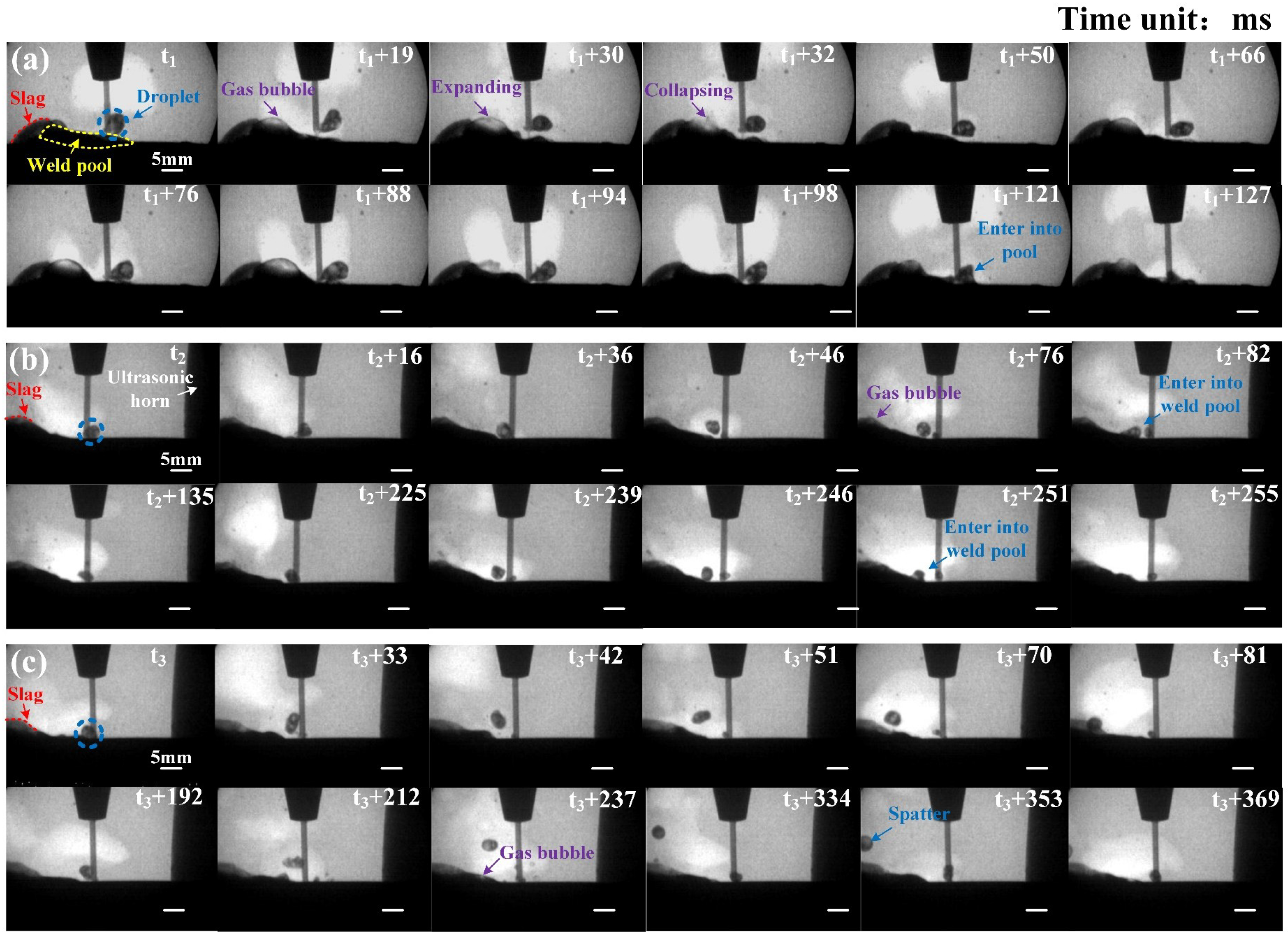

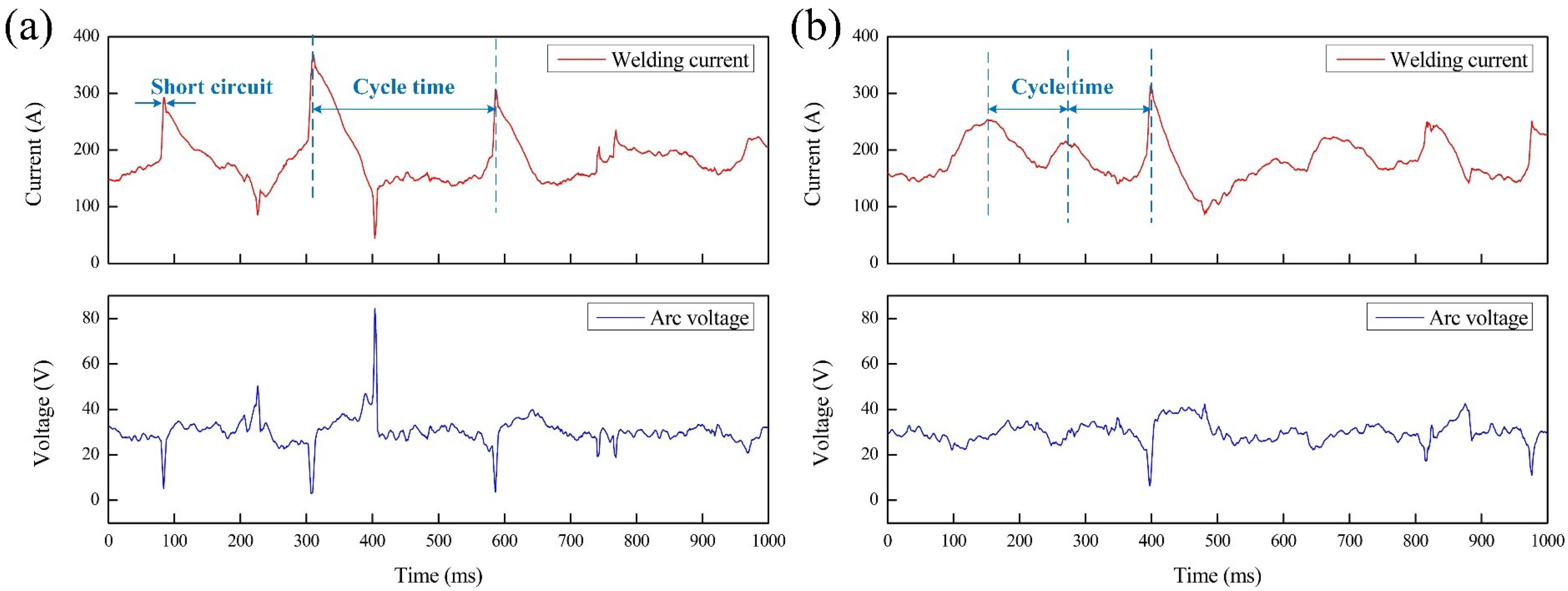

3.2. Droplet Transfer and Melt Flow

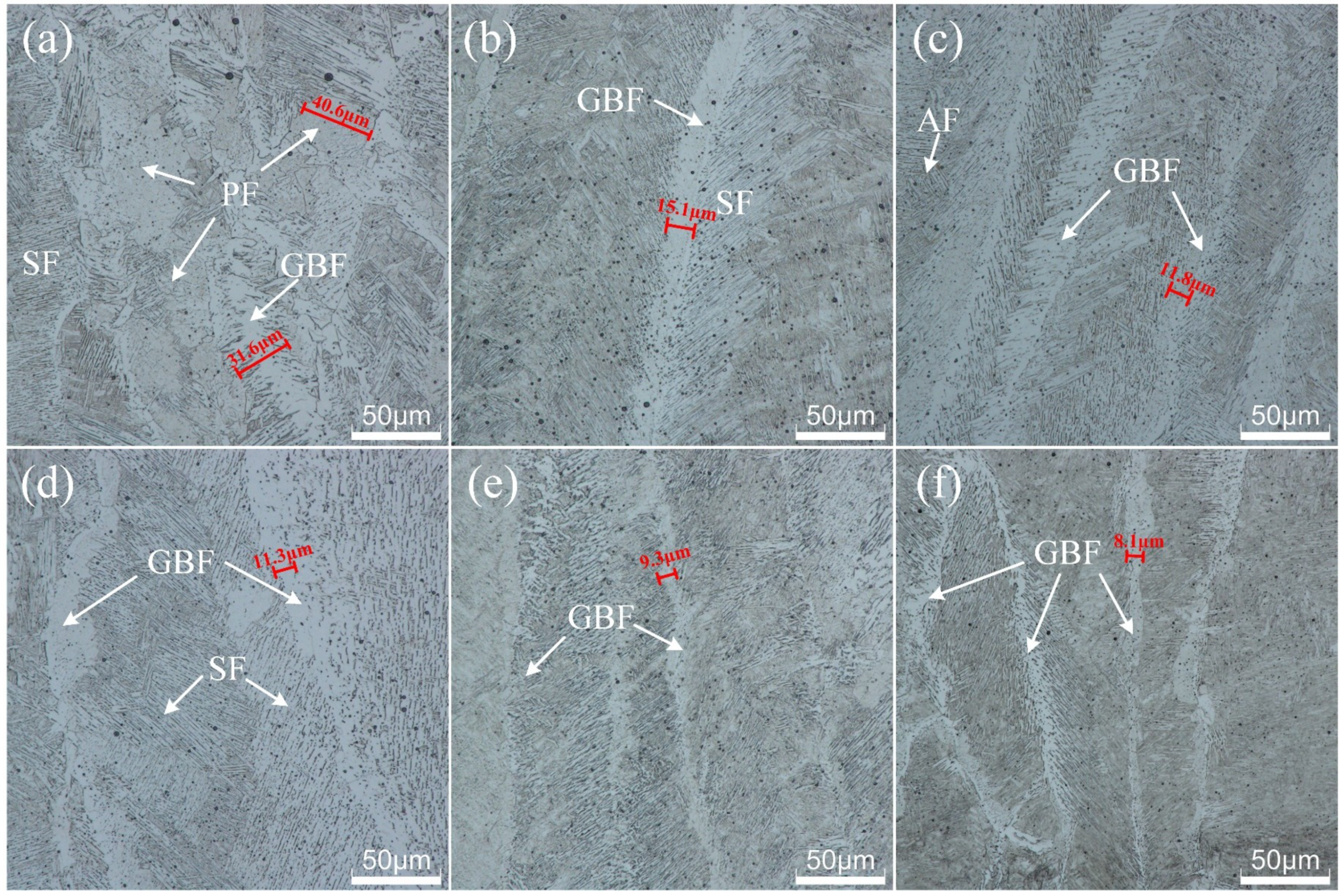

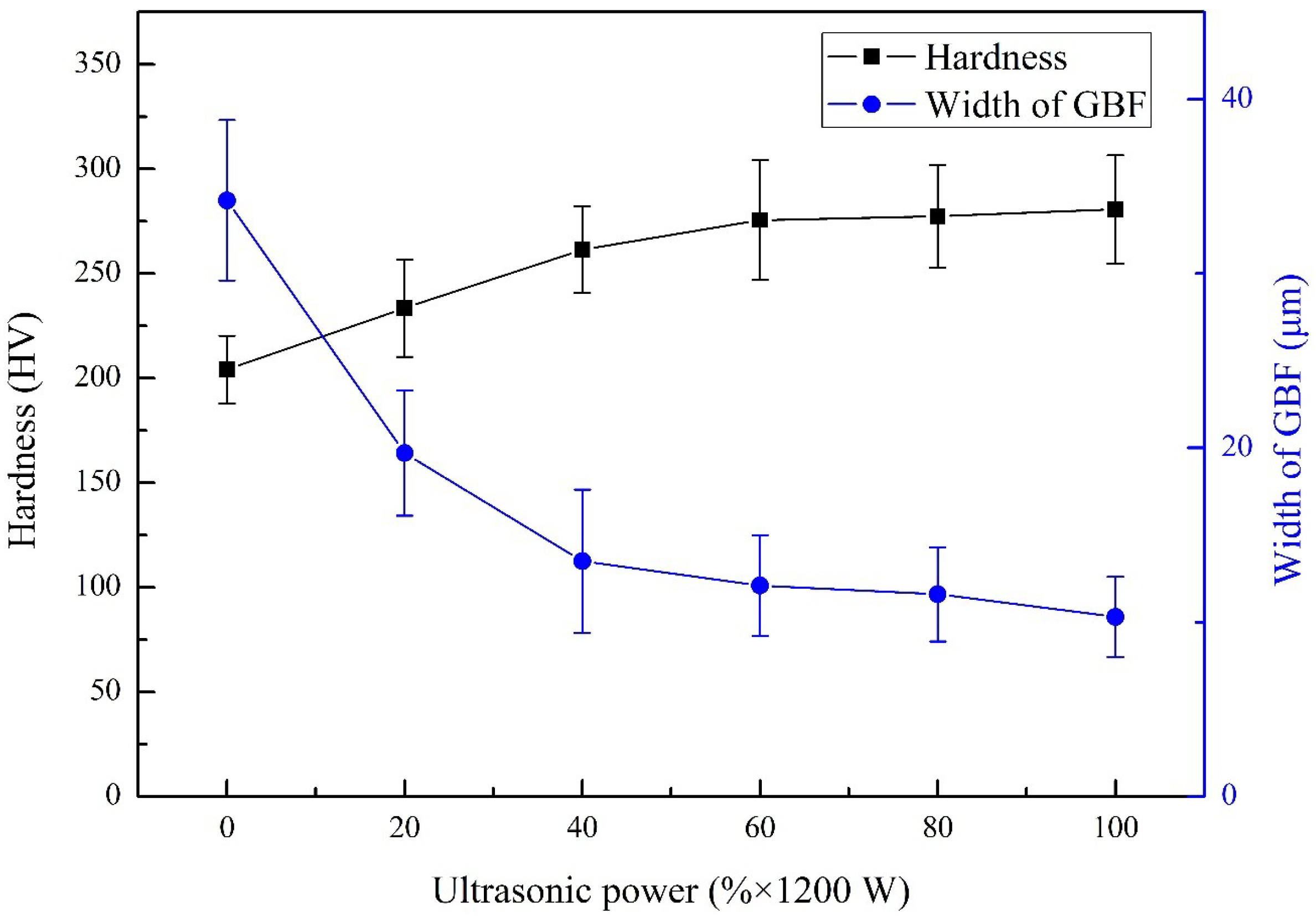

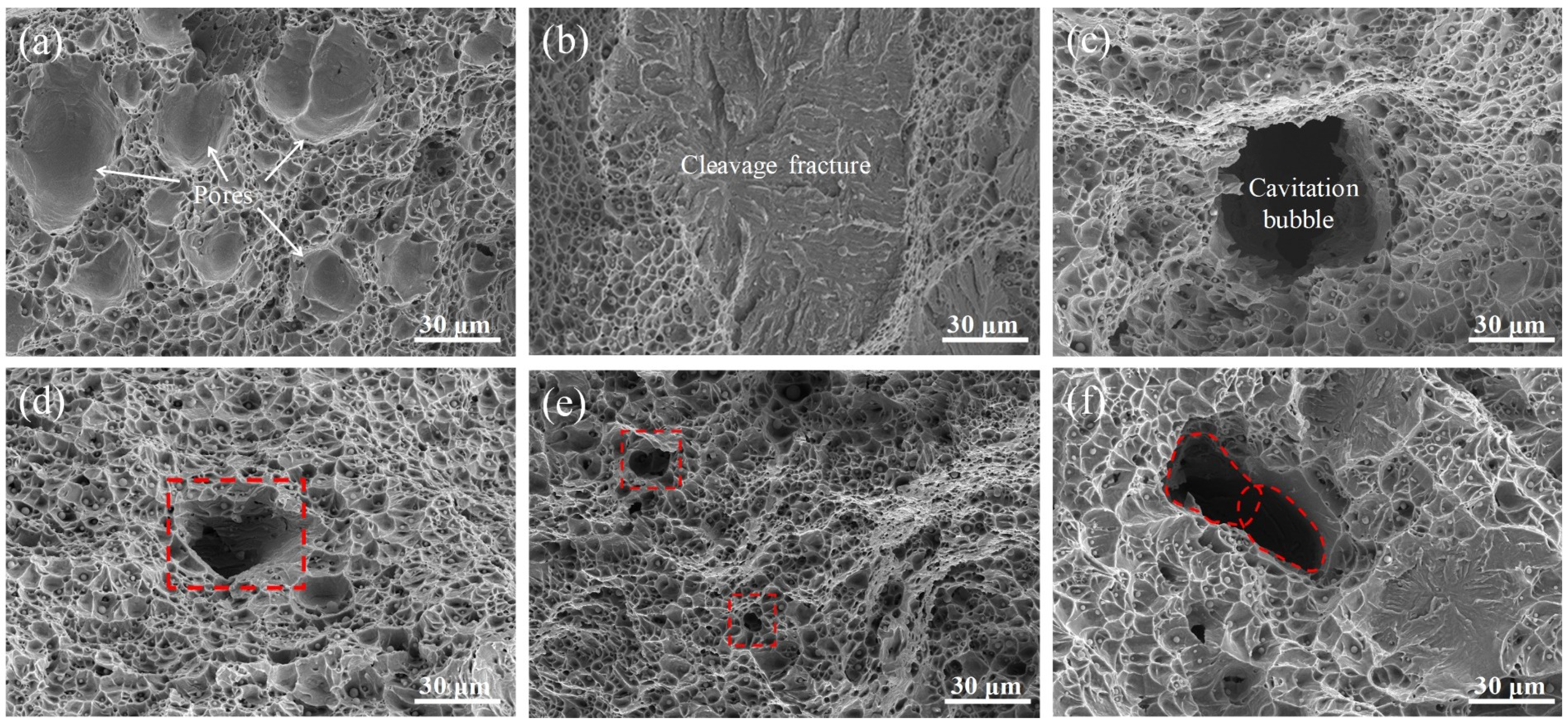

3.3. Microstructures and Microhardness

