A Comparative Study on the Effects of Three Nano-Materials on the Properties of Cement-Based Composites

Abstract

1. Introduction

2. Materials and Methodology

2.1. Raw Material

2.2. Experiment Mixture Proportions

2.3. Specimen Preparation

2.4. Test Methods

2.4.1. Compressive Strength

2.4.2. Flexural Strength

2.4.3. Water Absorption Rate

2.4.4. SEM

2.4.5. XRD

3. Results and Discussion

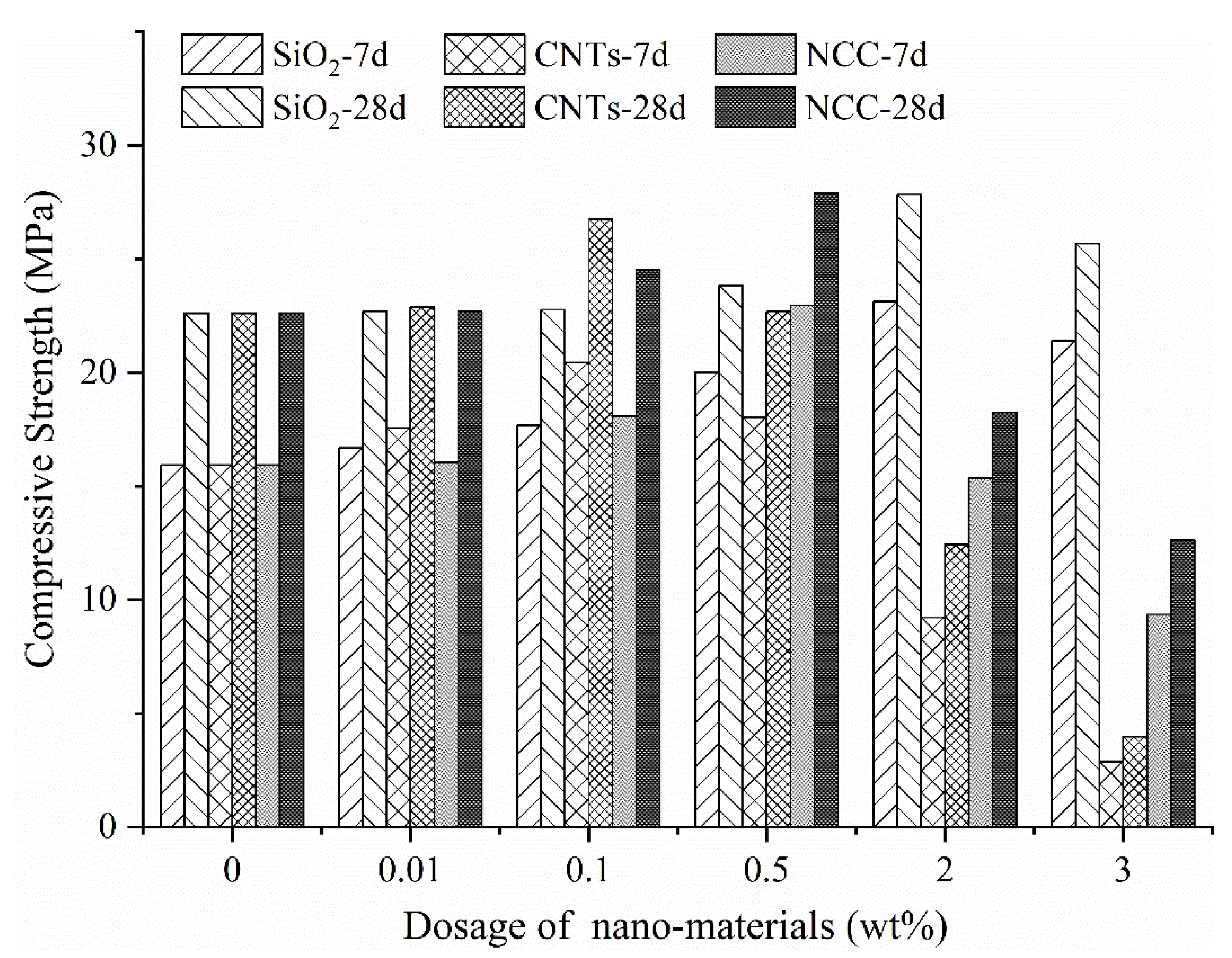

