The Surface Condition of Ni-Cr after SiC Abrasive Blasting for Applications in Ceramic Restorations

Abstract

1. Introduction

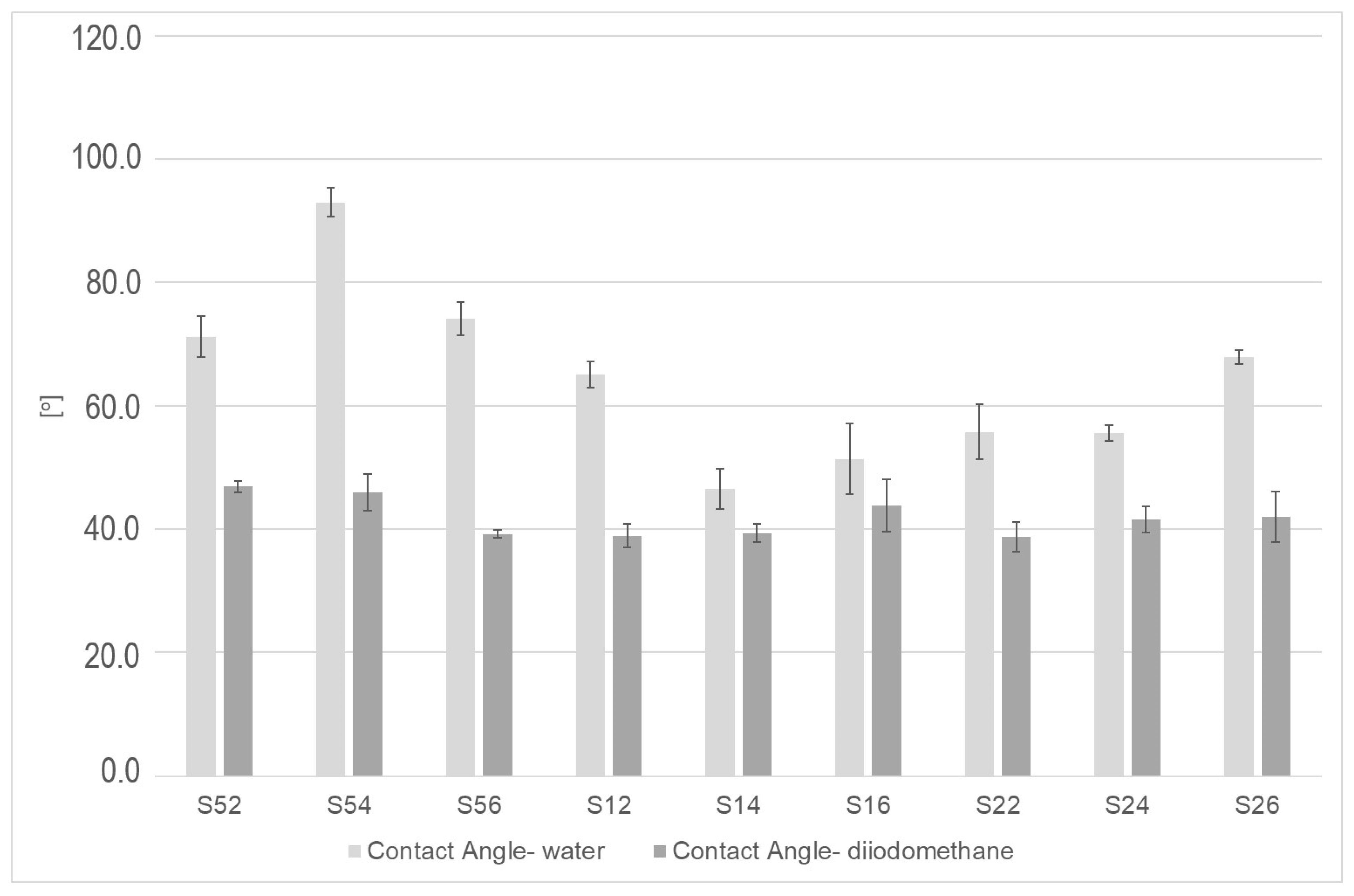

2. Materials and Methods

- -

- surface roughness;

- -

- the wettability of the surface;

- -

- the percentage of stuck abrasive particles.

