Degradation of Dynamic Elastic Modulus of Concrete under Periodic Temperature-Humidity Action

Abstract

1. Introduction

2. Experiment

2.1. Raw Materials and Mix Proportions

2.2. Specimen Preparation and Curing Conditions

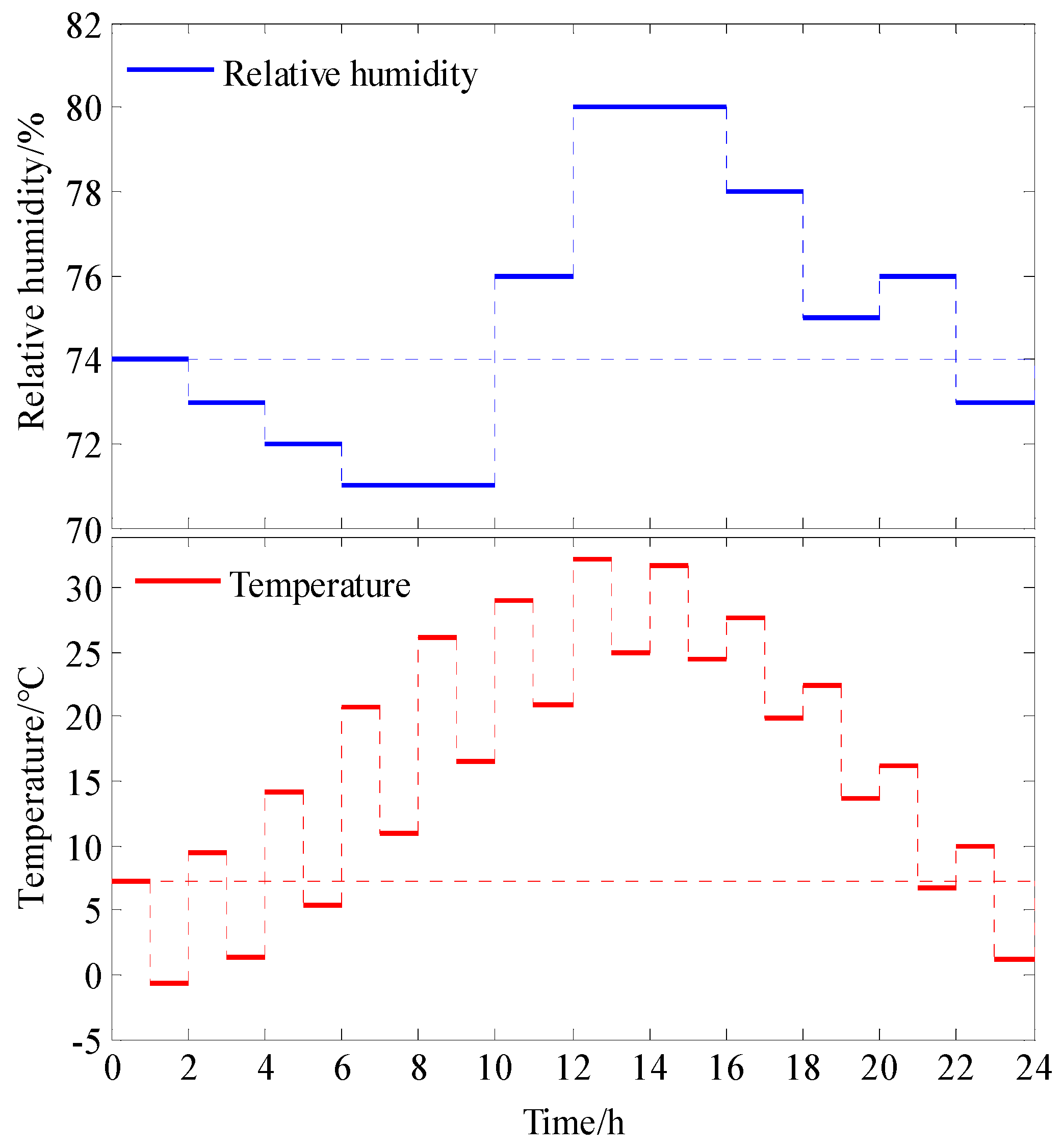

2.3. Periodic Temperature-Humidity

2.4. Test Methods

3. Experimental Results and Discussion

3.1. Experimental Results

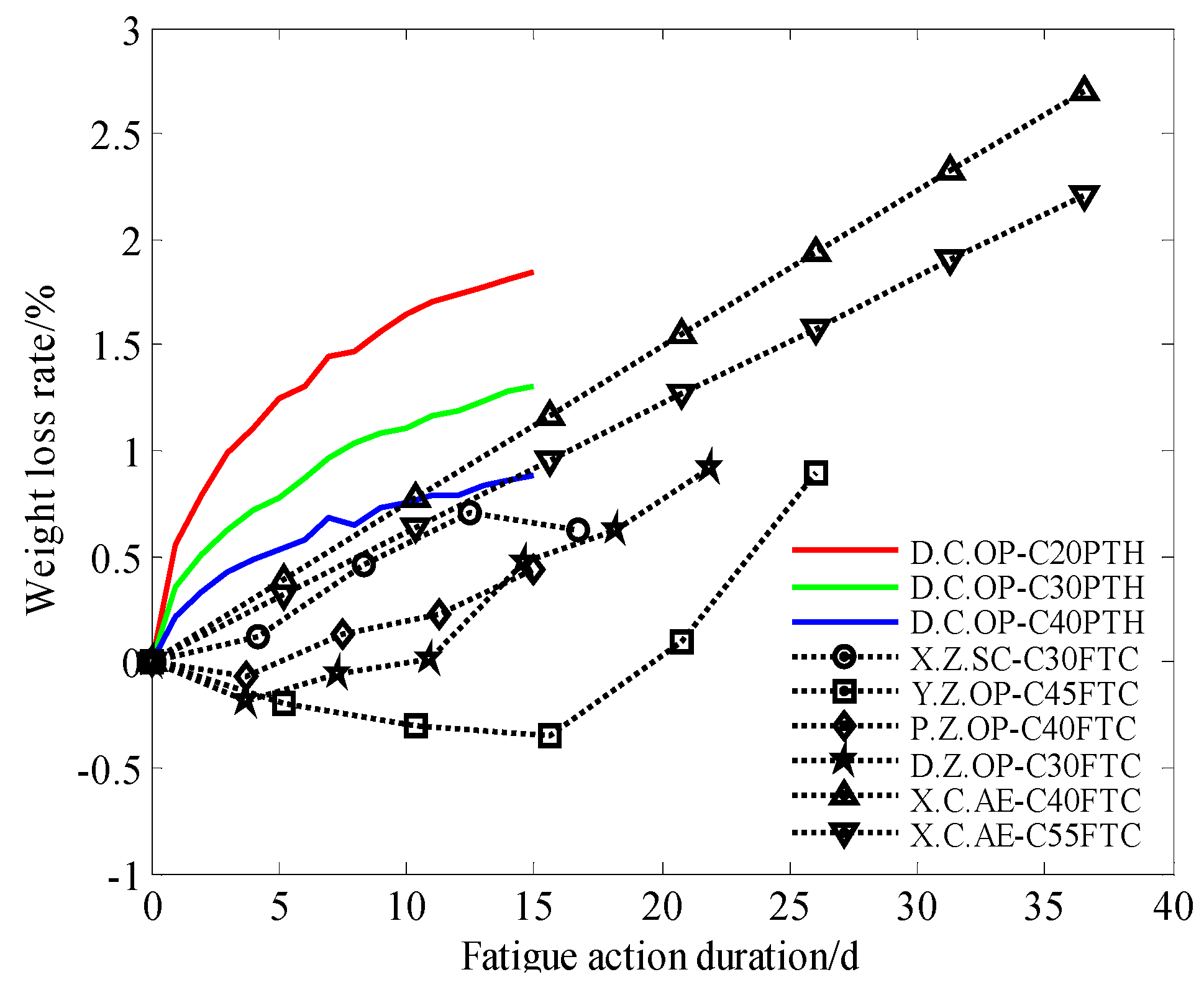

3.2. Weight Loss Rate

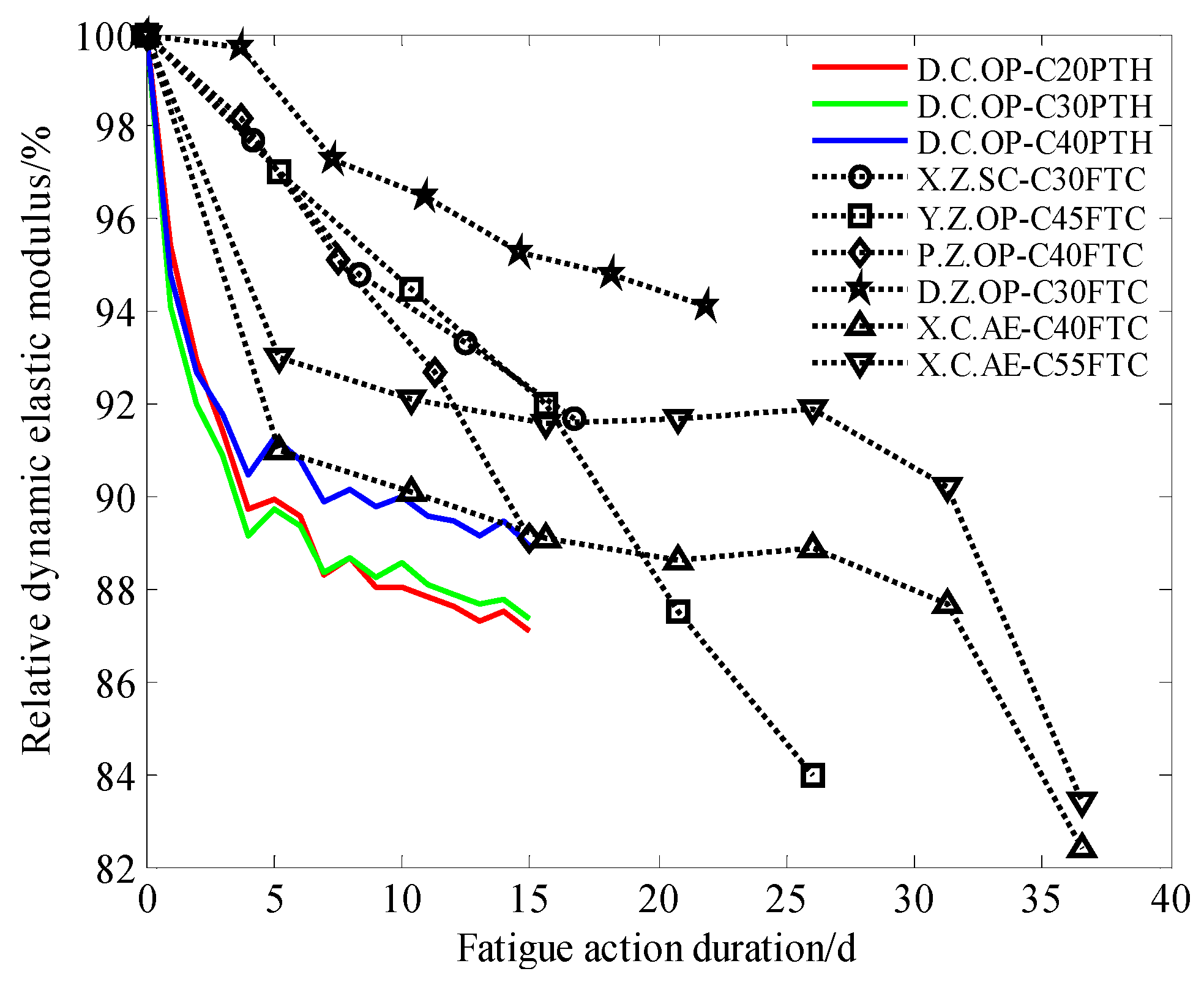

3.3. Relative Dynamic Elastic Modulus

4. Degradation Model of Dynamic Elastic Modulus Based on Fatigue Damage Theory

