The Friction-Induced Vibration of Water-Lubricated Rubber Bearings during the Shutdown Process

Abstract

1. Introduction

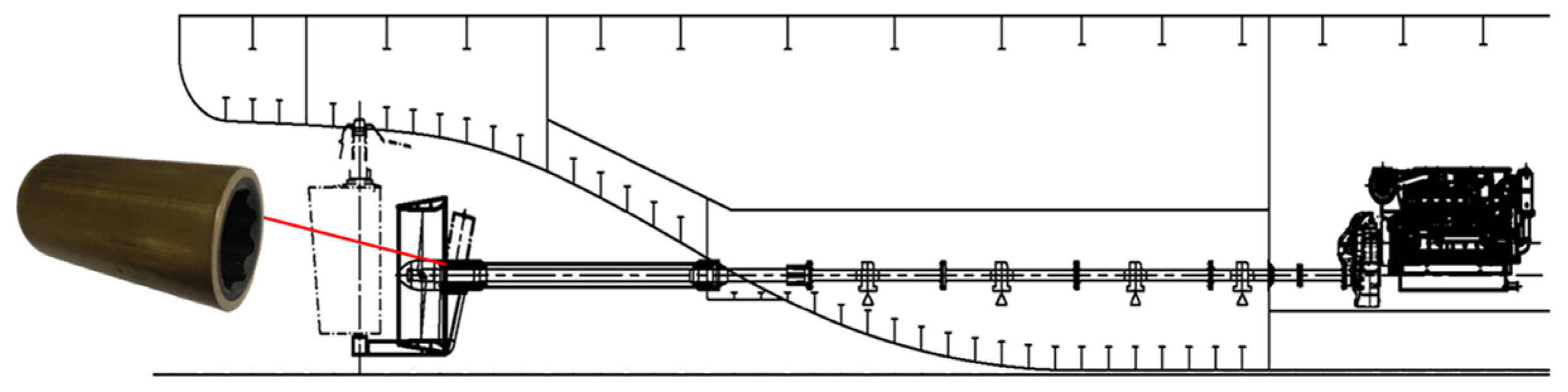

2. Establishing a Finite Element Model for a Water-Lubricated