Effect of Ni-Cr Alloy Surface Abrasive Blasting on Its Wettability by Liquid Ceramics

Abstract

1. Introduction

2. Materials and Methods

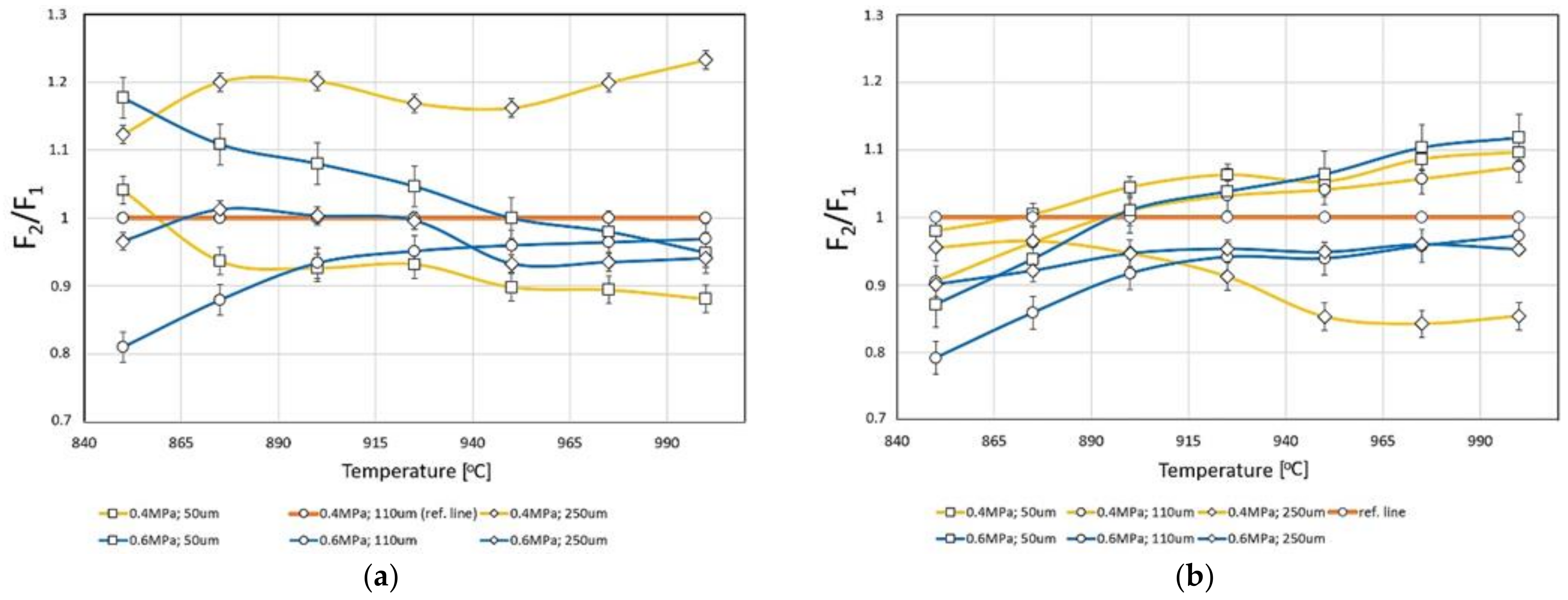

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Czepułkowska, W.; Wołowiec-Korecka, E.; Klimek, L. The role of mechanical, chemical and physical bonds in metal-ceramic bond strength. Arch. Mater. Sci. Eng. 2018, 92, 5–14. [Google Scholar] [CrossRef][Green Version]

- Makhija, S.K.; Lawson, N.C.; Gilbert, G.H.; Litaker, M.S.; McClelland, J.A.; Louis, D.R.; Gordan, V.V.; Pihlstrom, D.J.; Meyerowitz, C.; Mungia, R.; et al. Dentist material selection for single-unit crowns: Findings from the National Dental Practice-Based Research Network. J. Dent. 2016, 55, 40–47. [Google Scholar] [CrossRef] [PubMed]

