The Concept of Psychotextiles; Interactions between Changing Patterns and the Human Visual Brain, by a Novel Composite SMART Fabric

Abstract

1. Introduction

2. Experimental Methodology

2.1. Materials and Processing Methods

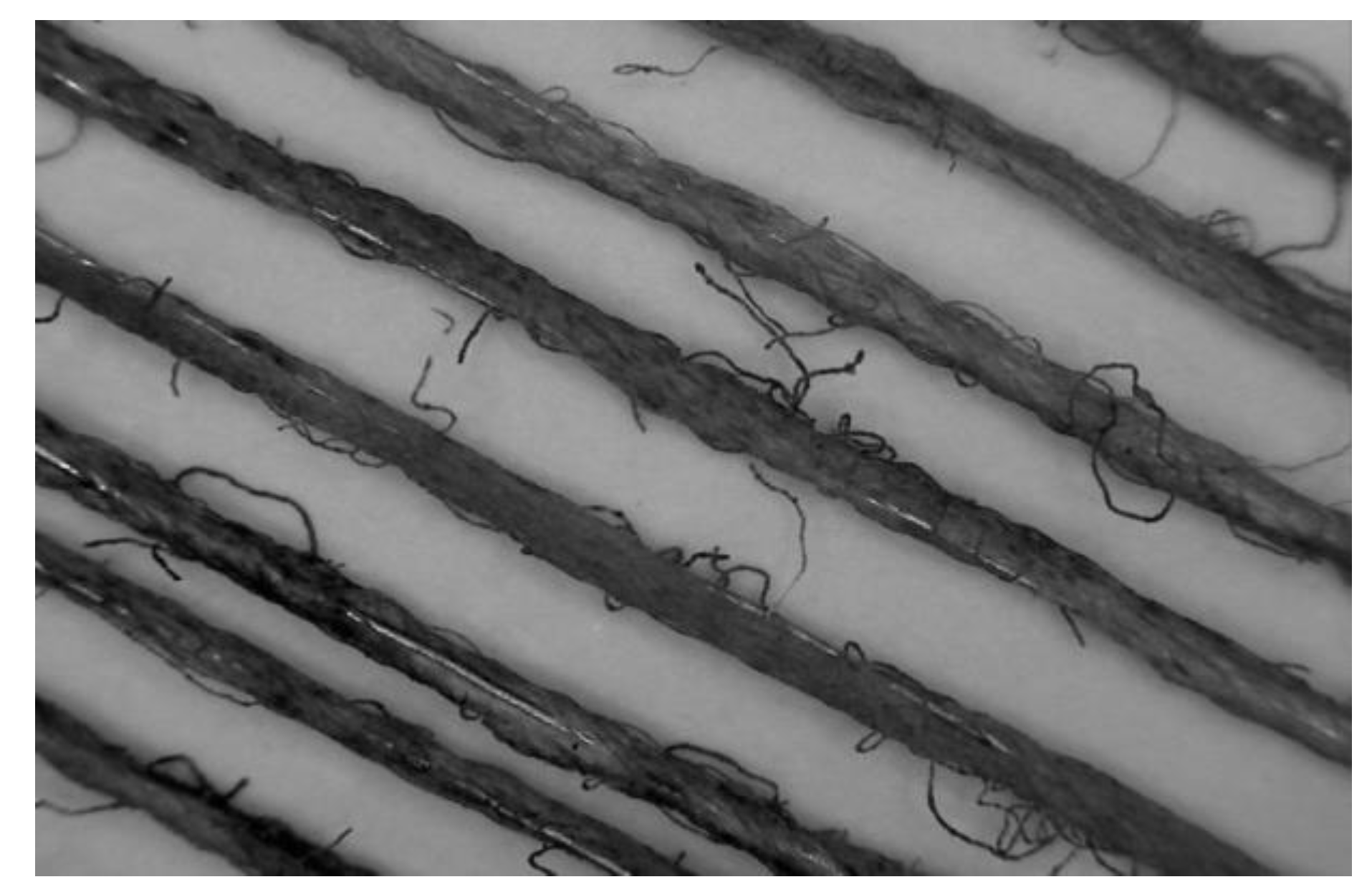

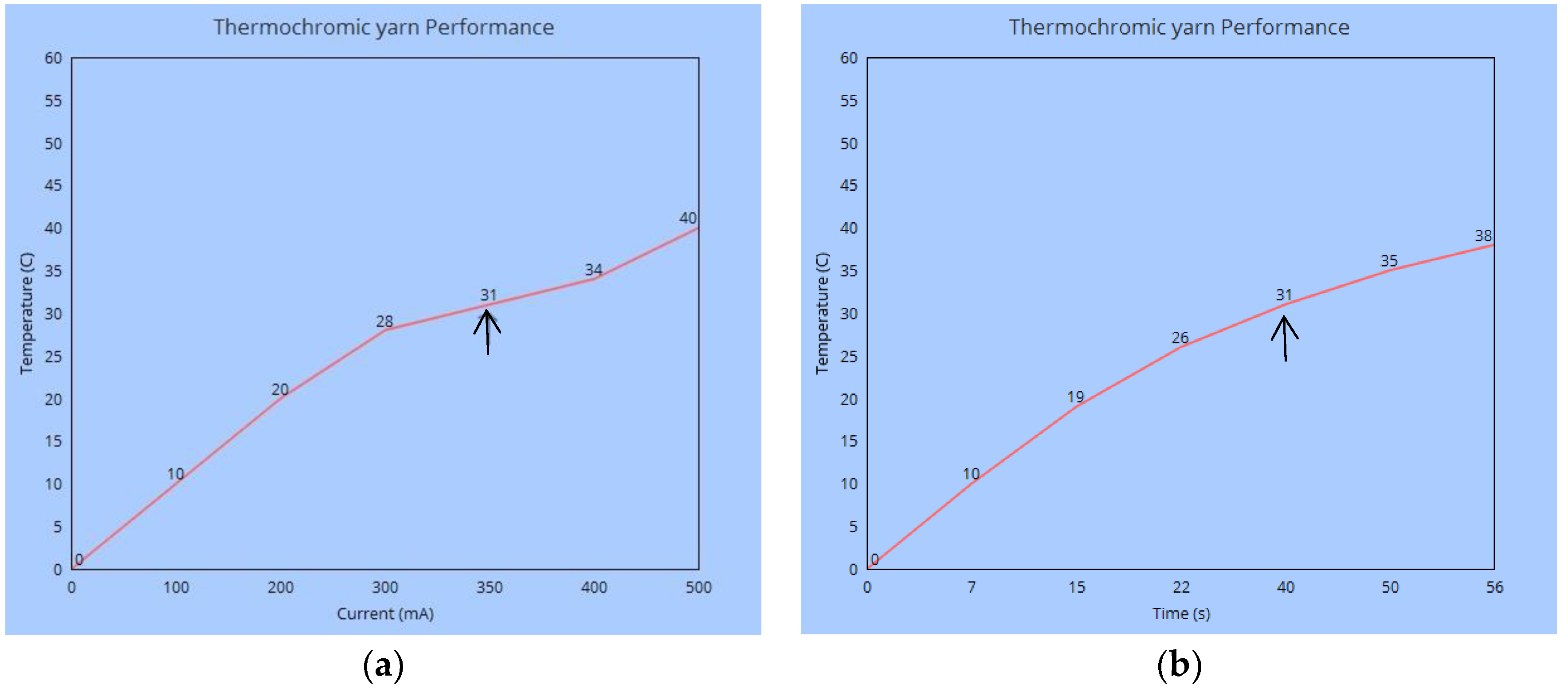

2.1.1. Yarn

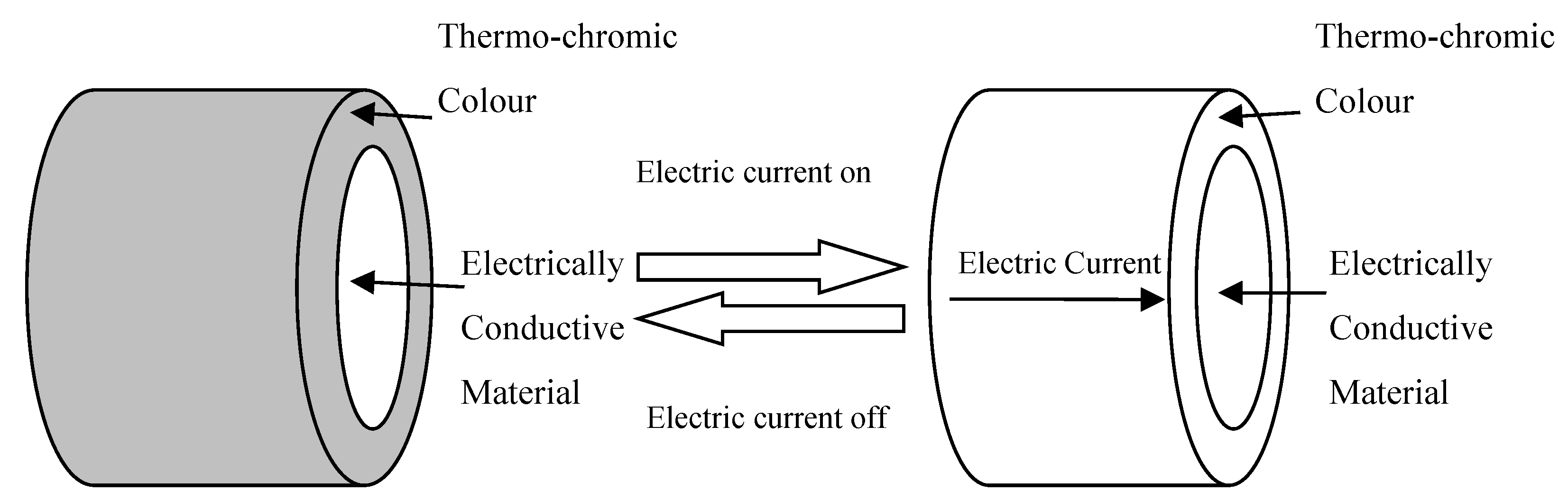

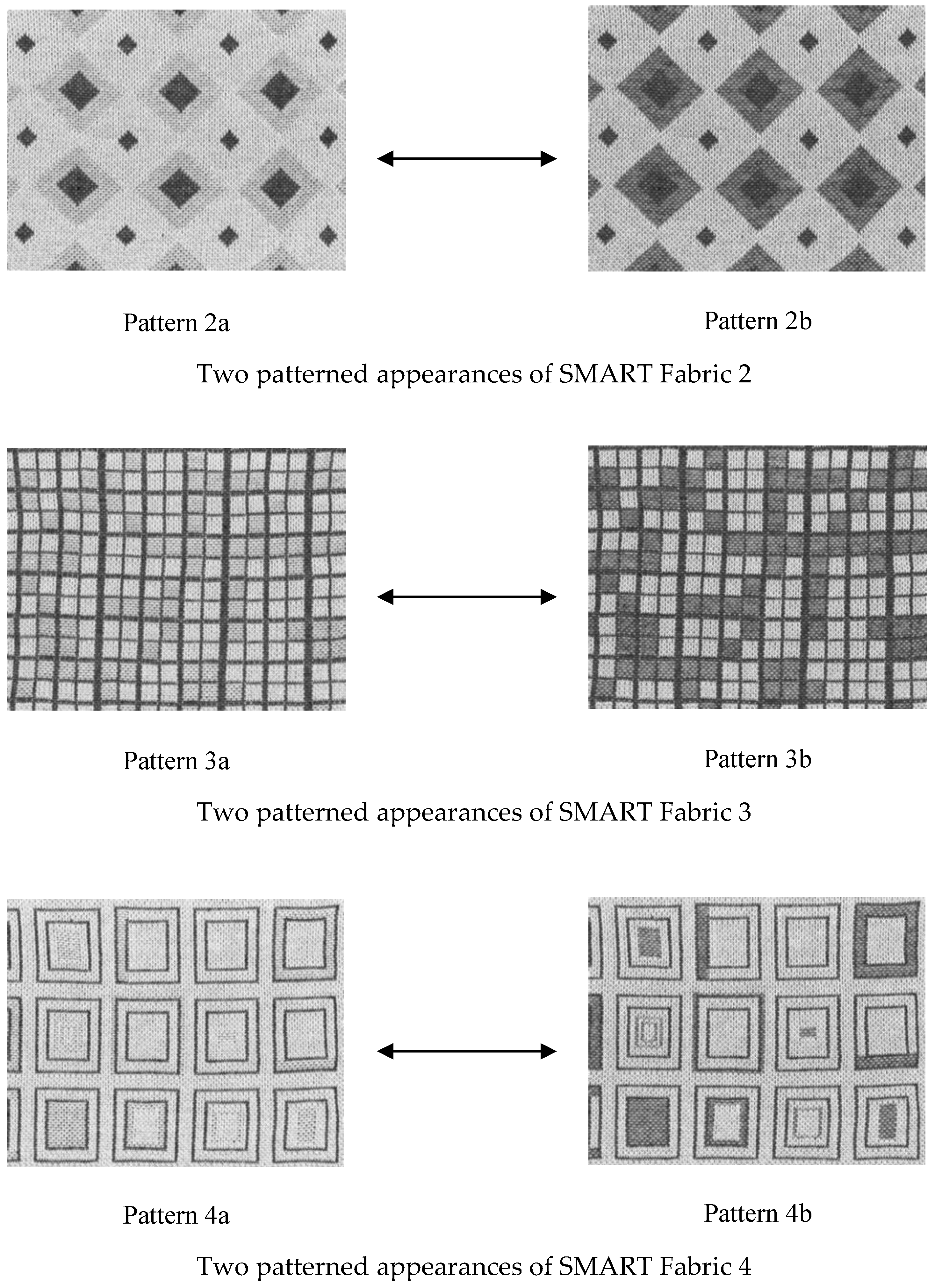

2.1.2. Pattern Changing Fabrics

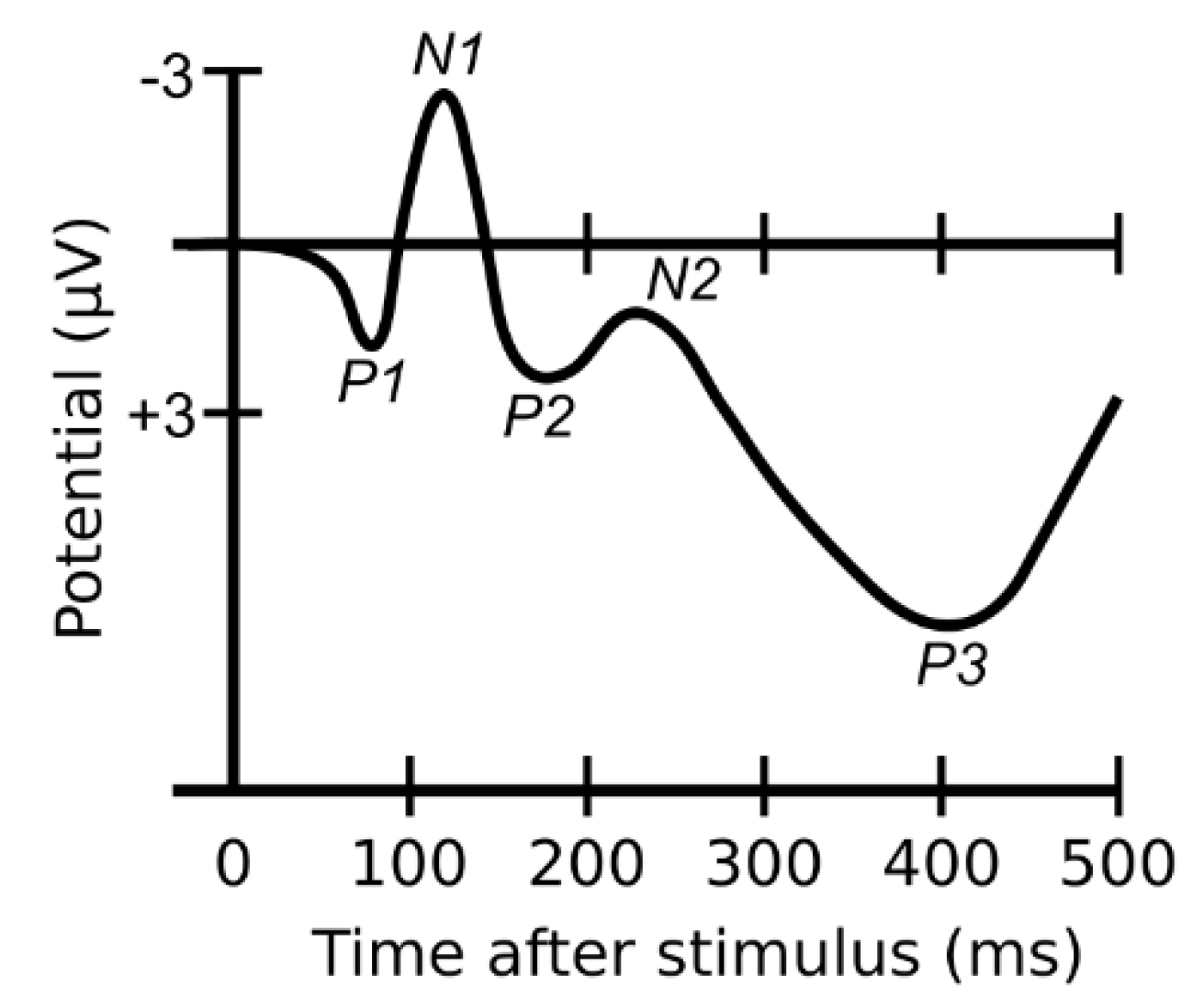