Bearing System

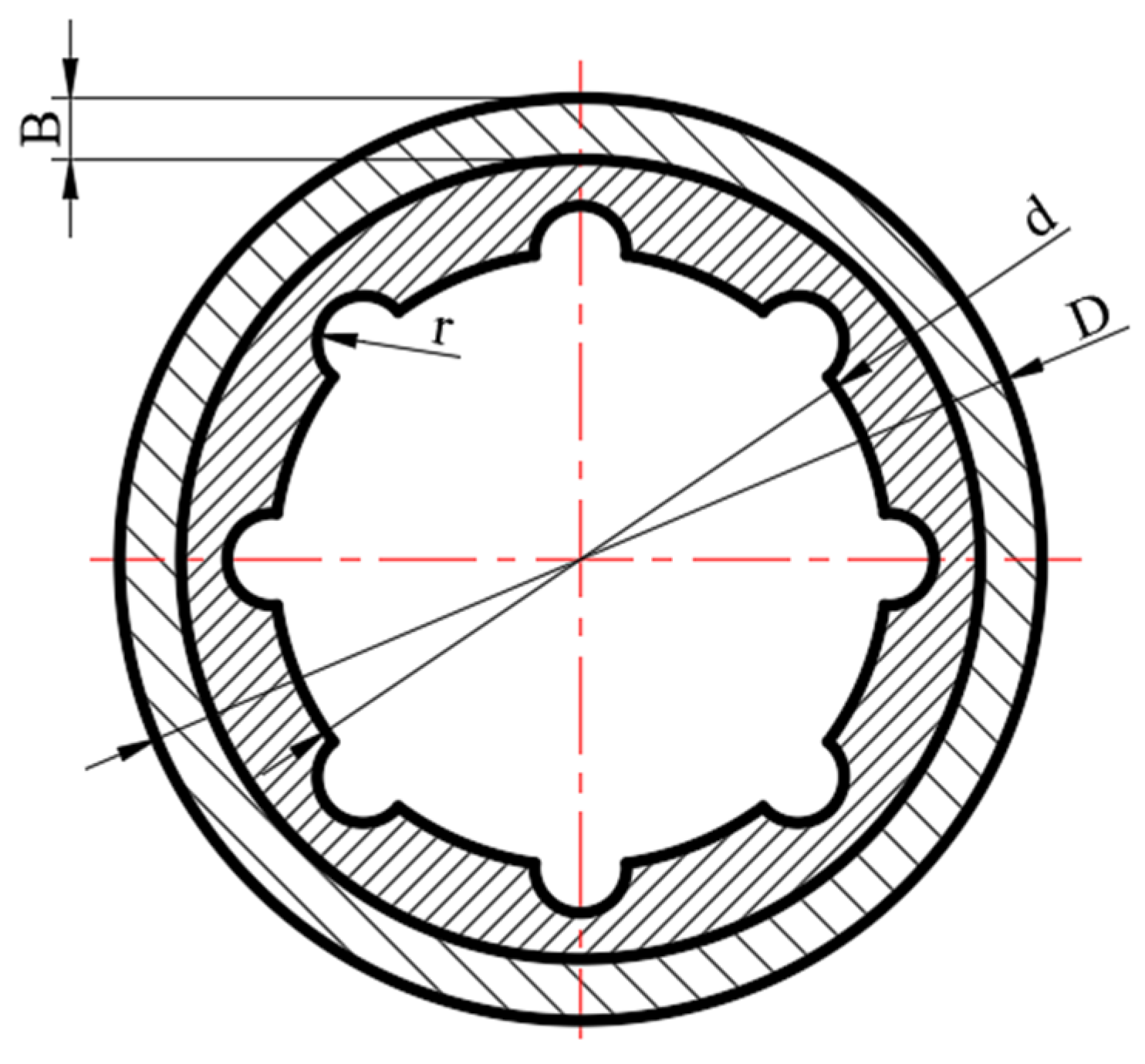

2.1. Dimensions of the Bearing System Model

