Bio-Based Polyurethane Composite Foams with Improved Mechanical, Thermal, and Antibacterial Properties

Abstract

1. Introduction

2. Experimental

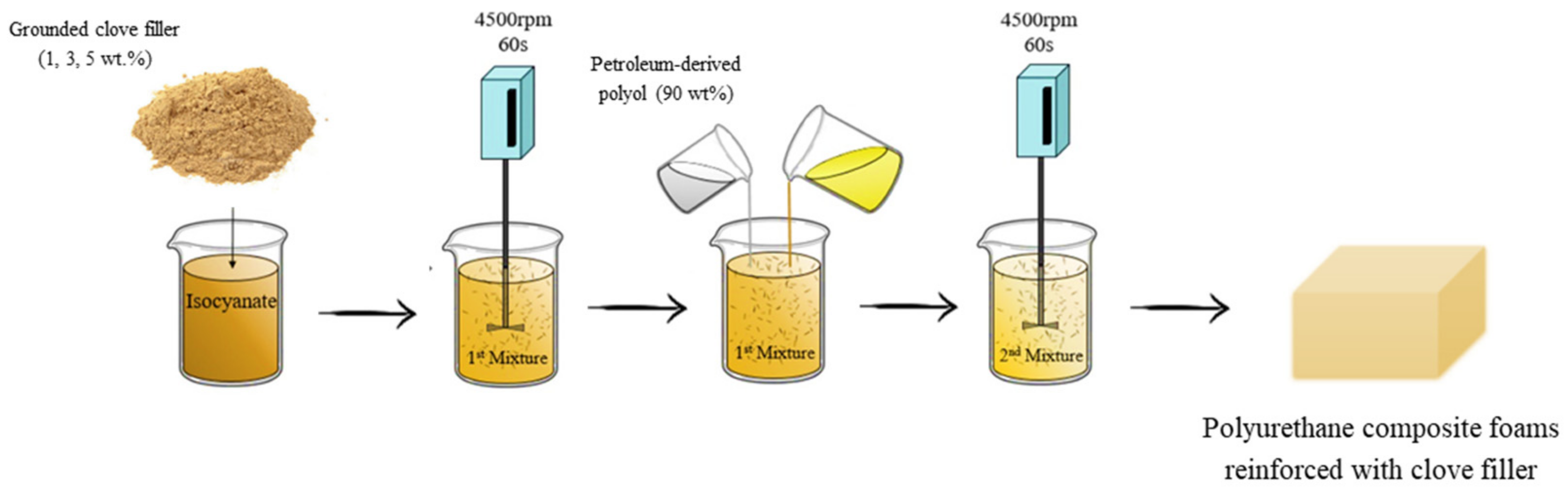

2.1. Materials and Manufacturing

2.2. Characterization Techniques

3. Results and Discussion

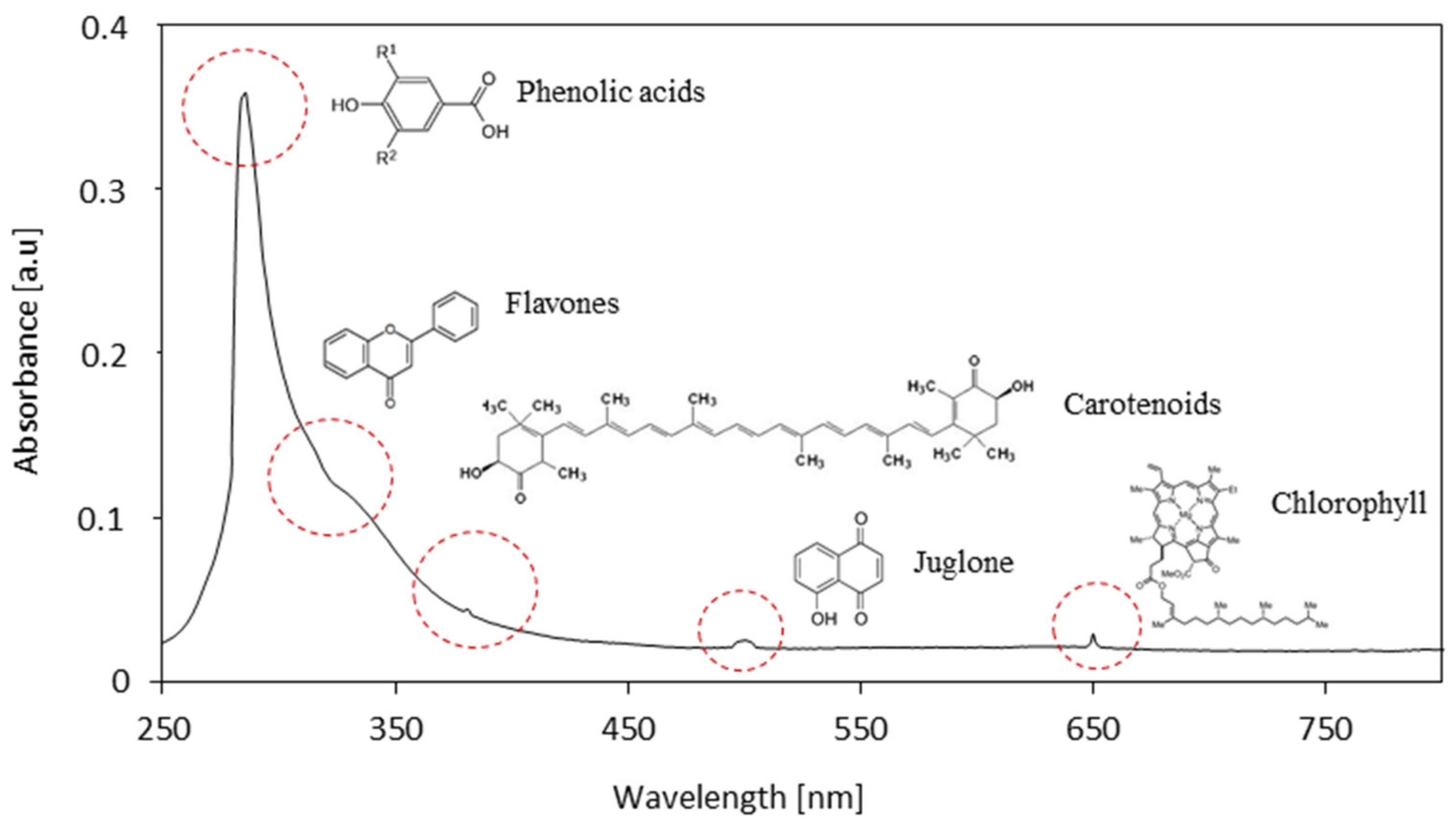

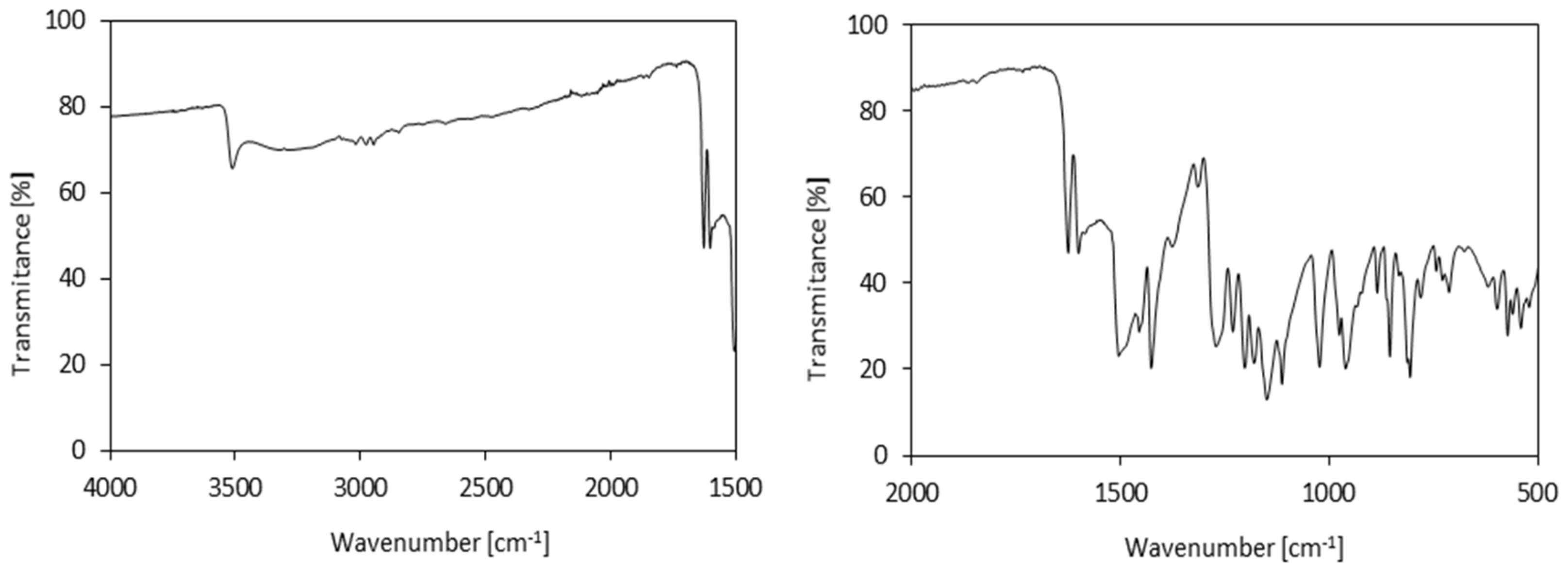

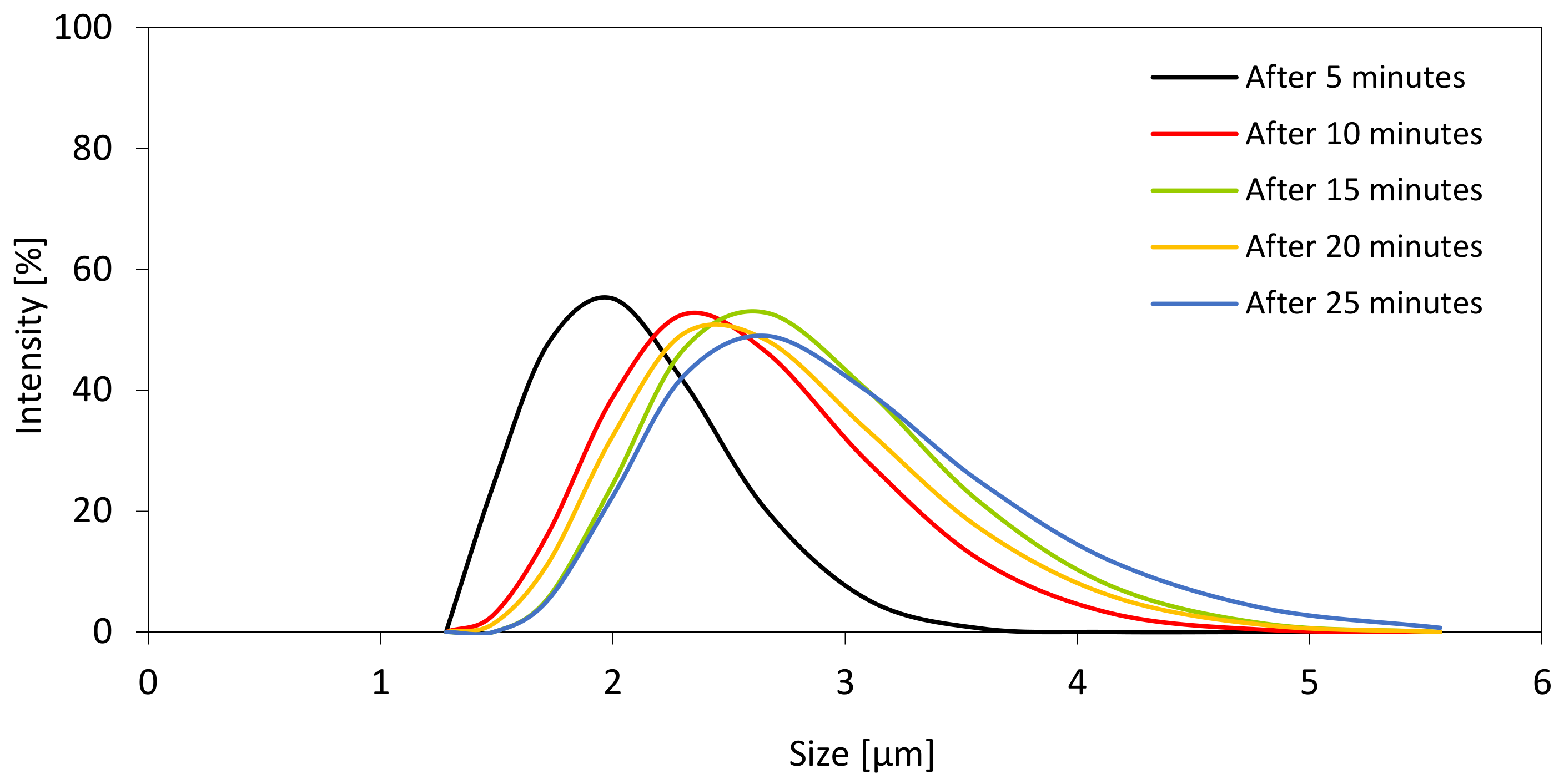

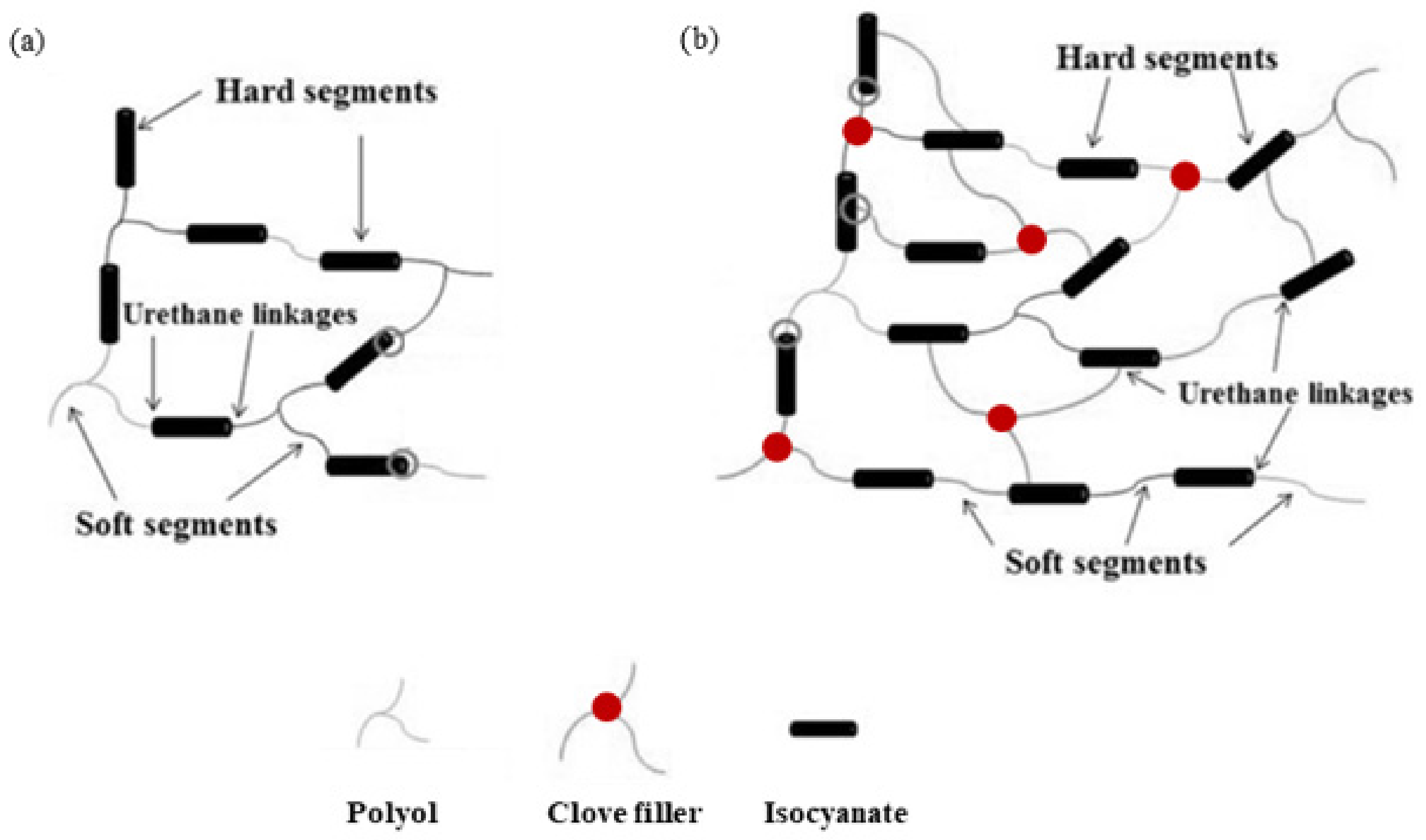

3.1. Characterization of Clove Filler

3.2. Foaming Behavior of PU Mixtures Containing Clove Filler

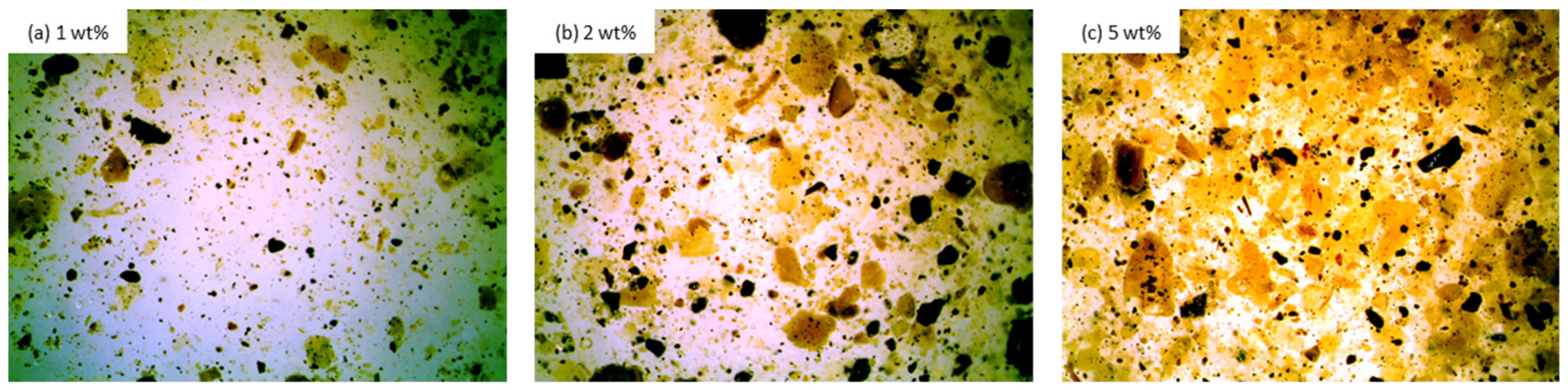

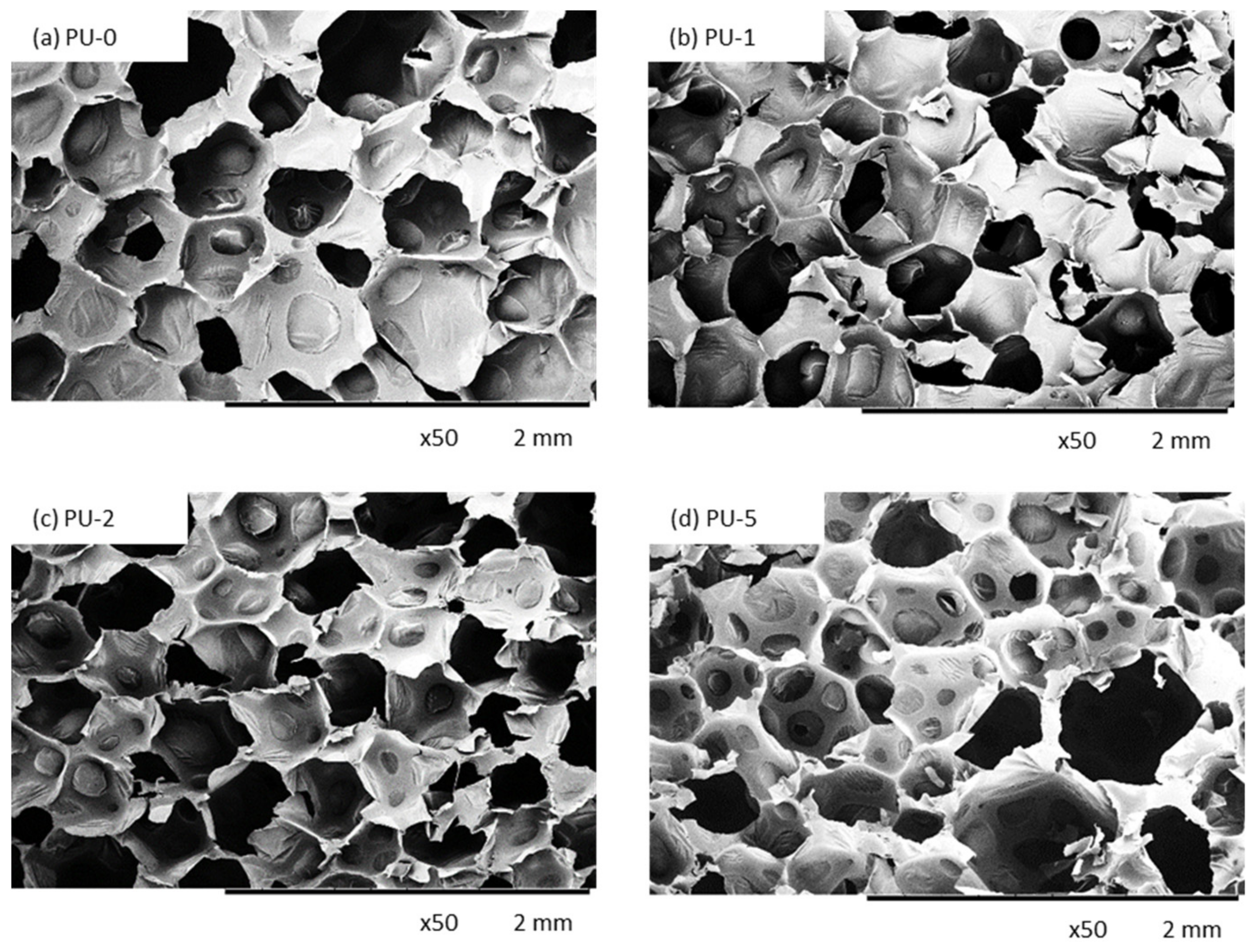

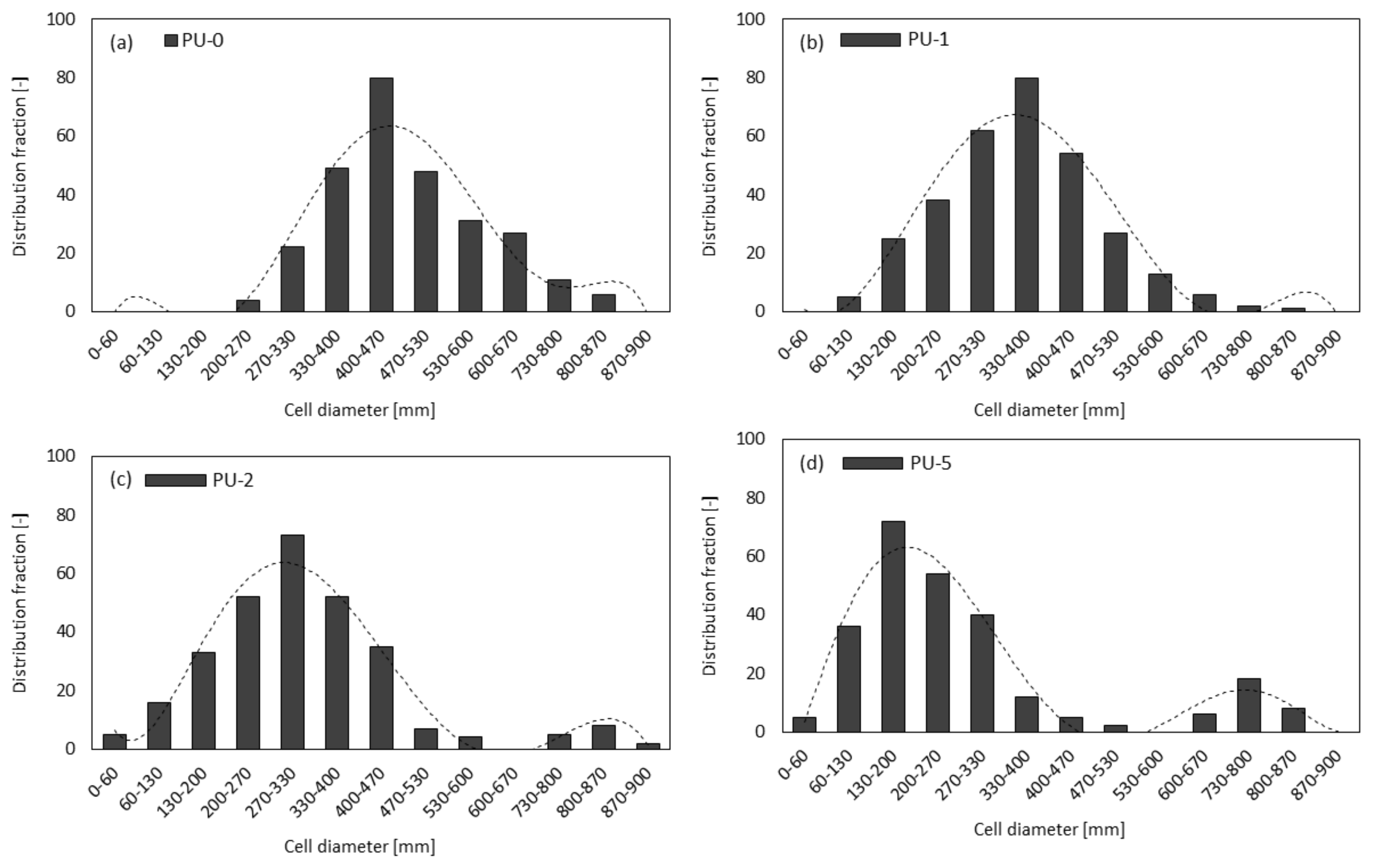

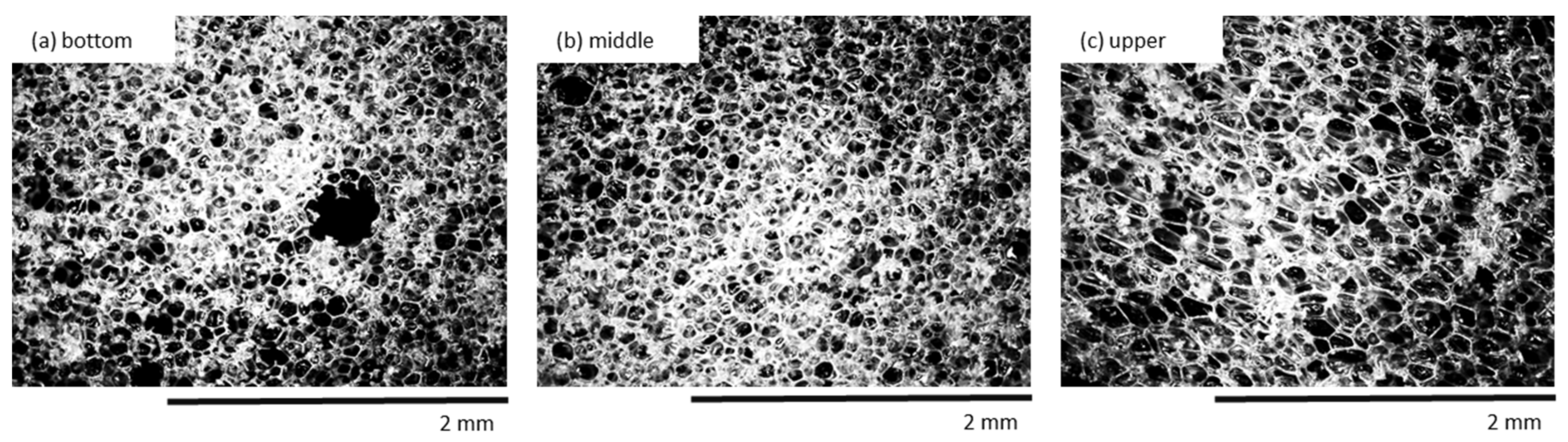

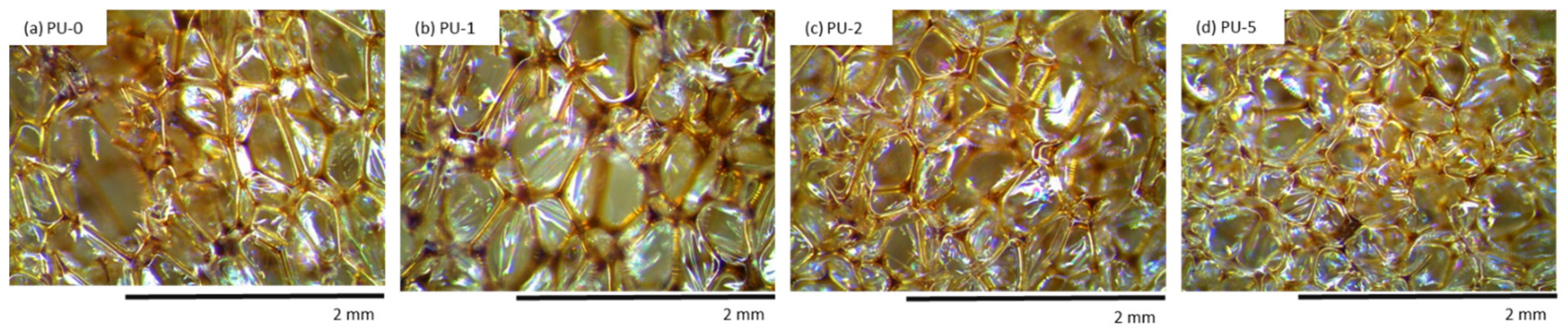

3.3. Cellular Structure of PU Composite Foams

