Performance Evaluation of Pavement Geomaterials Stabilized with Pond Ash and Brick Kiln Dust Using Advanced Cyclic Triaxial Testing

Abstract

1. Introduction

- An in-depth characterization of the waste materials was performed for understanding the governing mechanism responsible for imparting strength and stiffness to the waste stabilized geomaterial. Safe application of the waste was ensured by testing leachate emanating from the wastes for concentration of toxic elements.

- The performance evaluation of pond ash and brick kiln dust stabilized geomaterial was done using advanced cyclic triaxial testing to stimulate field conditions in the laboratory.

2. Test Materials

3. Test Methods

3.1. Characterization of Waste Materials

3.2. Engineering Characteristics of Waste Stabilized Geomaterial

3.3. Advanced Cyclic Triaxial Testing for Determination of Resilient Modulus

4. Results and Discussion

4.1. Characteristics of the Wastes

4.1.1. Physical

4.1.2. Chemical

4.1.3. Minerological

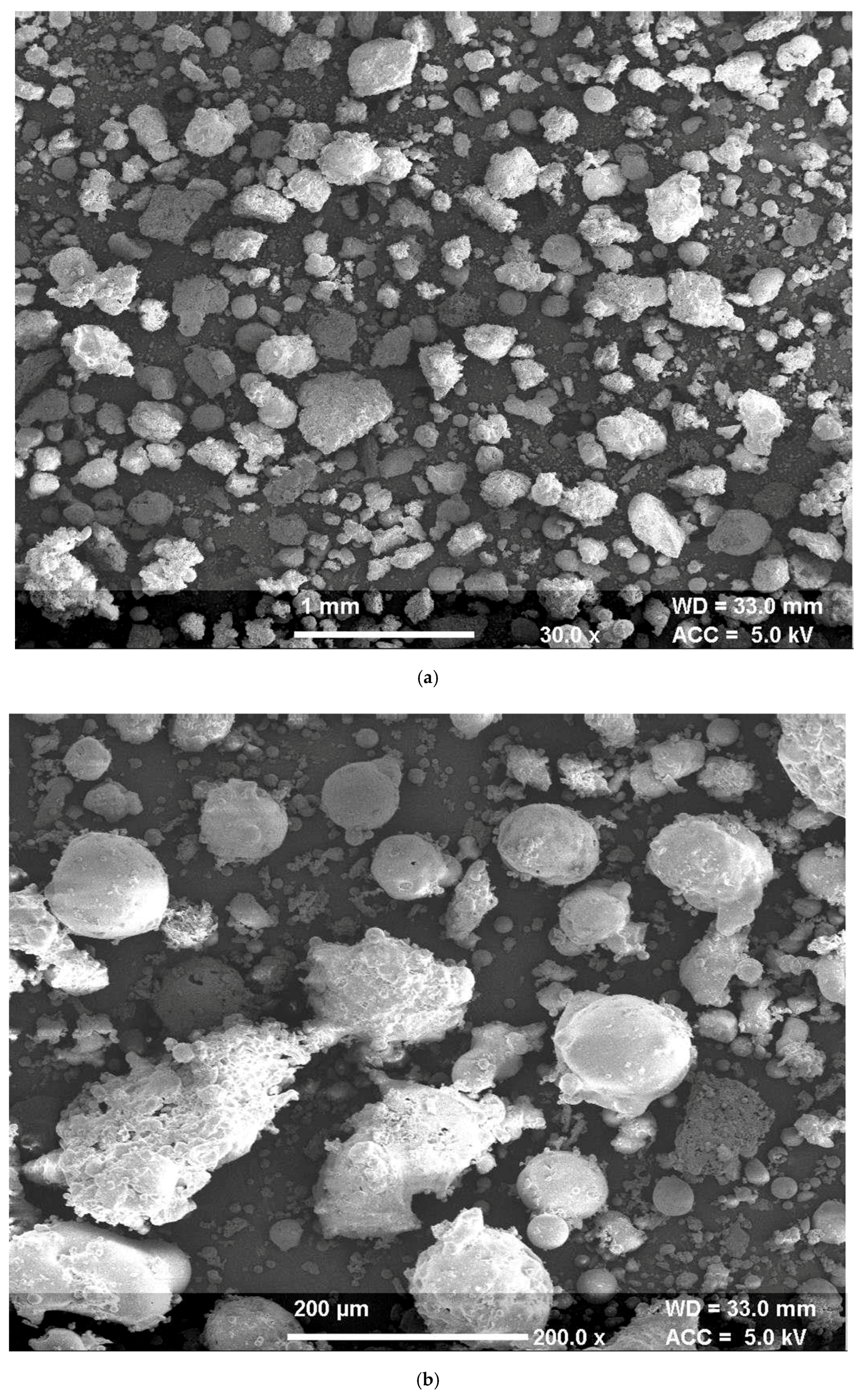

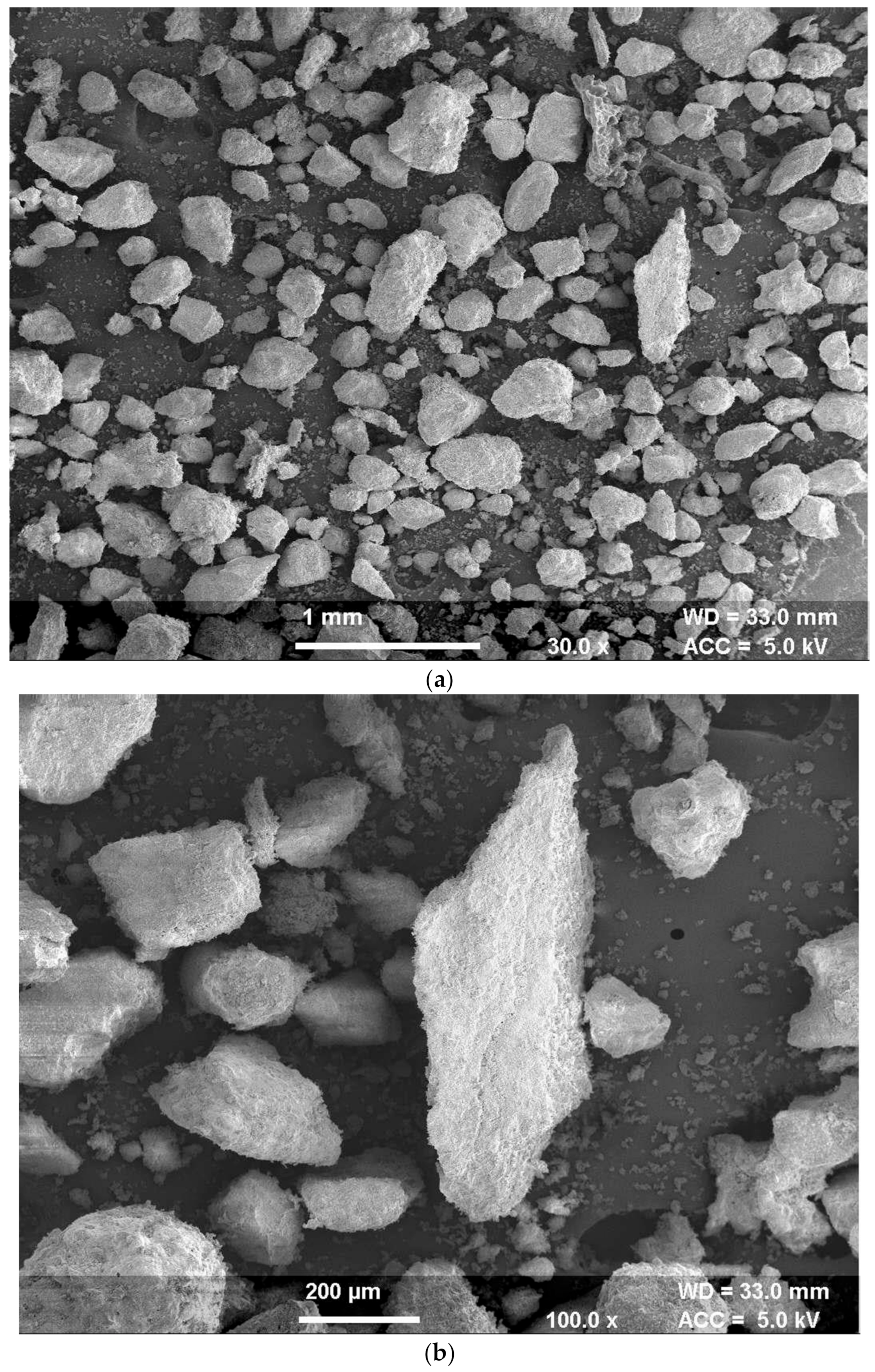

4.1.4. Microstructural

4.1.5. Mechanical

4.1.6. Toxicity

4.2. Engineering Characteristics of Waste Stabilized Geomaterial

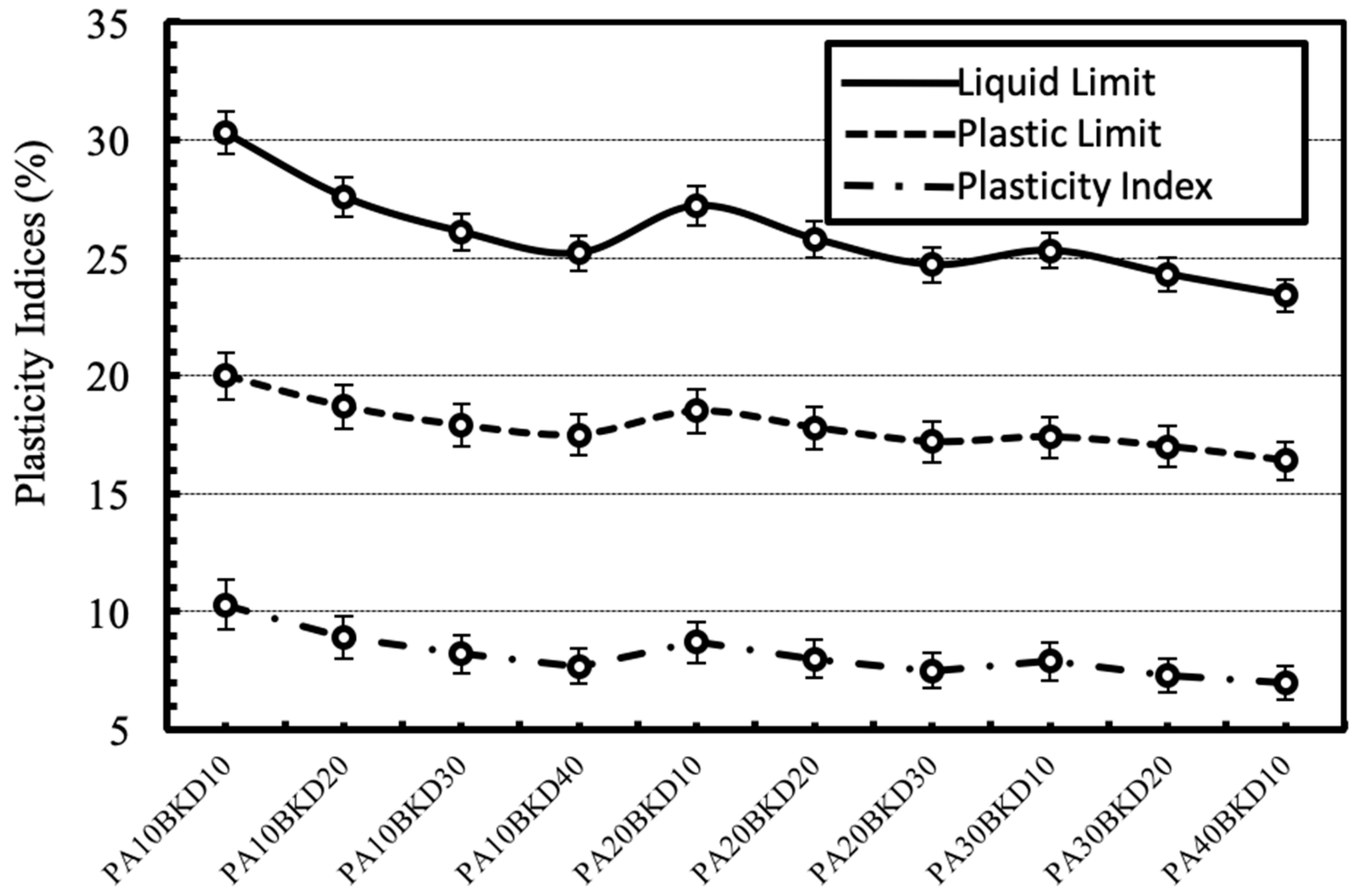

4.2.1. Plasticity

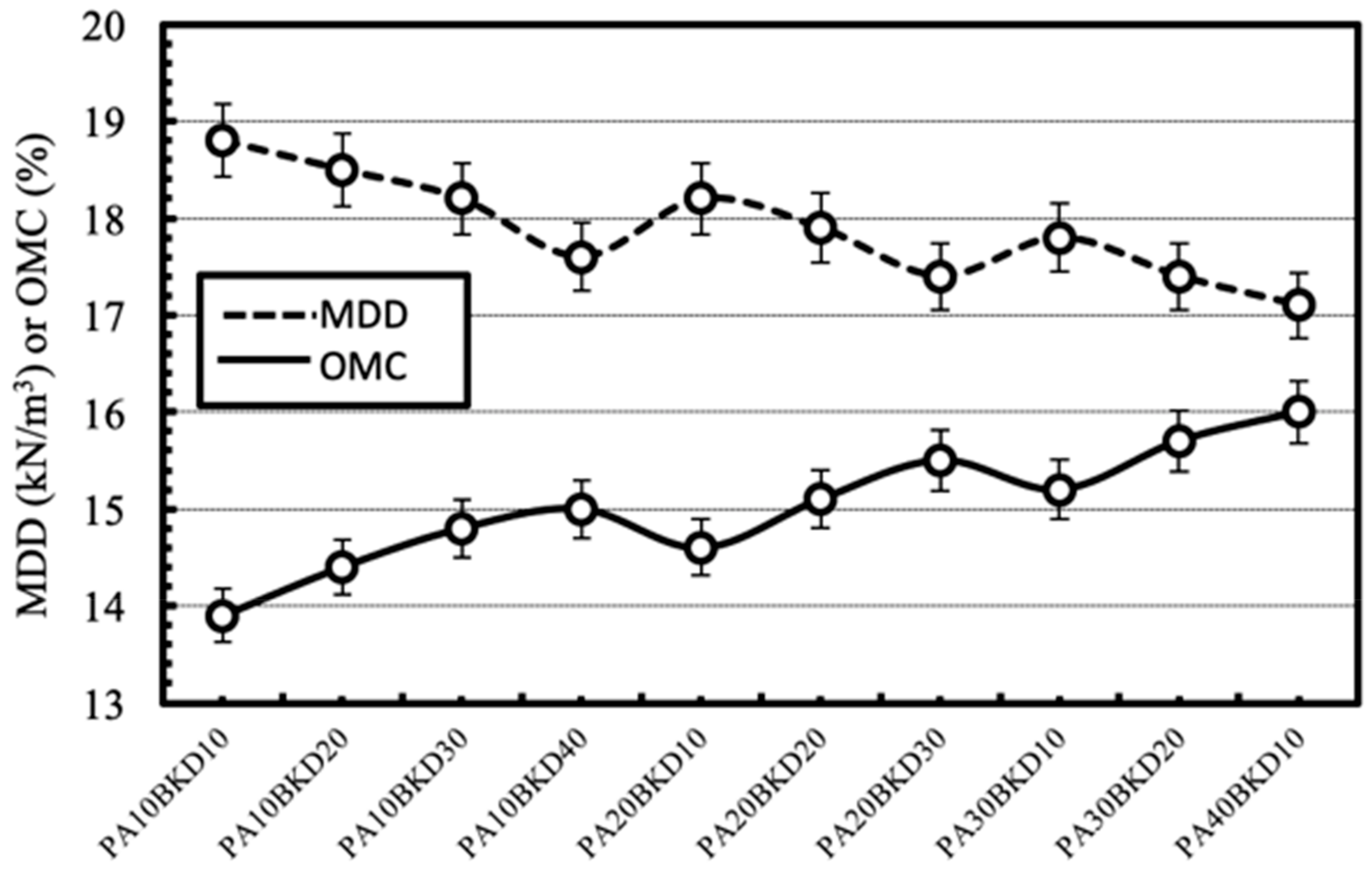

