Experimental Investigations of Timber Beams with Stop-Splayed Scarf Carpentry Joints

Abstract

1. Introduction

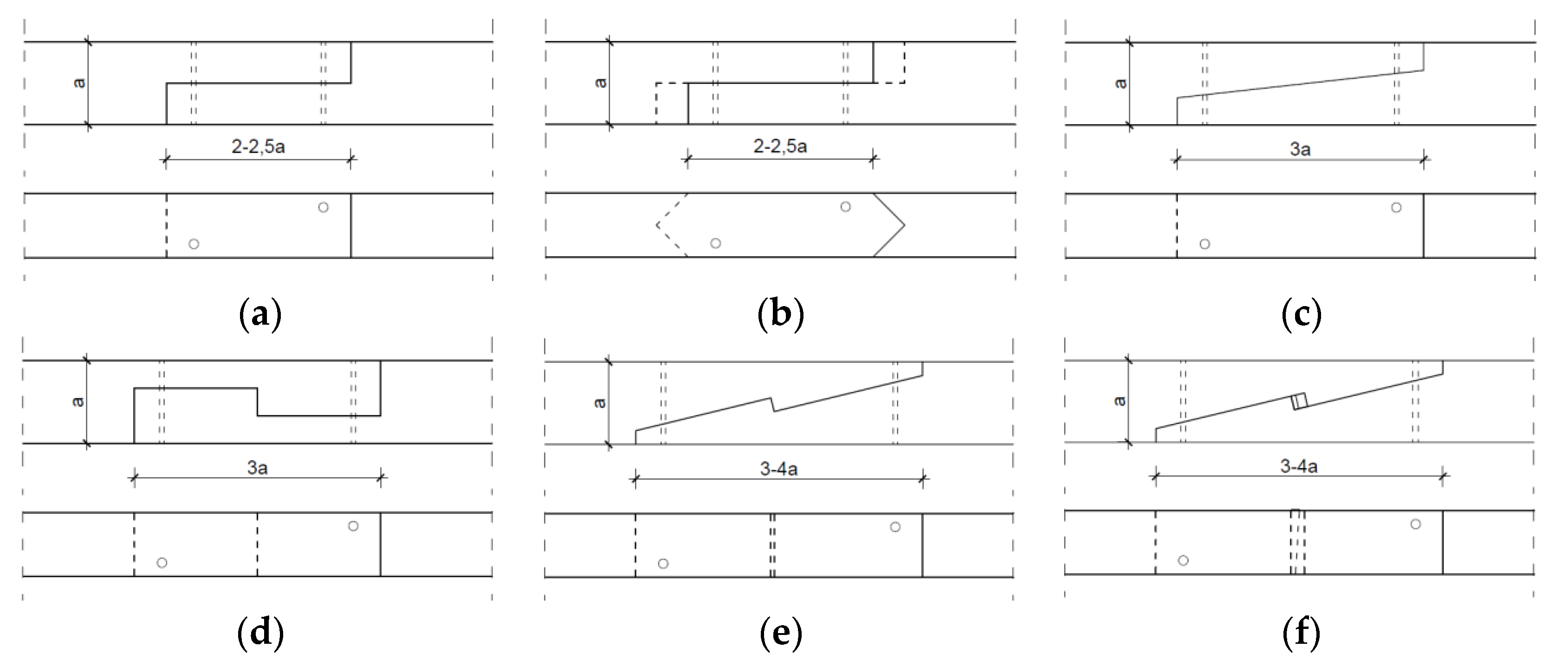

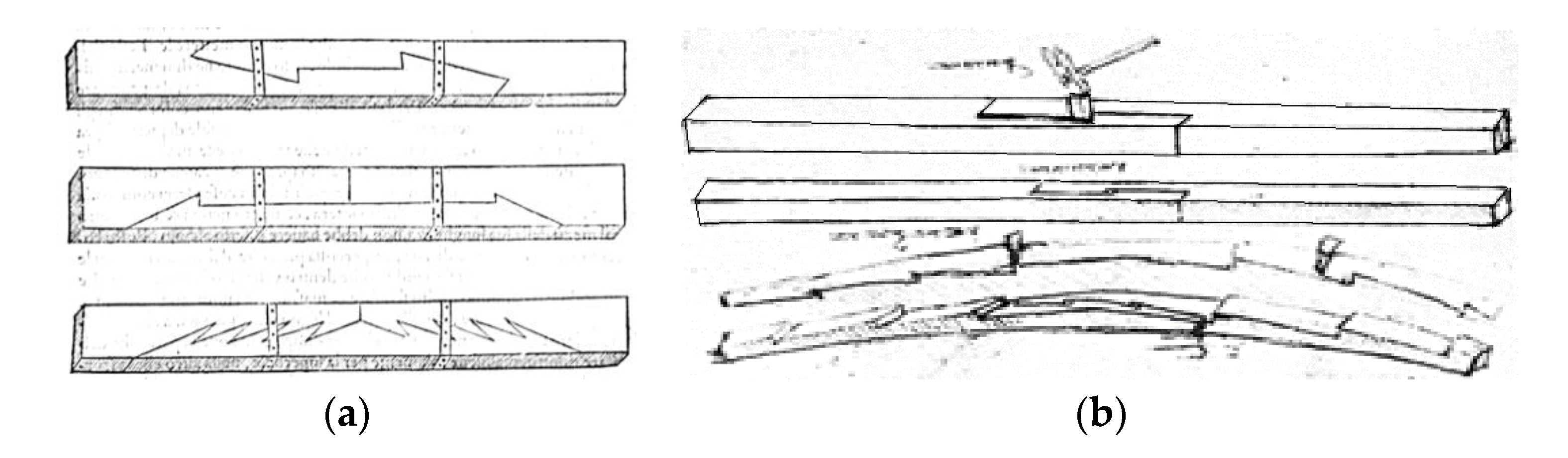

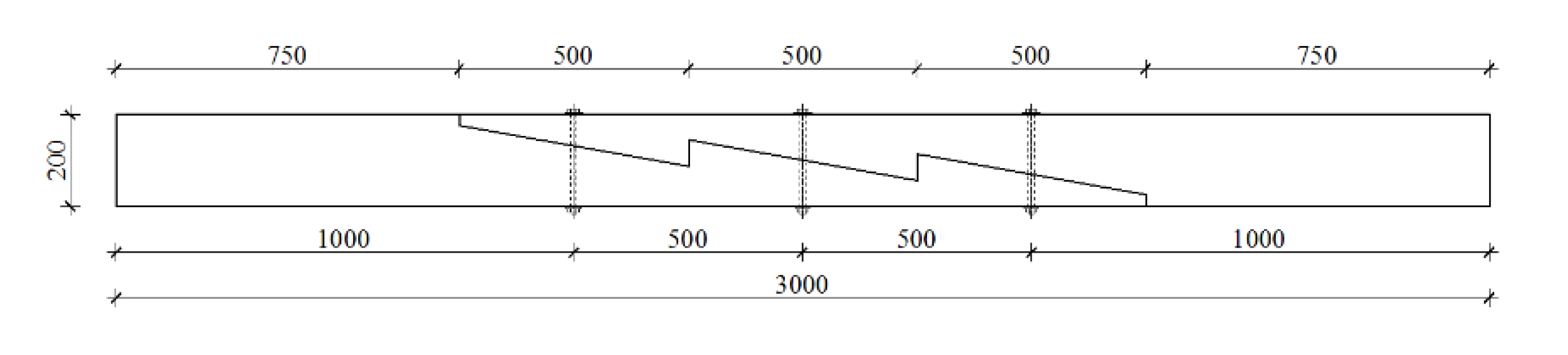