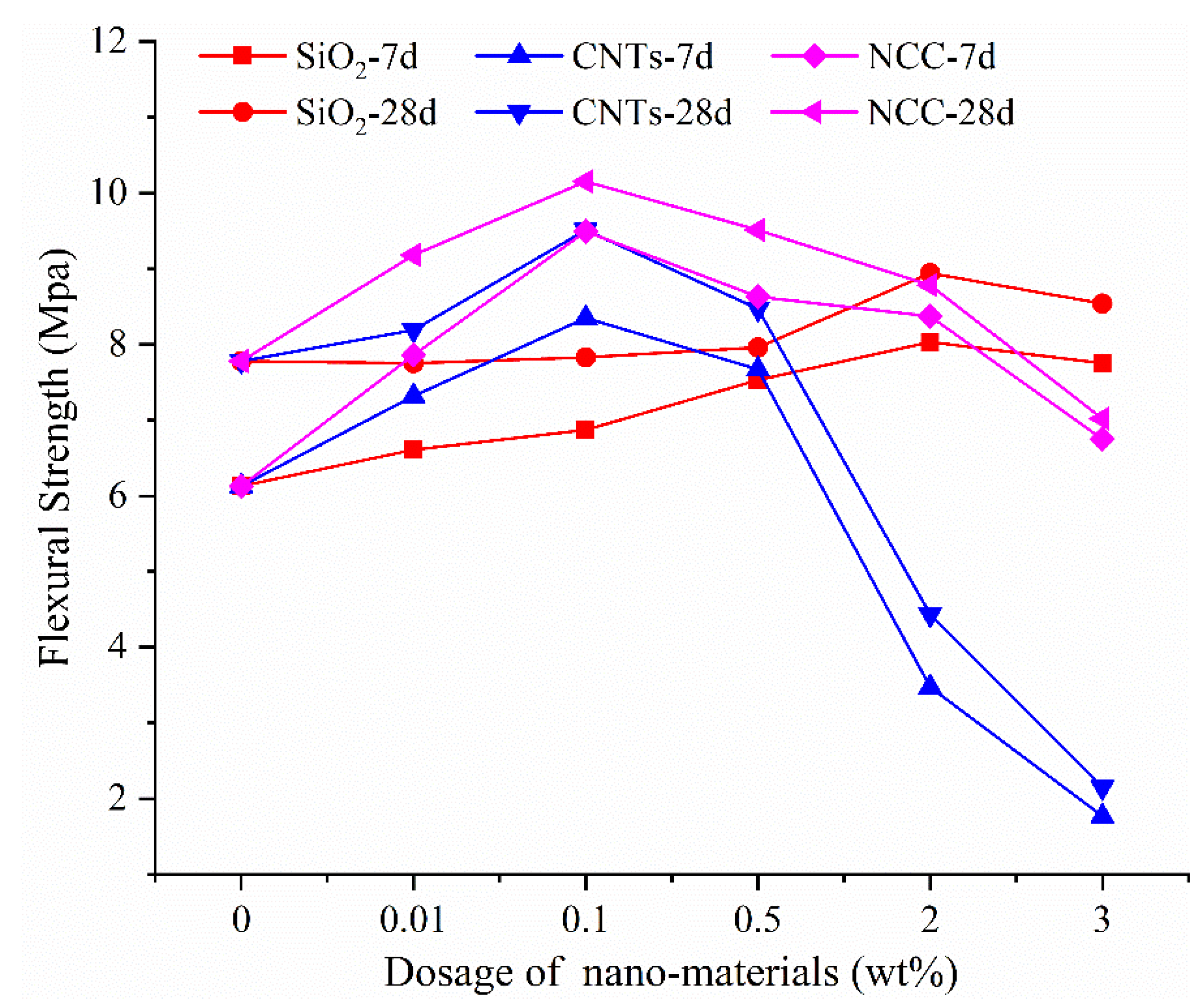

3.1. Compressive and Flexural Strength

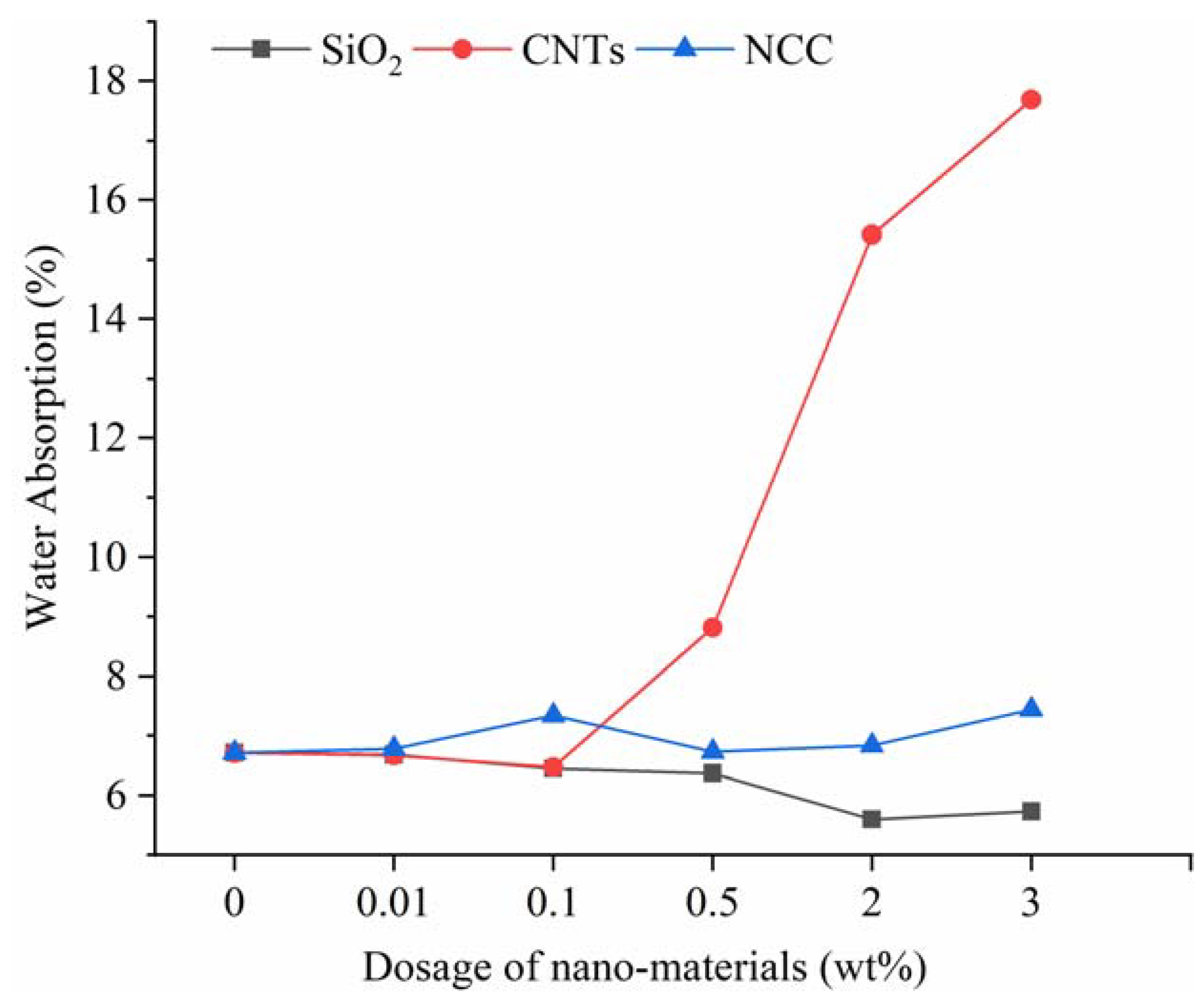

3.2. Water Absorption

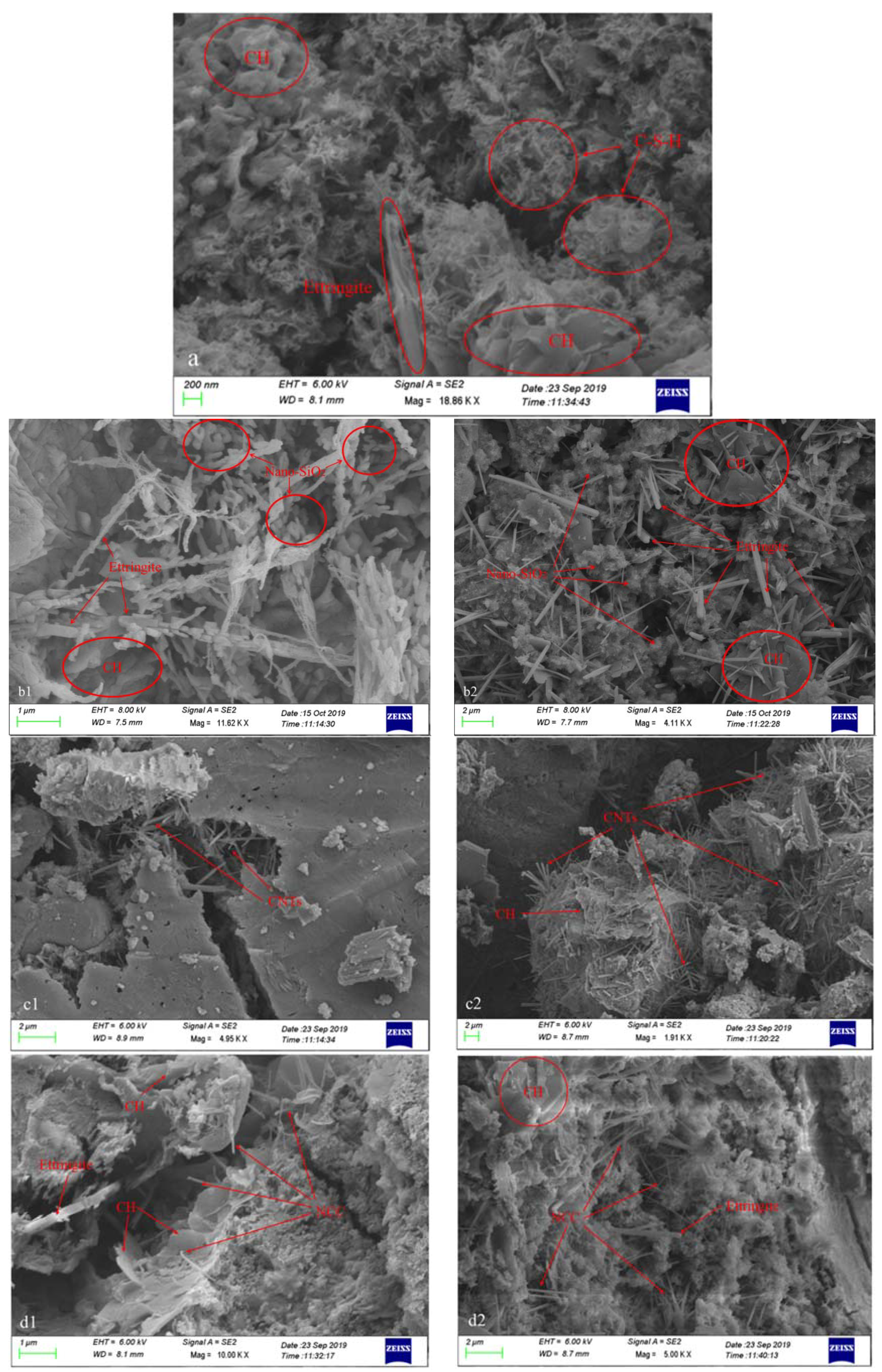

3.3. Microstructure Analysis

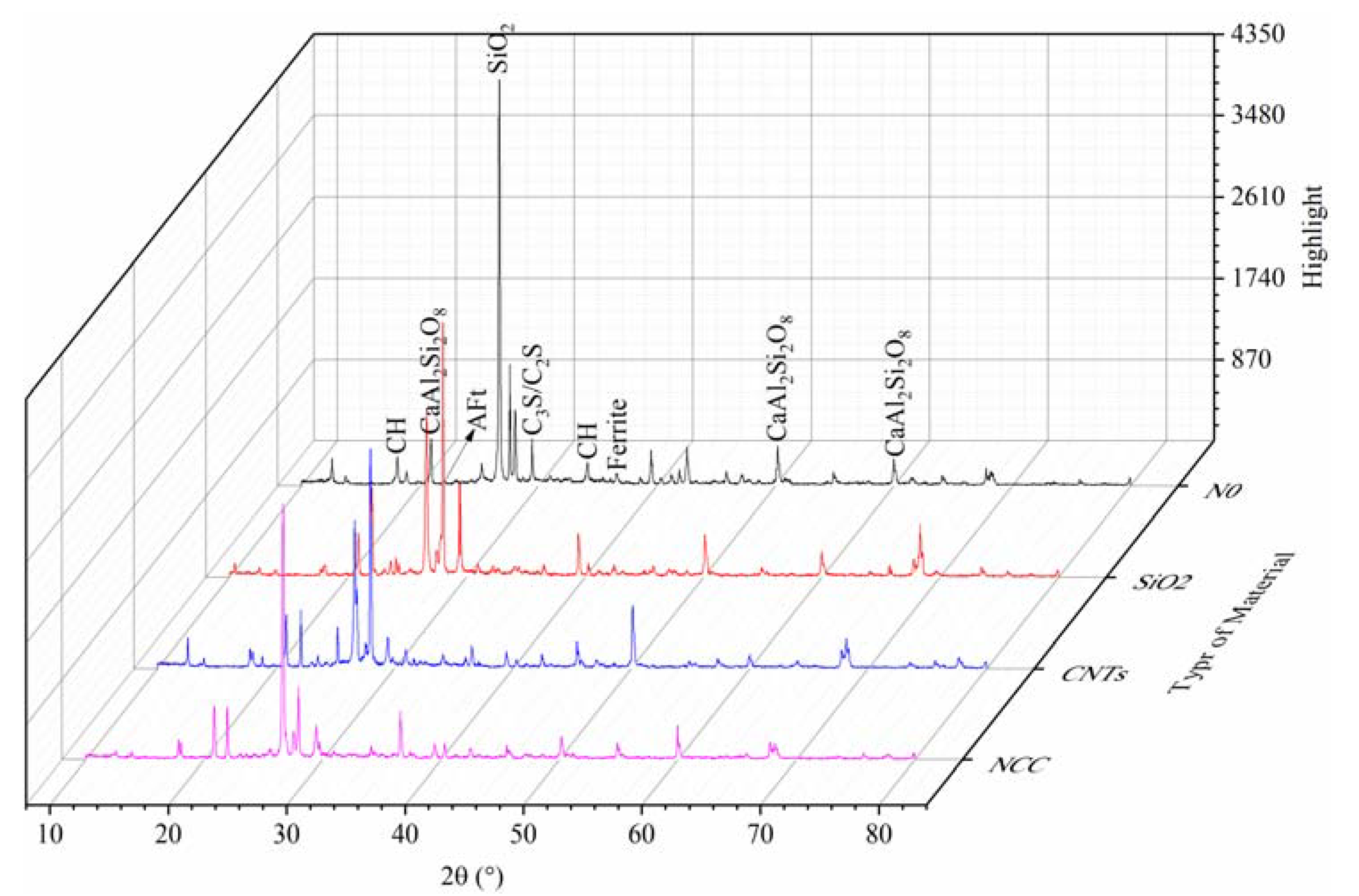

3.4. XRD Phase Analysis

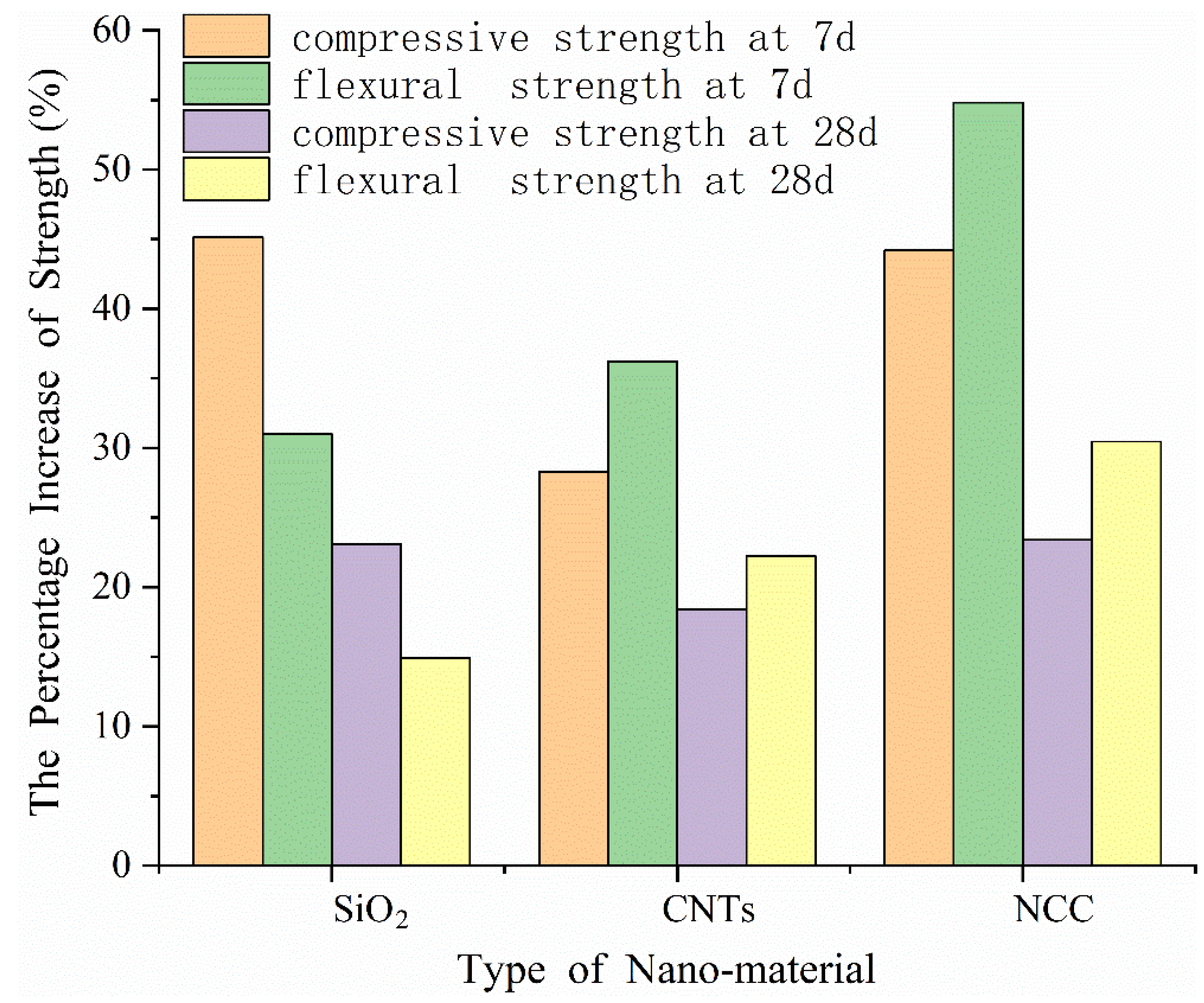

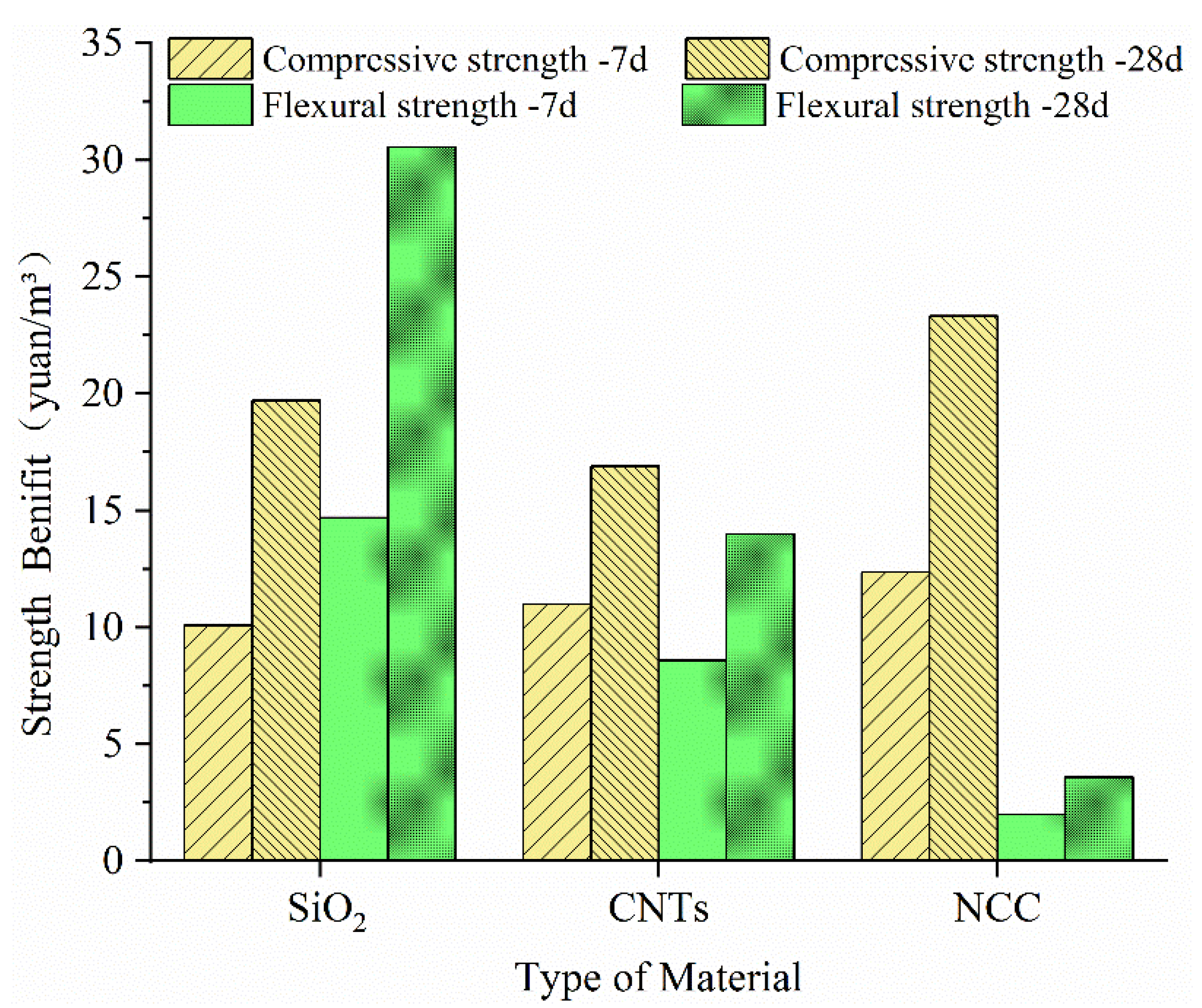

3.5. Strength Benefit Analysis

4. Conclusions

