Waste Rubber Recycling: A Review on the Evolution and Properties of Thermoplastic Elastomers

Abstract

1. Introduction

1.1. Microstructural Composition

1.1.1. Elastomers

1.1.2. Fillers

1.1.3. Other Additives

1.2. Rubbers Types

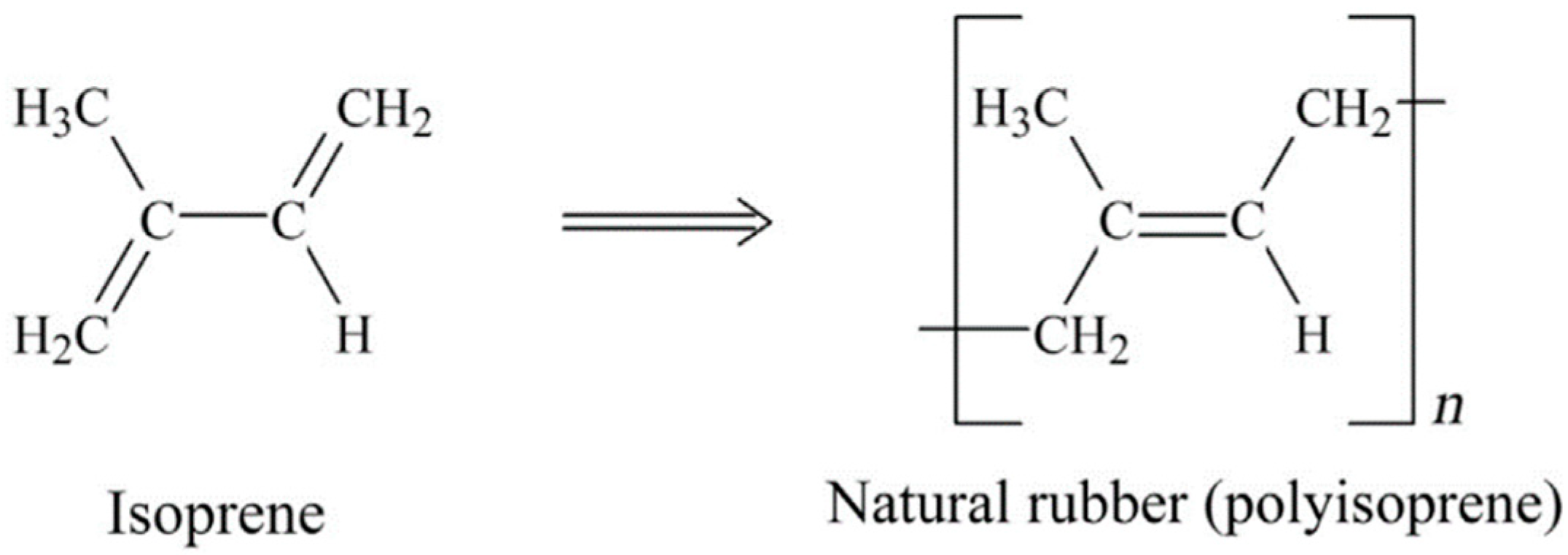

1.2.1. Natural Rubber

1.2.2. Synthetic Rubbers

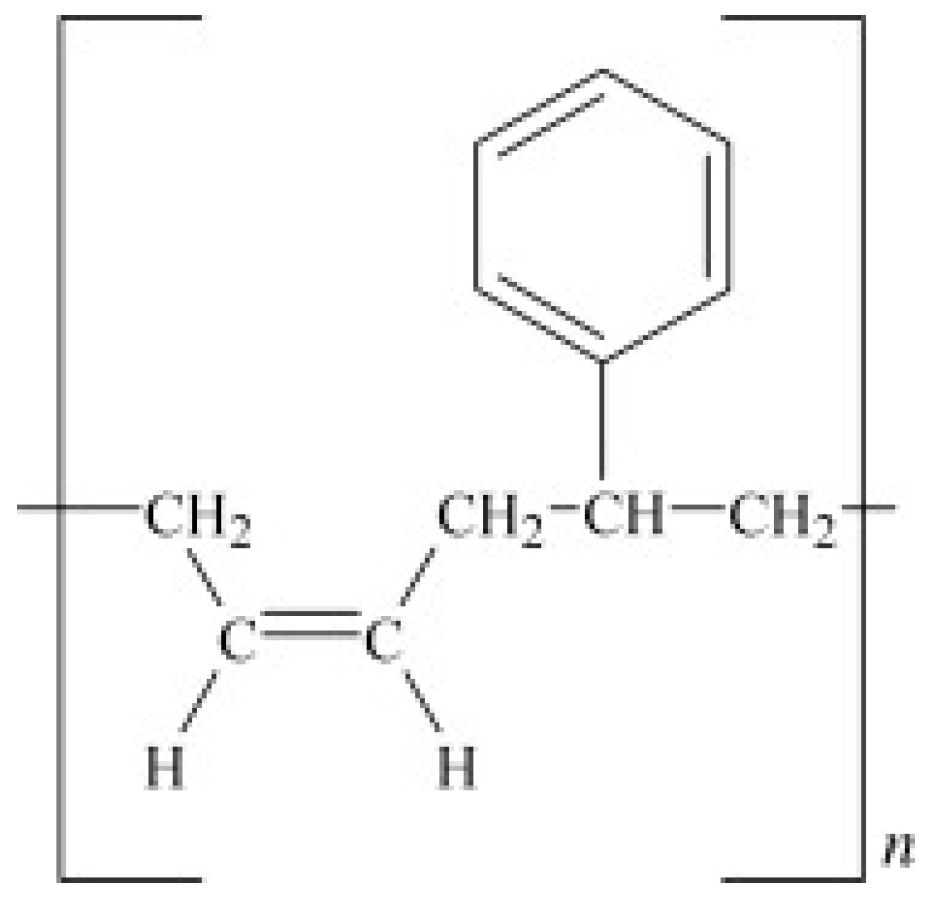

Styrene-Butadiene Rubber

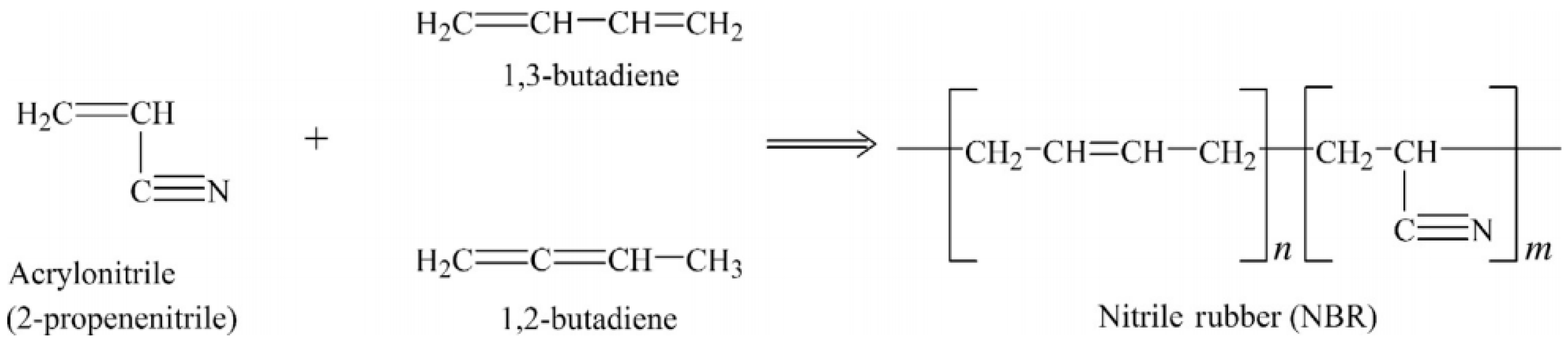

Nitrile-Butadiene Rubber

Ethylene-Propylene-Diene Monomer

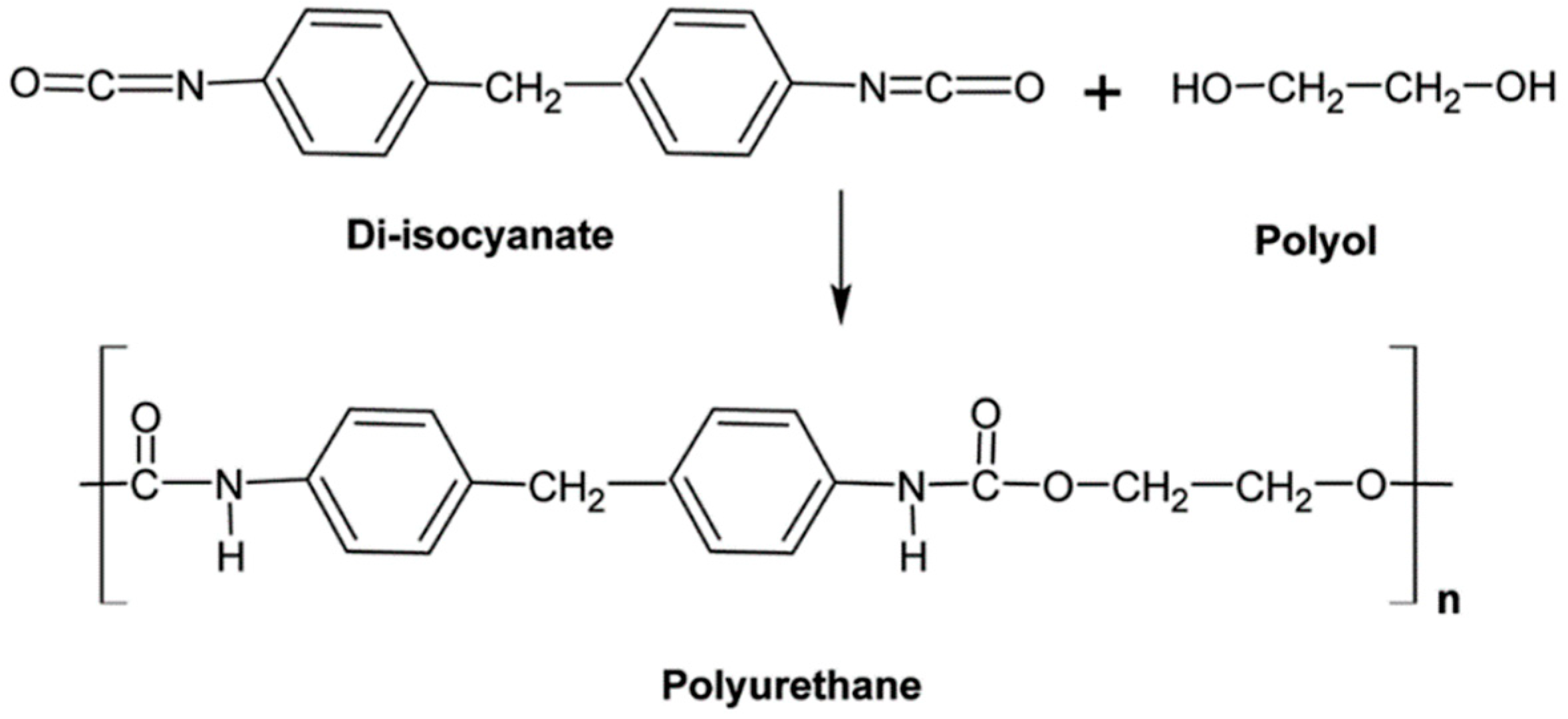

Polyurethane

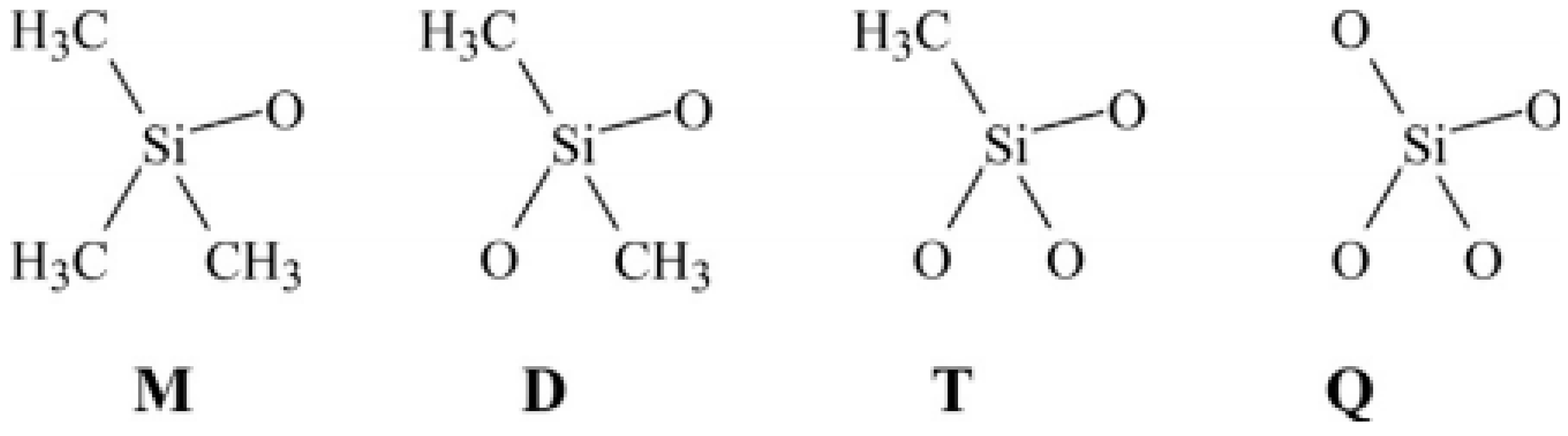

Silicone Rubber

2. Recycling

3. Thermoplastic Elastomers

3.1. TPE Structure

- Block copolymers consisting of elastic and non-elastic blocks;

- Rubber/thermoplastic blends;

- Dynamically vulcanized rubber/thermoplastic blends.