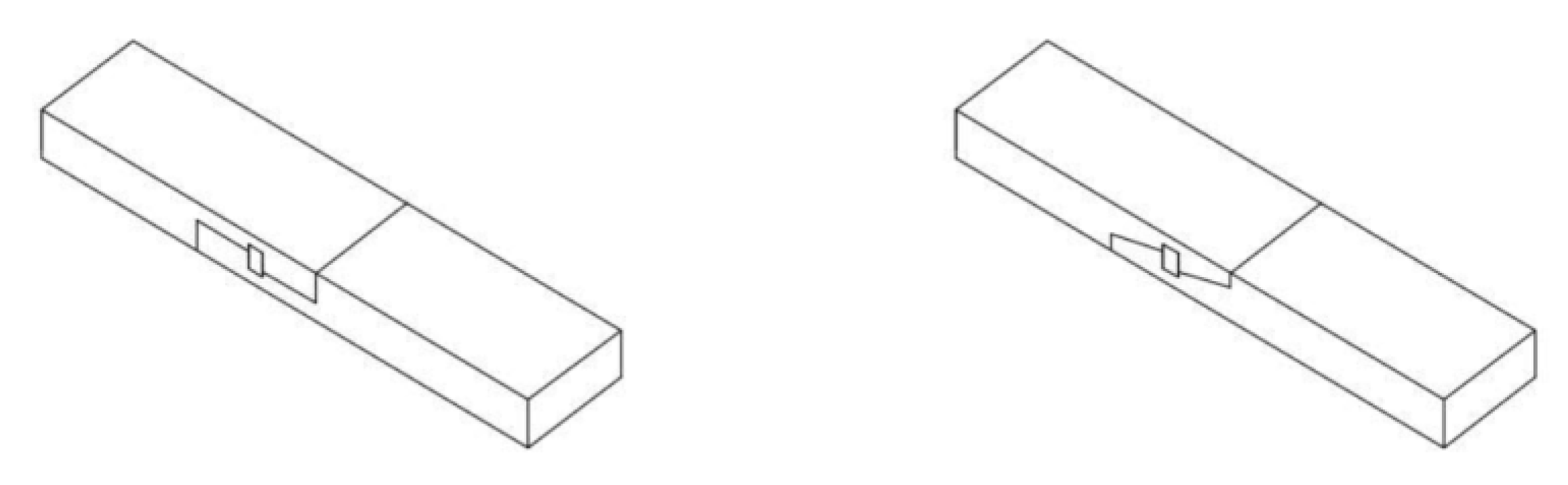

2. Stop-Splayed Scarf Joints (‘Bolt of Lightning’)

3. Experimental Tests

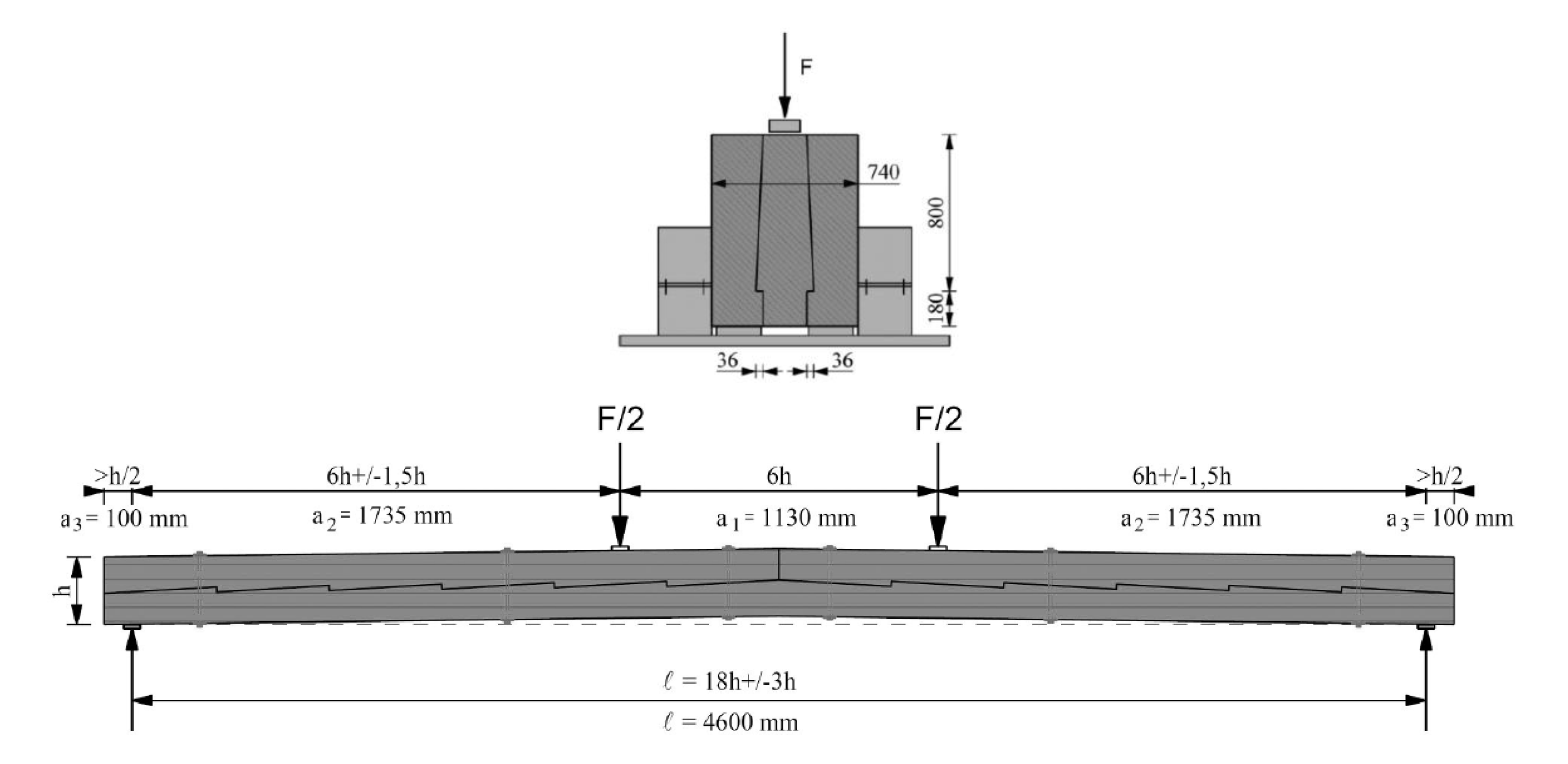

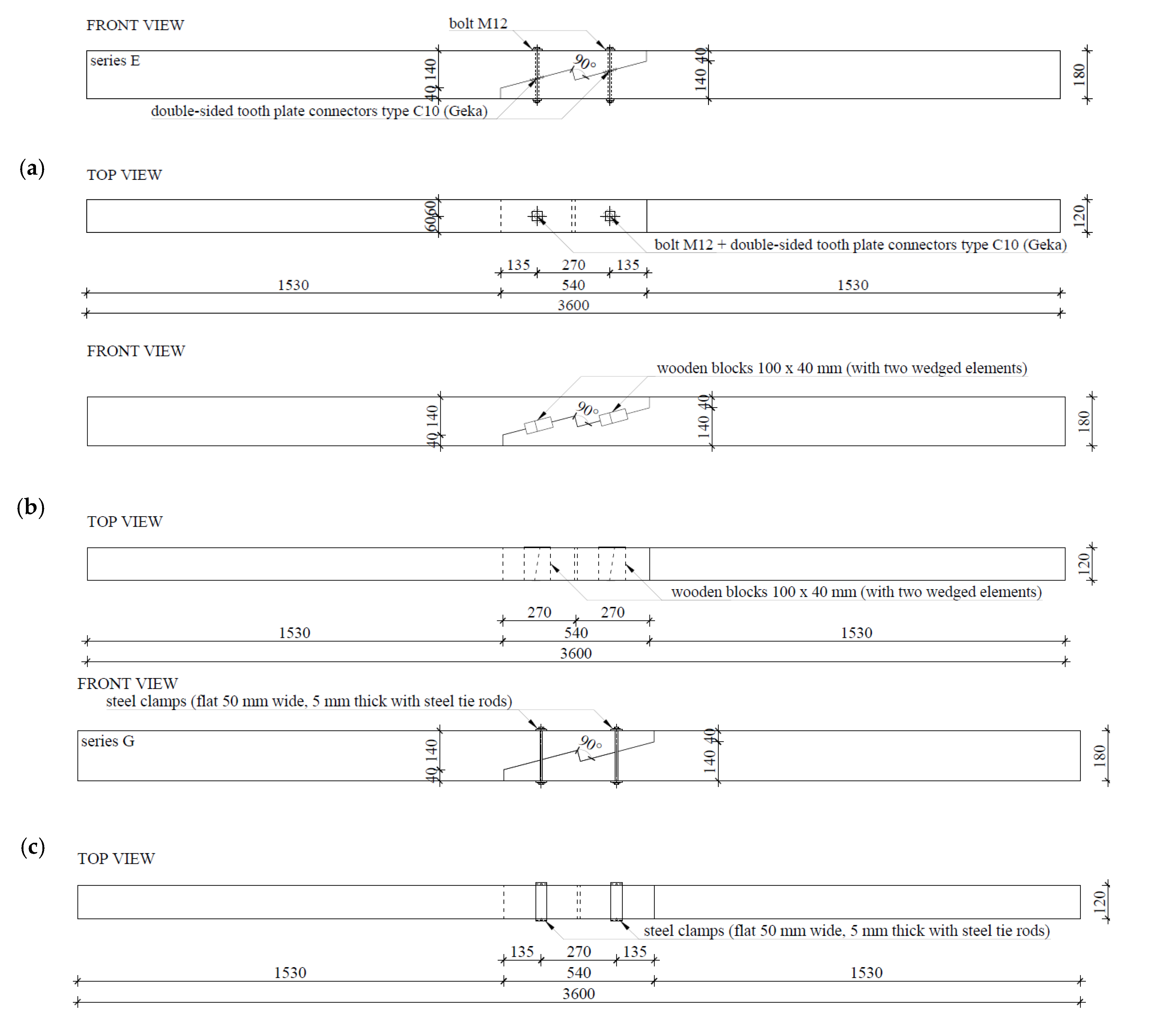

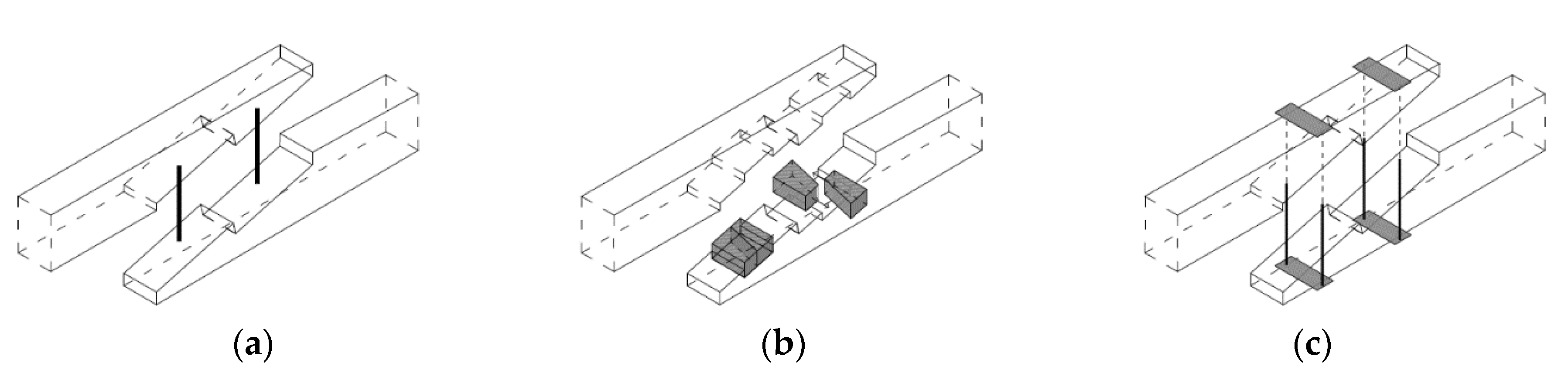

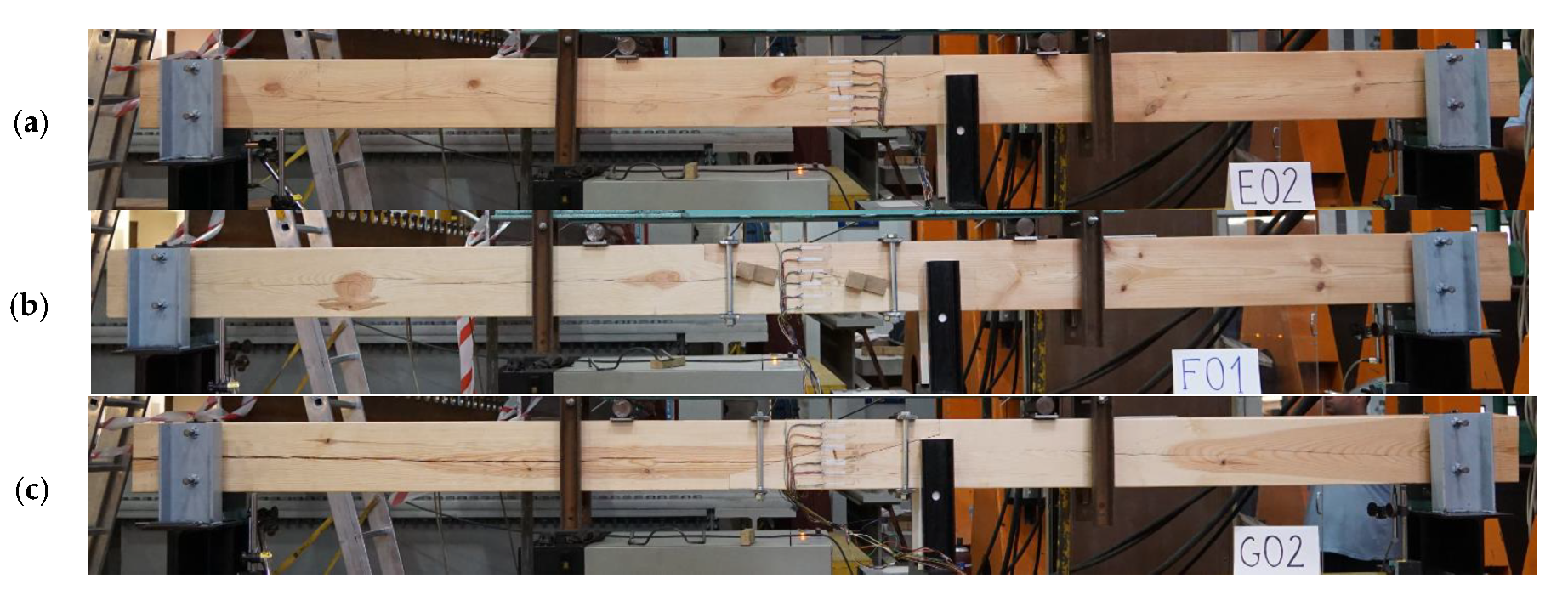