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zaborski, S.; Stechnij, T.; Poroś, D. The impact of the stream-abrasive processing on the geometric surface structure of selected non-ferrous metals. Mechanik 2016, 1080–1081. [Google Scholar] [CrossRef][Green Version]

- Wakuda, M.; Yamauchi, Y.; Kanzaki, S. Material response to particle impact during abrasive jet machining of alumina ceramics. J. Mater. Process. Technol. 2003, 132, 177–183. [Google Scholar] [CrossRef]

- Taga, Y.; Kawai, K.; Nokubi, T. New method for divesting cobalt-chromium alloy castings: Sandblasting with a mixed abrasive powder. J. Prosthet. Dent. 2001, 85, 357–362. [Google Scholar] [CrossRef] [PubMed]

- Golla, V.; Heitbrink, W. Control technology for crystalline sylica exposures in construction: Wet abrasive blasting. J. Occup. Environ. Hyg. 2004, 1, 26–32. [Google Scholar] [CrossRef]

- Momber, A. Blast Cleaning Technology; Springer: Cham, Switzerland, 2008; ISBN 9783540736448. [Google Scholar]

- Brezinová, J.; Guzanová, A.; Draganovská, D. Abrasive Blast Cleaning and Its Application; Trans Tech Publications: Bäch, Switzerland, 2015; ISBN 9783540773405. [Google Scholar]

- Pietnicki, K.; Wołowiec-Korecka, E.; Klimek, L. Modeling strength of the connection the metal substrate to the dental ceramics depending on the parameters of the prior abrasive blasting. Mechanik 2015, 266–269. [Google Scholar] [CrossRef]

- Czepułkowska, W.; Wołowiec-Korecka, E.; Klimek, L. The role of mechanical, chemical and physical bonds in metal-ceramic bond strength. Arch. Mater. Sci. Eng. 2018, 92, 5–14. [Google Scholar] [CrossRef][Green Version]

- Aboras, M.M.; Muchtar, A.; Azhari, C.H.; Yahaya, N. Types of failures in porcelain-fused-to-metal dental restoration. In Proceedings of the 6th European Conference of the International Federation for Medical and Biological Engineering, Dubrovnik, Croatia, 7–11 September 2014; Lacković, I., Vasic, D., Eds.; Springer International Publishing: Cham, Switzerland, 2015; Volume 45, pp. 345–348. [Google Scholar]

- Polish Committee for Standardization. Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Rules and Procedures for the Assessment of Surface Texture. PN-EN ISO 4288:2011. Available online: https://sklep.pkn.pl/pn-en-iso-4288-2011e.html (accessed on 27 November 2020).

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Bobzin, K.; Öte, M.; Linke, T.F.; Sommer, J.; Liao, X. Influence of Process Parameter on Grit Blasting as a Pretreatment Process for Thermal Spraying. J. Therm. Spray Technol. 2016, 25, 3–11. [Google Scholar] [CrossRef]

- Rudawska, A.; Danczak, I.; Müller, M.; Valasek, P. The effect of sandblasting on surface properties for adhesion. Int. J. Adhes. Adhes. 2016, 70, 176–190. [Google Scholar] [CrossRef]

- Külünk, T.; Kurt, M.; Ural, Ç.; Külünk, Ş.; Baba, S. Effect of different air-abrasion particles on metal-ceramic bond strength. J. Dent. Sci. 2011, 6, 140–146. [Google Scholar] [CrossRef]

- Thomas, T.R. Characterization of surface roughness. Precis. Eng. 1981, 3, 97–104. [Google Scholar] [CrossRef]

- Gołębiowski, M.; Wołowiec, E.; Klimek, L. Airborne-particle abrasion parameters on the quality of titanium-ceramic bonds. J. Prosthet. Dent. 2015, 113, 453–459. [Google Scholar] [CrossRef] [PubMed]