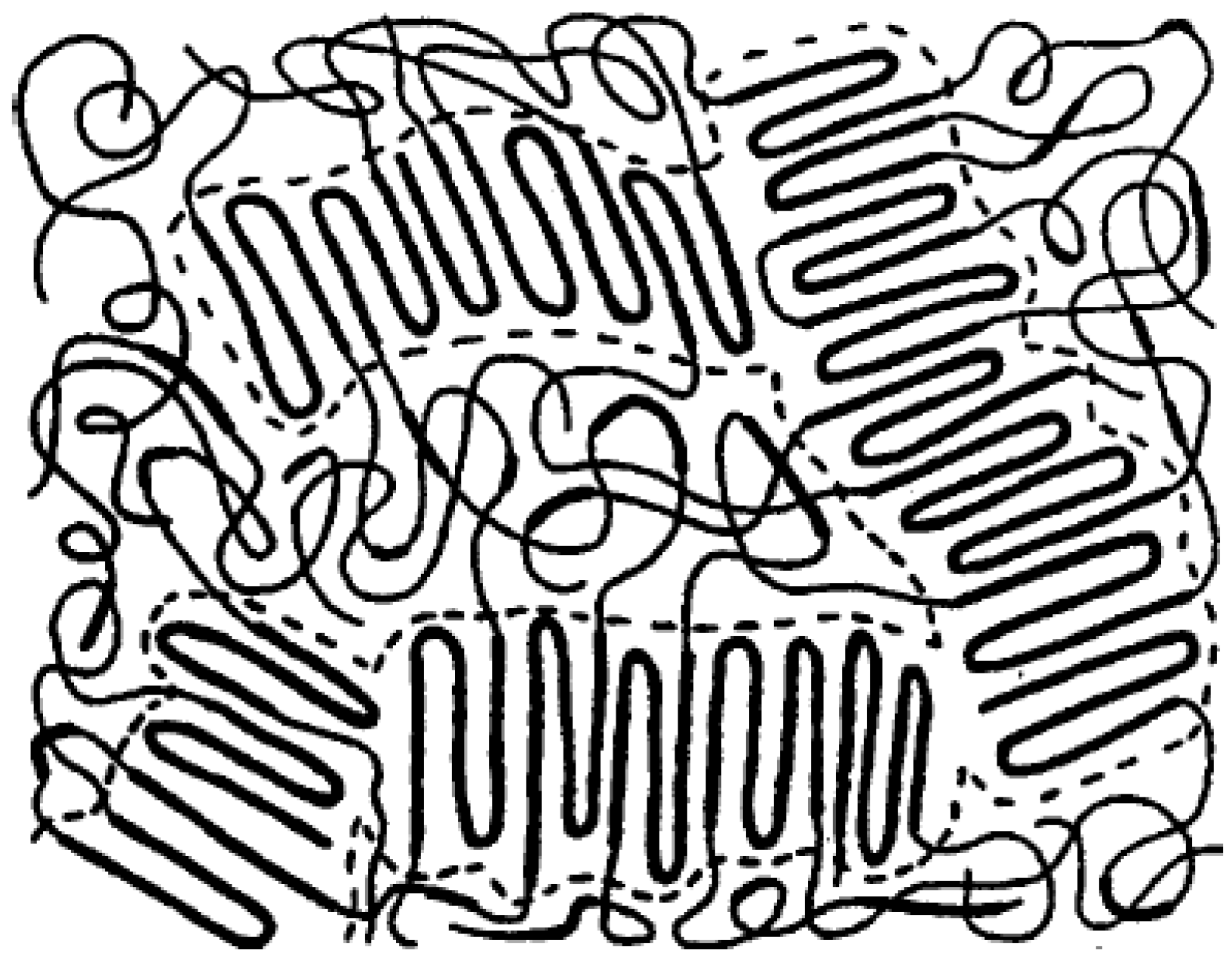

3.1.1. Block Copolymers

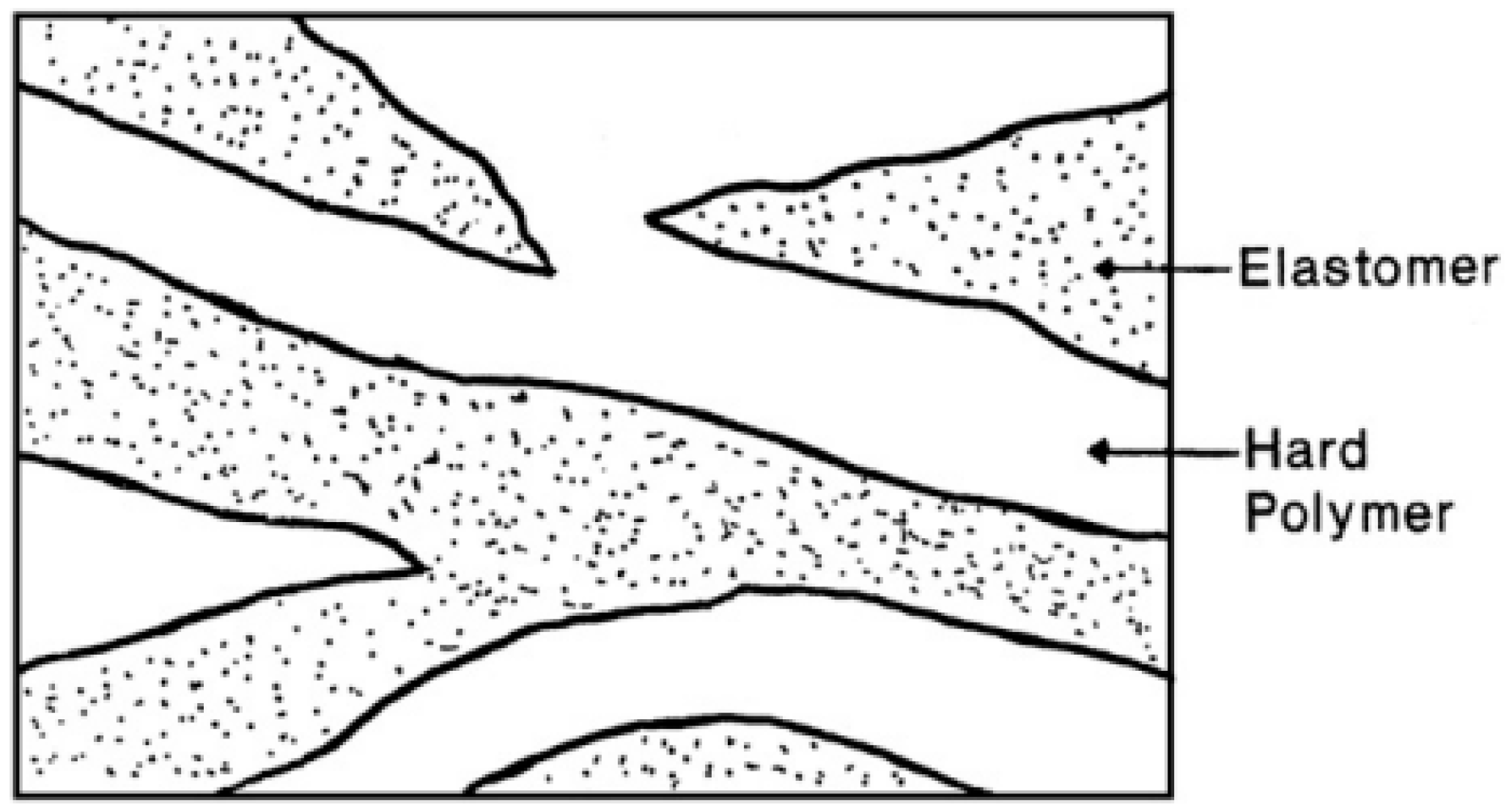

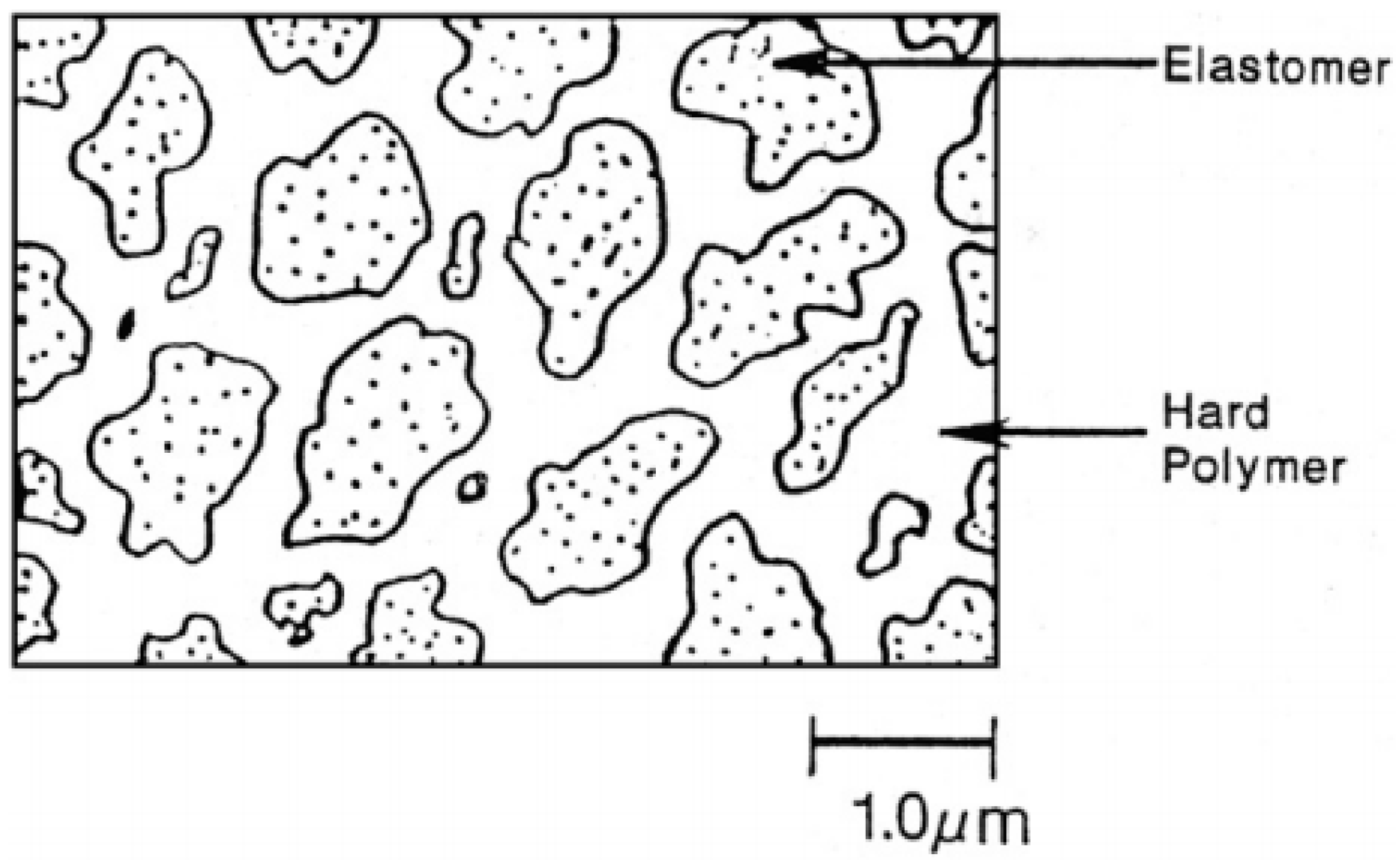

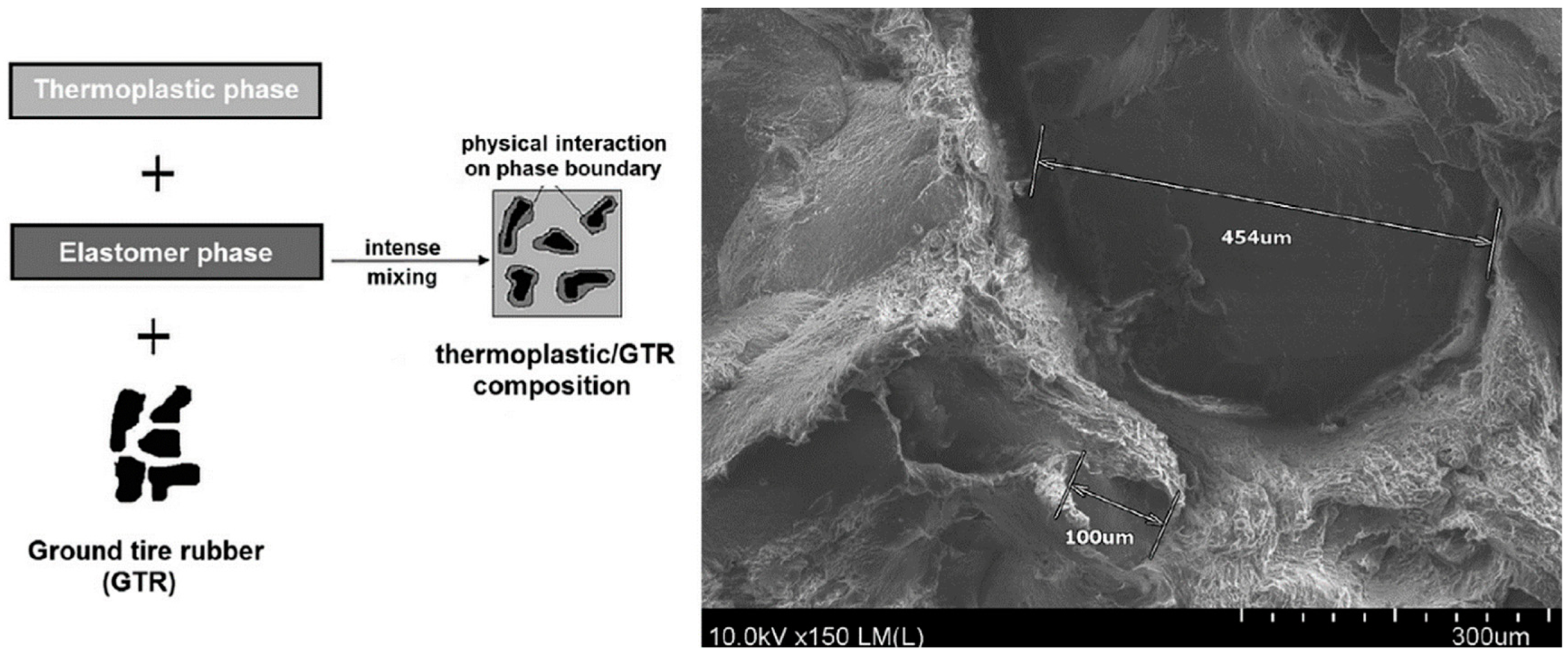

3.1.2. Rubber/Thermoplastic Blends

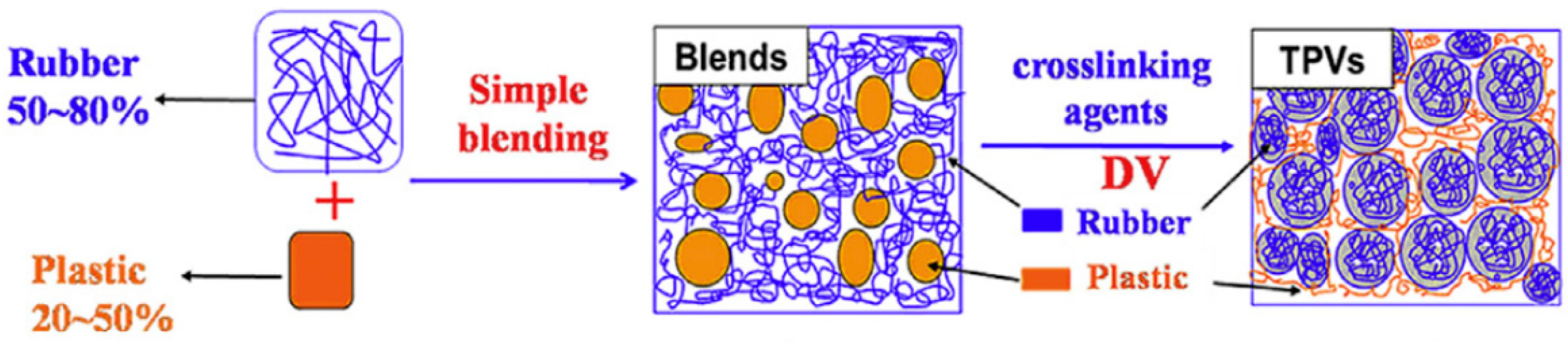

3.1.3. Thermoplastic Vulcanizates

4. Compatibility

- Lowering the interfacial tension,

- Controlling the morphology by size reduction and stabilisation of the dispersed droplets to prevent their coalescence,

- Increasing the interfacial adhesion between the phases, leading to better stress transfer and mechanical properties [45].