4.2.2. Compaction

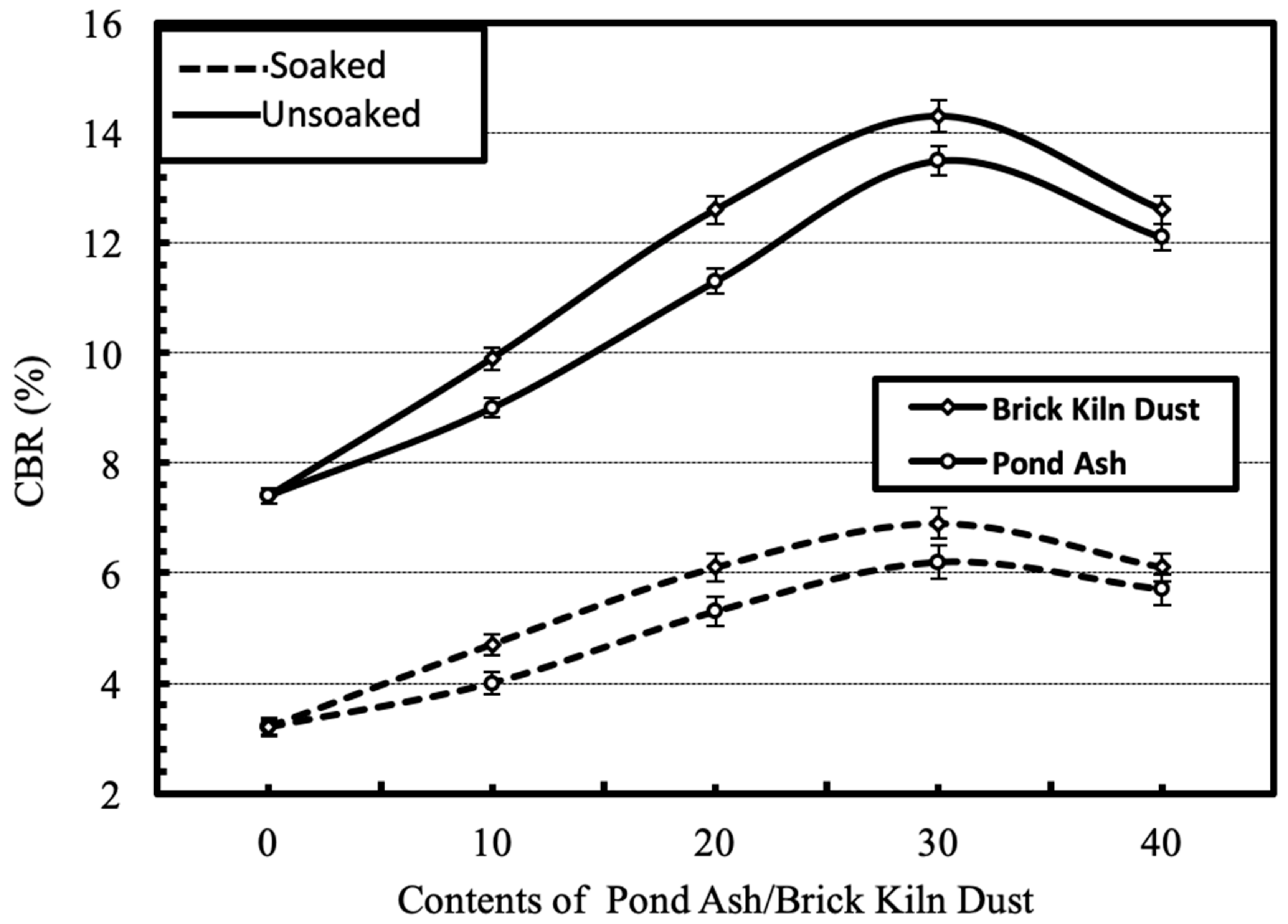

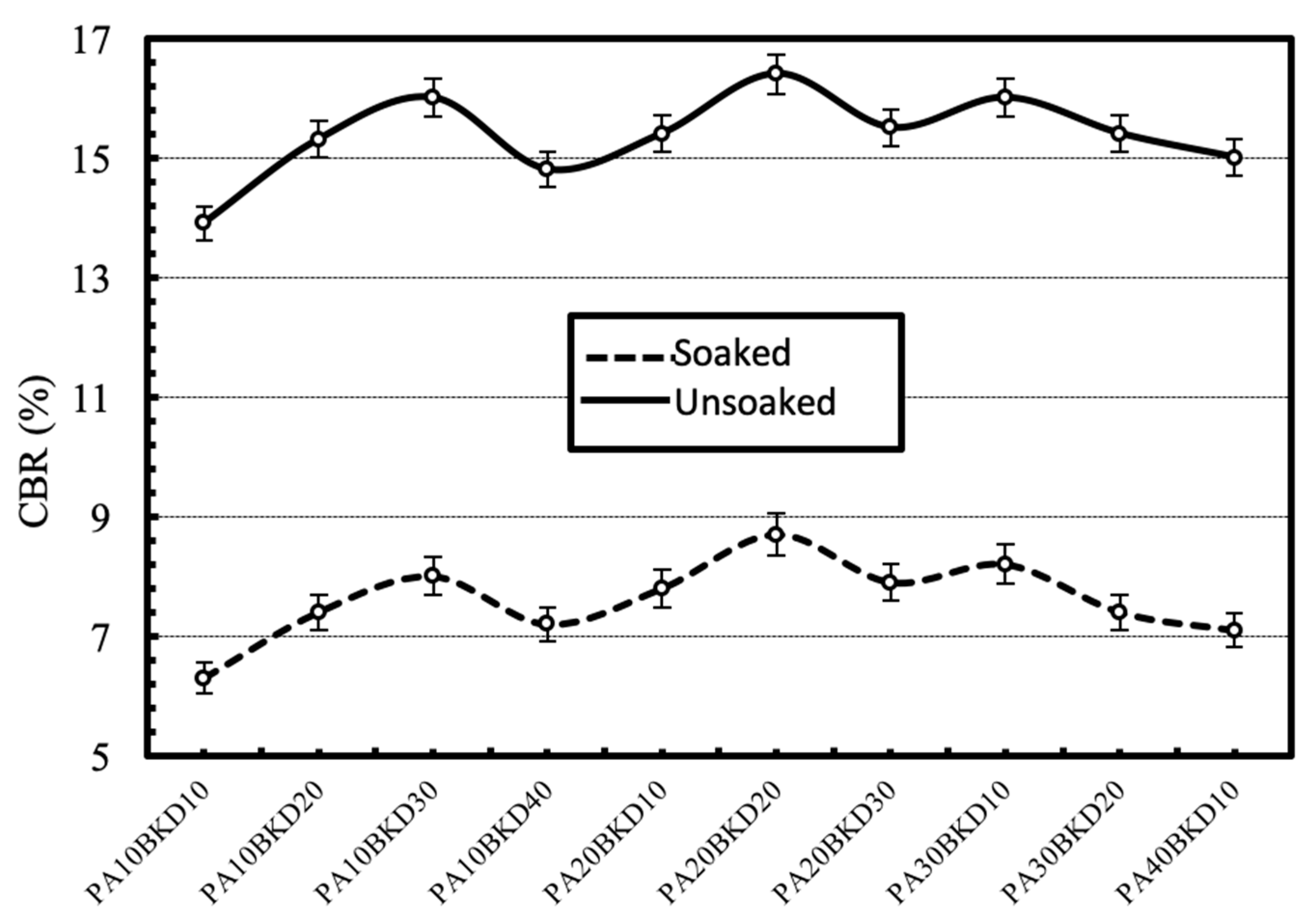

4.2.3. Strength

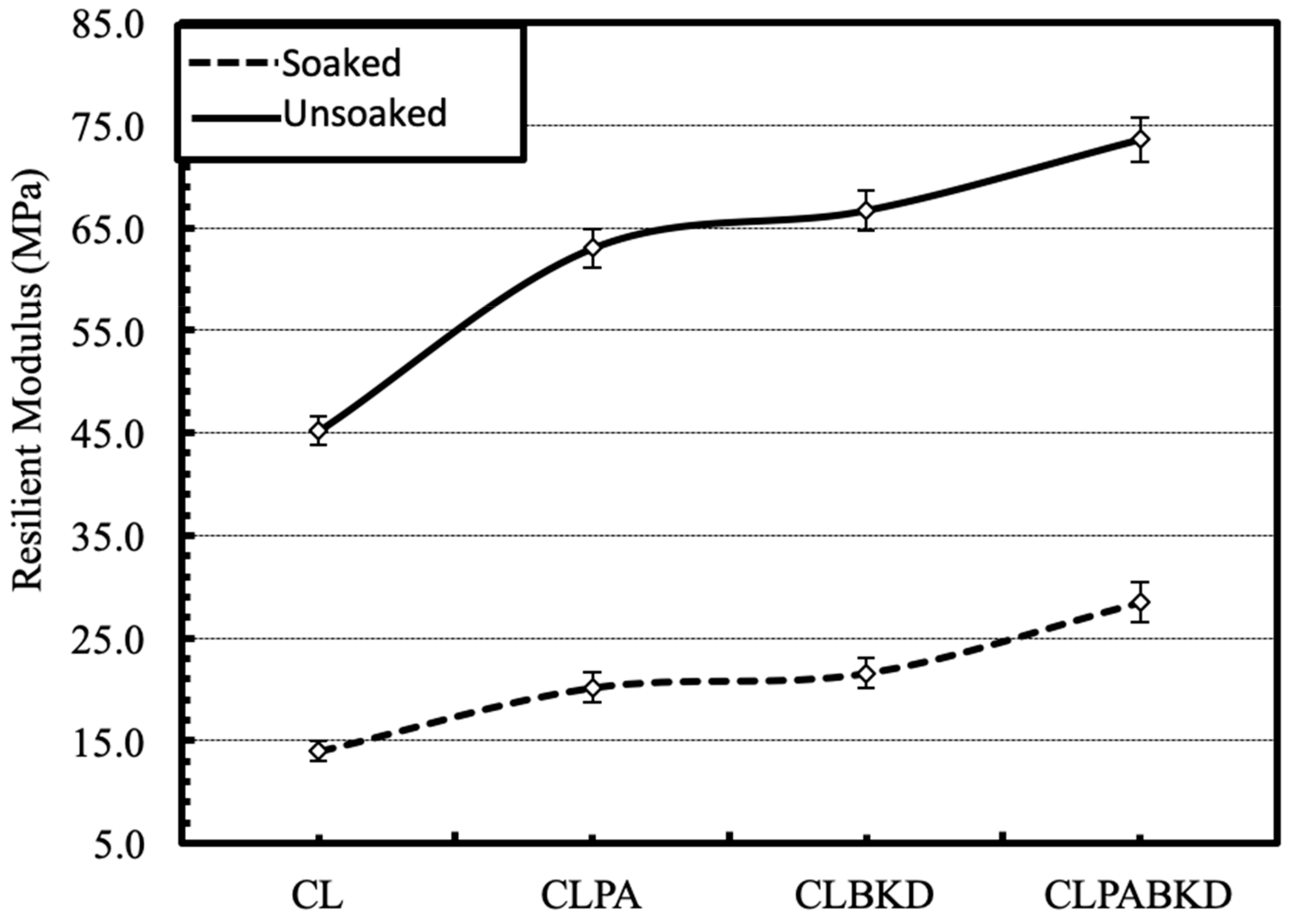

4.3. Resilient Modulus of Waste Stabilized Geomaterials

4.3.1. Effect of the Stabilization

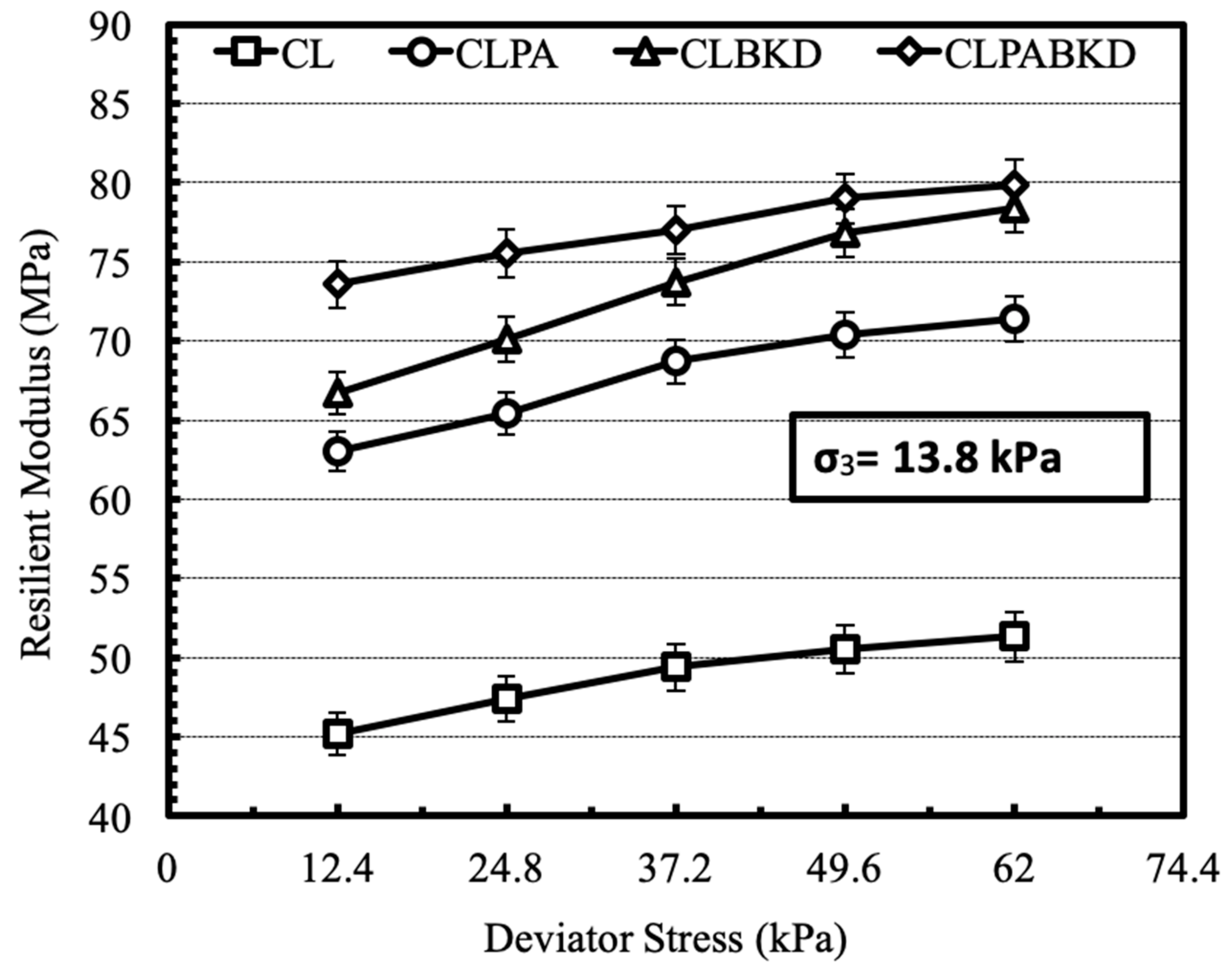

4.3.2. Effect of Deviator Stress

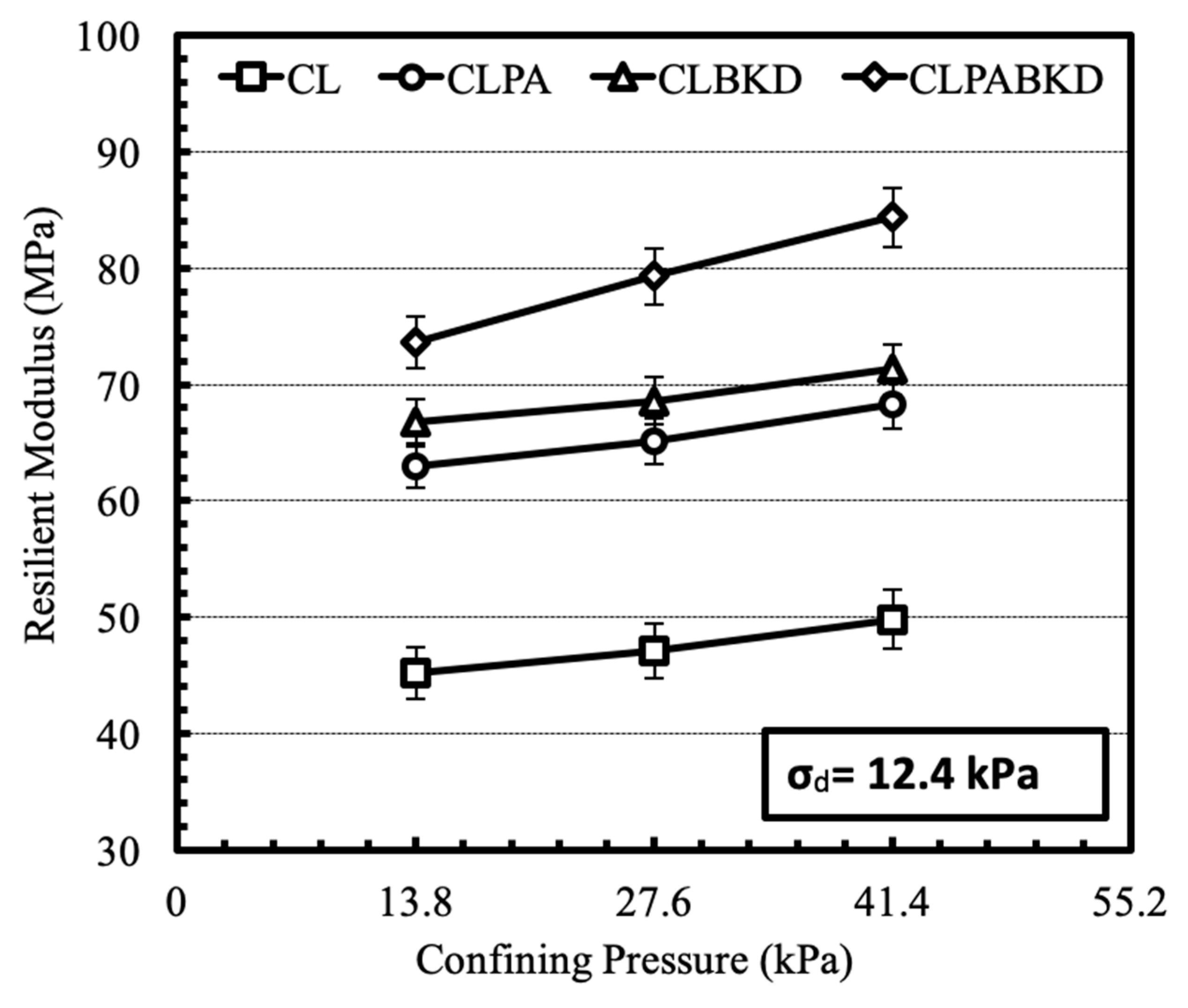

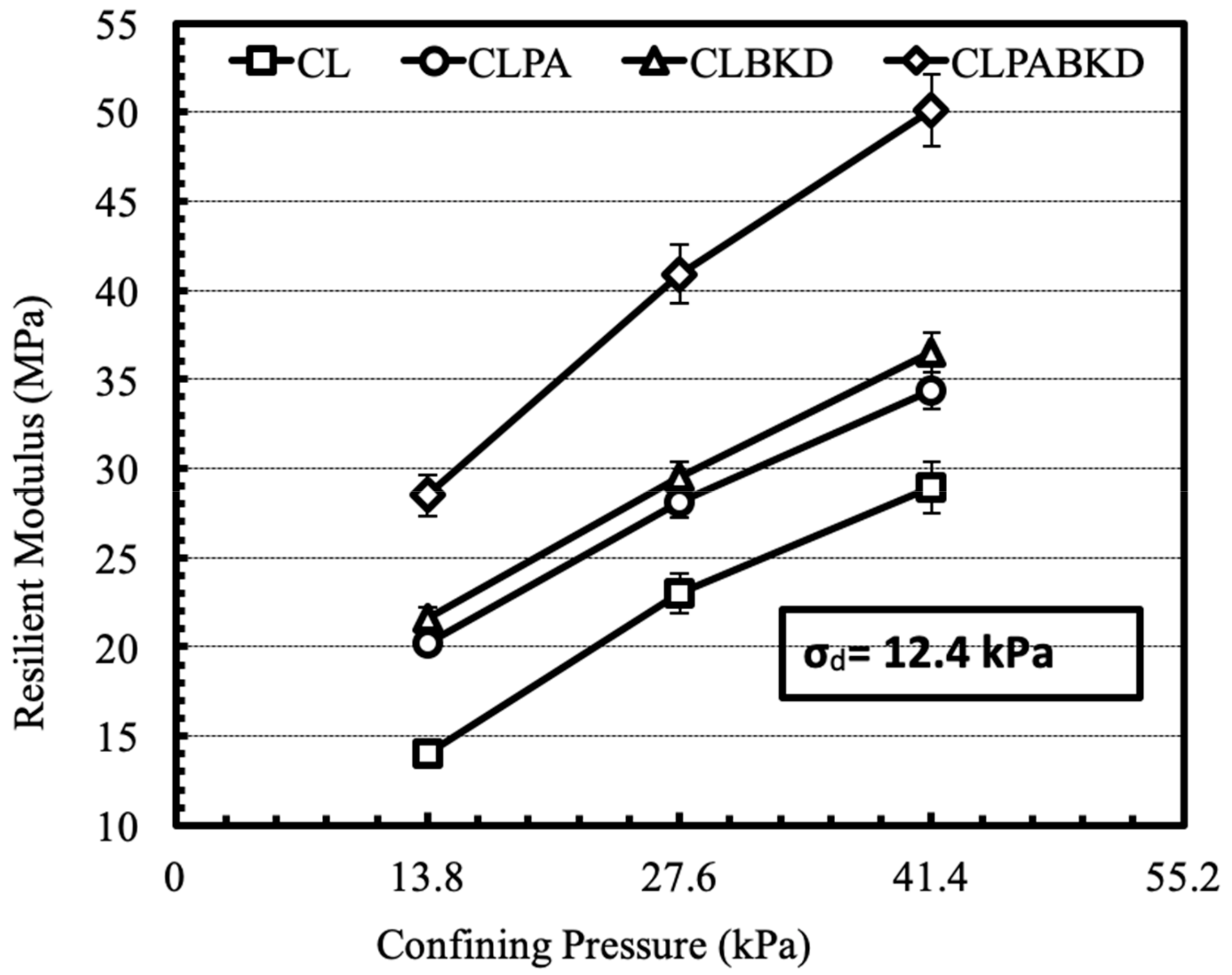

4.3.3. Effect of Confining Pressure

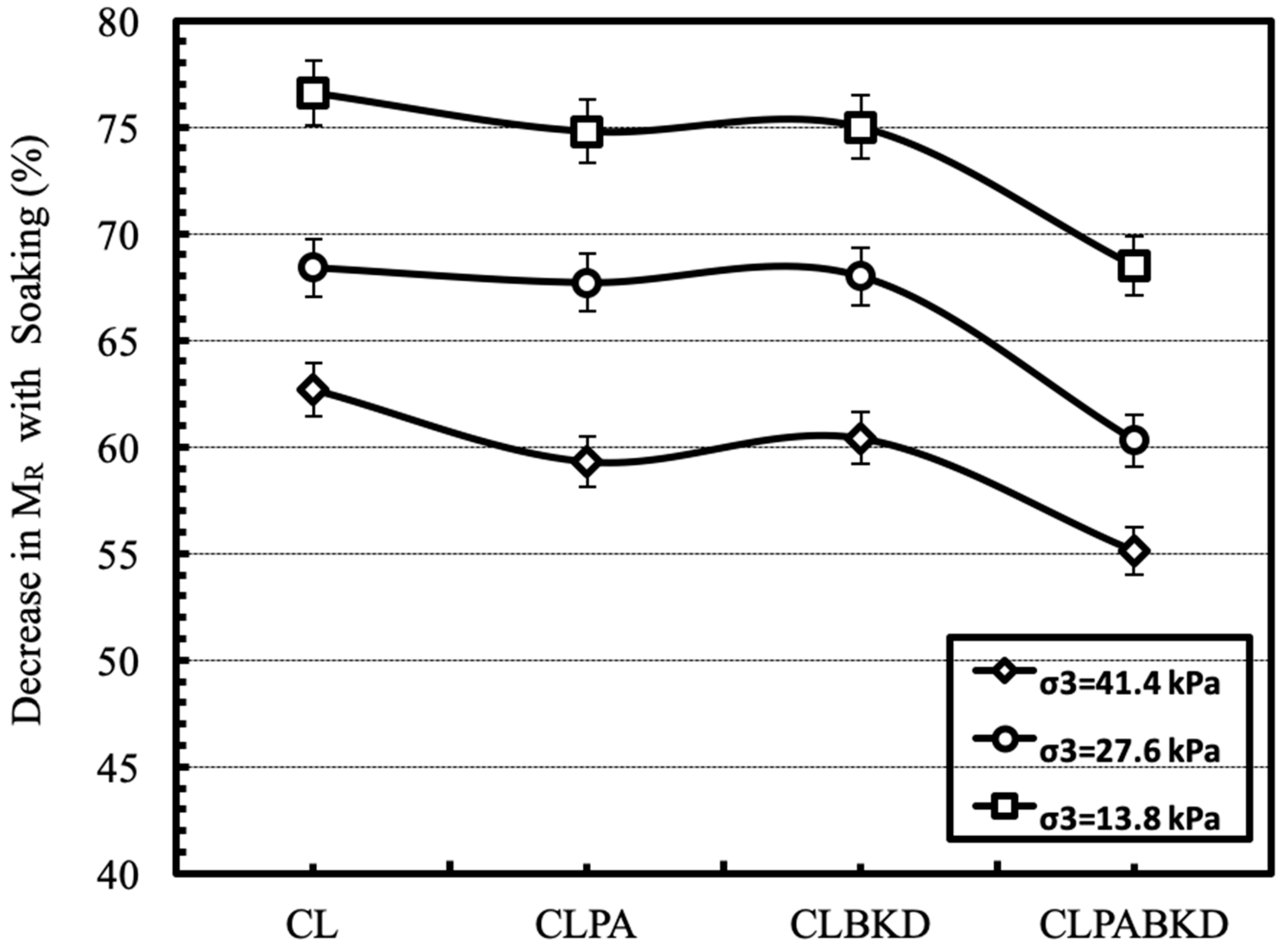

4.3.4. Effect of Saturation

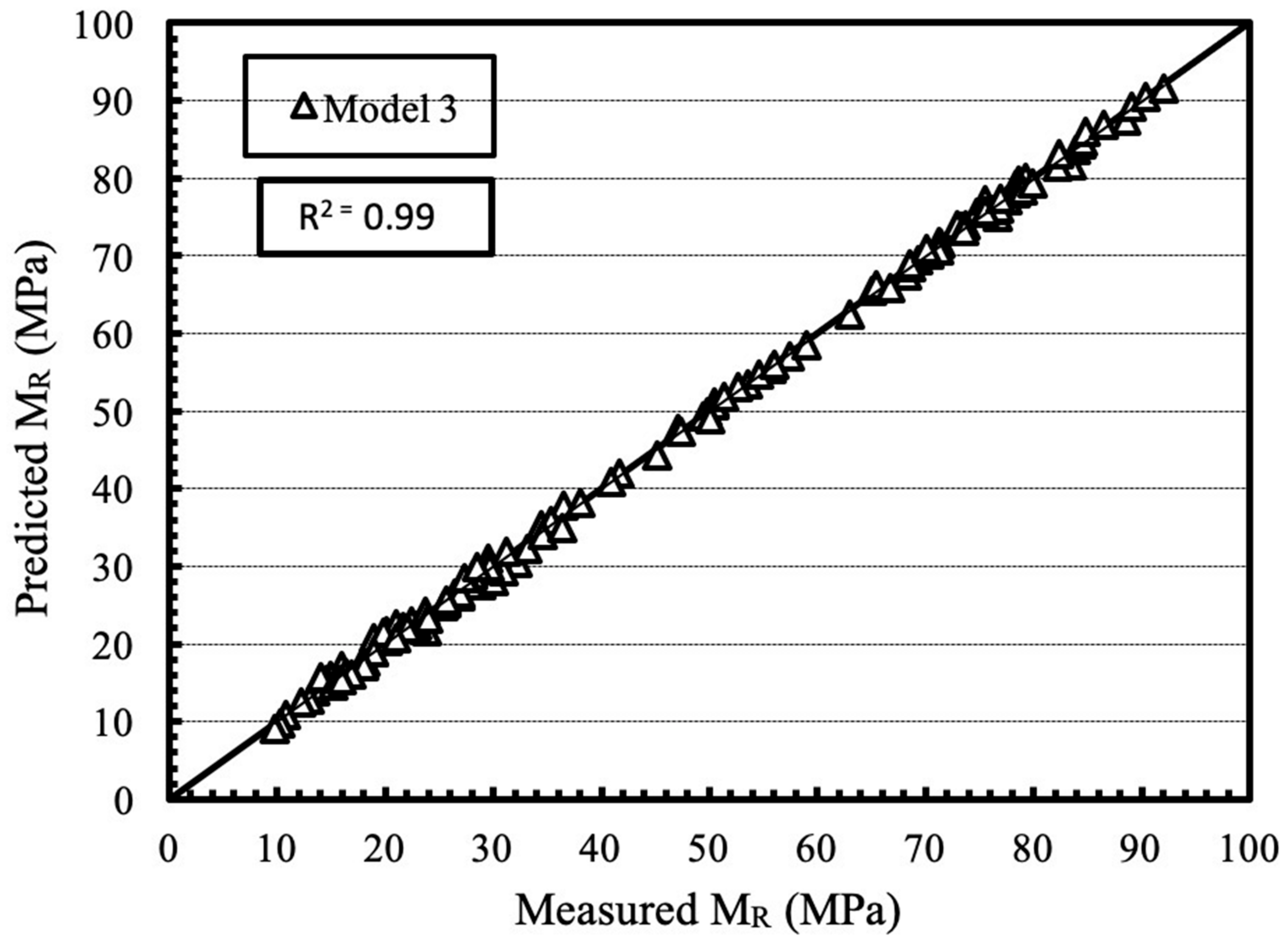

4.3.5. Mathematical Models for Prediction of Resilient Modulus

5. Conclusions

- Pond ash and brick kiln dust comprise of sand and silt size particles with low specific gravity that do not possess cementitious or pozzolanic properties. Spherical shape of pond ash particles and angular shape of brick kiln dust particles were observed through SEM analysis.

- With the increase in pond ash or brick kiln dust content, the maximum dry density and plasticity indices of the geomaterial decreases, and the optimum moisture content of the geomaterial increases.

- Increase in pond ash or brick kiln dust proportion continuously increases the CBR of the geomaterial up to the optimum contents of 30% pond ash, 30% brick kiln dust and a combination of 20% pond ash and 20% brick kiln dust, beyond which the CBR values decreases.