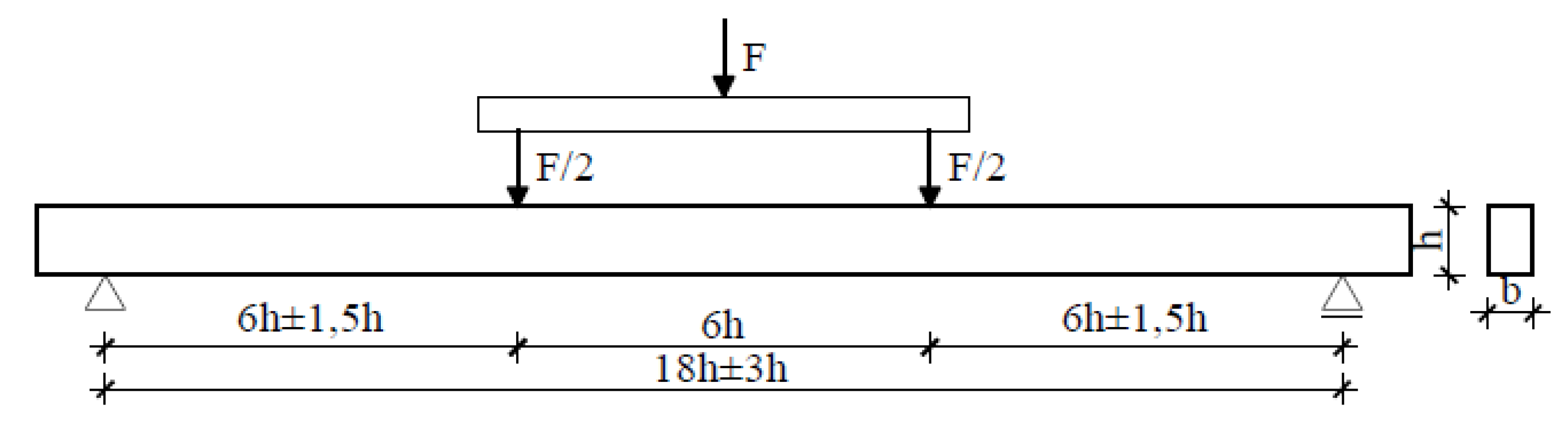

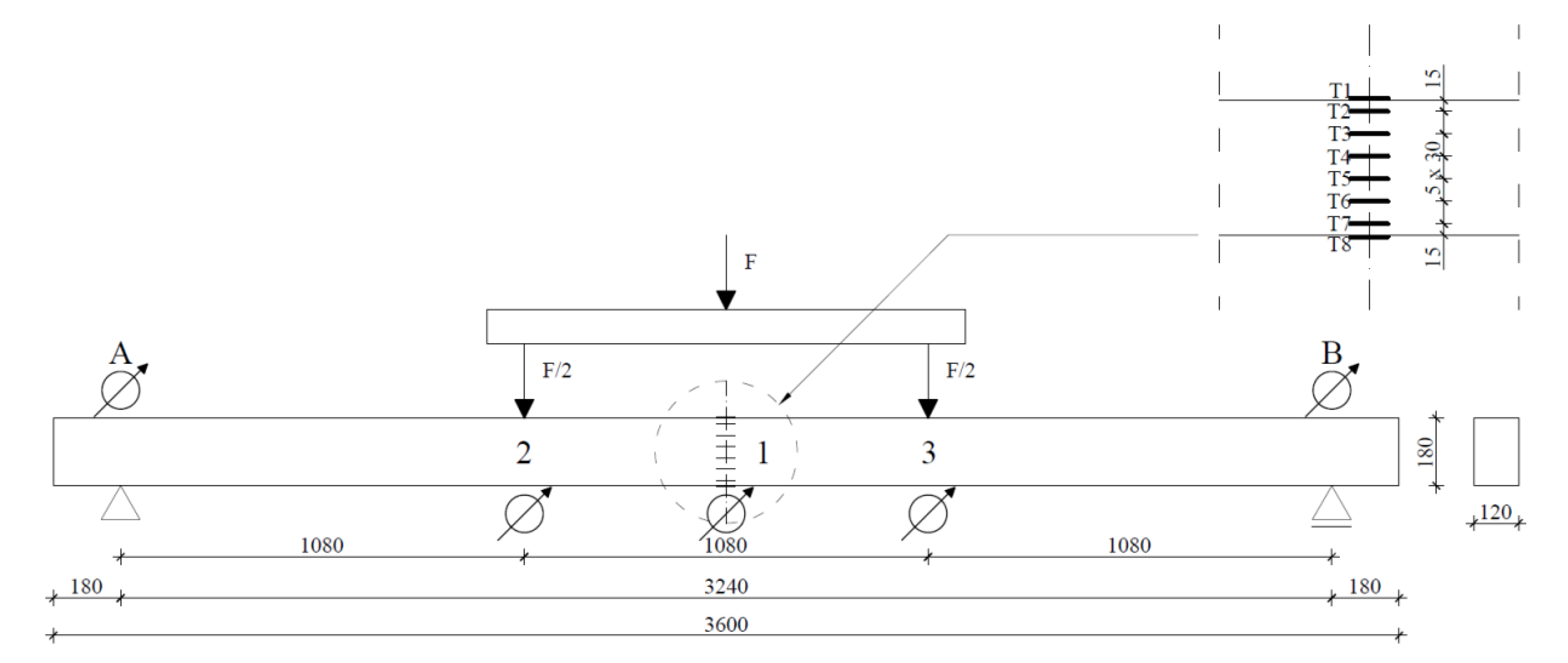

3.1. Static Schemes and Investigations Procedure

- series E—beams with stop-splayed scarf joints and two drawbolts (double-sided tooth plate connectors type C10 (Geka) + M12 screws);