4.1. Copolymers

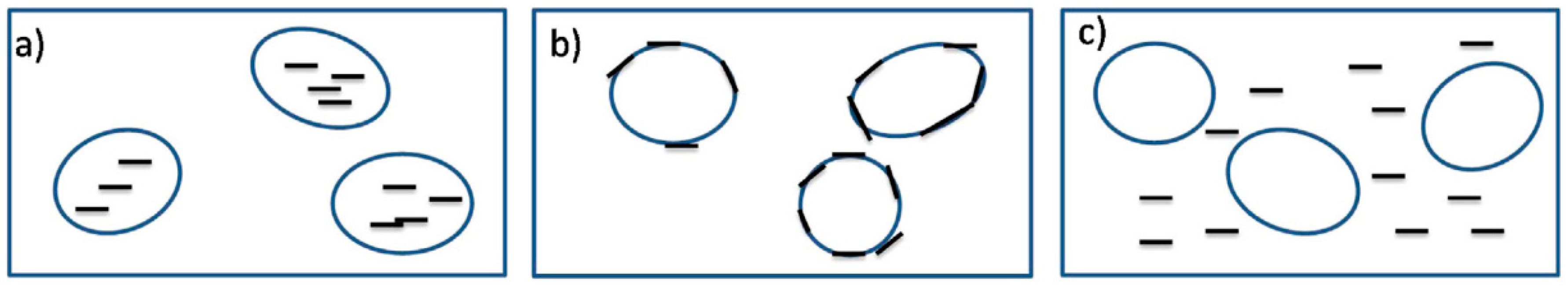

4.2. Nanoparticles (NP)

5. Rubber Modification

Reclamation and Devulcanisation

6. TPE Compatibilisation

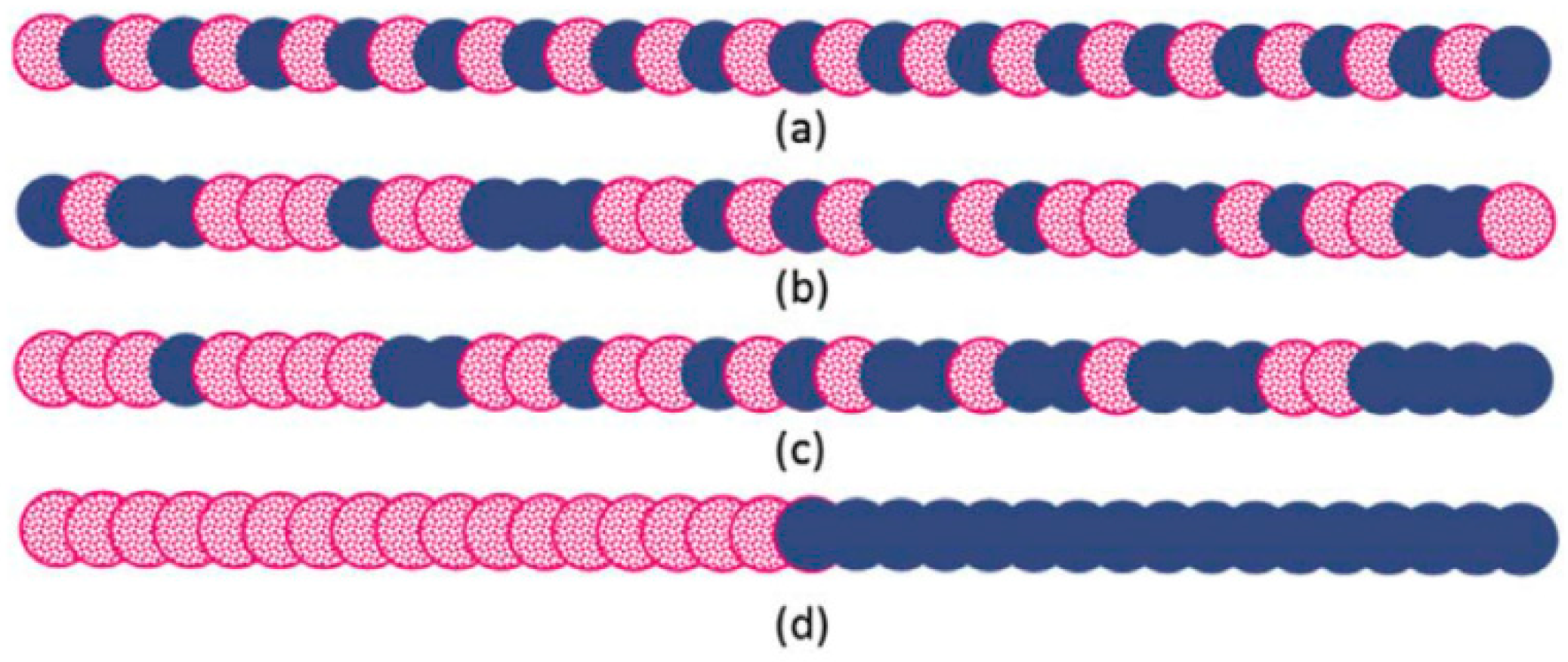

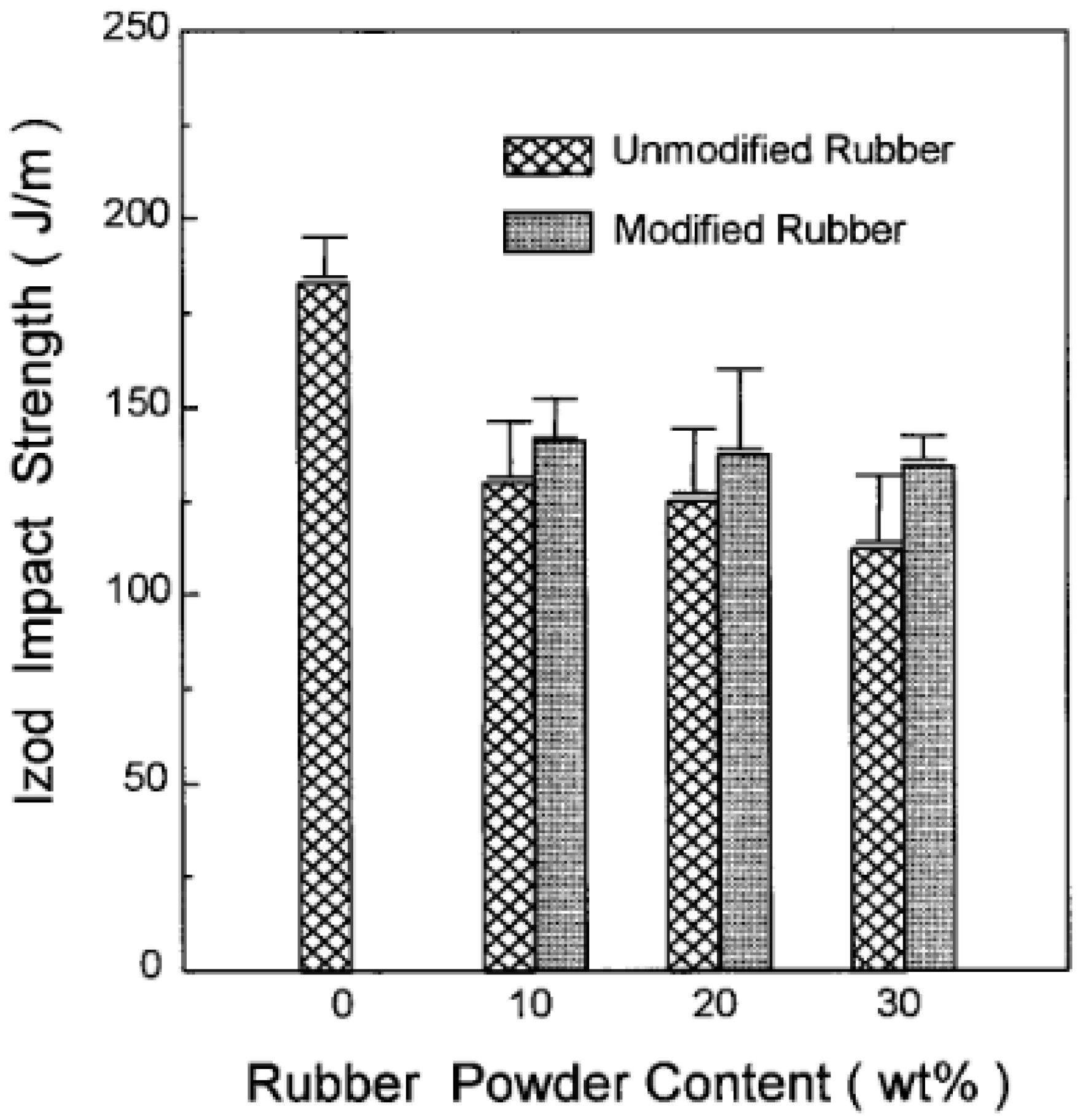

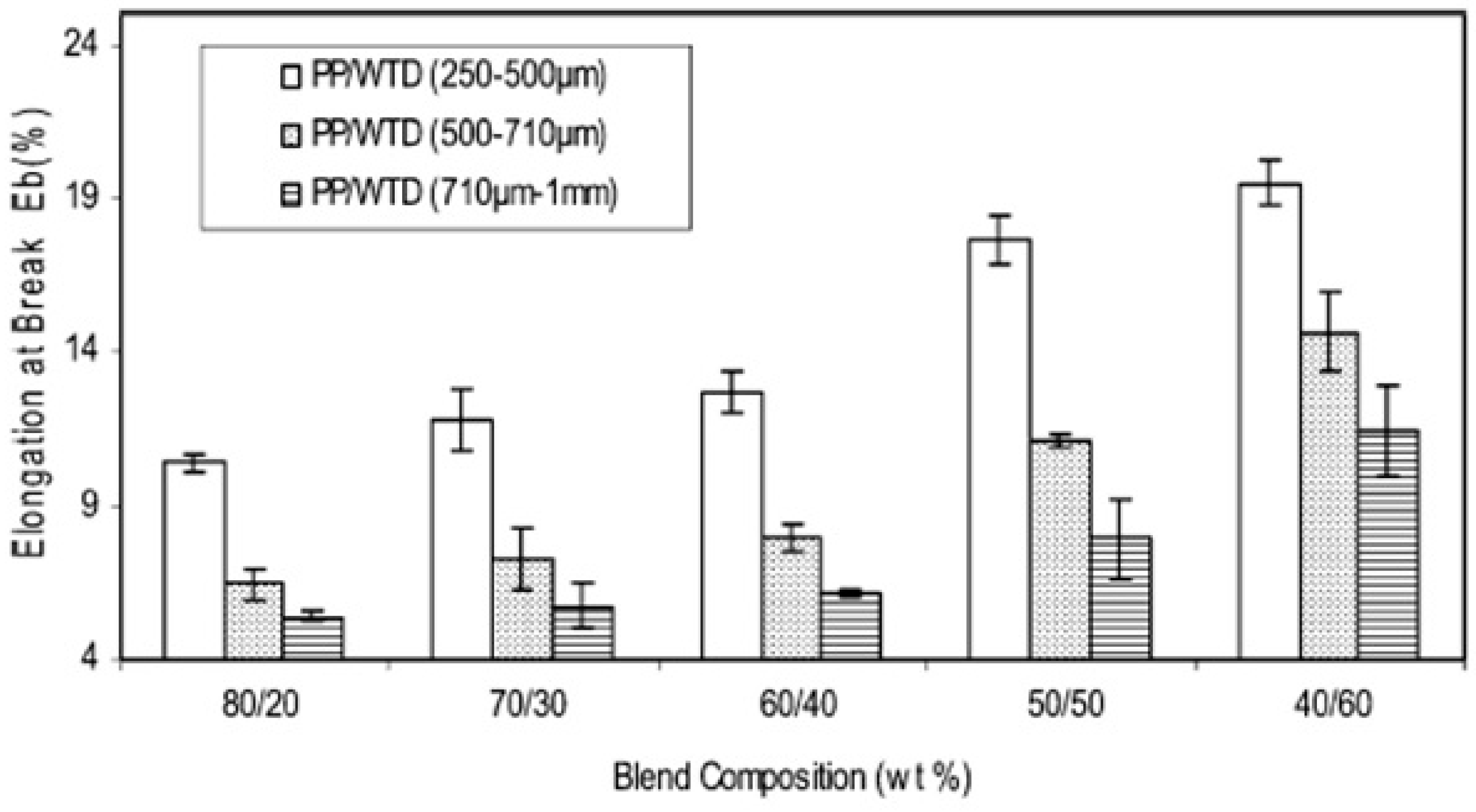

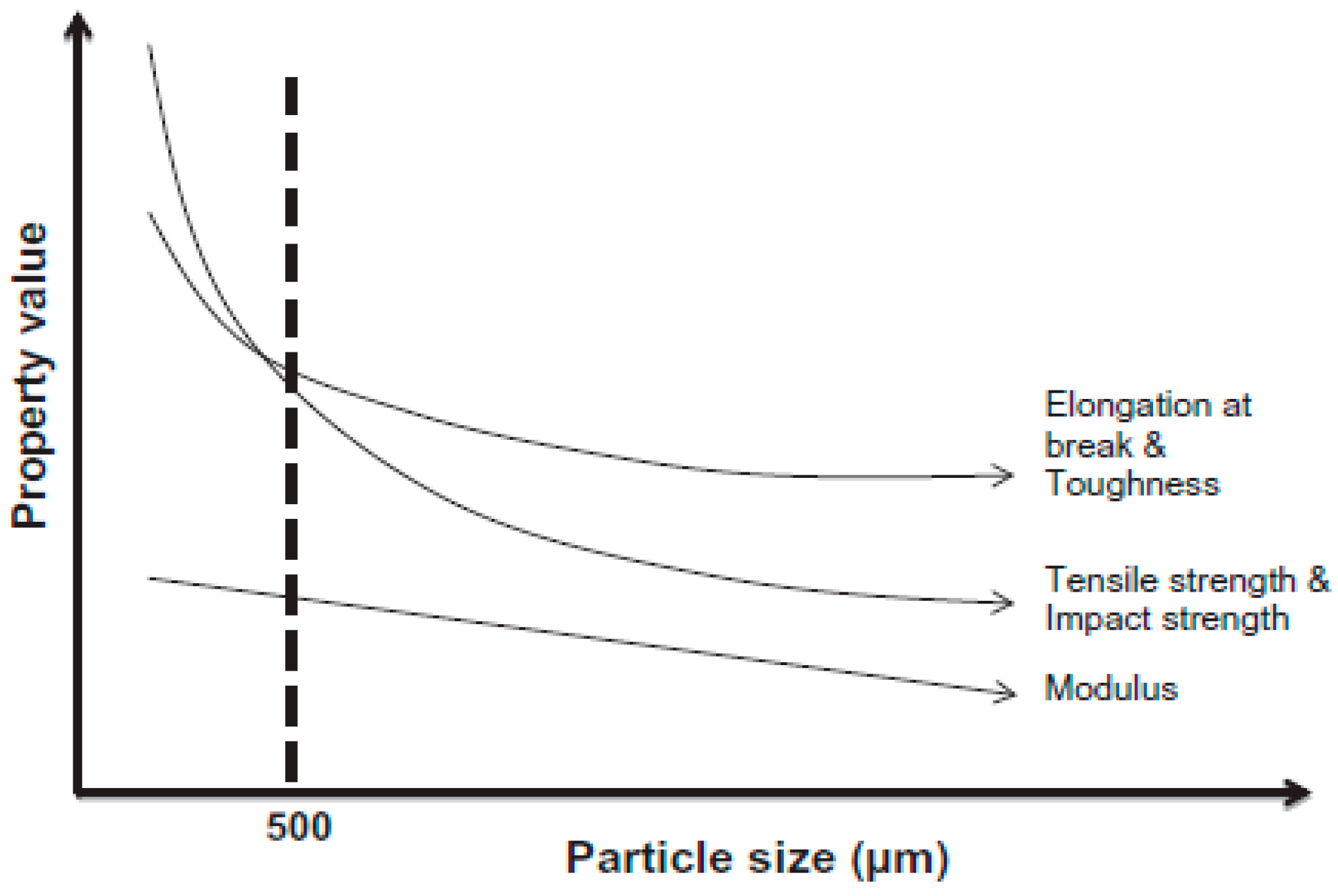

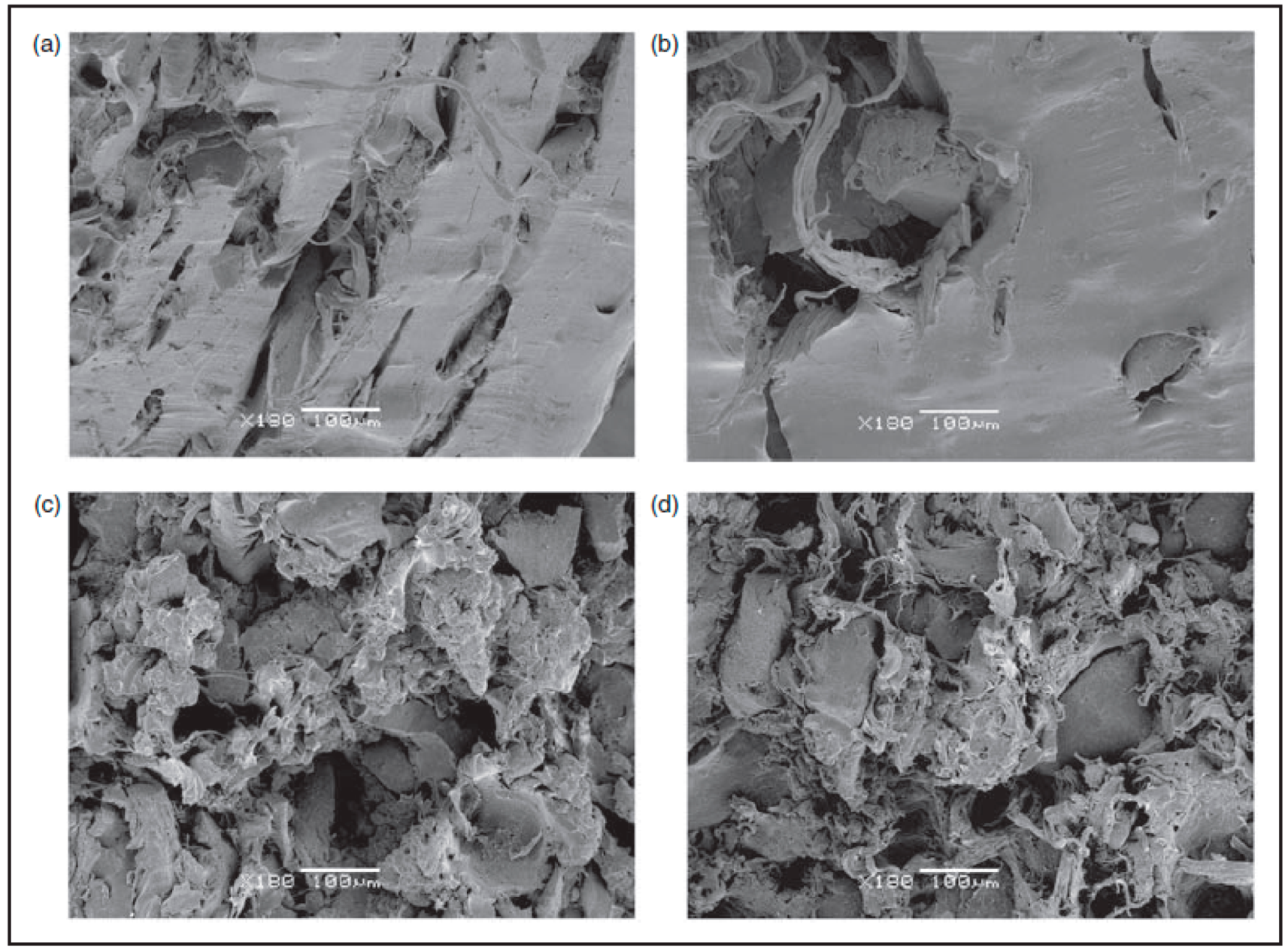

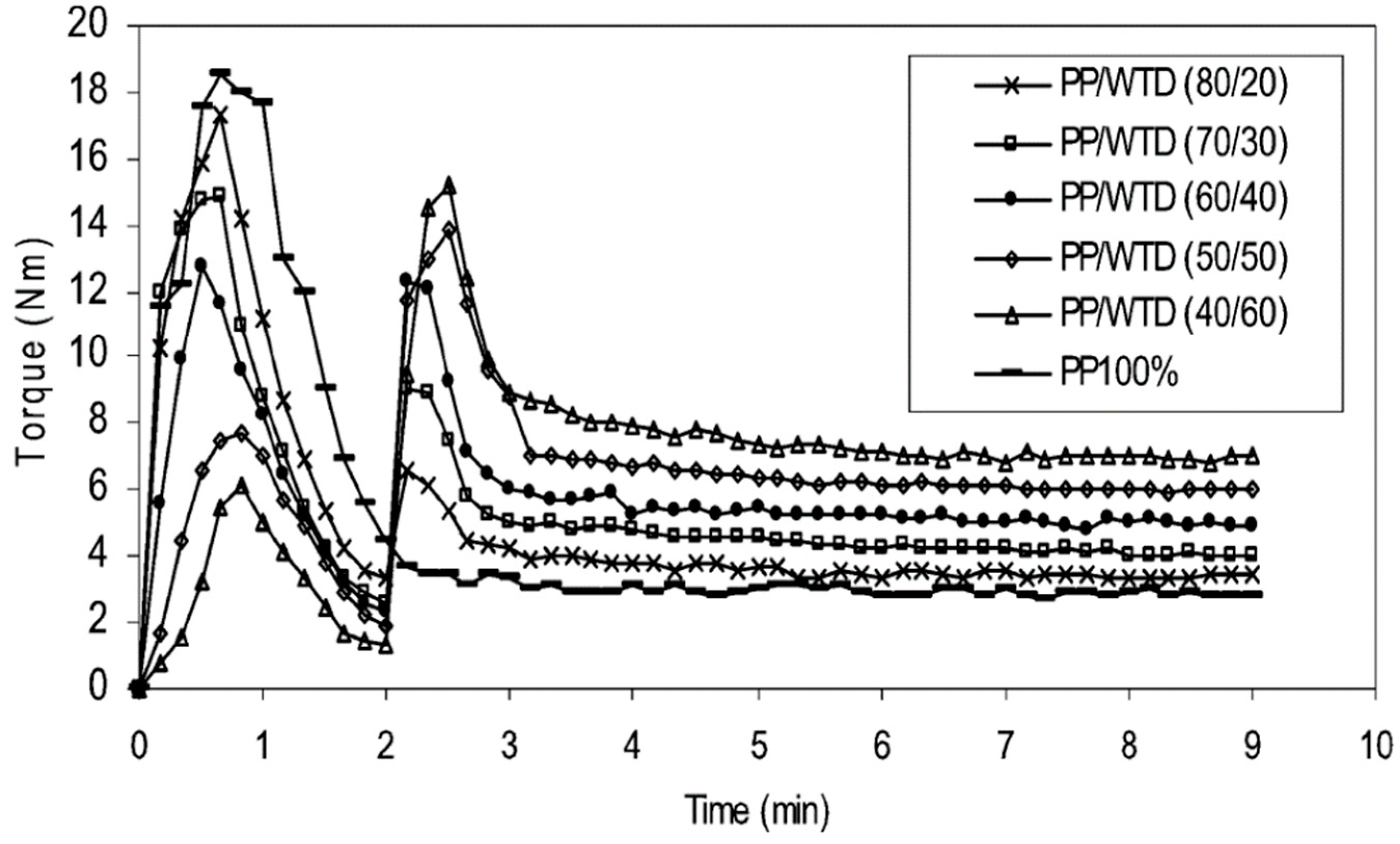

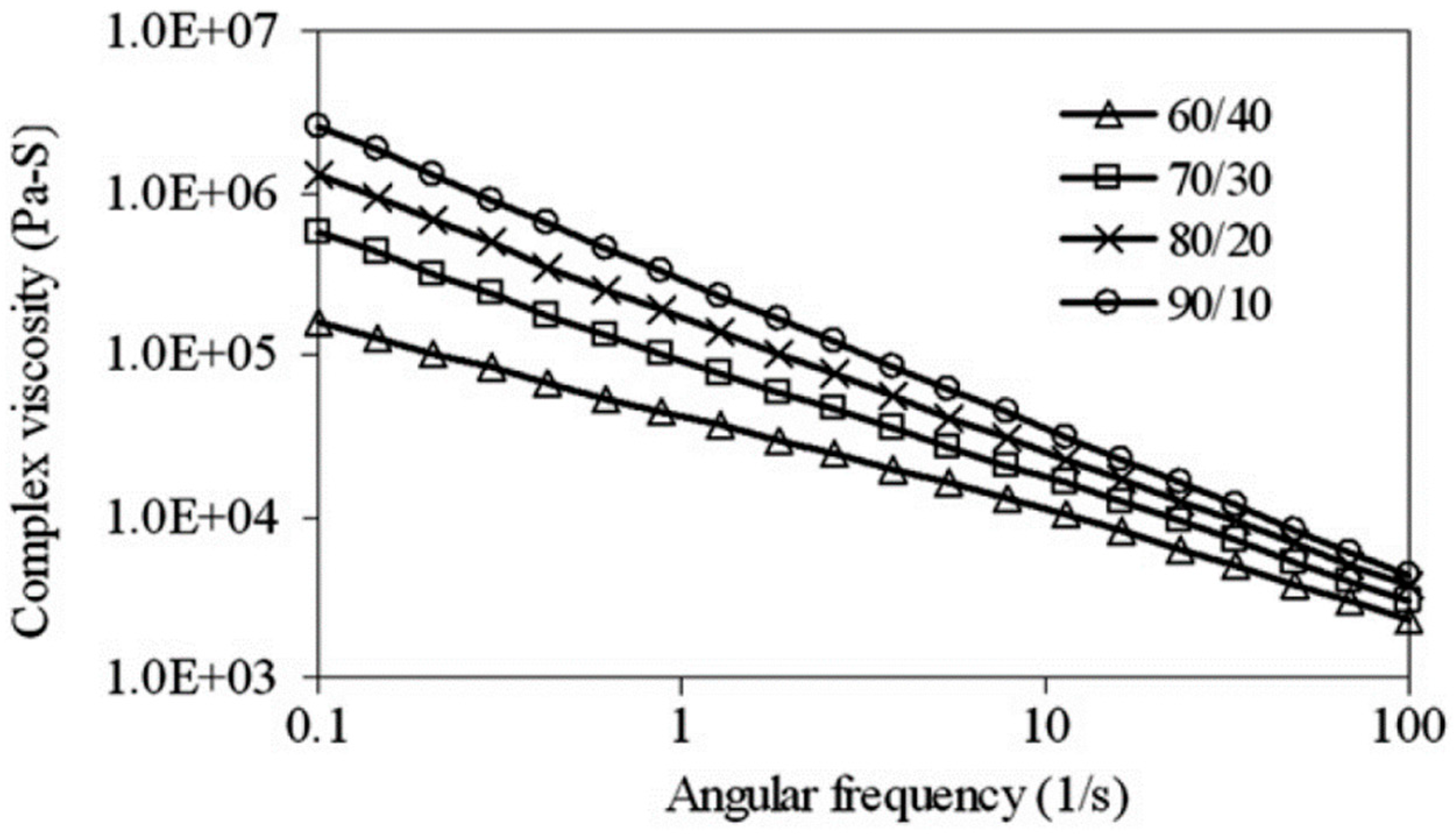

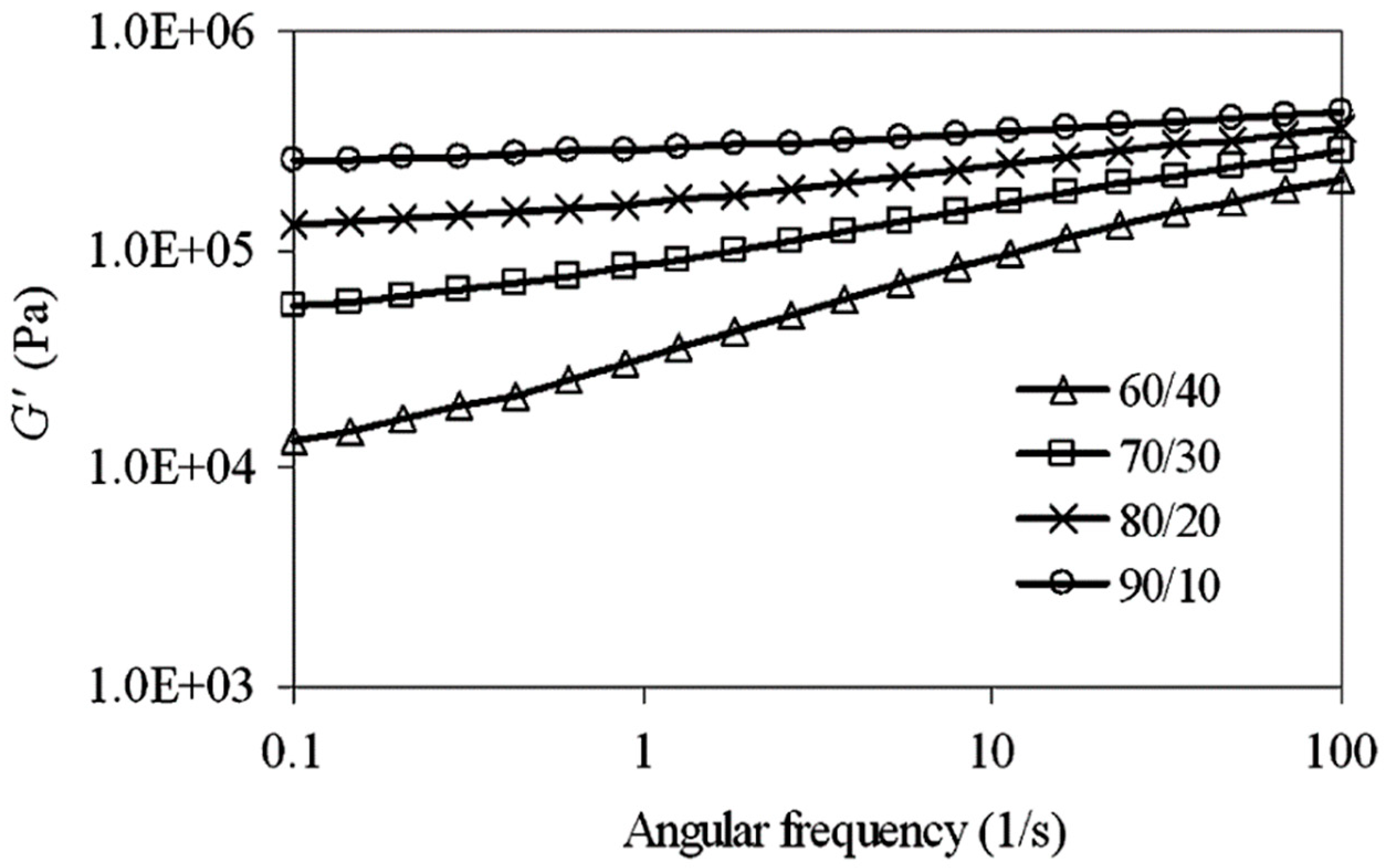

6.1. Effect of Rubber Particles’ Size and Loading

6.2. Non-Reactive Compatibilisation

6.3. Reactive Compatibilisation

6.4. Effect of NP Incorporation

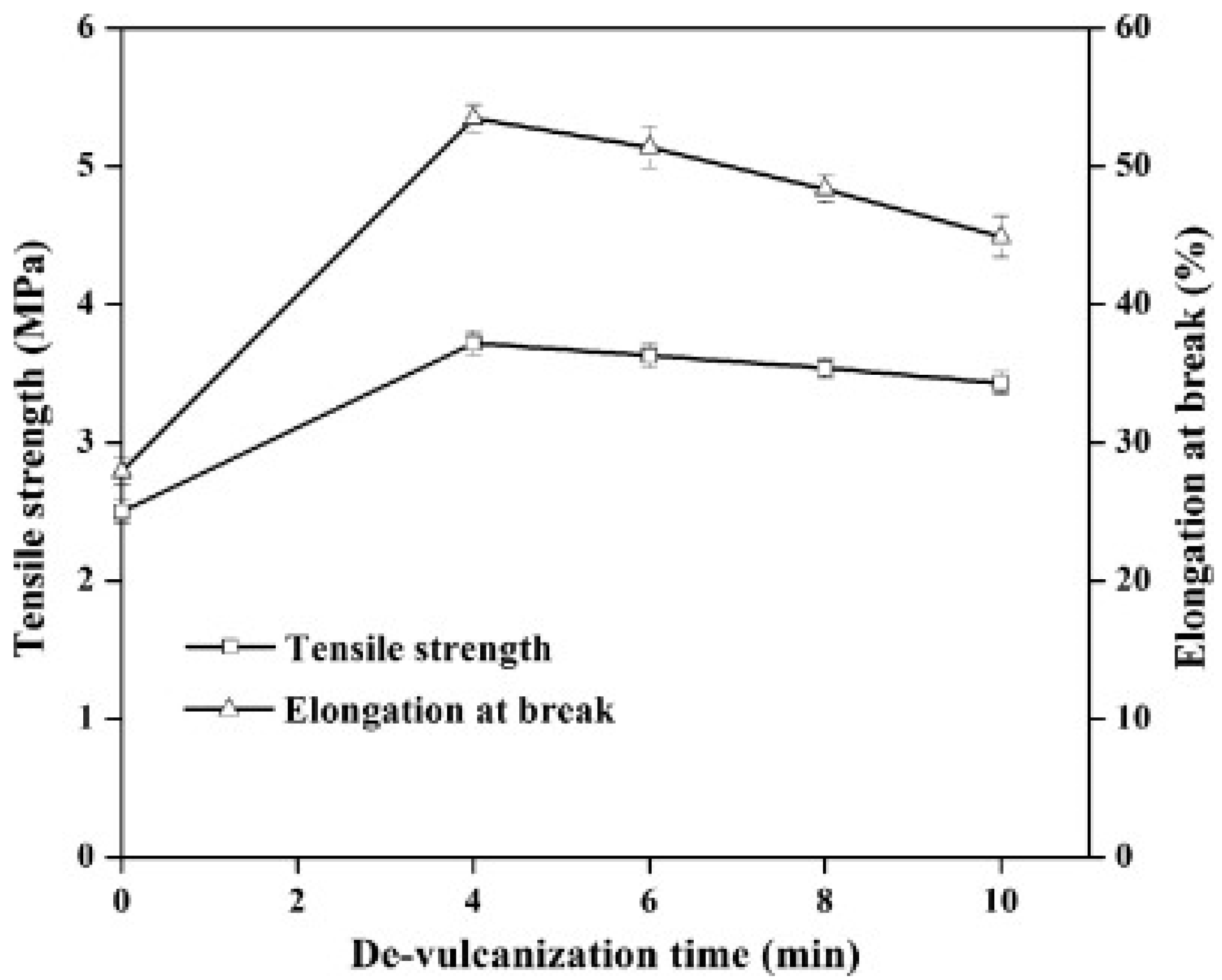

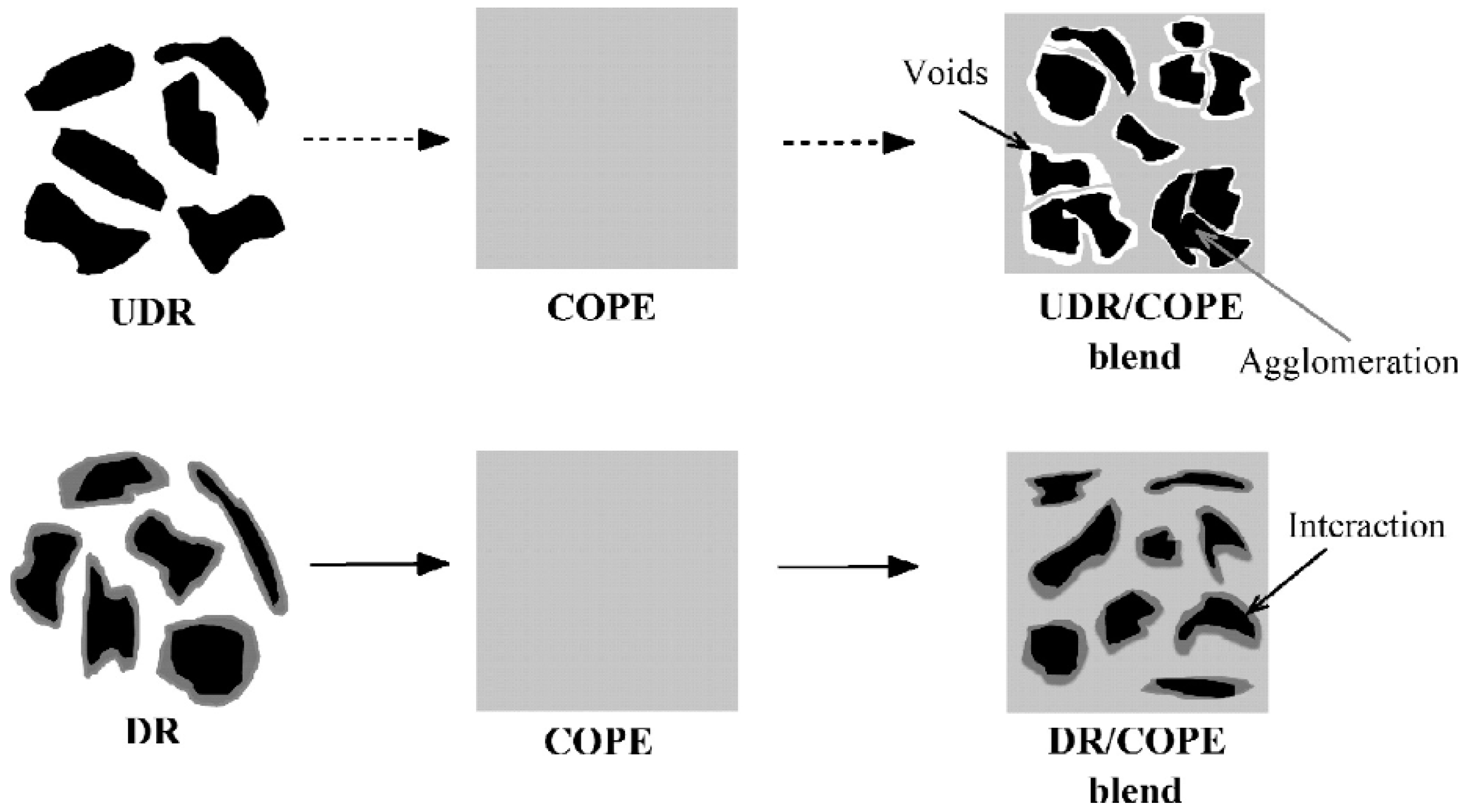

6.5. GTR Surface Modification and Devulcanisation

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ramarad, S.; Khalid, M.; Ratnam, C.; Chuah, A.L.; Rashmi, W. Waste tire rubber in polymer blends: A review on the evolution, properties and future. Prog. Mater. Sci. 2015, 72, 100–140. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Mészáros, L.; Bárány, T. Ground tyre rubber (GTR) in thermoplastics, thermosets, and rubbers. J. Mater. Sci. 2013, 48, 1–38. [Google Scholar] [CrossRef]

- Ikeda, Y.; Kato, A.; Kohjiya, S.; Nakajima, Y. Rubber Science; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Fukumori, K.; Matsushita, M.; Okamoto, H.; Sato, N.; Suzuki, Y.; Takeuchi, K. Recycling technology of tire rubber. JSAE Rev. 2002, 23, 259–264. [Google Scholar] [CrossRef]

- Nakajima, N. Science and Practice of Rubber Mixing; iSmithers Rapra Publishing: Shawbury, UK, 2000. [Google Scholar]