2.2. Material/Brain Interactions

2.3. EEG Experiment

2.3.1. Participants

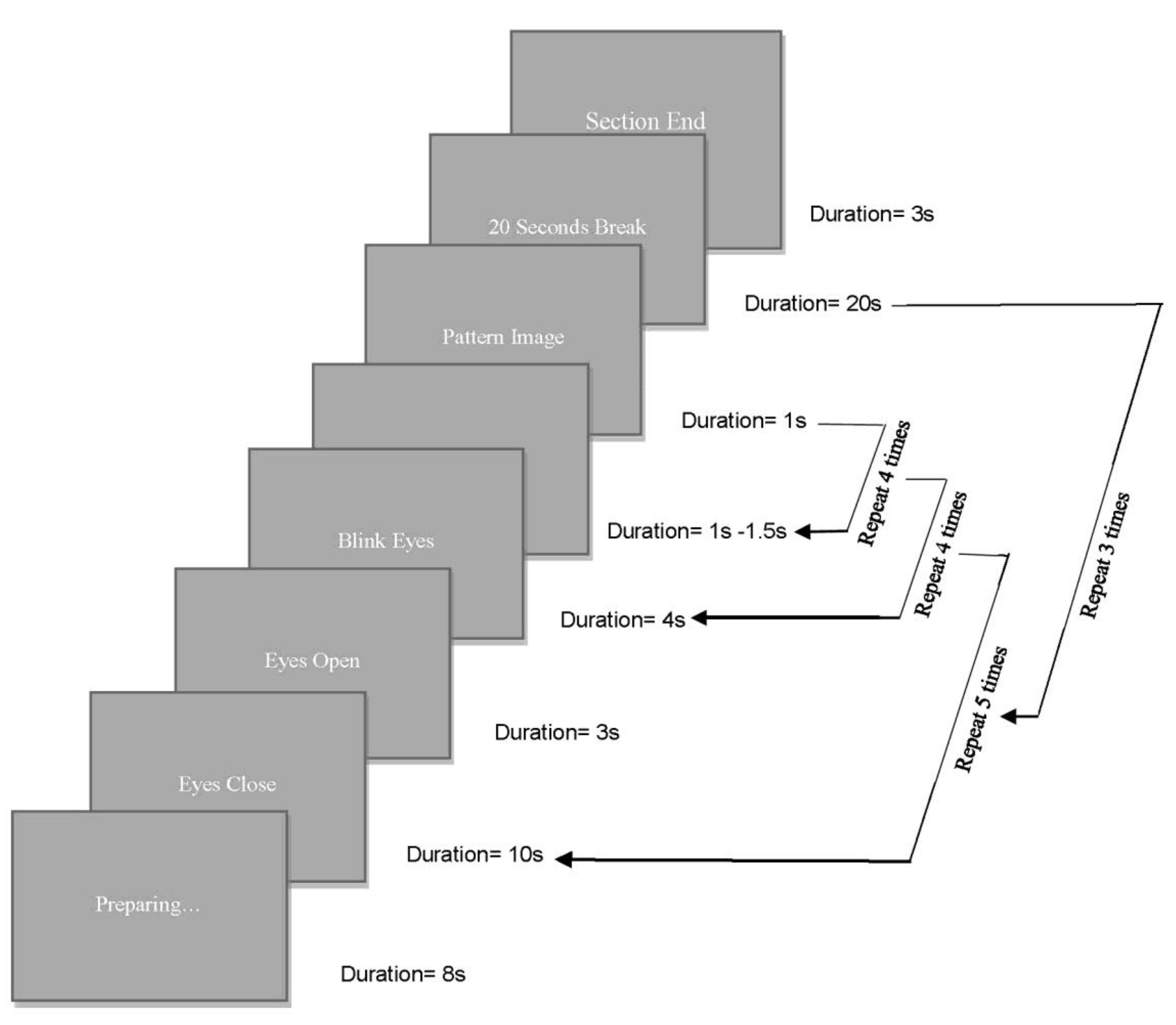

2.3.2. EEG Experiment Procedure

2.3.3. Brain Data Acquisition and Processing

3. Results

