Structural Applications of Thermal Insulation Alkali Activated Materials with Reduced Graphene Oxide

Abstract

1. Introduction

2. Materials and Methods

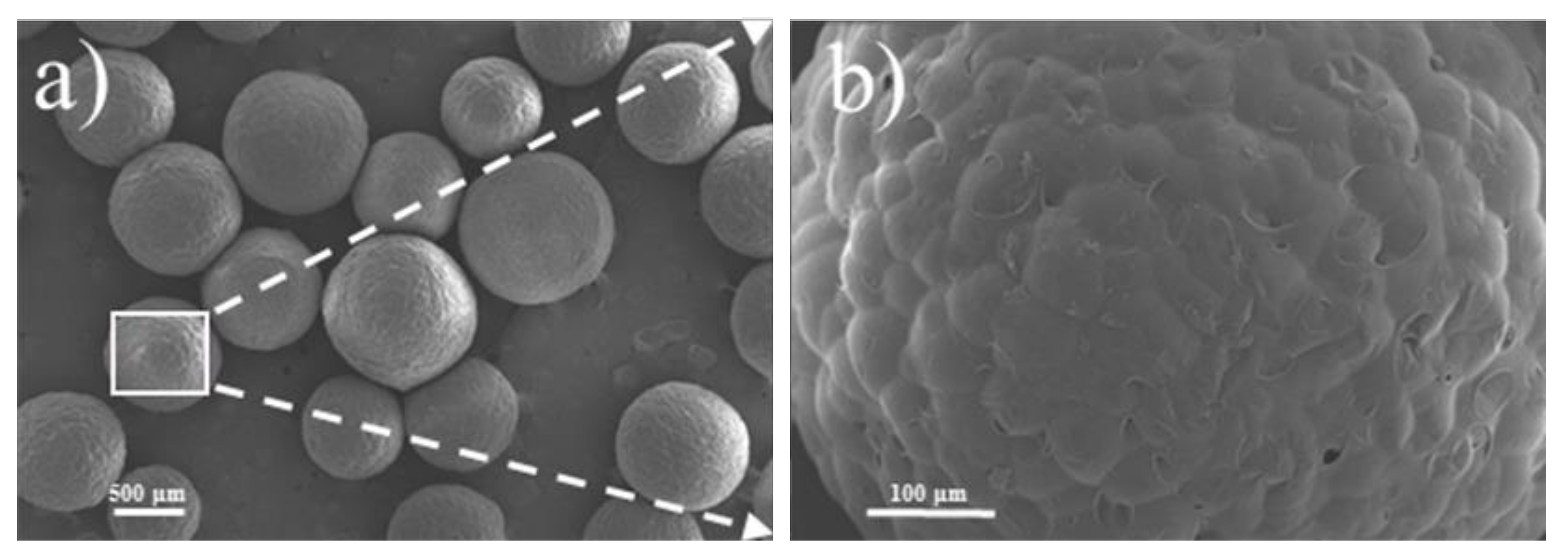

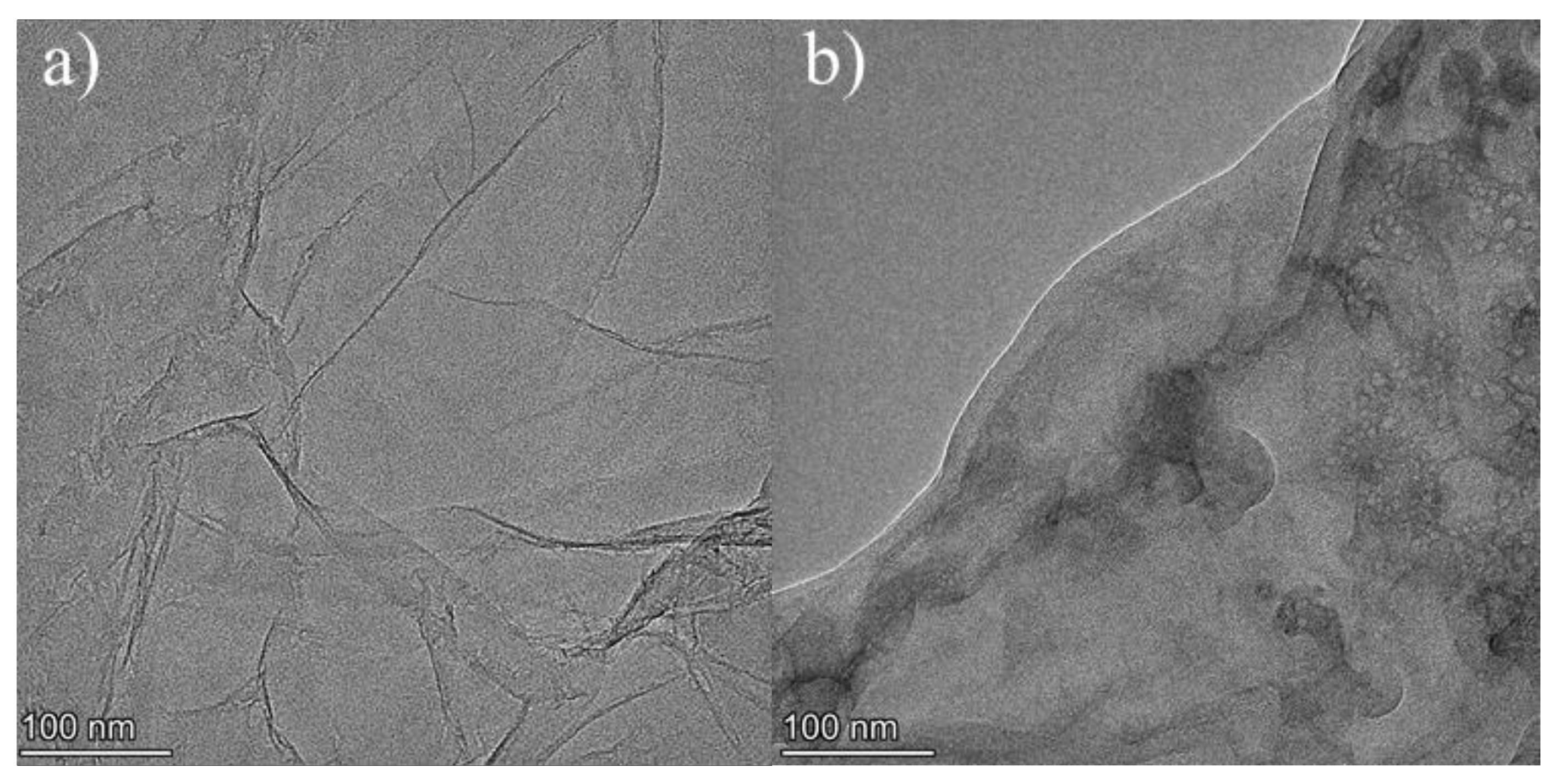

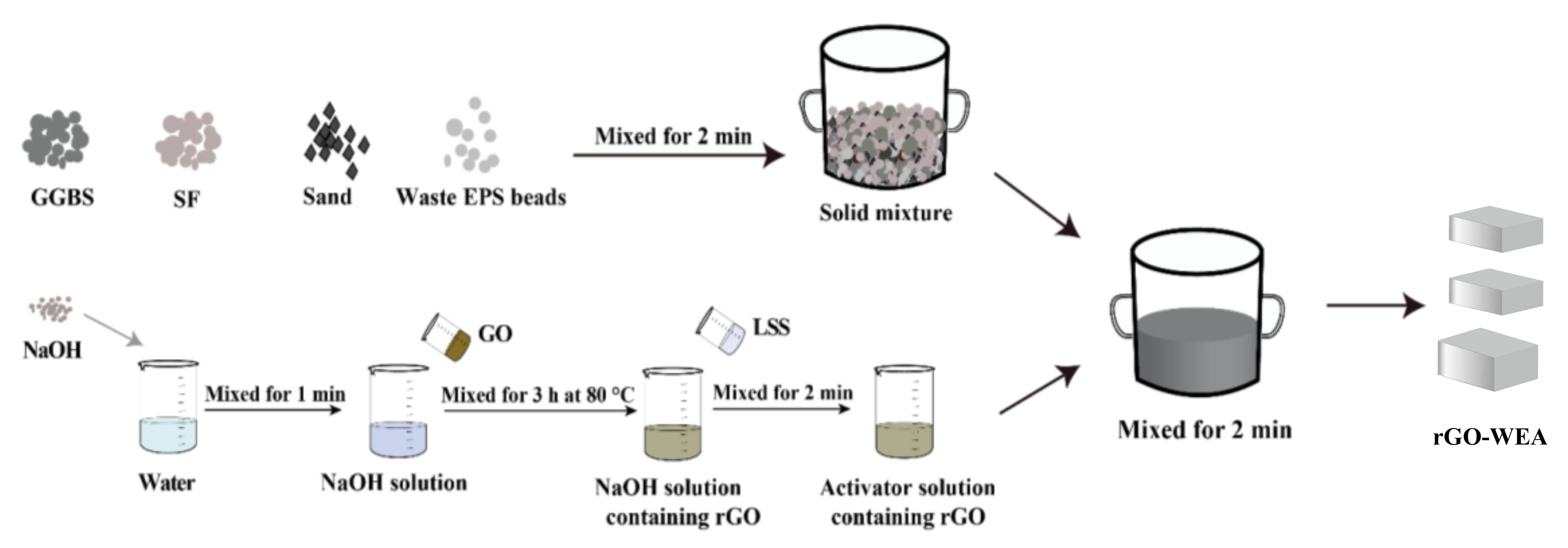

2.1. Raw Materials

2.2. Mix Design and Sample Preparation

2.3. Test Methods

2.3.1. Density Test

2.3.2. Mechanical Test

2.3.3. Thermal Conductivity Test

2.3.4. Microstructural Characterization Analysis

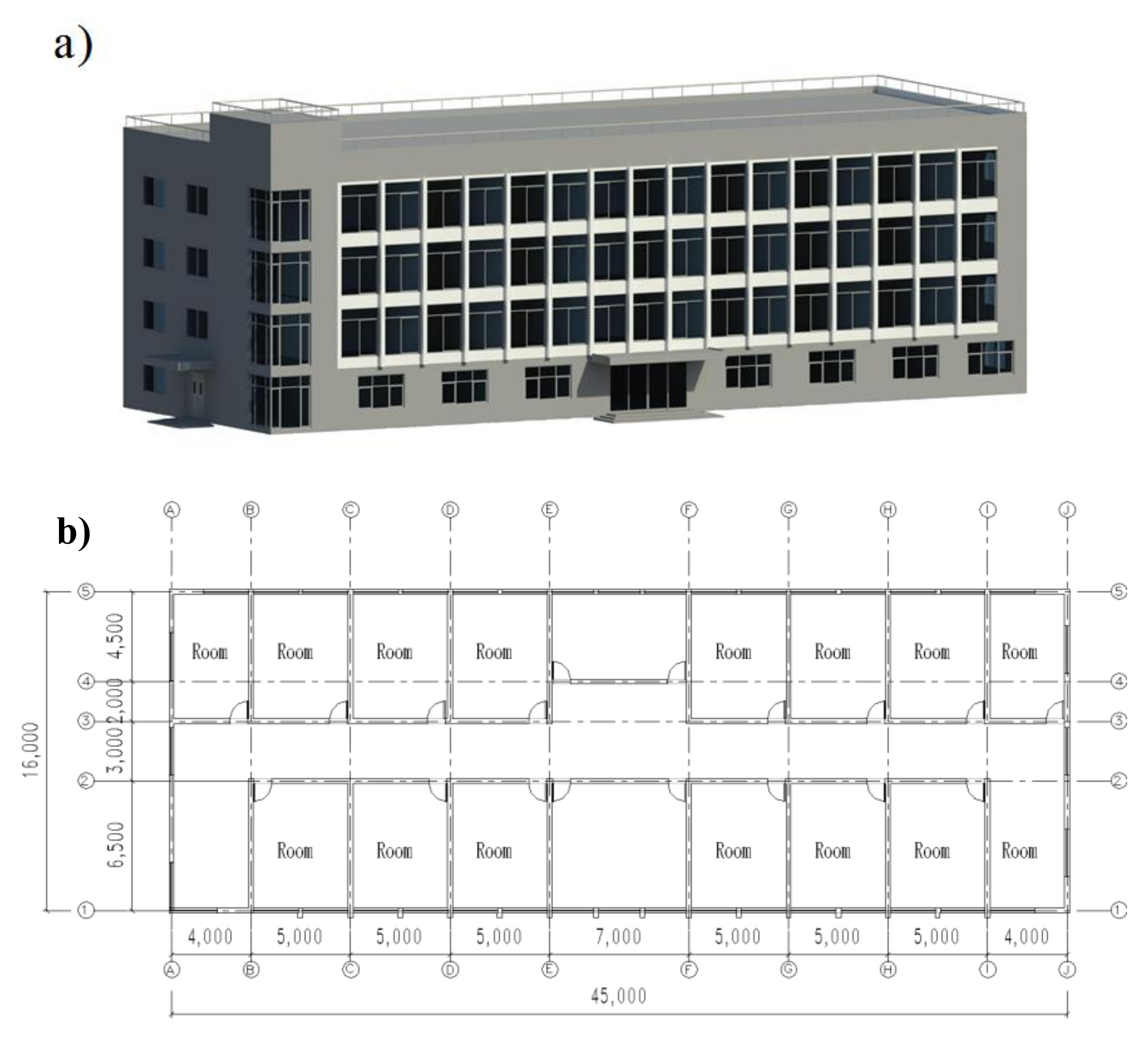

2.3.5. Energy Conservation Evaluation Method

