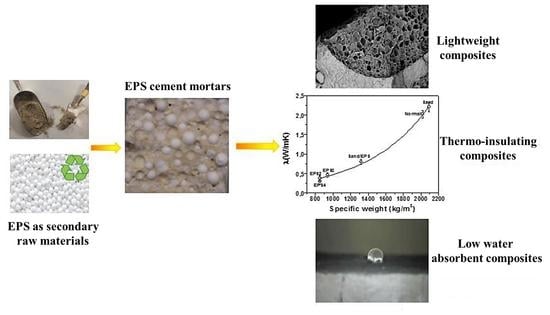

Recycled Expanded Polystyrene as Lightweight Aggregate for Environmentally Sustainable Cement Conglomerates

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of the Mortars

2.2. Rheological, Thermal and Mechanical Characterization

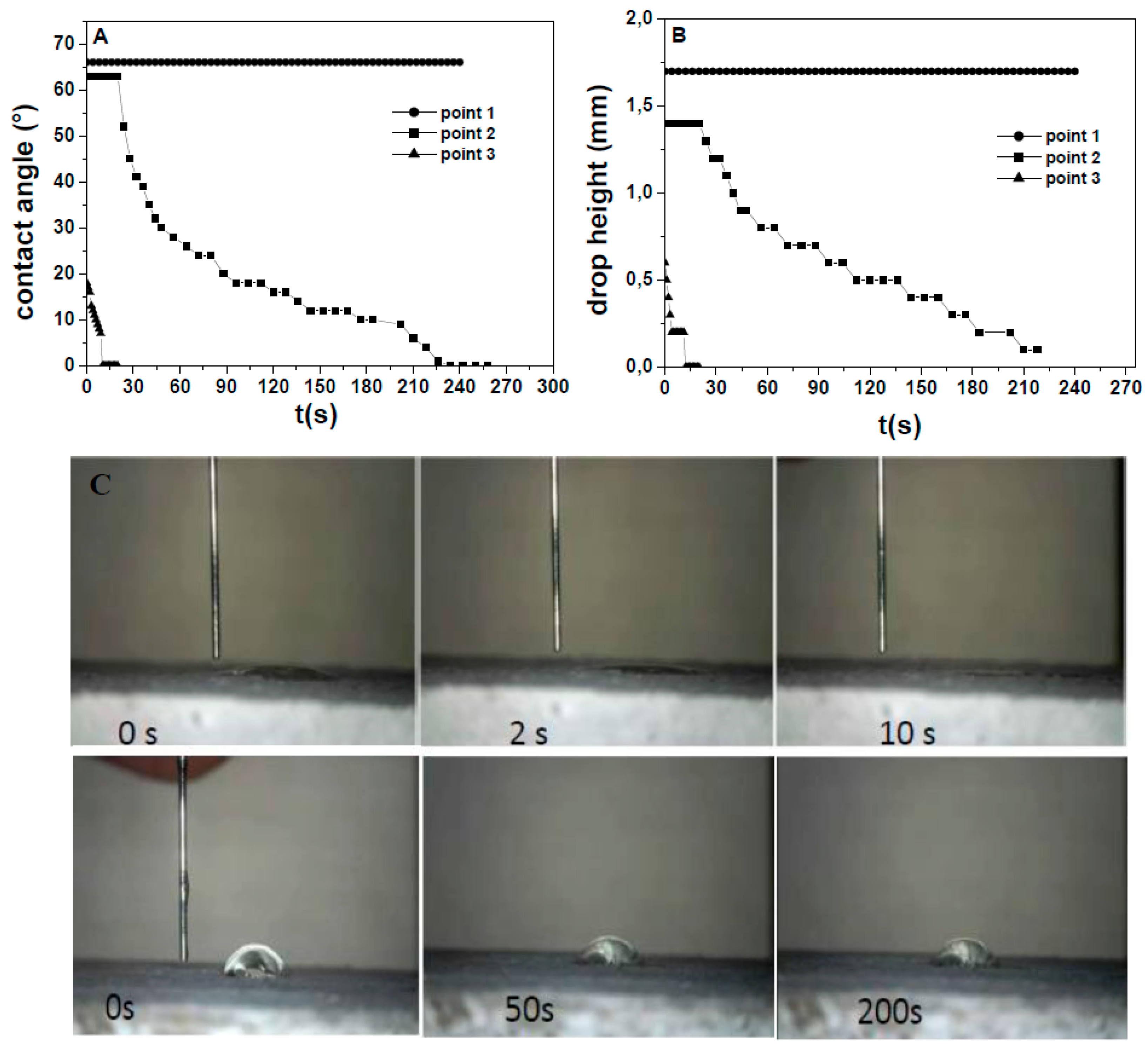

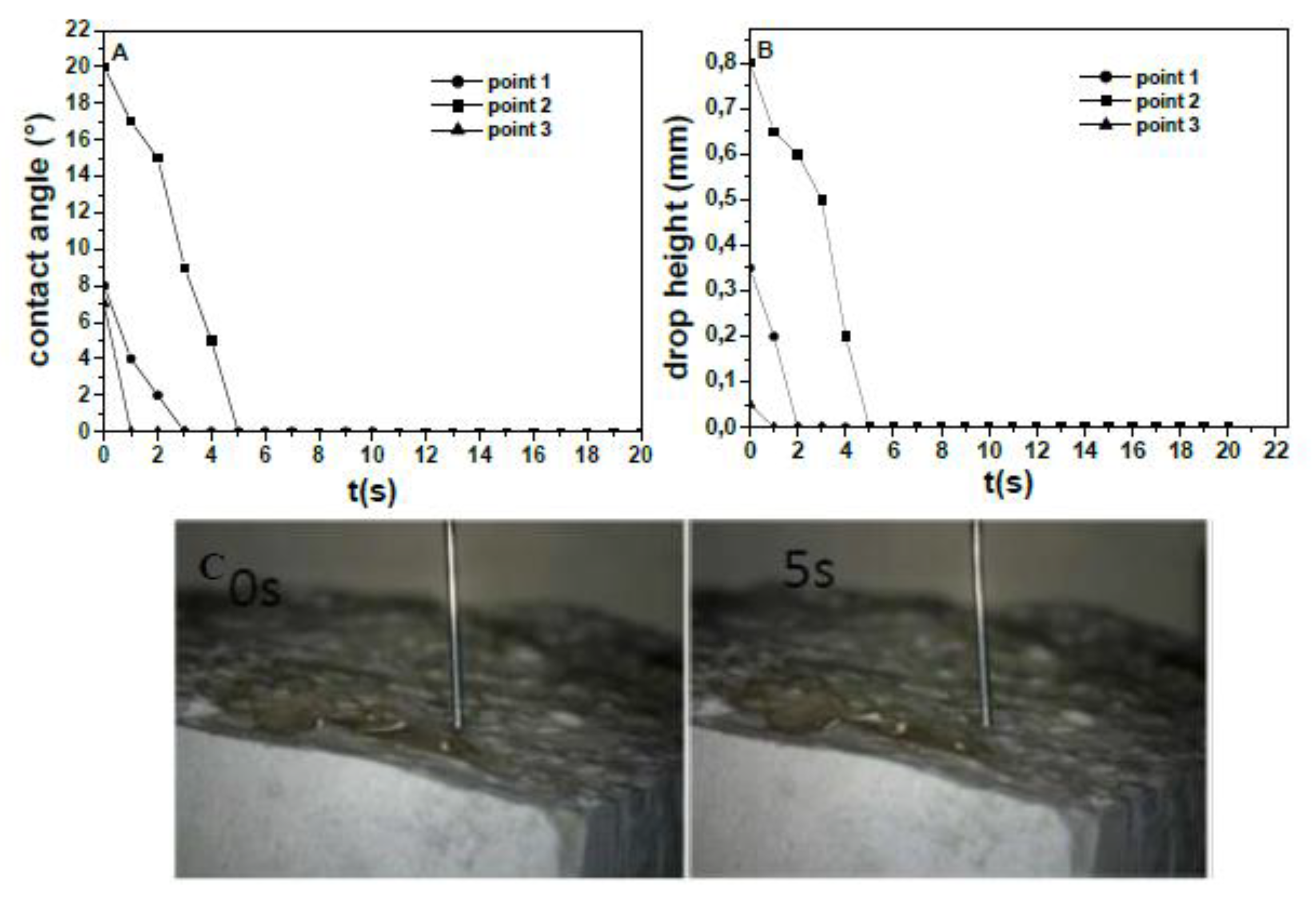

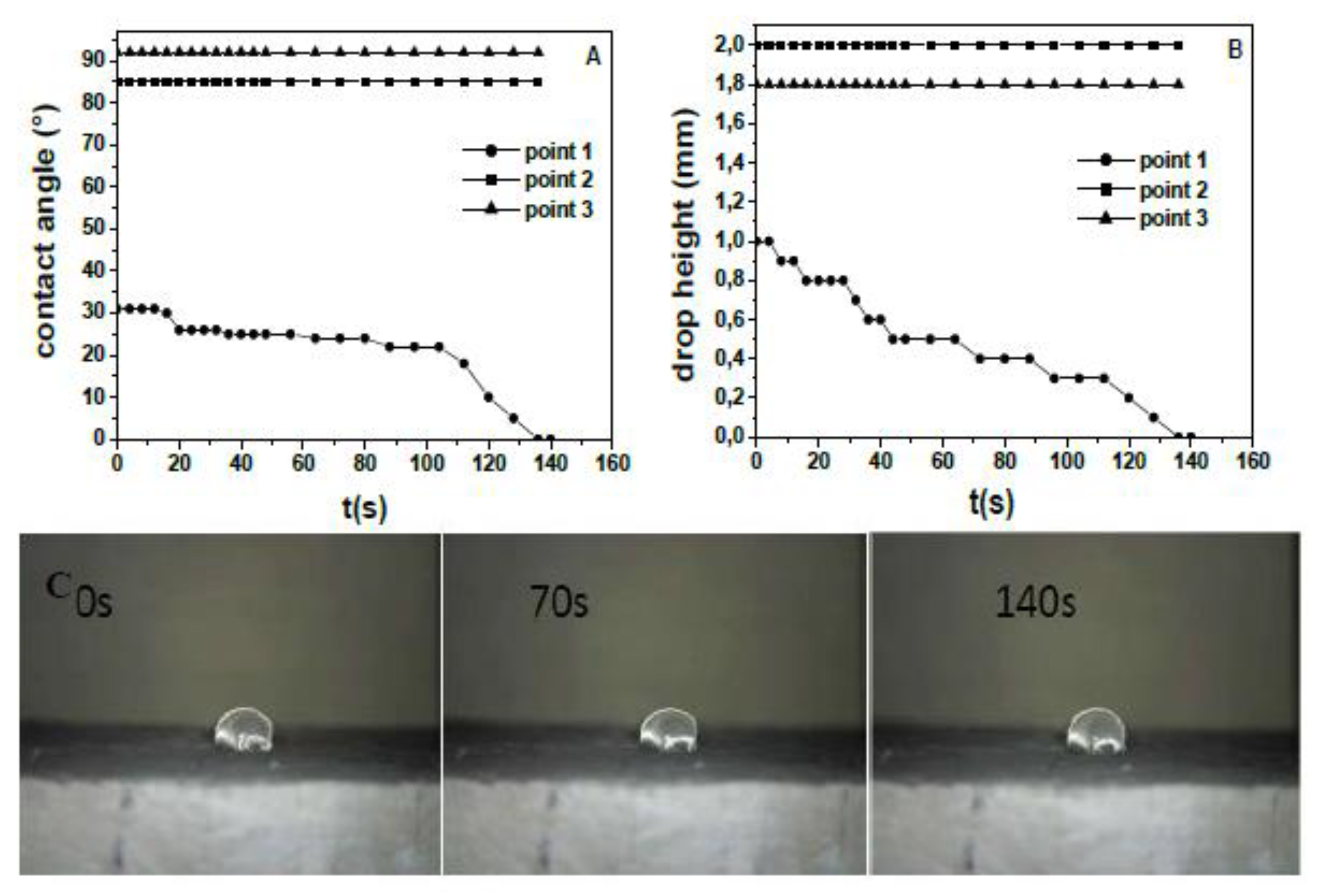

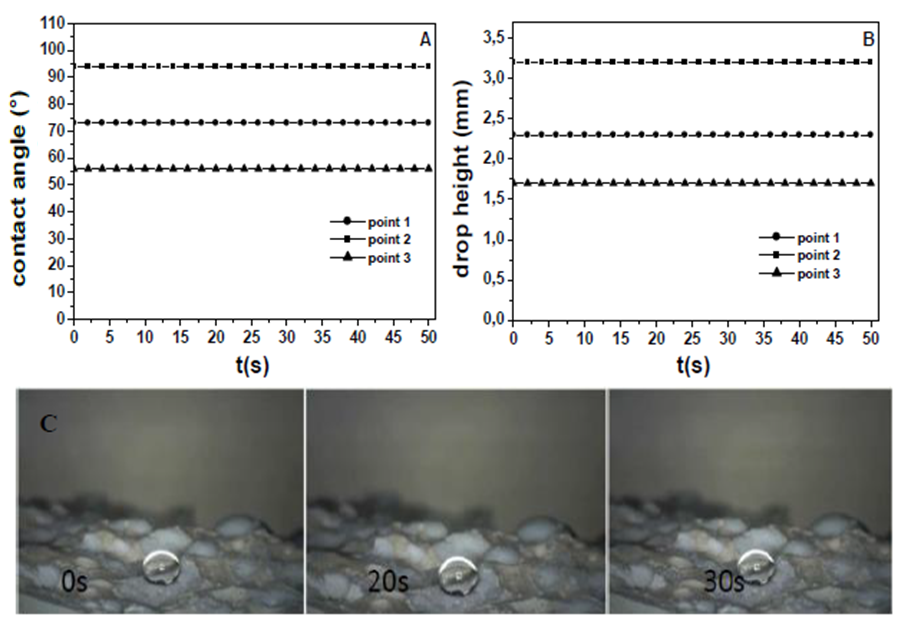

2.3. Measurements of the Contact Angle and of the Water Absorption

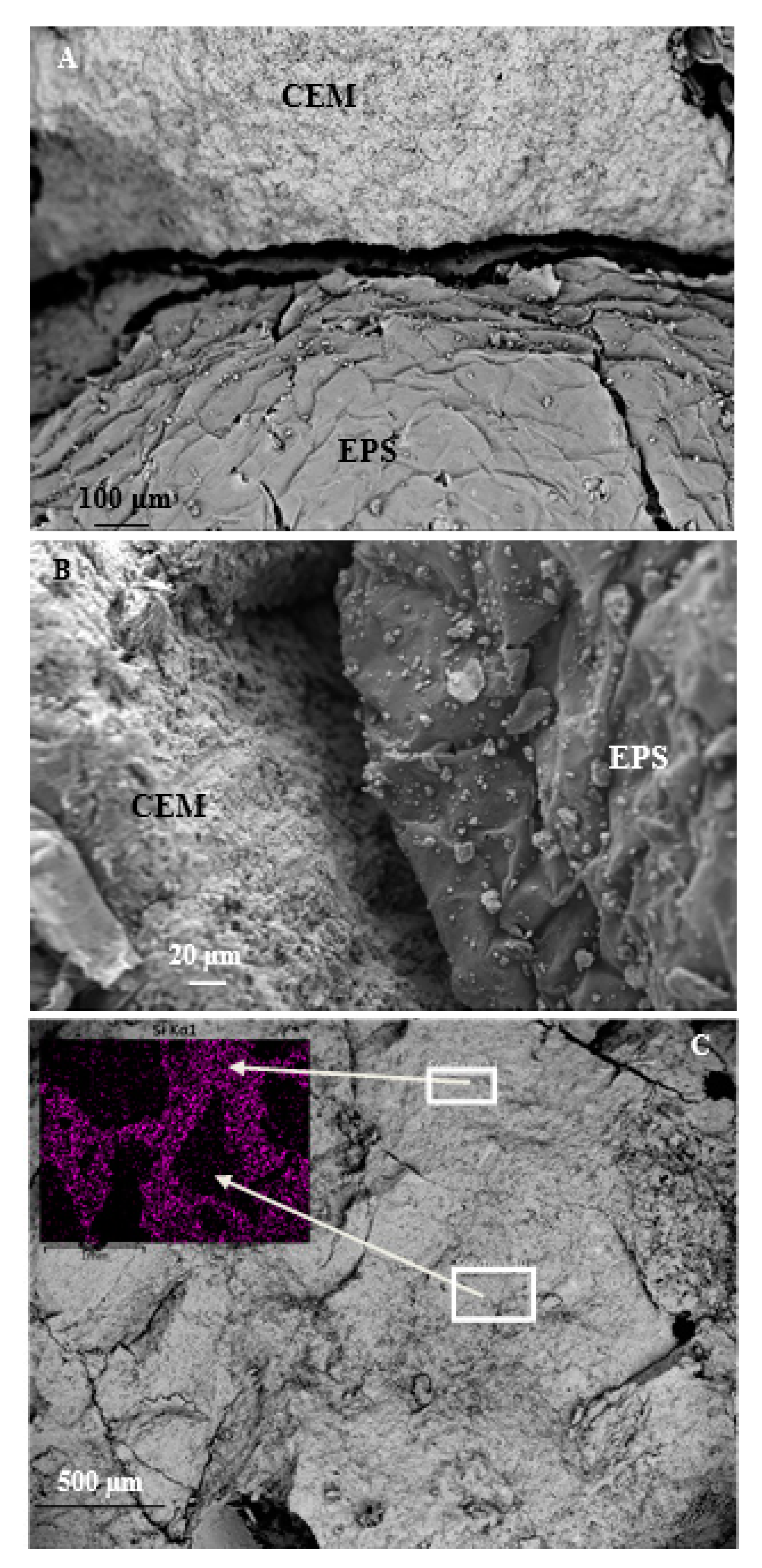