- The three nano-materials significantly improved the mechanical properties of cement-based materials. The 7 d compressive strength of SiO2, CNTs and NCC increased by 45.13%, 28.31% and 44.19%, and the 28 d compressive strength increased by 23.09%, 18.40% and 23.40%, respectively. The 7d flexural strength increased by 31.00%, 36.22% and 54.81%, and the 28d flexural strength increased by 14.91%, 22.23% and 30.46%, respectively. Overall, NCC has the best strength enhancement effect on cement-based materials.

- Among the three kinds of nanomaterial, SiO2 reduces the water absorption of test pieces due to its effective micro-porosity filling effect. The other two have a limited filling impact on the micro-pores due to their micro-morphology, and the materials themselves have a stronger water absorption, resulting in different degrees of improvement of the water absorption, especially CNTs, which water absorption rate reached nearly three times that of the blank group.

- Through SEM and XRD analysis, it was found that the three nanomaterials all promoted cement hydration, and also reduced the crystal orientation of the cement hydration product CH, but the specific principles of the strength improvements were different. Nano-SiO2 mainly makes the cement hydration more complete by acting as a crystal nucleus, and fills the internal micropores of cement-based materials to increase the compactness of materials and thus improve their mechanical properties. However, CNTs and NCC overlap with each other in cement-based materials, and bear a specific load through bridging action and the high elastic modulus of the nanomaterials themselves, while at the same time, by dispersing and changing the load transfer path to prevent the development of cracks they can effectively improve the mechanical properties of materials, especially the flexural strength.