- series F—beams with stop-splayed scarf joints and wooden keys made from oak wood and additional steel clamps;

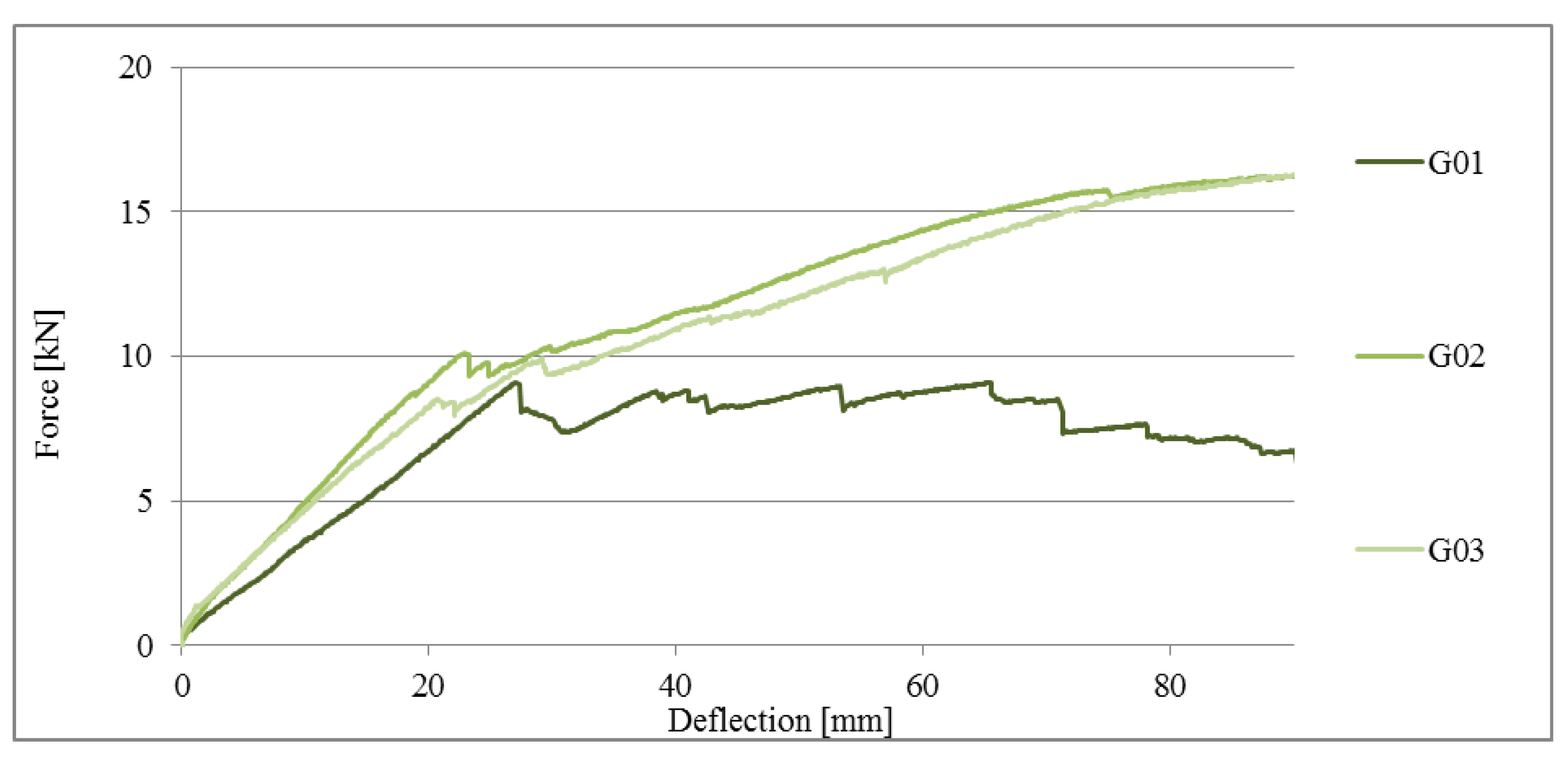

- series G—beams with stop-splayed scarf joints and flat steel clamps and steel tie-rods.

