Aerosol Jet Printing of Silver Lines with A High Aspect Ratio on A Heated Silicon Substrate

Abstract

1. Introduction

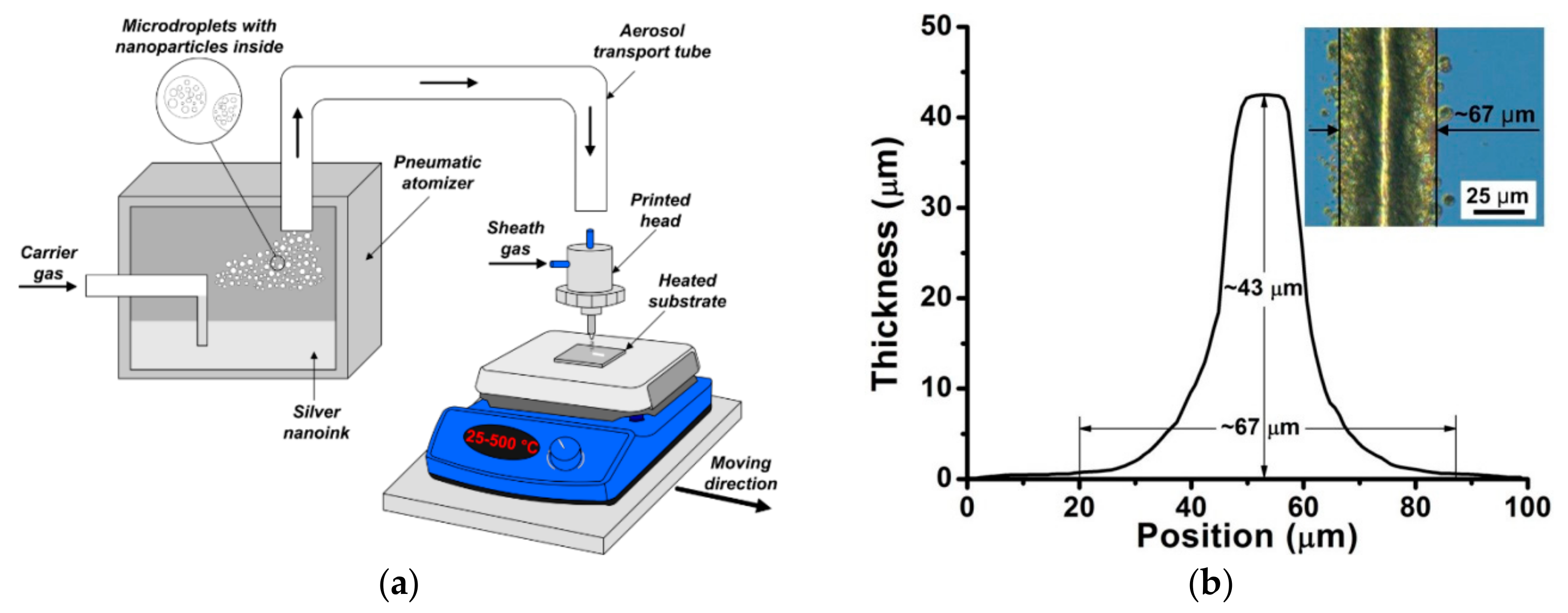

2. Experimental

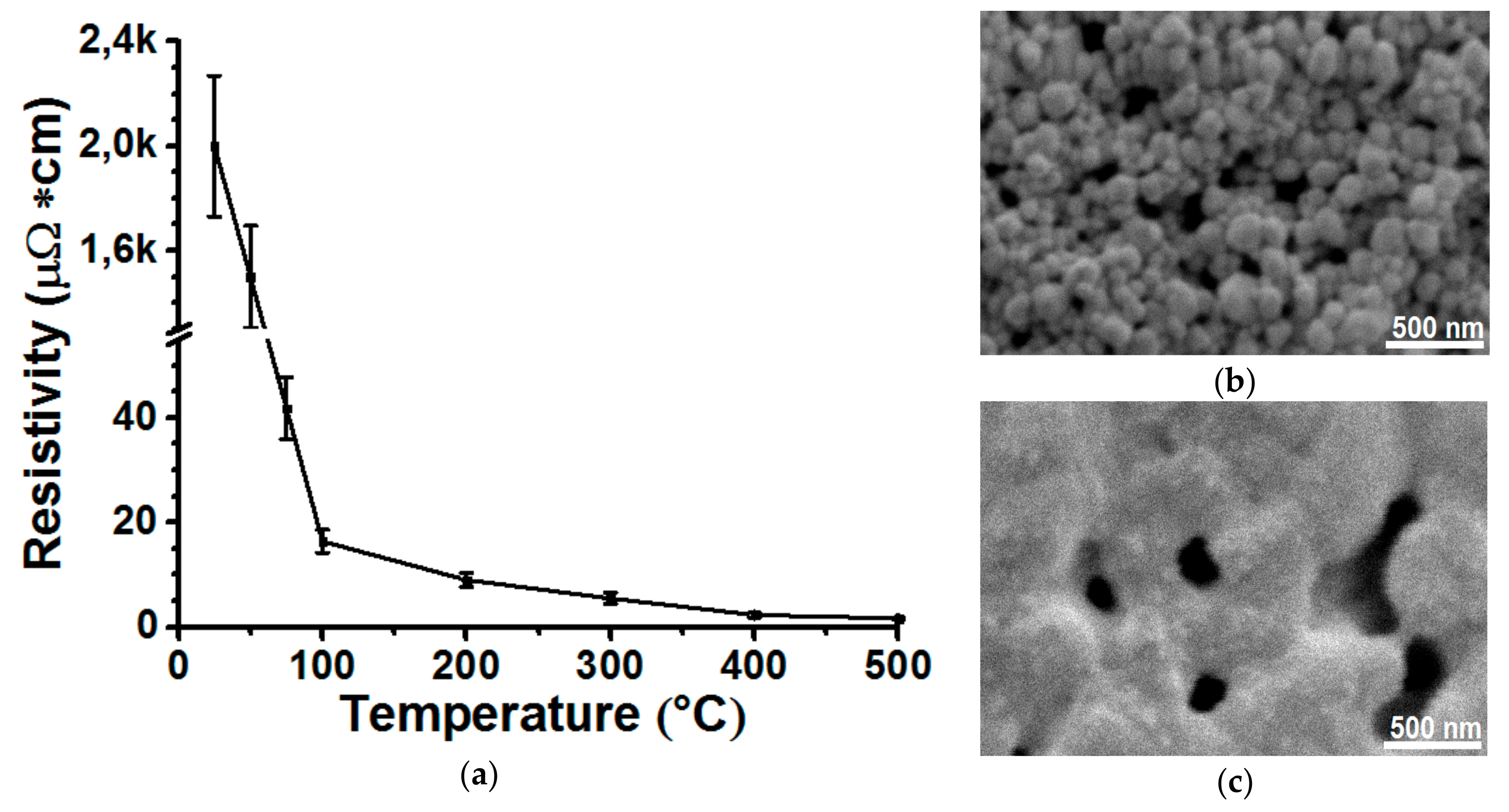

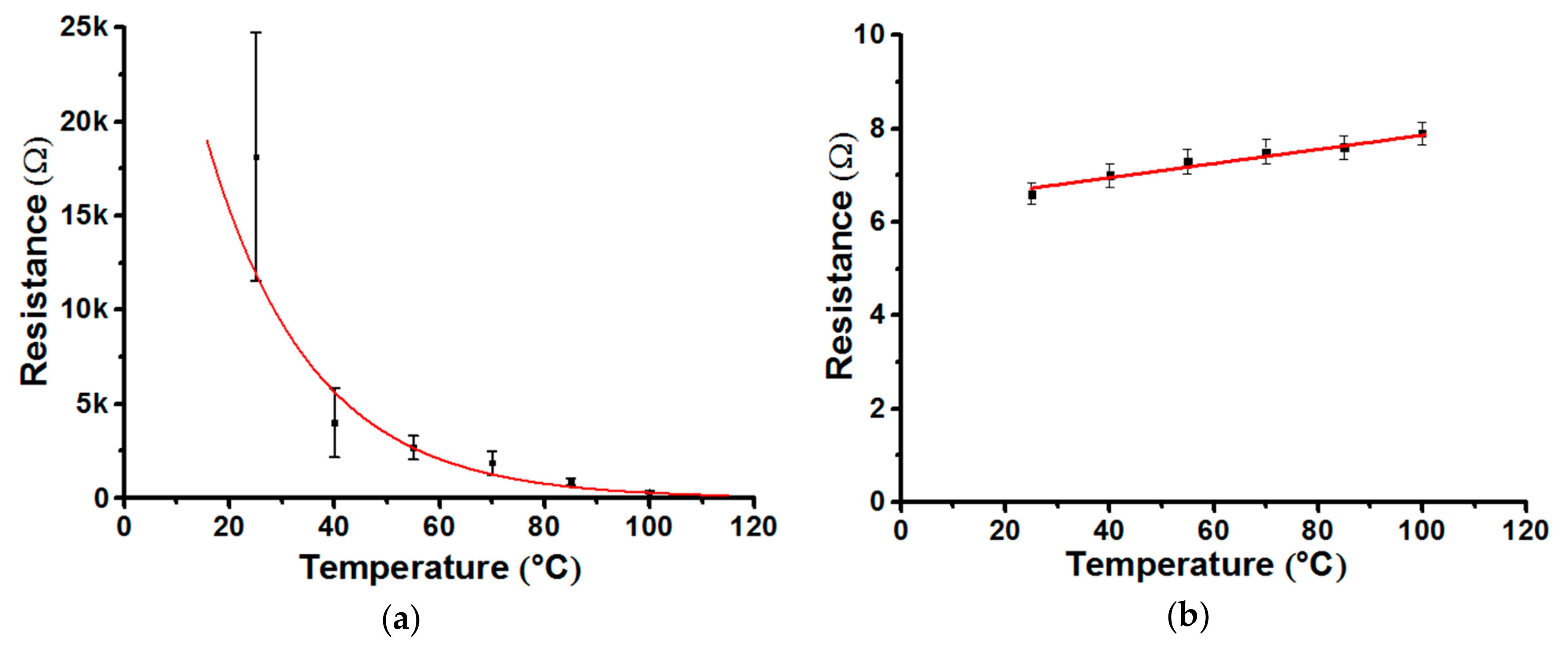

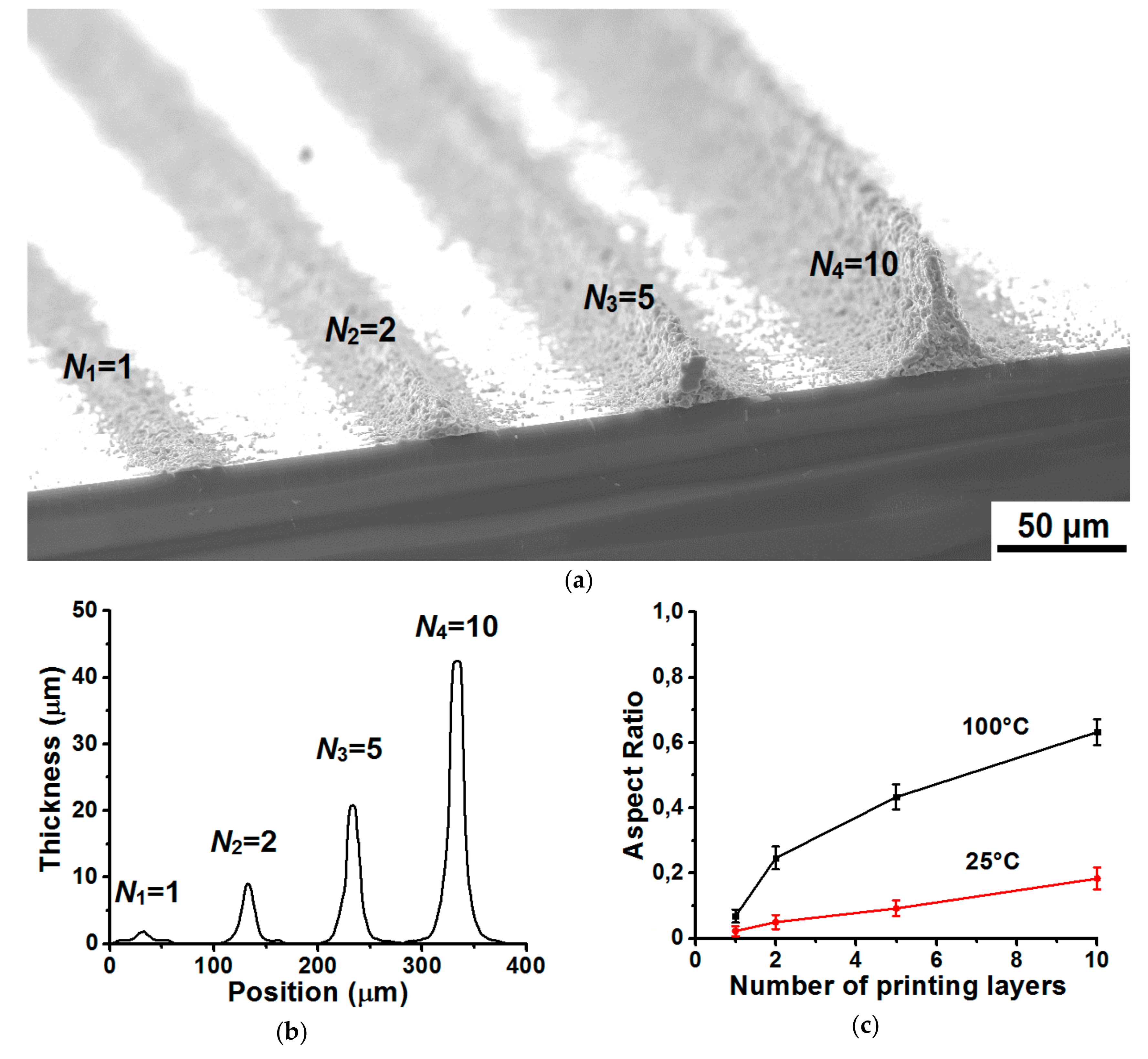

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Garlapati, S.K.; Divya, M.; Breitung, B.; Kruk, R.; Hahn, H.; Dasgupta, S. Printed Electronics Based on Inorganic Semiconductors: From Processes and Materials to Devices. Adv. Mater. 