- Through economic analysis and taking strength benefit as the evaluation index, it can be known that CNTs has the highest cost-performance ratio as far as compressive resistance is concerned, while for flexural resistance NCC has the highest cost-performance ratio. In practical applications, nanomaterials can be selected according to the different desired weights of compression and bending resistance.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Luo, J.L.; Duan, Z.D. Dispersivity of multiwalled carbon nanotubes (MWCNT) and mechanical properties of MWCNT reinforced cement-based composite. J. Build. Struct. 2008, 29, 246–250. [Google Scholar]

- Zile, E.; Zile, O. Effect of the fiber geometry on the pullout response of mechanically deformed steel fibers. Cem. Concr. Res. 2013, 44, 18–24. [Google Scholar] [CrossRef]

- Barhum, R.; Mechtcherine, V. Effect of short, dispersed glass and carbon fibres on the behaviour of textile-reinforced concrete under tensile loading. Eng. Fract. Mech. 2012, 92, 56–71. [Google Scholar] [CrossRef]

- Li, V.C.; Wu, C.; Wang, S.; Ogawa, A.; Saito, T. Interface tailoring for strain-hardening polyvinyl alcohol-engineered cementitious composite (PVA-ECC). Mater. J. 2002, 99, 463–472. [Google Scholar]

- Silvestre, J.; Silvestre, N.; De, B.J. Review on concrete nanotechnology. Eur. J. Environ. Civ. Eng. 2015, 20, 455–485. [Google Scholar] [CrossRef]

- Mounir, L.; Achraf, G.; Pierre, M.; Abdelhafid, K. Experimental study of the effect of addition of nano-silica on the behaviour of cement mortars. Procedia Eng. 2011, 10, 900–905. [Google Scholar]

- Kawashima, S.; Hou, P.K.; Corr, D.J.; Shah, S.P. Modification of cement-based materials with nanoparticles. Cem. Concr. Compos. 2013, 36, 8–15. [Google Scholar] [CrossRef]

- Byung, W.J.; Chang, H.K.; Ghiho, T.; Jong, B.P. Characteristics of cemem mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar]

- Madandoust, R.; Mohseni, E.; Mousavi, S.Y.; Namnevis, M. An experimental investigation on the durability of self-compacting mortarcontaining nano-SiO2, nano-Fe2O3 and nano-CuO. Constr. Build. Mater. 2015, 86, 44–50. [Google Scholar] [CrossRef]

- Ye, Q.; Zhang, Z.N.; Kong, D.Y.; Rongshen, C. Influence of nano-SiO2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar]

- Morsy, M.S.; Alsayed, S.H.; Aqel, M. Hybrid effect of carbon nanotube and nano-clay on physicomechanical properties of cement mortar. Constr. Build. Mater. 2011, 25, 145–149. [Google Scholar] [CrossRef]

- Arefi, M.R.; Javeri, M.R.; Mollaahmadi, E. To study the effect of adding Al2O3nanoparticle on themechanical properties and microstructure of cement mortar. Life Sci. J. 2011, 8, 613–617. [Google Scholar]

- Lee, B.Y.; Jayapalan, A.R.; Kurtis, K.E. Effects of nano-TiO2 on properties of cement-based materials. Mag. Concr. Res. 2013, 65, 1293–1302. [Google Scholar] [CrossRef]

- Senffa, L.; Tobaldib, D.M.; Lemes-Rachadelc, P.; Labrincha, J.A.; Hotza, D. HotzaThe influence of TiO2 and ZnO powder mixtures on photocatalytic activity and rheological behavior of cement pastes. Constr. Build. Mater. 2014, 65, 191–200. [Google Scholar] [CrossRef]

- Campillo, I.; Dolado, J.S.; Porro, A. High-performance nanostructured materials for construction. Spec. Publ. R. Soc. Chem. 2004, 292, 215–226. [Google Scholar]

- Onuaguluchi, O.; Panesar, D.K.; Sain, M. Properties of nanofibre reinforced cement composites. Constr. Build. Mater. 2014, 63, 119. [Google Scholar] [CrossRef]

- Flores, J.; Kamali, M.; Ghahremaninezhad, A. An investigation into the: properties and microstructure of cement mixtures modified with cellulose nano-crystal. Materials 2017, 10, 498. [Google Scholar] [CrossRef]

- Cao, Y.Z.; Zavaterri, P.; Youngblood, J.; Moon, R.; Weiss, J. The influence of cellulose nanocrystal additions on the performance of cement pastel. Cem. Concr. Compos. 2015, 56, 73. [Google Scholar] [CrossRef]

- Fu, T.F.; Montes, F.; Suraneni, P.; Youngblood, J.; Weiss, J. The infuence of cellulose nanocrystals on the hydration and flexural strength of portlandcement pastes. Polymers 2017, 9, 424. [Google Scholar] [CrossRef]

- Chen, Q.; Geng, Y.; Bai, F. Mechanical properties of cement incorporated with three kinds of carbon-based nanoparticles. J. Mater. Sci. Eng. 2018, 36, 964–969. [Google Scholar]