3.4. Apparent Density of PU Composite Foams

3.5. Compression Strength, Flexural Strength, and Impact Strength

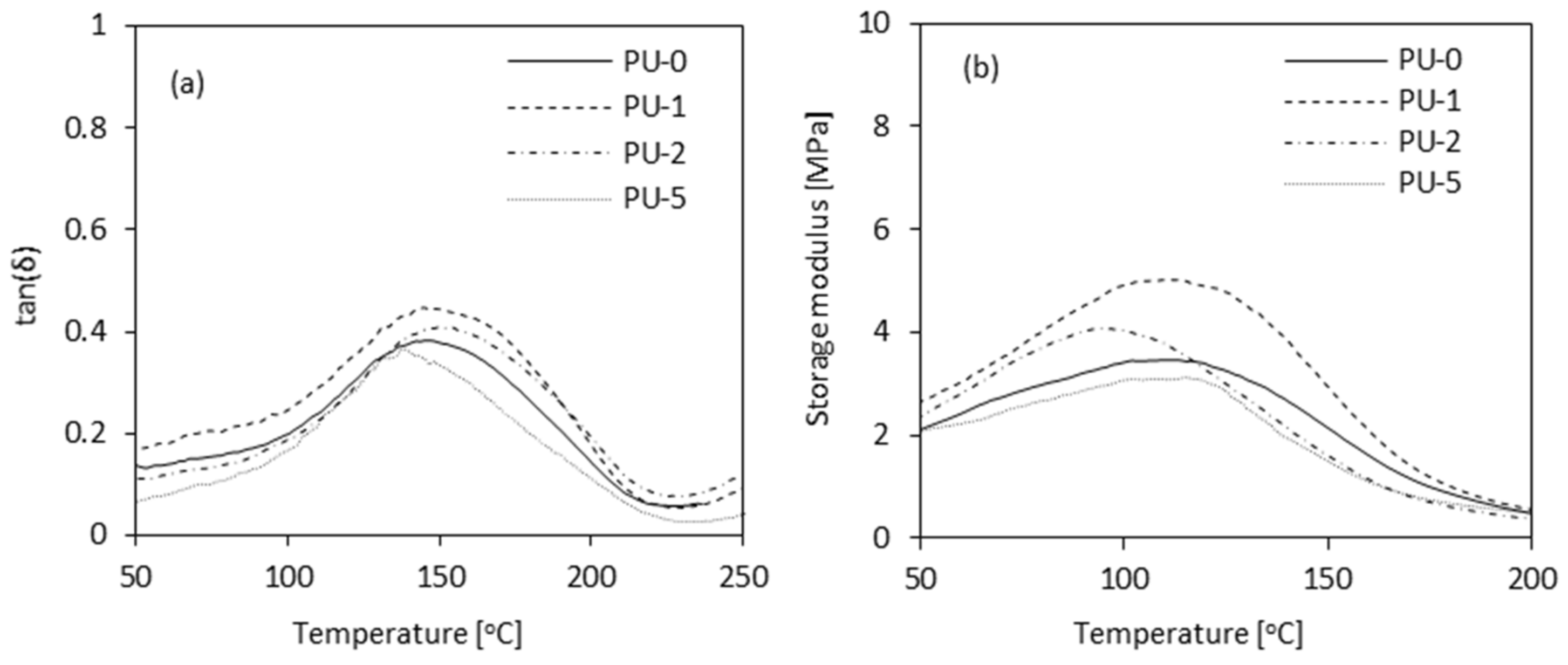

3.6. Dynamic Mechanical Analysis of PU Composite Foams

3.7. Thermogravimetric Analysis of PU Composite Foams

3.8. Microbial Properties of PU Composite Foams

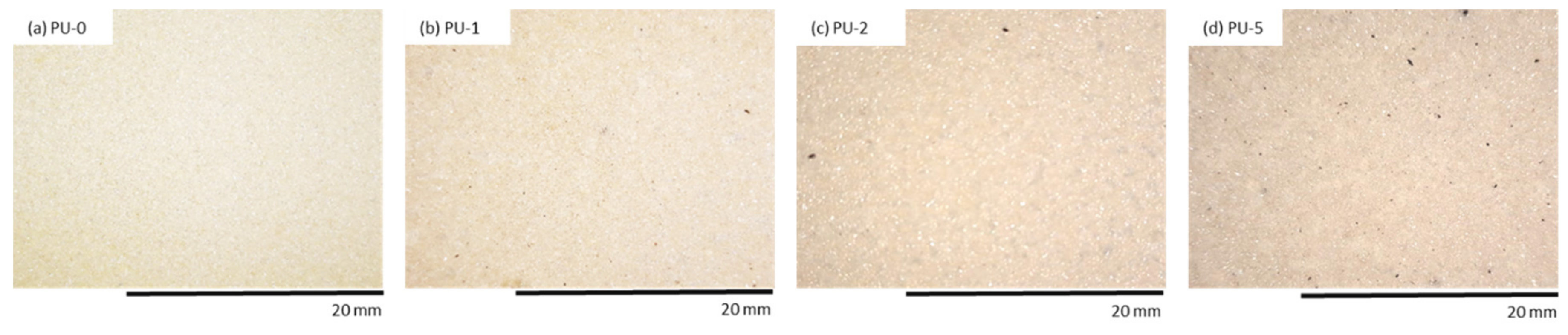

3.9. Color Analysis of PU Composite Foams

3.10. Contact Angle, Water Absorption, and Dimensional Stability

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ionescu, M. Chemistry and Technology of Polyols for Polyurethanes; Smithers Rapra Publishing: Shrewsbury, UK, 2005. [Google Scholar]

- Gama, N.V.; Ferreira, A.; Barros-Timmons, A. Polyurethane foams: Past, present, and future. Materials (Basel) 2018, 11. [Google Scholar] [CrossRef]