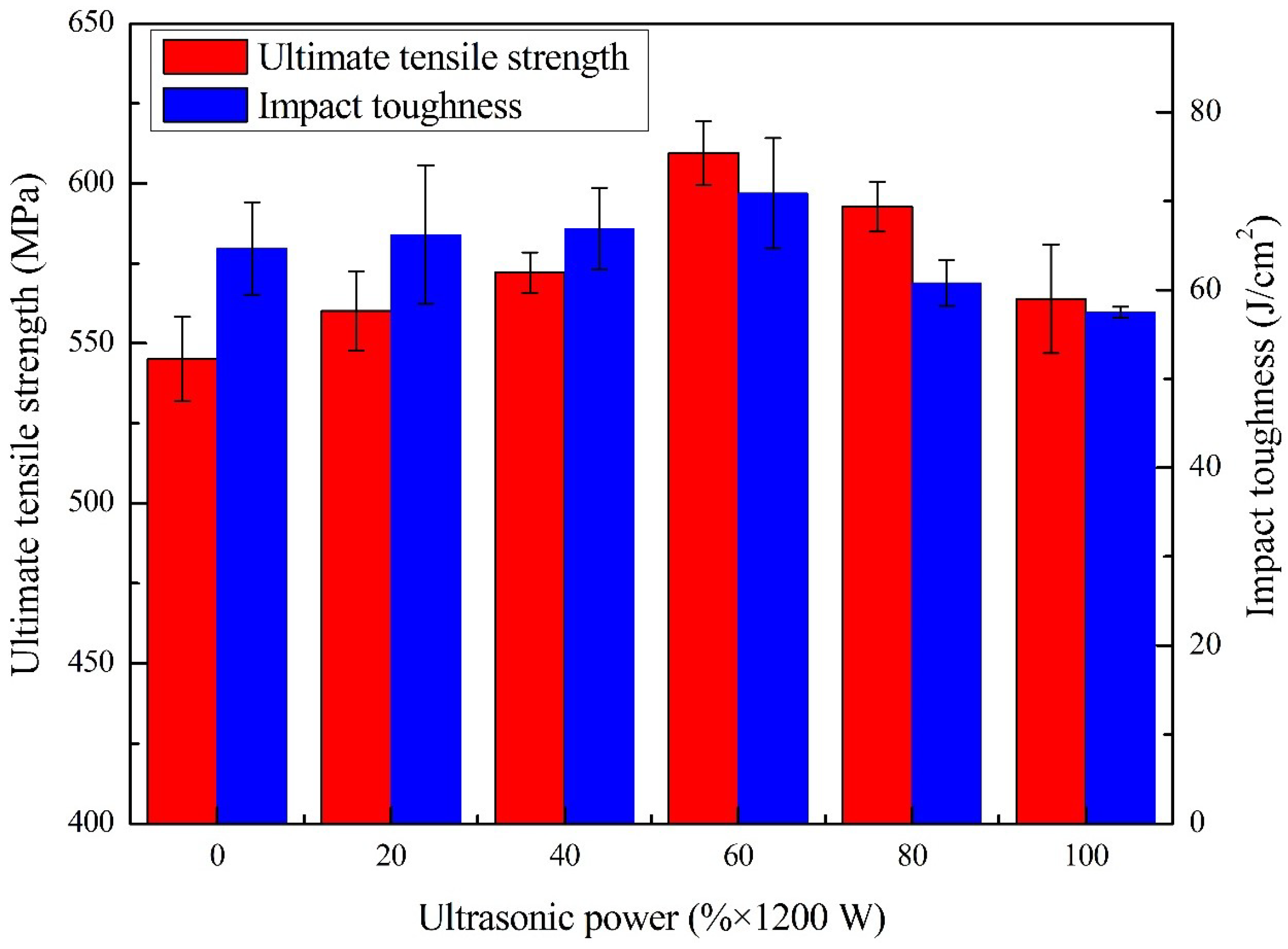

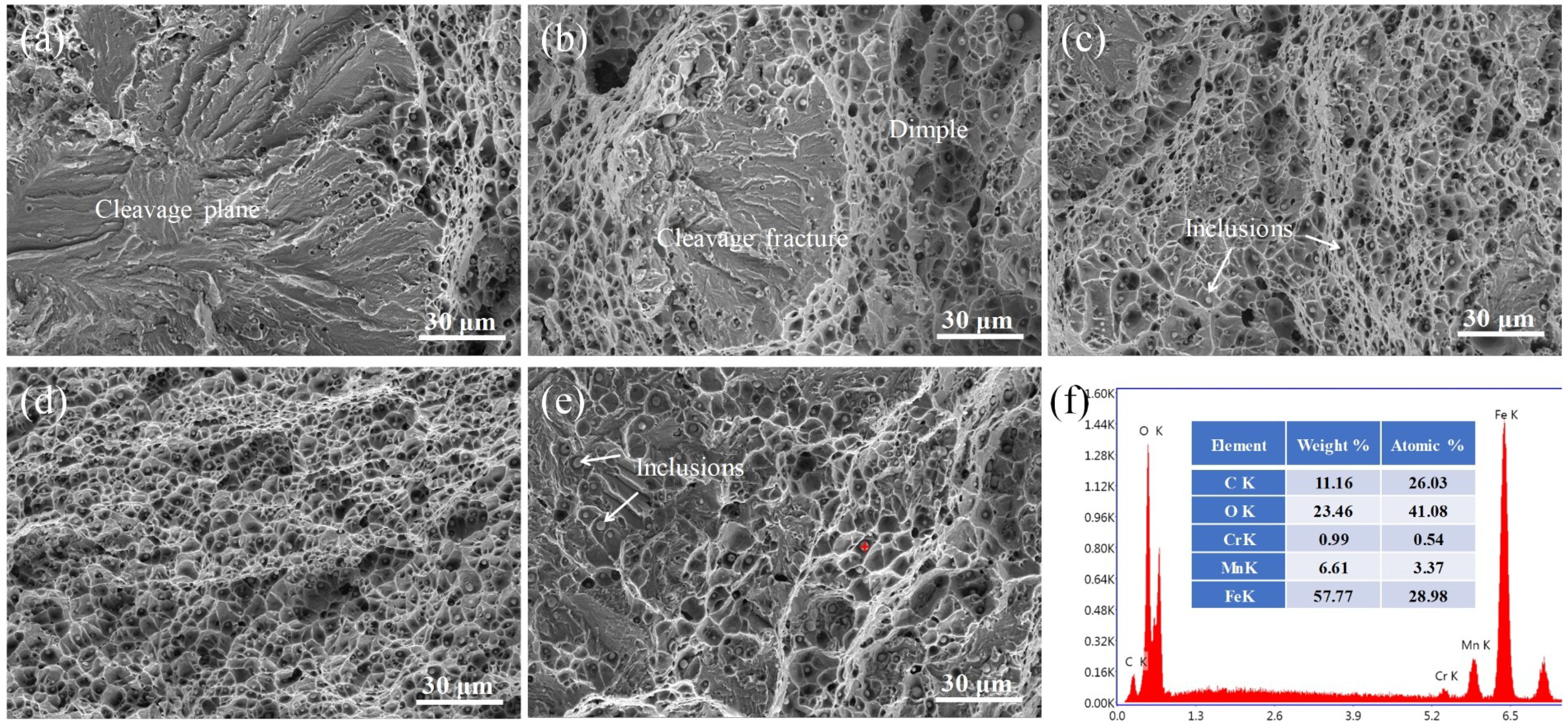

3.4. Mechanical Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Chen, H.; Guo, N.; Zhang, X.; Cheng, Q.; Zhou, L.; Wang, G. Effect of water flow on the microstructure, mechanical performance, and cracking