- Liu, Q.; Zhang, Y.; Xu, H. Properties of vulcanized rubber nanocomposites filled with nanokaolin and precipitated silica. Appl. Clay Sci. 2008, 42, 232–237. [Google Scholar] [CrossRef]

- Heinrich, G.; Vilgis, T.A. Contribution of entanglements to the mechanical properties of carbon black-filled polymer networks. Macromolecules. 1993, 26, 1109–1119. [Google Scholar] [CrossRef]

- Okada, A.; Usuki, A. The chemistry of polymer-clay hybrids. Mater. Sci. Eng. C. 1995, 3, 109–115. [Google Scholar] [CrossRef]

- Medina, N.F.; Garcia, R.; Hajirasouliha, I.; Pilakoutas, K.; Guadagnini, M.; Raffoul, S. Composites with recycled rubber aggregates: Properties and opportunities in construction. Constr. Build. Mater. 2018, 188, 884–897. [Google Scholar] [CrossRef]

- Niyogi, U.K. Introduction to Fibre Science and Rubber Technology B. In Rubber Technology; Shri Ram Institute for Industrial Research: Delhi, India, 2007. [Google Scholar]

- Mente, P.; Motaung, T.; Hlangothi, S. Natural rubber and reclaimed Rubber composites—A Systematic Review. Polym. Sci. 2016, 2, 1–19. [Google Scholar]

- Massey, L.K. The Effect of UV Light and Weather: On Plastics and Elastomers; William Andrew: Norwich, UK, 2006. [Google Scholar]

- Wypych, G. Handbook of Polymers, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Morton, M. Rubber Technology; Springer Science & Business Media: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Mitra, S.; Jørgensen, M.; Pedersen, W.B.; Almdal, K.; Banerjee, D. Structural determination of ethylene-propylene-diene rubber (EPDM) containing high degree of controlled long-chain branching. J. Appl. Polym. Sci. 2009, 113, 2962–2972. [Google Scholar] [CrossRef]

