Comparison of Different Locking Mechanisms in Total Hip Arthroplasty: Relative Motion between Cup and Inlay

Abstract

1. Introduction

2. Materials and Methods

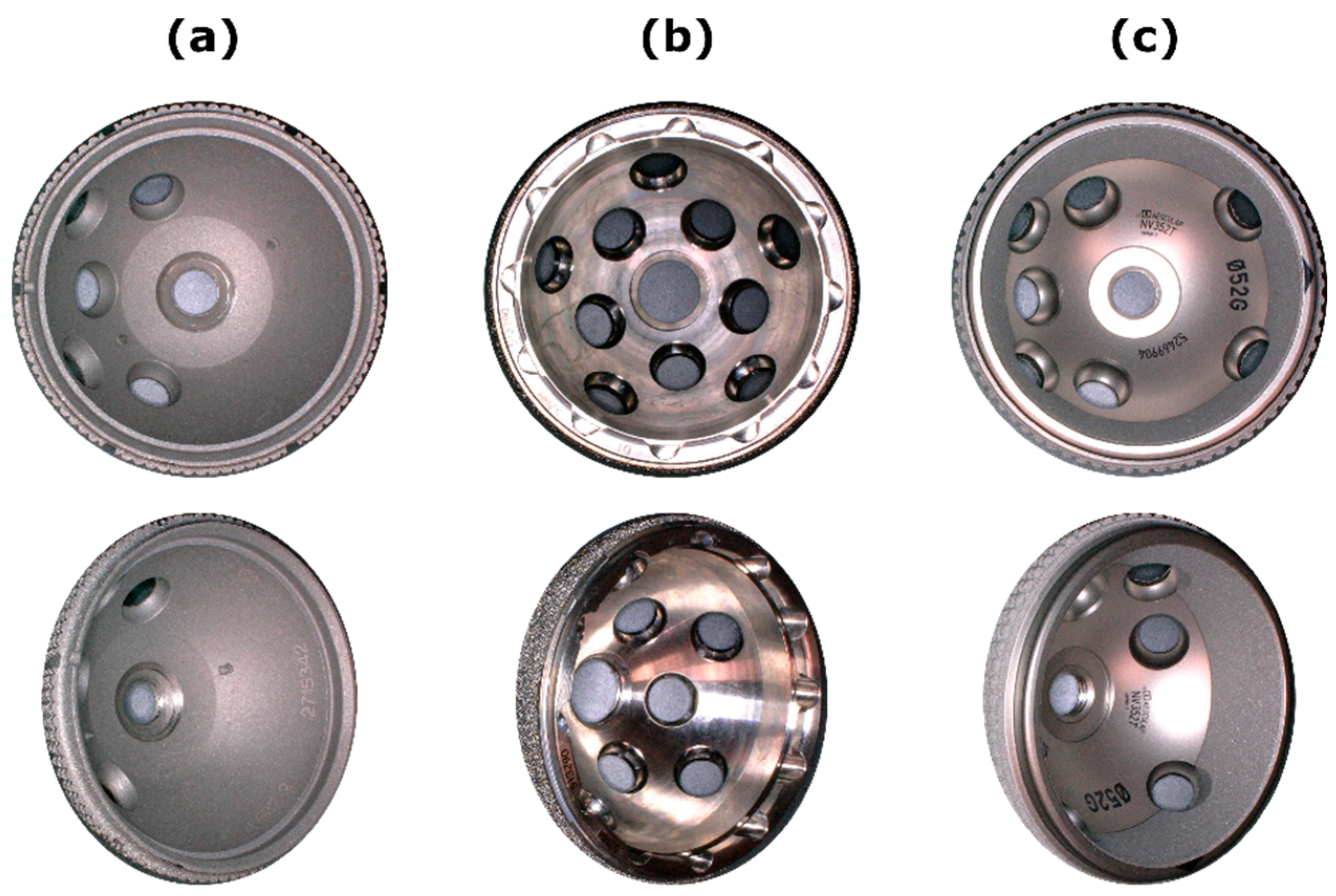

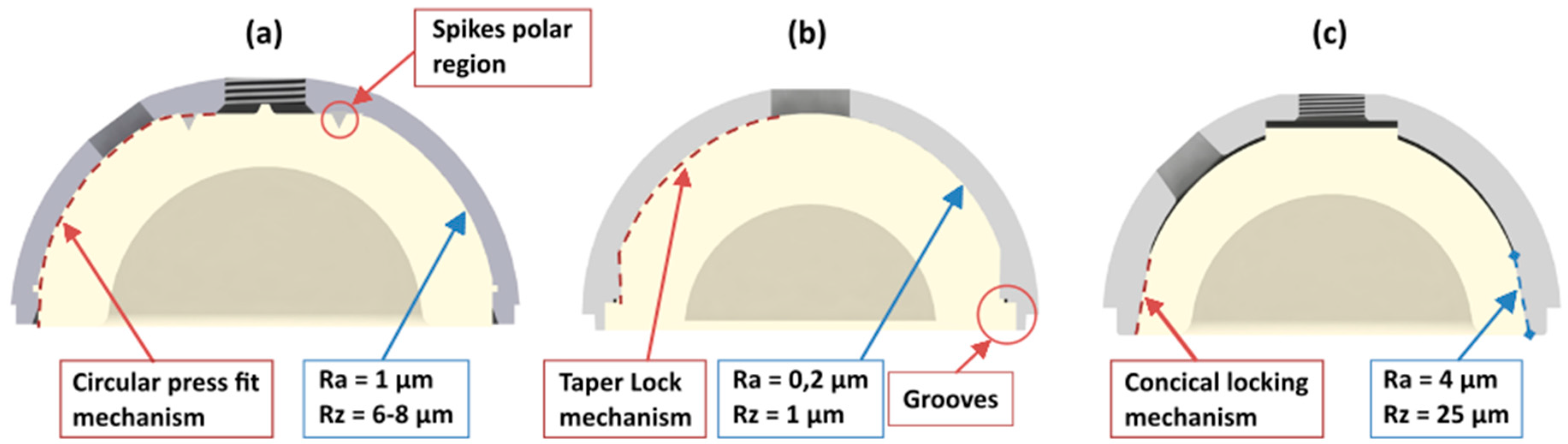

2.1. Acetabular Hip Cup Systems

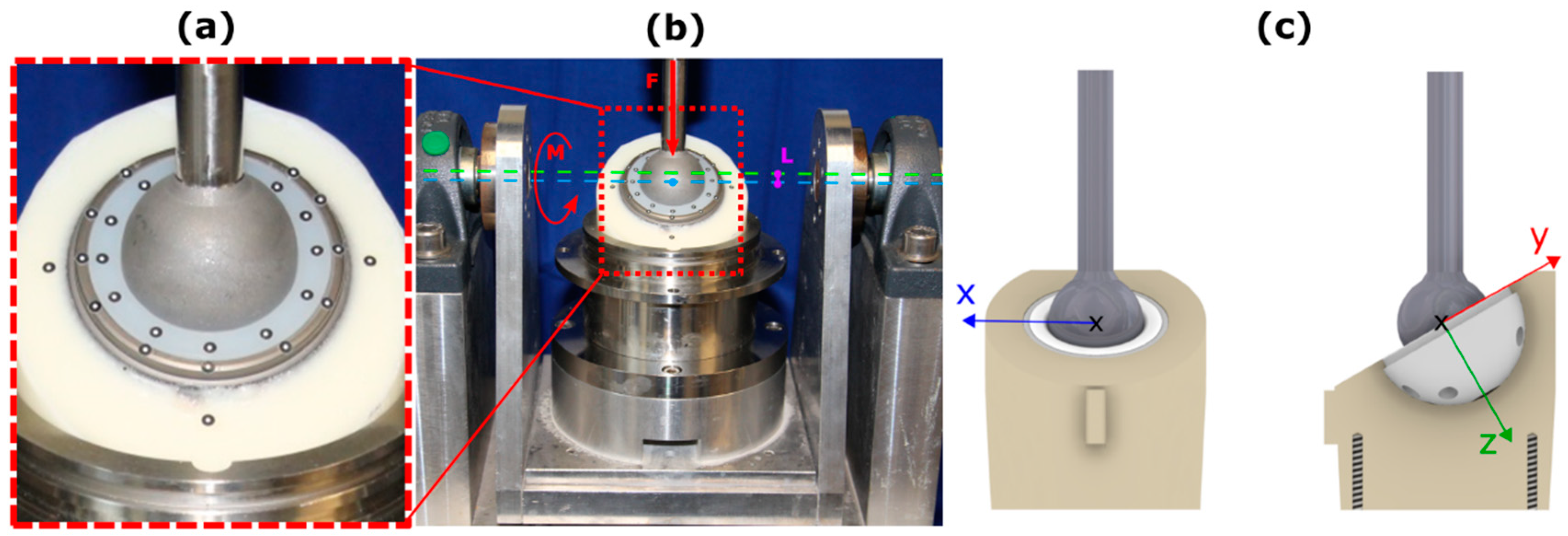

2.2. Test Setup