- Nergiz, I.; Schmage, P.; Herrmann, W. Effect of alloy type and surface conditioning on roughness and bond strength of metal brackets. Am. J. Orthod. Dentofac. Orthop. 2004, 125, 42–50. [Google Scholar] [CrossRef][Green Version]

- Srilatha, B.; Hisashi, D.; Ryota, K.; Hideki, A.; Takao, H.; Shohei, K. Effect of sandblasting on the mechanical properties of Y-TZP zirconia. Biomed. Mater. Eng. 2012, 383–398. [Google Scholar] [CrossRef]

- Liao, P.-B.; Cheng, H.-C.; Huang, C.-F.; Lin, Y.; Shen, Y.-K.; Fan, Y.-M.; Lee, C.-Y.; Chang, C.-W.; Hung, W.-C. The cell culture of titanium alloy surface modifications by micro-powder blasting and co-blast techniques. Surf. Eng. 2019, 35, 643–651. [Google Scholar] [CrossRef]

- Czepułkowska, W.; Wołowiec-Korecka, E.; Klimek, L. The condition of Ni-Cr alloy surface after abrasive blasting with various parameters. J. Mater. Eng. Perform. 2020, 29, 1439–1444. [Google Scholar] [CrossRef]

- Banaszek, K.; Pietnicki, K.; Klimek, L. The influence of parameters of abrasive jet machining processing on the number of stubble elements stuck in nickel-chrome alloy surface. Inż. Mater. 2011, 4, 312–315. (In Polish) [Google Scholar]

- Śmielak, B.; Klimek, L. Effect of air abrasion on the number of particles embedded in zirconia. Materials 2018, 11, 259. [Google Scholar] [CrossRef] [PubMed]

- Pietnicki, K.; Wołowiec, E.; Klimek, L. Modeling of the number of stubble stuck elements after abrasive jet machining-processing. Arch. Foundry Eng. 2011, 11, 51–54. [Google Scholar]