- Milani, G.; Milani, F. EPDM accelerated sulfur vulcanization: A kinetic model based on a genetic algorithm. J. Math. Chem. 2011, 49, 1357–1383. [Google Scholar] [CrossRef]

- Milani, G.; Milani, F. Simple kinetic numerical model based on rheometer data for Ethylene–Propylene–Diene Monomer accelerated sulfur crosslinking. J. Appl. Polym. Sci. 2012, 124, 311–324. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.; Ghazali, S.; Islam, M.; Jeyaratnam, N.; Yuvaraj, A. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Percec, V.; Pugh, C. Comprehensive Polymer Science and Supplements; Elsevier: Oxford, UK, 1989. [Google Scholar]

- Lievana, E.J. Recycling of Ground Tyre Rubber and Polyolefin Wastes by Producing Thermoplastic Elastomers. Ph.D. Thesis, Technical University of Kaiserslautern, Kaiserslautern, Germany, 2005. [Google Scholar]

- Fang, Y.; Zhan, M.; Wang, Y. The status of recycling of waste rubber. Mater. Des. 2001, 22, 123–128. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef]

- Amari, T.; Themelis, N.J.; Wernick, I.K. Resource recovery from used rubber tires. Resour. Policy. 1999, 25, 179–188. [Google Scholar] [CrossRef]

- Shah, J.; Jan, M.R.; Mabood, F. Catalytic conversion of waste tyres into valuable hydrocarbons. J. Polym. Environ. 2007, 15, 207–211. [Google Scholar] [CrossRef]

- Van Beukering, P.J.; Janssen, M.A. Trade and recycling of used tyres in Western and Eastern Europe. Resour. Conserv. Recycl. 2001, 33, 235–265. [Google Scholar] [CrossRef]

