Modification Effects of Carbon Nanotube Dispersion on the Mechanical Properties, Pore Structure, and Microstructure of Cement Mortar

Abstract

1. Introduction

2. Experimental

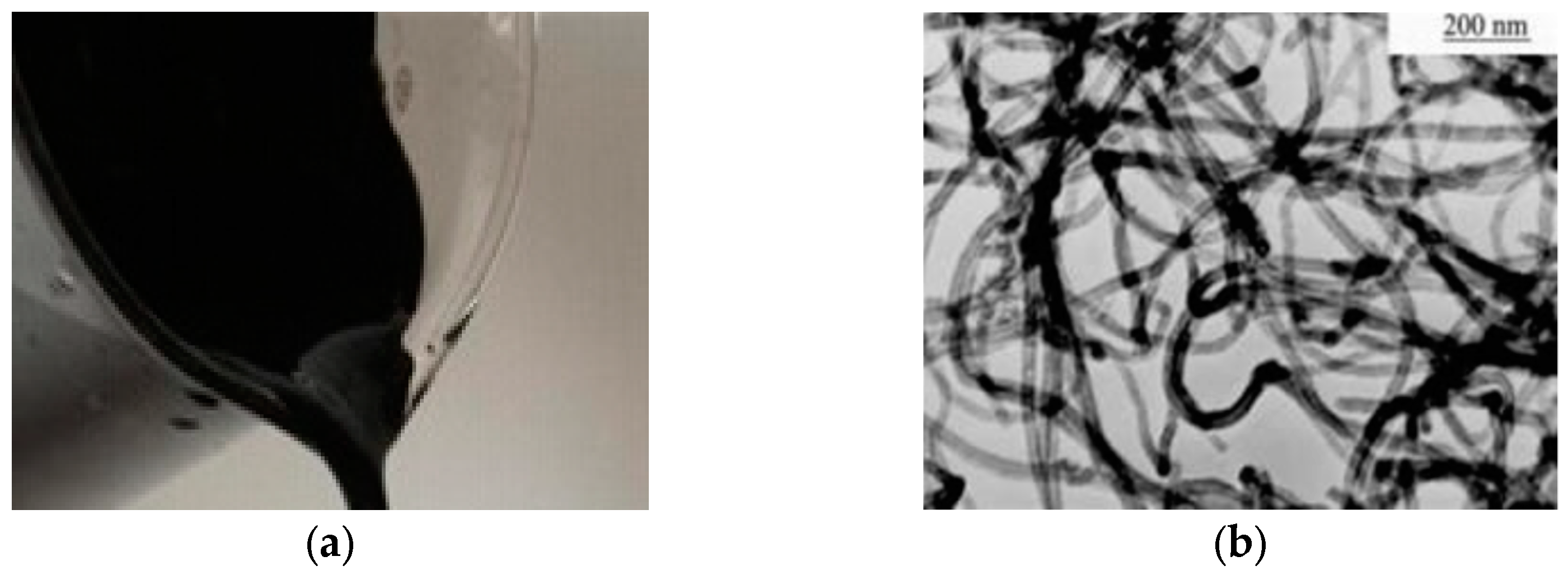

2.1. Raw Materials

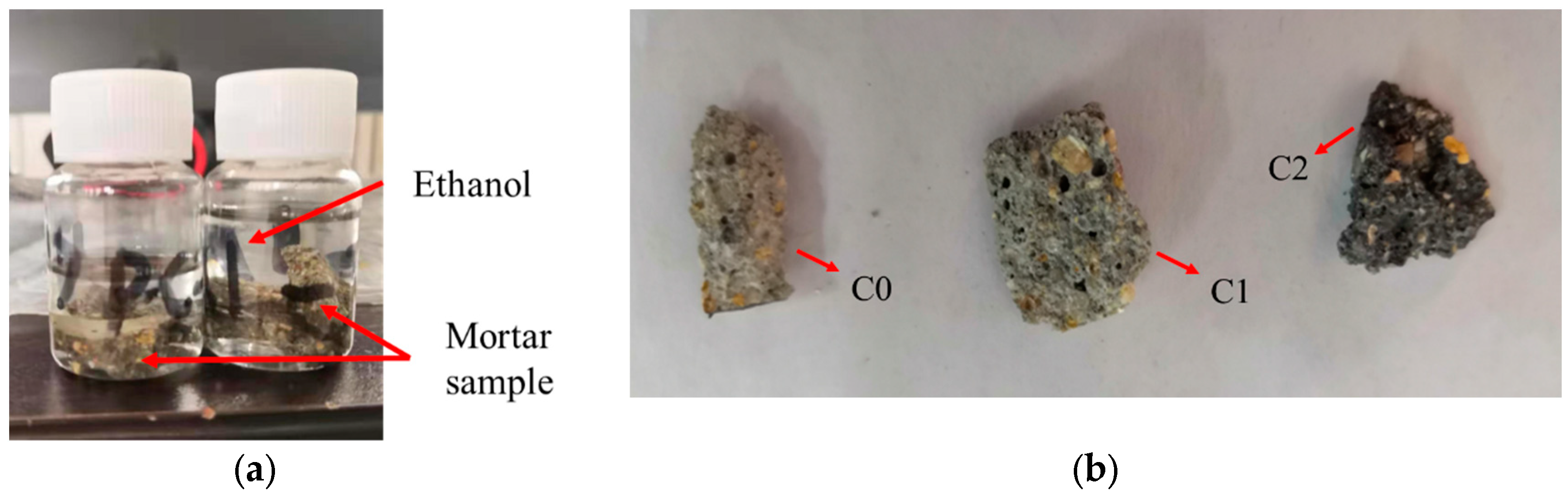

2.2. Sample Preparation

2.3. Testing Procedures