4.1. Fatigue Damage Evolution Equation

4.2. Degradation Model of the Dynamic Elastic Modulus

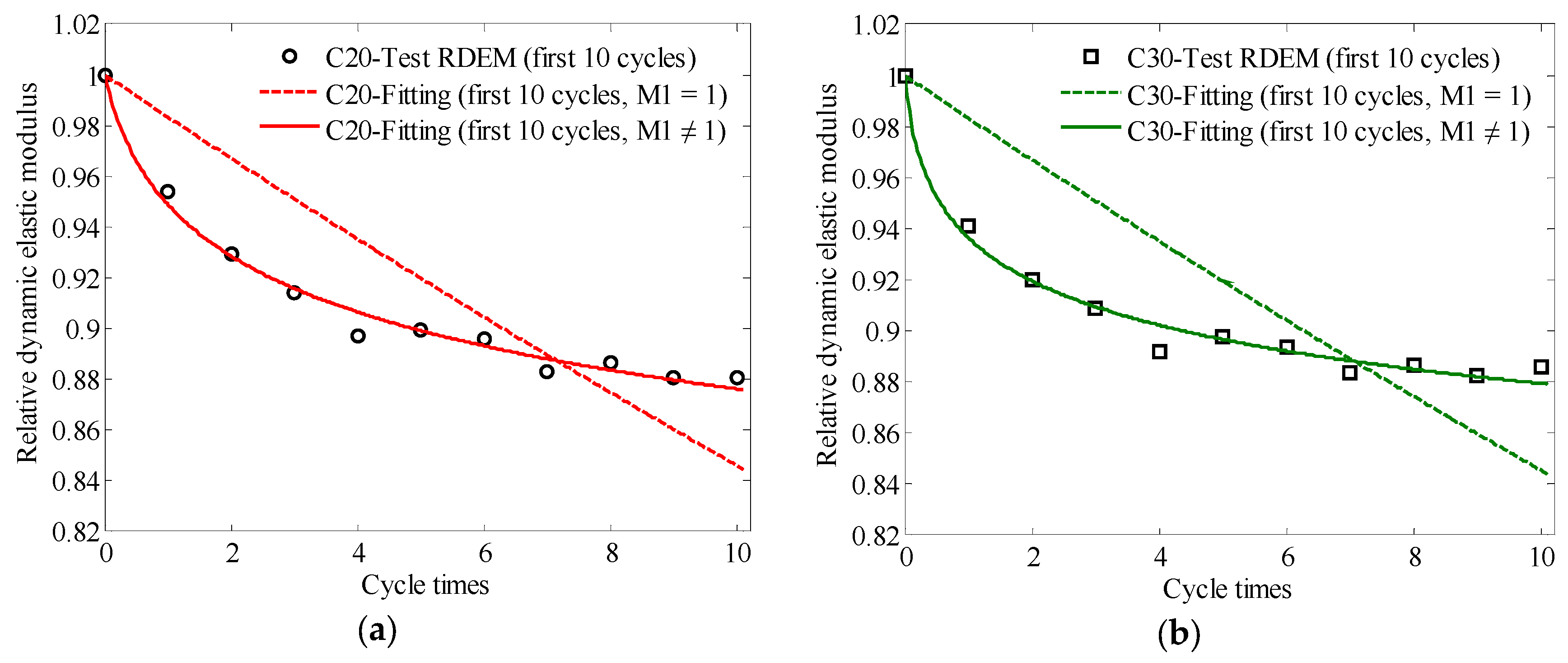

4.3. Fitting and Comparative Analysis

4.3.1. Fitting Analysis Method

4.3.2. Fitting Parameters

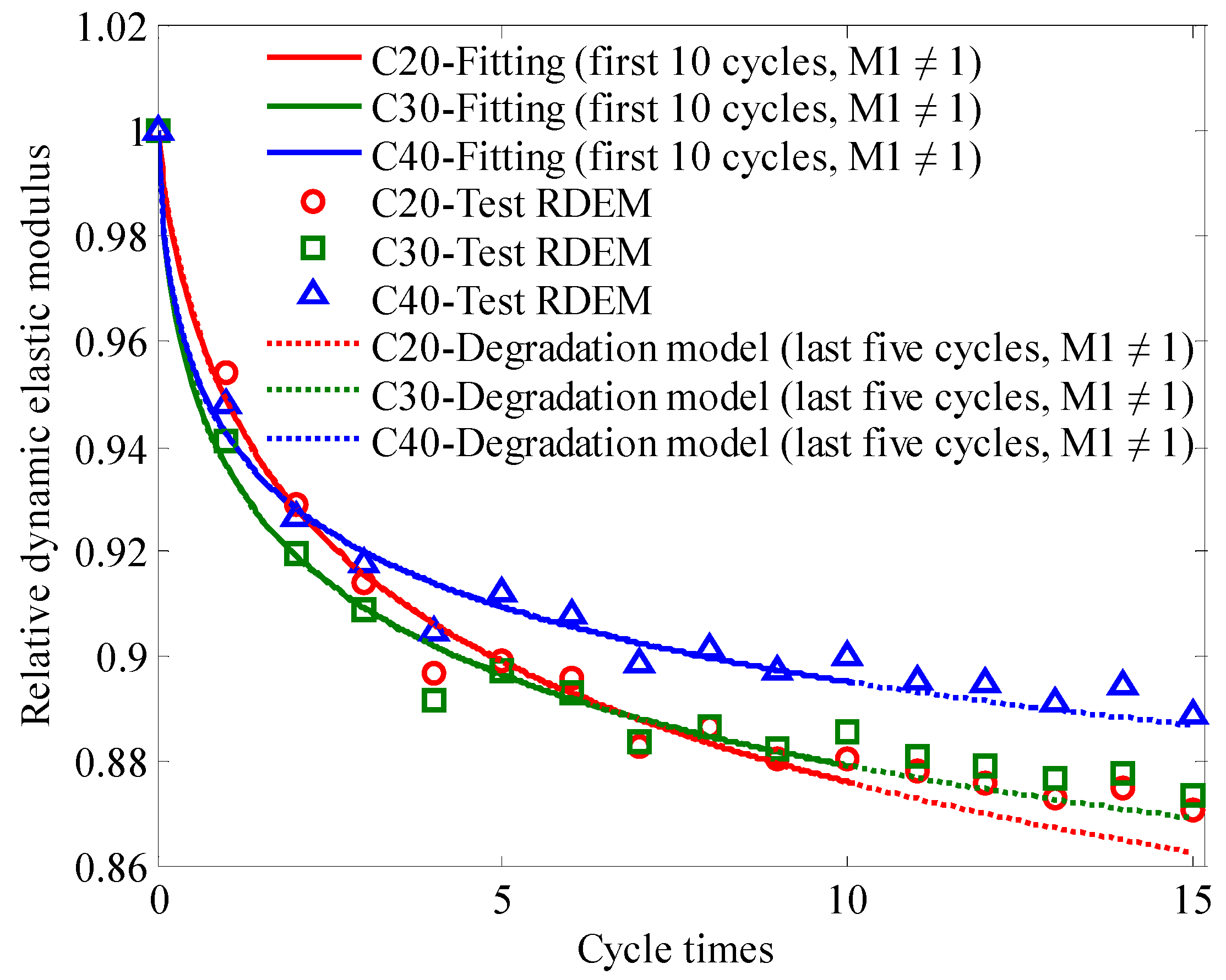

4.3.3. Degradation Model Evaluation and Prediction of Relative Dynamic Elastic Modulus

5. Conclusions

- The action of periodic temperature-humidity variation decreases the dynamic elastic modulus of concrete, and the dynamic elastic modulus loss rate tends to be stable after more cycles of periodic temperature-humidity. The dynamic modulus loss rate of C40 concrete is obviously lower than that of C30 and C20 after more cycles of periodic temperature-humidity, and is lower by over 12%.

- 2 The weight loss rate of concrete increases continuously, and, later, the growth rate slows down. The weight loss rate is also influenced by the strength grade of concrete and will decrease as the strength increases. The relative dynamic elastic modulus of high-strength-grade concrete was found to decrease slightly faster in the early stage but was significantly higher than that of low-strength-grade concrete later under periodic temperature-humidity action.

- Taking the loss rate of the dynamic elastic modulus as the damage variable, the dynamic elastic modulus deterioration model of concrete under periodic temperature-humidity action can be established based on the theory of fatigue damage and the evolution equation of fatigue damage.

- The two-parameter dynamic elastic modulus degradation model (M1 ≠ 1) is more suitable for describing the dynamic elastic modulus attenuation pattern of concrete under periodic temperature-humidity action than the single-parameter model (M1 = 1).