- İlkılıç, C.; Aydın, H. Fuel production from waste vehicle tires by catalytic pyrolysis and its application in a diesel engine. Fuel Process. Technol. 2011, 92, 1129–1135. [Google Scholar] [CrossRef]

- Adhikari, B.; De, D.; Maiti, S. Reclamation and recycling of waste rubber. Prog. Polym. Sci. 2000, 25, 909–948. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Sunthonpagasit, N.; Duffey, M.R. Scrap tires to crumb rubber: Feasibility analysis for processing facilities. Resour. Conserv. Recycl. 2004, 40, 281–299. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Zhang, Y. Morphology and mechanical properties of HDPE/SRP/elastomer composites: Effect of elastomer polarity. Polym. Test. 2004, 23, 83–90. [Google Scholar] [CrossRef]

- Kear, K.E. Developments in Thermoplastic Elastomers; iSmithers Rapra Publishing: Shawbury, UK, 2003; Volume 14. [Google Scholar]

- Holden, G. Thermoplastic Elastomers. In Applied Plastics Engineering Handbook; Kutz, M., Ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2011; pp. 77–91. [Google Scholar] [CrossRef]

- Drobny, J.G. Handbook of Thermoplastic Elastomers; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- Asaletha, R.; Kumaran, M.; Thomas, S. Thermoplastic elastomers from blends of polystyrene and natural rubber: Morphology and mechanical properties. Eur. Polym. J. 1999, 35, 253–271. [Google Scholar] [CrossRef]

- Carone Jr, E.; Kopcak, U.; Goncalves, M.; Nunes, S. In situ compatibilization of polyamide 6/natural rubber blends with maleic anhydride. Polymer 2000, 41, 5929–5935. [Google Scholar] [CrossRef]

- Ghazali, Z.; Johnson, A.; Dahlan, K. Radiation crosslinked thermoplastics natural rubber (TPNR) foams. Radiat. Phys. Chem. 1999, 55, 73–79. [Google Scholar] [CrossRef]

- Mina, M.; Ania, F.; Balta Calleja, F.; Asano, T. Microhardness studies of PMMA/natural rubber blends. J. Appl. Polym. Sci. 2004, 91, 205–210. [Google Scholar] [CrossRef]

- Nakason, C.; Nuansomsri, K.; Kaesaman, A.; Kiatkamjornwong, S. Dynamic vulcanization of natural rubber/high-density polyethylene blends: Effect of compatibilization, blend ratio and curing system. Polym. Test. 2006, 25, 782–796. [Google Scholar] [CrossRef]

- Nakason, C.; Jarnthong, M.; Kaesaman, A.; Kiatkamjornwong, S. Thermoplastic elastomers based on epoxidized natural rubber and high-density polyethylene blends: Effect of blend compatibilizers on the mechanical and morphological properties. J. Appl. Polym. Sci. 2008, 109, 2694–2702. [Google Scholar] [CrossRef]

- Grohens, Y.; Kumar, S.K.; Boudenne, A.; Weimin, Y. Recycling and Reuse of Materials and Their Products; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Pichaiyut, S.; Nakason, C.; Kaesaman, A.; Kiatkamjornwong, S. Influences of blend compatibilizers on dynamic, mechanical, and morphological properties of dynamically cured maleated natural rubber and high-density polyethylene blends. Polym. Test. 2008, 27, 566–580. [Google Scholar] [CrossRef]

- Ning, N.; Li, S.; Wu, H.; Tian, H.; Yao, P.; Guo-Hua, H.; Tian, M.; Zhang, L. Preparation, microstructure, and microstructure-properties relationship of thermoplastic vulcanizates (TPVs): A review. Prog. Polym. Sci. 2018, 79, 61–97. [Google Scholar] [CrossRef]

- Koning, C.; Van Duin, M.; Pagnoulle, C.; Jerome, R. Strategies for compatibilization of polymer blends. Prog. Polym. Sci. 1998, 23, 707–757. [Google Scholar] [CrossRef]

- Flory, P.J. Principles of Polymer Chemistry; Cornell University Press: Ithaca, NY, USA, 1953. [Google Scholar]

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stabil. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Iyer, S.; Schiraldi, D.A. Role of ionic interactions in the compatibility of polyester ionomers with poly (ethylene terephthalate) and nylon 6. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 2091–2103. [Google Scholar] [CrossRef]

- Ramezani Kakroodi, A. Production and Characterization of Thermoplastic Elastomers Based on Recycled Rubber. Ph.D. Thesis, Laval University, Quebec, QC, Canada, 2013. [Google Scholar]

- Kumar, C.R.; Fuhrmann, I.; Karger-Kocsis, J. LDPE-based thermoplastic elastomers containing ground tire rubber with and without dynamic curing. Polym. Degrad. Stabil. 2002, 76, 137–144. [Google Scholar] [CrossRef]

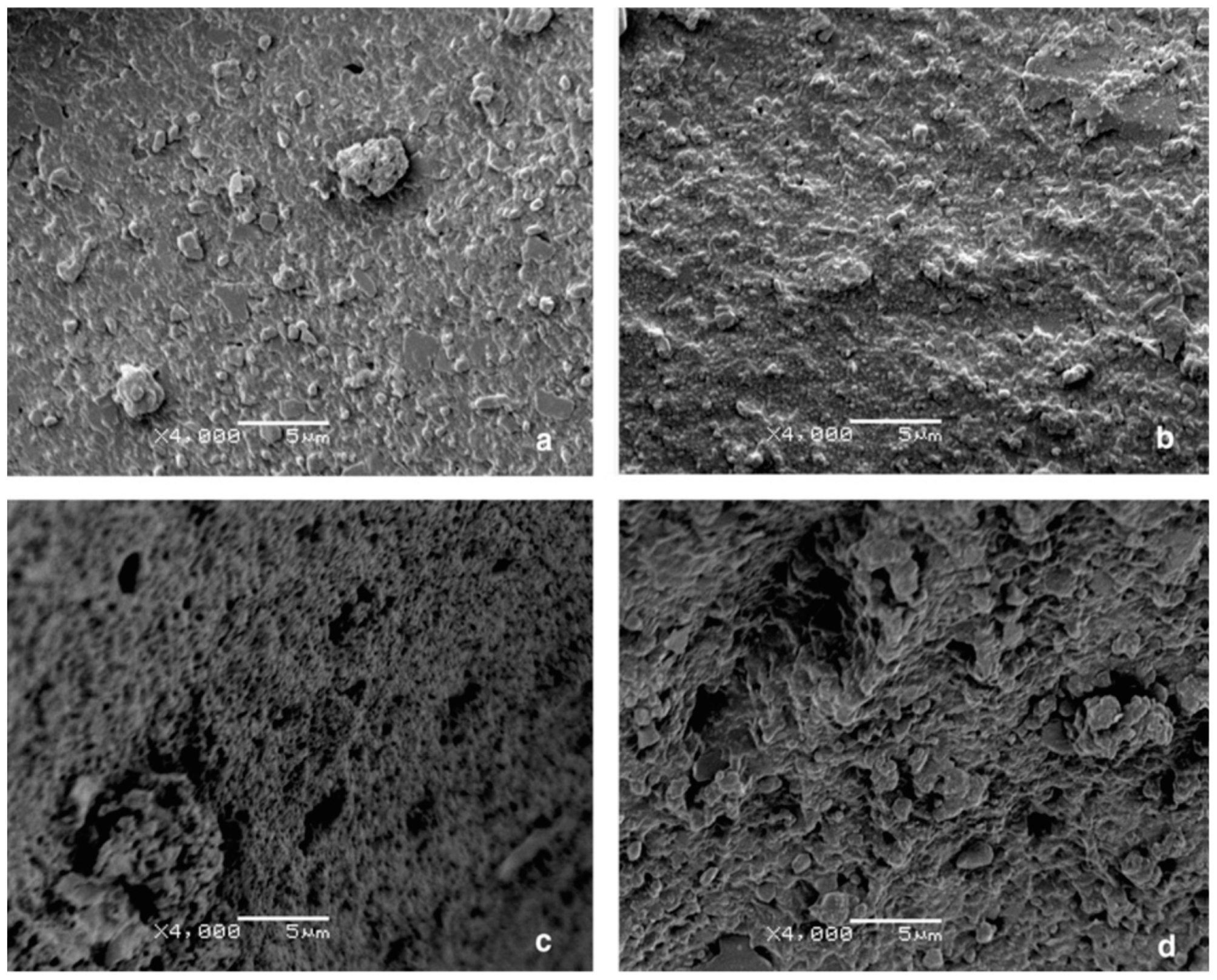

- Shanmugharaj, A.; Kim, J.K.; Ryu, S.H. UV surface modification of waste tire powder: Characterization and its influence on the properties of polypropylene/waste powder composites. Polym. Test. 2005, 24, 739–745. [Google Scholar] [CrossRef]

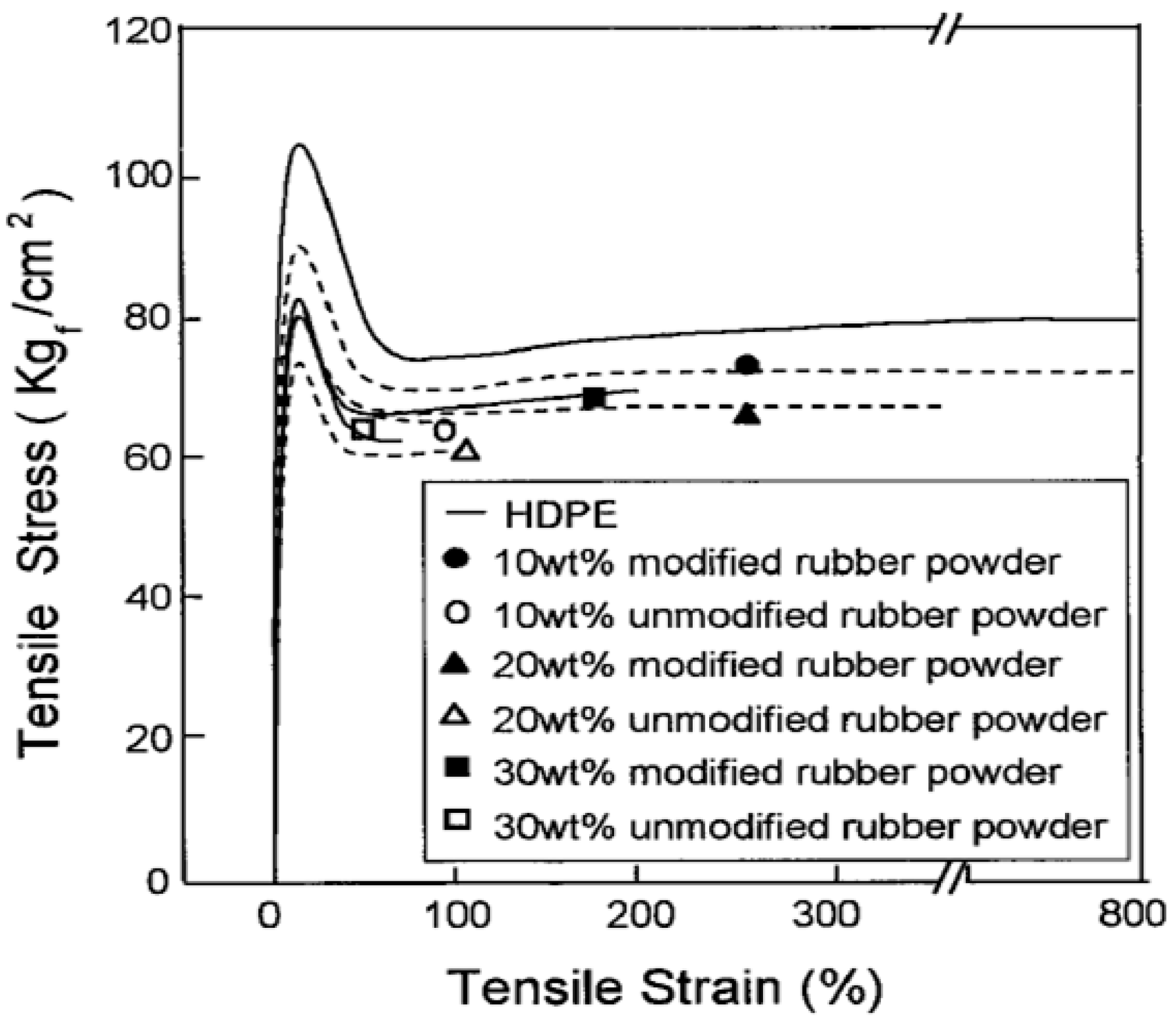

- Kim, J.; Ryu, S.; Chang, Y. Mechanical and dynamic mechanical properties of waste rubber powder/HDPE composite. J. Appl. Polym. Sci. 2000, 77, 2595–2602. [Google Scholar] [CrossRef]

- Guimarães Rocha, M.C.; Leyva, M.E.; Gomes de Oliveira, M. Thermoplastic elastomers blends based on linear low density polyethylene, ethylene-1-octene copolymers and ground rubber tire. Polímeros 2014, 24, 23–29. [Google Scholar]

- Magioli, M.; Sirqueira, A.S.; Soares, B.G. The effect of dynamic vulcanization on the mechanical, dynamic mechanical and fatigue properties of TPV based on polypropylene and ground tire rubber. Polym. Test. 2010, 29, 840–848. [Google Scholar] [CrossRef]

- Canavate, J.; Carrillo, F.; Casas, P.; Colom, X.; Sunol, J. The use of waxes and wetting additives to improve compatibility between hdpe and ground tyre rubber. J. Compos. Mater. 2010, 44, 1233–1245. [Google Scholar] [CrossRef]

- He, M.; Li, Y.; Qiao, B.; Ma, X.; Song, J.; Wang, M. Effect of dicumyl peroxide and phenolic resin as a mixed curing system on the mechanical properties and morphology of TPVs based on HDPE/ground tire rubber. Polym. Compos. 2015, 36, 1907–1916. [Google Scholar] [CrossRef]

- Fazli, A.; Moosaei, R.; Sharif, M.; Ashtiani, S.J. Developments of graphene-based polymer composites processing based on novel methods for innovative applications in newborn technologies. Indian J. Sci. Technol. 2015, 8, 38–44. [Google Scholar] [CrossRef]

- Peigney, A.; Laurent, C.; Flahaut, E.; Bacsa, R.; Rousset, A. Specific surface area of carbon nanotubes and bundles of carbon nanotubes. Carbon 2001, 39, 507–514. [Google Scholar] [CrossRef]

- Yu, Q. Application of nanomaterials in alkali-activated materials. In Nanotechnology in Eco-Efficient Construction; Elsevier: Amsterdam, The Netherlands, 2019; pp. 97–121. [Google Scholar]

- Taguet, A.; Cassagnau, P.; Lopez-Cuesta, J.-M. Structuration, selective dispersion and compatibilizing effect of (nano) fillers in polymer blends. Prog. Polym. Sci. 2014, 39, 1526–1563. [Google Scholar] [CrossRef]