2.2. Materials of the Bearing System

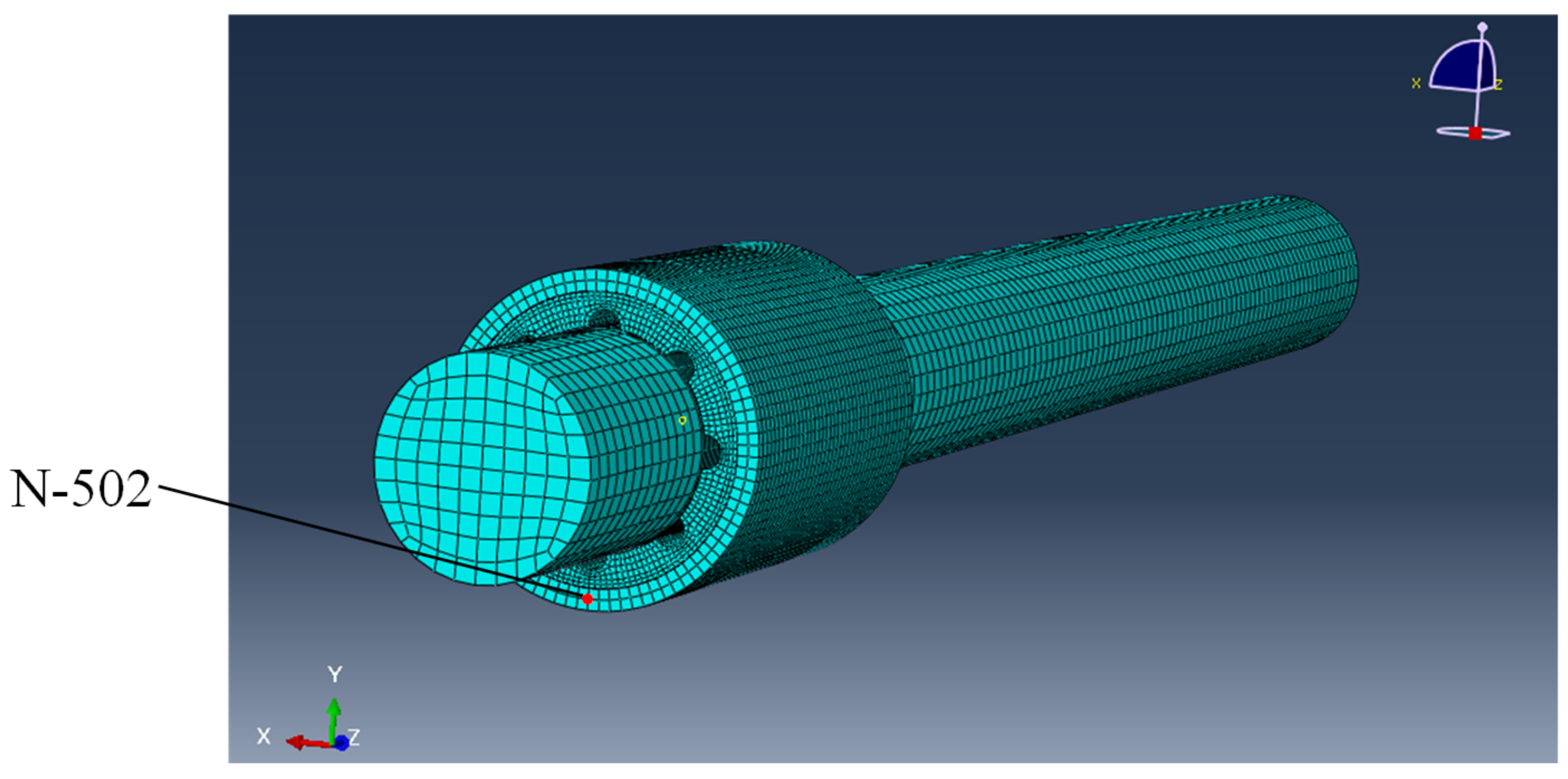

2.3. Division of the Finite Element Mesh