3. Results and Discussion

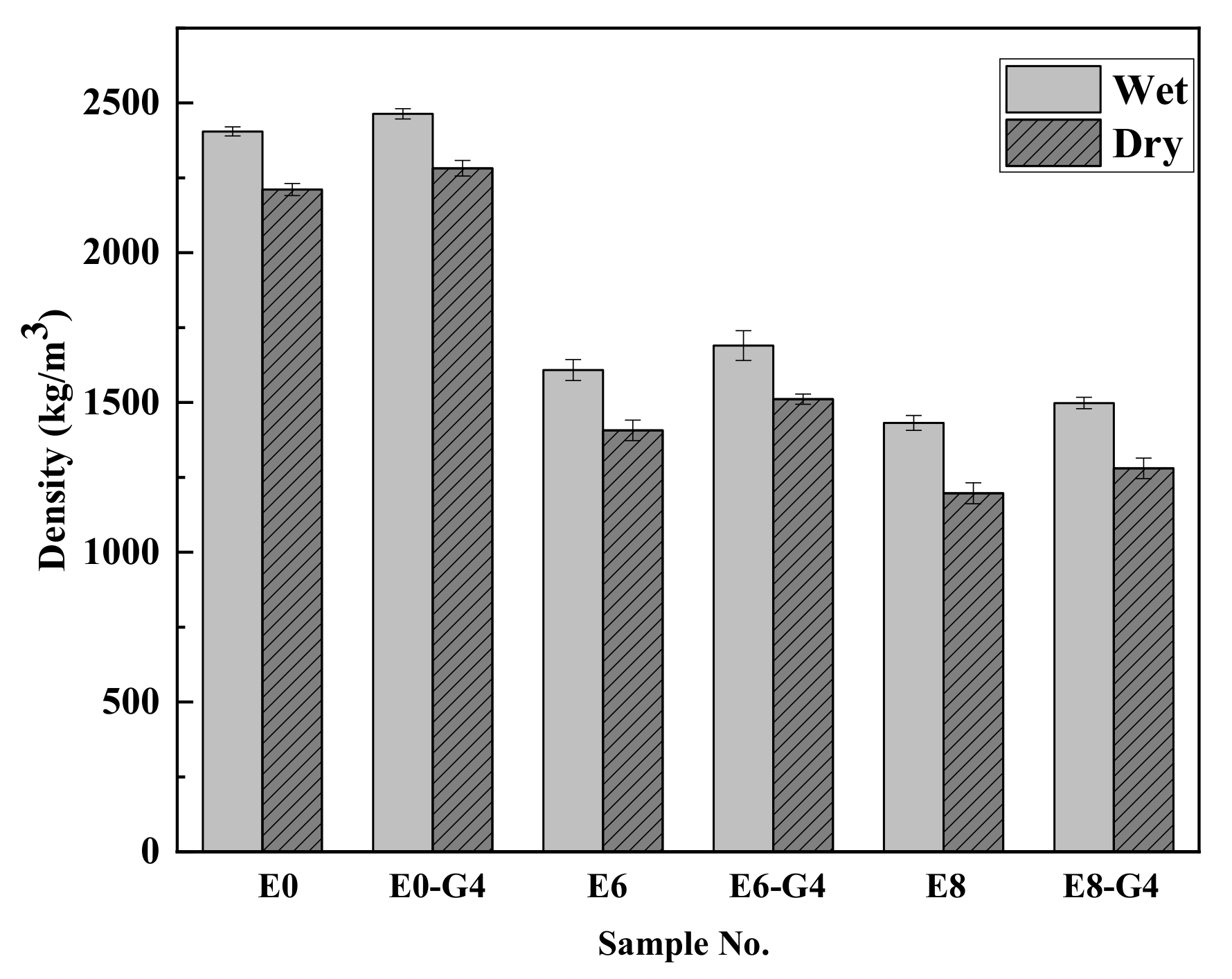

3.1. Density

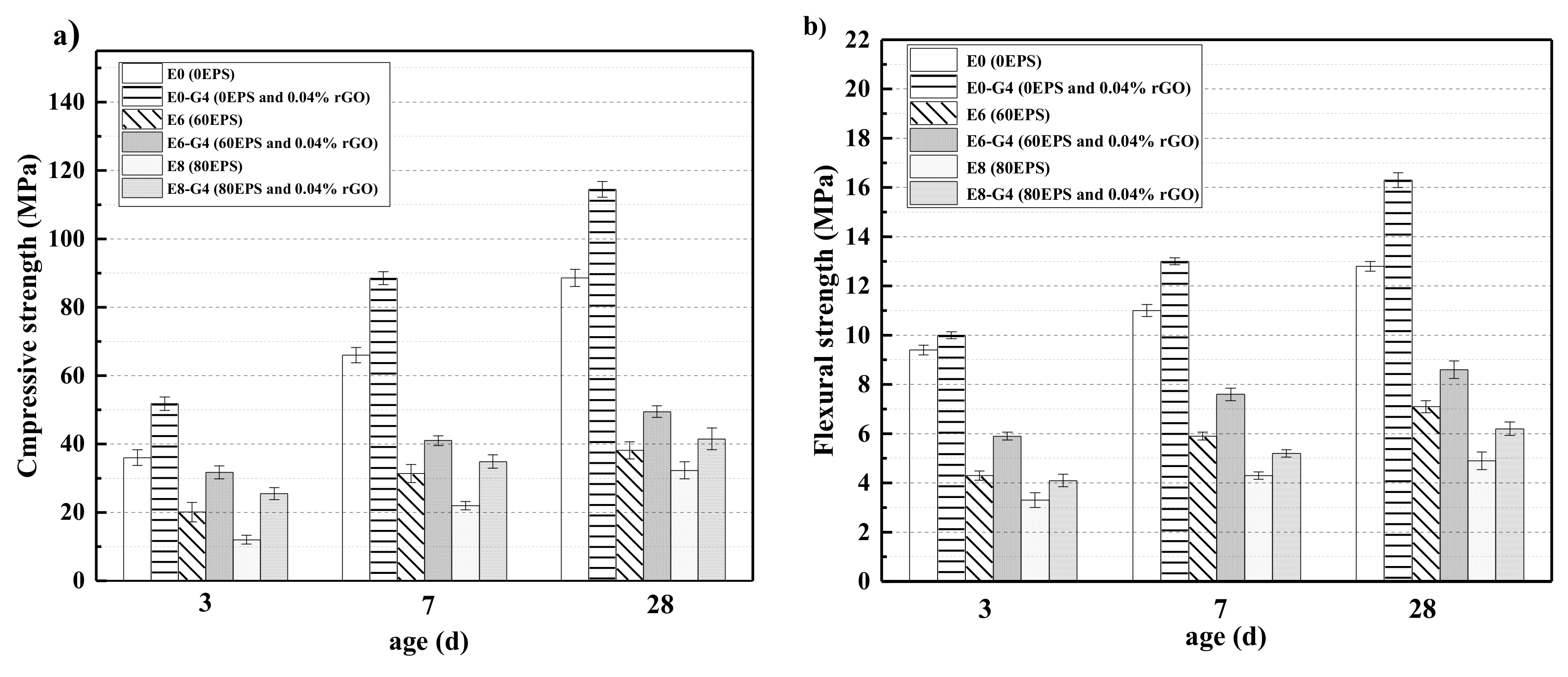

3.2. Mechanical Properties

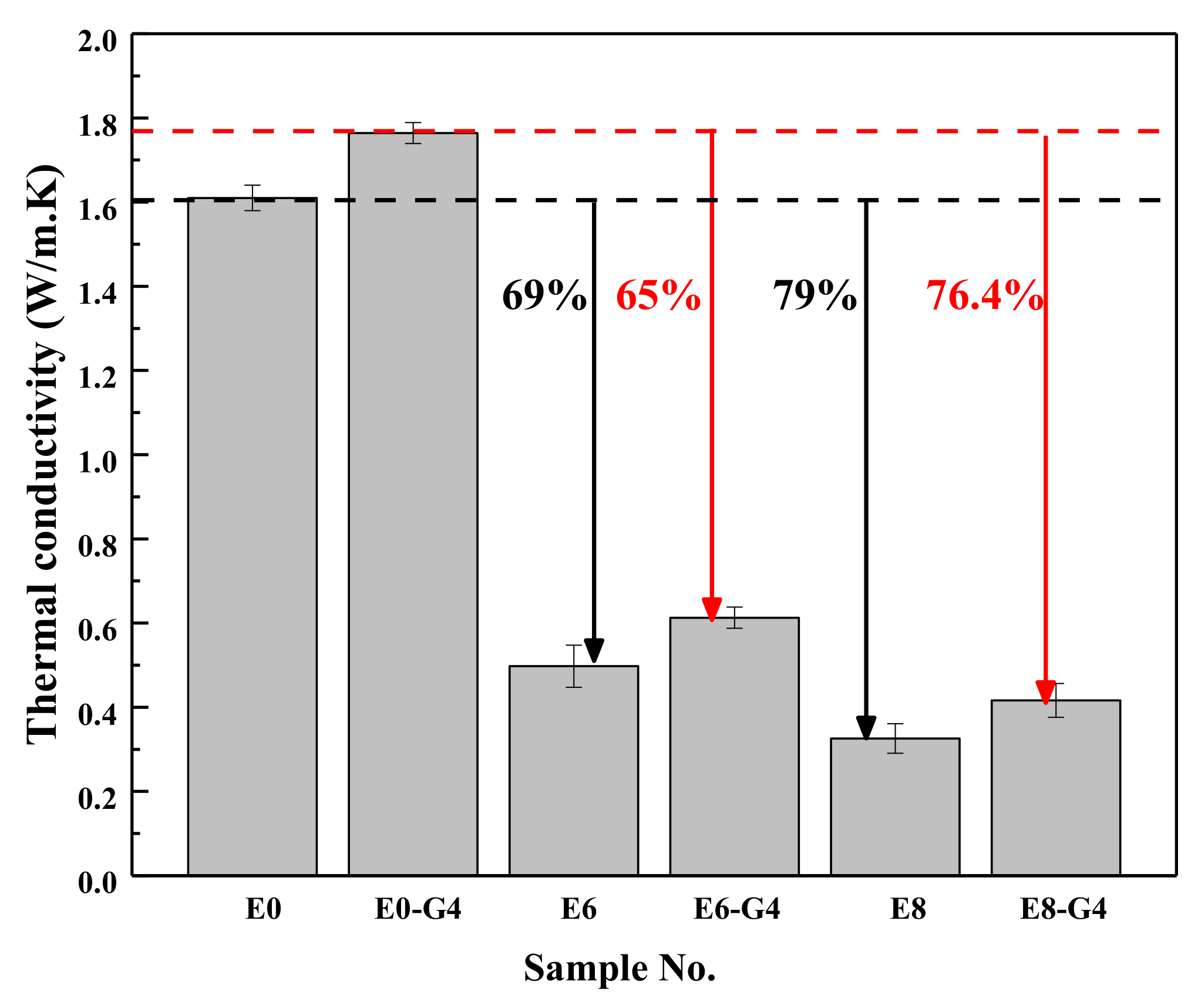

3.3. Thermal Conductivity

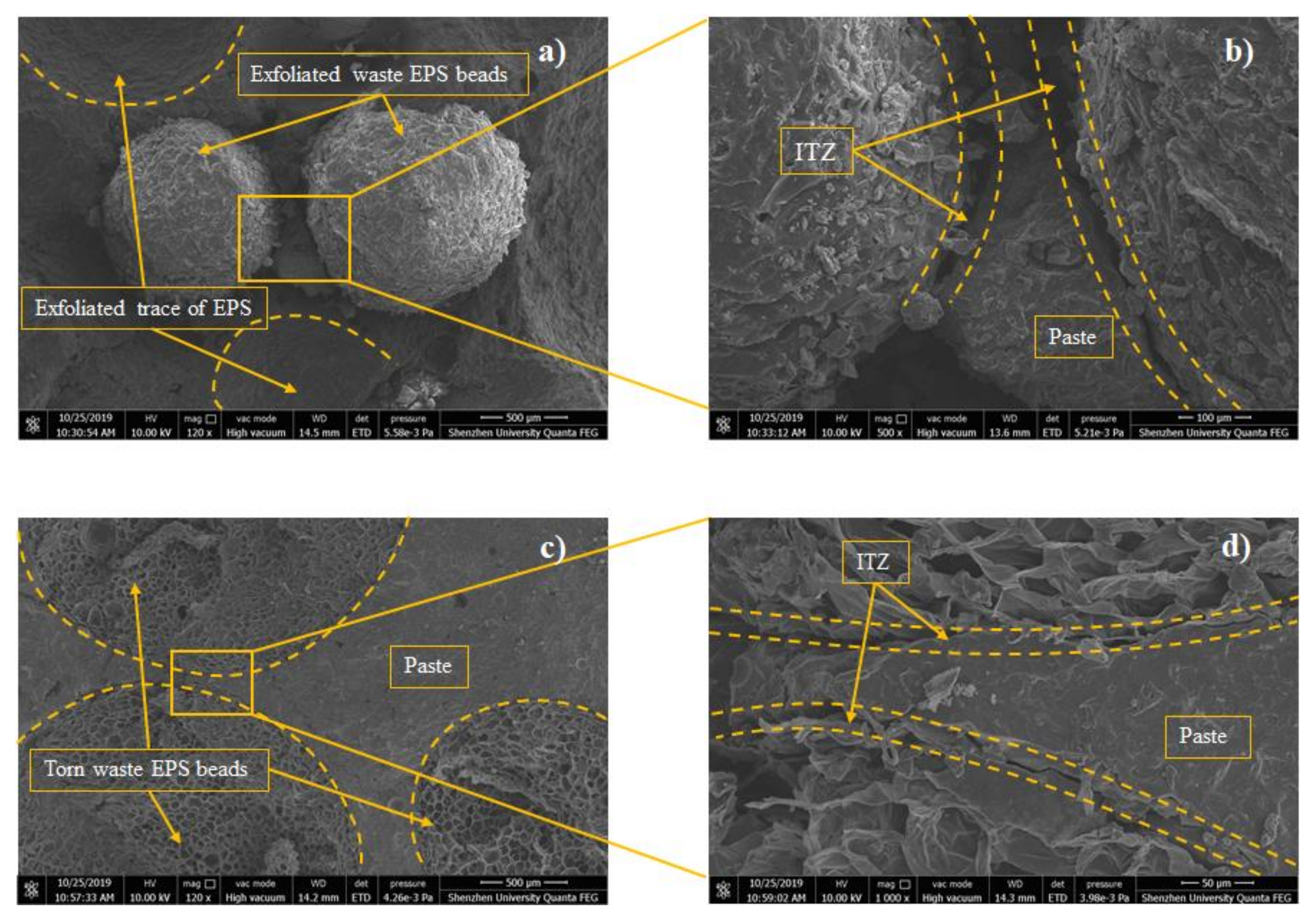

3.4. Microstructural Analysis

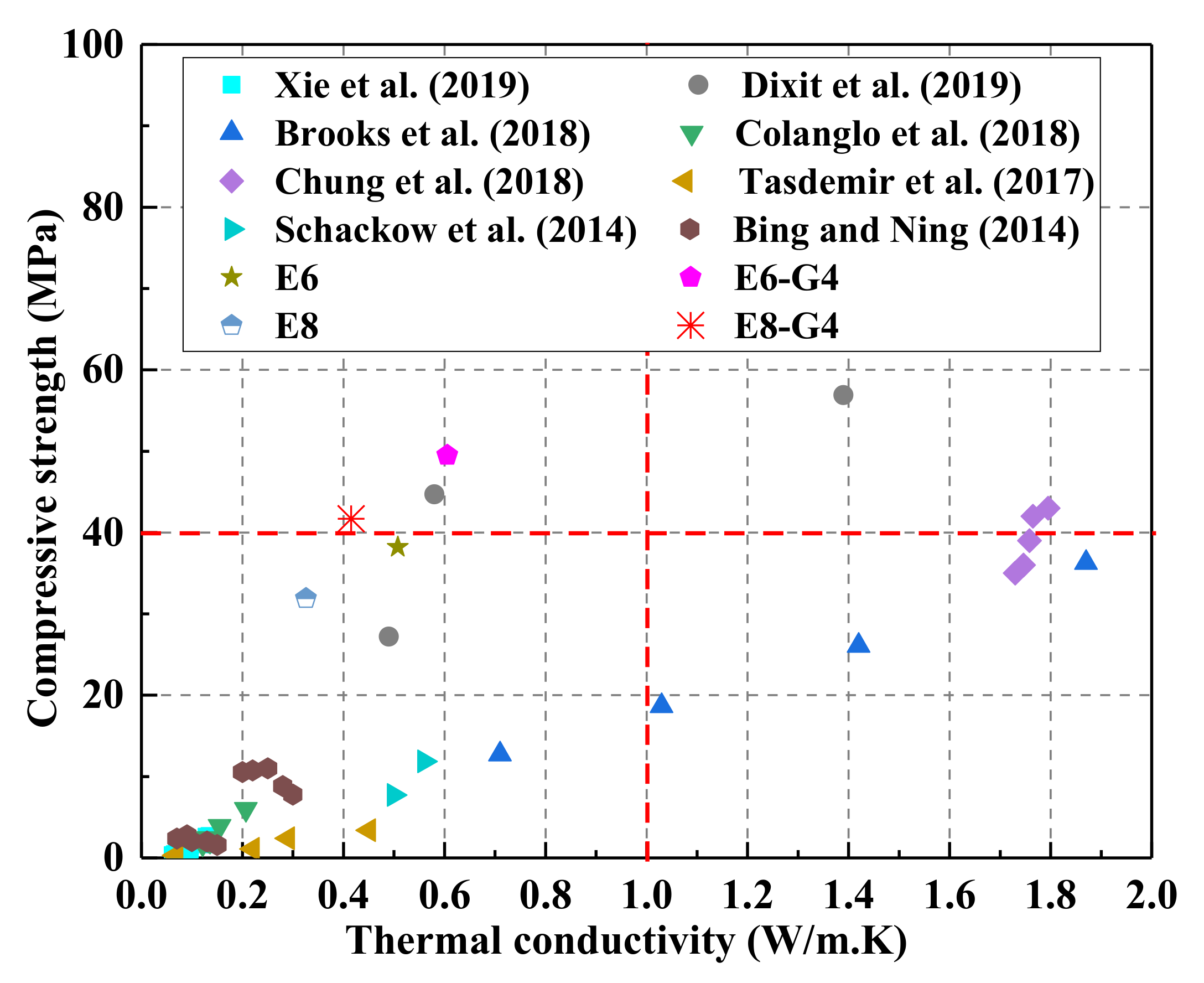

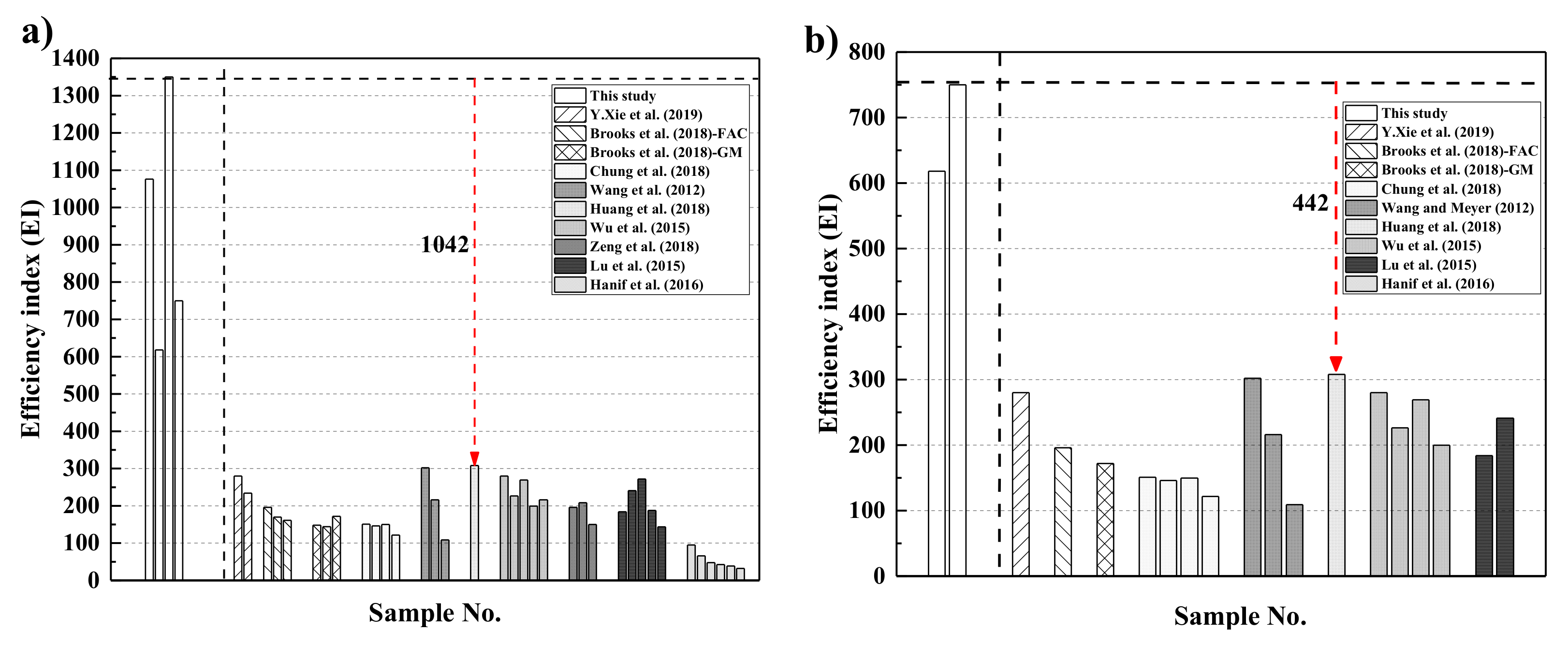

3.5. Synergetic Analysis of Thermal Conductivity, Strength, and Cost

3.6. Impact Assessment and Interpretation

3.6.1. Environmental and Economic Impacts Assessment of Samples