- Kosmela, P.; Gosz, K.; Kazimierski, P.; Hejna, A.; Haponiuk, J.T.; Piszczyk, Ł. Chemical structures, rheological and physical properties of biopolyols prepared via solvothermal liquefaction of Enteromorpha and Zostera marina biomass. Cellulose 2019, 26, 5893–5912. [Google Scholar] [CrossRef]

- Hejna, A.; Kosmela, P.; Kirpluks, M.; Cabulis, U.; Klein, M.; Haponiuk, J.; Piszczyk, Ł. Structure, mechanical, thermal and fire behavior assessments of environmentally friendly crude glycerol-based rigid polyisocyanurate foams. J. Polym. Environ. 2018, 26, 1854–1868. [Google Scholar] [CrossRef]

- Haponiuk, J.T.; Hejna, A.; Piszczyk, Ł.; Datta, J.; Formela, K. Renewable resources for polyurethanes and polyurethane composites: A review. In Chemical Engineering of Polymers; Apple Academic Press: Waretown, NJ, USA, 2017; Volume 407, pp. 407–432. [Google Scholar]

- Kurańska, M.; Pinto, J.A.; Salach, K.; Barreiro, M.F.; Prociak, A. Synthesis of thermal insulating polyurethane foams from lignin and rapeseed based polyols: a comparative study. Ind. Crops Prod. 2020, 143, 111882. [Google Scholar] [CrossRef]

- Kurańska, M.; Banaś, J.; Polaczek, K.; Banaś, M.; Prociak, A.; Kuc, J.; Uram, K.; Lubera, T. Evaluation of application potential of used cooking oils in the synthesis of polyol compounds. J. Environ. Chem. Eng. 2019, 7, 103506. [Google Scholar] [CrossRef]

- Prociak, A.; Szczepkowski, L.; Ryszkowska, J.; Kurańska, M.; Auguścik, M.; Malewska, E.; Gloc, M.; Michałowski, S. Influence of chemical structure of petrochemical polyol on properties of bio-polyurethane foams. J. Polym. Environ. 2019, 27, 2360–2368. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Czupryński, B.; Tomaszewska, E.; Liszkowska, J. Oenothera biennis seed oil as an alternative raw material for production of bio-polyol for rigid polyurethane-polyisocyanurate foams. Ind. Crops Prod. 2018, 126, 208–217. [Google Scholar] [CrossRef]

- Ionescu, M.; Radojčić, D.; Wan, X.; Shrestha, M.L.; Petrović, Z.S.; Upshaw, T.A. Highly functional polyols from castor oil for rigid polyurethanes. Eur. Polym. J. 2016, 84, 736–749. [Google Scholar] [CrossRef]

- Kreye, O.; Mutlu, H.; Meier, M.A.R. Sustainable routes to polyurethane precursors. Green Chem. 2013, 15, 1431. [Google Scholar] [CrossRef]

- Miao, S.; Sun, L.; Wang, P.; Liu, R.; Su, Z.; Zhang, S. Soybean oil-based polyurethane networks as candidate biomaterials: Synthesis and biocompatibility. Eur. J. Lipid Sci. Technol. 2012, 114, 1165–1174. [Google Scholar] [CrossRef]