2.4. Boundary Conditions

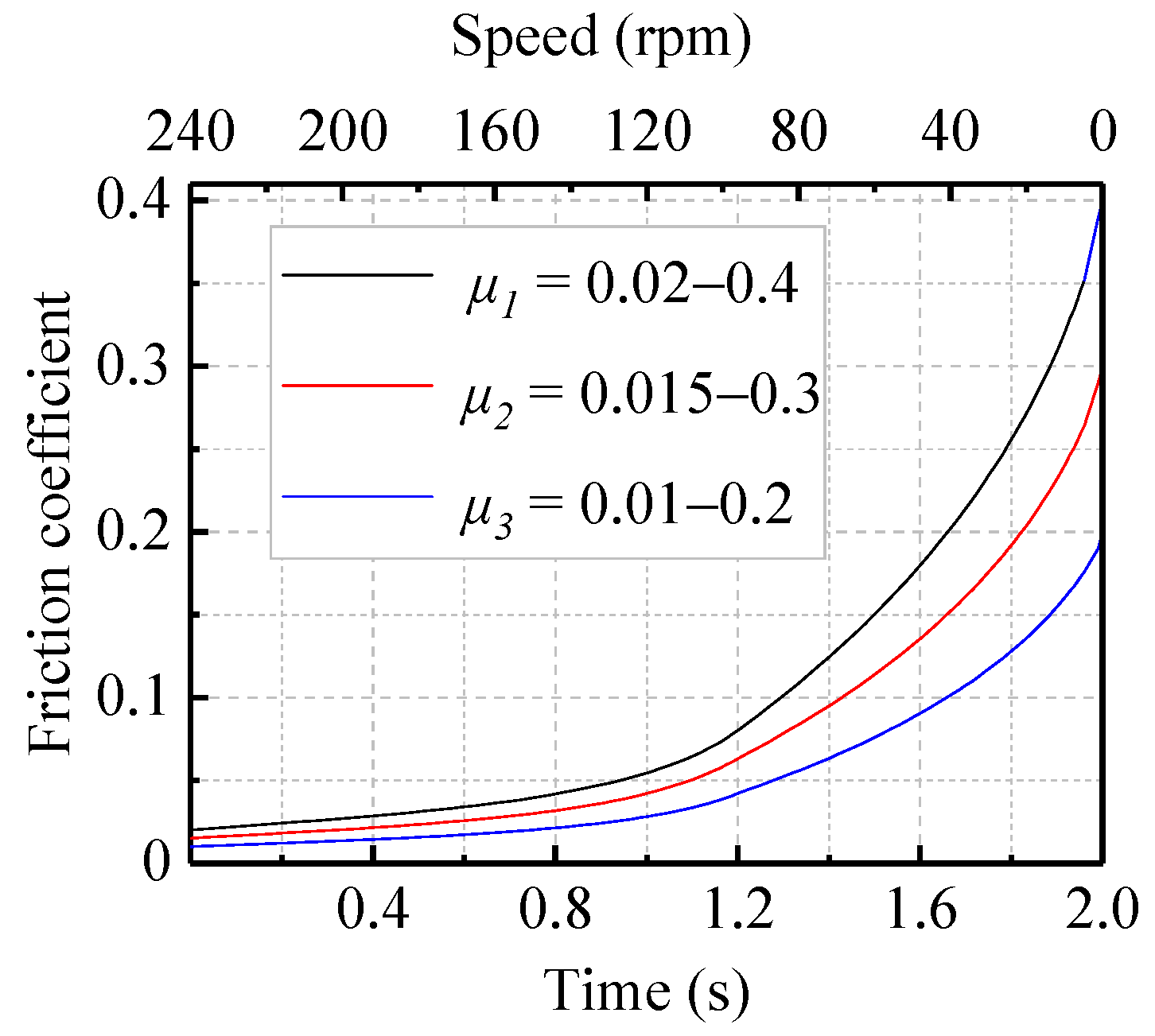

2.5. Analysis Step

3. Results and Discussion