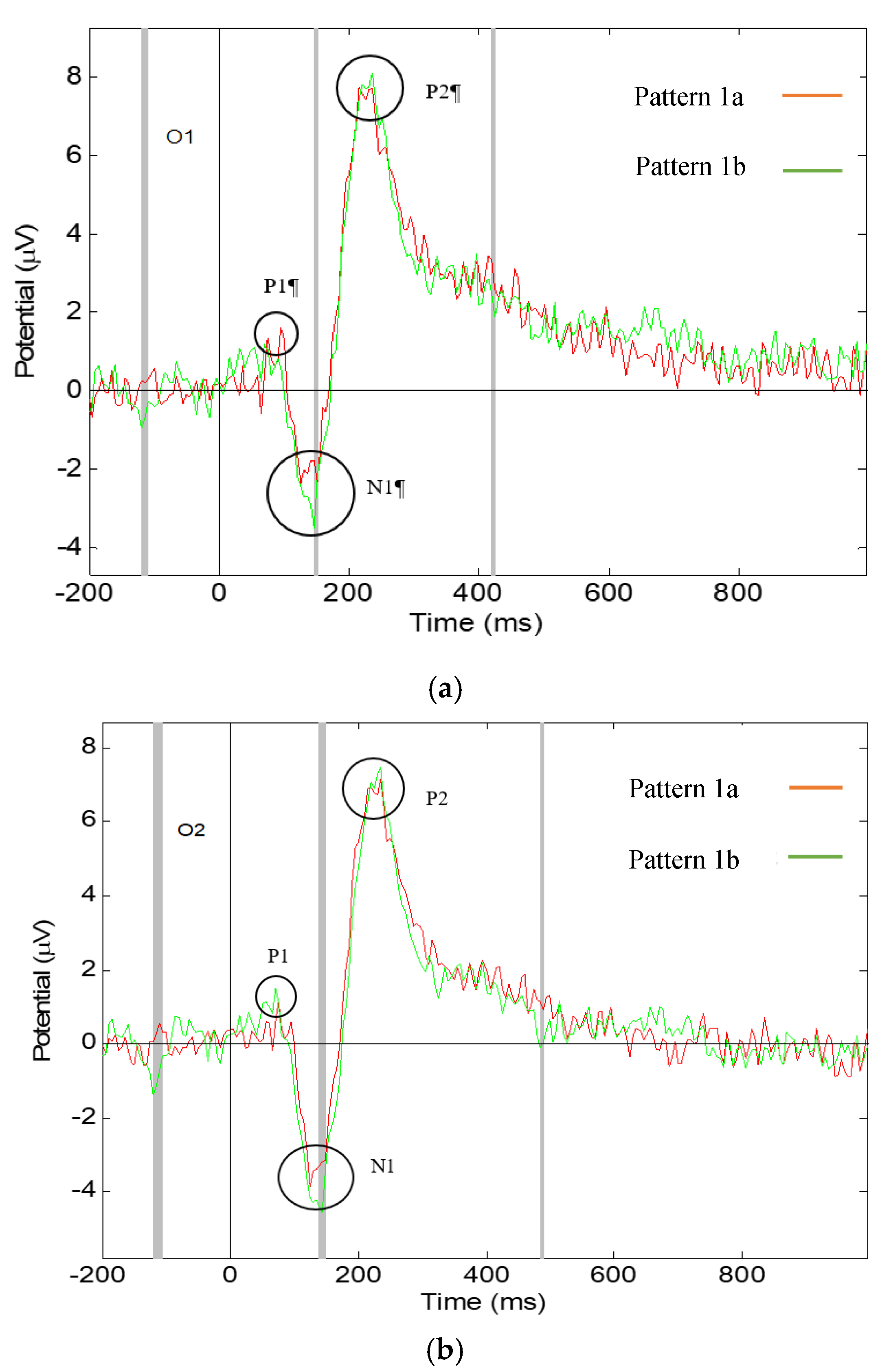

3.1. Significant Differences in the Visual ERPs Evoked by Pattern 1a,b of Fabric 1

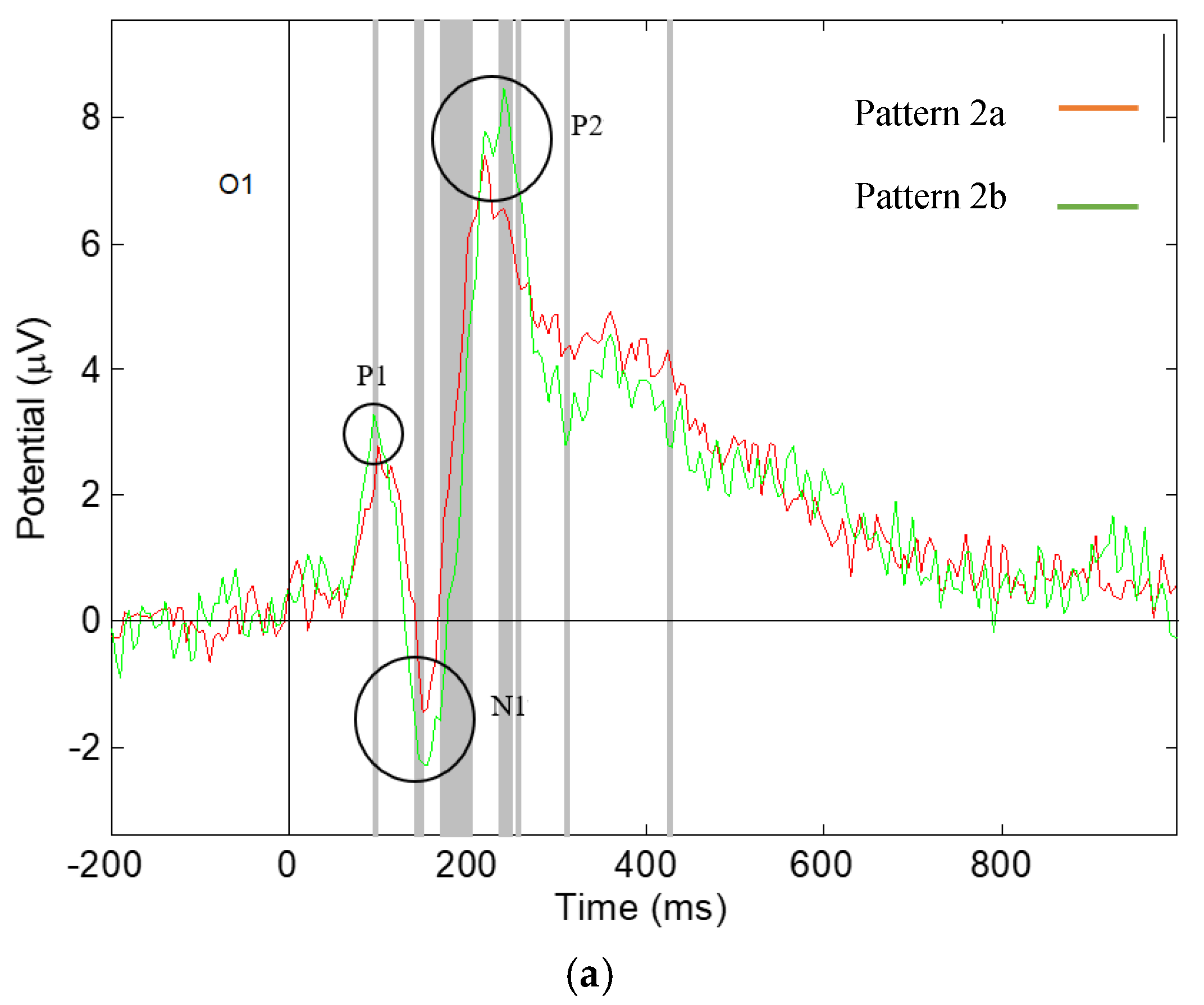

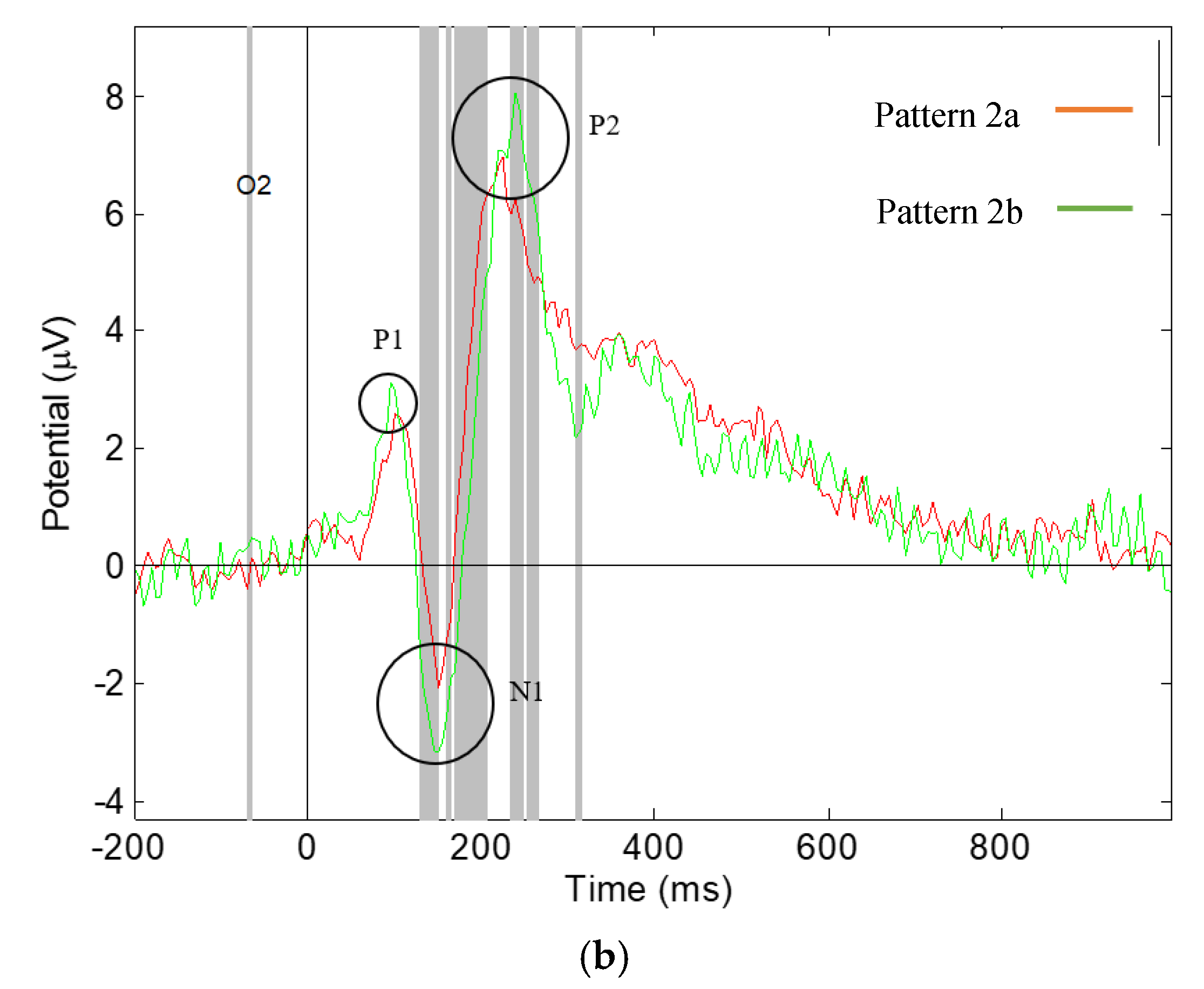

3.2. Significant Differences in the