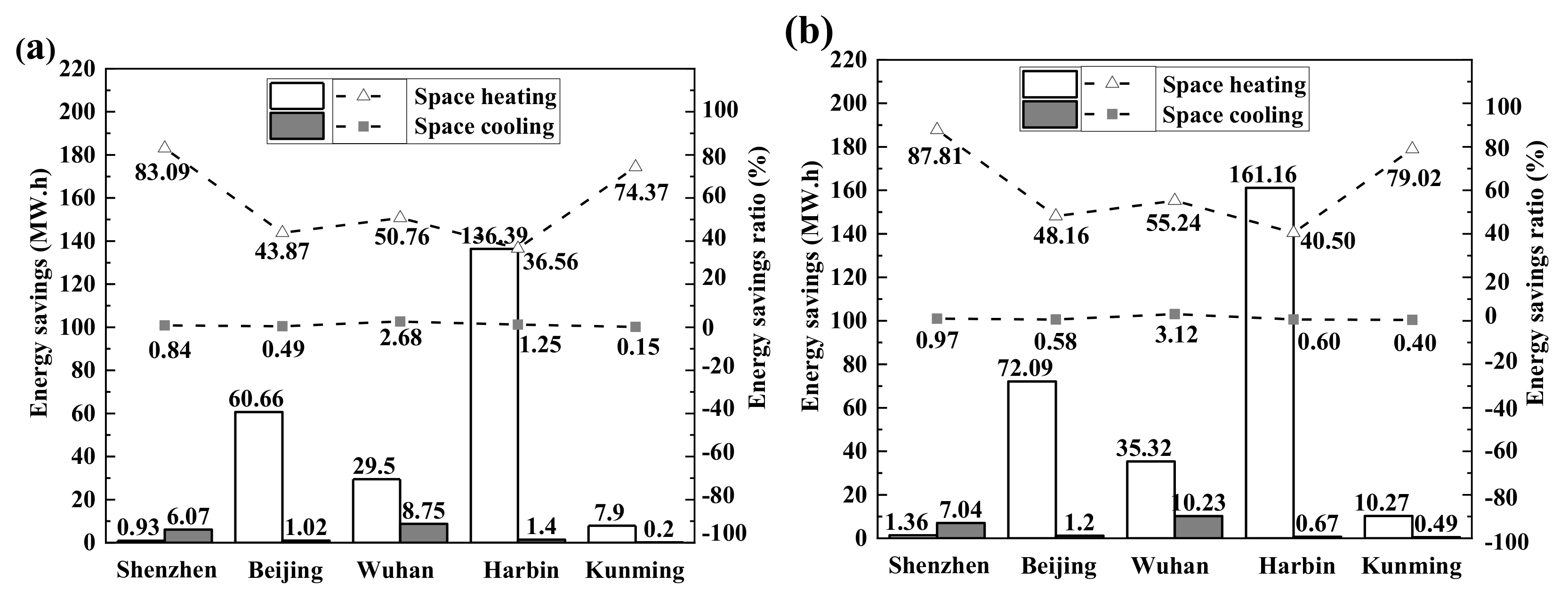

3.6.2. Energy Conservation Evaluation during the Operation Period

4. Conclusions

- (1)

- The wet and dry densities of rGO-WEA decreased with the increase of waste EPS beads. The lower the density is, the lower the thermal conductivity is. The addition of rGO slightly increased the density of rGO-WEA owning more reaction products caused by rGO. However, the rGO content adopted in this study was relatively low. Thus, the increase in wet and dry densities of rGO-WEA were not significant.

- (2)

- The introduction of rGO into AAMs is an effective method to improve the ITZ between waste EPS beads and paste and counter the degradation of compressive strength caused by the addition of waste EPS beads. Even with 80 vol.% EPS replacement, the compressive strength measured in E8–G4 was 41.5 MPa, which meets the minimum 28th day compressive strength of the ACI 213R-03 standard for structural applications.

- (3)

- The thermal conductivity of E8-G4 at the 28th day reduced by 76.4% and 74% compared with E0–G4 and E0, respectively, because of lowering of rGO-WEA density with the increased content of waste EPS beads in the AAMs matrix. Therefore, rGO-WEA has the potential to accelerate waste EPS recycling, and promote sustainable structural and functional cementitious composites for the construction industry.

- (4)

- The EI value of E8–G4 is 750 and increases by 442 from the previous highest value. This indicates that rGO-WEA can help strike a fine balance between the compressive strength, thermal conductivity, and cost as a structurally and functionally integrated material.