- Haugen, H.J.; Soltvedt, B.M.; Nguyen, P.N.; Ronold, H.J.; Johnsen, G.F. Discrepancy in alloy composition of imported and non-imported porcelain-fused-to-metal (PFM) crowns produced by Norwegian dental laboratories. Biomater. Investig. Dent. 2020, 7, 41–49. [Google Scholar] [CrossRef]

- Jamal, S.; Ghafoor, R.; Khan, F.R.; Zafar, K. Five year evaluation of the complications observed in porcelain fused to metal (PFM) crowns placed at a university hospital. J. Pak. Med. Assoc. 2020, 70, 845–850. [Google Scholar] [CrossRef] [PubMed]

- Aksoy, G.; Polat, H.; Polat, M.; Coskun, G. Effect of various treatment and glazing (coating) techniques on the roughness and wettability of ceramic dental restorative surfaces. Colloids Surf. B Biointerfaces 2006, 53, 254–259. [Google Scholar] [CrossRef] [PubMed]

- De Melo, R.M.; Travassos, A.C.; Neisser, M.P. Shear bond strengths of a ceramic system to alternative metal alloys. J. Prosthet. Dent. 2005, 93, 64–69. [Google Scholar] [CrossRef]

- Külünk, T.; Kurt, M.; Ural, Ç.; Külünk, Ş.; Baba, S. Effect of different air-abrasion particles on metal-ceramic bond strength. J. Dent. Sci. 2011, 6, 140–146. [Google Scholar] [CrossRef]

- Lopes, S.C.; Pagnano, V.O.; De Almeida Rollo, J.M.D.; Leal, M.B.; Bezzon, O.L. Correlation between metal-ceramic bond strength and coefficient of linear thermal expansion difference. J. Appl. Oral Sci. 2009, 17, 122–128. [Google Scholar] [CrossRef]

- Schweitzer, D.M.; Goldstein, G.R.; Ricci, J.L.; Silva, N.R.F.A.; Hittelman, E.L. Comparison of bond strength of a pressed ceramic fused to metal versus feldspathic porcelain fused to metal. J. Prosthodont. 2005, 14, 239–247. [Google Scholar] [CrossRef] [PubMed]

- Aboras, M.M.; Muchtar, A.; Azhari, C.H.; Yahaya, N. Types of Failures in Porcelain-Fused-to-Metal Dental Restoration; Lacković, I., Vasic, D., Eds.; Springer International Publishing: Cham, Switzerland, 2015; Volume 45, pp. 345–348. [Google Scholar]

- Ozcan, M. Fracture reasons in ceramic-fused-to-metal restorations. J. Oral Rehabil. 2003, 30, 265–269. [Google Scholar] [CrossRef] [PubMed]

- Mühlemann, S.; Lakha, T.; Jung, R.E.; Hämmerle, C.H.F.; Benic, G.I. Prosthetic outcomes and clinical performance of CAD-CAM monolithic zirconia versus porcelain-fused-to-metal implant crowns in the molar region: 1-year results of a RCT. Clin. Oral Implants Res. 2020, 31, 856–864. [Google Scholar] [CrossRef]

- Ren, W.; Yang, L.; Du, F.; Huang, J.; Huang, Z.; Liang, T.; Li, F.; Li, Y.; Jiang, Q.; Yang, X.; et al. Chipped porcelain-fused-to-metal restoration repaired by the novel self-glazed zirconia veneering with a digital workflow. Adv. Appl. Ceram. 2020, 119, 317–322. [Google Scholar] [CrossRef]

- Pietnicki, K.; Wołowiec, E.; Klimek, L. The effect of abrasive blasting on the strength of a joint between dental porcelain and metal base. Acta Bioeng. Biomech. 2014, 16, 63–68. [Google Scholar]

- Czepułkowska, W.; Wołowiec-Korecka, E.; Klimek, L. The condition of Ni-Cr alloy surface after abrasive blasting with various parameters. J. Mater. Eng. Perform. 2019, 29, 1439–1444. [Google Scholar] [CrossRef]