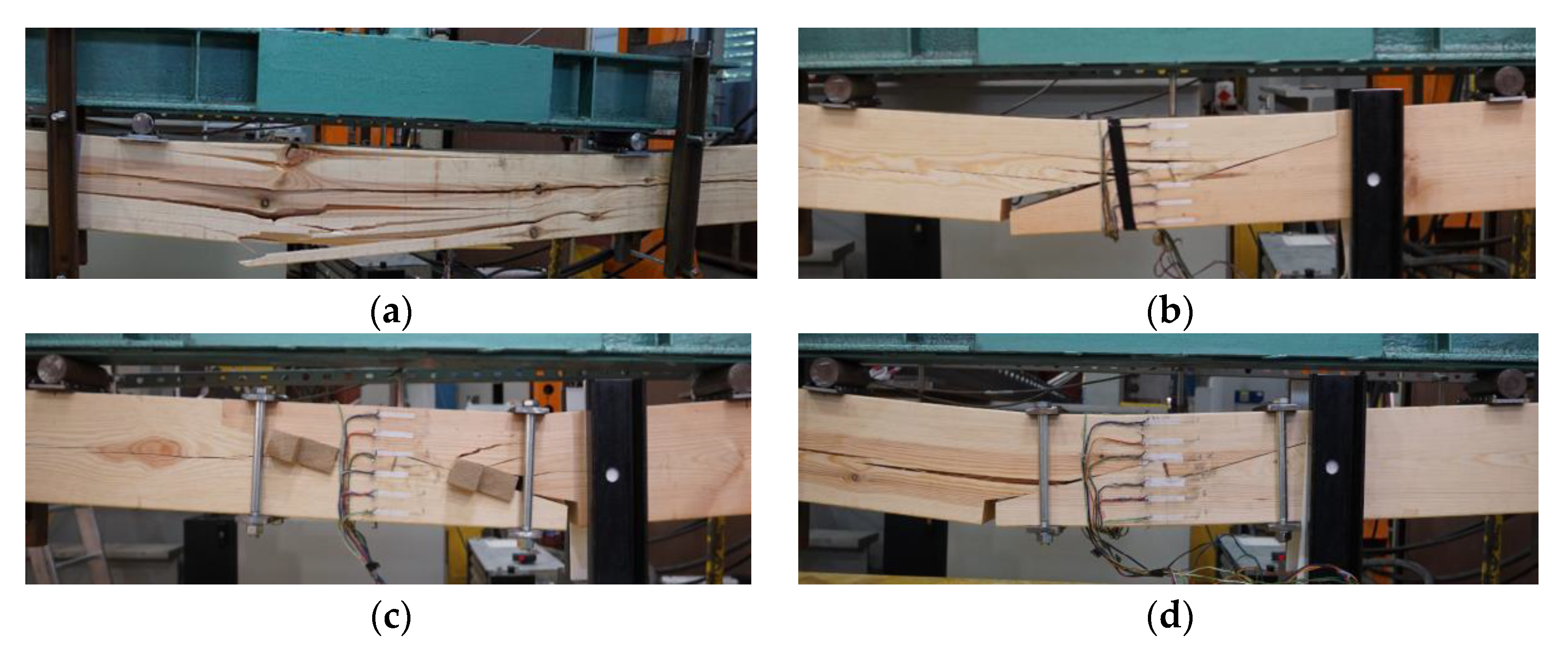

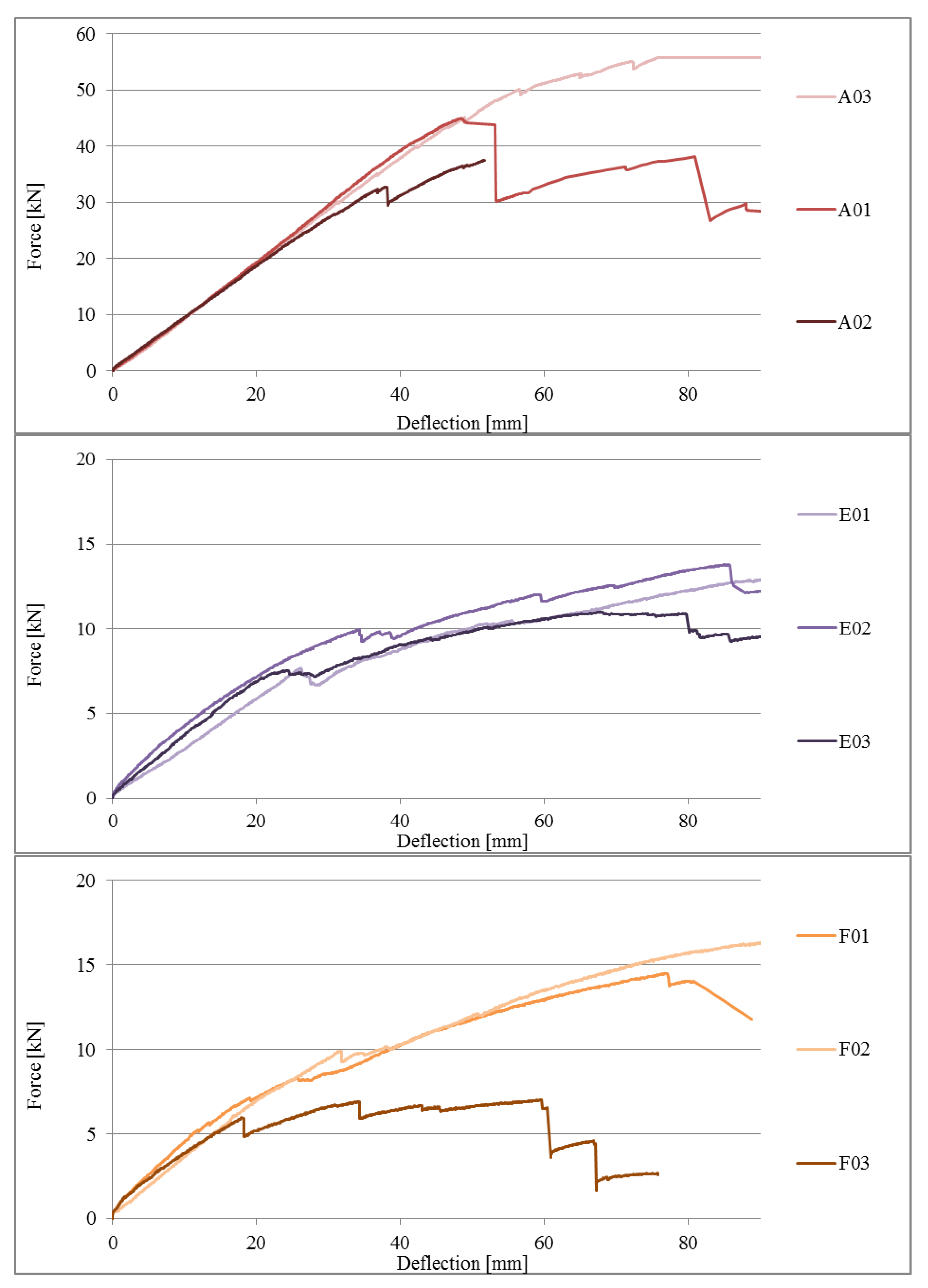

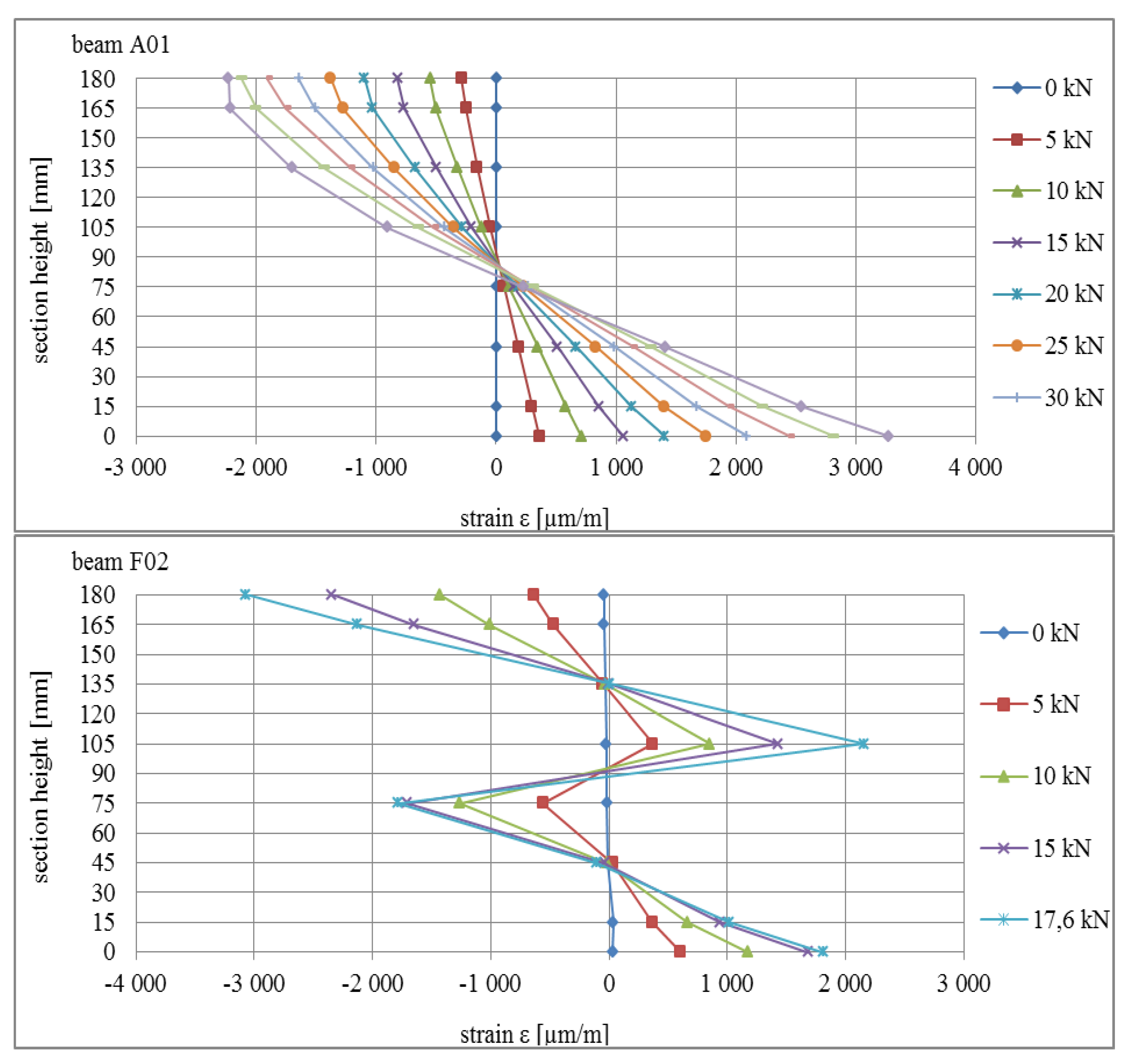

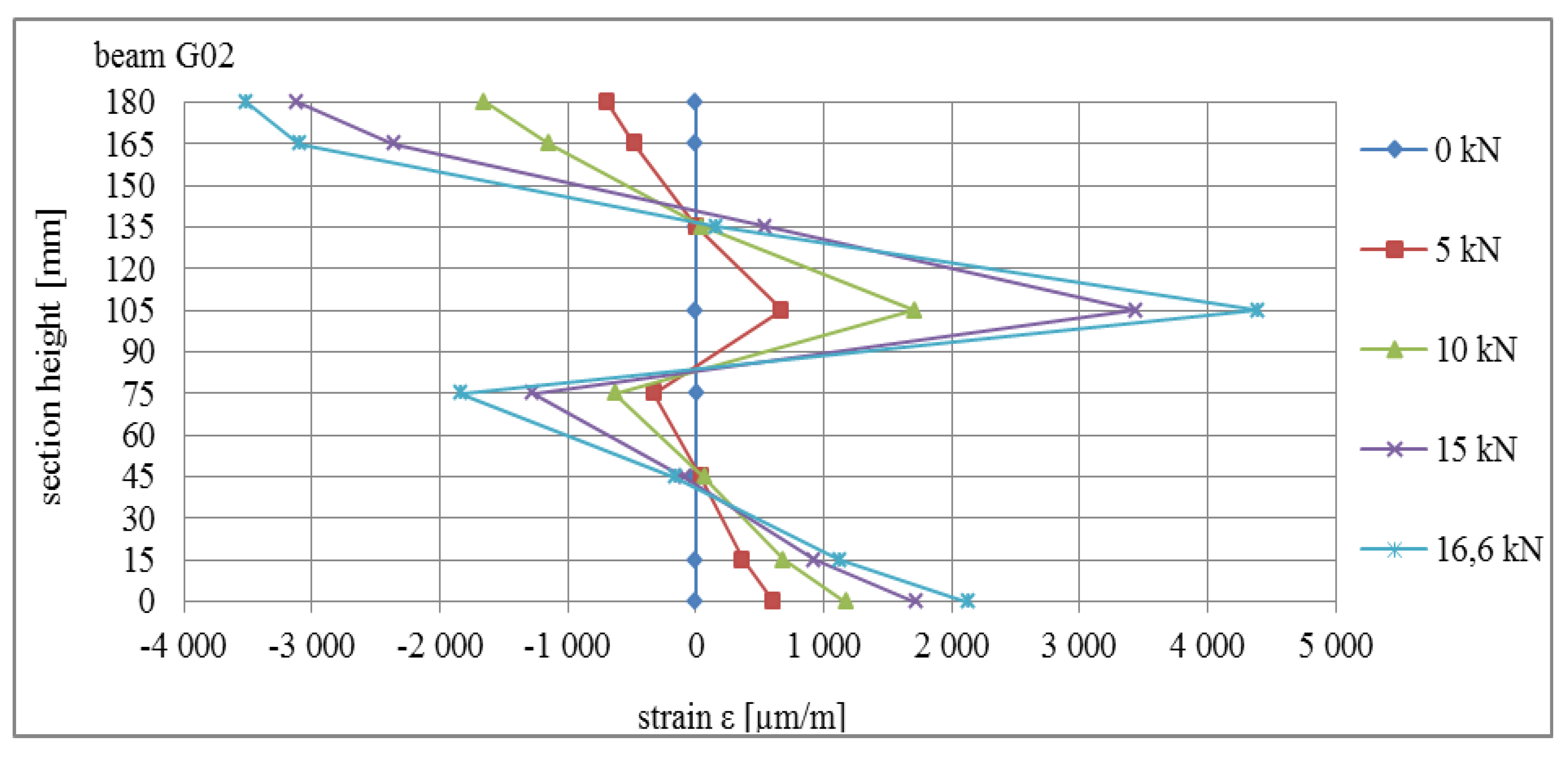

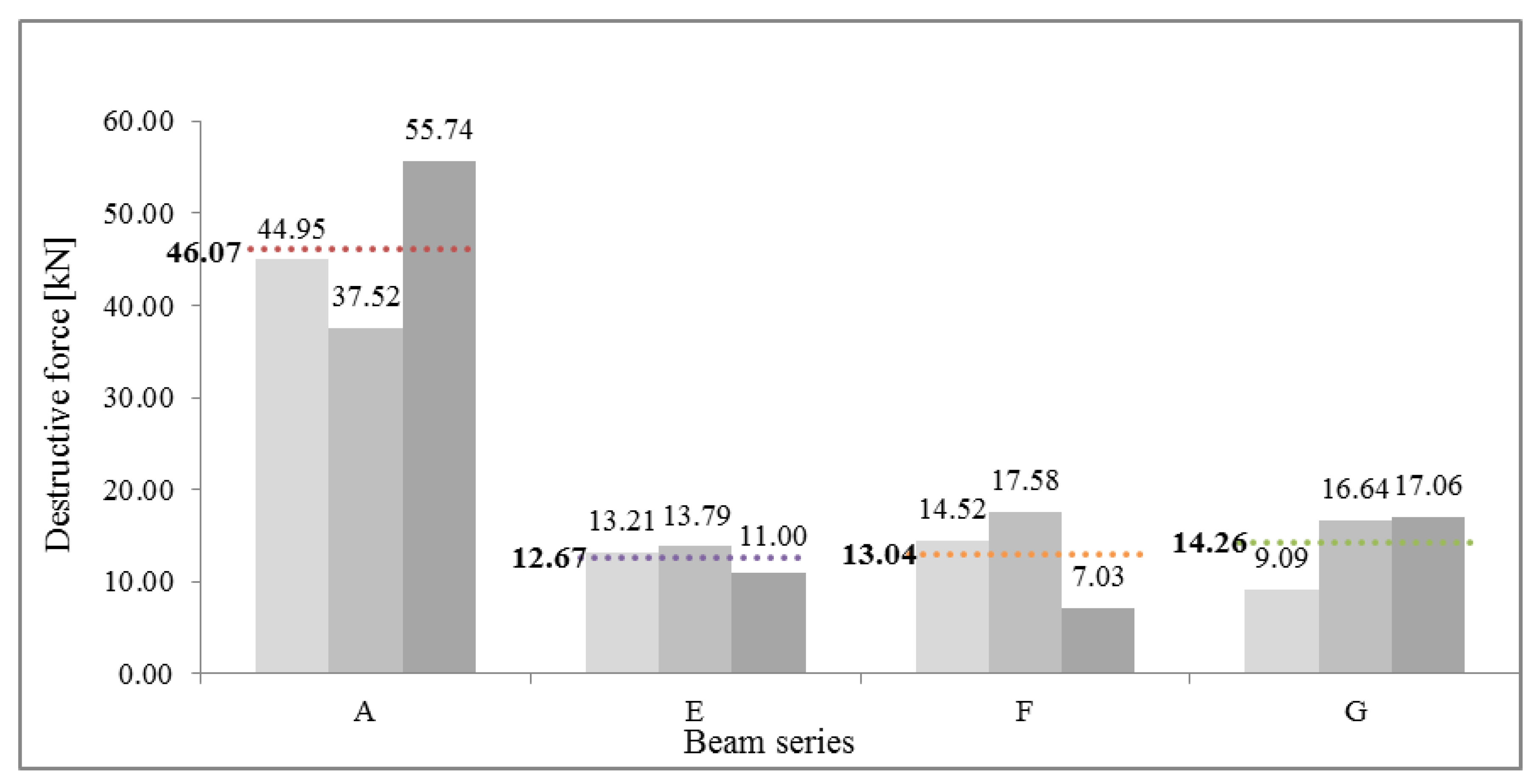

3.2. Results

3.3. Analysis of Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nowak, T.; Karolak, A.; Sobótka, M.; Wyjadłowski, M. Assessment of the Condition of Wharf Timber Sheet Wall Material by Means of Selected Non-Destructive Methods. Materials 2019, 12, 1532. [Google Scholar] [CrossRef] [PubMed]

- Jasieńko, J.; Nowak, T.; Karolak, A. Historical carpentry joints. Wiad. Konserw. J. Herit. Conserv. 2014, 40, 58–82. [Google Scholar]

- Branco, J.M.; Descamps, T. Analysis and strengthening of carpentry joints. Constr. Build. Mater. 2015, 97, 34–47. [Google Scholar] [CrossRef]

- Yeomans, D. The Repair of Historic Timber Structures; Thomas Telford Ltd.: London, UK, 2003; Volume 3, p. 7. [Google Scholar]

- Kłosowski, P.; Lubowiecka, I.; Pestka, A.; Szepietowska, K. Historical carpentry corner log joints—Numerical analysis within stochastic framework. Eng. Struct. 2018, 176, 64–73. [Google Scholar] [CrossRef]

- Corradi, M.; Osofero, A.I.; Borri, A. Repair and Reinforcement of Historic Timber Structures with Stainless Steel—A Review. Metals 2019, 9, 106. [Google Scholar] [CrossRef]