- (5)

- The results of the coupled LCA–BIM environmental evaluation approve the rGO-WEA in this study, which can conserve large amounts of energy and reduce CO2 emissions in the building structural application, especially, in developing countries. The ECO2e of E8–G4 was reduced by 16.8% when compared with E0. Furthermore, in cold areas such as Harbin, using E8–G4 in building envelopes can save space heating energy consumption by 40.50% and, in hot areas, such as Wuhan, can save space cooling energy consumption by 3.12%, when compared with traditional concrete.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Islam, C.J.; Yukun, H.; Ismail, H.; Nazmiye, B.O.; George, M.; Liz, V. Reducing industrial energy demand in the UK: A review of energy efficiency technologies and energy saving potential in selected sectors. Renew. Sustain. Energy Rev. 2018, 94, 1153–1178. [Google Scholar]

- Wang, T.; Lin, B. Fuel consumption in road transport: A comparative study of China and OECD countries. J. Clean. Prod. 2019, 206, 156–170. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, S.T.; Mao, C. Greenhouse gas emissions during the construction phase of a building: A case study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef]

- Xia, J.J.; Hong, T.Z.; Shen, Q.; Feng, W.; Yang, L.; Im, P.; Lu, A.; Bhandari, M. Comparison of building energy use data between the United States and China. Energy Build. 2014, 78, 165–175. [Google Scholar] [CrossRef]

- Shi, Q.; Chen, J.; Shen, L. Driving factors of the changes in the carbon emissions in the Chinese construction industry. J. Clean. Prod. 2017, 166, 615–627. [Google Scholar] [CrossRef]

- Beyer, B.; Geldermann, J.; Lauven, L.P. Agent-based model of the German heating market: Simulations concerning the use of wood pellets and the sustainability of the market. In Proceedings of the 2017 14th International Conference on the European Energy Market (EEM), Dresden, Germany, 6–9 June 2017; pp. 99–101. [Google Scholar]

- Gi, K.; Sano, F.; Hayashi, A.; Tomoda, T.; Akimoto, K. A global analysis of residential heating and cooling service demand and cost-effective energy consumption under different climate change scenarios up to 2050. Mitig. Adapt. Strateg. Glob. Chang. 2018, 23, 1–29. [Google Scholar] [CrossRef]

- Abramski, M. In improving thermal insulation properties for prefabricated wall components made of lightweight aggregate concrete with open structure. Mater. Sci. Eng. Conf. Ser. 2017, 245, 22–34. [Google Scholar] [CrossRef]

- Latroch, N.; Benosman, A.S.; Bouhamou, N.E.; Senhadji, Y.; Mouli, M. Physico-mechanical and thermal properties of composite mortars containing lightweight aggregates of expanded polyvinyl chloride. Constr. Build. Mater. 2018, 175, 77–87. [Google Scholar] [CrossRef]

- Rui, W.; Miao, R.; Gao, X.; Ling, Q. Preparation and properties of fatty acids based thermal energy storage aggregate concrete. Constr. Build. Mater. 2018, 165, 1–10. [Google Scholar]

- Dissanayake, D.M.K.W.; Jayasinghe, C.; Jayasinghe, M.T.R. A comparative embodied energy analysis of a house with recycled expanded polystyrene (EPS) based foam concrete wall panels. Energy Build. 2017, 135, 85–94. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; Abdou, A.E.H.; Ahmed, S.B. Conversion of waste styrofoam into engineered adsorbents for efficient removal of cadmium, lead and mercury from water. ACS Sustain. Chem. 2016, 4, 11–49. [Google Scholar] [CrossRef]

- Sunny, J.V. Recycling of Polymers (Epoxy Blends): Methods, Characterization and Applications; Wiley-VCH Verlag GmbH & Co. KgaA: Weinheim, Germany, 2016; pp. 209–220. [Google Scholar]

- Gil-Jasso, N.D.; Segura-González, M.A.; Soriano-Giles, G.; Neri-Hipolito, J.; López, N.; Mas-Hernández, E.; Barrera-Díaz, C.E.; Varela-Guerrero, V.; Ballesteros-Rivas, M.F. Dissolution and recovery of waste expanded polystyrene using alternative essential oils. Fuel 2019, 239, 611–616. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Abdi, R.; Tabatabaei, M. Expanded polystyrene waste application for improving biodiesel environmental performance parameters from lifecycle assessment point of view. Renew. Sustain. Energy Rev. 2017, 74, 278–298. [Google Scholar] [CrossRef]

- Mohammed, B.S.; Khed, V.C.; Nuruddin, M.F. Rubbercrete mixture optimization using response surface methodology. J. Clean. Prod. 2018, 171, 1605–1621. [Google Scholar] [CrossRef]

- Lotfy, A.; Hossain, K.M.A.; Lachemi, M. Lightweight self-consolidating concrete with expanded shale aggregates: Modelling and optimization. Int. J. Concr. Struct. Mater. 2014, 9, 185–206. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K. Hardened properties of concrete mixtures containing pre-coated crumb rubber and silica fume. J. Clean. Prod. 2015, 82, 125–131. [Google Scholar] [CrossRef]

- Shin, C.; Chase, G.G.; Reneker, D.H. Recycled expanded polystyrene nanofibers applied in filter media. Colloids Surf. A Physicochem. Eng. Asp. 2005, 262, 211–215. [Google Scholar] [CrossRef]

- Verma, R.; Vinoda, K.S.; Papireddy, M.; Gowda, A.N.S. Toxic pollutants from plastic Waste—A review. Procedia Environ. Sci. 2016, 35, 701–708. [Google Scholar] [CrossRef]

- Sayadi, A.A.; Tapia, J.V.; Neitzert, T.R.; Clifton, G.C. Effects of expanded polystyrene (EPS) particles on fire resistance, thermal conductivity and compressive strength of foamed concrete. Constr. Build. Mater. 2016, 112, 716–724. [Google Scholar] [CrossRef]

- Babu, K.G.; Babu, D.S. Behaviour of lightweight expanded polystyrene concrete containing silica fume. Cem. Concr. Res. 2003, 33, 755–762. [Google Scholar] [CrossRef]

- Brooks, A.L.; Zhou, H.; Hanna, D. Comparative study of the mechanical and thermal properties of lightweight cementitious composites. Constr. Build. Mater. 2018, 159, 316–328. [Google Scholar] [CrossRef]

- Miled, K.; Sab, K.; Roy, R.L. Particle size effect on EPS lightweight concrete compressive strength: Experimental investigation and modelling. Mech. Mater. 2007, 39, 222–240. [Google Scholar] [CrossRef]

- Fernando, P.L.N.; Jayasinghe, M.T.R.; Jayasinghe, C. Structural feasibility of Expanded Polystyrene (EPS) based lightweight concrete sandwich wall panels. Constr. Build. Mater. 2017, 139, 45–51. [Google Scholar] [CrossRef]

- Ru, W.; Meyer, C. Performance of cement mortar made with recycled high impact polystyrene. Cem. Concr. Compos. 2012, 34, 975–981. [Google Scholar]

- Bing, C.; Ning, L. A novel lightweight concrete-fabrication and its thermal and mechanical properties. Constr. Build. Mater. 2013, 44, 691–698. [Google Scholar]

- Chung, S.Y.; Elrahman, M.A.; Stephan, D. Effects of expanded polystyrene (EPS) sizes and arrangements on the properties of lightweight concrete. Mater. Struct. 2018, 51, 57. [Google Scholar] [CrossRef]

- Colangelo, F.; Roviello, G.; Ricciotti, L.; Ferrándiz-Mas, V.; Messina, F.; Ferone, C.; Tarallo, O.; Cioffi, R.; Cheeseman, C.R. Mechanical and thermal properties of lightweight geopolymer composites. Cem. Concr. Compos. 2017, 86, 17–47. [Google Scholar] [CrossRef]

- Dixit, A.; Pang, S.D.; Kang, S.-H.; Moon, J. Lightweight structural cement composites with expanded polystyrene (EPS) for enhanced thermal insulation. Cem. Concr. Compos. 2019, 102, 185–197. [Google Scholar] [CrossRef]

- Ning, L.; Bing, C. Experimental study of the influence of EPS particle size on the mechanical properties of EPS lightweight concrete. Constr. Build. Mater. 2014, 68, 227–232. [Google Scholar]

- Schackow, A.; Effting, C.; Folgueras, M.V.; Güths, S.; Mendes, G.A. Mechanical and thermal properties of lightweight concretes with vermiculite and EPS using air-entraining agent. Constr. Build. Mater. 2014, 57, 190–197. [Google Scholar] [CrossRef]

- Tasdemir, C.; Sengul, O.; Tasdemir, M.A. A comparative study on the thermal conductivities and mechanical properties of lightweight concretes. Energy Build. 2017, 151, 469–475. [Google Scholar] [CrossRef]

- Xie, Y.; Li, J.; Lu, Z.; Jiang, J.; Niu, Y. Preparation and properties of ultra-lightweight EPS concrete based on pre-saturated bentonite. Constr. Build. Mater. 2019, 195, 505–514. [Google Scholar] [CrossRef]

- Yi, X.; Jiang, L.; Xu, J.; Yang, L. Mechanical properties of expanded polystyrene lightweight aggregate concrete and brick. Constr. Build. Mater. 2012, 27, 32–38. [Google Scholar]

- ACI. ACI 213R-03: Guide for Structural Lightweight-Aggregate Concrete; ACI: Farmington Hills, Mi, USA, 2003. [Google Scholar]