- de Luna, M.S.; Filippone, G. Effects of nanoparticles on the morphology of immiscible polymer blends–challenges and opportunities. Eur. Polym. J. 2016, 79, 198–218. [Google Scholar] [CrossRef]

- Amani, M.; Sharif, M.; Kashkooli, A.; Rahnama, N.; Fazli, A. Effect of mixing conditions on the selective localization of graphite oxide and the properties of polyethylene/high-impact polystyrene/graphite oxide nanocomposite blends. RSC Adv. 2015, 5, 77723–77733. [Google Scholar] [CrossRef]

- Bai, L.; Sharma, R.; Cheng, X.; Macosko, C.W. Kinetic control of graphene localization in co-continuous polymer blends via melt compounding. Langmuir 2017, 34, 1073–1083. [Google Scholar] [CrossRef] [PubMed]

- Favis, B.D.; Chalifoux, J.-P. The effect of viscosity ratio on the morphology of polypropylene/polycarbonate blends during processing. Polym. Eng. Sci. 1987, 27, 1591–1600. [Google Scholar] [CrossRef]

- Favis, B.D. Polymer alloys and blends: Recent advances. Can. J. Chem. Eng. 1991, 69, 619–625. [Google Scholar] [CrossRef]

- Li, L.; Miesch, C.; Sudeep, P.; Balazs, A.C.; Emrick, T.; Russell, T.P.; Hayward, R.C. Kinetically trapped co-continuous polymer morphologies through intraphase gelation of nanoparticles. Nano Lett. 2011, 11, 1997–2003. [Google Scholar] [CrossRef]

- Huang, S.; Bai, L.; Trifkovic, M.; Cheng, X.; Macosko, C.W. Controlling the morphology of immiscible cocontinuous polymer blends via silica nanoparticles jammed at the interface. Macromolecules 2016, 49, 3911–3918. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

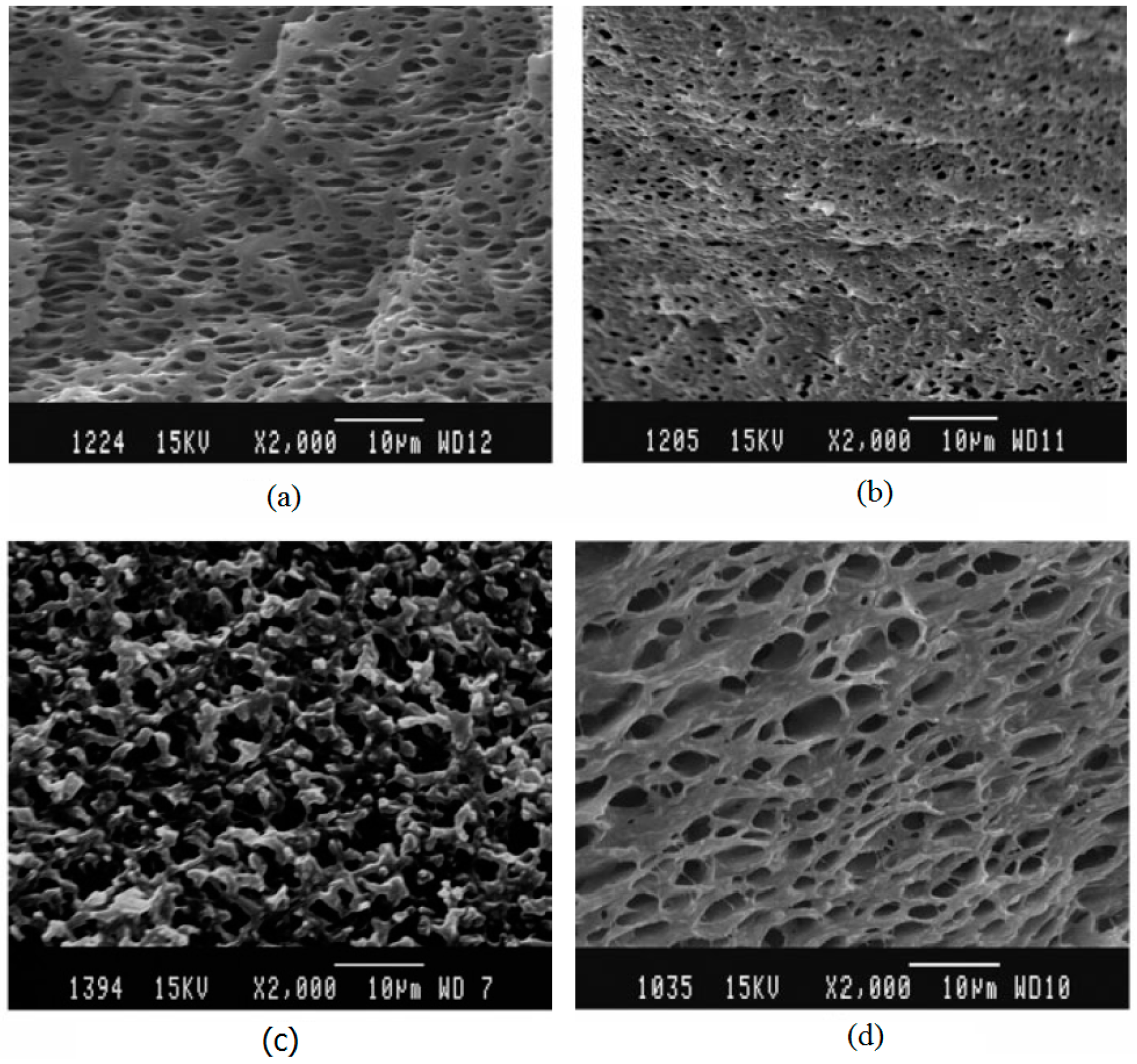

- Sonnier, R.; Leroy, E.; Clerc, L.; Bergeret, A.; Lopez-Cuesta, J. Polyethylene/ground tyre rubber blends: Influence of particle morphology and oxidation on mechanical properties. Polym. Test. 2007, 26, 274–281. [Google Scholar] [CrossRef]

- Yehia, A.; Mull, M.; Ismail, M.; Hefny, Y.; Abdel-Bary, E. Effect of chemically modified waste rubber powder as a filler in natural rubber vulcanizates. J. Applied Polym. Sci. 2004, 93, 30–36. [Google Scholar] [CrossRef]

- Colom, X.; Cañavate, J.; Carrillo, F.; Velasco, J.; Pages, P.; Mujal, R.; Nogues, F. Structural and mechanical studies on modified reused tyres composites. Eur. Polym. J. 2006, 42, 2369–2378. [Google Scholar] [CrossRef]

- Sonnier, R.; Leroy, E.; Clerc, L.; Bergeret, A.; Lopez-Cuesta, J.-M.; Bretelle, A.-S.; Ienny, P. Compatibilizing thermoplastic/ground tyre rubber powder blends: Efficiency and limits. Polym. Test. 2008, 27, 901–907. [Google Scholar] [CrossRef]

- Diao, B.; Isayev, A.; Levin, V.Y. Basic study of continuous ultrasonic devulcanization of unfilled silicone rubber. Rubber Chem. Technol. 1999, 72, 152–164. [Google Scholar] [CrossRef]

- Lievana, E.; Karger-Kocsis, J. Use of ground tyre rubber (GTR) in thermoplastic polyolefin elastomer compositions. Prog. Rubber Plast. Recycl. Technol. 2004, 20, 1–10. [Google Scholar] [CrossRef]

- Ismail, H.; Awang, M.; Hazizan, M. Effect of waste tire dust (WTD) size on the mechanical and morphological properties of polypropylene/waste tire dust (PP/WTD) blends. Polym. Plast. Technol. Eng. 2006, 45, 463–468. [Google Scholar] [CrossRef]

- Mujal-Rosas, R.; Orrit-Prat, J.; Ramis-Juan, X.; Marin-Genesca, M.; Rahhali, A. Study on dielectric, thermal, and mechanical properties of the ethylene vinyl acetate reinforced with ground tire rubber. J. Reinf. Plast. Compos. 2011, 30, 581–592. [Google Scholar] [CrossRef]

- Oliphant, K.; Baker, W.E. The use of cryogenically ground rubber tires as a filler in polyolefin blends. Polym. Eng. Sci. 1993, 33, 166–174. [Google Scholar] [CrossRef]

- Choudhury, N.R.; Bhowmick, A.K. Adhesion between individual components and mechanical properties of natural rubber-polypropylene thermoplastic elastomeric blends. J. Adhes. Sci. Technol. 1988, 2, 167–177. [Google Scholar] [CrossRef]

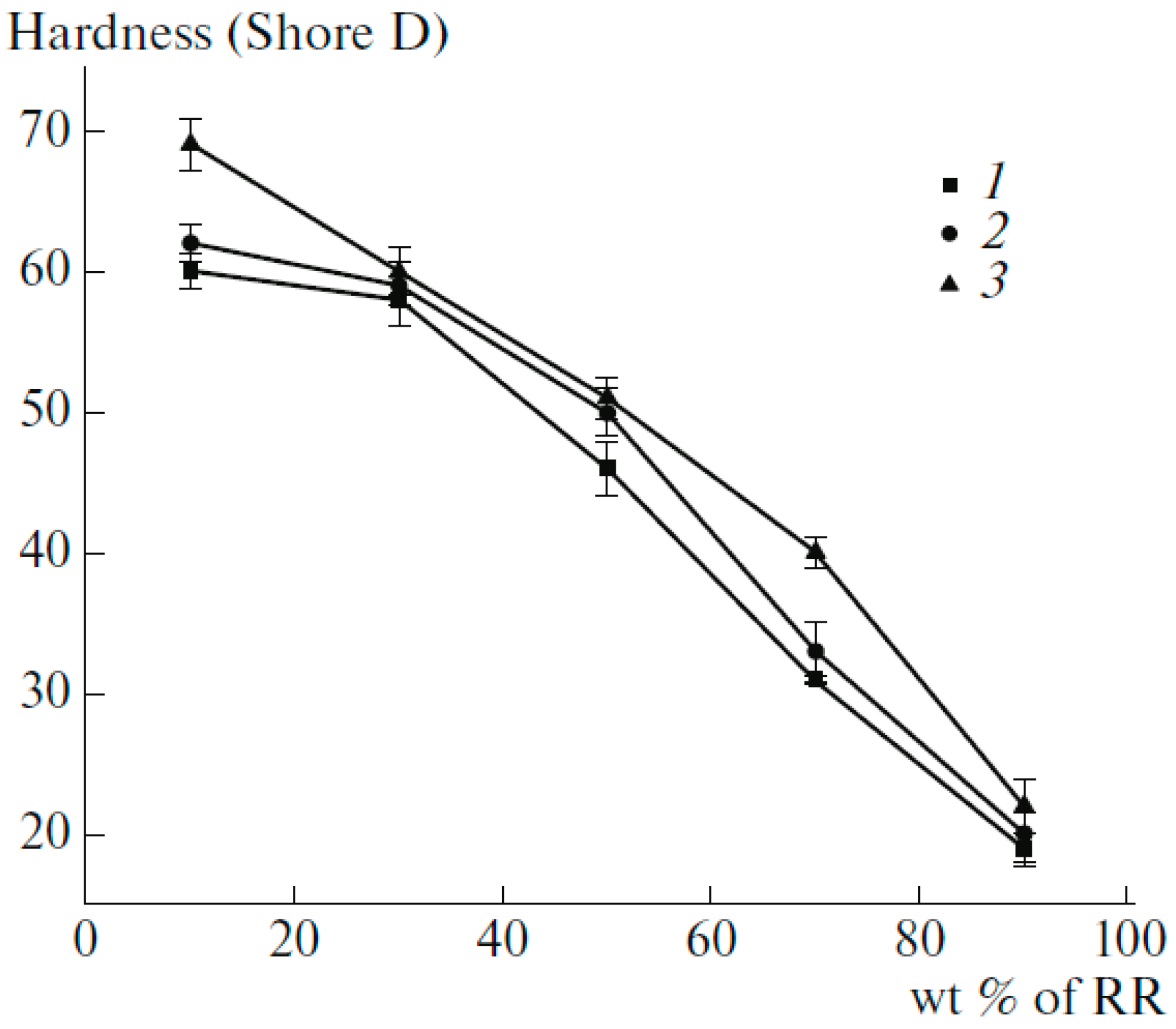

- Esmizadeh, E.; Naderi, G.; Bakhshandeh, G.R.; Fasaie, M.R.; Ahmadi, S. Reactively compatibilized and dynamically vulcanized thermoplastic elastomers based on high-density polyethylene and reclaimed rubber. Polym. Sci. Ser. B 2017, 59, 362–371. [Google Scholar] [CrossRef]

- Rajalingam, P.; Sharpe, J.; Baker, W.E. Ground rubber tire/thermoplastic composites: Effect of different ground rubber tires. Rubber Chem. Technol. 1993, 66, 664–677. [Google Scholar] [CrossRef]

- Noriman, N.; Ismail, H.; Rashid, A.A. Characterization of styrene butadiene rubber/recycled acrylonitrile-butadiene rubber (SBR/NBRr) blends: The effects of epoxidized natural rubber (ENR-50) as a compatibilizer. Polym. Test. 2010, 29, 200–208. [Google Scholar] [CrossRef]

- Formela, K.; Korol, J.; Saeb, M.R. Interfacially modified LDPE/GTR composites with non-polar elastomers: From microstructure to macro-behavior. Polym. Test. 2015, 42, 89–98. [Google Scholar] [CrossRef]

- Song, P.; Li, S.; Wang, S. Interfacial interaction between degraded ground tire rubber and polyethylene. Polym. Degrad. Stabil. 2017, 143, 85–94. [Google Scholar] [CrossRef]

- Sae-Oui, P.; Sirisinha, C.; Sa-nguanthammarong, P.; Thaptong, P. Properties and recyclability of thermoplastic elastomer prepared from natural rubber powder (NRP) and high density polyethylene (HDPE). Polym. Test. 2010, 29, 346–351. [Google Scholar] [CrossRef]

- Kakroodi, A.R.; Rodrigue, D. Highly filled thermoplastic elastomers from ground tire rubber, maleated polyethylene and high density polyethylene. Plast. Rubber Compos. 2013, 42, 115–122. [Google Scholar] [CrossRef]

- Wang, Y.-H.; Chen, Y.-K.; Rodrigue, D. Production of Thermoplastic Elastomers Based on Recycled PE and Ground Tire Rubber: Morphology, Mechanical Properties and Effect of Compatibilizer Addition. Int. Polym. Process. 2018, 33, 525–534. [Google Scholar] [CrossRef]