Visual ERPs Evoked by Pattern 2a,b of Fabric 2

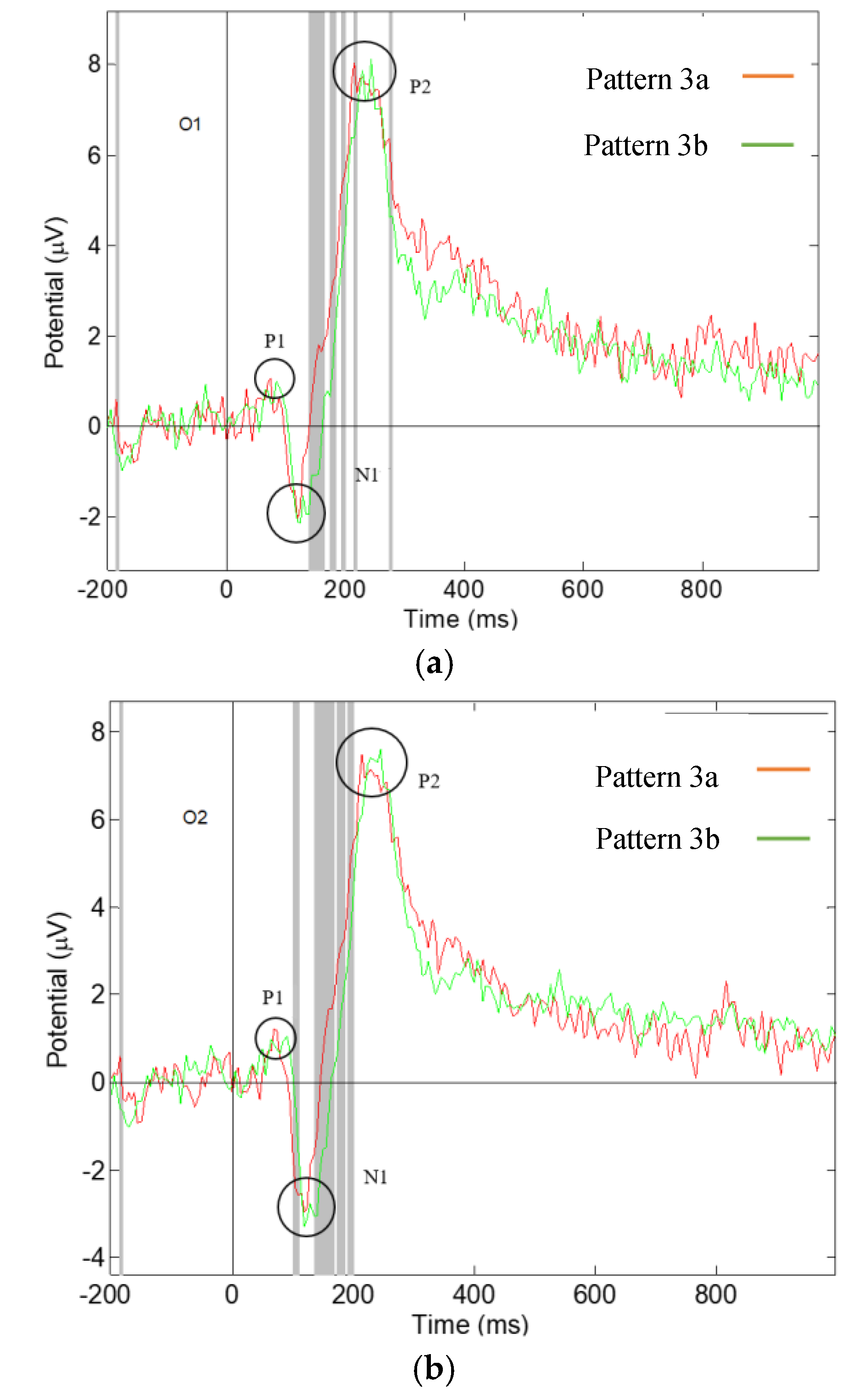

3.3. Significant Differences in the Visual ERPs Evoked by Pattern 3a,b of Fabric 3

3.4. Significant Differences in the Visual ERPs Evoked by Pattern 4a,b of Fabric 4

4. Discussion and Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Stylios, G. Engineering textile and clothing aesthetics using shape changing materials. Intell. Text. Cloth. 2006, 54, 528. [Google Scholar]