- Šobra, K.; Fonseca Ferreira, C.; Riggio, M.; D’Ayala, D.; Arriaga, F.; Aira, J.R. A new tool for the structural assessment of historic carpentry joints. In Proceedings of the 3rd International Conference on Structural Health Assessment of Timber Structures—SHATIS’15, Wrocław, Poland, 9–11 September 2015. [Google Scholar]

- Ross, P. Appraisal and Repair of Timber Structures; Thomas Telford Ltd.: London, UK, 2002. [Google Scholar]

- Thelandersson, S.; Larsen, H.J. Timber Engineering; John Wiley & Sons Ltd.: Chichester, UK, 2003; Volume 16. [Google Scholar]

- Ilharco, T.; Lechner, T.; Nowak, T. Assessment of timber floors by means of non-destructive testing methods. Constr. Build. Mater. 2015, 101, 1206–1214. [Google Scholar] [CrossRef]

- Parisi, M.A.; Piazza, M. Seismic strengthening of traditional carpentry joints. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Parisi, M.A.; Piazza, M. Seismic strengthening of traditional timber structures. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Perez, L.P. Design and construction of timber roof structures, built over different structural systems. Cases studium at the Valencia Community. In Proceedings of the First International Congress on Construction History, Madrid, Spain, 20–24 January 2003. [Google Scholar]