- Advanced cyclic triaxial testing results show that the MR for the optimized CLPA mixture increase by 39.1% and 44.3%, CLBKD mixture increase by 47.2% and 54.4%, CLPABKD mixture increase by 62.8% and 103.6% for samples tested for unsoaked and soaked conditions.

- Strain hardening was witnessed in samples tested under unsoaked conditions whereas strain softening was witnessed in samples tested under soaked conditions, during cyclic loading. The MR was reported to increase with increase in confining pressure for all the mixtures. Samples tested under soaked conditions showed a decrease in the range of 60% to 70% as compared to MR of the unsoaked sample. The three-parameter model (Model 3) provided the best fit among different models.

- The concentrations of toxic elements in pond ash and brick kiln dust were well below the allowable limits for hazardous wastes and thereby are permitted for use as construction materials. A low value of LOI (<5%) assures no risk of spontaneous heating or combustion of the wastes.

Author Contributions

Funding

Conflicts of Interest

References

- Mishra, U.C. Environmental impact of coal industry and thermal power plants in India. J. Environ. Radioact. 2004, 72, 35–40. [Google Scholar] [CrossRef]

- Chikkatur, A.P.; Sagar, A.D.; Sankar, T.L. Sustainable development of the Indian coal sector. Energy 2009, 34, 942–953. [Google Scholar] [CrossRef]

- Dudhley, B. BP Statistical Review of World Energy 2019; British Petroleum: London, UK, 2019. [Google Scholar]

- Jakka, R.S.; Datta, M.; Ramana, G.V. Liquefaction behaviour of loose and compacted pond ash. Soil Dyn. Earthq. Eng. 2010, 30, 580–590. [Google Scholar] [CrossRef]

- Singh, G. Ash Availability & Utilization Portal. Available online: https://www.ntpc.co.in/en/ash-availability (accessed on 3 October 2019).

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Mills, S. Coal Use in the New Economies of China, India and South Africa; IEA Clean Coal Centre: London, UK, 2010. [Google Scholar]

- Singh, A.L.; Asgher, M.S. Impact of brick kilnson land use/land cover changes around Aligarhcity, India. HabitatInt. 2005, 29, 591–602. [Google Scholar]

- Lalchandani, D.; Maithel, S. Towards Cleaner Brick Kilns in India. Available online: https://shaktifoundation.in/wp-content/uploads/2014/02/CATF-2013-Towards-Cleaner-Brick-Kilns-in-India.pdf (accessed on 4 October 2019).

- Upadhyay, E. Impact of Particulate Air Pollutants on Brassicajuncea L. and Linumusitatissimum L. Ph.D. Thesis, Aligarh Muslim University, Aligarh, India, 2004. [Google Scholar]