- The current research in this paper is insufficient, and further research is required. The service load of the actual concrete structure is also an important factor in the deterioration of concrete performance, so the degradation of the dynamic elastic modulus and damage evolution under the combined action of the service load and periodic temperature-humidity are worthy of further study. The micromechanical mechanism of concrete cracking and elastic modulus degradation under periodic temperature and humidity needs to be further studied by means of microscopic analysis, for example via scanning electron microscopy, and finite element analysis. In addition, temperature-humidity conditions closer to the actual service environment should be considered in further research, for example by using the highest (lowest) daily temperature in a certain month as the representative value of the highest (lowest) monthly temperature. The deformation and failure micromechanism of airport or pavement concrete under the coupling effect of wheel load-temperature-humidity in areas with severe temperature and humidity changes is also worthy of attention.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tian, Y.; Jin, N.; Jin, X. Coupling effect of temperature and relative humidity diffusion in concrete under ambient conditions. Constr. Build. Mater. 2018, 159, 673–689. [Google Scholar] [CrossRef]

- Zhang, D.; Mao, M.; Zhang, S.; Yang, Q. Influence of stress damage and high temperature on the freeze-thaw resistance of concrete with fly ash as fine aggregate. Constr. Build. Mater. 2019, 229, 116845. [Google Scholar] [CrossRef]

- Lu, C.; Yuan, Y. Micro-environment temperature response prediction for fly ash concrete in artificial climate environment. J. Chin. Uni. Min. Tech. 2012, 41, 571–577, 612. [Google Scholar]

- Chen, D.; Miao, C.; Liu, J.; Tang, M. Advances in multi-scale simulation of hygro-thermo- mechanical deformation behavior of structural concrete. Int. J. Civ. Eng. 2015, 13, 267–277. [Google Scholar]

- Chen, D.; Qian, C.; Liu, C. A numerical simulation approach to calculating hygro-thermal deformation of concrete based on heat and moisture transfer in porous medium. Int. J. Civ. Eng. 2010, 8, 287–296. [Google Scholar]

- Min, H.; Zhang, W.; Gu, X.; Černý, R. Coupled heat and moisture transport in damaged concrete under an atmospheric environment. Constr. Build. Mater. 2017, 143, 607–620. [Google Scholar] [CrossRef]

- Bao, J.; Li, S.; Zhang, P.; Ding, X.; Xue, S.; Cui, Y.; Zhao, T. Influence of the incorporation of recycled coarse aggregate on water absorption and chloride penetration into concrete. Constr. Build. Mater. 2020, 239, 117845. [Google Scholar] [CrossRef]

- Norris, A.; Saafi, M.; Romine, P. Temperature and moisture monitoring in concrete structures using embedded nanotechnology/microelectromechanical systems (MEMS) sensors. Constr. Build. Mater. 2008, 22, 111–120. [Google Scholar] [CrossRef]

- Gawin, D.; Wyrzykowski, M.; Pesavento, F. Modeling hygro-thermal performance and strains of cementitious building materials maturing in variable conditions. J. Build. Phys. 2008, 31, 301–318. [Google Scholar] [CrossRef]

- Andrade, C.; Sarría, J.; Alonso, C. Relative humidity in the interior of concrete exposed to natural and artificial weathering. Cem. Concr. Res. 1999, 29, 1249–1259. [Google Scholar] [CrossRef]

- Zhao, Y.; Fan, X.; Wang, L.; Shi, J. Attenuation model of mechanical properties of concrete under different freezing and thawing. Acta Mater. Compos. Sin. 2017, 34, 463–470. (In Chinese) [Google Scholar]

- Hong, J.; Miao, C.; Liu, J.; Yun, W. Degradation law of mechanical properties of concrete subjected to freeze-thaw cycles. J. Build. Mater. 2012, 15, 173–178. (In Chinese) [Google Scholar]

- Wang, H.; Fan, W.; Liu, T.; An, Z. Experimental study on properties of fully-graded concrete under uniaxial dynamic compressive stress state after freezing-thawing cycles. J. Hydraul. Eng. 2015, 46, 732–738. (In Chinese) [Google Scholar]

- Tian, W.; Han, N.; Zhang, P. Experimental study on the dynamic damage mechanism of concrete under freeze-thaw cycles. J. Vibrat. Shock 2017, 36, 79–85. (In Chinese) [Google Scholar]

- Zhang, P.; Wittmann, F.H.; Vogel, M.; Müller, H.S.; Zhao, T. Influence of freeze-thaw cycles on capillary absorption and chloride penetration into concrete. Cem. Concr. Res. 2017, 100, 60–67. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Zhang, P.; Ma, Y.; Zhao, T.; Wang, H.; Zhang, Z. Water absorption and chloride diffusivity of concrete under the coupling effect of uniaxial compressive load and freeze–thaw cycles. Constr. Build. Mater. 2019, 209, 566–576. [Google Scholar] [CrossRef]

- Zhang, P. Experimental Study on Dynamic Mechanical Behavior of Concrete under Freezing-Thawing Cycles. Master’s Thesis, Chang’an University, Xi’an, China, June 2017. (In Chinese). [Google Scholar]

- Xiao, Q.; Niu, D. Damage model for concrete subjected to freeze-thaw cycles and carbonation. J. Build. Mater. 2015, 18, 763–766. (In Chinese) [Google Scholar]

- Jiang, L.; Niu, D. Damage degradation law of concrete in sulfate solution and freeze-thaw environment. J. Cent. South. Uni. (Sci. Tech.) 2016, 47, 3208–3216. (In Chinese) [Google Scholar]

- Yin, C.; Ling, W.; Wang, Z.; Yao, Y. Deterioration of concrete caused by freeze-thaw cycles combined with chloride attack under flexural load. J. Build. Mater. 2016, 19, 821–825. (In Chinese) [Google Scholar]

- Chen, Z.F.; Liu, G.F.; Qin, Y.L.; Jian-Min, X.U. Strength and durability of concrete with manufactured-sand in severe environment. J. Build. Mater. 2012, 15, 391–394. (In Chinese) [Google Scholar]