- Pietnicki, K.; Wołowiec-Korecka, E.; Klimek, L. Modeling strength of the connection the metal substrate to the dental ceramics depending on the parameters of the prior abrasive blasting. Mechanik 2015, 266–269. [Google Scholar] [CrossRef]

- Śmielak, B.; Klimek, L.; Wojciechowski, R.; Bąkała, M. Effect of zirconia surface treatment on its wettability by liquid ceramics. J. Prosthet. Dent. 2019, 122, 410.e1–410.e6. [Google Scholar] [CrossRef]

- Gołębiowski, M.; Wołowiec, E.; Klimek, L. Airborne-particle abrasion parameters on the quality of titanium-ceramic bonds. J. Prosthet. Dent. 2015, 113, 453–459. [Google Scholar] [CrossRef] [PubMed]

- Marefati, M.T.; Hadian, A.M.; Hooshmand, T.; Hadian, A.; Yekta, B.E. Wetting Characteristics of a Nano Y-TZP Dental Ceramic by a Molten Feldspathic Veneer. Procedia Mater. Sci. 2015, 11, 157–161. [Google Scholar] [CrossRef]

- Marefati, M.T.; Hadian, A.M.; Hooshmand, T.; Yekta, B.E.; Koohkan, R. Wettability of zirconia by feldspathic veneer in dental restorations: Effect of firing atmosphere and surface roughness. Ceram. Int. 2018, 44, 4307–4312. [Google Scholar] [CrossRef]

- Śmielak, B.; Klimek, L. Effect of air abrasion on the number of particles embedded in zironia. Materials 2018, 11, 259. [Google Scholar] [CrossRef] [PubMed]

- Pietnicki, K.; Wołowiec-Korecka, E.; Klimek, L. Modeling of the number of stubble stuck elements after abrasive jet machining-processing. Arch. Foundry Eng. 2011, 11, 51–54. [Google Scholar]