2.4. SEM/EDX and Porosimetric Analyses

3. Results and Discussion

4. Conclusions

- -

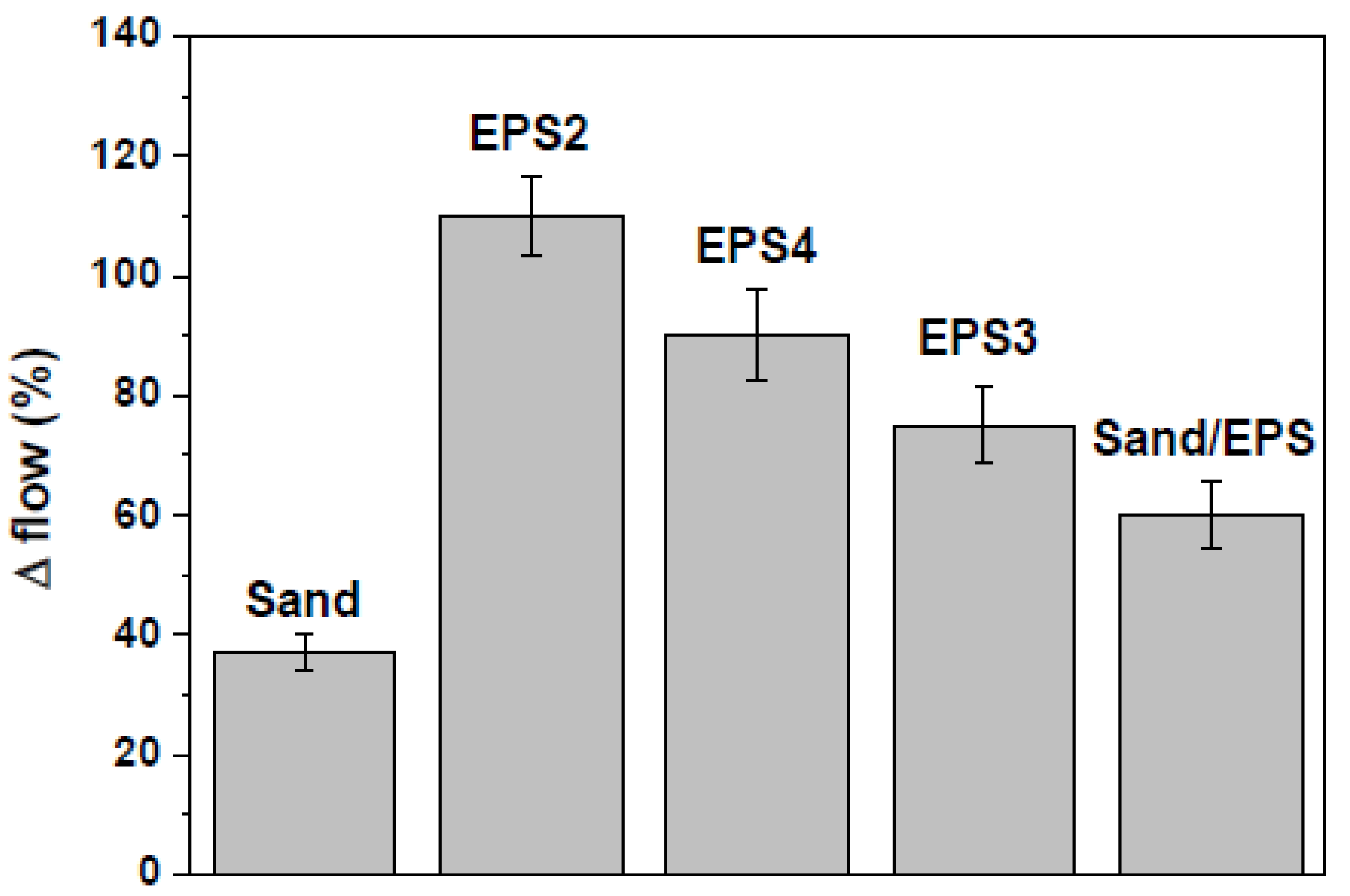

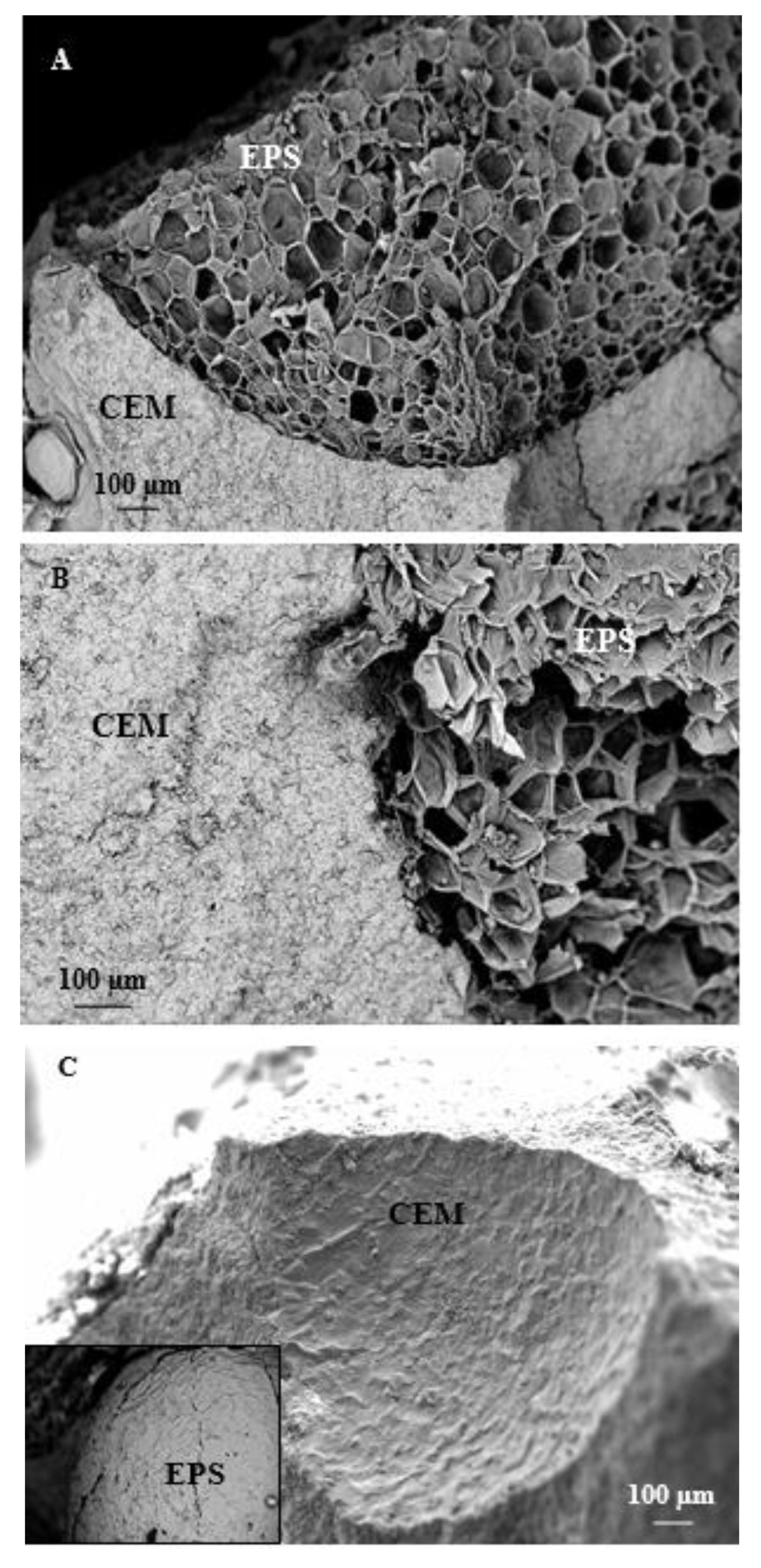

- EPS samples resulted in having more fluid than the references, in particular the sample characterized by EPS grains in the 2–4 mm (50%) and 4–6 mm (50%) bead size range (EPS3) had the most plastic with good particle distribution and cohesion between the ligand and the organic aggregates as also observed in microstructural and porosimetric detections.