2.3.1. Mechanical Strength Test

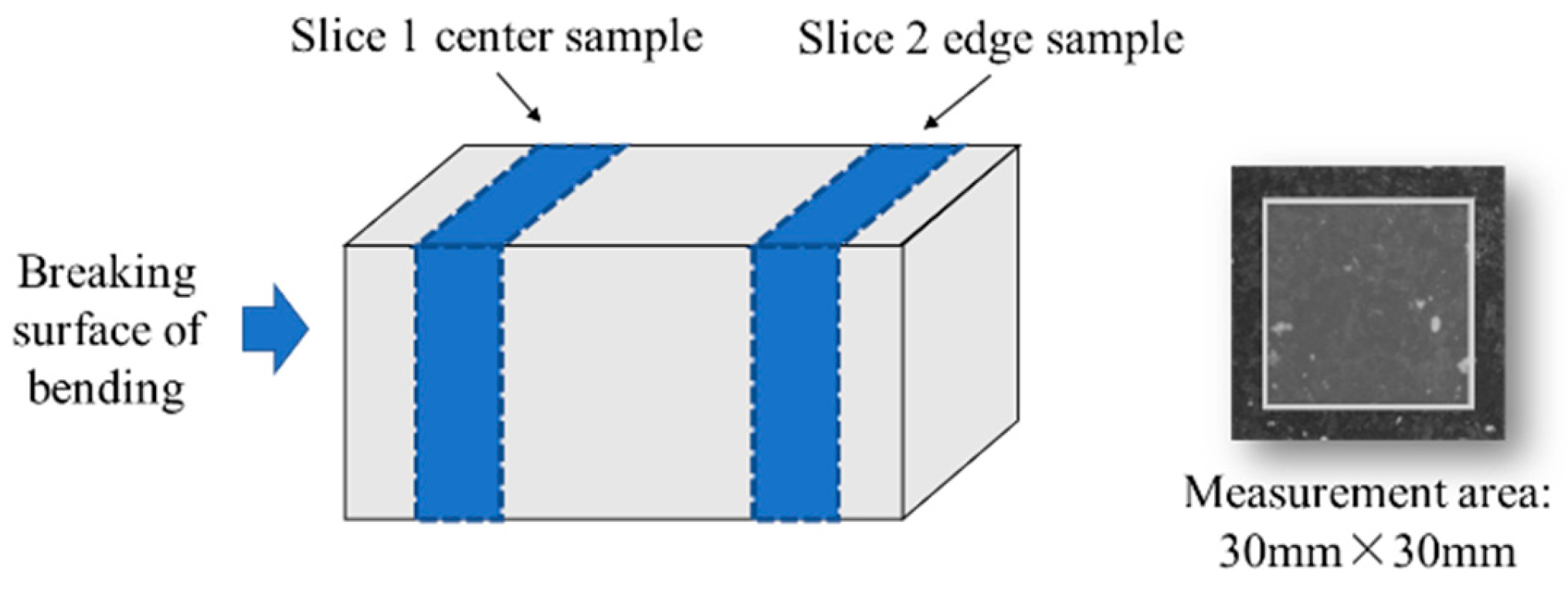

2.3.2. Pore Structure Measurement

2.3.3. SEM Test

3. Results

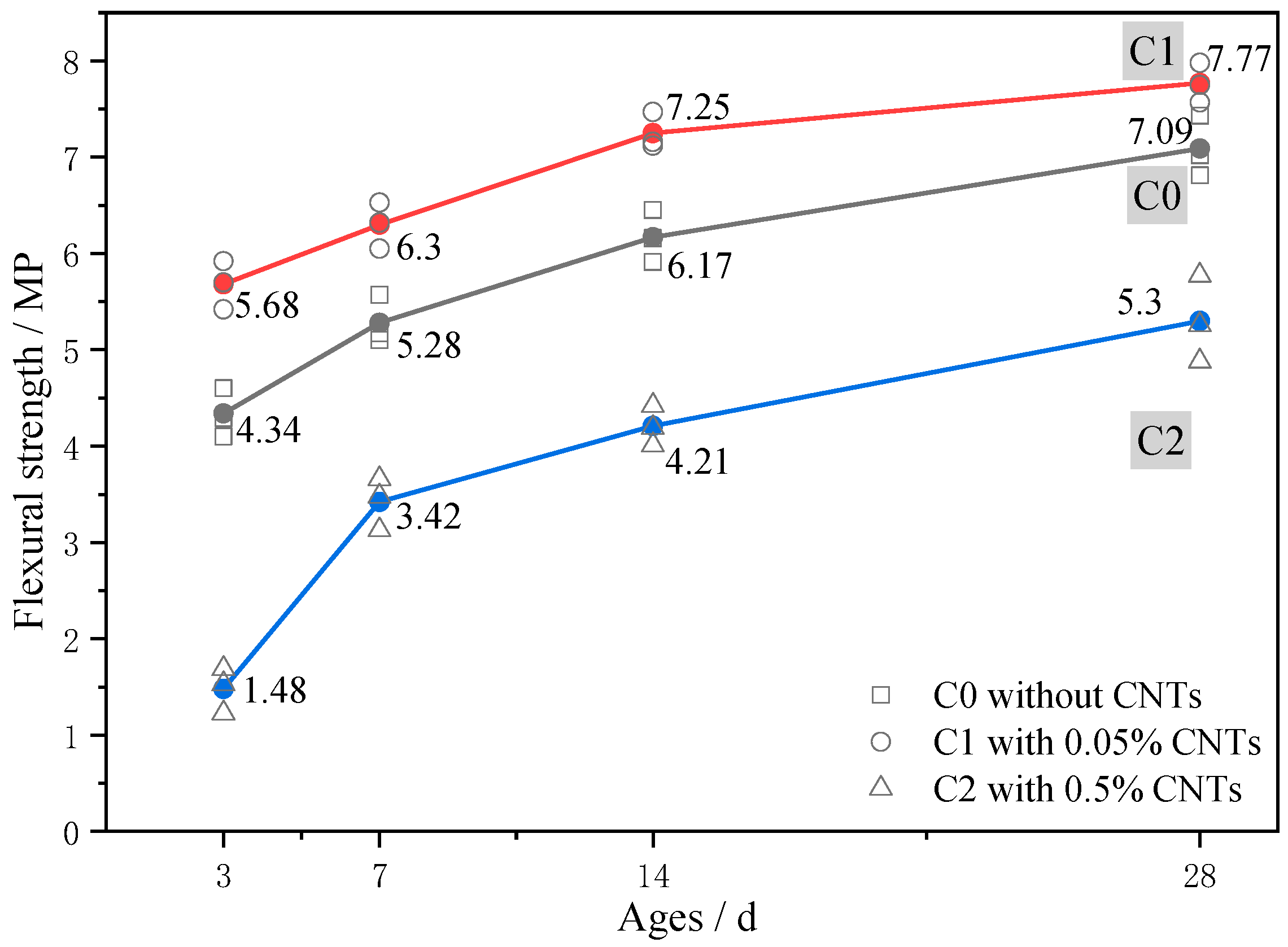

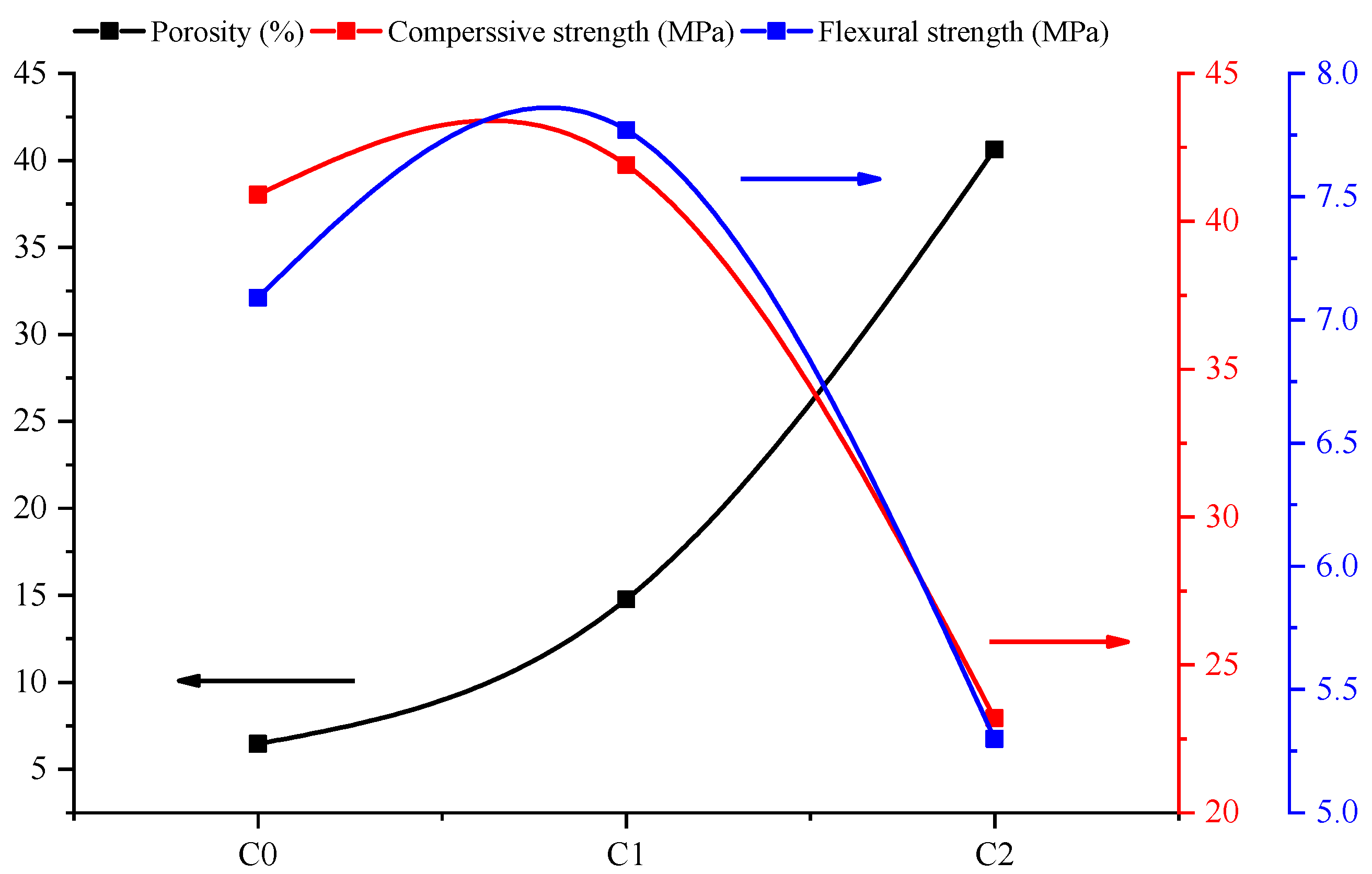

3.1. Mechanical Properties

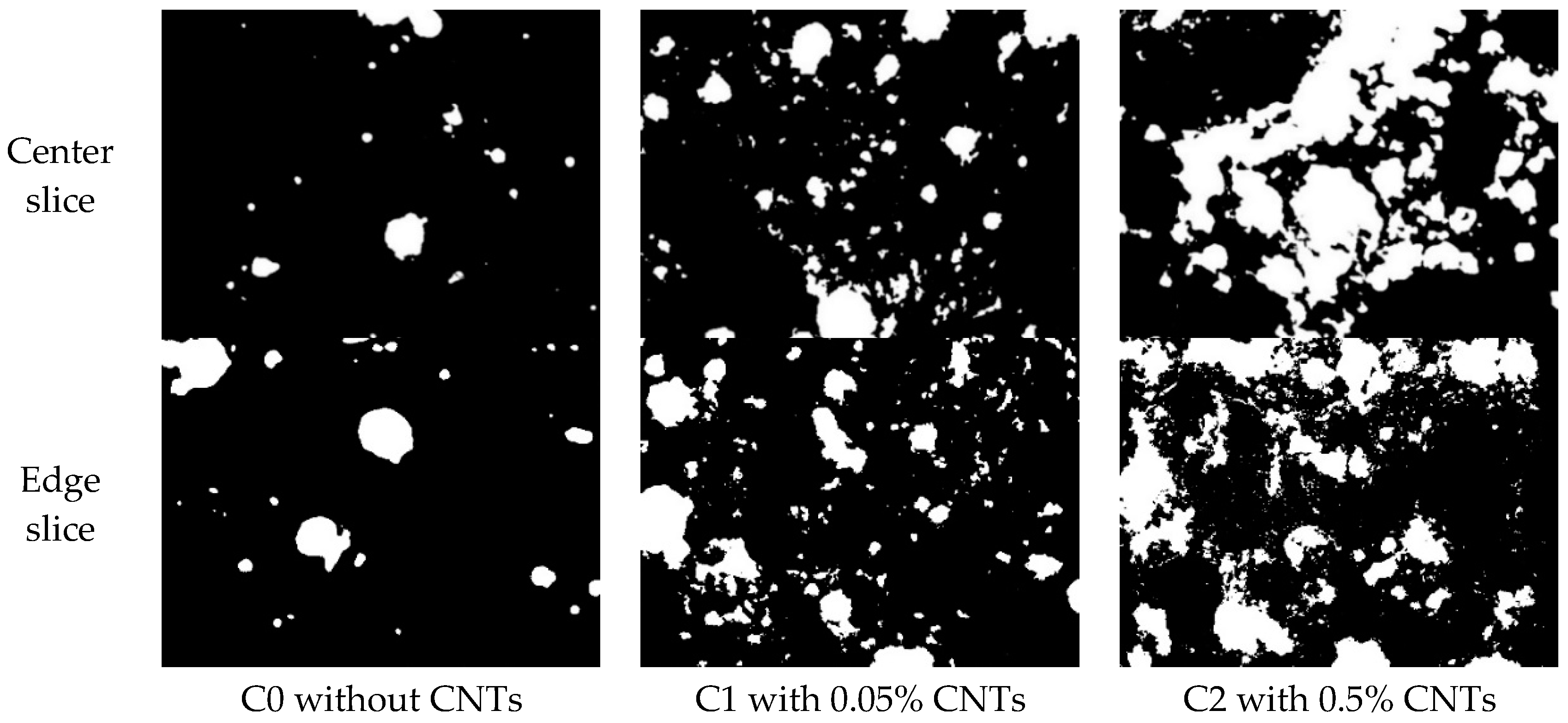