| Ni | Cr | Mo | Fe | Mn | Ta | Si | Nb |

|---|---|---|---|---|---|---|---|

| 59.3 | 24.0 | 10.0 | 1.5 | 1.5 | 1.5 | 1.2 | 1.0 |

| Alloy Properties | |

|---|---|

| Density | 8.3 g/cm3 |

| Melting temperature | 1190–1300 °C |

| Coefficient of thermal expansion (25–500 °C) | 14.1 µm/m × K |

| Young’s modulus | 227 GPa |

| Yield point | 350 MPa |

| Elongation at break | 20% |

| Hardness [HV 10] | 185 HV |

| Abrasive Particle Size [µm] | Processing Pressure [MPa] | ||

|---|---|---|---|

| 0.2 | 0.4 | 0.6 | |

| 50 | S52 | S54 | S54 |

| 110 | S12 | S14 | S16 |

| 250 | S22 | S24 | S26 |

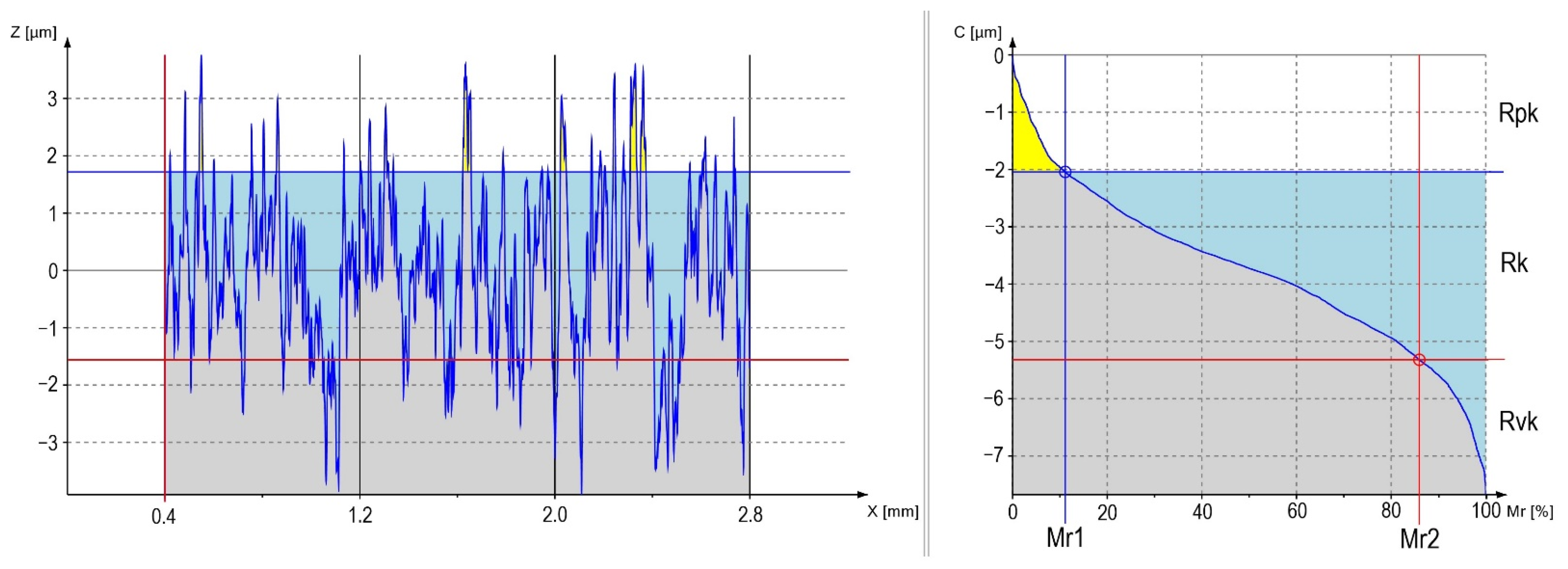

| Sample Number | Roughness Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Ra [µm] | Rz [µm] | Rt [µm] | Rp [µm] | Rv [µm] | Rq [µm] | Rc [µm] | Rsm [mm] | RVo [mm3/cm2] | |

| S52 | 0.67 ± 0.06 | 4.87 ± 0.62 | 6.51 ± 2.05 | 2.65 ± 0.37 | 2.22 ± 0.28 | 0.85 ± 0.08 | 2.16 ± 0.17 | 0.053 ± 0.01 | 0.004621 ± 0.004444 |

| S54 | 1.04 ± 0.05 | 6.81 ± 0.27 | 8.35 ± 0.62 | 3.67 ± 0.28 | 3.15 ± 0.12 | 1.3 ± 0.05 | 3.29 ± 0.15 | 0.064 ± 0.012 | 0.007899 ± 0.003347 |

| S56 | 1.05 ± 0.07 | 7.34 ± 0.66 | 9.09 ± 1.52 | 3.99 ± 0.54 | 3.34 ± 0.28 | 1.35 ± 0.11 | 3.42 ± 0.24 | 0.06 ± 0.006 | 0.007015 ± 0.003543 |

| S12 | 0.98 ± 0.08 | 6.74 ± 0.64 | 8.22 ± 0.82 | 3.58 ± 0.42 | 3.16 ± 0.27 | 1.24 ± 0.09 | 3.11 ± 0.32 | 0.052 ± 0.001 | 0.004303 ± 0.001137 |

| S14 | 1.56 ± 0.06 | 10.92 ± 0.66 | 14.21 ± 1.9 | 6.05 ± 0.56 | 4.86 ± 0.34 | 1.99 ± 0.07 | 5.06 ± 0.32 | 0.073 ± 0.006 | 0.009353 ± 0.003343 |

| S16 | 1.54 ± 0.13 | 10.01 ± 0.95 | 11.8 ± 1.07 | 5.23 ± 0.79 | 4.78 ± 0.45 | 1.93 ± 0.15 | 4.88 ± 0.22 | 0.082 ± 0.01 | 0.007461 ± 0.003409 |

| S22 | 1.87 ± 0.1 | 12.71 ± 1.01 | 16.93 ± 4.8 | 6.42 ± 1.01 | 6.29 ± 0.58 | 2.39 ± 0.13 | 5.92 ± 0.28 | 0.091 ± 0.011 | 0.011335 ± 0.003755 |