2.3. Determination of Relative Motion

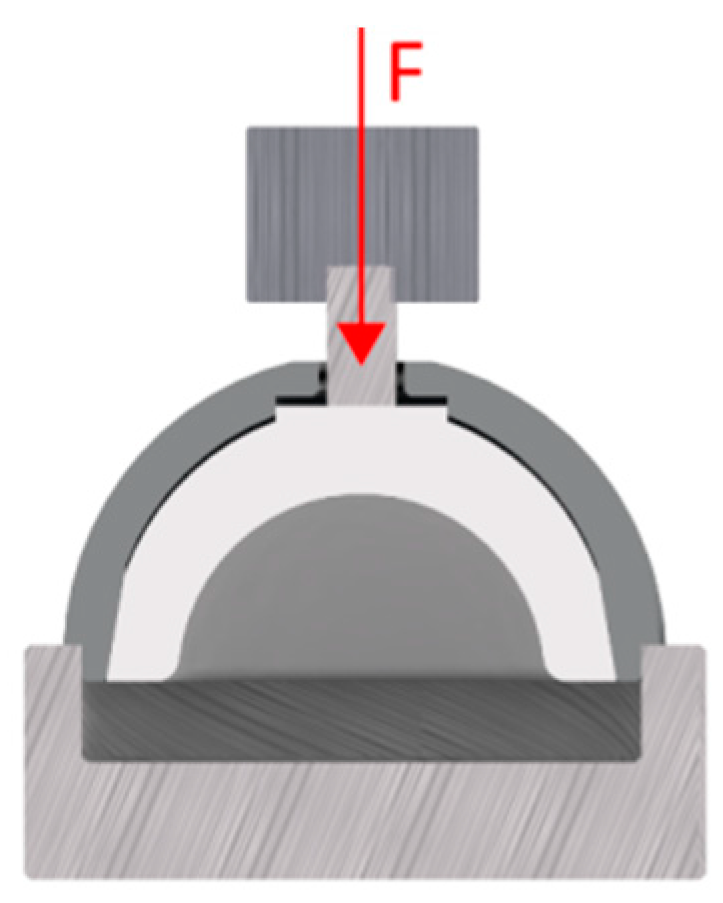

2.4. Disassembly Test

2.5. Statistical Analysis

3. Results

3.1. Relative Motion

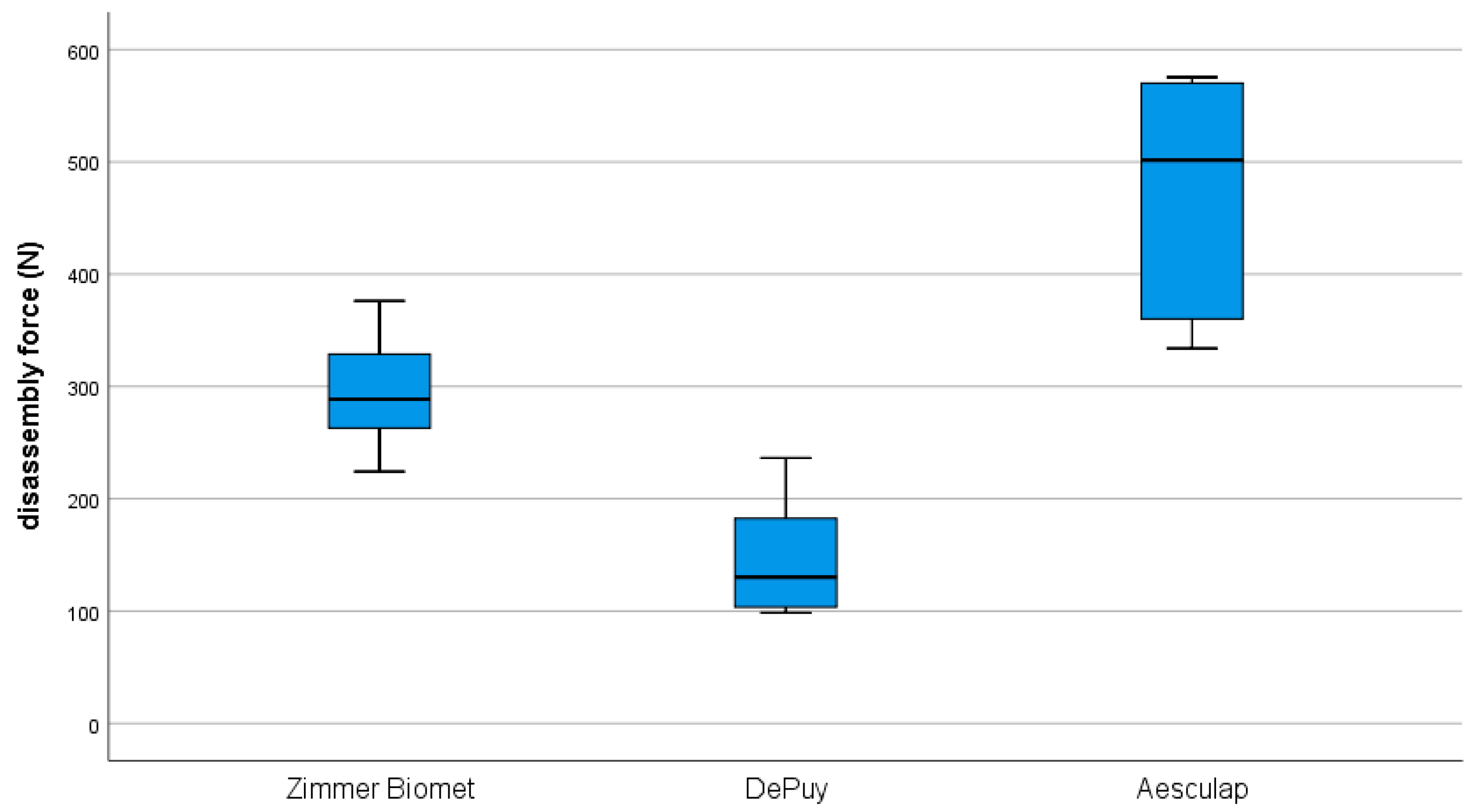

3.2. Disassembly Test

4. Discussion

Limitations

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Crawford, R.W.; Murray, D.W. Total hip replacement: Indications for surgery and risk factors for failure. Ann. Rheum. Dis. 1997, 56, 455–457. [Google Scholar] [CrossRef] [PubMed]

- Pivec, R.; Johnson, A.J.; Mears, S.C.; Mont, M.A. Hip arthroplasty. Lancet 2012, 380, 1768–1777. [Google Scholar] [CrossRef]

- Makarewich, C.A.; Anderson, M.B.; Gililland, J.M.; Pelt, C.E.; Peters, C.L. Ten-year survivorship of primary total hip arthroplasty in patients 30 years of age or younger. Bone Jt. J. 2018, 100-B, 867–874. [Google Scholar] [CrossRef] [PubMed]

- Hallab, N.J.; Jacobs, J.J. Biologic effects of implant debris. Bull. NYU Hosp. Jt. Dis. 2009, 67, 182–188. [Google Scholar]