- Zhang, J.; Ran, J.; Ma, B.; Wang, J. Influence of carbonation on frost resistance of concrete and its mechanism. J. Build. Mater. 2017, 20, 12–17. (In Chinese) [Google Scholar]

- Wu, Y.; Wu, B. Residual compressive strength and freeze–thaw resistance of ordinary concrete after high temperature. Constr. Build. Mater. 2014, 54, 596–604. [Google Scholar] [CrossRef]

- Matsumura, T.; Shirai, K.; Saegusa, T. Verification method for durability of reinforced concrete structures subjected to salt attack under high temperature conditions. Nucl. Eng. Des. 2008, 238, 1181–1188. [Google Scholar] [CrossRef]

- Nadeem, A.; Memon, S.A.; Lo, T.Y. The performance of Fly ash and Metakaolin concrete at elevated temperatures. Constr. Build. Mater. 2014, 62, 67–76. [Google Scholar] [CrossRef]

- Ripani, M.; Etse, G.; Vrech, S.; Mroginski, J. Thermodynamic gradient-based poroplastic theory for concrete under high temperatures. Int. J. Plast. 2014, 61, 157–177. [Google Scholar] [CrossRef]

- Elrahman, M.A.; Hillemeier, B. Influence of hydrothermal conditions with 200 °C and 15.5 bars on the properties of hardened HPC. Constr. Build. Mater. 2015, 85, 38–48. [Google Scholar] [CrossRef]

- Jiang, J.; Yuan, Y. Quantitative models of climate load and its effect in concrete structure. Constr. Build. Mater. 2012, 29, 102–107. [Google Scholar] [CrossRef]

- Zhang, D.; Xie, X.M. Study of temperature and humidity on properties of concrete in Doha Port. Constr. Tech. 2017, S1, 348–350. (In Chinese) [Google Scholar]

- Chen, Y.; Jin, Z. Temperature response of concrete Iinfluenced by different environment. Bull.Chin Ceram. Soc. 2017, 36, 1345–1350. (In Chinese) [Google Scholar]

- Ma, W.; Li, G. Research on temperature and humidity response law of concrete under natural climate environment. Chin. Concr. Cem. Prod. 2007, 2, 18–21. (In Chinese) [Google Scholar]

- Joshaghani, A.; Balapour, M.; Ramezanianpour, A.A. Effect of controlled environmental conditions on mechanical, microstructural and durability properties of cement mortar. Constr. Build. Mater. 2018, 164, 134–149. [Google Scholar] [CrossRef]

- Brue, F.N.G.; Davy, C.A.; Burlion, N.; Skoczylas, F.; Bourbon, X. Five year drying of high performance concretes: Effect of temperature and cement-type on shrinkage. Cem. Concr. Res. 2017, 99, 70–85. [Google Scholar] [CrossRef]

- Yalçınkaya, Ç.; Yazıcı, H. Effects of ambient temperature and relative humidity on early-age shrinkage of UHPC with high-volume mineral admixtures. Constr. Build. Mater. 2017, 144, 252–259. [Google Scholar] [CrossRef]

- Li, M. Study on the Volume Deformation and Cracking of Concrete Exposed to Temperature and Humidity of China’s Western Region. Master’s Thesis, Harbin Institute of Technology, Harbin, China, June 2013. [Google Scholar]

- Fan, J.; Guan, W. Study on thermal durability of foam concrete insulation board in precast concrete sandwich wall. Chin. Concr. Cem. Prod. 2014, 6, 58–61. (In Chinese) [Google Scholar]

- Jurowski, K.; Grzeszczyk, S. Influence of selected factors on the relationship between the dynamicelastic modulus and compressive strength of concrete. Materials 2018, 11, 477. [Google Scholar] [CrossRef]

- Luo, Q.; Bungey, J.H. Using compression wave ultrasonic transducers to measure the velocity of surface waves and hence determine dynamic modulus of elasticity for concrete. Constr. Build. Mater. 1996, 10, 237–242. [Google Scholar]

- Lu, X.; Sun, Q.; Feng, W.; Tian, J. Evaluation of dynamic modulus of elasticity of concrete using impact-echo method. Constr. Build. Mater. 2013, 47, 231–239. [Google Scholar] [CrossRef]

- Carrillo, J.; Ramirez, J.; Lizarazo-Marriaga, J. Modulus of elasticity and Poisson’s ratio of fiber-reinforced concrete in Colombia from ultrasonic pulse velocities. J. Build. Eng. 2019, 23, 18–26. [Google Scholar] [CrossRef]

- Guo, J.; Wang, K.; Guo, T.; Yang, Z.; Zhang, P. Effect of dry–wet ratio on properties of concrete under sulfate attack. Materials 2019, 12, 2755. [Google Scholar] [CrossRef]

- Gao, J.; Yu, Z.; Song, L.; Wang, T.; Wei, S. Durability of concrete exposed to sulfate attack under flexural loading and drying–wetting cycles. Constr. Build. Mater. 2013, 39, 33–38. [Google Scholar] [CrossRef]

- Chen, F.; Qiao, P. Probabilistic damage modeling and service-life prediction of concrete under freeze–thaw action. Mater. Struct. 2015, 48, 2697–2711. [Google Scholar] [CrossRef]