susceptibility of underwater wet welded Q235 and E40 Steel. J. Mater. Process. Technol. 2020, 277, 116435. [Google Scholar] [CrossRef]

- Guo, N.; Zhang, X.; Xu, C.; Chen, H.; Fu, Y.; Cheng, Q. Effect of parameters change on the weld appearance in stainless steel underwater wet welding with flux-cored wire. Metals 2019, 9, 951. [Google Scholar] [CrossRef]

- Li, H.; Liu, D.; Ma, Q.; Guo, N.; Song, X.; Feng, J. Microstructure and mechanical properties of dissimilar welds between 16Mn and 304L in underwater wet welding. Sci. Technol. Weld. Join. 2018, 24, 1–7. [Google Scholar] [CrossRef]

- Zhao, B.; Chen, J.; Jia, C.; Wu, C. Numerical analysis of molten pool behavior during underwater wet FCAW process. J. Manuf. Process. 2018, 32, 538–552. [Google Scholar] [CrossRef]

- Tomków, J.; Fydrych, D.; Rogalski, G. Role of bead sequence in underwater welding. Materials 2019, 12, 3372. [Google Scholar] [CrossRef]

- Zhang, Y.; Jia, C.; Zhao, B.; Hu, J.; Wu, C. Heat input and metal transfer influences on the weld geometry and microstructure during underwater wet FCAW. J. Mater. Process. Technol. 2016, 238, 373–382. [Google Scholar] [CrossRef]