- Warren, C.J.; Dudas, M.J. Leaching behaviour of selected trace elements in chemically weathered alkaline fly ash. Sci. Total Environ. 1988, 76, 229–246. [Google Scholar] [CrossRef]

- Sushil, S.; Batra, V.S. Analysis of fly ash heavy metal content and disposal in three thermal power plants in India. Fuel 2006, 85, 2676–2679. [Google Scholar] [CrossRef]

- Praharaj, T.; Powell, M.A.; Hart, B.R.; Tripathy, S. Leachability of elements from subbituminous coal fly ash from India. Environ. Int. 2002, 27, 609–615. [Google Scholar] [CrossRef]

- Mondal, A.; Das, S.; Sah, R.K.; Bhattacharyya, P.; Bhattacharya, S.S. Environmental footprints of brick kiln bottom ashes: Geostatistical approach for assessment of metal toxicity. Sci. Total Environ. 2017, 609, 215–224. [Google Scholar] [CrossRef]

- Nicholson, P.G.; Kashyap, V. Fly ash stabilization of tropical Hawaiian soils. Fly Ash Soil Improv. 1993, 36, 15–29. [Google Scholar]

- Cokca, E. Use of class C fly ashes for the stabilization of an expansive soil. J. Geotech. Geoenviron. Eng. 2002, 127, 568–573. [Google Scholar] [CrossRef]

- Seed, H.B.; Chan, C.K.; Monismith, C.L. Effects of repeated loading on the strength and deformation of compacted clay. Proc. Highw. Res. Board 1955, 34, 541–558. [Google Scholar]

- AASHTO. Mechanistic-Empirical Pavement Design Guide: A Manual of Practice; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015. [Google Scholar]