- ASTM C150/C150M-12. Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- GB 175-2007. Common Portland Cement; Chinese Standard Institution Press: Beijing, China, 2007. [Google Scholar]

- GB/T 50082-2009. Standard for Test Method of Long-Term Performance and Durability of Ordinary Concrete; Chinese Standard Institution Press: Beijing, China, 2009. [Google Scholar]

- Zhao, X. Experimental Study on Tunnels Sprayed Concrete Frost-Resistance and Durability. Master’s Thesis, Chang’an University, Xi’an, China, June 2011. (In Chinese). [Google Scholar]

- Cao, X.; Cao, Z.; Yu, X. Experimental study on the influence of freeze-thaw cycle on concrete mass loss and relative dynamic modulus. Railw. Eng. 2013, 43, 125–127. (In Chinese) [Google Scholar]

- Chaboche, J.L.; Lesne, P.M. A non-linear continuous fatigue damage model. Fatigue Fract. Eng. Mater. Struct. 1988, 11, 1–17. [Google Scholar] [CrossRef]

- Zhang, J.; Fan, Z.; Fang, K.; Pei, J.; Xu, L. Development and validation of nonlinear viscoelastic damage (NLVED) model for three-stage permanent deformation of asphalt concrete. Constr. Build. Mater. 2016, 102, 384–392. [Google Scholar] [CrossRef]

- Chaboche, J.L. Continuum Damage Mechanics: Part II—Damage Growth, Crack Initiation, and Crack Growth. J. Appl. Mech. 1988, 55, 65–72. [Google Scholar] [CrossRef]

- Lemaitre, J.; Plumtree, A. Application of Damage Concepts to Predict Creep-Fatigue Failures. J. Eng. Mater. Technol. 1979, 101, 284–292. [Google Scholar] [CrossRef]

- Shang, D.; Wang, D.; Yao, W. Study on nonlinear continuum multiaxial fatigue cumulative damage model. Acta Mech. Solida Sin. 1999, 20, 325–330. (In Chinese) [Google Scholar]

- Pei, W. Model analysis of freeze-thaw damage deterioration of concrete based on fatigue damage theory. Railway Constr. Tech. 2014, 31, 51–54. (In Chinese) [Google Scholar]

- Baktheer, A.; Chudoba, R. Classification and evaluation of phenomenological numerical models for concrete fatigue behavior under compression. Constr. Build. Mater. 2019, 221, 661–677. [Google Scholar] [CrossRef]

| Constituent (wt.%) | SiO2 | Al2O3 | CaO | MgO | SO3 | Fe2O3 | Na2O | K2O | LOI 1 |

|---|---|---|---|---|---|---|---|---|---|

| PO42.5 | 32.25 | 13.04 | 43.24 | 1.25 | 2.1 | 3.56 | 0.45 | 0.85 | 3.02 |

| PC32.5R | 38.23 | 18.51 | 25.36 | 2.76 | 2.31 | 3.75 | 0.22 | 1.76 | 6.97 |

| Strength | Group | Water-Cement Ratio | Material Dosage (kg) | |||

|---|---|---|---|---|---|---|

| Water | Cement | Sand | Gravel | |||

| C20 | OC-1 | 0.51 | 195 | 382 | 620 | 1203 |

| C30 | OC-2 | 0.49 | 195 | 398 | 605 | 1202 |

| C40 | OC-3 | 0.38 | 195 | 513 | 557 | 1185 |

| Months | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Average relative humidity (%) | 74 | 73 | 72 | 71 | 71 | 76 | 80 | 80 | 78 | 75 | 76 | 73 |

| Maximum average temperature (°C) | 7.2 | 9.5 | 14.2 | 20.7 | 26.2 | 29.1 | 32.2 | 31.7 | 27.7 | 22.5 | 16.2 | 9.9 |

| Minimum average temperature (°C) | −0.7 | 1.4 | 5.3 | 11 | 16.5 | 21 | 24.9 | 24.4 | 19.9 | 13.6 | 6.8 | 1.1 |