- Wang, P.M.; Zhu, H.M.; Zhang, G.F. Effect of nano-Si02 Oil the properties of cement-based decorative mortars. New Build. Mater. 2010, 37, 14–16. [Google Scholar]

- Liu, S. Dispersion of Carbon Nanotubes and the Durability of Carbon Nanotubes Reinforced Cement-Based Composites; Dalian University of Technology: Dalian, China, 2015. [Google Scholar]

- Wang, D.G. Mechanical Simulation of Carbon Nanotube Reinforced Cement Composites; Dalian University of Technology: Dalian, China, 2011. [Google Scholar]

- Sindu, B.S.; Sasmal, S.; Gopinath, S. A multi-scale approach for evaluating the mechanical characteristics of carbon nanotube incorporated cementitious composites. Constr. Build. Mater. 2014, 50, 317–327. [Google Scholar] [CrossRef]

- Rong, Z.D.; Jiang, G.; Sun, W. Effects of nano-SiO2 and nano-CaCO3 on properties of ultra-high performance cementitious composites. J. Southeast Univ. Nat. Sci. Ed. 2015, 45, 393–398. [Google Scholar]

- Sun, X.X.; Wu, Q.L.; Lee, S.Y.; Qing, Y.; Wu, Y. Cellulose nanofibers as a modifier for rheology, curing and mechanical performance of oil well. Sci. Rep. 2016, 6, 31654. [Google Scholar] [CrossRef] [PubMed]

- Hussin, A.; Poole, C. Petrography evidence of the interfacial transition zone (ITZ) in the normal strength concrete containing granitic and limestone aggregates. Constr. Build. Mater. 2011, 25, 2298–2303. [Google Scholar] [CrossRef]

| Material | Properties |

|---|---|

| Nano-SiO2 | Purchased from Beijing Shenghe Haoyuan Technology Co. Ltd. (Beijing, China); white powder, SiO2 content not less than 99.5%, particle size is 20–30 nm, specific surface area not less than 250 m2/g |

| CNTs | Purchased from Suzhou Tanfeng Graphene Technology Co. Ltd. (Suzhou, China); black lightweight powder, inner diameter is 3–5 nm, outer diameter is 8–15 nm, length is 3–12 microns, specific surface area not less than 233 m2/g, C > 95%, ash content C < 3%, volume density 0.15 g/cm3 |

| NCC | Purchased from Zhongshan NFC Bio-materials Co. Ltd. (Zhongshan, China); transparent gel with a concentration of 2.5% ± 0.5%, a width of 5–100 nm, a length of > 1 μm, an elastic modulus of 6.2–6.9 GPa, and a tensile strength of 222–233 MPa |

| Materials | Dosage (wt% of Cement) | ||||

|---|---|---|---|---|---|

| CNTs | 0.01 | 0.1 | 0.5 | 2 | 3 |

| NCC | 0.01 | 0.1 | 0.5 | 2 | 3 |

| Nano-SiO2 | 0.01 | 0.1 | 0.5 | 2 | 3 |

| Sample | Crystal | |||||

|---|---|---|---|---|---|---|

| CH/(001) | CH/(101) | CaAl2Si2O8·4H2O | AFt | SiO2 | C3S | |

| NO | 324 | 264 | 516 | 68 | 4354 | 1306 |

| Nano-SiO2 | 144 | 125 | 486 | 966 | 1814 | 294 |

| CNTs | 194 | 165 | 578 | 636 | 1598 | 284 |

| NCC | 188 | 160 | 584 | 570 | 2744 | 312 |

| Sample | CH/(001 | CH/(101) | Orientation of CH Crystal |

|---|---|---|---|

| N0 | 324 | 264 | 1.657 |

| SiO2 | 144 | 125 | 1.555 |

| CNTs | 194 | 165 | 1.587 |

| NCC | 188 | 160 | 1.586 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, C.; Xie, C.; Liu, J.; Wei, X.; Wu, D. A Comparative Study on the Effects of Three Nano-Materials on the Properties of Cement-Based Composites. Materials 2020, 13, 857. https://doi.org/10.3390/ma13040857

Fu C, Xie C, Liu J, Wei X, Wu D. A Comparative Study on the Effects of Three Nano-Materials on the Properties of Cement-Based Composites. Materials. 2020; 13(4):857. https://doi.org/10.3390/ma13040857

Chicago/Turabian StyleFu, Chao, Chunyan Xie, Jing Liu, Xiuli Wei, and Dake Wu. 2020. "A Comparative Study on the Effects of Three Nano-Materials on the Properties of Cement-Based Composites" Materials 13, no. 4: 857. https://doi.org/10.3390/ma13040857

APA StyleFu, C., Xie, C., Liu, J., Wei, X., & Wu, D. (2020). A Comparative Study on the Effects of Three Nano-Materials on the Properties of Cement-Based Composites. Materials, 13(4), 857. https://doi.org/10.3390/ma13040857