- Austroads. Guide to Pavement Technology Part 2: Pavement Structural Design; Publication No: AGPT02-17 Edition 4.2; Austroads: Sydney, Australia, 2018. [Google Scholar]

- Indian Road Congress. Guidelines for the Design of Flexible Pavements Publication No. 37; Indian Road Congress: New Delhi, India, 2018. [Google Scholar]

- Bera, A.K.; Kumar, A. Effect of pond ash content on engineering properties of fine grained soil. In Proceedings of the Indian Geotechnical Society-Geotrendz, Indian Geotechnical Society, Mumbai, India, 16–18 December 2010; pp. 405–408. [Google Scholar]

- Gupta, D.; Kumar, A. Strength characterization of cement stabilized and fiber reinforced clay–pond ash mixes. Int. J. Geosynth. Ground Eng. 2016, 2, 32. [Google Scholar] [CrossRef]

- Gupta, D.; Kumar, A. Performance evaluation of cement-stabilized pond ash-rice husk ash-clay mixture as a highway construction material. J. Rock Mech. Geotech. Eng. 2017, 9, 159–169. [Google Scholar] [CrossRef]

- Gupta, G.; Sood, H.; Gupta, P.K. Brick kiln dust waste management through soil stabilization. In International Conference on Sustainable Waste Management Through Design; Singh, H., Garg, P., Kaur, I., Eds.; Springer: Cham, Switzerland, 2018; pp. 422–431. [Google Scholar]