- -

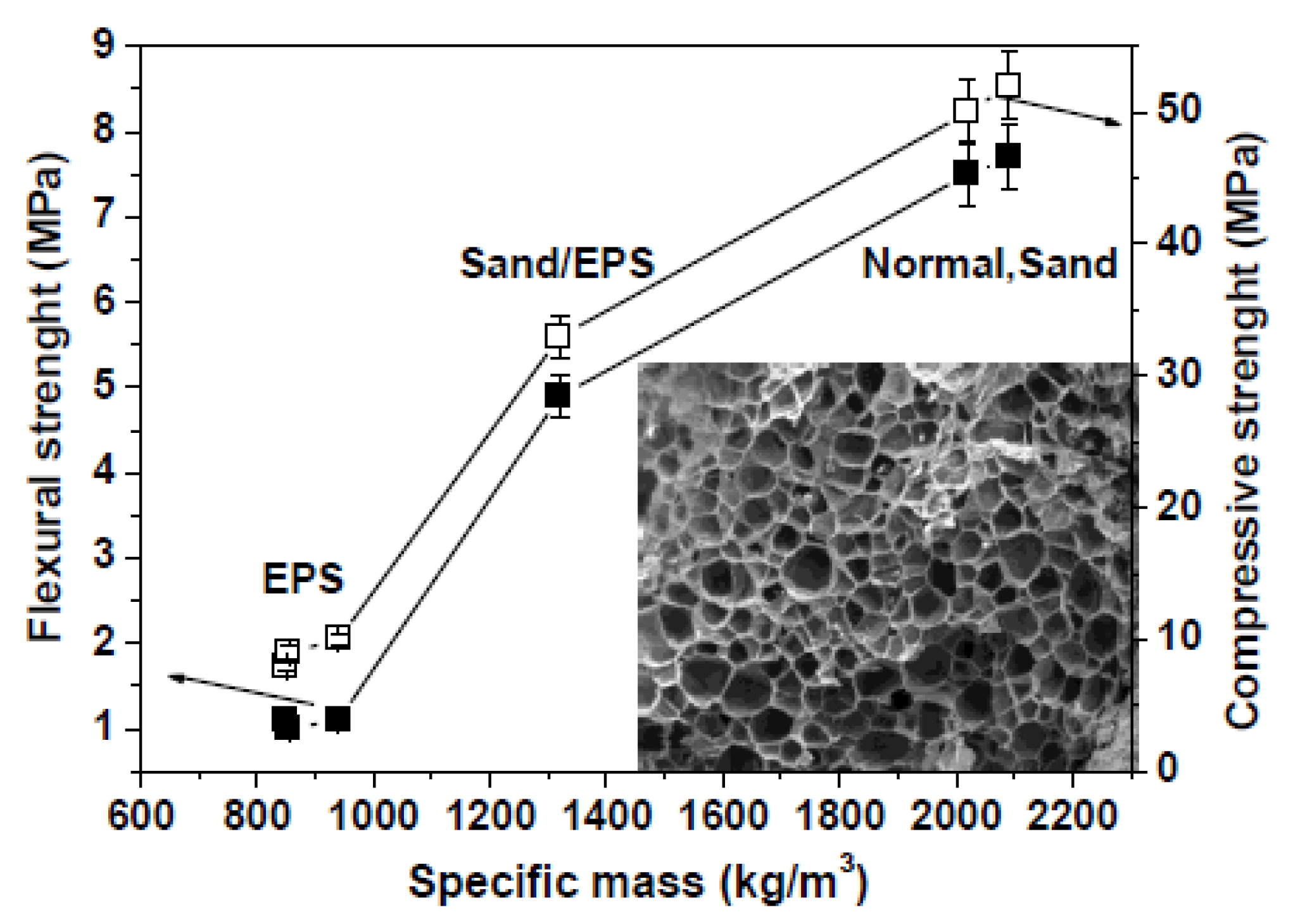

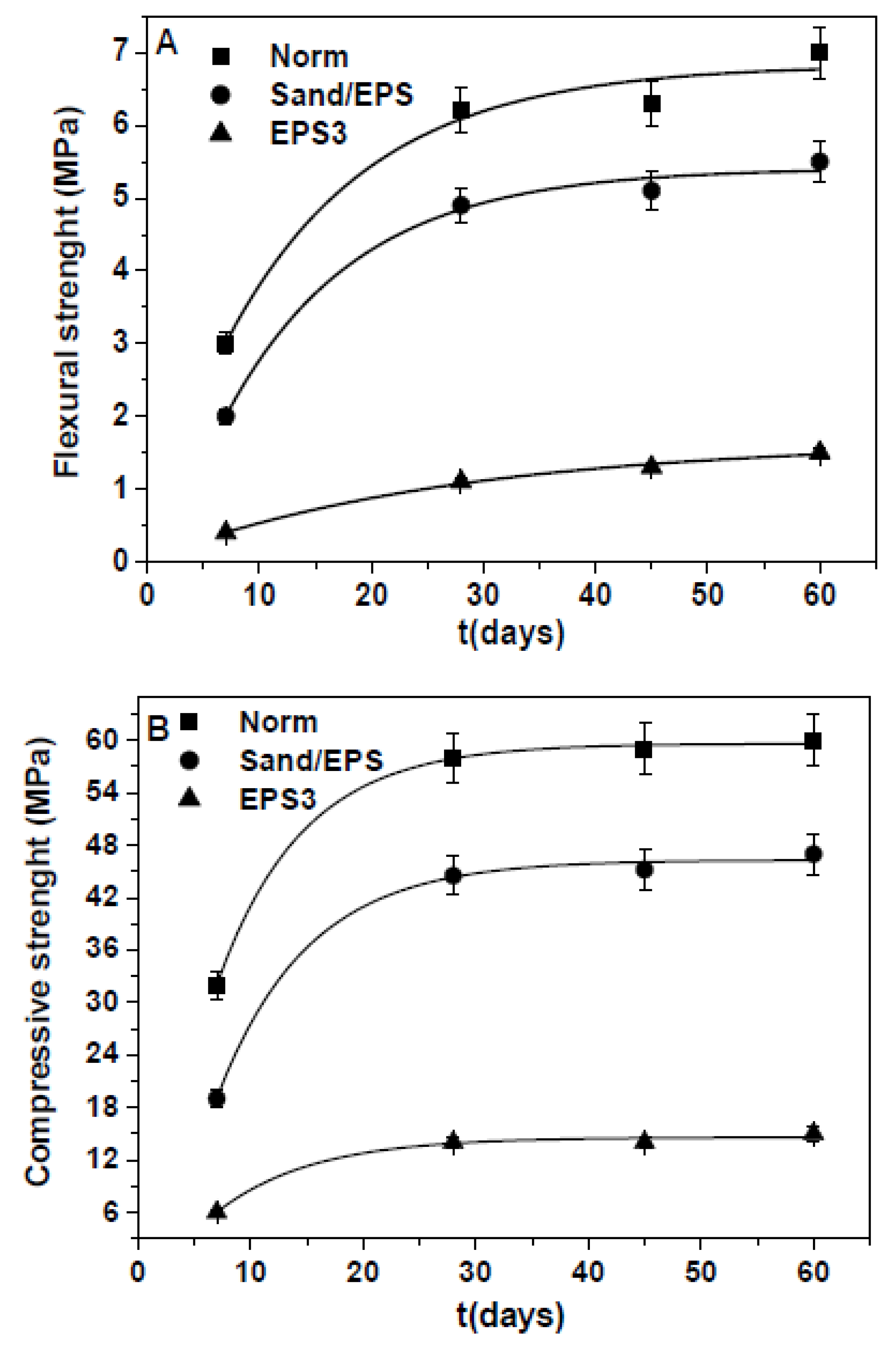

- The mechanical resistances of the EPS samples were lower with respect to the controls due to the lower specific mass. An increase of the strengths was observed with a stabilization after 45 days. At 60 days the values did not sensibly change thus demonstrating stability of the materials in consideration of the specific water curing/conservation conditions of the conglomerates.

- -

- The EPS based mortars showed lower thermal conductivities and diffusivities as compared to the references based on sand due to a lower density ascribed to the low density of the aggregates and to the spaces at the EPS/cement paste interface.

- -

- Interesting results in term of high mechanical resistances and low thermal conductivity were obtained in the case of sand-EPS mixtures.