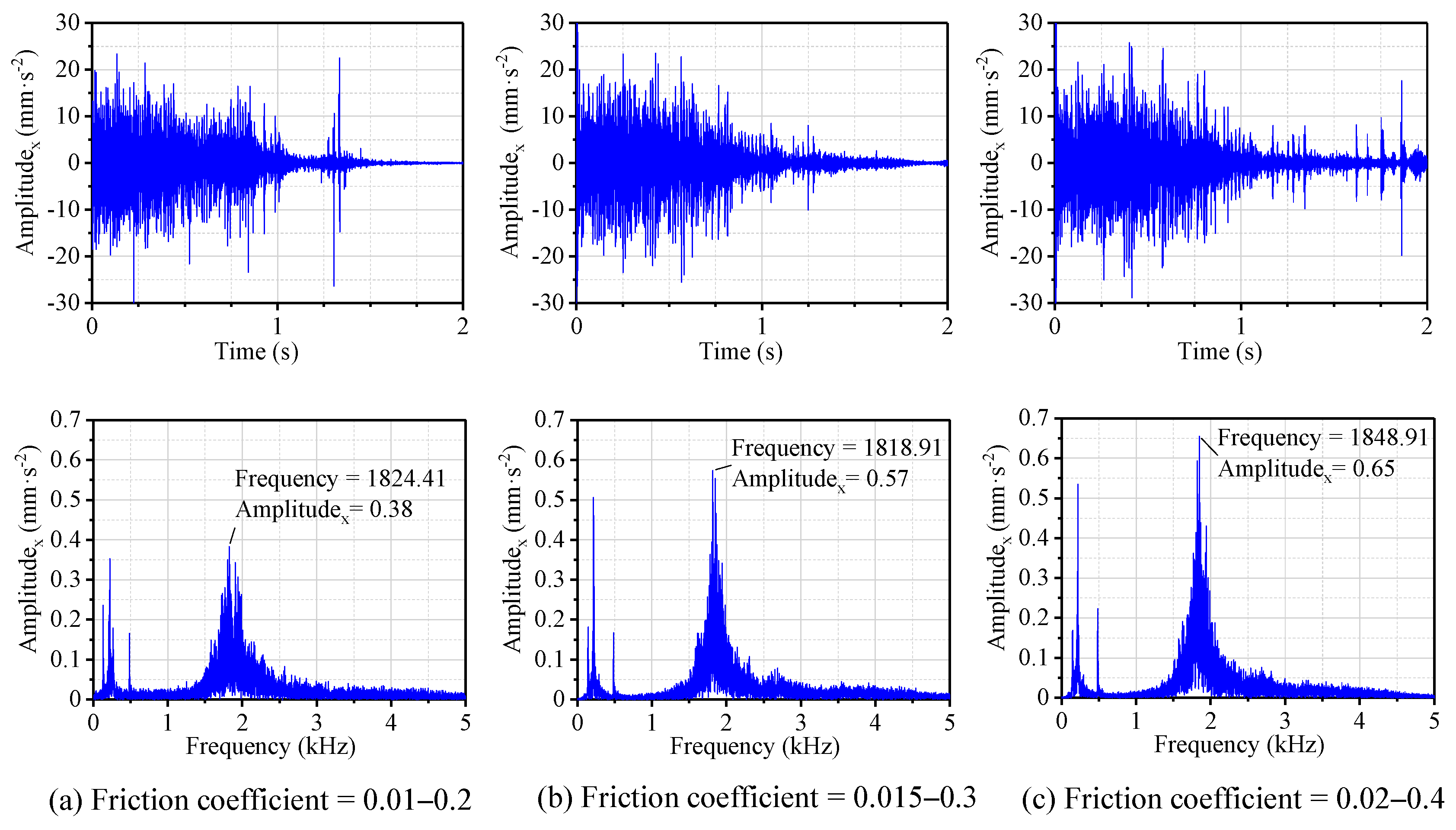

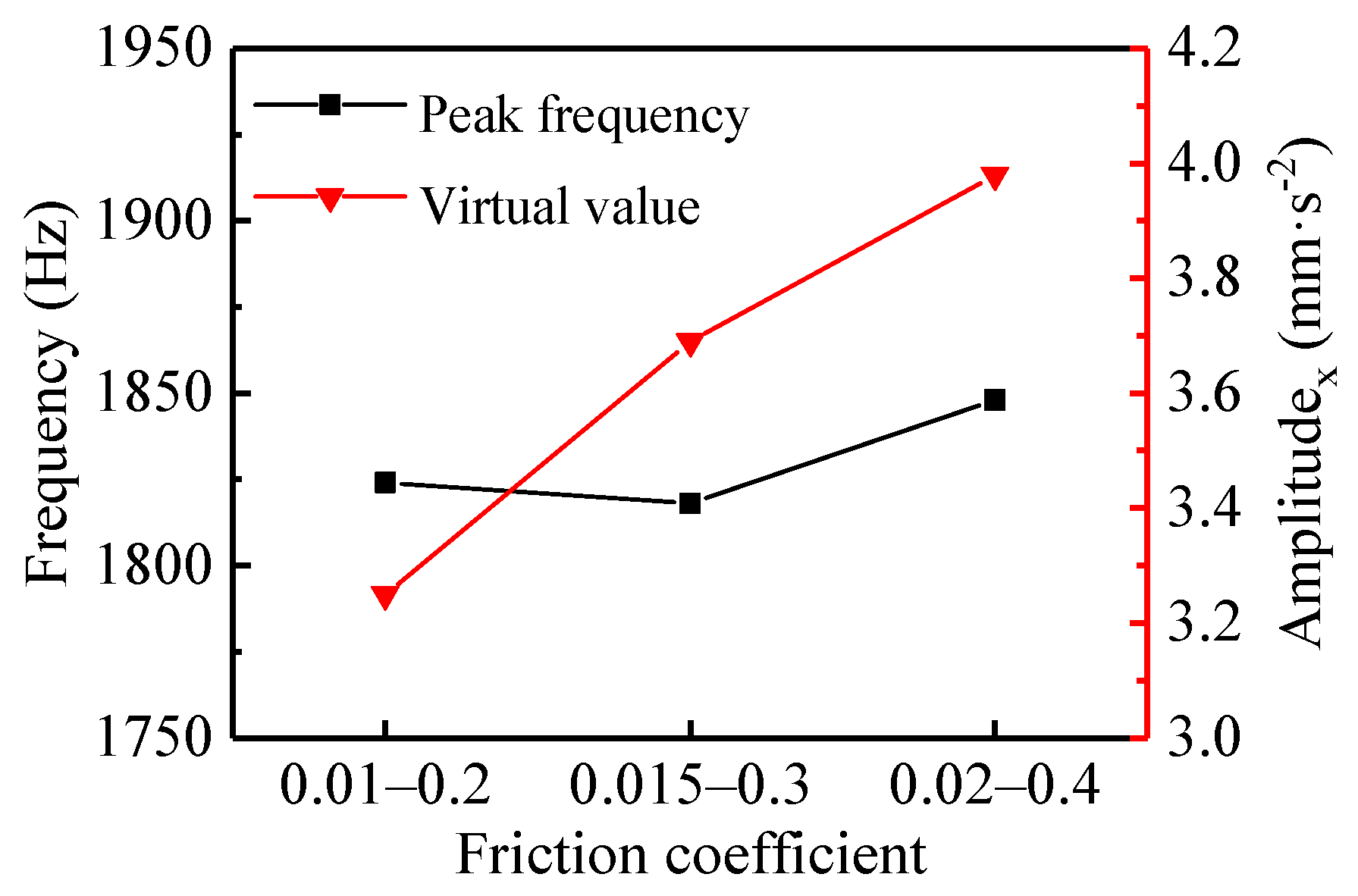

3.1. Effects from