| S24 | 2.74 ± 0.15 | 17.72 ± 1.53 | 22.35 ± 3.37 | 8.55 ± 0.75 | 9.17 ± 0.96 | 3.46 ± 0.16 | 9.19 ± 0.77 | 0.108 ± 0.006 | 0.025713 ± 0.010871 |

| S26 | 2.76 ± 0.12 | 17.35 ± 0.78 | 23.38 ± 2.11 | 8.32 ± 1.03 | 9.03 ± 0.36 | 3.46 ± 0.16 | 8.77 ± 1.1 | 0.117 ± 0.02 | 0.026591 ± 0.012697 |

| Sample Number | Roughness Parameters | ||||

|---|---|---|---|---|---|

| Rk [µm] | Rpk [µm] | Rvk [µm] | Mr1 [%] | Mr2 [%] | |

| S52 | 2.18 ± 0.15 | 0.92 ± 0.18 | 0.83 ± 0.43 | 11.72 ± 1.05 | 90.28 ± 3.49 |

| S54 | 3.42 ± 0.27 | 1.52 ± 0.29 | 1.37 ± 0.26 | 10.43 ± 2.21 | 88.68 ± 2.81 |

| S56 | 3.32 ± 0.17 | 1.58 ± 0.2 | 1.28 ± 0.35 | 11.96 ± 1.95 | 89.62 ± 3.07 |

| S12 | 3.10 ± 0.26 | 1.06 ± 0.18 | 0.91 ± 0.14 | 9.35 ± 1.33 | 90.65 ± 1.83 |

| S14 | 4.93 ± 0.29 | 2.24 ± 0.3 | 1.76 ± 0.52 | 10.01 ± 1.24 | 89.44 ± 1.99 |

| S16 | 4.99 ± 0.7 | 2.05 ± 0.46 | 1.63 ± 0.47 | 9.29 ± 3.78 | 91.17 ± 1.51 |

| S22 | 5.92 ± 0.47 | 2.87 ± 0.47 | 2.27 ± 0.47 | 11.27 ± 1.12 | 90.16 ± 1.7 |

| S24 | 8.76 ± 0.63 | 3.61 ± 0.69 | 3.98 ± 0.43 | 11.29 ± 2.46 | 87.26 ± 4.51 |

| S26 | 9.24 ± 0.38 | 3.21 ± 0.94 | 4.08 ± 1.21 | 8.35 ± 1.22 | 87.53 ± 2.49 |

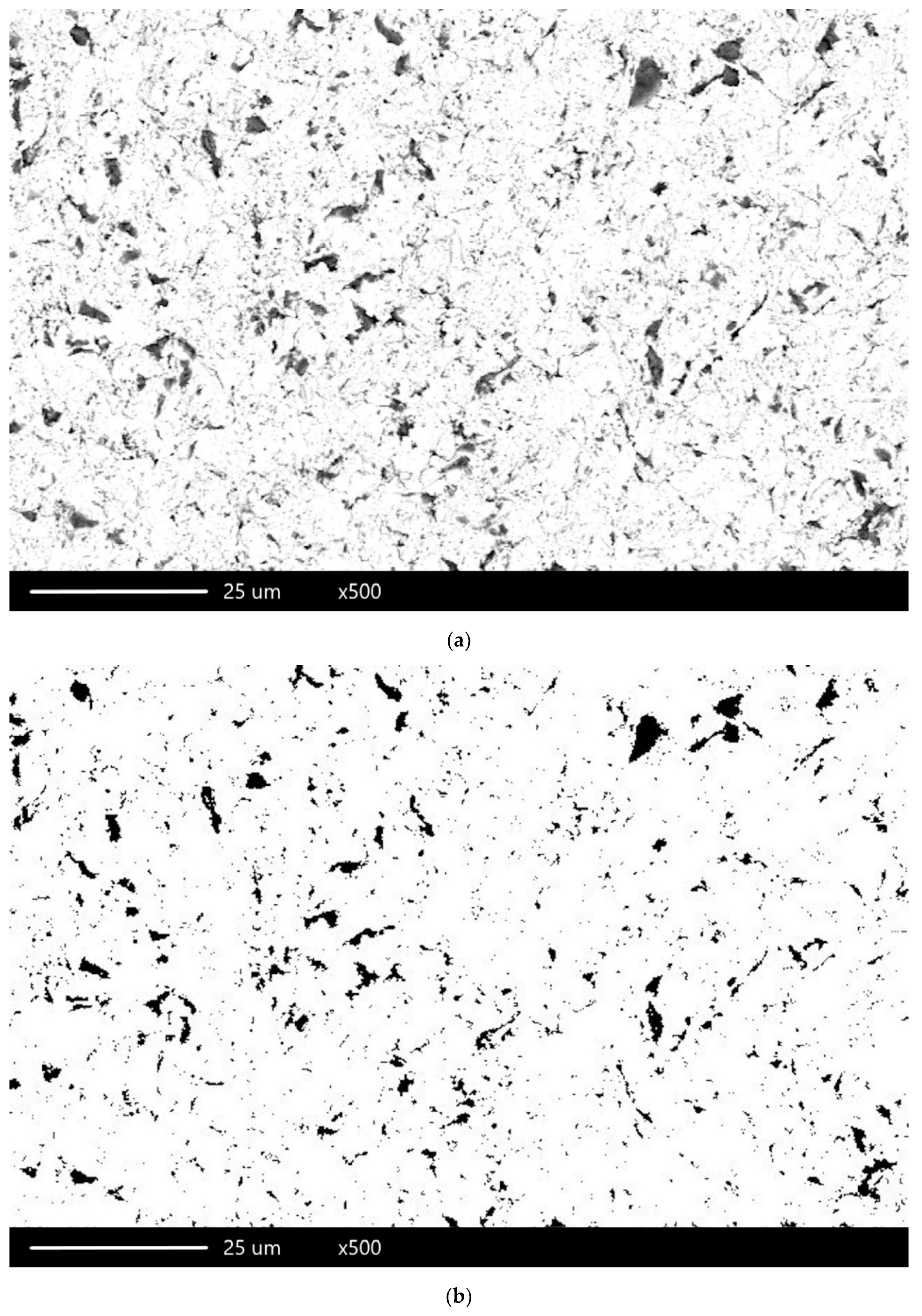

| Sample Number | Percentage of Stuck Abrasive Particles [%] |