- Dumbleton, J.H.; Manley, M.T.; Edidin, A.A. A literature review of the association between wear rate and osteolysis in total hip arthroplasty. J. Arthroplast. 2002, 17, 649–661. [Google Scholar] [CrossRef]

- Harris, W.H. Wear and periprosthetic osteolysis: The problem. Clin. Orthop. Relat. Res. 2001, 393, 66–70. [Google Scholar] [CrossRef]

- Prokopovich, P. Interactions between mammalian cells and nano- or micro-sized wear particles: Physico-chemical views against biological approaches. Adv. Colloid Interface Sci. 2014, 213, 36–47. [Google Scholar] [CrossRef]

- Akbari, A.; Roy, M.E.; Whiteside, L.A.; Katerberg, B.J.; Schnettgoecke, D.J. Minimal backside surface changes observed in retrieved acetabular liners. J. Arthroplast. 2011, 26, 686–692. [Google Scholar] [CrossRef]

- Braun, S.; Sonntag, R.; Schroeder, S.; Mueller, U.; Jaeger, S.; Gotterbarm, T.; Kretzer, J.P. Backside wear in acetabular hip joint replacement. Acta Biomater. 2019, 83, 467–476. [Google Scholar] [CrossRef]

- Kretzer, J.P.; Zietz, C.; Schröder, C.; Reinders, J.; Middelborg, L.; Paulus, A.; Sonntag, R.; Bader, R.; Utzschneider, S. Grundlagen zur tribologischen analyse von endoprothesen. Der Orthopäde 2012, 41, 844–852. [Google Scholar] [CrossRef]

- McKellop, H.A. The lexicon of polyethylene wear in artificial joints. Biomaterials 2007, 28, 5049–5057. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M.; Ochoa, J.A.; White, C.V.; Srivastav, S.; Cournoyer, J. Backside nonconformity and locking restraints affect liner/shell load transfer mechanisms and relative motion in modular acetabular components for total hip replacement. J. Biomech. 1998, 31, 431–437. [Google Scholar] [CrossRef]

- Kyle, R.F.; Riddle, C.D.; Kyle, M.; Rockswold, S.; Bourgeault, C. Factors influencing the initial micromotion between polyethylene acetabular cups and titanium alloy shells. J. Arthroplast. 2006, 21, 443–448. [Google Scholar] [CrossRef]

- Williams, V.G., 2nd; Whiteside, L.A.; White, S.E.; McCarthy, D.S. Fixation of ultrahigh-molecular-weight polyethylene liners to metal-backed acetabular cups. J. Arthroplast. 1997, 12, 25–31. [Google Scholar] [CrossRef]

- Braun, S.; Vardag, S.; Mueller, U.; Schroeder, S.; Sonntag, R.; Bormann, T.; Gotterbarm, T.; Kretzer, J.P. Backside wear, particle migration and effectiveness of screw hole plugs in acetabular hip joint replacement with cross-linked polyethylene. Acta Biomater. 2019, 97, 239–246. [Google Scholar] [CrossRef]

- Beckmann, N.A.; Bitsch, R.G.; Gondan, M.; Schonhoff, M.; Jaeger, S. Comparison of the stability of three fixation techniques between porous metal acetabular components and augments. Bone Jt. Res. 2018, 7, 282–288. [Google Scholar] [CrossRef]

- ASTM F1820-13. Standard Test Method for Determining the Forces for Disassembly of Modular Acetabular Devices; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Barrack, R.L.; Folgueras, A.; Munn, B.; Tvetden, D.; Sharkey, P. Pelvic lysis and polyethylene wear at 5-8 years in an uncemented total hip. Clin. Orthop. Relat. Res. 1997, 335, 211–217. [Google Scholar] [CrossRef]