- Ramakrishnan, S.; Wang, X.; Sanjayan, J.; Wilson, J. Thermal performance assessment of phase change material integrated cementitious composites in buildings: Experimental and numerical approach. Appl. Energy 2017, 207, 654–664. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, J.G.; Puertas, F. Alkali-activated slag mortars: Mechanical strength behaviour. Cem. Concr. Res. 1999, 29, 1313–1321. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Khooshechin, M.; Tanzadeh, J. Experimental and mechanical performance of shotcrete made with nanomaterials and fiber reinforcement. Constr. Build. Mater. 2018, 165, 199–205. [Google Scholar] [CrossRef]

- Long, W.J.; Zheng, D.; Duan, H.B.; Han, N.X.; Xing, F. Performance enhancement and environmental impact of cement composites containing graphene oxide with recycled fine aggregates. J. Clean. Prod. 2018, 194, 193–202. [Google Scholar] [CrossRef]

- Ng, S.; Jelle, B.P.; Zhen, Y.; Wallevik, Ó.H. Effect of storage and curing conditions at elevated temperatures on aerogel-incorporated mortar samples based on UHPC recipe. Constr. Build. Mater. 2016, 106, 640–649. [Google Scholar] [CrossRef]

- Peyvandi, A.; Soroushian, P.; Farhadi, N.; Balachandra, A.M. Evaluation of the reinforcement efficiency of low-cost graphite nanomaterials in high-performance concrete. Ksce J. Civ. Eng. 2018, 22, 1–8. [Google Scholar] [CrossRef]

- Gholampour, A.; Valizadeh Kiamahalleh, M.; Tran, D.N.H.; Ozbakkaloglu, T.; Losic, D. From graphene oxide to reduced graphene oxide: Impact on physiochemical and mechanical properties of graphene? Cement composites. ACS Appl. Mater. Interfaces 2017, 9, 43275–43286. [Google Scholar] [CrossRef] [PubMed]

- Murugan, M.; Santhanam, M.; Gupta, S.S.; Pradeep, T.; Shah, S.P. Influence of 2D rGO nanosheets on the properties of OPC paste. Cem. Concr. Compos. 2016, 70, 48–59. [Google Scholar] [CrossRef]

- Saafi, M.; Tang, L.; Fung, J.; Rahman, M.; Liggat, J. Enhanced properties of graphene/fly ash geopolymeric composite cement. Cem. Concr. Res. 2015, 67, 292–299. [Google Scholar] [CrossRef]

- Wang, S.; Sun, X.; Wang, Y.; Sun, K.; Bi, J. Properties of reduced graphene/carbon nanotubes reinforced calcium phosphate bone cement in a microwave environment. J. Mater. Sci. Mater. Med. 2019, 30, 37. [Google Scholar] [CrossRef] [PubMed]

- Long, W.J.; Ye, T.H.; Luo, Q.L.; Wang, Y.C.; Mei, L. Reinforcing mechanism of reduced graphene oxide on flexural strength of geopolymers: A synergetic analysis of hydration and chemical composition. Nanomaterials 2019, 31, 31. [Google Scholar] [CrossRef] [PubMed]

- Yan, S.; He, P.; Jia, D.; Duan, X.; Yang, Z.; Wang, S.; Zhou, Y.; Colombo, P. In situ processing of graphene/leucite nanocomposite through graphene oxide/geopolymer. J. Am. Ceram. Soc. 2016, 99, 1164–1173. [Google Scholar] [CrossRef]

- Yan, S.; He, P.; Jia, D.; Yang, Z.; Duan, X.; Wang, S.; Zhou, Y. Effect of reduced graphene oxide content on the microstructure and mechanical properties of graphene-geopolymer nanocomposites. Ceram. Int. 2016, 42, 752–758. [Google Scholar] [CrossRef]

- Lewandowska, A. In environmental life cycle assessment as a tool for identification and assessment of environmental aspects in environmental management systems (EMS) part 1: Methodology. Int. J. Life Cycle Assess. 2011, 16, 178–186. [Google Scholar] [CrossRef]

- Peng, T.; Ou, X.; Yan, X. Development and application of an electric vehicles life-cycle energy consumption and greenhouse gas emissions analysis model. Chem. Eng. Res. Des. 2018, 131, 699–708. [Google Scholar] [CrossRef]

- Shin, Y.; Cho, K. BIM application to select appropriate design alternative with consideration of LCA and LCCA. Math. Probl. Eng. 2015, 2015, 1–14. [Google Scholar] [CrossRef]

- Soust-Verdaguer, B.; Llatas, C.; García-Martínez, A. Critical review of bim-based LCA method to buildings. Energy Build. 2017, 136, 110–120. [Google Scholar] [CrossRef]

- Pomares, J.C.; González, A.; Saura, P. Simple and resistant construction built with concrete voussoirs for developing countries. J. Constr. Eng. Manag. 2018, 144. [Google Scholar] [CrossRef]

- GB/T 18046-2008 Ground Granulated Blast Furnace Slag Used for Cement And Concrete; Chinese National Standard: Beijing, China, 2008.

- GB/T 27690-2011 Silica Fume for Cement Mortar and Concrete; Chinese National Standard: Beijing, China, 2011.

- GB/T 14684-2001 Sand Standard for Construction; Chinese National Standard: Beijing, China, 2001.

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80, 1334–1339. [Google Scholar] [CrossRef]

- Long, W.J.; Wei, J.J.; Ma, H.Y.; Xing, F. Uniformly dispersed and Re-agglomerated graphene oxide-based cement pastes: A comparison of rheological properties, mechanical properties and microstructure. Nanomaterials 2018, 8, 31. [Google Scholar] [CrossRef]

- Rajaura, R.S.; Srivastava, S.; Sharma, V.; Sharma, P.K.; Lal, C.; Singh, M.; Palsania, H.S.; Vijay, Y.K. Role of interlayer spacing and functional group on the hydrogen storage properties of graphene oxide and reduced graphene oxide. Int. J. Hydrog. Energy 2016, 41, 9454–9461. [Google Scholar] [CrossRef]

- Fan, X.; Peng, W.; Yang, L.; Li, X.; Zhang, F. Deoxygenation of exfoliated graphite oxide under alkaline conditions: A green route to graphene preparation. Adv. Mater. 2010, 20, 4490–4493. [Google Scholar] [CrossRef]

- Pei, S.; Cheng, H.M. The reduction of graphene oxide. Carbon 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Yan, S.; He, P.; Jia, D.; Yang, Z.; Duan, X.; Wang, S.; Zhou, Y. Effects of treatment temperature on the reduction of GO under alkaline solution during the preparation of graphene/geopolymer composites. Ceram. Int. 2016, 42, 18181–18188. [Google Scholar] [CrossRef]

- Long, W.-J.; Gu, Y.-C.; Xing, F.; Khayat, K.H. Microstructure development and mechanism of hardened cement paste incorporating graphene oxide during carbonation. Cem. Concr. Compos. 2018, 94, 72–84. [Google Scholar] [CrossRef]

- ASTM C 642-13 Standard Test Method for Density, Absorption, and Voids in Hardened; American Concrete Institute: Farmington Hills, Mi, USA, 2013.

- GB/T 17671-1999 Method of Testing Cement-determination of Strength; Chinese National Standard: Beijing, China, 1999.