the Friction Coefficient

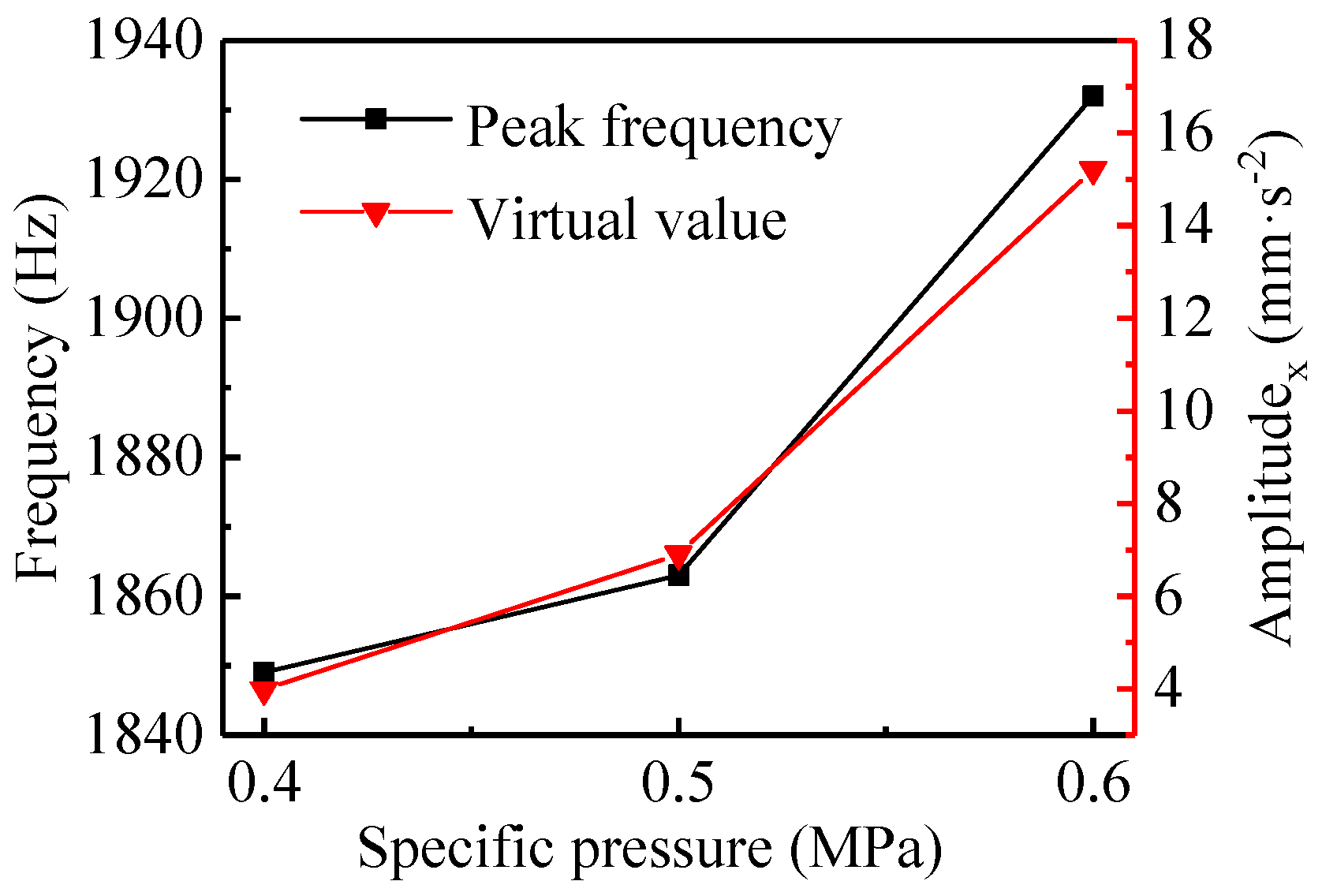

3.2. Effects from the Specific Pressure