|---|---|

| S52 | 4.78 ± 1.16 |

| S54 | 6.85 ± 0.64 |

| S56 | 9.58 ± 1.76 |

| S12 | 7.61 ± 0.88 |

| S14 | 10.08 ± 1.26 |

| S16 | 9.83 ± 1.4 |

| S22 | 9.69 ± 1.48 |

| S24 | 13.19 ± 2.13 |

| S26 | 12.91 ± 3.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czepułkowska-Pawlak, W.; Wołowiec-Korecka, E.; Klimek, L. The Surface Condition of Ni-Cr after SiC Abrasive Blasting for Applications in Ceramic Restorations. Materials 2020, 13, 5824. https://doi.org/10.3390/ma13245824

Czepułkowska-Pawlak W, Wołowiec-Korecka E, Klimek L. The Surface Condition of Ni-Cr after SiC Abrasive Blasting for Applications in Ceramic Restorations. Materials. 2020; 13(24):5824. https://doi.org/10.3390/ma13245824

Chicago/Turabian StyleCzepułkowska-Pawlak, Weronika, Emilia Wołowiec-Korecka, and Leszek Klimek. 2020. "The Surface Condition of Ni-Cr after SiC Abrasive Blasting for Applications in Ceramic Restorations" Materials 13, no. 24: 5824. https://doi.org/10.3390/ma13245824

APA StyleCzepułkowska-Pawlak, W., Wołowiec-Korecka, E., & Klimek, L. (2020). The Surface Condition of Ni-Cr after SiC Abrasive Blasting for Applications in Ceramic Restorations. Materials, 13(24), 5824. https://doi.org/10.3390/ma13245824