- Baurley, S. Interactive and experiential design in smart textile products and applications. Pers. Ubiquitous Comput. 2004, 8, 274–281. [Google Scholar] [CrossRef]

- Stead, L.J. ‘The Emotional Wardrobe’: A Fashion Perspective on the Integration of Technology and Clothing; University of the Arts London: London, UK, 2005. [Google Scholar]

- Philips. Philips Design SKIN Probe Receives Prestigious “Best of the Best” in Red Dot Award: Design Concept 2007. Available online: http://www.newscenter.philips.com/main/design/about/design/designnews/pressreleases/skin_reddot2007.wpd#.VLPmvtKsXTo (accessed on 12 January 2015).

- Sensoree. GER Mood Sweater. Available online: http://sensoree.com/artifacts/ger-mood-sweater/ (accessed on 22 December 2019).

- Yang, D. The Design of Mood Changing Clothing Based on Fibre Optics and Photovoltaic Technologies; Heriot-Watt University: Edinburgh, UK, 2012. [Google Scholar]

- The Dress that Changes Colour with Your Emotions. 29 October 2014. Available online: http://www.bbc.co.uk/news/technology-29691662 (accessed on 13 January 2015).

- Pinner, M. Interactive Synapse Dress by Anouk Wipprecht Reveals Wearer’s Metal States. 2014. Available online: http://fashioningtech.com/profiles/blogs/interactive-synapse-dress-reveals-wearers-metal-states (accessed on 13 January 2015).

- White, C.T. Evoked cortical responses and patterned stimuli. Am. Psychol. 1969, 24, 211. [Google Scholar] [CrossRef] [PubMed]

- Spehlman, R. The average electrical responses to diffuse and to patterned light in the human. Electroencephalogr. Clin. Neurophysiol. 1965, 19, 560–569. [Google Scholar] [CrossRef]

- Armington, J.C.; Corwin, T.R.; Marsetta, R. Simultaneously Recorded Retinal and Cortical Responses to Patterned Stimuli. J. Opt. Soc. Am. 1971, 61, 1514–1521. [Google Scholar] [CrossRef] [PubMed]

- Harter, M.R.; White, C. Effects of contour sharpness and check-size on visually evoked cortical potentials. Vis. Res. 1968, 8, 701–711. [Google Scholar] [CrossRef]

- Ito, M.; Sugata, T. Visual evoked potentials to geometric forms. Jpn. Psychol. Res. 1995, 37, 221–228. [Google Scholar] [CrossRef][Green Version]

- Moskowitz, A.F.; Armington, J.C.; Timberlake, G. Corners, receptive fields, and visually evoked cortical potentials. Percept. Psychophys. 1974, 15, 325–330. [Google Scholar] [CrossRef]

- Ito, M.; Sugata, T.; Kuwabara, H.; Wu, C.; Kojima, K. Effects of angularity of the figures with sharp and round corners on visual evoked potentials. Jpn. Psychol. Res. 1999, 41, 91–101. [Google Scholar] [CrossRef]

- Wagemans, J. Detection of visual symmetries. In Human Symmetry Perception and Its Computational Analysis; Psychology Press: London, UK, 1996; pp. 25–48. [Google Scholar]

- Stylios, G.K.; Chen, M. 11—Psychotextiles and Their Interaction with the Human Brain; Elsevier Ltd.: Amsterdam, The Netherlands, 2016; pp. 197–239. [Google Scholar]

- Bear, M.F.; Connors, B.W.; Michael, A. Paradiso Neuroscience: Exploring the Brain; Lippincott Williams & Wilkins: Philadelphia, PA, USA, 2001; p. 608. [Google Scholar]

- Andreassi, J.L. Psychophysiology: Human Behavior and Physiological Response, 5th ed.; Lawrence Erlbaum: Hillsdale, NJ, USA, 2007. [Google Scholar]

- Cooper, R.; Osselton, J.W.; Shaw, J.C. EEG Technology, 3rd ed.; Butterworths & Co.: London, UK, 1980. [Google Scholar]

- Luck, S.J. An Introduction to the Event-Related Potential Technique; MIT Press: Cambridge, MA, USA, 2005. [Google Scholar]

- Rentzeperis, I.; Nikolaev, A.R.; Kiper, D.C.; Van Leeuwen, C. Relationship between neural response and adaptation selectivity to form and color: An ERP study. Front. Hum. Neurosci. 2012, 6, 89. [Google Scholar] [CrossRef] [PubMed]

- Olofsson, J.K.; Nordin, S.; Sequeira, H.; Polich, J. Affective picture processing: An integrative review of ERP findings. Biol. Psychol. 2008, 77, 247–265. [Google Scholar] [CrossRef] [PubMed]

- Luo, W.; Feng, W.; He, W.; Wang, N.Y.; Luo, Y.J. Three stages of facial expression processing: ERP study with rapid serial visual presentation. Neuroimage 2010, 49, 1857–1867. [Google Scholar] [CrossRef] [PubMed]

- Jasper, H. Report of the committee on methods of clinical examination in electroencephalography. Electroencephalogr. Clin. Neurophysiol. 1958, 10, 370–375. [Google Scholar]

- Delorme, A.; Makeig, S. EEGLAB: An open source toolbox for analysis of single-trial EEG dynamics including independent component analysis. J. Neurosci. Methods 2004, 134, 9–21. [Google Scholar] [CrossRef]

- Makeig, S.; Bell, A.J.; Jung, T.P.; Sejnowski, T.J. Independent component analysis of electroencephalographic data. In Advances in Neural Information Processing Systems 8; MIT Press: Cambridge, MA, USA, 1996; pp. 145–151. [Google Scholar]