- -

- Reference sand-based mortars showed hydrophilicity (low WCA) and high water penetration, particularly on the fracture surface of the composites, conversely to what was observed in the case of EPS samples which were generally more hydrophobic and less water absorbent. The best results (high WCA and negligible water penetration on the fracture surface) were obtained with the EPS3 sample. This property was ascribed to the low surface energy of the organic aggregate combined with its better particle distribution and compaction within the hydrophilic domains of the cement paste in the composite.

- -

- These lightweight thermo-insulating composites may be used in the building industry as non-structural components, with specific reference to indoor applications (panels, plasters). Moreover, the conglomerates can be considered environmentally sustainable because they are prepared with secondary raw materials (recycled EPS) and are cost-effective because a cheap preparation route was used since the renewable aggregates were not pre-treated and a complex technique of production was not required.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Garcia, D.; You, F. Systems engineering opportunities for agricultural and organic waste management in the food–water–energy nexus. Curr. Opin. Chem. Eng. 2017, 18, 23–31. [Google Scholar] [CrossRef]

- Sengupta, A.; Gupta, N.K. MWCNTs based sorbents for nuclear waste management: A review. J. Environ. Chem. Eng. 2017, 5, 5099–5114. [Google Scholar] [CrossRef]

- Li, M.; Liu, J.; Han, W. Recycling and management of waste lead-acid batteries: A mini-review. Waste Manag. Res. 2016, 34, 298–306. [Google Scholar] [CrossRef]

- Asefi, H.; Lim, S. A novel multi-dimensional modeling approach to integrated municipal solid waste management. J. Clean. Prod. 2017, 166, 1131–1143. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal properties of clayey plasters with olive fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Coppola, L.; Bellezze, T.; Belli, A.; Bignozzi, M.C.; Bolzoni, F.; Brenna, A.; Cabrini, M.; Candamano, S.; Cappai, M.; Caputo, D.; et al. Binders alternative to Portland cement and waste management for sustainable construction-part 1. J. Appl. Biomater. Funct. Mater. 2018, 16, 186–202. [Google Scholar]

- Coppola, L.; Bellezze, T.; Belli, A.; Bignozzi, M.C.; Bolzoni, F.; Brenna, A.; Cabrini, M.; Candamano, S.; Cappai, M.; Caputo, D.; et al. Binders alternative to Portland cement and waste management for sustainable construction-part 2. J. Appl. Biomater. Funct. Mater. 2018, 16, 207–221. [Google Scholar]

- Ossa, A.; García, J.L.; Botero, E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Gómez-Meijide, B.; Pérez, I.; Pasandín, A.R. Recycled construction and demolition waste in cold asphalt mixtures: Evolutionary properties. J. Clean. Prod. 2016, 112, 588–598. [Google Scholar] [CrossRef]

- Petrella, A.; Cosma, P.; Rizzi, V.; De Vietro, N. Porous alumosilicate aggregate as lead ion sorbent in wastewater treatments. Separations 2017, 4, 25. [Google Scholar] [CrossRef]

- Xuan, D.X.; Molenaar, A.A.A.; Houben, L.J.M. Evaluation of cement treatment of reclaimed construction and demolition waste as road bases. J. Clean. Prod. 2015, 100, 77–83. [Google Scholar] [CrossRef]

- Petrella, A.; Petruzzelli, V.; Ranieri, E.; Catalucci, V.; Petruzzelli, D. Sorption of Pb(II), Cd(II) and Ni(II) from single- and multimetal solutions by recycled waste porous glass. Chem. Eng. Commun. 2016, 203, 940–947. [Google Scholar] [CrossRef]

- Petrella, A.; Petrella, M.; Boghetich, G.; Basile, T.; Petruzzelli, V.; Petruzzelli, D. Heavy metals retention on recycled waste glass from solid wastes sorting operations: A comparative study among different metal species. Ind. Eng. Chem. Res. 2012, 51, 119–125. [Google Scholar] [CrossRef]

- Petrella, A.; Petruzzelli, V.; Basile, T.; Petrella, M.; Boghetich, G.; Petruzzelli, D. Recycled porous glass from municipal/industrial solid wastes sorting operations as a lead ion sorbent from wastewaters. React. Funct. Polym. 2010, 70, 203–209. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Lopez, G.; Artetxe, M.; Amutio, M.; Alvarez, J.; Bilbao, J.; Olazar, M. Recent advances in the gasification of waste plastics: A critical overview. Renew Sustain. Energy Rev. 2018, 82, 576–596. [Google Scholar] [CrossRef]

- Lopez, G.; Artetxe, M.; Amutio, M.; Bilbao, J.; Olazar, M. Thermochemical routes for the valorization of waste polyolefinic plastics to produce fuels and chemicals: A review. Renew Sustain. Energy Rev. 2017, 73, 346–368. [Google Scholar] [CrossRef]

- Rajaeifar, M.A.; Abdi, R.; Tabatabaei, M. Expanded polystyrene waste application for improving biodiesel environmental performance parameters from life cycle assessment point of view. Renew Sustain. Energy Rev. 2017, 74, 278–298. [Google Scholar] [CrossRef]

- Maharana, T.; Negi, Y.S.; Mohanty, B. Review article: Recycling of polystyrene. Polym. Plast. Technol. Eng. 2007, 46, 729–736. [Google Scholar] [CrossRef]

- Herki, B. Combined effects of densified polystyrene and unprocessed fly ash on concrete engineering properties. Buildings 2017, 7, 77. [Google Scholar] [CrossRef]

- Bayoumi, T.A.; Tawfik, M.E. Immobilization of sulfate waste simulate in polymer–cement composite based on recycled expanded polystyrene foam waste: Evaluation of the final waste form under freeze–thaw treatment. Polym. Compos. 2017, 38, 637–645. [Google Scholar] [CrossRef]

- Song, H.Y.; Cheng, X.X.; Chu, L. Effect of density and ambient temperature on coefficient of thermal conductivity of heat-insulated EPS and PU materials for food packaging. Appl. Mech. Mater. 2014, 469, 152–155. [Google Scholar] [CrossRef]

- Loddo, V.; Marcì, G.; Palmisano, G.; Yurdakal, S.; Brazzoli, M.; Garavaglia, L.; Palmisano, L. Extruded expanded polystyrene sheets coated by TiO2 as new photocatalytic materials for foodstuffs packaging. Appl. Surf. Sci. 2012, 261, 783–788. [Google Scholar] [CrossRef]

- Cai, S.; Zhang, B.; Cremaschi, L. Review of moisture behavior and thermal performance of polystyrene insulation in building applications. Build. Environ. 2017, 123, 50–65. [Google Scholar] [CrossRef]

- Haibo, L. Experimental study on preparation of fly ash polystyrene new insulation building material. Chem. Eng. Trans. 2017, 59, 295–300. [Google Scholar]

- Khoukhi, M.; Fezzioui, N.; Draoui, B.; Salah, L. The impact of changes in thermal conductivity of polystyrene insulation material under different operating temperatures on the heat transfer through the building envelope. Appl. Therm. Eng. 2016, 105, 669–674. [Google Scholar] [CrossRef]