- Bali, K.; McCalden, R.W.; Naudie, D.D.; MacDonald, S.J.; Teeter, M.G. Backside wear is not dependent on the acetabular socket design in crosslinked polyethylene liners. Clin. Orthop. Relat. Res. 2016, 474, 374–382. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Kligman, M.; Furman, B.D.; Padgett, D.E.; Wright, T.M. Impingement contributes to backside wear and screw-metallic shell fretting in modular acetabular cups. J. Arthroplast. 2007, 22, 258–264. [Google Scholar] [CrossRef] [PubMed]

- Lieberman, J.R.; Kay, R.M.; Hamlet, W.P.; Park, S.H.; Kabo, J.M. Wear of the polyethylene liner-metallic shell interface in modular acetabular components. An in vitro analysis. J. Arthroplast. 1996, 11, 602–608. [Google Scholar] [CrossRef]

- Wasielewski, R.C.; Jacobs, J.J.; Arthurs, B.; Rubash, H.E. The acetabular insert-metal backing interface: An additional source of polyethylene wear debris. J. Arthroplast. 2005, 20, 914–922. [Google Scholar] [CrossRef] [PubMed]

- Tradonsky, S.; Postak, P.D.; Froimson, A.I.; Greenwald, A.S. A comparison of the disassociation strength of modular acetabular components. Clin. Orthop. Relat. Res. 1993, 296, 154–160. [Google Scholar] [CrossRef]

- O’Neill, C.K.; Napier, R.J.; Diamond, O.J.; O’Brien, S.; Beverland, D.E. Acetabular liner dissociation following total hip arthroplasty: A rare but serious complication that may be easily misinterpreted in the emergency department. Case Rep. Emerg. Med. 2015, 2015, 802753. [Google Scholar] [CrossRef] [PubMed]

- Puente Reyna, A.L.; Jager, M.; Floerkemeier, T.; Frecher, S.; Delank, K.S.; Schilling, C.; Grupp, T.M. Backside wear analysis of retrieved acetabular liners with a press-fit locking mechanism in comparison to wear simulation in vitro. BioMed Res. Int. 2016, 2016, 8687131. [Google Scholar] [CrossRef] [PubMed]

- Long, W.J.; Nayyar, S.; Chen, K.K.; Novikov, D.; Davidovitch, R.I.; Vigdorchik, J.M. Early aseptic loosening of the tritanium primary acetabular component with screw fixation. Arthroplast. Today 2018, 4, 169–174. [Google Scholar] [CrossRef]

| Load Level (kN) | Zimmer Biomet | DePuy | Aesculap |

|---|---|---|---|

| 0.5 | 58.8 ± 32.6 | 15.2 ± 8.3 | 6.2 ± 1.1 |

| 1.5 | 74.3 ± 33.7 | 43.9 ± 14.5 | 12.5 ± 6.4 |

| 2.5 | 82.8 ± 33.5 | 66.3 ± 16.1 | 25.1 ± 8.8 |

| 3.5 | 86.5 ± 32.7 | 81.1 ± 18.5 | 38.2 ± 9.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaeger, S.; Uhler, M.; Schroeder, S.; Beckmann, N.A.; Braun, S. Comparison of Different Locking Mechanisms in Total Hip Arthroplasty: Relative Motion between Cup and Inlay. Materials 2020, 13, 1392. https://doi.org/10.3390/ma13061392

Jaeger S, Uhler M, Schroeder S, Beckmann NA, Braun S. Comparison of Different Locking Mechanisms in Total Hip Arthroplasty: Relative Motion between Cup and Inlay. Materials. 2020; 13(6):1392. https://doi.org/10.3390/ma13061392

Chicago/Turabian StyleJaeger, Sebastian, Maximilian Uhler, Stefan Schroeder, Nicholas A. Beckmann, and Steffen Braun. 2020. "Comparison of Different Locking Mechanisms in Total Hip Arthroplasty: Relative Motion between Cup and Inlay" Materials 13, no. 6: 1392. https://doi.org/10.3390/ma13061392

APA StyleJaeger, S., Uhler, M., Schroeder, S., Beckmann, N. A., & Braun, S. (2020). Comparison of Different Locking Mechanisms in Total Hip Arthroplasty: Relative Motion between Cup and Inlay. Materials, 13(6), 1392. https://doi.org/10.3390/ma13061392