- Gupta, G.; Sood, H.; Gupta, P.K. Life-cycle cost analysis of brick kiln dust stabilized perpetual pavements for lowering greenhouse gas emissions in India. In Urbanization Challenges in Emerging Economies: Resilience and Sustainability of Infrastructure; Singh, U.P., Babu, G.L.S., Eds.; ASCE: Reston, VA, USA, 2018; pp. 377–390. [Google Scholar]

- Edil, T.B.; Acosta, H.A.; Benson, C.H. Stabilizing soft fine-grained soils with fly ash. J. Mater. Civ. Eng. 2006, 18, 283–294. [Google Scholar] [CrossRef]

- Solanki, P.; Khoury, N.; Zaman, M.M. Engineering properties and moisture susceptibility of silty clay stabilized with lime, class C fly ash, and cement kiln dust. J. Mater. Civ. Eng. 2009, 21, 749–757. [Google Scholar] [CrossRef]

- Orakoglu, M.E.; Liu, J.; Lin, R.; Tian, Y. Performance of clay soil reinforced with fly ash and lignin fiber subjected to freeze-thawcycles. J. Cold Reg. Eng. 2017, 31, 04017013. [Google Scholar] [CrossRef]

- Choudhary, P.M.; Joshi, G.J.; Solanki, C.H.; Patel, S.; Reddy, L.M. Resilient modulus and permanent strain of clayey subgrade stabilized with fly ash. J. Eng. Technol. 2018, 7, 292–306. [Google Scholar]

- Vizcarra, G.O.; Casagrande, M.D.; da Motta, L.M. Applicability of municipal solid waste incineration ash on base layers of pavements. J. Mater. Civ. Eng. 2014, 26, 06014005. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, Y.; Wang, F.; Che, G.; Li, Q. Experimental research on resilient modulus of silty clay modified by oil shale ash and fly ash after freeze-thaw cycles. Appl. Sci. 2018, 8, 1298. [Google Scholar] [CrossRef]

- Asefzadeh, A.; Hashemian, L.; Bayat, A. The effect of bottom ash on soil suction and resilient modulus of medium plasticity clay. Transp. Res. Rec. 2018, 2672, 96–107. [Google Scholar] [CrossRef]

- Munoz, J.S.; Kaseer, F.; Arambula, E.; Martin, A.E. Use of the resilient modulus test to characterize asphalt mixtures with recycled materials and recycling agents. Transp. Res. Rec. 2015, 2506, 45–53. [Google Scholar] [CrossRef]

- Stafford, C.M.; Harrison, C.; Beers, K.L.; Karim, A.; Amis, E.J.; Van Landingham, M.R.; Kim, H.C.; Volksen, W.; Miller, R.D.; Simonyi, E.E. A buckling-based metrology for measuring the elastic moduli of polymeric thin films. Nat. Mater. 2004, 3, 545. [Google Scholar] [CrossRef] [PubMed]

- Bureau of Indian Standards. Method of Test for Soils Part 8: Determination of Water Content-Dry Density Relation Using Heavy Compaction; Publication No.IS 2720 Part 8; Bureau of Indian Standards: New Delhi, India, 1983.

- Bureau of Indian Standards. Method of Test for Soils Part16: Laboratory Determination of CBR; Publication No. IS 2720 Part 16; Bureau of Indian Standards: New Delhi, India, 1987.

- Bureau of Indian Standards. Chemical Analysis of Quartzite and High Silica Sand—Determination of Loss on Ignition; Publication No. IS1917 Part 1; Bureau of Indian Standards: New Delhi, India, 1991.

- Toxicity Characteristic Leaching Procedure. Method1311.InEPASW-846: Test method for Evaluating Solid Waste, Physical/Chemical Methods; USEPA: Washington, DC, USA, 1992.

- Bureau of Indian Standards. Method of Test for Soils Part 5: Determination of Liquid Limit and Plastic Limit; Publication No. IS 2720 Part 5; Bureau of Indian Standards: New Delhi, India, 1985.

- American Association of State Highway and Transportation Officials. Standard Method of Test for Determining the Resilient Modulus of Soils and Aggregate Materials; Publication No. AASHTO T-307-99; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2017. [Google Scholar]

- Barksdale, R.D. Compressive stress pulse times in flexible pavements for use in dynamic testing. Highw. Res. Rec. 1971, 345, 32–44. [Google Scholar]

- Pandian, N.S. Fly ash characterization with reference to geotechnical applications. J. Indian Inst. Sci. 2013, 84, 189–216. [Google Scholar]

- Trivedi, A.S.; Sud, V.K. Grain characteristics and engineering properties of coal ash. Granul. Matter 2002, 4, 93–101. [Google Scholar] [CrossRef]

- Suthar, M.; Aggarwal, P. Environmental impact and physicochemical assessment of pond ash for its potential application as a fill material. Int. J. Geosynth. Ground Eng. 2016, 2, 20. [Google Scholar] [CrossRef]

- Mohanty, S.; Patra, N.R. Geotechnical characterization of Panki and Panipat pond ash in India. Int. J. Geo-Eng. 2015, 6, 13. [Google Scholar] [CrossRef]

- Riaz, M.H.; Khitab, A.; Ahmed, S. Evaluation of sustainable clay bricks incorporating brick kiln dust. J. Build. Eng. 2019, 24, 100725. [Google Scholar] [CrossRef]

- Metwally, S.S.; El-Sherief, E.A.; Mekhamer, H.S. Fixed-bed column for the removal of cesium, strontium and lead ions from aqueous solution using brick kiln waste. Sep. Sci. Technol. 2019. [Google Scholar] [CrossRef]

- Ahmad, I.; Khan, M.I.; Khan, H.; Ishaq, M.; Khan, R.; Gul, K.; Ahmad, W. Pyrolysis of HDPE into fuel like products: Evaluating catalytic performance of plain and metal oxides impregnated waste brick kiln dust. J. Anal. Appl. Pyrolysis 2017, 124, 195–203. [Google Scholar] [CrossRef]

- Jakka, R.S.; Ramana, G.V.; Datta, M. Shear behaviour of loose and compacted pond ash. Geotech. Geol. Eng. 2010, 28, 763–778. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as a Mineral Admixture in Concrete; Publication No. ASTMC 618-19; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Ministry of Road Transport and Highways. Specifications for Road and Bridge Works; Fifth Revision; Indian Road Congress: New Delhi, India, 2013.

- Ng, K.; Henrichs, Z.R.; Ksaibati, K.; Wulff, S.S. Resilient modulus of subgrade materials for mechanistic-empirical pavement design guide. Road Mater. Pavement Des. 2017, 19, 1523–1545. [Google Scholar] [CrossRef]

- Witczak, M.; Uzan, J. The Universal Airport Design System; Report I of IV: Granular Material Characterization; Department of Civil Engineering, University of Maryland: College Park, MD, USA, 1988. [Google Scholar]

- Hicks, R.G.; Monismith, C.L. Factors influencing the resilient response of granular materials. Highw. Res. Rec. 1971, 345, 15–31. [Google Scholar]

- NCHRP (National Cooperative Highway Research Program). Laboratory Determination of Resilient Modulus for Flexible Pavement Design; Document 14 for Project 1–28; Transportation Research Board: Washington, DC, USA, 1997. [Google Scholar]

- Puppala, A.J.; Hoyos, L.R.; Potturi, A.K. Resilient moduli response of moderately cement treated reclaimed asphalt pavement aggregates. J. Mater. Civ. Eng. 2011, 23, 990–998. [Google Scholar] [CrossRef]

| Characteristics | Pond Ash | Brick Kiln Dust | Clay Geomaterial |

|---|---|---|---|

| Particle size distribution (%) | |||

| Gravel size (20.0–4.75 mm) | 0.0 | 0.0 | 0.0 |

| Sand size (4.75–0.075 mm) | 54.1 | 72.3 | 8.9 |

| Silt size (0.075–0.002 mm) | 45.9 | 27.7 | 72.4 |

| Clay size (<0.002 mm) | 0.0 | 0.0 | 18.7 |

| Colour | Grey | Red Brown | Brown |

| Specific Gravity | 2.0 | 2.20 | 2.76 |

| D60, mm | 0.10 | 0.18 | - |

| D30, mm | 0.030 | 0.079 | - |

| D10, mm | 0.015 | 0.038 | - |

| Uniformity coefficient (CU) | 6.7 | 4.7 | - |

| Coefficient of curvature (CC) | 0.6 | 0.9 | - |

| Liquid Limit (%) | - | - | 37.3 |

| Plastic Limit (%) | - | - | 24.9 |

| Plasticity Index (%) | Non-plastic | Non-plastic | 12.4 |

| USCS Classification | SM | SM | CL |

| Designation of the Mixtures | Pond Ash (%) | Brick Kiln Dust (%) | Clay Geomaterial (%) |

|---|---|---|---|

| PA10BKD10 | 10 | 10 | 80 |

| PA10BKD20 | 10 | 20 | 70 |

| PA10BKD30 | 10 | 30 | 60 |

| PA10BKD40 | 10 | 40 | 50 |

| PA20BKD10 | 20 | 10 | 70 |

| PA20BKD20 | 20 | 20 | 60 |

| PA20BKD30 | 20 | 30 | 50 |

| PA30BKD10 | 30 | 10 | 60 |

| PA30BKD20 | 30 | 20 | 50 |

| PA40BKD10 | 40 | 10 | 50 |

| Sequence No. | Confining Stress (kPa) | Cyclic Deviator Stress (kPa) | Contact Stress (kPa) | Total Cycles |