2018, 30, 1707600. [Google Scholar] [CrossRef] [PubMed]

- Subramanian, V.; Chang, J.B.; de la Fuente Vornbrock, A.; Huang, D.C.; Jagannathan, L.; Liao, F.; Mattis, B.; Molesa, S.; Redinger, D.R.; Soltman, D.; et al. Printed electronics for low-cost electronic systems: Technology status and application development. In Proceedings of the ESSCIRC 2008 - 34th European Solid-State Circuits Conference; 2008; pp. 17–24. [Google Scholar] [CrossRef]

- Maeng, S.-Y.; Lee, D.-K.; Choi, J.-W.; Kim, H.-J.; Kang, C.-Y.; Nahm, S.; Yoon, S.-J. Design and fabrication of multilayer actuator using floating electrode. Mater. Chem. Phys. 2005, 90, 405–410. [Google Scholar] [CrossRef]

- Rivadeneyra, A.; Loghin, F.C.; Falco, A. Technological Integration in Printed Electronics. Flex. Electron. 2018. [Google Scholar] [CrossRef]

- Efimov, A.A.; Arsenov, P.V.; Volkov, I.A.; Urazov, M.N.; Ivanov, V.V. Study of aerosol jet printing with dry nanoparticles synthesized by spark discharge. J. Phys. Conf. Ser. 2017, 917, 092020. [Google Scholar] [CrossRef]

- Kumar, L.; Islam, T.; Mukhopadhyay, S.C. Sensitivity Enhancement of a PPM Level Capacitive Moisture Sensor. Electronics 2017, 6, 41. [Google Scholar] [CrossRef]

- Seifert, T.; Sowade, E.; Roscher, F.; Wiemer, M.; Gessner, T.; Baumann, R.R. Additive Manufacturing Technologies Compared: Morphology of Deposits of Silver Ink Using Inkjet and Aerosol Jet Printing. Ind. Eng. Chem. Res. 2015, 54, 769–779. [Google Scholar] [CrossRef]