- Patiño-Herrera, R.; Catarino-Centeno, R.; González-Alatorre, G.; Gama Goicochea, A.; Pérez, E. Enhancement of the hydrophobicity of recycled polystyrene films using a spin coating unit. J. Appl. Polym. Sci. 2017, 134, 45365. [Google Scholar] [CrossRef]

- Mohajerani, A.; Ashdown, M.; Abdihashi, L.; Nazem, M. Expanded polystyrene geofoam in pavement construction. Constr. Build. Mater. 2017, 157, 438–448. [Google Scholar] [CrossRef]

- Tawfik, M.E.; Eskander, S.B.; Nawwar, G.A.M. Hard wood-composites made of rice straw and recycled polystyrene foam wastes. J. Appl. Polym. Sci. 2017, 134, 44770. [Google Scholar] [CrossRef]

- Kim, H.; Park, S.; Lee, S. Acoustic performance of resilient materials using acrylic polymer emulsion resin. Materials 2016, 9, 592. [Google Scholar] [CrossRef]

- Dissanayake, D.M.K.W.; Jayasinghe, C.; Jayasinghe, M.T.R. A comparative embodied energy analysis of a house with recycled expanded polystyrene (EPS) based foam concrete wall panels. Energy Build. 2017, 135, 85–94. [Google Scholar] [CrossRef]

- Herki, B.A.; Khatib, J.M. Valorisation of waste expanded polystyrene in concrete using a novel recycling technique. Eur. J. Environ. Civ. Eng. 2017, 21, 1384–1402. [Google Scholar] [CrossRef]

- Babu, D.S.; Ganesh Babu, K.; Tiong-Huan, W. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Fernando, P.L.N.; Jayasinghe, M.T.R.; Jayasinghe, C. Structural feasibility of Expanded Polystyrene (EPS) based lightweight concrete sandwich wall panels. Constr. Build. Mater. 2017, 139, 45–51. [Google Scholar] [CrossRef]

- Sethi, S.K.; Manik, G. Recent progress in super hydrophobic/hydrophilic self-cleaning surfaces for various industrial applications: A review. Polym. Plast. Technol. 2018, 57, 1932–1952. [Google Scholar] [CrossRef]

- Di Mundo, R.; Bottiglione, F.; Carbone, G. Cassie state robustness of plasma generated randomly nano-rough surfaces. Appl. Surf. Sci. 2014, 16, 324–332. [Google Scholar] [CrossRef]

- Di Mundo, R.; D’Agostino, R.; Palumbo, F. Long-lasting antifog plasma modification of transparent plastics. ACS Appl. Mater. Interfaces 2014, 6, 17059–17066. [Google Scholar] [CrossRef]

- Di Mundo, R.; Dilonardo, E.; Nacucchi, M.; Carbone, G.; Notarnicola, M. Water absorption in rubber-cement composites: 3D structure investigation by X-ray computed tomography. Constr. Build. Mater. 2019, 228, 116602. [Google Scholar] [CrossRef]

- Yue, P.; Renardy, Y. Spontaneous penetration of a non-wetting drop into an exposed pore. Phys. Fluids 2013, 25, 052104. [Google Scholar] [CrossRef]

- Neto, E.; Magina, S.; Camoes, A.; Cachim, L.P.; Begonha, A.; Evtuguin, D.V. Characterization of concrete surface in relation to graffiti protection coatings. Constr. Build. Mater. 2016, 102, 435–444. [Google Scholar] [CrossRef]

- Weisheit, S.; Unterberger, S.H.; Bader, T.; Lackner, R. Assessment of test methods for characterizing the hydrophobic nature of surface-treated High Performance Concrete. Constr. Build. Mater. 2016, 110, 145–153. [Google Scholar] [CrossRef]

- European Committee for Standardization. Products and Systems for the Protection and Repair of Concrete Structures. Definitions, Requirements, Quality Control and Evaluation of Conformity in Part 2: Surface Materials and Structures Protection Systems for Concretes. BS EN 1504-2. Available online: https://shop.bsigroup.com/ProductDetail/?pid=000000000030036789 (accessed on 21 July 2019).

- Ramachandran, R.; Sobolev, K.; Nosonovsky, M. Dynamics of droplet impact on hydrophobic/icephobic concrete with the potential for superhydrophobicity. Langmuir 2015, 31, 1437–1444. [Google Scholar] [CrossRef] [PubMed]

- Flores-Vivian, I.; Hejazi, V.; Khozhukova, M.I.; Nosonovsky, M.; Sobolev, K. Self-assembling particle-siloxane coatings for superhydrophobic concrete. ACS Appl. Mater. Interfaces 2013, 5, 13284–13294. [Google Scholar] [CrossRef] [PubMed]

- Italian Organization for Standardization (UNI). Cement Composition, Specifications and Conformity Criteria for Common Cements. EN 197-1. Available online: http://store.uni.com/magento-1.4.0.1/index.php/en-197-1-2011.html (accessed on 14 September 2011).

- Italian Organization for Standardization (UNI). Methods of Testing Cement-Part 1: Determination of Strength. EN 196-1. Available online: http://store.uni.com/magento-1.4.0.1/index.php/en-196-1-2016.html (accessed on 27 April 2016).

- International Organization for Standardization (ISO). Cement, Test Methods, Determination Of Strength. ISO 679. Available online: http://store.uni.com/magento-1.4.0.1/index.php/iso-679-2009.html (accessed on 24 April 2009).

- Petrella, A.; Spasiano, D.; Rizzi, V.; Cosma, P.; Race, M.; De Vietro, N. Lead ion sorption by perlite and reuse of the exhausted material in the construction field. Appl. Sci. 2018, 8, 1882. [Google Scholar] [CrossRef]

- Petrella, A.; Petrella, M.; Boghetich, G.; Petruzzelli, D.; Ayr, U.; Stefanizzi, P.; Calabrese, D.; Pace, L. Thermo-acoustic properties of cement-waste-glass mortars. Proc. Inst. Civ. Eng. Constr. Mater. 2009, 162, 67–72. [Google Scholar] [CrossRef]

- Petrella, A.; Spasiano, D.; Acquafredda, P.; De Vietro, N.; Ranieri, E.; Cosma, P.; Rizzi, V.; Petruzzelli, V.; Petruzzelli, D. Heavy metals retention (Pb (II), Cd (II), Ni (II)) from single and multimetal solutions by natural biosorbents from the olive oil milling operations. Process Saf. Environ. Prot. 2018, 114, 79–90. [Google Scholar] [CrossRef]

- Italian Organization for Standardization (UNI). Determination of Consistency of Cement Mortars Using a Flow Table. 7044. Available online: http://store.uni.com/magento-1.4.0.1/index.php/uni-7044-1972.html (accessed on 20 April 1972).