- Zhou, X.; Sain, M.M. Semi-rigid biopolyurethane foams based on palm-oil polyol and reinforced with cellulose nanocrystals. Compos. Part A Appl. Sci. Manuf. 2016, 83, 56–62. [Google Scholar] [CrossRef]

- Ng, W.S.; Lee, C.S.; Chuah, C.H.; Cheng, S.-F. Preparation and modification of water-blown porous biodegradable polyurethane foams with palm oil-based polyester polyol. Ind. Crops Prod. 2017, 97, 65–78. [Google Scholar] [CrossRef]

- Kairytė, A.; Vėjelis, S. Evaluation of forming mixture composition impact on properties of water blown rigid polyurethane (PUR) foam from rapeseed oil polyol. Ind. Crops Prod. 2015, 66, 210–215. [Google Scholar] [CrossRef]

- Fourati, Y.; Hassen, R.B.; Bayramoğlu, G.; Boufi, S. A one step route synthesis of polyurethane newtwork from epoxidized rapeseed oil. Prog. Org. Coatings 2017, 105, 48–55. [Google Scholar] [CrossRef]

- Ribeiro Da Silva, V.; Mosiewicki, M.A.; Yoshida, M.I.; Coelho Da Silva, M.; Stefani, P.M.; Marcovich, N.E. Polyurethane foams based on modified tung oil and reinforced with rice husk ash II: Mechanical characterization. Polym. Test. 2013, 32, 665–672. [Google Scholar] [CrossRef]

- Das, B.; Konwar, U.; Mandal, M.; Karak, N. Sunflower oil based biodegradable hyperbranched polyurethane as a thin film material. Ind. Crops Prod. 2013, 44, 396–404. [Google Scholar] [CrossRef]

- Kong, X.; Liu, G.; Curtis, J.M. Novel polyurethane produced from canola oil based poly(ether ester) polyols: Synthesis, characterization and properties. Eur. Polym. J. 2012, 48, 2097–2106. [Google Scholar] [CrossRef]

- Miao, S.; Wang, P.; Su, Z.; Zhang, S. Vegetable-oil-based polymers as future polymeric biomaterials. Acta Biomater. 2014, 10, 1692–1704. [Google Scholar] [CrossRef]

- Dave, V.J.; Patel, H.S. Synthesis and characterization of interpenetrating polymer networks from transesterified castor oil based polyurethane and polystyrene. J. Saudi Chem. Soc. 2017, 21, 18–24. [Google Scholar] [CrossRef]

- Barczewski, M.; Kurańska, M.; Sałasińska, K.; Michałowski, S.; Prociak, A.; Uram, K.; Lewandowski, K. Rigid polyurethane foams modified with thermoset polyester-glass fiber composite waste. Polym. Test. 2020, 81, 106190. [Google Scholar] [CrossRef]

- Qi, X.; Zhang, Y.; Chang, C.; Luo, X.; Li, Y. Thermal, mechanical, and morphological properties of rigid crude glycerol-based polyurethane foams reinforced with nanoclay and microcrystalline cellulose. Eur. J. Lipid Sci. Technol. 2018, 120, 1–11. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, L.; Lv, J. Effects of expandable graphite and modified ammonium polyphosphate on the flame-retardant and mechanical properties of wood flour-polypropylene composites. Polym. Polym. Compos. 2013, 21, 449–456. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Kairytė, A.; Vaitkus, S. Composites of rigid polyurethane foams and silica powder filler enhanced with ionic liquid. Polym. Test. 2019, 75, 12–25. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.H. Influence of filler surface characteristics on morphological, physical, acoustic properties of polyurethane composite foams filled with inorganic fillers. Compos. Sci. Technol. 2017, 146, 147–154. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Strzelec, K.; Adamus-Włodarczyk, A.; Kairytė, A.; Vaitkus, S.; Członka, S.; Strąkowska, A.; Strzelec, K.; Adamus-Włodarczyk, A.; et al. Composites of rigid polyurethane foams reinforced with POSS. Polymers (Basel) 2019, 11, 336. [Google Scholar] [CrossRef] [PubMed]

- Strąkowska, A.; Członka, S.; Strzelec, K. POSS Compounds as modifiers for rigid polyurethane foams (composites). Polymers (Basel) 2019, 11, 1092. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Czupryński, B.; Borowicz, M.; Liszkowska, J. Rigid polyurethane–polyisocyanurate foams modified with grain fraction of fly ashes. J. Cell. Plast. 2020, 56, 53–72. [Google Scholar] [CrossRef]

- Liszkowska, J.; Borowicz, M.; Paciorek-Sadowska, J.; Isbrandt, M.; Czupryński, B.; Moraczewski, K. Assessment of photodegradation and biodegradation of RPU/PIR foams modified by natural compounds of plant origin. Polymers (Basel) 2020, 12. [Google Scholar] [CrossRef]

- Borowicz, M.; Paciorek-Sadowska, J.; Lubczak, J.; Czupryński, B. Biodegradable, flame-retardant, and bio-based rigid polyurethane/polyisocyanurate foams for thermal insulation application. Polymers (Basel) 2019, 11. [Google Scholar] [CrossRef]

- Paciorek-Sadowska, J.; Borowicz, M.; Isbrandt, M.; Czupryński, B.; Apiecionek, Ł. The use of waste from the production of rapeseed oil for obtaining of new polyurethane composites. Polymers (Basel) 2019, 11. [Google Scholar] [CrossRef]

- Zhou, X.; Sethi, J.; Geng, S.; Berglund, L.; Frisk, N.; Aitom??ki, Y.; Sain, M.M.; Oksman, K. Dispersion and reinforcing effect of carrot nanofibers on biopolyurethane foams. Mater. Des. 2016, 110, 526–531. [Google Scholar] [CrossRef]

- Paberza, A.; Cabulis, U.; Arshanitsa, A. Wheat straw lignin as filler for rigid polyurethane foams on the basis of tall oil amide. Polimery/Polymers 2014, 59, 477–481. [Google Scholar] [CrossRef]

- Zieleniewska, M.; Leszczyński, M.K.; Szczepkowski, L.; Bryśkiewicz, A.; Krzyżowska, M.; Bień, K.; Ryszkowska, J. Development and applicational evaluation of the rigid polyurethane foam composites with egg shell waste. Polym. Degrad. Stab. 2016, 132, 78–86. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K. Rigid polyurethane foams reinforced with industrial potato protein. Polym. Test. 2018, 68, 135–145. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K.; Strąkowska, A.; Masłowski, M. Rigid polyurethane foams reinforced with solid waste generated in leather industry. Polym. Test. 2018, 69, 225–237. [Google Scholar] [CrossRef]

- Członka, S.; Sienkiewicz, N.; Strąkowska, A.; Strzelec, K. Keratin feathers as a filler for rigid polyurethane foams on the basis of soybean oil polyol. Polym. Test. 2018, 72, 32–45. [Google Scholar] [CrossRef]

- Chaieb, K.; Hajlaoui, H.; Zmantar, T.; Kahla-Nakbi, A.B.; Rouabhia, M.; Mahdouani, K.; Bakhrouf, A. The chemical composition and biological activity of clove essential oil, eugenia caryophyllata (Syzigium aromaticum L. myrtaceae): A short review. Phyther. Res. 2007, 21, 501–506. [Google Scholar] [CrossRef]

- Performance Standards for Antimicrobial Disk Susceptibility Tests—Approved Standard; M2-A8; Clinical and Laboratory Standards Institute: Wayne, PA, USA, 2003.