| Ni | Cr | Mo | Fe | Mn | Ta | Si | Co | Nb |

|---|---|---|---|---|---|---|---|---|

| residue | 24.63 | 9.21 | 1.53 | 0.42 | 0.19 | 1.54 | 0.15 | 0.48 |

| Type of Abrasive | Abrasive Particle Size [µm] | Processing Pressure [kPa] | |

|---|---|---|---|

| 400 | 600 | ||

| Al2O3 | 50 | A54 | A56 |

| 110 | A14 | A16 | |

| 250 | A24 | A26 | |

| SiC | 50 | S54 | S65 |

| 110 | S14 | S16 | |

| 250 | S24 | S26 | |

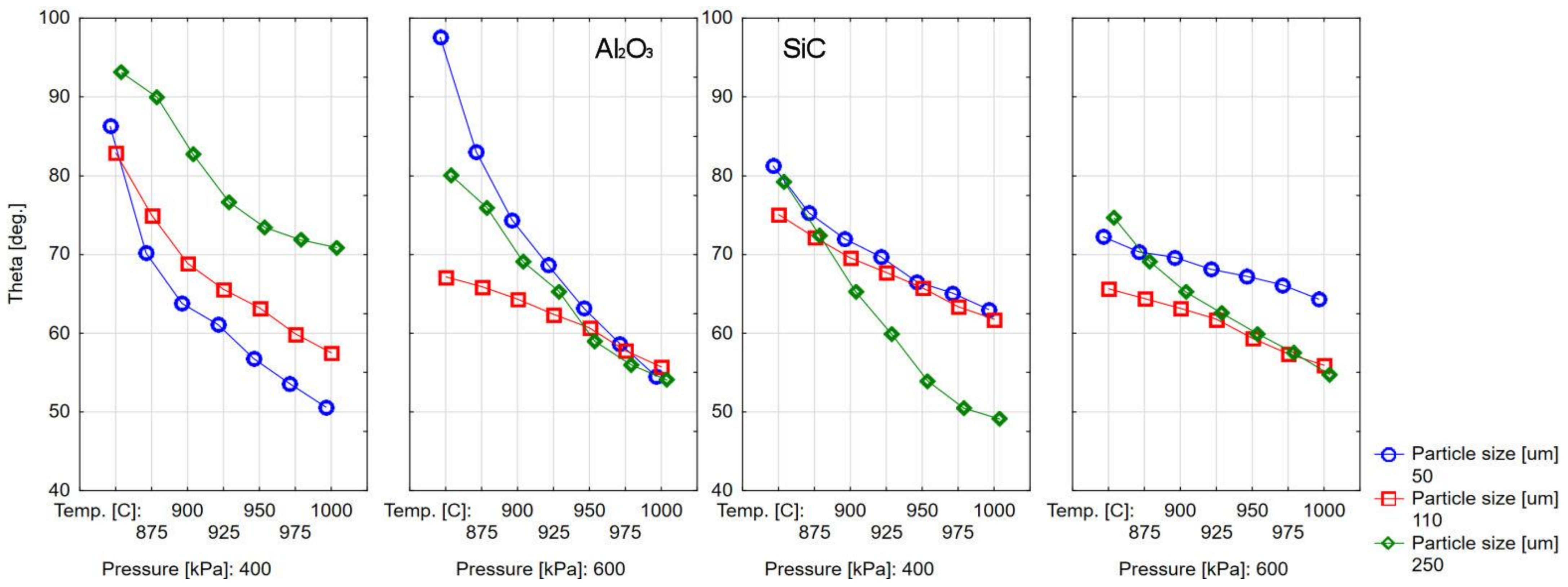

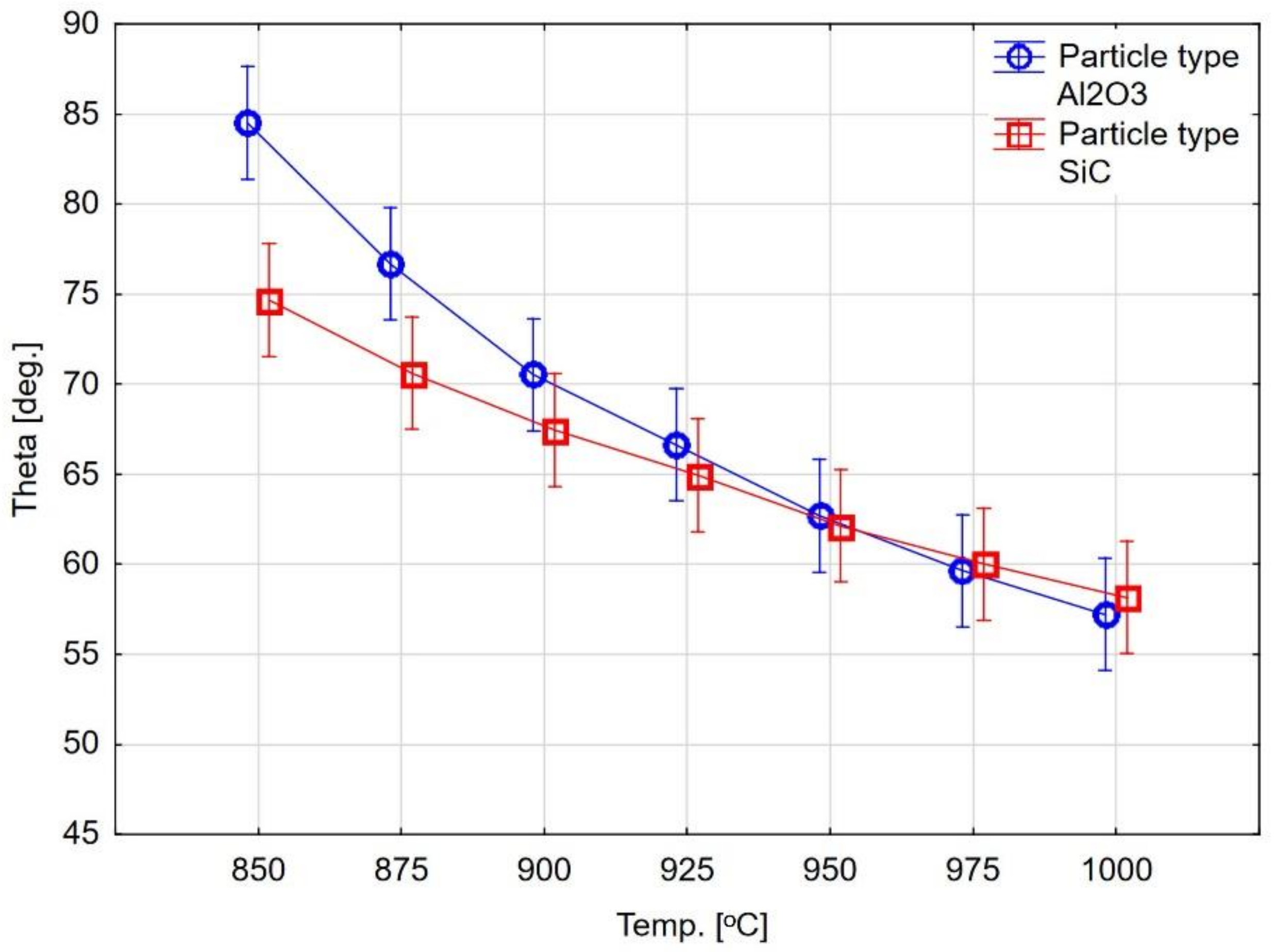

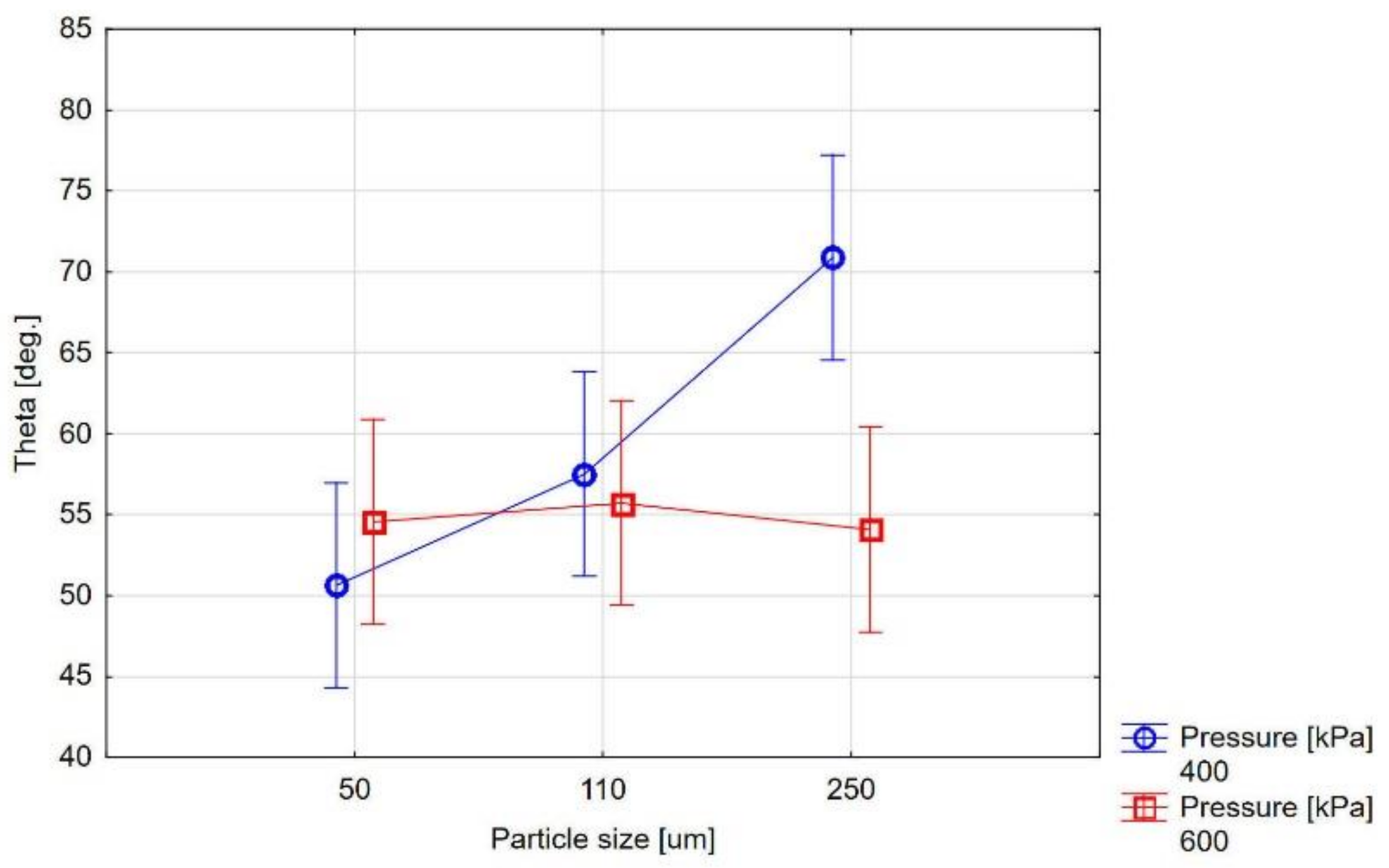