- Chen, H.; Guo, N.; Shi, X.; Du, Y.; Feng, J.; Wang, G. Effect of hydrostatic pressure on protective bubble characteristic and weld quality in underwater flux-cored wire wet welding. J. Mater. Process. Technol. 2018, 259, 159–168. [Google Scholar] [CrossRef]

- Li, H.; Liu, D.; Yan, Y.; Guo, N.; Liu, Y.; Feng, J. Effects of heat input on arc stability and weld quality in underwater wet flux-cored arc welding of E40 steel. J. Manuf. Process. 2018, 31, 833–843. [Google Scholar] [CrossRef]

- Gao, W.; Wang, D.; Cheng, F.; Di, X.; Deng, C.; Xu, W. Microstructural and mechanical performance of underwater wet welded S355 steel. J. Mater. Process. Technol. 2016, 238, 333–340. [Google Scholar] [CrossRef]

- Zhang, H.T.; Dai, X.Y.; Feng, J.C.; Hu, L.L. Preliminary investigation on real-time induction heating-assisted underwater wet welding. Weld. J. 2015, 94, 8–15. [Google Scholar]

- Tomków, J.; Rogalski, G.; Fydrych, D.; Łabanowski, J. Advantages of the application of the temper bead welding technique during wet welding. Materials 2019, 12, 915. [Google Scholar] [CrossRef]

- Tomków, J.; Rogalski, G.; Fydrych, D.; Łabanowski, J. Improvement of S355G10+N steel weldability in water environment by temper bead welding. J. Mater. Process. Technol. 2018, 262, 372–381. [Google Scholar] [CrossRef]

- Guo, N.; Liu, D.; Guo, W.; Li, H.; Feng, J. Effect of Ni on microstructure and mechanical properties of underwater wet welding joint. Mater. Des. 2015, 77, 25–31. [Google Scholar] [CrossRef]

- Zhang, C.; Gao, M.; Zeng, X. Workpiece vibration augmented wire arc additive manufacturing of high strength aluminum alloy. J. Mater. Process. Technol. 2019, 271, 85–92. [Google Scholar] [CrossRef]

- Sun, Q.J.; Cheng, W.Q.; Liu, Y.B.; Wang, J.F.; Cai, C.W.; Feng, J.C. Microstructure and mechanical properties of ultrasonic assisted underwater wet welding joints. Mater. Des. 2016, 103, 63–70. [Google Scholar] [CrossRef]

- Yuan, T.; Kou, S.; Luo, Z. Grain refining by ultrasonic stirring of the weld pool. Acta Mater. 2016, 106, 144–154. [Google Scholar] [CrossRef]

- Chen, Q.; Lin, S.; Yang, C.; Fan, C.; Ge, H. Grain fragmentation in ultrasonic-assisted TIG weld of pure aluminum. Ultrason. Sonochem. 2017, 39, 403–413. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Q.; Zhang, T.; Tao, X.; Jin, P.; Feng, J. Arc stability indexes evaluation of ultrasonic wave-assisted underwater FCAW using electrical signal analysis. Int. J. Adv. Manuf. Technol. 2019, 103, 2593–2608. [Google Scholar] [CrossRef]

- Krajewski, A.; Włosiński, W.; Chmielewski, T.; Kołodziejczak, P. Ultrasonic-vibration assisted arc-welding of aluminum alloys. Bull. Pol. Acad. Sci. Tech. Sci. 2012, 60, 841–852. [Google Scholar] [CrossRef]

- Liu, X.; Xue, J.; Zhao, Q.; Le, Q.; Zhang, Z. Effects of radiator shapes on the bubble diving and dispersion of ultrasonic argon process. Ultrason. Sonochem. 2018, 41, 600–607. [Google Scholar] [CrossRef]

- Eskin, D.G.; Tzanakis, I.; Wang, F.; Lebon, G.S.B.; Subroto, T.; Pericleous, K.; Mi, J. Fundamental studies of ultrasonic melt processing. Ultrason. Sonochem. 2019, 52, 455–467. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Momono, T.; Tayu, Y.; Fu, Y. Application of ultrasonic treating to degassing of metal ingots. Mater. Lett. 2008, 62, 4152–4154. [Google Scholar] [CrossRef]

- Li, Y.; Wu, C.; Chen, M. Numerical analysis of the ultrasound induced arc pressure increment in plasma arc welding. J. Phys. D Appl. Phys. 2019, 52, 035201. [Google Scholar] [CrossRef]

- Wang, J.; Sun, Q.; Ma, J.; Teng, J.; Jin, P.; Feng, J. Investigation of acoustic radiator affecting bubble-acoustic interaction in ultrasonic wave-assisted UWW at shallow water. J. Manuf. Process. 2019, 37, 563–577. [Google Scholar] [CrossRef]