| Cycle Times | Resonant Frequency (Hz) | Weight (g) | ||||

|---|---|---|---|---|---|---|

| C20 | C30 | C40 | C20 | C30 | C40 | |

| Initial value | 2034.33 | 2032.67 | 2100.56 | 9782.00 | 9772.00 | 9736.67 |

| 1 | 1989.11 | 1973.89 | 2051.44 | 9728.00 | 9736.67 | 9716.67 |

| 2 | 1966.78 | 1954.67 | 2031.22 | 9704.67 | 9722.00 | 9704.67 |

| 3 | 1951.44 | 1942.67 | 2020.33 | 9684.67 | 9710.67 | 9696.00 |

| 4 | 1935.11 | 1924.11 | 2005.22 | 9674.00 | 9701.33 | 9690.00 |

| 5 | 1937.00 | 1931.44 | 2014.11 | 9660.00 | 9695.33 | 9685.33 |

| 6 | 1933.56 | 1928.56 | 2010.44 | 9654.67 | 9686.67 | 9680.67 |

| 7 | 1924.00 | 1918.56 | 2000.78 | 9640.00 | 9678.67 | 9670.00 |

| 8 | 1926.33 | 1922.67 | 2004.89 | 9638.00 | 9671.33 | 9673.33 |

| 9 | 1922.78 | 1919.44 | 2000.33 | 9629.33 | 9666.67 | 9666.00 |

| 10 | 1923.56 | 1921.33 | 2004.00 | 9621.33 | 9664.67 | 9663.33 |

| 11 | 1920.56 | 1916.89 | 1998.89 | 9616.00 | 9658.67 | 9660.00 |

| 12 | 1920.00 | 1916.78 | 1997.78 | 9611.33 | 9656.00 | 9659.33 |

| 13 | 1915.56 | 1912.89 | 1995.33 | 9608.67 | 9650.67 | 9655.33 |

| 14 | 1918.22 | 1914.89 | 1998.33 | 9604.67 | 9646.67 | 9652.67 |

| 15 | 1913.56 | 1911.78 | 1993.67 | 9602.00 | 9645.33 | 9651.33 |

| Researchers | Concrete Type | Strength Grade (MPa) | Fatigue Cycle (h) | Maximum Number of Cycles | Equivalent Duration (d) | Type of Fatigue Action | Legend in Figure |

|---|---|---|---|---|---|---|---|

| Zhao, X. [47] | Shotcrete | C30 | 4 | 100 | 17 | Freeze-thaw cycle (FTC) | X.Z.SC-C30FT |

| Zhao, Y. [11] | Ordinary (OP) | C45 | 5 | 250 | 52.1 | Y.Z.OP-C45FT | |

| Zhang, P. [17] | C40 | 3.6 | 100 | 15 | P.Z.OP-C40FT | ||

| Zhang, D. [2] | C30 | 4 | 150 | 21.9 | D.Z.OP-C30FT | ||

| Cao, X. [48] | Air-entrained | C40 | 2.5 | 350 | 36.5 | X.C.AE-C40FT | |

| C45 | X.C.AE-C55FT | ||||||

| Chen, D. (this paper) | Ordinary (OP) | C20 | 24 | 15 | 15 | Periodic temperature and humidity (PTH) | D.C.OP-C20PTH |

| C30 | D.C.OP-C30PTH | ||||||

| C40 | D.C.OP-C40PTH |

| Number of Cycles | Relative Dynamic Elastic Modulus of Concrete | ||

|---|---|---|---|

| C20 | C30 | C40 | |

| Initial Value | 1 | 1 | 1 |

| 1 | 0.9541 | 0.9412 | 0.9480 |

| 2 | 0.9293 | 0.9198 | 0.9267 |

| 3 | 0.9144 | 0.9090 | 0.9179 |

| 4 | 0.8972 | 0.8917 | 0.9048 |

| 5 | 0.8992 | 0.8975 | 0.9124 |

| 6 | 0.8960 | 0.8934 | 0.9080 |

| 7 | 0.8829 | 0.8838 | 0.8990 |

| 8 | 0.8867 | 0.8867 | 0.9018 |

| 9 | 0.8805 | 0.8826 | 0.8976 |

| 10 | 0.8805 | 0.8858 | 0.9001 |

| 11 | 0.8785 | 0.8811 | 0.8957 |

| 12 | 0.8762 | 0.8791 | 0.8949 |

| 13 | 0.8732 | 0.8768 | 0.8916 |

| 14 | 0.8753 | 0.8779 | 0.8946 |

| 15 | 0.8709 | 0.8738 | 0.8892 |

| Concrete | M1 ≠ 1 | M2 (M1 = 1) | |

|---|---|---|---|

| M1 | M2 | ||

| C20 | 26.54 | 0.1103 | 0.01672 |

| C30 | 36.11 | 0.2566 | 0.0168 |

| C40 | 44.53 | 0.2798 | 0.0145 |

| Model Types | Concrete Strength | Parameter | |||

|---|---|---|---|---|---|

| SSE | R-Square | Adjusted R-Square | RMSE | ||

| M1 = 1 | C20 | 0.007366 | 0.4708 | 0.4708 | 0.02714 |

| C30 | 0.01057 | 0.1528 | 0.1528 | 0.03251 | |

| C40 | 0.00865 | 0.0734 | 0.0734 | 0.02941 | |

| M1 ≠ 1 | C20 | 0.0001785 | 0.9872 | 0.9858 | 0.004453 |

| C30 | 0.0002001 | 0.984 | 0.9822 | 0.004715 | |

| C40 | 0.0001799 | 0.9809 | 0.9788 | 0.004446 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, D.; Zou, J.; Zhao, L.; Xu, S.; Xiang, T.; Liu, C. Degradation of Dynamic Elastic Modulus of Concrete under Periodic Temperature-Humidity Action. Materials 2020, 13, 611. https://doi.org/10.3390/ma13030611

Chen D, Zou J, Zhao L, Xu S, Xiang T, Liu C. Degradation of Dynamic Elastic Modulus of Concrete under Periodic Temperature-Humidity Action. Materials. 2020; 13(3):611. https://doi.org/10.3390/ma13030611

Chicago/Turabian StyleChen, Depeng, Jiajia Zou, Liang Zhao, Shidai Xu, Tengfei Xiang, and Chunlin Liu. 2020. "Degradation of Dynamic Elastic Modulus of Concrete under Periodic Temperature-Humidity Action" Materials 13, no. 3: 611. https://doi.org/10.3390/ma13030611

APA StyleChen, D., Zou, J., Zhao, L., Xu, S., Xiang, T., & Liu, C. (2020). Degradation of Dynamic Elastic Modulus of Concrete under Periodic Temperature-Humidity Action. Materials, 13(3), 611. https://doi.org/10.3390/ma13030611