- Tampone, G.; Semplici, M. Rescuing the Hidden European Wooden Churches Heritage, an International Methodology for Implementing a Data Base for Restoration Projects; In Cooperation with Fly Events and Alter Ego Ing Arch, S.r.l.: Città di Castello, Italy, 2006. [Google Scholar]

- Aira, J.R.; Arriaga, F.; Íñiguez-González, G.; Guaita, M. Failure modes in halved and tabled tenoned timber scarf joint by tension test. Constr. Build. Mater. 2015, 96, 360–367. [Google Scholar] [CrossRef]

- Mirabella-Roberti, G.; Bondanelli, M. Study and analysis of XIV century timber built-up beams in Verona. Adv. Mater. Res. 2013, 778, 511–516. [Google Scholar] [CrossRef]

- Rug, W.; Linke, G. Study on the load bearing capacity and the load-deferral behavior of wooden composite beams with a teethed joint. In Proceedings of the 3rd International Conference on Structural Health Assessment of Timber Structures—SHATIS’15, Wrocław, Poland, 9–11 September 2015. [Google Scholar]

- Rug, W.; Thoms, F.; Grimm, U.; Eichbaum, G.; Abel, S. Untersuchungen zur Biegetragfähigkeit von verzahnten Balken. Bautechnik 2012, 89, 26–36. [Google Scholar] [CrossRef]

- Alberti, L.B. L’Architettura di Leon Batista Alberti, Tradotta in lingua Fiorentina da Cosimo Bartoli. Con la aggiunta de disegni. Et altri diuersi Trattati del medesimo Auttore; Appresso Lionardo Torrentino: Nel Monte Regale, Italy, 1565. (In Italian) [Google Scholar]