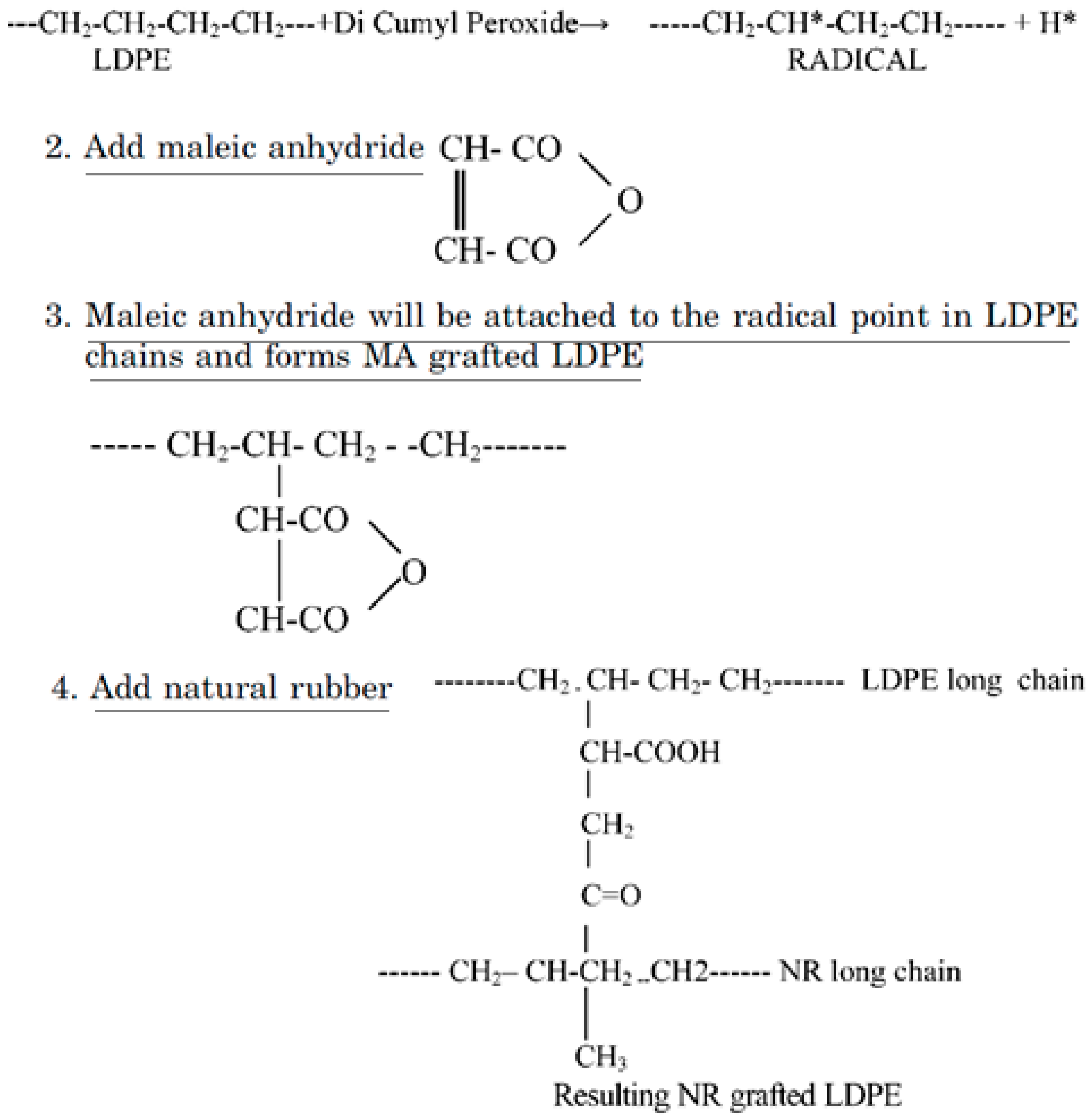

- Patel, G.; Patel, H.; Sharma, P.; Patel, H.; John, N. A study on grafting of natural rubber and nitrile rubber on thermoplastic low density polyethylene using maleic anhydride and acrylic acid. Int. J. Polym. Mater. 2006, 55, 413–424. [Google Scholar] [CrossRef]

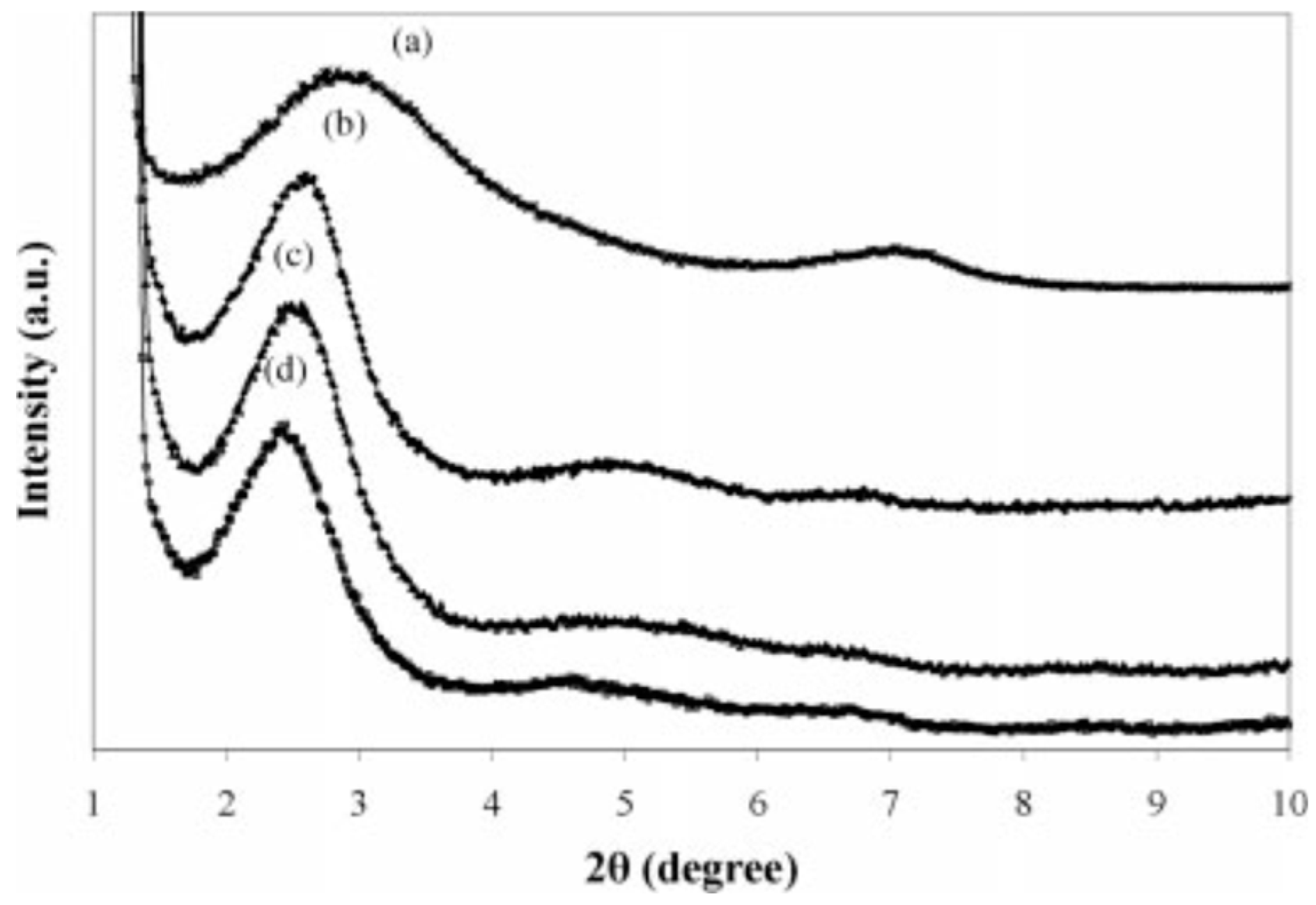

- Mehta, S.; Mirabella, F.M.; Rufener, K.; Bafna, A. Thermoplastic olefin/clay nanocomposites: Morphology and mechanical properties. J. Appl. Polym. Sci. 2004, 92, 928–936. [Google Scholar] [CrossRef]

- Naderi, G.; Lafleur, P.G.; Dubois, C. The influence of matrix viscosity and composition on the morphology, rheology, and mechanical properties of thermoplastic elastomer nanocomposites based on EPDM/PP. Polym. Compos. 2008, 29, 1301–1309. [Google Scholar] [CrossRef]

- Lopattananon, N.; Tanglakwaraskul, S.; Kaesaman, A.; Seadan, M.; Sakai, T. Effect of nanoclay addition on morphology and elastomeric properties of dynamically vulcanized natural rubber/polypropylene nanocomposites. Int. Polym. Process. 2014, 29, 332–341. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo, F.; Canavate, J. Composites reinforced with reused tyres: Surface oxidant treatment to improve the interfacial compatibility. Compos. Part A Appl. Sci. Manuf. 2007, 38, 44–50. [Google Scholar] [CrossRef]

- Liu, H.; Mead, J.; Stacer, R. Process Development of Scrap Rubber/Thermoplastic Blends; Chelsea Center for Recycling and Economic Development: Chelsea, MA, USA, 2001. [Google Scholar]

- Sripornsawat, B.; Saiwari, S.; Pichaiyut, S.; Nakason, C. Influence of ground tire rubber devulcanization conditions on properties of its thermoplastic vulcanizate blends with copolyester. Eur. Polym. J. 2016, 85, 279–297. [Google Scholar] [CrossRef]

- Macsiniuc, A.; Rochette, A.; Brisson, J.; Rodrigue, D. Polystyrene/recycled SBR powder compounds produced in an internal batch mixer. Prog. Rubber Plast. Recycl. Technol. 2014, 30, 185–210. [Google Scholar] [CrossRef]

- Veilleux, J.; Rodrigue, D. Properties of recycled PS/SBR blends: Effect of SBR pretreatment. Prog. Rubber Plast. Recycl. Technol. 2016, 32, 111–128. [Google Scholar] [CrossRef]

- Veilleux, J.; Rodrigue, D. Processing optimization of a polymer blend based on recycled polystyrene and styrene-butadiene rubber. In Proceedings of the Third US-Mexico Meeting “Advances in Polymer Science” and XXVII SPM National Congress, Nueva Vallarta, Mexico, 3–6 December 2014. [Google Scholar]

| Material | Cars/Passenger (wt.%) | Trucks (wt.%) |

|---|---|---|

| Rubber | 41–48 | 41–45 |

| Carbon Black | 22–28 | 20–28 |

| Metal | 13–16 | 20–27 |

| Textile | 4–6 | 0–10 |

| Additives | 10–12 | 7–10 |

| Methods | Description | Advantages | Disadvantages |

|---|---|---|---|

| Ambient (0.3 mm rough, irregular) | Repeated grinding following shredder, mills, knife, granulators, and rolling mills | High surface area and volume ratio | Temperature could rise up to 130 °C |

| Oxidation on the surface of granulates | |||

| Cooling needed to prevent combustion | |||

| Wet ambient (100 μm rough, irregular) | Grinding suspension of shredded rubber using grindstone | Lower level of degradation on granulates | Requires drying step and shredding of tires before grinding |

| Water cools granulates and grindstone | High surface area and volume | ||

| Water jet (rough, irregular) | Used for large sized tires (trucks and tractors) | Environmentally safe, energy saving, low level of noise, and no pollutants | Requires high pressure and trained personnel |

| Water jet of >2000 bar pressure and high velocity used to strip rubber | |||

| Berstoff’s method (rough, irregular) | Combines a rolling mill with a specially designed twin screw extruder in a line. | Small grain size, large specific area, and low humidity | Not disclosed |

| Cryogenic (75 μm sharp edge flat/smooth) | Rubber cooled in liquid nitrogen and shattered using impact type mill | No surface oxidation of granulates and cleaner granulates | High cost of liquid nitrogen |

| High humidity of granulates |

| Type of Bond | Energy Required for Cleavage (kJ/mol) |

|---|---|

| C–C | 348 |

| C–S–C | 285 |

| C–S–S–C | 268 |

| C–Sx–C | 251 |

| Sample Code | Tensile Strength (MPa) | Tensile Modulus (MPa) | Elongation at Break (%) |

|---|---|---|---|

| H-R30 | 11.0 ± 0.1 | 166.7 ± 7.3 | 31.5 ± 2.7 |

| H-R50 | 6.0 ± 0.6 | 101.4 ± 2.8 | 61.3 ± 5.5 |

| H-R70 | 2.3 ± 0.1 | 26.3 ± 5.8 | 125 ± 6.2 |

| H-R90 | 0.6 ± 0.2 | 1.6 ± 0.7 | 149 ± 4.3 |

| H-R30-C | 12.2 ± 4.1 | 218.4 ± 6.1 | 45.1 ± 5.7 |

| H-R50-C | 7.3 ± 3.2 | 122.4 ± 3.8 | 78.9 ± 7.1 |

| H-R70-C | 3.0 ± 0.7 | 29.8 ± 1.8 | 138.6 ± 2.4 |

| H-R90-C | 0.9 ± 0.2 | 2.1 ± 0.9 | 183 ± 4.9 |

| H-R30-P | 13.5 ± 5.1 | 346.6 ± 7.4 | 58 ± 8.2 |

| H-R50-P | 9.4 ± 2.6 | 184.9 ± 5.8 | 94.1 ± 3.4 |

| H-R70-P | 6.0 ± 1.7 | 36.5 ± 2.7 | 152.2 ± 1.5 |

| H-R90-P | 2.7 ± 0.8 | 2.8 ± 1.5 | 213.5 ± 6.1 |

| LDPE/NBR | LDPE/NR | Ungrafted | Acrylic Acid (AA) Grafted | Maleic Anhydride (MA) Grafted |

|---|---|---|---|---|

| - | 80/20 | 90 | 97 | 95 |

| - | 60/40 | 82 | 90 | 85 |

| - | 40/60 | 65 | 70 | 69 |

| - | 20/80 | 55 | 57 | 58 |

| 80/20 | - | 95 | 97 | 98 |

| 60/40 | - | 85 | 86 | 87 |

| 40/60 | - | 65 | 70 | 72 |

| 20/80 | - | 55 | 58 | 56 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fazli, A.; Rodrigue, D. Waste Rubber Recycling: A Review on the Evolution and Properties of Thermoplastic Elastomers. Materials 2020, 13, 782. https://doi.org/10.3390/ma13030782

Fazli A, Rodrigue D. Waste Rubber Recycling: A Review on the Evolution and Properties of Thermoplastic Elastomers. Materials. 2020; 13(3):782. https://doi.org/10.3390/ma13030782

Chicago/Turabian StyleFazli, Ali, and Denis Rodrigue. 2020. "Waste Rubber Recycling: A Review on the Evolution and Properties of Thermoplastic Elastomers" Materials 13, no. 3: 782. https://doi.org/10.3390/ma13030782

APA StyleFazli, A., & Rodrigue, D. (2020). Waste Rubber Recycling: A Review on the Evolution and Properties of Thermoplastic Elastomers. Materials, 13(3), 782. https://doi.org/10.3390/ma13030782