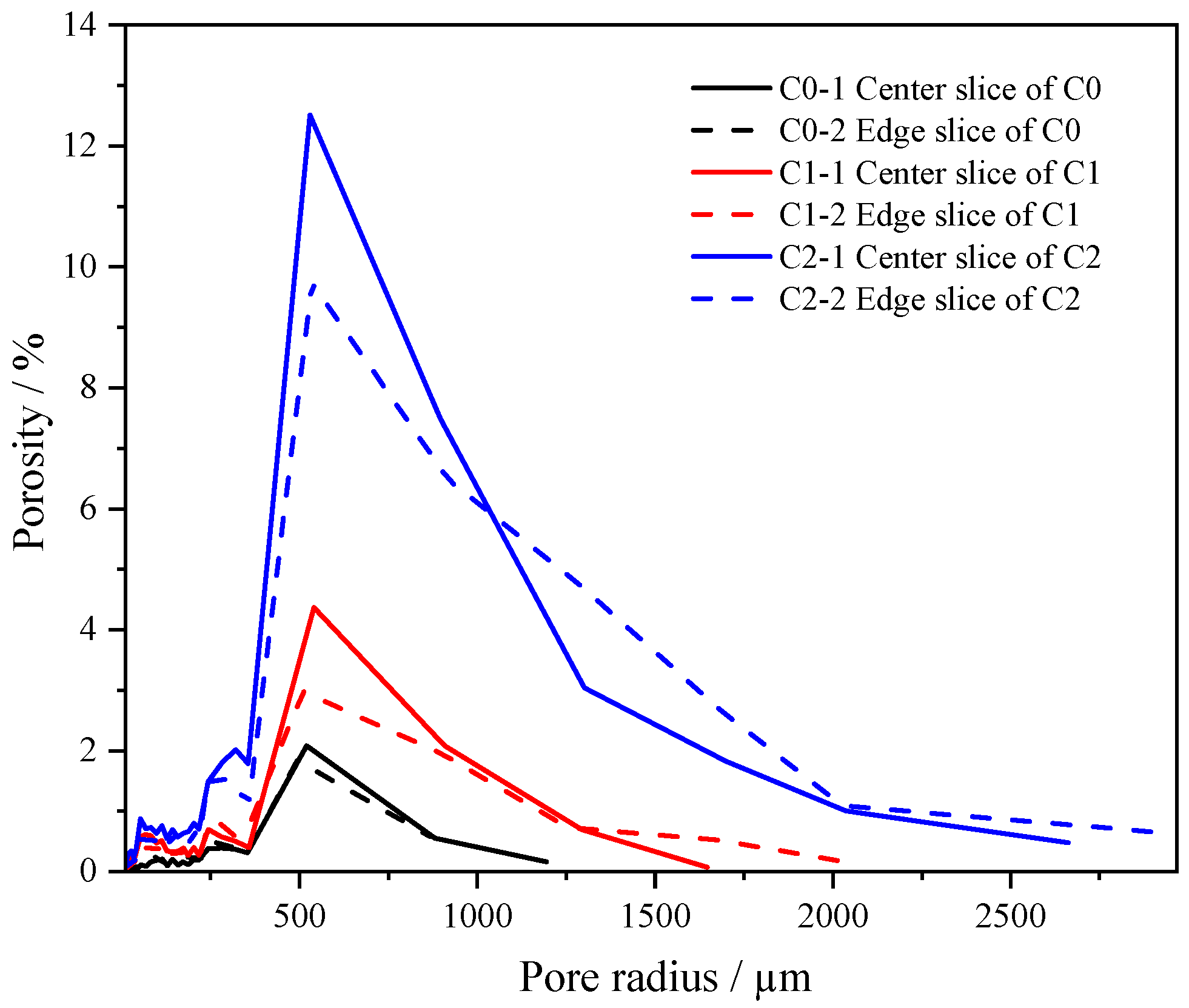

3.2. LTM Results

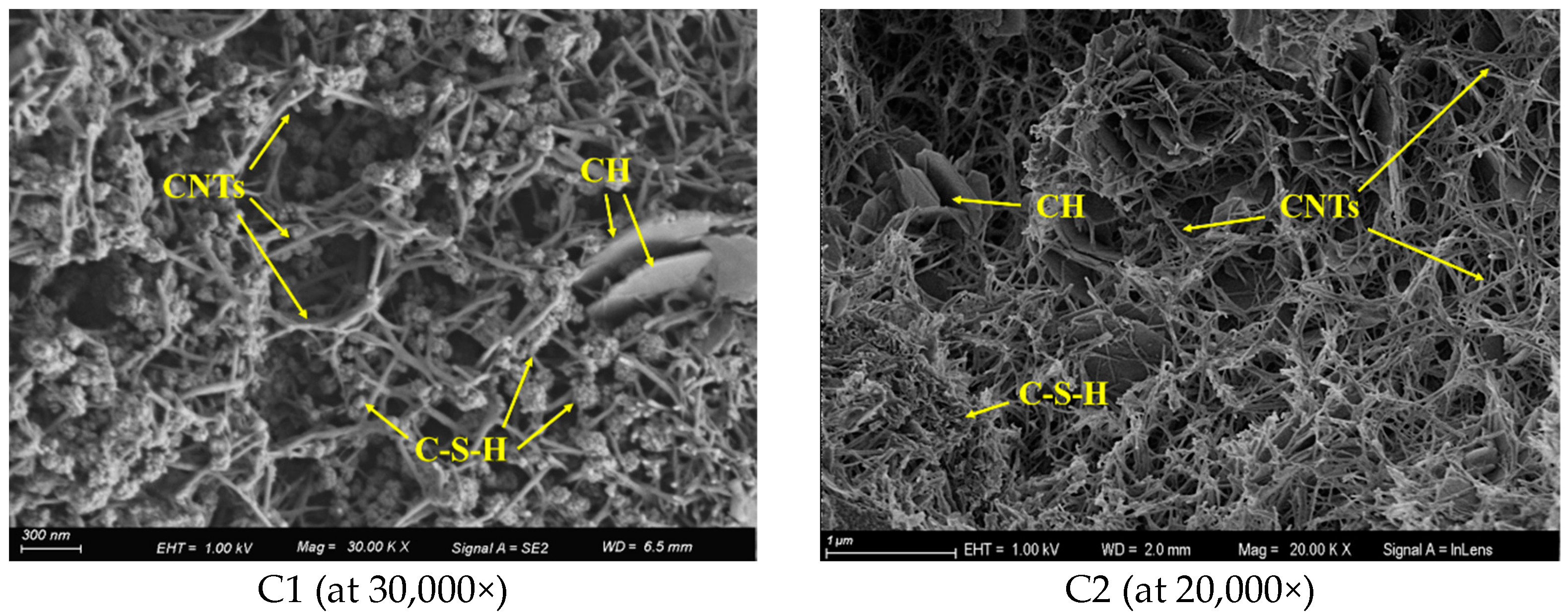

3.3. SEM Results

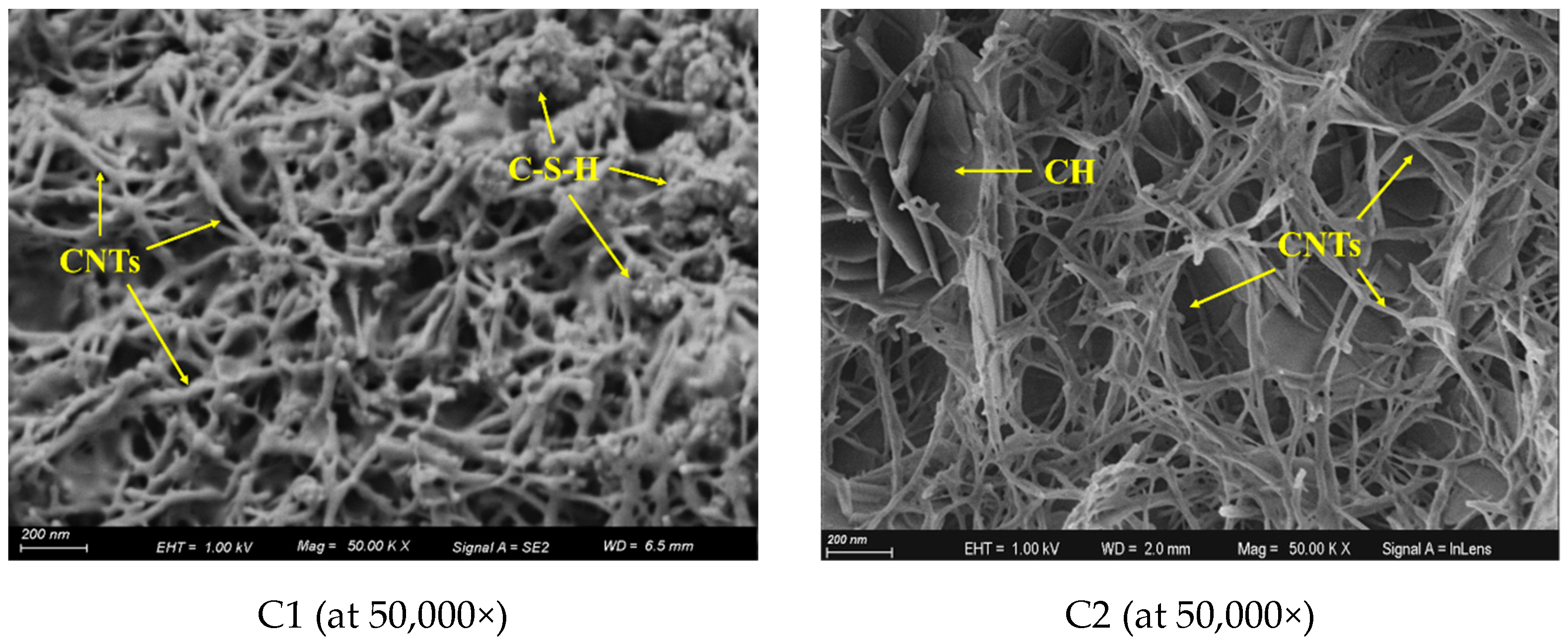

3.3.1. CNTs in Cement-Based Materials

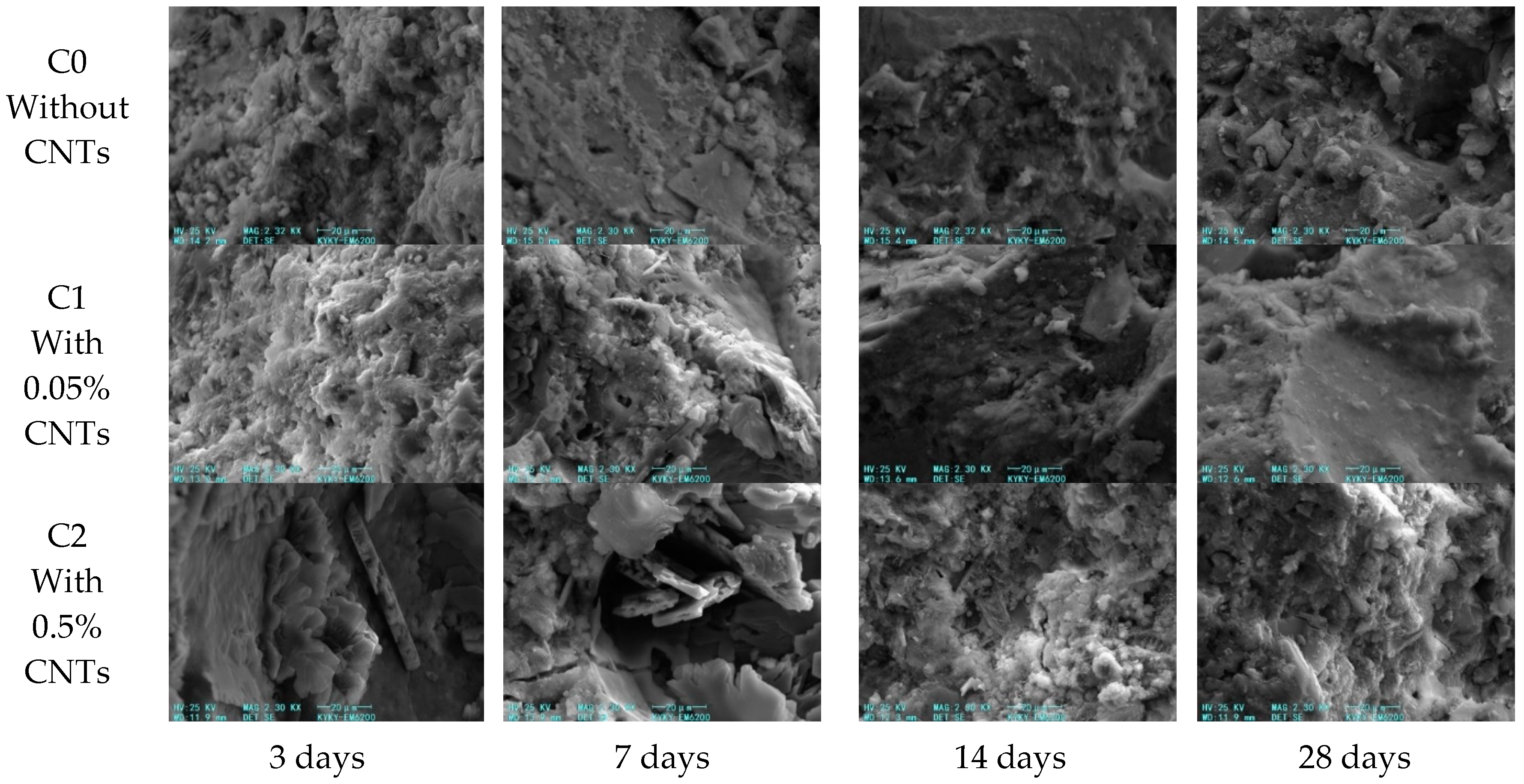

3.3.2. Morphology of Hydration Products

4. Discussion

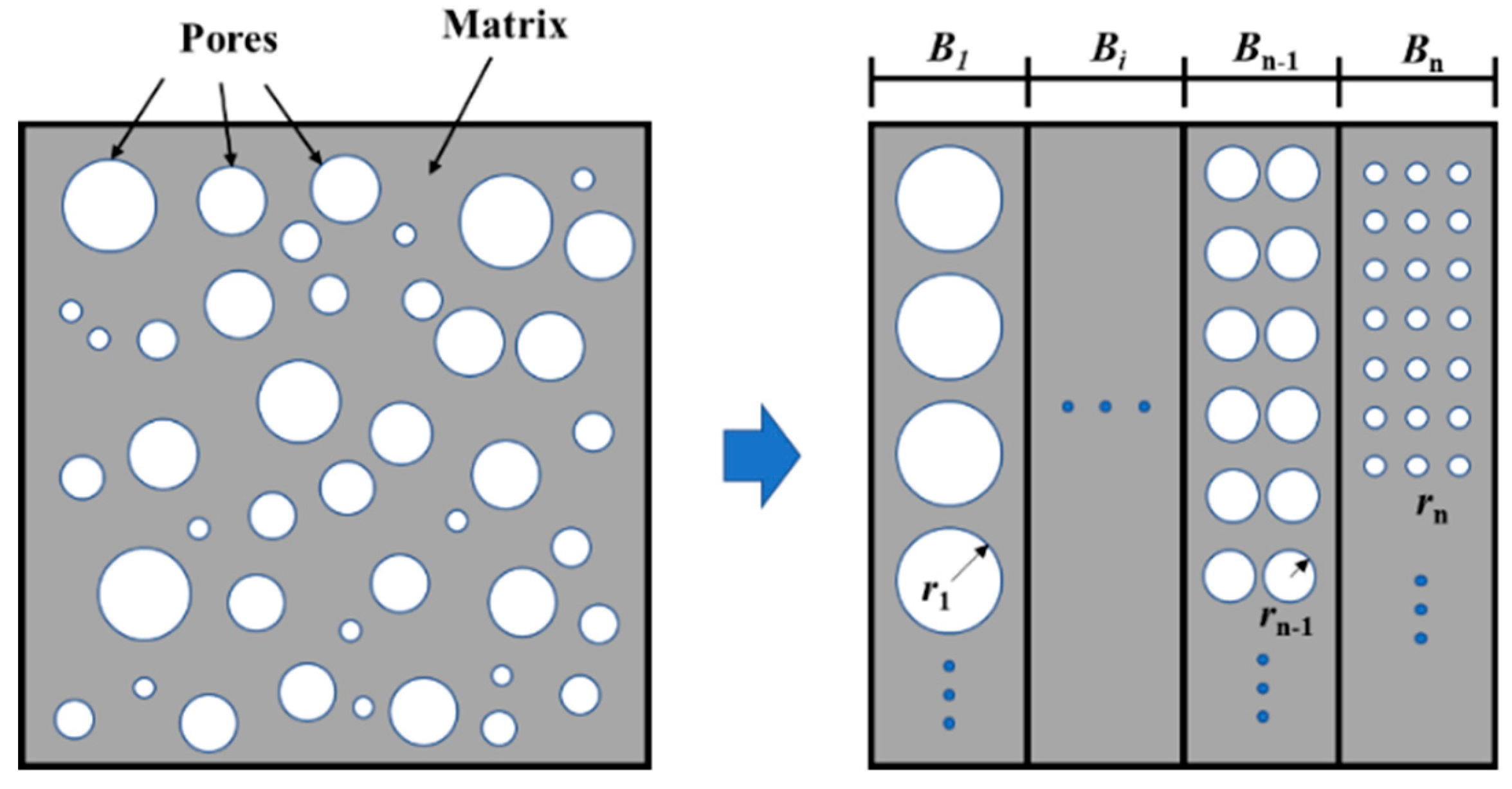