| Temp. [°C] | Al2O3 Abrasive Blasting Parameters | ||||||

|---|---|---|---|---|---|---|---|

| 400 kPa | 600 kPa | Total | |||||

| 50 µm | 110 µm | 250 µm | 50 µm | 110 µm | 250 µm | ||

| 850 | 86.33 ± 3.51 | 82.93 ± 6.83 | 93.10 ± 2.55 | 97.56 ± 7.66 | 67.07 ± 0.81 | 80.05 ± 3.04 | 84.51 ± 4.07 |

| 875 | 70.20 ± 3.40 | 74.98 ± 5.63 | 89.98 ± 2.20 | 83.10 ± 6.22 | 65.57 ± 1.33 | 75.90 ± 2.45 | 76.62 ± 3.54 |

| 900 | 63.80 ± 4.61 | 68.88 ± 1.41 | 82.73 ± 3.11 | 74.38 ± 5.34 | 64.30 ± 1.66 | 69.27 ± 1.90 | 70.56 ± 3.00 |

| 925 | 60.23 ± 2.83 | 65.60 ± 1.72 | 76.68 ± 1.43 | 68.65 ± 1.17 | 62.40 ± 1.14 | 64.17 ± 4.72 | 66.29 ± 2.17 |

| 950 | 56.75 ± 3.03 | 63.20 ± 1.92 | 73.43 ± 1.82 | 63.18 ± 2.25 | 60.65 ± 1.42 | 58.93 ± 5.26 | 62.69 ± 2.62 |

| 975 | 53.58 ± 2.49 | 59.93 ± 0.75 | 71.85 ± 1.43 | 58.70 ± 2.75 | 57.78 ± 1.49 | 56.00 ± 5.91 | 59.64 ± 5.91 |

| 1000 | 50.63 ± 2.40 | 57.50 ± 0.51 | 70.88 ± 0.83 | 54.55 ± 2.66 | 55.73 ± 1.69 | 54.08 ± 6.14 | 57.23 ± 6.14 |

| Total | 63.07± 3.18 | 67.57 ± 2.68 | 79.80 ± 1.91 | 71.45 ± 4.01 | 61.93 ± 1.36 | 65.48 ± 4.20 | - |