- Arsenov, P.V.; Efimov, A.A.; Ivanov, V.V. Effect of Methods of Changing in Focusing Ratio on Line Geometry in Aerosol Jet Printing. Key Eng. Mater. 2018, 779, 159–164. [Google Scholar] [CrossRef]

- Protas, N.V.; Efimov, A.A.; Zemlyanoy, V.K.; Ivanov, V.V. Computer simulation of aerosol nanoparticles focusing and deposition process for functional microstructure fabrication. J. Phys. Conf. Ser. 2018, 1124, 081033. [Google Scholar] [CrossRef]

- Borghetti, M.; Serpelloni, M.; Sardini, E. Printed Strain Gauge on 3D and Low-Melting Point Plastic Surface by Aerosol Jet Printing and Photonic Curing. Sens. 2019, 19, 4220. [Google Scholar] [CrossRef]

- Jabari, E.; Toyserkani, E. Aerosol-Jet printing of highly flexible and conductive graphene/silver patterns. Mater. Lett. 2016, 174, 40–43. [Google Scholar] [CrossRef]

- Hong, K.; Kim, S.H.; Mahajan, A.; Frisbie, C.D. Aerosol Jet Printed p- and n-type Electrolyte-Gated Transistors with a Variety of Electrode Materials: Exploring Practical Routes to Printed Electronics. ACS Appl. Mater. Interfaces. 2014, 6, 18704–18711. [Google Scholar] [CrossRef] [PubMed]

- Vasiliev, A.A.; Varfolomeev, A.E.; Volkov, I.A.; Simonenko, N.P.; Arsenov, P.V.; Vlasov, I.S.; Ivanov, V.V.; Pislyakov, A.V.; Lagutin, A.S.; Jahatspanian, I.E.; et al. Reducing Humidity Response of Gas Sensors for Medical Applications: Use of Spark Discharge Synthesis of Metal Oxide Nanoparticles. Sensors 2018, 18. [Google Scholar] [CrossRef] [PubMed]

- Vasiliev, A.; Varfolomeev, A.; Volkov, I.; Arsenov, P.; Efimov, A.; Ivanov, V. Gas Sensor with Reduced Humidity Response Based on Metal Oxide Nanoparticles Synthesized by Spark Discharge. Orient. J. Chem. 2018, 34, 648–654. [Google Scholar] [CrossRef]

- Tortorich, R.P.; Shamkhalichenar, H.; Choi, J.-W. Inkjet-Printed and Paper-Based Electrochemical Sensors. Appl. Sci. 2018, 8, 288. [Google Scholar] [CrossRef]

- Mette, A.; Richter, P.L.; Hörteis, M.; Glunz, S.W. Metal aerosol jet printing for solar cell metallization. Prog. Photovolt. Res. Appl. 2007, 15, 621–627. [Google Scholar] [CrossRef]

- Arsenov, P.V.; Vlasov, I.S.; Efimov, A.A.; Minkov, K.N.; Ivanov, V.V. Aerosol Jet Printing of Platinum Microheaters for the Application in Gas Sensors. IOP Conf. Ser. Mater. Sci. Eng. 2019, 473, 012042. [Google Scholar] [CrossRef]

- Yuxiao, H.; Oakley, C.; Chahal, P.; Albrecht, J.; Papapolymerou, J. Aerosol Jet printed 24 GHz end-fire quasi-Yagi-Uda antenna on a 3-D printed cavity substrate. In Proceedings of the 2017 International Workshop on Antenna Technology: Small Antennas, Innovative Structures, and Applications (iWAT), Athens, Greece, 1–3 March 2017; pp. 179–182. [Google Scholar] [CrossRef]

- Cai, F.; Pavlidis, S.; Papapolymerou, J.; Chang, Y.H.; Wang, K.; Zhang, C.; Wang, B. Aerosol jet printing for 3-D multilayer passive microwave circuitry. In Proceedings of the 2014 44th European Microwave Conference, Rome, Italy, 6–9 October 2014; pp. 512–515. [Google Scholar] [CrossRef]