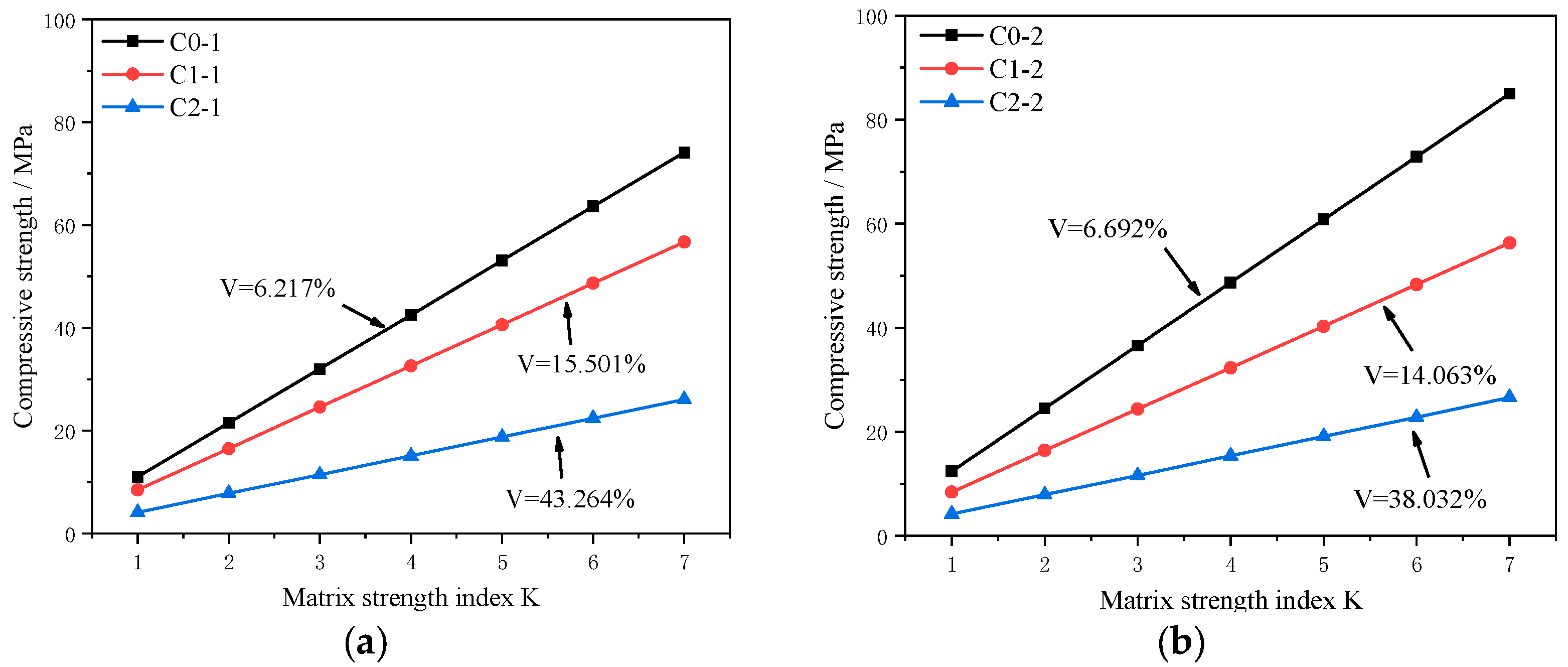

4.1. Quantitative Relationship between Strength and Porosity

4.2. Calculation and Result Analysis

5. Conclusions

- (1)

- The mechanical properties of 0.05% and 0.5% CNT mortars were evaluated. The experimental results show that the strength of mortar is improved by adding 0.05% CNT, while the negative impact occurred with the addition content of CNTs up to 0.5%.

- (2)

- The pore structure of mortars was studied. The total porosity of mortar containing 0.05% ~ 0.5% CNTs were increased by 15% ~ 40% compared to that of the reference normal mortar. In addition, the increase of pores mainly appeared in the range of pores with diameter of 500–1000 um.

- (3)

- The microstructure of CNT–cement composites was observed. The CNTs can be well dispersed in mortar when they are used with dispersant, and CNT meshwork will form in cement matrix, the compressive strength of which can be improved accordingly.