- Vespe, V.C.; Boltz, D.F. Ultraviolet spectrophotometric study of eugenol-isoeugenol system. Anal. Chem. 1952, 24, 664–666. [Google Scholar] [CrossRef]

- Pramod, K.; Ilyas, U.K.; Kamal, Y.T.; Ahmad, S.; Ansari, S.H.; Ali, J. Development and validation of RP-HPLC-PDA method for the quantification of eugenol in developed nanoemulsion gel and nanoparticles. J. Anal. Sci. Technol. 2013, 4. [Google Scholar] [CrossRef]

- Kolev, T.M.; Velcheva, E.A.; Stamboliyska, B.A.; Spiteller, M. DFT and experimental studies of the structure and vibrational spectra of curcumin. Int. J. Quantum Chem. 2005, 102, 1069–1079. [Google Scholar] [CrossRef]

- Chowdhry, B.Z.; Ryall, J.P.; Dines, T.J.; Mendham, A.P. Infrared and raman spectroscopy of eugenol, isoeugenol, and methyl eugenol: conformational analysis and vibrational assignments from density functional theory calculations of the anharmonic fundamentals. J. Phys. Chem. A 2015, 119, 11280–11292. [Google Scholar] [CrossRef] [PubMed]

- Kuranska, M.; Prociak, A.; Michalowski, S.; Cabulis, U.; Kirpluks, M. Microcellulose as a natural filler in polyurethane foams based on the biopolyol from rapeseed oil. Polimery/Polymers 2016, 61, 625–632. [Google Scholar] [CrossRef]

- Yan, D.; Xu, L.; Chen, C.; Tang, J.; Ji, X.; Li, Z. Enhanced mechanical and thermal properties of rigid polyurethane foam composites containing graphene nanosheets and carbon nanotubes. Polym. Int. 2012, 61, 1107–1114. [Google Scholar] [CrossRef]

- Kairytė, A.; Kizinievič, O.; Kizinievič, V.; Kremensas, A. Synthesis of biomass-derived bottom waste ash based rigid biopolyurethane composite foams: rheological behaviour, structure and performance characteristics. Compos. Part A Appl. Sci. Manuf. 2019, 117, 193–201. [Google Scholar] [CrossRef]

- Carriço, C.S.; Fraga, T.; Pasa, V.M.D. Production and characterization of polyurethane foams from a simple mixture of castor oil, crude glycerol and untreated lignin as bio-based polyols. Eur. Polym. J. 2016, 85, 53–61. [Google Scholar] [CrossRef]

- Formela, K.; Hejna, A.; Zedler, Ł.; Przybysz, M.; Ryl, J.; Saeb, M.R.; Piszczyk, Ł. Structural, thermal and physico-mechanical properties of polyurethane/brewers’ spent grain composite foams modified with ground tire rubber. Ind. Crops Prod. 2017, 108, 844–852. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, H.; Wang, X.; Li, S.; Zhou, Y.; Zhang, F.; Wang, Y.; Qu, W.; Wang, D.; Pang, X. Effects of flame-retardant ramie fiber on enhancing performance of the rigid polyurethane foams. Polym. Adv. Technol. 2019. [Google Scholar] [CrossRef]

- Tanaka, R.; Hirose, S.; Hatakeyama, H. Preparation and characterization of polyurethane foams using a palm oil-based polyol. Bioresour. Technol. 2008, 99, 3810–3816. [Google Scholar] [CrossRef]

- Hoseinabadi, M.; Naderi, M.; Najafi, M.; Motahari, S.; Shokri, M. A study of rigid polyurethane foams: The effect of synthesized polyols and nanoporous graphene. J. Appl. Polym. Sci. 2017, 134, 1–6. [Google Scholar] [CrossRef]

- Viksne, A.; Bledzki, A.K.; Rence, L.; Berzina, R. Water uptake and mechanical characteristics of wood fiber-polypropylene composites. Polymer (Guildf) 2006, 42, 73–82. [Google Scholar] [CrossRef]

- Widya, T.; Macosko, C. Nanoclay-modified rigid polyurethane foam. J. Macromol. Sci. Part B Phys. 2005, 44, 897–908. [Google Scholar] [CrossRef]

- Petrović, Z.S.; Milić, J.; Zhang, F.; Ilavsky, J. Fast-responding bio-based shape memory thermoplastic polyurethanes. Polymer (Guildf) 2017, 121, 26–37. [Google Scholar] [CrossRef] [PubMed]

- Javni, I.; Bilić, O.; Bilić, N.; Petrović, Z.S.; Eastwood, E.A.; Zhang, F.; Ilavský, J. Thermoplastic polyurethanes with controlled morphology based on methylenediphenyldiisocyanate/isosorbide/butanediol hard segments. Polym. Int. 2015, 64, 1607–1616. [Google Scholar] [CrossRef]

- Zhao, W.; Pizzi, A.; Fierro, V.; Du, G.; Celzard, A. Effect of composition and processing parameters on the characteristics of tannin-based rigid foams. Part I: Cell structure. Mater. Chem. Phys. 2010, 122, 175–182. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Kurańska, M.; Prociak, A. The influence of rapeseed oil-based polyols on the foaming process of rigid polyurethane foams. Ind. Crops Prod. 2016, 89, 182–187. [Google Scholar] [CrossRef]

- Prociak, A.; Kurańska, M.; Cabulis, U.; Kirpluks, M. Rapeseed oil as main component in synthesis of bio-polyurethane-polyisocyanurate porous materials modified with carbon fibers. Polym. Test. 2017, 59, 478–486. [Google Scholar] [CrossRef]

- Dolomanova, V.; Jens, C.M.R.; Jensen, L.R.; Pyrz, R.; Timmons, A.B. Mechanical properties and morphology of nano-reinforced rigid PU foam. J. Cell. Plast. 2011, 47, 81–93. [Google Scholar] [CrossRef]

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Gloc, M.; Kulesza, M.; Kowalski, M.; Krauze, S.; Lewandowska, M. Flammability, mechanical properties and structure of rigid polyurethane foams with different types of carbon reinforcing materials. Compos. Struct. 2016, 140, 67–76. [Google Scholar] [CrossRef]

- Gu, R.; Konar, S.; Sain, M. Preparation and characterization of sustainable polyurethane foams from soybean oils. J. Am. Oil Chem. Soc. 2012, 89, 2103–2111. [Google Scholar] [CrossRef]

- Wu, L.; Gemert, J.V.; Camargo, R.E. Rheology Study in Polyurethane Rigid Foams; Huntsman Corporation: Auburn Hills, MI, USA, 2008. [Google Scholar]

- Silva, M.C.; Takahashi, J.A.; Chaussy, D.; Belgacem, M.N.; Silva, G.G. Composites of rigid polyurethane foam and cellulose fiber residue. J. App. Polym. Sci. 2010, 117, 3665–3672. [Google Scholar] [CrossRef]

- Trandafir, I.; Cosmulescu, S.; Botu, M.; Nour, V. Antioxidant activity, and phenolic and mineral contents of the walnut kernel ( Juglans regia L.) as a function of the pellicle color. Fruits 2016, 71, 177–184. [Google Scholar] [CrossRef]

- Dhuique-Mayer, C.; Tbatou, M.; Carail, M.; Caris-Veyrat, C.; Dornier, M.; Amiot, M.J. Thermal degradation of antioxidant micronutrients in citrus juice: kinetics and newly formed compounds. J. Agric. Food Chem. 2007, 55, 4209–4216. [Google Scholar] [CrossRef] [PubMed]