- Elmogi, A.; Soenen, W.; Ramon, H.; Yin, X.; Missinne, J.; Spiga, S.; Amann, M.-C.; Srinivasan, A.; De Heyn, P.; Van Campenhout, J.; et al. Aerosol-Jet Printed Interconnects for 2.5 D Electronic and Photonic Integration. J. Light. Technol. 2018, 36, 3528–3533. [Google Scholar] [CrossRef]

- Bag, S.; Deneault, J.R.; Durstock, M.F. Aerosol-Jet-Assisted Thin-Film Growth of CH3NH3PbI3 Perovskites—A Means to Achieve High Quality, Defect-Free Films for Efficient Solar Cells. Adv. Energy Mater. 2017, 7, 1701151. [Google Scholar] [CrossRef]

- Mahajan, A.; Frisbie, C.D.; Francis, L.F. Optimization of aerosol jet printing for high-resolution, high-aspect ratio silver lines. ACS Appl. Mater. Interfaces. 2013, 5, 4856–4864. [Google Scholar] [CrossRef]

- Kopola, P.; Zimmermann, B.; Filipovic, A.; Schleiermacher, H.-F.; Greulich, J.; Rousu, S.; Hast, J.; Myllylä, R.; Würfel, U. Aerosol jet printed grid for ITO-free inverted organic solar cells. Sol. Energy Mater. Sol. Cells 2012, 107, 252–258. [Google Scholar] [CrossRef]

- Chu, T.-Y.; Zhang, Z.; Tao, Y. Printing Silver Conductive Inks with High Resolution and High Aspect Ratio. Adv. Mater. Technol. 2018, 3, 1700321. [Google Scholar] [CrossRef]

- Kocabas, C.; Meitl, M.A.; Gaur, A.; Shim, M.; Rogers, J.A. Aligned arrays of single-walled carbon nanotubes generated from random networks by orientationally selective laser ablation. Nano. Lett. 2004, 4, 2421–2426. [Google Scholar] [CrossRef]

- Renn, M.J.; Schrandt, M.; Renn, J.; Feng, J.Q. Localized Laser Sintering of Metal Nanoparticle Inks Printed with Aerosol Jet® Technology for Flexible Electronics. J. Microelectron. Electron. Packag. 2017, 14, 132–139. [Google Scholar] [CrossRef]

- Khabarov, K.; Kornyushin, D.; Masnaviev, B.; Tuzhilin, D.; Saprykin, D.; Efimov, A.; Ivanov, V. The Influence of Laser Sintering Modes on the Conductivity and Microstructure of Silver Nanoparticle Arrays Formed by Dry Aerosol Printing. Appl. Sci. 2020, 10, 246. [Google Scholar] [CrossRef]

- Khabarov, K.M.; Kornyushin, D.V.; Masnaviev, B.I.; Tuzhilin, D.N.; Efimov, A.A.; Saprykin, D.L.; Ivanov, V.V. Laser sintering of silver nanoparticles deposited by dry aerosol printing. J. Phys. Conf. Ser. 2019, 1410, 012217. [Google Scholar] [CrossRef]

- PRINTED ELECTRONICS. Available online: https://www.iparu.com/printed-electronics (accessed on 24 January 2020).

- Vogeler, F.; Verheecke, W.; Voet, A.; Valkenaers, H. Aerosol Jet® printed interconnections on extrusion based 3D printed substrates. In International Conference on Polymers and Moulds Innovations (PMI); Ghent, Belgium, 12–14 September 2012.

- ISO 4624: 2016 (en). Paints and varnishes - Pull-off test for adhesion. Available online: https://www.sis.se/api/document/preview/920202/ (accessed on 5 February 2020).

- Rietz, U.; Lerche, D.; Hielscher, S.; Beck, U. Centrifugal Adhesion Testing Technology (CATT) - A Valuable Tool for Strength Determination. J. Adhesion Soc. Jap. 2015, 51, 293–297. [Google Scholar] [CrossRef][Green Version]

- Laurent, P.; Stoukatch, S.; Dupont, F.; Kraft, M. Electrical characterization of Aerosol Jet Printing (AJP) deposited conductive silver tracks on organic materials. Microelectron. Eng. 2018, 197, 67–75. [Google Scholar] [CrossRef]