- (4)

- There is no doubt that both of the strength of cement matrix and porosity of mortar are increase with the addition of CNTs. But the compressive strength of mortar is irregular under the combined effect of the matrix strength and mortar porosity. The strength decrease of the mortar with 0.5% CNTs is mainly due to the sharp increase of porosity, which may be caused by the use of dispersant. Therefore, it is necessary to study the application method of CNTs to take the advantage of the excellent improvement capability of CNTs to cement matrix strength.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sumio, I. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar]

- Shuchen, Z.; Na, Z.; Jin, Z. Controlled Synthesis of Carbon Nanotubes: Past, Present and Future. Acta Phys-Chim. Sin. 2020, 36, 1–16. [Google Scholar]

- Parvez, A.; Foster, S.J. Fatigue of Steel-Fibre-Reinforced Concrete Prestressed Railway Sleepers. Eng. Struct. 2017, 141, 241–250. [Google Scholar] [CrossRef]

- Long, N.M.; Phan-Vu, P.; Tran-Thanh, D.; Truong, Q.P.; Rovnak, M. Flexural-strengthening efficiency of CFRP sheets for unbonded post-tensioned concrete T-beams. Eng. Struct. 2018, 166, 1–15. [Google Scholar]

- Han, B.; Yu, X.; Ou, J. Multifunctional and Smart Carbon Nanotube Reinforced Cement-Based Materials; Springer-Verlag: Berlin/Heidelberg, Germany, 2011; pp. 1–47. [Google Scholar]

- Habermehl-Cwirzen, K.; Penttala, V.; Cwirzen, A. Surface decoration of carbon nanotubes and mechanical properties of cement/carbon nanotube composites. Adv. Cem. Res. 2008, 20, 65–73. [Google Scholar] [CrossRef]

- Morsy, M.S.; Alsayed, S.H.; Aqel, M. Hybrid effect of carbon nanotube and nano-clay on physico-mechanical properties of cement mortar. Constr. Build. Mate. 2011, 25, 145–149. [Google Scholar] [CrossRef]

- María, D.C.C.; Galao, O.; Baeza, F.; Zornoza, E.; Garcés, P. Mechanical Properties and Durability of CNT Cement Composites. Materials 2014, 7, 1640–1651. [Google Scholar]

- Wang, B.M.; Liu, S.; Han, Y.; Leng, P. Preparation and Durability of Cement-Based Composites Doped with Multi-Walled Carbon Nanotubes. Nanosc. Nanotech. Let. 2015, 7, 411–416. [Google Scholar] [CrossRef]

- Xie, Z. Mechanical and Frost Resistance Performance of Multi-walled Carbon Nanotubes Reinforced Cement Composites. B. Chin. Ceram. Soc. 2015, 34, 268–272. [Google Scholar]

- Li, W.W.; Wei-Ming, J.; Yao-Cheng, W.; Yi, L.; Ruo-Xu, S.; Feng, X. Investigation on the Mechanical Properties of a Cement-Based Material Containing Carbon Nanotube under Drying and Freeze-Thaw Conditions. Materials 2015, 8, 8780–8792. [Google Scholar] [CrossRef]

- Qinghua, L.; Songjie, X.; Shilang, X.; Yao, L.; Jintao, K.; Yuxing, W. Improvement of the initial fracture toughness of fiber mortar by carbon nanotubes. J. Build. Mater. 2017, 20, 185–190. [Google Scholar]

- Shi, T.; Zexin, L.; Shanshan, L. Autogenous shrinkage and crack resistance of carbon nanotubes reinforced cement based composites. Acta. Mater. Compos. Sin. 2019, 36, 1528–1535. [Google Scholar]

- Xu, S.; Liu, J.; Li, Q. Mechanical properties and microstructure of multi-walled carbon nanotube-reinforced cement paste. Constr. Build. Mater. 2015, 76, 16–23. [Google Scholar] [CrossRef]

- Zuo, J.; Wu, Y.; Wu, K. Seebeck Effect and Mechanical Properties of Carbon Nanotube-Carbon Fiber/Cement Nanocomposites. Fullerene Sci. Techn. 2014, 23, 383–391. [Google Scholar] [CrossRef]

- Gengying, L.; Peiming, W. Micrstructure and mechanical properties of carbon nanotubes-cement matrix composites. J. Chin. Ceram. Soc. 2005, 33, 105–108. [Google Scholar]

- Li, G.Y.; Wang, P.M.; Zhao, X. Pressure-sensitive properties and microstructure of carbon nanotube reinforced cement composites. Cem. Concr. Compos. 2007, 29, 377–382. [Google Scholar] [CrossRef]

- Yan, X.; Hongzhi, C.; Qinghua, Q.; Waiching, T.; Xiangming, Z. Study on Utilization of Carboxyl Group Decorated Carbon Nanotubes and Carbonation Reaction for Improving Strengths and Microstructures of Cement Paste. Nanomaterials 2016, 6, 153. [Google Scholar] [CrossRef]

- Nochaiya, T.; Chaipanich, A. Behavior of multi-walled carbon nanotubes on the porosity and microstructure of cement-based materials. Appl. Surf. Sci. 2011, 257, 1941–1945. [Google Scholar] [CrossRef]

- Ping, Z.; Guanghui, D.; Xudong, S. Review on Dispersion Methods of Carbon Nanotubes in Cement-based Composites. Mater. Rev. 2018, 32, 149–158. [Google Scholar]

- Rana, S.; Fangueiro, R. A Review on Nanomaterial Dispersion, Microstructure, and Mechanical Properties of Carbon Nanotube and Nanofiber Reinforced Cementitious Composites. J. Nanomater. 2013, 2013, 80. [Google Scholar]

- Jiyan, L.; Xiaofeng, S.; Ji, Q.; Xin, L. Influences on dispersion of SiO2 nanopowder in aqueous system. B. Chin. Ceram. Soc. 2010, 29, 1447–1450. [Google Scholar]

- Yaoqun, X.; Shuguang, L.; Juan, W.; Xiaopeng, W. Study on influence of nano-material on durability and functionality of concrete. Wat. Rec. Hydro. Engin. 2017, 48, 208–215. [Google Scholar]

- Jie, H.; Yujun, Z.; Peng, L. Electron microscopic study on disperse state of carbon nanotubes. J. Chin. Elect. Micro. Soc. 2003, 22, 415–418. [Google Scholar]

- Ibarra, Y.S.D.; Gaitero, J.J.; Erkizia, E.; Campillo, I. Atomic force microscopy and nanoindentation of cement pastes with nanotube dispersions. Phys. Status. Solidi. 2006, 203, 1076–1081. [Google Scholar] [CrossRef]

- Shao, H.; Chen, B.; Li, B.; Tang, S.; Li, Z. Influence of dispersants on the properties of CNTs reinforced cement-based materials. Constru. Build. Mater. 2017, 131, 186–194. [Google Scholar] [CrossRef]

- Kumar, R.; Bhattacharjee, B. Porosity, pore size distribution and in situ strength of concrete. Cem. Concr. Res. 2003, 33, 155–164. [Google Scholar] [CrossRef]

- Bu, J.; Tian, Z. Relationship between pore structure and compressive strength of concrete: Experiments and statistical modeling. Sadha 2016, 41, 337–344. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive strength, chloride diffusivity and pore structure of high performance metakaolin and silica fume concrete. Constru. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- GB8076-2008, Concrete Admixtures; China Building Materials Academy: Beijing, China, 2008; (Chinese National Standard).