- Badri, K.H.; Ahmad, S.H.; Zakaria, S. Production of a high-functionality rbd palm kernel oil-based polyester polyol. J. Appl. Polym. Sci. 2001, 81, 384–389. [Google Scholar] [CrossRef]

| Foam Symbol | Comments | Mass Content (By Weight) | |||

|---|---|---|---|---|---|

| Izopianol 30/10/C | ERGOPLAST® ES | Purocyn B | Clove Filler | ||

| PU-0 | Reference foam (unfilled) | 90 | 10 | 160 | 0 |

| PU-1 | Foam reinforced with 1 wt% of clove filler | 90 | 10 | 160 | 1 |

| PU-2 | Foam reinforced with 2 wt% of clove filler | 90 | 10 | 160 | 2 |

| PU-5 | Foam reinforced with 5 wt% of clove filler | 90 | 10 | 160 | 5 |

| Foam Symbol | Dynamic Viscosity η (MPa·s) | ||||

|---|---|---|---|---|---|

| 10 RPM | 20 RPM | 30 RPM | 40 RPM | 100 RPM | |

| PU-0 | 650 ± 8 | 330 ± 8 | 270 ± 6 | 160 ± 5 | 120 ± 6 |

| PU-1 | 890 ± 8 | 520 ± 10 | 360 ± 5 | 190 ± 5 | 130 ± 4 |

| PU-2 | 1390 ± 10 | 1030 ± 10 | 840 ± 5 | 660 ± 8 | 320 ± 5 |

| PU-5 | 1850 ± 10 | 1410 ± 10 | 1260 ± 6 | 840 ± 7 | 540 ± 5 |

| Foam Symbol | PU-0 | PU-1 | PU-2 | PU-5 |

|---|---|---|---|---|

| Temperature (°C) | 125 ± 2 | 123 ± 1 | 122 ± 1 | 119 ± 1 |

| Cream time (s) | 43 ± 4 | 57 ± 2 | 58 ± 2 | 60 ± 2 |

| Expansion time (s) | 214 ± 10 | 228 ± 11 | 230 ± 8 | 238 ± 9 |

| Tack-free time (s) | 341 ± 14 | 347 ± 12 | 351 ± 12 | 368 ± 10 |

| Cell size (µm) | 390 ± 9 | 380 ± 8 | 330 ± 6 | 310 ± 8 |

| Closed-cell content (%) | 88 ± 1 | 90 ± 1 | 87 ± 1 | 80 ± 1 |

| Apparent density (kg m−3) (bottom) | 36 ± 9 | 36 ± 9 | 37 ± 9 | 37 ± 9 |

| Apparent density (kg m−3) (middle) | 39 ± 1 | 41 ± 1 | 42 ± 2 | 44 ± 2 |

| Apparent density (kg m−3) (upper) | 38 ± 9 | 41 ± 9 | 42 ± 9 | 44 ± 9 |

| Foam Symbol | Compressive Strength σ10% (Parallel) (kPa) | Specific Compressive Strength (Parallel) (kPa kg−1 m−3) | Compressive Strength σ10 (Perpendicular) (kPa) | Specific Compressive Strength (Parallel) (kPa kg−1 m−3) | Flexural Strength εf (MPa) | Impact Strength (MPa) |

|---|---|---|---|---|---|---|

| PU-0 | 250 ± 9 | 6.4 ± 0.4 | 144 ± 4 | 3.7 ± 0.5 | 0.402 ± 0.008 | 0.389 ± 0.008 |

| PU-1 | 296 ± 8 | 7.2 ± 0.6 | 176 ± 5 | 4.2 ± 0.6 | 0.472 ± 0.010 | 0.460 ± 0.009 |

| PU-2 | 283 ± 6 | 6.7 ± 0.4 | 148 ± 4 | 3.9 ± 0.5 | 0.440 ± 0.009 | 0.431 ± 0.009 |

| PU-5 | 210 ± 6 | 4.7 ± 0.4 | 130 ± 6 | 2.9 ± 0.6 | 0.412 ± 0.009 | 0.420 ± 0.008 |

| Foam Symbol | Tg (°C) | T10 (°C) | T50 (°C) | T80 (°C) | Char Residue (%) |

|---|---|---|---|---|---|

| PU-0 | 145 ± 1 | 265 ± 1 | 454 ± 1 | 591 ± 1 | 28.4 ± 0.2 |

| PU-1 | 148 ± 1 | 238 ± 1 | 440 ± 1 | 580 ± 1 | 23.5 ± 0.4 |

| PU-2 | 152 ± 1 | 231 ± 1 | 436 ± 1 | 572 ± 1 | 22.2 ± 0.2 |

| PU-5 | 142 ± 1 | 226 ± 1 | 438 ± 1 | 570 ± 1 | 20.2 ± 0.2 |

| Foam Symbol | Staphylococcus Aureus | Escherichia Coli | ||

|---|---|---|---|---|

| Initial Bacterial Suspension (CFU/mL) | Bacterial Suspension Measured after 24 h (CFU/mL) | Initial Bacterial Suspension (CFU/mL) | Bacterial Suspension Measured after 24 h (CFU/mL) | |

| PU-0 | 74 × 106 | 74 × 106 | 74 × 106 | 74 × 106 |

| PU-1 | 74 × 106 | 48 × 106 | 74 × 106 | 42 × 106 |

| PU-2 | 74 × 106 | 33 × 106 | 74 × 106 | 28 × 106 |

| PU-5 | 74 × 106 | 18 × 106 | 74 × 106 | 16 × 106 |

| Foam Symbol | Colorimetric Parameters | |||

|---|---|---|---|---|

| L* | a* | b* | ΔE* | |

| PU-0 | 11.7 | 22.4 | −5.1 | 5.0 |

| PU-1 | 25.3 | 72.5 | −3.9 | 18.0 |

| PU-2 | 49.5 | 75.6 | −3.1 | 29.6 |

| PU-5 | 58.5 | 77.9 | 0.2 | 34.1 |

| Foam Symbol | Colorimetric Parameters | |||

|---|---|---|---|---|

| L* | a* | b* | ΔE* | |

| PU-0 | 18.7 | 24.2 | −4.2 | 22.5 |

| PU-1 | 28.3 | 75.4 | −3.1 | 23.2 |

| PU-2 | 49.5 | 75.1 | −2.5 | 28.6 |

| PU-5 | 60.5 | 79.2 | 0.3 | 30.4 |

| Foam Symbol | Contact Angle (°) | Water Absorption (%) | Temperature of +70 °C | Temperature of −20 °C | ||||

|---|---|---|---|---|---|---|---|---|

| Δl (%) | ΔV (%) | Δm (%) | Δl (%) | ΔV (%) | Δm (%) | |||

| PU-0 | 129 ± 1 | 11.3 ± 0.8 | 1.75 ± 0.00 | 1.40 ± 0.01 | 1.54 ± 0.01 | 1.75 ± 0.01 | 1.65 ± 0.01 | 1.74 ± 0.01 |

| PU-1 | 124 ± 2 | 11.5 ± 0.5 | 1.58 ± 0.00 | 1.42 ± 0.01 | 1.68 ± 0.01 | 1.74 ± 0.01 | 1.87 ± 0.01 | 1.68 ± 0.01 |

| PU-2 | 121 ± 2 | 12.8 ± 0.8 | 1.52 ± 0.00 | 1.41 ± 0.01 | 1.90 ± 0.01 | 1.76 ± 0.01 | 1.69 ± 0.01 | 1.88 ± 0.01 |

| PU-5 | 115 ± 1 | 14.7 ± 0.6 | 1.69 ± 0.00 | 1.90 ± 0.01 | 1.47 ± 0.01 | 2.12 ± 0.01 | 1.79 ± 0.01 | 1.69 ± 0.01 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Członka, S.; Strąkowska, A.; Strzelec, K.; Kairytė, A.; Kremensas, A. Bio-Based Polyurethane Composite Foams with Improved Mechanical, Thermal, and Antibacterial Properties. Materials 2020, 13, 1108. https://doi.org/10.3390/ma13051108

Członka S, Strąkowska A, Strzelec K, Kairytė A, Kremensas A. Bio-Based Polyurethane Composite Foams with Improved Mechanical, Thermal, and Antibacterial Properties. Materials. 2020; 13(5):1108. https://doi.org/10.3390/ma13051108

Chicago/Turabian StyleCzłonka, Sylwia, Anna Strąkowska, Krzysztof Strzelec, Agnė Kairytė, and Arūnas Kremensas. 2020. "Bio-Based Polyurethane Composite Foams with Improved Mechanical, Thermal, and Antibacterial Properties" Materials 13, no. 5: 1108. https://doi.org/10.3390/ma13051108

APA StyleCzłonka, S., Strąkowska, A., Strzelec, K., Kairytė, A., & Kremensas, A. (2020). Bio-Based Polyurethane Composite Foams with Improved Mechanical, Thermal, and Antibacterial Properties. Materials, 13(5), 1108. https://doi.org/10.3390/ma13051108