- Efimov, A.A.; Minkov, K.N.; Arsenov, P.V.; Protas, N.V.; Ivanov, V.V. Investigation of sintering of silver lines on a heated plastic substrate in the dry aerosol jet printing. J. Phys. Conf. Ser. 2018, 1124, 081041. [Google Scholar] [CrossRef]

- Wünscher, S.; Abbel, R.; Perelaer, J.; Schubert, U.S. Progress of alternative sintering approaches of inkjet-printed metal inks and their application for manufacturing of flexible electronic devices. J. Mater. Chem. C. 2014, 2, 10232–10261. [Google Scholar] [CrossRef]

- Lefky, C.; Mamidanna, A.; Huang, Y.; Hildreth, O. Impact of solvent selection and temperature on porosity and resistance of printed self-reducing silver inks. physica status solidi (a) 2016, 213, 2751–2758. [Google Scholar] [CrossRef]

- Kim, D.; Moon, J. Highly Conductive Ink Jet Printed Films of Nanosilver Particles for Printable Electronics. Electrochem. Solid-State Lett. 2005, 8, J30–J33. [Google Scholar] [CrossRef]

- ISO/IEC Guide 98-3:2008(en). Uncertainty of measurement — Part 3: Guide to the expression of uncertainty in measurement (GUM:1995). Available online: https://www.sis.se/api/document/preview/910301/ (accessed on 5 February 2020).

- Efimov, A.A.; Arsenov, P.V.; Protas, N.V.; Minkov, K.N.; Urazov, M.N.; Ivanov, V.V. Dry aerosol jet printing of conductive silver lines on a heated silicon substrate. IOP Conf. Ser. Mater. Sci. Eng. 2018, 307, 012082. [Google Scholar] [CrossRef]

- Lizunova, A.A.; Efimov, A.A.; Arsenov, P.V.; Ivanov, V.V. Influence of the sintering temperature on morphology and particle size of silver synthesized by spark discharge. IOP Conf. Ser. Mater. Sci. Eng. 2018, 307, 012081. [Google Scholar] [CrossRef]

- Kahng, S.-J.; Cerwyn, C.; Dincau, B.M.; Kim, J.-H.; Novosselov, I.V.; Anantram, M.P.; Chung, J.-H. Nanoink bridge-induced capillary pen printing for chemical sensors. Nanotechnol. 2018, 29, 335304. [Google Scholar] [CrossRef] [PubMed]

- Ratautas, K.; Jagminienė, A.; Stankevičienė, I.; Sadauskas, M.; Norkus, E.; Račiukaitis, G. Evaluation and optimization of the SSAIL method for laser-assisted selective electroless copper deposition on dielectrics. Results Phys. 2020, 16, 102943. [Google Scholar] [CrossRef]

| Number of Printing Layers N | Substrate Temperature Ts (°C) | Printing Speed Vs (mm/min) | Focusing Ratio FR |