- Ceraldi, C.; Costa, A.; Lippiello, M. Stop-Splayed Scarf-Joint Reinforcement with Timber Pegs Behaviour. In Structural Analysis of Historical Constructions; Aguilar, R., Torrealva, D., Moreira, S., Pando, M., Ramos, L.F., Eds.; Springer: Cham, Switzerland, 2019; pp. 360–369. [Google Scholar]

- Hirst, E.; Brett, A.; Thomson, A.; Walker, P.; Harris, R. The structural performance of traditional oak tension & scarf joints. In Proceedings of the 10th World Conference on Timber Engineering, Miyazaki, Japan, 2–5 June 2008. [Google Scholar]

- Sangree, R.H.; Schafer, B.W. Experimental and numerical analysis of a halved and tabled traditional scarf joint. Constr. Build. Mater. 2009, 23, 615–624. [Google Scholar] [CrossRef]

- Sangree, R.H.; Schafer, B.W. Experimental and numerical analysis of a stop-splayed traditional scarf joint with key. Constr. Build. Mater. 2009, 23, 376–385. [Google Scholar] [CrossRef]

- Arciszewska-Kędzior, A.; Kunecký, J.; Hasníková, H. Mechanical response of a lap scarf joint with inclined faces and wooden dowels under combined loading. Wiad. Konserw. J. Herit. Conserv. 2016, 46, 80–88. [Google Scholar]

- Arciszewska-Kędzior, A.; Kunecký, J.; Hasníková, H.; Sebera, V. Lapped scarf joint with inclined faces and wooden dowels: Experimental and numerical analysis. Eng. Struct. 2015, 94, 1–8. [Google Scholar] [CrossRef]

- Kunecký, J.; Hasníková, H.; Kloiber, M.; Milch, J.; Sebera, V.; Tippner, J. Structural assessment of a lapped scarf joint applied to historical timber constructions in central Europe. Int. J. Archit. Herit. 2018, 12, 666–682. [Google Scholar] [CrossRef]

- Kunecký, J.; Sebera, V.; Hasníková, H.; Arciszewska-Kędzior, A.; Tippner, J.; Kloiber, M. Experimental assessment of full-scale lap scarf timber joint accompanied by a finite element analysis and digital correlation. Constr. Build. Mater. 2015, 76, 24–33. [Google Scholar] [CrossRef]

- Kunecký, J.; Sebera, V.; Tippner, J.; Hasníková, H.; Kloiber, M.; Arciszewska- Kędzior, A.; Milch, J. Mechanical performance and contact zone of timber joint with oblique faces. Acta Univ. Agric. Et Silvic. Mendel. Brun. 2015, 63, 1153–1159. [Google Scholar] [CrossRef]

- Kunecký, J.; Sebera, V.; Tippner, J.; Kloiber, M. Numerical assessment of behavior of a historical central European wooden joint with a dowel subjected to bending. In Proceedings of the 9th International Conference on Structural Analysis of Historical Constructions, Mexico City, Mexico, 15–17 October 2014. [Google Scholar]

- Fajman, P.; Máca, J. Stiffness of scarf joints with dowels. Comput. Struct. 2018, 207, 194–199. [Google Scholar] [CrossRef]

- Fajman, P.; Máca, J. The effect of inclination of scarf joints with four pins. Int. J. Archit. Herit. 2018, 12, 599–606. [Google Scholar] [CrossRef]

- Fajman, P. A scarf joint for reconstructions of historical structures. Adv. Mater. Res. 2015, 969, 9–15. [Google Scholar] [CrossRef]

- Fajman, P.; Máca, J. Scarf joints with pins or keys and dovetails. In Proceedings of the 3rd International Conference on Structural Health Assessment of Timber Structures—SHATIS’15, Wrocław, Poland, 9–11 September 2015. [Google Scholar]

- Fajman, P.; Máca, J. The effect of key stiffness on forces in a scarf joint. In Proceedings of the 9th International Conference on Engineering Computational Technology, Naples, Italy, 2–5 September 2014; Civil-Comp Press: Stirlingshire, UK, 2014; Volume 40. [Google Scholar]

- Šobra, K.; Fajman, P. Utilization of splice skew joint with a key in the reconstruction of historical trusses. Adv. Mater. Res. 2013, 668, 207–212. [Google Scholar] [CrossRef]

- Structural Timber—Determination of Characteristic Values of Mechanical Properties and Density; PN-EN 384: 2016-10; PKN: Polish Committee for Standardization: Warsaw, Poland, 2016.

- Timber Structures. Structural Timber and Glued Laminated Timber. Determination of Some Physical and Mechanical Properties; PN-EN 408+A1: 2012; PKN: Polish Committee for Standardization: Warsaw, Poland, 2012.

| Beam Series | |||||

|---|---|---|---|---|---|

| A | E | F | G | ||

| Ultimate force Fu | [kN] | 44.95 | 13.21 | 14.52 | 9.09 |

| 37.52 | 13.79 | 17.58 | 16.64 | ||

| 55.74 | 11.00 | 7.03 | 17.06 | ||

| Mean ultimate force for each beam series | [kN] | 46.07 | 12.67 | 13.04 | 14.26 |

| Standard deviation s | [kN] | 9.16 | 1.47 | 5.43 | 4.49 |

| Variation coefficient ν | [%] | 19.89 | 11.62 | 41.61 | 31.45 |

| Ratio of mean destruction force for specified series to reference beam series | 1.00 | 0.27 | 0.28 | 0.31 | |

| Beam Series | |||||

|---|---|---|---|---|---|

| A | E | F | G | ||

| Mean ultimate force for each beam series | [kN] | 46.07 | 12.67 | 13.04 | 14.26 |

| Mean load-bearing for bending for each beams series | [kNm] | 24.88 | 6.84 | 7.04 | 7.70 |

| Ratio of load-bearing for specified series to reference beam series | 1.00 | 0.27 | 0.28 | 0.31 | |

| Beam Series | ||||

|---|---|---|---|---|

| A | E | F | G | |

| Beam Type (Strengthening of the Joint) | Reference-Continuous Beam | Drawbolts | Wooden Pegs (keys) | Steel Clamps |

| Mean ultimate force [kN] | 46.07 | 12.67 | 13.04 | 14.26 |

| Mean load-bearing in bending [kNm] | 24.88 | 6.84 | 7.04 | 7.70 |

| Ratio of load-bearing as compared to reference beam series | 1.00 | 0.27 | 0.28 | 0.31 |

| Mean deflection u1 in the middle of the span with a load of 10 kN [mm] | 12.34 | 37.44 | 32.48 | 24.59 |

| Ratio of deflection as compared to reference beam series | 1.00 | 3.03 | 2.63 | 1.99 |

| Mean stiffness parameter k [kN/mm] | 0.94 | 0.29 | 0.32 | 0.39 |

| Stiffness parameter as compared to the reference beam series | 1.00 | 0.32 | 0.35 | 0.43 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karolak, A.; Jasieńko, J.; Nowak, T.; Raszczuk, K. Experimental Investigations of Timber Beams with Stop-Splayed Scarf Carpentry Joints. Materials 2020, 13, 1435. https://doi.org/10.3390/ma13061435

Karolak A, Jasieńko J, Nowak T, Raszczuk K. Experimental Investigations of Timber Beams with Stop-Splayed Scarf Carpentry Joints. Materials. 2020; 13(6):1435. https://doi.org/10.3390/ma13061435

Chicago/Turabian StyleKarolak, Anna, Jerzy Jasieńko, Tomasz Nowak, and Krzysztof Raszczuk. 2020. "Experimental Investigations of Timber Beams with Stop-Splayed Scarf Carpentry Joints" Materials 13, no. 6: 1435. https://doi.org/10.3390/ma13061435

APA StyleKarolak, A., Jasieńko, J., Nowak, T., & Raszczuk, K. (2020). Experimental Investigations of Timber Beams with Stop-Splayed Scarf Carpentry Joints. Materials, 13(6), 1435. https://doi.org/10.3390/ma13061435