- Carrillo-De-La-Peña, M.; Holguín, S.R.; Corral, M.; Cadaveira, F. The effects of stimulus intensity and age on visual-evoked potentials (VEPs) in normal children. Psychophysiology 1999, 36, 693–698. [Google Scholar] [CrossRef] [PubMed]

- Mangun, G.R.; Hillyard, S.A. Allocation of visual attention to spatial locations: Tradeoff functions for event-related brain potentials and detection performance. Prerception Psychophys. 1990, 47, 532–550. [Google Scholar] [CrossRef] [PubMed]

- Paz-Caballero, M.D.; Garcia-Austt, E. ERP components related to stimulus selection precesses. Electroencephalogr. Clin. Neurophysiol. J. 1992, 82, 369–376. [Google Scholar] [CrossRef]

| O1 Electrode Channel. | ||||||||

|---|---|---|---|---|---|---|---|---|

| N1 | Latency (ms) | N | Mean | StDev | SE Mean | 90% CI | T | p |

| 20 | 4.5 | 9.99 | 2.23 | (0.64, 8.36) | 2.02 | 0.058 | ||

| O2 Electrode Channel | ||||||||

| N1 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 90% CI | T | p |

| 20 | 1.023 | 2.527 | 0.565 | (0.046, 2.000) | 1.81 | 0.086 | ||

| P2 | Latency (ms) | N | Mean | St Dev | SE Mean | 90% CI | T | p |

| 20 | −9.5 | 12.97 | 2.9 | (−14.51, −4.49) | −3.28 | 0.004 | ||

| O1 Electrode Channel | ||||||||

|---|---|---|---|---|---|---|---|---|

| N1 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 95% CI | T | p |

| 20 | 2.143 | 2.662 | 0.595 | (0.898, 3.389) | 3.6 | 0.002 | ||

| P2 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 95% CI | T | p |

| 20 | −3.024 | 3.271 | 0.731 | (−4.555, −1.493) | −4.13 | 0.001 | ||

| O2 Electrode Channel | ||||||||

| N1 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 98% CI | T | p |

| 20 | 2.201 | 2.469 | 0.552 | (0.799, 3.603) | 3.99 | 0.001 | ||

| P2 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 95% CI | T | p |

| 20 | −2.943 | 3.048 | 0.681 | (−4.369, −1.516) | −4.32 | 0 | ||

| Latency (ms) | N | Mean | St Dev | SE Mean | 95% CI | T | p | |

| 20 | −7.75 | 10.82 | 2.42 | (−12.81, −2.69) | −3.2 | 0.005 | ||

| O1 Electrode Channel | ||||||||

|---|---|---|---|---|---|---|---|---|

| P1 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 85% CI | T | p |

| 20 | −0.905 | 2.641 | 0.591 | (−1.791, −0.019) | −1.53 | 0.142 | ||

| N1 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 80% CI | T | p |

| 20 | −1.333 | 4.044 | 0.904 | (−2.534, −0.133) | −1.47 | 0.157 | ||

| Latency (ms) | N | Mean | St Dev | SE Mean | 89% CI | T | p | |

| 19 | −3.68 | 9.4 | 2.16 | (−7.31, −0.06) | −1.71 | 0.105 | ||

| P2 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 85% CI | T | p |

| 18 | −0.645 | 1.785 | 0.421 | (−1.279, −0.011) | −1.53 | 0.143 | ||

| O2 Electrode Channel | ||||||||

| N1 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 83% CI | T | p |

| 20 | −1.074 | 3.319 | 0.742 | (−2.132, −0.015) | −1.45 | 0.164 | ||

| O1 Electrode Channel | ||||||||

|---|---|---|---|---|---|---|---|---|

| P1 | Latency (ms) | N | Mean | St Dev | SE Mean | 90% CI | T | p |

| 18 | −8.06 | 16.37 | 3.86 | (−14.77, −1.34) | −2.09 | 0.052 | ||

| N1 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 95% CI | T | p |

| 17 | −11.33 | 5.91 | 1.43 | (−14.37, −8.29) | −7.91 | 0 | ||

| Latency (ms) | N | Mean | St Dev | SE Mean | 95% CI | T | p | |

| 18 | 10.28 | 17.1 | 4.03 | (1.77, 18.78) | 2.55 | 0.021 | ||

| P2 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 95% CI | T | p |

| 17 | −1.934 | 2.992 | 0.726 | (−3.473, −0.396) | −2.67 | 0.017 | ||

| Latency (ms) | N | Mean | St Dev | SE Mean | 80% CI | T | p | |

| 19 | 3.95 | 11.74 | 2.69 | (0.37, 7.53) | 1.47 | 0.16 | ||

| O2 Electrode Channel | ||||||||

| N1 | Latency (ms) | N | Mean | St Dev | SE Mean | 88% CI | T | p |

| 20 | 5.5 | 14.95 | 3.34 | (0.06, 10.94) | 1.65 | 0.116 | ||

| P2 | Amplitude (µv) | N | Mean | St Dev | SE Mean | 91% CI | T | p |

| 20 | −1.253 | 3.093 | 0.692 | (−2.488, −0.017) | −1.81 | 0.086 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stylios, G.K.; Chen, M. The Concept of Psychotextiles; Interactions between Changing Patterns and the Human Visual Brain, by a Novel Composite SMART Fabric. Materials 2020, 13, 725. https://doi.org/10.3390/ma13030725

Stylios GK, Chen M. The Concept of Psychotextiles; Interactions between Changing Patterns and the Human Visual Brain, by a Novel Composite SMART Fabric. Materials. 2020; 13(3):725. https://doi.org/10.3390/ma13030725

Chicago/Turabian StyleStylios, George K., and Meixuan Chen. 2020. "The Concept of Psychotextiles; Interactions between Changing Patterns and the Human Visual Brain, by a Novel Composite SMART Fabric" Materials 13, no. 3: 725. https://doi.org/10.3390/ma13030725

APA StyleStylios, G. K., & Chen, M. (2020). The Concept of Psychotextiles; Interactions between Changing Patterns and the Human Visual Brain, by a Novel Composite SMART Fabric. Materials, 13(3), 725. https://doi.org/10.3390/ma13030725