|---|---|---|---|

| 1, 2, 5, 10 | 25, 100 | 100 | 5 |

| 10 | 25, 50, 100, 200, 300 | 100 | 2 |

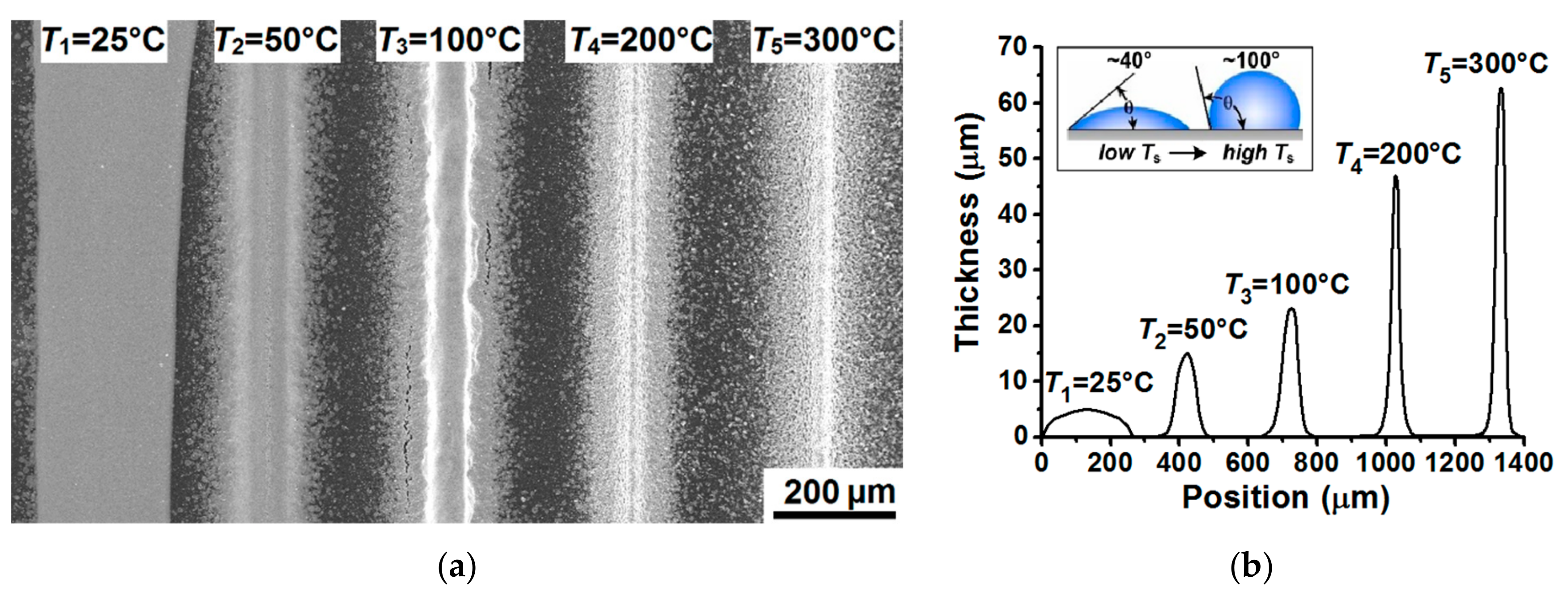

| Ts (°C) | 25 | 50 | 100 | 200 | 300 |

| ρ (µΩ∙cm) | 2.96 ± 0.28 | 2.69 ± 0.28 | 2.56 ± 0.24 | 3.53 ± 0.32 | 6.98 ± 0.73 |

| AR | 0.020 ± 0.004 | 0.11 ± 0.02 | 0.17 ± 0.03 | 0.47 ± 0.08 | 0.70 ± 0.12 |

| t (μm) | 5.1 ± 0.9 | 15.2 ± 2.1 | 23.1 ± 3.2 | 46.9 ± 6.3 | 62.6 ± 8.4 |

| W (μm) | 250.3 ± 23.6 | 134.2 ± 15.1 | 135.5 ± 14.6 | 99.1 ± 10.2 | 90.6 ± 9.4 |

| S (μm2) | 1170 ± 234 | 970 ± 175 | 1280 ± 225 | 1462 ± 249 | 2072 ± 352 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Efimov, A.; Arsenov, P.; Kornyushin, D.; Lizunova, A.; Volkov, I.; Ivanov, V. Aerosol Jet Printing of Silver Lines with A High Aspect Ratio on A Heated Silicon Substrate. Materials 2020, 13, 730. https://doi.org/10.3390/ma13030730

Efimov A, Arsenov P, Kornyushin D, Lizunova A, Volkov I, Ivanov V. Aerosol Jet Printing of Silver Lines with A High Aspect Ratio on A Heated Silicon Substrate. Materials. 2020; 13(3):730. https://doi.org/10.3390/ma13030730

Chicago/Turabian StyleEfimov, Alexey, Pavel Arsenov, Denis Kornyushin, Anna Lizunova, Ivan Volkov, and Victor Ivanov. 2020. "Aerosol Jet Printing of Silver Lines with A High Aspect Ratio on A Heated Silicon Substrate" Materials 13, no. 3: 730. https://doi.org/10.3390/ma13030730

APA StyleEfimov, A., Arsenov, P., Kornyushin, D., Lizunova, A., Volkov, I., & Ivanov, V. (2020). Aerosol Jet Printing of Silver Lines with A High Aspect Ratio on A Heated Silicon Substrate. Materials, 13(3), 730. https://doi.org/10.3390/ma13030730