- Gustafsson, S.E. Transient plane source techniques for thermal conductivity and thermal diffusivity measurements of solid materials. Rev. Sci. Instrum. 1991, 62, 797–804. [Google Scholar] [CrossRef]

- Di Mundo, R.; Petrella, A.; Notarnicola, M. Surface and bulk hydrophobic cement composites by tyre rubber addition. Constr. Build. Mater. 2018, 172, 176–184. [Google Scholar] [CrossRef]

- Petrella, A.; Spasiano, D.; Liuzzi, S.; Ayr, U.; Cosma, P.; Rizzi, V.; Petrella, M.; Di Mundo, R. Use of cellulose fibers from wheat straw for sustainable cement mortars. J. Sustain. Cem. Based Mater. 2019, 8, 161–179. [Google Scholar] [CrossRef]

- Spasiano, D.; Luongo, V.; Petrella, A.; Alfè, M.; Pirozzi, F.; Fratino, U.; Piccinni, A.F. Preliminary study on the adoption of dark fermentation as pretreatment for a sustainable hydrothermal denaturation of cement-asbestos composites. J. Clean. Prod. 2017, 166, 172–180. [Google Scholar] [CrossRef]

- Al-Manaseer, A.A.; Dalal, T.R. Concrete containing plastic aggregates. Concr. Int. 1997, 19, 47–52. [Google Scholar]

- Li, G.; Stubblefield, M.A.; Garrick, G.; Eggers, J.; Abadie, C.; Huang, B. Development of waste tire modified concrete. Cem. Concr. Res. 2004, 34, 2283–2289. [Google Scholar] [CrossRef]

- Ganesh Babu, K.; Saradhi Babu, D. Behaviour of lightweight expanded polystyrene concrete containing silica fume. Cem. Concr. Res. 2003, 33, 755–762. [Google Scholar] [CrossRef]

- Saradhi Babu, D.; Ganesh Babu, K.; Wee, T.H. Properties of lightweight expanded polystyrene aggregate concretes containing fly ash. Cem. Concr. Res. 2005, 35, 1218–1223. [Google Scholar] [CrossRef]

- Laukaitis, A.; Zurauskas, R.; Keriene, J. The effect of foam polystyrene granules on cement composite properties. Cem. Concr. Compos. 2005, 27, 41–47. [Google Scholar] [CrossRef]

- Petrella, A.; Spasiano, D.; Rizzi, V.; Cosma, P.; Race, M.; De Vietro, N. Thermodynamic and kinetic investigation of heavy metals sorption in packed bed columns by recycled lignocellulosic materials from olive oil production. Chem. Eng. Commun. 2019, 206, 1715–1730. [Google Scholar] [CrossRef]

- Petrella, A.; Spasiano, D.; Race, M.; Rizzi, V.; Cosma, P.; Liuzzi, S.; De Vietro, N. Porous waste glass for lead removal in packed bed columns and reuse in cement conglomerates. Materials 2019, 12, 94. [Google Scholar] [CrossRef]

- Giannuzzi, G.; Gaudioso, C.; Di Mundo, R.; Mirenghi, L.; Fraggelakis, F.; Kling, R.; Lugarà, P.M.; Ancona, A. Short and long term surface chemistry and wetting behaviour of stainless steel with 1D and 2D periodic structures induced by burst of femtosecond laser pulses. Appl. Surf. Sci. 2019, 494, 1055–1065. [Google Scholar] [CrossRef]

- Song, Z.; Xue, X.; Li, Y.; Yang, J.; He, Z.; Shen, S.; Jiang, L.; Zhang, W.; Xu, L.; Zhang, H.; et al. Experimental exploration of the waterproofing mechanism of inorganic sodium silicate-based concrete sealers. Constr. Build. Mater. 2016, 104, 276–283. [Google Scholar] [CrossRef]

- Li, F.; Yang, Y.; Tao, M.; Li, X. A cement paste–tail sealant interface modified with a silane coupling agent for enhancing waterproofing performance in a concrete lining system. RSC Adv. 2019, 9, 7165–7175. [Google Scholar] [CrossRef]

- Petrella, A.; Petrella, M.; Boghetich, G.; Petruzzelli, D.; Calabrese, D.; Stefanizzi, P.; De Napoli, D.; Guastamacchia, M. Recycled waste glass as aggregate for lightweight concrete. Proc. Inst. Civ. Eng. Constr. Mater. 2007, 160, 165–170. [Google Scholar] [CrossRef]

| Normal | Normalized Sand | ||

|---|---|---|---|

| Sand | sand (1–2 mm) 25% | sand (2–4 mm) 25% | sand (4–6 mm) 50% |

| Sand-EPS | sand(1–2 mm) 25% | sand(2–4 mm) 25% | EPS (4–6 mm) 50% |

| EPS 2 | EPS (4–6 mm) 100% | ||

| EPS 3 | EPS (2–4 mm) 50% | EPS (4–6 mm) 50% | |

| EPS 4 | EPS (1–2 mm) 25% | EPS (2–4 mm) 25% | EPS (4–6 mm) 50% |

| Sample | Cement (g) | Water (cm3) | Sand Volume (cm3) | EPS Volume (cm3) | ρ (Kg/m3) | Porosity % |

|---|---|---|---|---|---|---|

| Normal | 450 | 225 | 810 | 0 | 2020 | 22 |

| Sand | 450 | 225 | 500 | 0 | 2090 | 20 |

| Sand-EPS | 450 | 225 | 250 | 250 | 1320 | 32 |

| EPS 2 | 450 | 225 | 0 | 500 | 850 | 49 |

| EPS 3 | 450 | 225 | 0 | 500 | 940 | 42 |

| EPS 4 | 450 | 225 | 0 | 500 | 855 | 48 |

| Sample | ρ (Kg/m3) | RF (MPa) | RC (MPa) |

|---|---|---|---|

| Normal | 2020 | 7.5 | 50 |

| Sand | 2090 | 7.7 | 52 |

| Sand-EPS | 1320 | 4.9 | 33 |

| EPS 2 | 850 | 1.1 | 8 |

| EPS 3 | 940 | 1.1 | 10 |

| EPS 4 | 855 | 1 | 9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrella, A.; Di Mundo, R.; Notarnicola, M. Recycled Expanded Polystyrene as Lightweight Aggregate for Environmentally Sustainable Cement Conglomerates. Materials 2020, 13, 988. https://doi.org/10.3390/ma13040988

Petrella A, Di Mundo R, Notarnicola M. Recycled Expanded Polystyrene as Lightweight Aggregate for Environmentally Sustainable Cement Conglomerates. Materials. 2020; 13(4):988. https://doi.org/10.3390/ma13040988

Chicago/Turabian StylePetrella, Andrea, Rosa Di Mundo, and Michele Notarnicola. 2020. "Recycled Expanded Polystyrene as Lightweight Aggregate for Environmentally Sustainable Cement Conglomerates" Materials 13, no. 4: 988. https://doi.org/10.3390/ma13040988

APA StylePetrella, A., Di Mundo, R., & Notarnicola, M. (2020). Recycled Expanded Polystyrene as Lightweight Aggregate for Environmentally Sustainable Cement Conglomerates. Materials, 13(4), 988. https://doi.org/10.3390/ma13040988