| ANOVA | Factor | F | P | Partial eta2 | Power | ||

| Particle size | 5.462 | <0.01 | 0.3777 | 0.7806 | |||

| Pressure × Particle size | 6.332 | <0.01 | 0.4130 | 0.8409 | |||

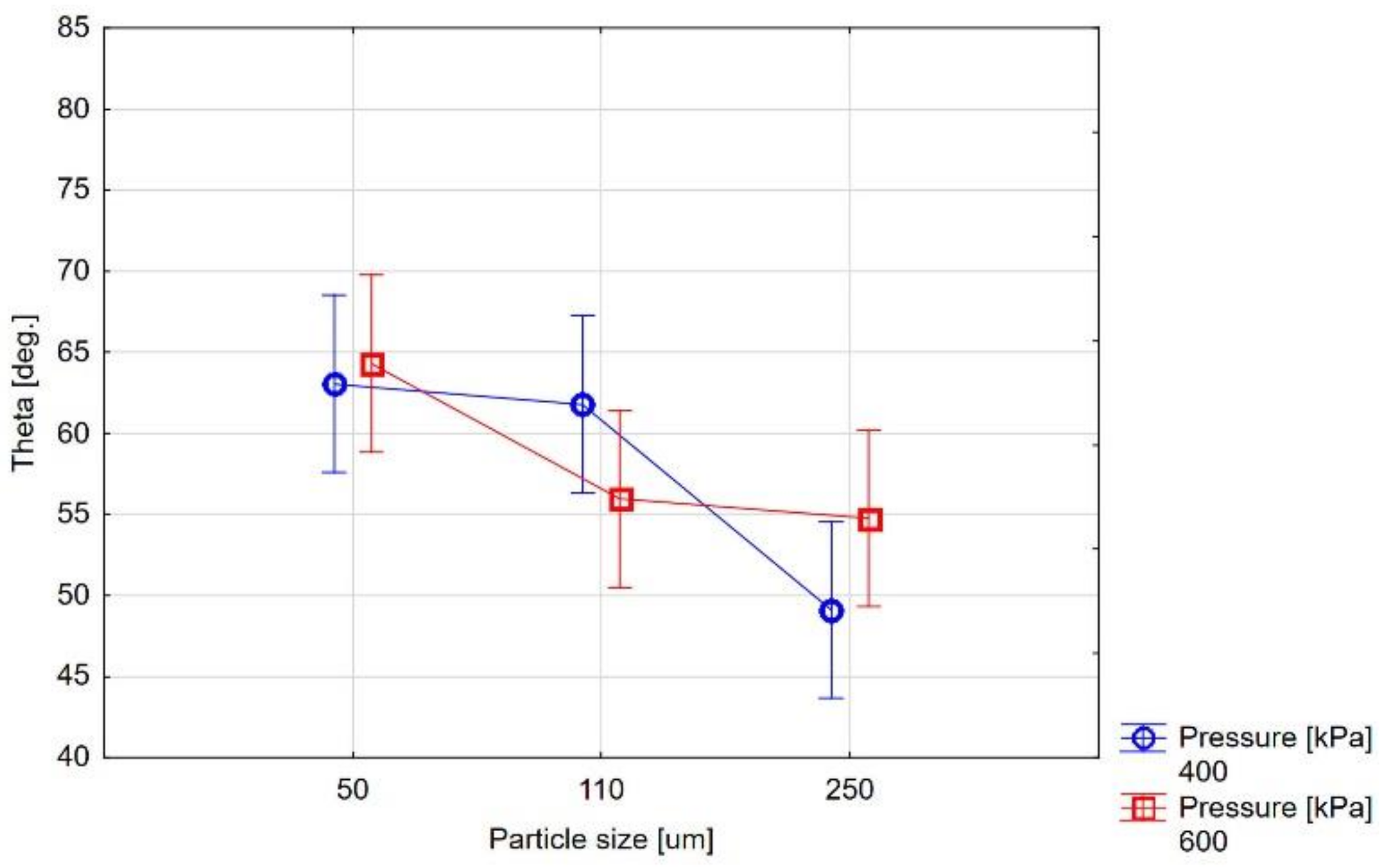

| Temp. [°C] | SiC Abrasive Blasting Parameters | ||||||

|---|---|---|---|---|---|---|---|

| 400 kPa | 600 kPa | Total | |||||

| 50 µm | 110 µm | 250 µm | 50 µm | 110 µm | 250 µm | ||

| 850 | 81.25 ± 2.62 | 74.67 ± 0.86 | 79.23 ± 5.40 | 72.23 ± 0.49 | 65.57 ± 0.86 | 74.68 ± 3.64 | 74.60 ± 2.31 |