|---|---|---|---|---|

| 0 | 41.4 | 24.8 | 2.8 | 500–1000 |

| 1 | 41.4 | 12.4 | 1.4 | 100 |

| 2 | 41.4 | 24.8 | 2.8 | 100 |

| 3 | 41.4 | 37.3 | 4.1 | 100 |

| 4 | 41.4 | 49.7 | 5.5 | 100 |

| 5 | 41.4 | 62.0 | 6.9 | 100 |

| 6 | 27.6 | 12.4 | 1.4 | 100 |

| 7 | 27.6 | 24.8 | 2.8 | 100 |

| 8 | 27.6 | 37.3 | 4.1 | 100 |

| 9 | 27.6 | 49.7 | 5.5 | 100 |

| 10 | 27.6 | 62.0 | 6.9 | 100 |

| 11 | 13.8 | 12.4 | 1.4 | 100 |

| 12 | 13.8 | 24.8 | 2.8 | 100 |

| 13 | 13.8 | 37.3 | 4.1 | 100 |

| 14 | 13.8 | 49.7 | 5.5 | 100 |

| 15 | 13.8 | 62.0 | 6.9 | 100 |

| Elements as Oxides | Pond Ash (%) | Brick Kiln Dust (%) |

|---|---|---|

| SiO2 | 59.2 | 50.6 |

| Al2O3 | 30.9 | 19.4 |

| Fe2O3 | 4.2 | 11.4 |

| SiO2 + Al2O3 + Fe2O3 | 94.3 | 81.5 |

| CaO | 0.94 | 5.93 |

| K2O | 1.34 | 2.23 |

| TiO2 | 1.93 | 0.93 |

| P2O5 | 0.51 | 2.94 |

| MgO | 0.48 | 1.72 |

| Na2O | 0.17 | 0.87 |

| SO3 | 0.12 | 3.66 |

| MnO | 0.04 | 0.06 |

| LOI | 2.1 | 1.1 |

| Property | Pond Ash | Brick Kiln Dust |

|---|---|---|

| MDD (kN/m3) | 13.1 | 16.8 |

| OMC (%) | 21.2 | 18.5 |

| CBR (unsoaked) (%) | 9.4 | 11.2 |

| CBR (soaked) (%) | 6.1 | 7.8 |

| Permeability (cm/s) | 5.01 × 10−5 | 7.29 × 10−5 |

| Toxic Elements | Concentration (mg/L) | ||

|---|---|---|---|

| Pond Ash | Brick Kiln Dust | USEPA Limits for Hazardous Waste | |

| Chromium | BDL | BDL | 5.0 |

| Lead | 0.28 | 0.11 | 5.0 |

| Arsenic | BDL | 0.13 | 5.0 |

| Mercury | BDL | BDL | 0.2 |

| Cadmium | BDL | BDL | 1.0 |

| Zinc | 0.83 | 0.85 | Not reported |

| Copper | BDL | BDL | Not reported |

| Nickel | BDL | BDL | Not reported |

| Optimum Mix Designation | Pond Ash (%) | Brick Kiln Dust (%) | Clay Geomaterial (%) |

|---|---|---|---|

| CLPA | 30 | 0 | 70 |

| CLBKD | 0 | 30 | 70 |

| CLPABKD | 20 | 20 | 60 |

| Sequence No. | Confining Stress (kPa) | Cyclic Deviator Stress (kPa) | Resilient Modulus (MPa) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Unsoaked | Soaked | |||||||||

| CL | CLPA | CLBKD | CLPABKD | CL | CLPA | CLBKD | CLPABKD | |||

| 1 | 41.4 | 12.4 | 49.8 | 68.3 | 71.3 | 84.4 | 28.9 | 34.4 | 36.5 | 50.1 |

| 2 | 41.4 | 24.8 | 53.6 | 71.3 | 76.1 | 88.6 | 23.8 | 32.2 | 33.2 | 41.7 |

| 3 | 41.4 | 37.3 | 55.8 | 73.3 | 78.3 | 89.1 | 19.0 | 30.1 | 31.0 | 38.0 |

| 4 | 41.4 | 49.7 | 57.4 | 74.7 | 83.5 | 90.4 | 16.0 | 26.4 | 27.8 | 35.3 |

| 5 | 41.4 | 62.0 | 59.0 | 77.6 | 83.9 | 92.0 | 15.0 | 25.7 | 27.0 | 34.6 |

| 6 | 27.6 | 12.4 | 47.1 | 65.1 | 68.6 | 79.3 | 23.0 | 28.1 | 29.5 | 40.9 |

| 7 | 27.6 | 24.8 | 50.5 | 69.3 | 72.9 | 82.4 | 18.2 | 25.4 | 26.9 | 36.4 |

| 8 | 27.6 | 37.3 | 52.7 | 71.2 | 75.5 | 84.6 | 14.6 | 22.4 | 23.7 | 31.2 |

| 9 | 27.6 | 49.7 | 54.6 | 73.2 | 78.6 | 84.8 | 13.5 | 20.1 | 21.0 | 29.7 |

| 10 | 27.6 | 62.0 | 56.0 | 76.7 | 82.2 | 86.5 | 13.0 | 19.0 | 19.9 | 27.4 |

| 11 | 13.8 | 12.4 | 45.2 | 63.0 | 66.7 | 73.6 | 14.0 | 20.2 | 21.6 | 28.5 |

| 12 | 13.8 | 24.8 | 47.4 | 65.4 | 70.1 | 75.5 | 12.2 | 17.9 | 19.0 | 25.6 |

| 13 | 13.8 | 37.3 | 49.4 | 68.7 | 73.7 | 77.0 | 10.8 | 16.4 | 18.0 | 24.0 |

| 14 | 13.8 | 49.7 | 50.5 | 70.4 | 76.8 | 79.0 | 10.3 | 15.7 | 16.9 | 22.1 |

| 15 | 13.8 | 62.0 | 51.3 | 71.4 | 78.4 | 79.9 | 9.8 | 15.2 | 16.0 | 21.0 |

| Mixtures | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| k1 | k2 | R2 | k3 | k4 | R2 | k5 | k6 | k7 | R2 | |

| CL | 36.97 | 0.10 | 0.547 | 20.56 | 0.20 | 0.829 | 0.11 | 0.67 | 0.10 | 0.987 |

| CLPA | 52.75 | 0.08 | 0.683 | 36.06 | 0.14 | 0.738 | 0.07 | 0.85 | 0.08 | 0.972 |

| CLBKD | 52.44 | 0.11 | 0.786 | 36.57 | 0.15 | 0.627 | 0.06 | 0.93 | 0.11 | 0.967 |

| CLPABKD | 69.43 | 0.05 | 0.196 | 34.37 | 0.19 | 0.970 | 0.13 | 1.05 | 0.05 | 0.990 |

| Mixtures | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| k1 | k2 | R2 | k3 | k4 | R2 | k5 | k6 | k7 | R2 | |

| CL | 50.37 | −0.34 | 0.397 | 3.01 | 0.34 | 0.151 | 0.51 | 0.21 | −0.34 | 0.967 |

| CLPA | 46.15 | −0.21 | 0.209 | 3.25 | 0.41 | 0.308 | 0.50 | 0.35 | −0.21 | 0.975 |

| CLBKD | 49.18 | −0.21 | 0.229 | 3.92 | 0.38 | 0.285 | 0.49 | 0.36 | −0.23 | 0.974 |

| CLPABKD | 68.91 | −0.23 | 0.279 | 6.14 | 0.35 | 0.245 | 0.45 | 0.46 | −0.23 | 0.991 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, G.; Sood, H.; Gupta, P. Performance Evaluation of Pavement Geomaterials Stabilized with Pond Ash and Brick Kiln Dust Using Advanced Cyclic Triaxial Testing. Materials 2020, 13, 553. https://doi.org/10.3390/ma13030553

Gupta G, Sood H, Gupta P. Performance Evaluation of Pavement Geomaterials Stabilized with Pond Ash and Brick Kiln Dust Using Advanced Cyclic Triaxial Testing. Materials. 2020; 13(3):553. https://doi.org/10.3390/ma13030553

Chicago/Turabian StyleGupta, Gaurav, Hemant Sood, and Pardeep Gupta. 2020. "Performance Evaluation of Pavement Geomaterials Stabilized with Pond Ash and Brick Kiln Dust Using Advanced Cyclic Triaxial Testing" Materials 13, no. 3: 553. https://doi.org/10.3390/ma13030553

APA StyleGupta, G., Sood, H., & Gupta, P. (2020). Performance Evaluation of Pavement Geomaterials Stabilized with Pond Ash and Brick Kiln Dust Using Advanced Cyclic Triaxial Testing. Materials, 13(3), 553. https://doi.org/10.3390/ma13030553