- ASHRAE 90. 1-2013 Energy Standard for Buildings Except Low-Rise Residentia; American Society of Heating, Refrigerating, and Air-Conditioning Engineers Inc.: Atlanta, GA, USA, 2013. [Google Scholar]

- Wang, Z.; Wu, J.; Zhao, P.; Dai, N.; Zhai, Z.; Ai, T. Improving cracking resistance of cement mortar by thermo-sensitive poly N-isopropyl acrylamide (PNIPAM) gels. J. Clean. Prod. 2018, 176, 1292–1303. [Google Scholar] [CrossRef]

- Lu, Z.; Hanif, A.; Chao, N.; Shao, H.; Ran, Y.; Li, Z. Steric stabilization of graphene oxide in alkaline cementitious solutions: Mechanical enhancement of cement composite. Mater. Des. 2017, 127, 154–161. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Panesar, D.K. Impact of graphene oxide and highly reduced graphene oxide on cement based composites. Constr. Build. Mater. 2019, 206, 71–83. [Google Scholar] [CrossRef]

- Durán-Herrera, A.; Campos-Dimas, J.K.; Valdez-Tamez, P.L.; Bentz, D.P. Effect of a micro-copolymer addition on the thermal conductivity of fly ash mortars. J. Build. Phys. 2016, 40, 3–16. [Google Scholar] [CrossRef] [PubMed]

- Croy, D.E.; Dougherty, D.A. Handbook of Thermal Insulation Applications; Noyes Publications: Norwich, NY, USA, 1984; pp. 145–150. [Google Scholar]

- Sengul, O.; Azizi, S.; Karaosmanoglu, F.; Tasdemir, M.A. Effect of expanded perlite on the mechanical properties and thermal conductivity of lightweight concrete. Energy Build. 2011, 43, 671–676. [Google Scholar] [CrossRef]

- Wongsa, A.; Sata, V.; Nematollahi, B.; Sanjayan, J.; Chindaprasirt, P. Mechanical and thermal properties of lightweight geopolymer mortar incorporating crumb rubber. J. Clean. Prod. 2018, 195, 1069–1080. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Jumaat, M.Z.; Mo, K.H. Evaluation of thermal conductivity, mechanical and transport properties of lightweight aggregate foamed geopolymer concrete. Energy Build. 2014, 72, 238–245. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, J.Y.; Monteiro, P.J.M.; Zhang, M.H. Development of ultra-lightweight cement composites with low thermal conductivity and high specific strength for energy efficient buildings. Constr. Build. Mater. 2015, 87, 100–112. [Google Scholar] [CrossRef]

- Chen, K.; Chen, K. Modeling the annual growth rate of electricity consumption of China in the 21st century: Trends and prediction. In Proceedings of the 2016 US-China Green Energy Summit on Developing Energy Internets to Combat Climate Change, Chengdu, China, 21 October 2017; pp. 1–4. [Google Scholar]

| Authors | EPS to Aggregate Ratio (%) | Thermal Conductivity (W/m·K) | Density (kg/m3) | 28th-Day Compressive Strength (MPa) |

|---|---|---|---|---|

| Xie et al. (2019) | 20–40 | 0.129–0.139 | 300–600 | 1.91–2.47 |

| Dixit et al. (2019) | 0–45 | 0.49–2.14 | 1463–2301 | 27.2–149.8 |

| Brooks et al. (2018) | 0–28.5 | 0.71–2.5 | 1300–2084 | 12.4–43.6 |

| Colangelo et al. (2018) | 65–72.5 | 0.13–0.17 | 545–750 | 1.8–2.4 |

| Chung et al. (2018) | 0–70 | 1.730–1.790 | 1698–2093 | 35–43 |

| Tasdemir et al. (2017) | 0–60 | 0.23–0.45 | 300–1600 | 0.3–18.7 |

| Ning and Bing (2014) | 0–46.5 | - | 1124–2084 | 7.5–62.6 |

| Schackow et al. (2014) | 55–65 | 0.50–0.56 | 1110–1250 | 7.74–11.85 |

| Bing and Ning (2013) | 0–20 | 0.2–0.3 | 805–1100 | 7.79–10.56 |

| Yi et al. (2012) | 15–25 | - | 1720–2060 | 11.22–20.77 |

| Component (wt.%) | CaO | SiO2 | Al2O3 | MgO | TiO2 | Fe2O3 | MnO | Na2O | K2O | [OH] | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|

| GGBFS | 38.95 | 35.24 | 14.93 | 7.36 | 0.57 | 0.20 | 0.69 | 0.33 | 0.38 | 0.58 | 0.77 |

| SF | 0.49 | 93.26 | 1.29 | 0.95 | - | 1.97 | - | 0.42 | 1.05 | - | 0.57 |

| Fine Aggregates | Sand | EPS | Standard Requirement (GB/T18046) |

|---|---|---|---|

| Thermal conductivity (W/m·K) | 0.5 | 0.042 | ≤1.0 |

| Apparent density (g/cm3) | 2.63 | 0.028 | ≤3.0 |

| Mass density (g/cm3) | 1.49 | 0.018 | ≤2.0 |

| Compact density (g/cm3) | 1.58 | - | ≤2.0 |

| Sample No. | GGBFS (g) | EPS (g) | Sand (g) | Water (g) | NaOH (g) | LSS (g) | SF (g) | rGO (g) | rGO/Binder (wt.%) |

|---|---|---|---|---|---|---|---|---|---|

| E0 | 1080 | 0 | 1800 | 209.6 | 25.6 | 156.7 | 120 | 0 | 0 |

| E0–G4 | 1080 | 0 | 1800 | 209.6 | 25.6 | 156.7 | 120 | 0.48 | 0.04 |

| E6 | 1080 | 11.5 | 720 | 209.6 | 25.6 | 156.7 | 120 | 0 | 0 |

| E6–G4 | 1080 | 11.5 | 720 | 209.6 | 25.6 | 156.7 | 120 | 0.48 | 0.04 |

| E8 | 1080 | 15.4 | 360 | 209.6 | 25.6 | 156.7 | 120 | 0 | 0 |

| E8–G4 | 1080 | 15.4 | 360 | 209.6 | 25.6 | 156.7 | 120 | 0.48 | 0.04 |

| Building Materials | Density (kg/m3) | Thermal Conductivity (W/m·K) |

|---|---|---|

| Concrete* | 2300 | 1.95 |

| Mortar* | 1900 | 1.50 |

| E0 | 2405 | 1.61 |

| E8–G4 | 1498 | 0.42 |

| Material | EE* (MJ/kg) | ECO2e* (kg/kg) | Cost (USD/ton) |

|---|---|---|---|

| Waste EPS | −0.3409 | −3.181 | 213.17 |

| Natural/river sand | 0.0148 | 0.0014 | 8.53 |

| GGBFS | 1.6 | 0.083 | 44.05 |

| LSS | 15.98 | 1.237 | 92.37 |

| NaOH | 20.55 | 1.414 | 284.22 |

| Water | 0.0025 | 0.0002 | 1 |

| SF | 0.018 | 0.014 | 200 |

| rGO | 33.5007 | 0.367 | 1.3 × 105 |

| Mix ID | TC (W/m·K) | CS (MPa) | Cost (USD/m3) | CS–TC Ratio | EI |

|---|---|---|---|---|---|

| E0 | 1.61 | 88.6 | 75.8 | 55.0 | 726 |

| E0–G4 | 1.77 | 114.5 | 137.6 | 64.7 | 470 |

| E6 | 0.50 | 38.2 | 71.1 | 76.4 | 1076 |

| E6–G4 | 0.61 | 49.4 | 132.8 | 81.0 | 618 |

| E8 | 0.33 | 31.9 | 70.2 | 95.3 | 1357 |

| E8–G4 | 0.42 | 41.5 | 131.7 | 98.8 | 750 |

| Mix ID | EE* | ECO2e* | Cost* |

|---|---|---|---|

| (MJ/m3) | (kgCO2e/m3) | (USD/m3) | |

| E0 | 3389.7 | 229.3 | 75.8 |

| E0–G4 | 3401.1 | 229.4 | 137.6 |

| E6 | 3375.6 | 202.7 | 71.0 |

| E6–G4 | 3387.0 | 202.8 | 132.8 |

| E8 | 3370.9 | 190.6 | 70.3 |

| E8–G4 | 3382.3 | 190.7 | 131.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, W.-J.; Lin, C.; Tan, X.-W.; Tao, J.-L.; Ye, T.-H.; Luo, Q.-L. Structural Applications of Thermal Insulation Alkali Activated Materials with Reduced Graphene Oxide. Materials 2020, 13, 1052. https://doi.org/10.3390/ma13051052

Long W-J, Lin C, Tan X-W, Tao J-L, Ye T-H, Luo Q-L. Structural Applications of Thermal Insulation Alkali Activated Materials with Reduced Graphene Oxide. Materials. 2020; 13(5):1052. https://doi.org/10.3390/ma13051052

Chicago/Turabian StyleLong, Wu-Jian, Can Lin, Xiao-Wen Tan, Jie-Lin Tao, Tao-Hua Ye, and Qi-Ling Luo. 2020. "Structural Applications of Thermal Insulation Alkali Activated Materials with Reduced Graphene Oxide" Materials 13, no. 5: 1052. https://doi.org/10.3390/ma13051052

APA StyleLong, W.-J., Lin, C., Tan, X.-W., Tao, J.-L., Ye, T.-H., & Luo, Q.-L. (2020). Structural Applications of Thermal Insulation Alkali Activated Materials with Reduced Graphene Oxide. Materials, 13(5), 1052. https://doi.org/10.3390/ma13051052