- GB/T 17671-1999, Method of Testing Cements-Determination of Strength; State Bureau of Building Materials Industry: Beijing, China, 1999; (Chinese National Standard).

- SL352-2006, Test Code for Hydraulic Concrete; China Renewable Energy Engineering Institute: Beijing, China, 2006; (Chinese National Standard).

- Peng, Z.; Jinyi, W.; Kejin, W.; Qingfu, L. Influence of nano-SiO2 on properties of fresh and hardened high performance concrete: A state-of-the-art review. Constru. Build. Mater. 2017, 148, 648–658. [Google Scholar]

- Li, W.; Weiming, J.; Forood, T.I.; Yaocheng, W.; Gengying, L.; Yi, L.; Feng, X. Nano-Silica Sol-Gel and Carbon Nanotube Coupling Effect on the Performance of Cement-Based Materials. Nanomaterials 2017, 7, 185. [Google Scholar] [CrossRef]

- Qin, W.; Shiyu, L.; Jian, W.; Shuo, P.; Chunxiang, L.; Xinyou, C.; Ziwei, G. Effect of Graphene Oxide on Hydration Process and Main Hydration Products of Cement. J. Chin. Ceram. Soc. 2018, 46, 163–172. [Google Scholar]

- Kearsley, E.P.; Wainwright, P.J. The effect of porosity on the strength of foamed concrete. Cem. Concr. Res. 2002, 32, 233–239. [Google Scholar] [CrossRef]

- Tang, L. A study of the quantitative relationship between strength and pore-size distribution of porous materials. Cem. Concr. Res. 1986, 16, 87–96. [Google Scholar]

- Yongxin, L.; Yimin, C.; Xinyang, H.; Jiangxiong, W.; Wensheng, Z. Pore volume fractal dimension of fly ash-cement paste and its relationship between the pore structure and strength. J. Chin. Ceram. Soc. 2003, 31, 774–779. [Google Scholar]

- Nanguo, J.; Xianyu, J.; Jianfei, G. Relationship modeling of pore structure and strength of concrete. J. Zhejiang Univ-ES. 2004, 39, 1680–1684. [Google Scholar]

- Krause, B.; Mende, M.; Ptschke, P.; Petzold, G. Dispersability and particle size distribution of CNTs in an aqueous surfactant dispersion as a function of ultrasonic treatment time. Carbon 2010, 48, 2746–2754. [Google Scholar] [CrossRef]

- Qian, C.; Yao, G.; Fan, B.; Rui, H. Mechical properties of cement incorporated with three kinds of carbon-based nanoparticles. J. Adhes. Sci. Technol. 2018, 36, 108–113. [Google Scholar]

| Appearance | Outer Diameter (nm) | Purity | Length (µm) | Specific Surface Area (m2/g) | Tap Density (g/cm3) | True Density (g/cm3) | Solvent | Content |

|---|---|---|---|---|---|---|---|---|

| Black liquid | 30–80 | 98% | 10 | >60 | 0.18 | ~2.1 | Water | 10% |

| Chemical Compositions | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | SO3 | Loss on Ignition | Specific Gravity | Specific Surface (cm2/g) | Bulk Density (g/cm3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Composition (%) | 20.56 | 4.6 | 3.23 | 62.56 | 2.57 | 0.59 | 2.95 | 2.94 | 3.13 | 3530 | 1.7 |

| Aggregate Types | Visual Density (kg/m3) | Fineness Modulus | Water Absorption (%) | Mud Content (%) |

|---|---|---|---|---|

| Natural river sand | 2744 | 2.94 | 0.58 | 3.7 |

| Specimen | Sand (g) | Cement (g) | Water/Cement | Admixture (g) | |

|---|---|---|---|---|---|

| CNTs | Water Reducer | ||||

| C0 | 5400 | 1800 | 0.5 | 0 | 18 |

| C1 | 5400 | 1800 | 0.5 | 0.9 | 18 |

| C2 | 5400 | 1800 | 0.5 | 9 | 18 |

| Size Range | C0-1 | C0-2 | C1-1 | C1-2 | C2-1 | C2-2 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ri | Vi (%) | ri | Vi (%) | ri | Vi (%) | ri | Vi (%) | ri | Vi (%) | ri | Vi (%) | |

| <50 | 19.6 | 0.16 | 16.5 | 0.10 | 24.8 | 0.97 | 23.1 | 0.73 | 21.5 | 1.47 | 21.3 | 0.74 |

| 50–100 | 74.3 | 0.77 | 76.2 | 0.57 | 70.4 | 2.27 | 70.5 | 1.60 | 69.4 | 2.95 | 71.2 | 1.97 |

| 100–200 | 146.1 | 1.29 | 142.9 | 0.90 | 141.4 | 2.19 | 142.4 | 2.08 | 144.5 | 3.88 | 145.3 | 3.12 |

| 200–500 | 344.6 | 3.89 | 268.5 | 1.86 | 262.8 | 2.86 | 276.9 | 3.27 | 277.4 | 8.60 | 270.3 | 6.80 |

| 500–1000 | 866.4 | 0.58 | 569.4 | 2.64 | 621.7 | 6.45 | 615.2 | 4.95 | 624.5 | 20.01 | 642.4 | 16.22 |

| >1000 | None | 1194.7 | 0.16 | 1321.4 | 0.77 | 1707.9 | 1.44 | 1.815 | 6.36 | 1844.5 | 9.18 | |

| V (%) | 6.69 | 6.22 | 15.50 | 14.06 | 43.26 | 38.03 | ||||||

| fc (MPa) | 40.9 | 41.9 | 23.2 | |||||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, S.; Xu, Y.; Wang, J.; Zhang, P.; Guo, J. Modification Effects of Carbon Nanotube Dispersion on the Mechanical Properties, Pore Structure, and Microstructure of Cement Mortar. Materials 2020, 13, 1101. https://doi.org/10.3390/ma13051101

Hu S, Xu Y, Wang J, Zhang P, Guo J. Modification Effects of Carbon Nanotube Dispersion on the Mechanical Properties, Pore Structure, and Microstructure of Cement Mortar. Materials. 2020; 13(5):1101. https://doi.org/10.3390/ma13051101

Chicago/Turabian StyleHu, Shaowei, Yaoqun Xu, Juan Wang, Peng Zhang, and Jinjun Guo. 2020. "Modification Effects of Carbon Nanotube Dispersion on the Mechanical Properties, Pore Structure, and Microstructure of Cement Mortar" Materials 13, no. 5: 1101. https://doi.org/10.3390/ma13051101

APA StyleHu, S., Xu, Y., Wang, J., Zhang, P., & Guo, J. (2020). Modification Effects of Carbon Nanotube Dispersion on the Mechanical Properties, Pore Structure, and Microstructure of Cement Mortar. Materials, 13(5), 1101. https://doi.org/10.3390/ma13051101