| 875 | 75.30 ± 1.24 | 72.20 ± 2.15 | 72.38 ± 3.98 | 70.35 ± 1.00 | 64.38 ± 0.73 | 69.05 ± 3.06 | 70.61 ± 2.03 |

| 900 | 71.95 ± 0.60 | 69.58 ± 2.87 | 65.23 ± 3.49 | 69.60 ± 0.61 | 63.15 ± 1.41 | 65.20 ± 1.25 | 67.45 ± 1.70 |

| 925 | 69.73 ± 0.52 | 67.70 ± 1.04 | 59.85 ± 0.74 | 68.13 ± 1.46 | 61.75 ± 1.50 | 62.55 ± 0.46 | 64.95 ± 0.95 |

| 950 | 66.55 ± 0.36 | 65.80 ± 1.08 | 53.90 ± 3.01 | 67.18 ± 1.52 | 59.35 ± 0.65 | 59.95 ± 1.48 | 62.12 ± 1.35 |

| 975 | 65.10 ± 0.78 | 63.35 ± 4.21 | 50.48 ± 2.20 | 66.13 ± 1.73 | 57.40 ± 1.00 | 57.53 ± 1.44 | 60.00 ± 1.89 |

| 1000 | 63.05 ± 1.01 | 61.80 ± 4.33 | 49.10 ± 4.06 | 64.30 ± 1.63 | 55.87 ± 0.71 | 54.78 ± 1.10 | 58.15 ± 2.14 |

| Total | 70.42 ± 1.02 | 67.87 ± 2.36 | 61.45 ± 3.27 | 68.27 ± 1.20 | 61.07 ± 0.98 | 63.39 ± 1.78 | - |

| ANOVA | Factor | F | P | Partial eta2 | Power | ||

| Particle size | 10.325 | <0.01 | 0.5343 | 0.9694 | |||

| Type of Abrasive | Particle Size [µm] | Treatment Pressure [kPa] | |

|---|---|---|---|

| 400 | 600 | ||

| Al2O3 | 50 | <850 | 863 °C |

| 110 | <850 °C | <850 °C | |

| 250 | 875 °C | <850 °C | |

| SiC | 50 | <850 °C | <850 °C |

| 110 | <850 °C | <850 °C | |

| 250 | <850 °C | <850 °C | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czepułkowska-Pawlak, W.; Klimek, L.; Makówka, M.; Wołowiec-Korecka, E. Effect of Ni-Cr Alloy Surface Abrasive Blasting on Its Wettability by Liquid Ceramics. Materials 2021, 14, 2007. https://doi.org/10.3390/ma14082007

Czepułkowska-Pawlak W, Klimek L, Makówka M, Wołowiec-Korecka E. Effect of Ni-Cr Alloy Surface Abrasive Blasting on Its Wettability by Liquid Ceramics. Materials. 2021; 14(8):2007. https://doi.org/10.3390/ma14082007

Chicago/Turabian StyleCzepułkowska-Pawlak, Weronika, Leszek Klimek, Marcin Makówka, and Emilia Wołowiec-Korecka. 2021. "Effect of Ni-Cr Alloy Surface Abrasive Blasting on Its Wettability by Liquid Ceramics" Materials 14, no. 8: 2007. https://doi.org/10.3390/ma14082007

APA StyleCzepułkowska-Pawlak, W., Klimek, L., Makówka, M., & Wołowiec-Korecka, E. (2021). Effect of Ni-Cr Alloy Surface Abrasive Blasting on Its Wettability by Liquid Ceramics. Materials, 14(8), 2007. https://doi.org/10.3390/ma14082007