- Lebon, G.S.B.; Tzanakis, I.; Pericleous, K.; Eskin, D.; Grant, P.S. Ultrasonic liquid metal processing: The essential role of cavitation bubbles in controlling acoustic streaming. Ultrason. Sonochem. 2019, 55, 243–255. [Google Scholar] [CrossRef]

- Leung, C.L.A.; Marussi, S.; Atwood, R.C.; Towrie, M.; Withers, P.J.; Lee, P.D. In situ X-ray imaging of defect and molten pool dynamics in laser additive manufacturing. Nat. Commun. 2018, 9, 1355. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed X-ray imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef]

- Lisiecki, A.; Ślizak, D. Hybrid laser deposition of Fe-based metallic powder under cryogenic conditions. Metals 2020, 10, 190. [Google Scholar] [CrossRef]

- Ji, H.; Qiao, Y.; Li, M. Rapid formation of intermetallic joints through ultrasonic-assisted die bonding with Sn–0.7Cu solder for high temperature packaging application. Scr. Mater. 2016, 110, 19–23. [Google Scholar] [CrossRef]

- Cheng, F.; Ji, W.; Qian, C.; Xu, J. Cavitation bubbles dynamics and cavitation erosion in water jet. Res. Phys. 2018, 9, 1585–1593. [Google Scholar] [CrossRef]

- Li, Z.; Xu, Z.; Ma, L.; Wang, S.; Liu, X.; Yan, J. Cavitation at filler metal/substrate interface during ultrasonic-assisted soldering. Part II: Cavitation erosion effect. Ultrason. Sonochem. 2019, 50, 278–288. [Google Scholar] [CrossRef] [PubMed]

- Chang, B.; Allen, C.; Blackburn, J.; Hilton, P.; Du, D. Fluid flow characteristics and porosity behavior in full penetration laser welding of a titanium alloy. Metall. Mater. Trans. B 2015, 46, 906–918. [Google Scholar] [CrossRef]

- Chen, H.; Guo, N.; Xu, K.; Xu, C.; Zhou, L.; Wang, G. In-situ observations of melt degassing and hydrogen removal enhanced by ultrasonics in underwater wet welding. Mater. Des. 2020, 188, 108482. [Google Scholar] [CrossRef]

- Chen, Q.; Ge, H.; Yang, C.; Lin, S.; Fan, C. Study on pores in ultrasonic-assisted TIG weld of aluminum alloy. Metals 2017, 7, 53. [Google Scholar] [CrossRef]

| Material | C | Mn | Ni | Cr | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|

| E40 | 0.17 | 1.35 | 0.04 | 0.01 | 0.46 | 0.005 | 0.30 | Bal. |

| H08A | 0.10 | 0.40 | 0.01 | 0.01 | 0.05 | 0.025 | 0.025 | Bal. |

| Ultrasonic Power (% × 1200W) | 0 | 20 | 40 | 60 | 80 | 100 |

|---|---|---|---|---|---|---|

| Ultimate strength (MPa) | 545 | 560 | 572 | 610 | 593 | 564 |

| Fracture location | Welds | Welds | Welds | BM | Welds | Welds |

| Impact toughness (J/cm2) | 65 | 66 | 67 | 71 | 61 | 58 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, H.; Guo, N.; Xu, K.; Liu, C.; Wang, G. Investigating the Advantages of Ultrasonic-assisted Welding Technique Applied in Underwater Wet Welding by in-situ X-ray Imaging Method. Materials 2020, 13, 1442. https://doi.org/10.3390/ma13061442

Chen H, Guo N, Xu K, Liu C, Wang G. Investigating the Advantages of Ultrasonic-assisted Welding Technique Applied in Underwater Wet Welding by in-situ X-ray Imaging Method. Materials. 2020; 13(6):1442. https://doi.org/10.3390/ma13061442

Chicago/Turabian StyleChen, Hao, Ning Guo, Kexin Xu, Cheng Liu, and Guodong Wang. 2020. "Investigating the Advantages of Ultrasonic-assisted Welding Technique Applied in Underwater Wet Welding by in-situ X-ray Imaging Method" Materials 13, no. 6: 1442. https://doi.org/10.3390/ma13061442

APA StyleChen, H., Guo, N., Xu, K., Liu, C., & Wang, G. (2020). Investigating the Advantages of Ultrasonic-assisted Welding Technique Applied in Underwater Wet Welding by in-situ X-ray Imaging Method. Materials, 13(6), 1442. https://doi.org/10.3390/ma13061442