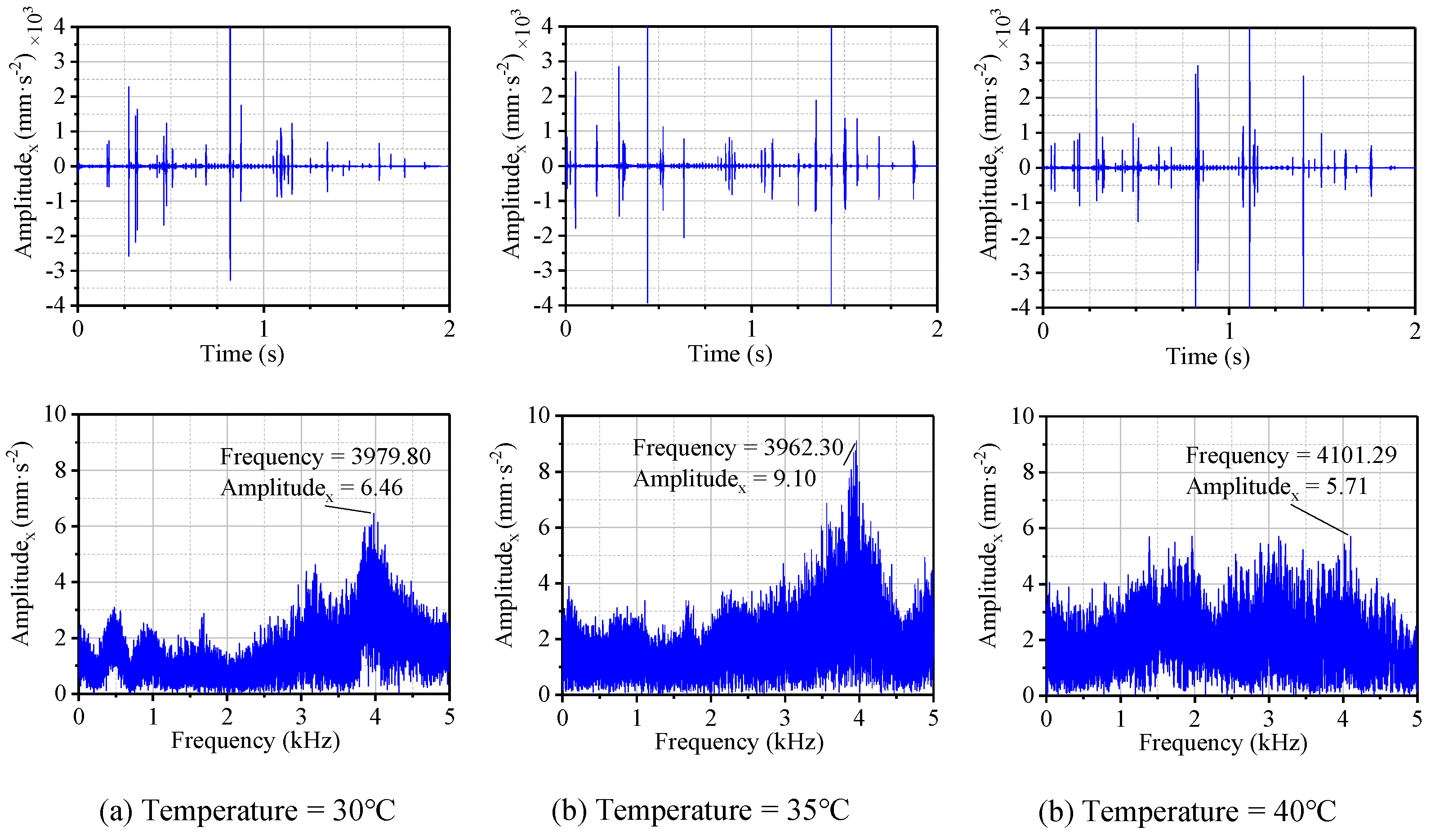

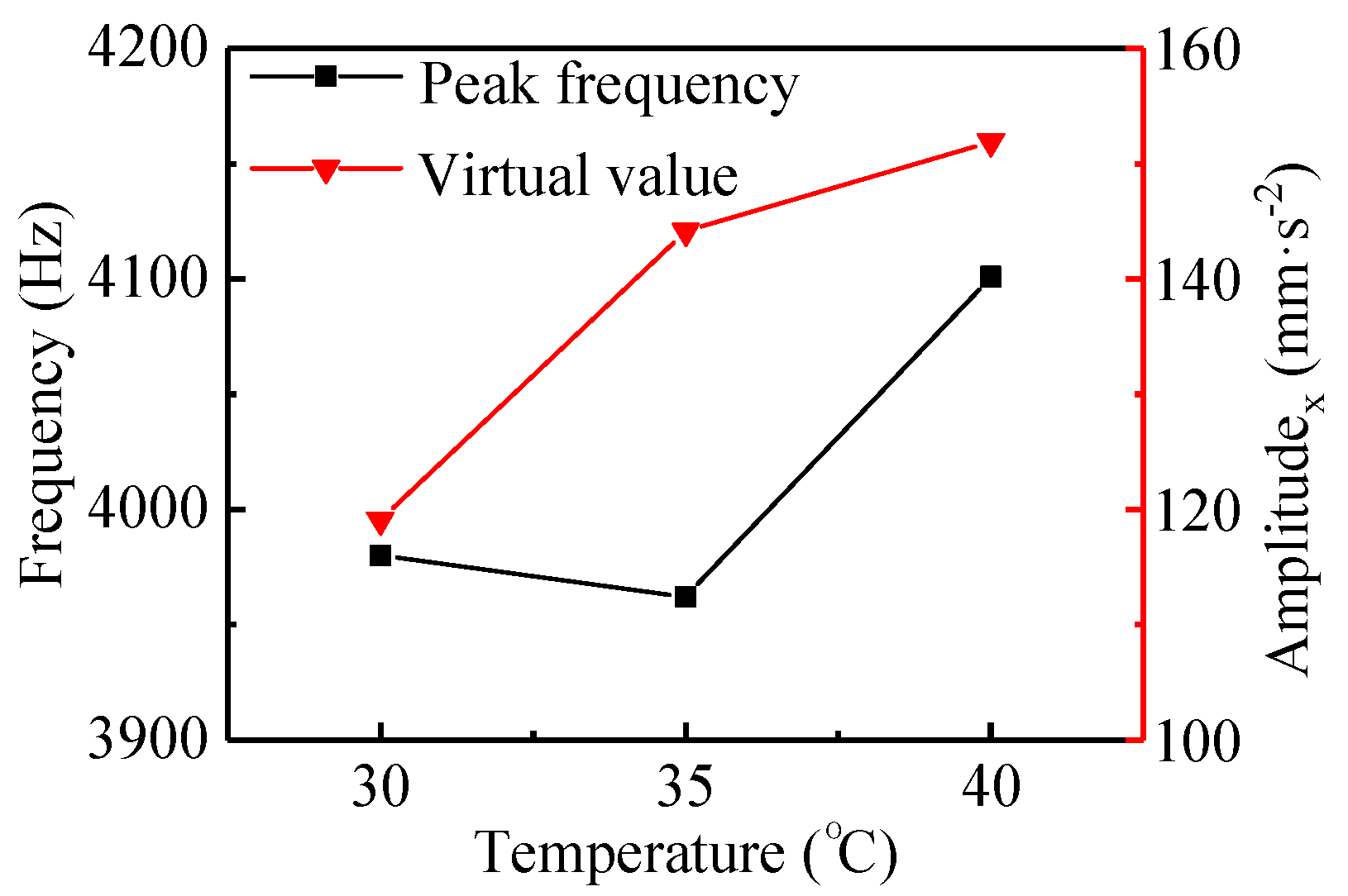

3.3. Effects from Temperature

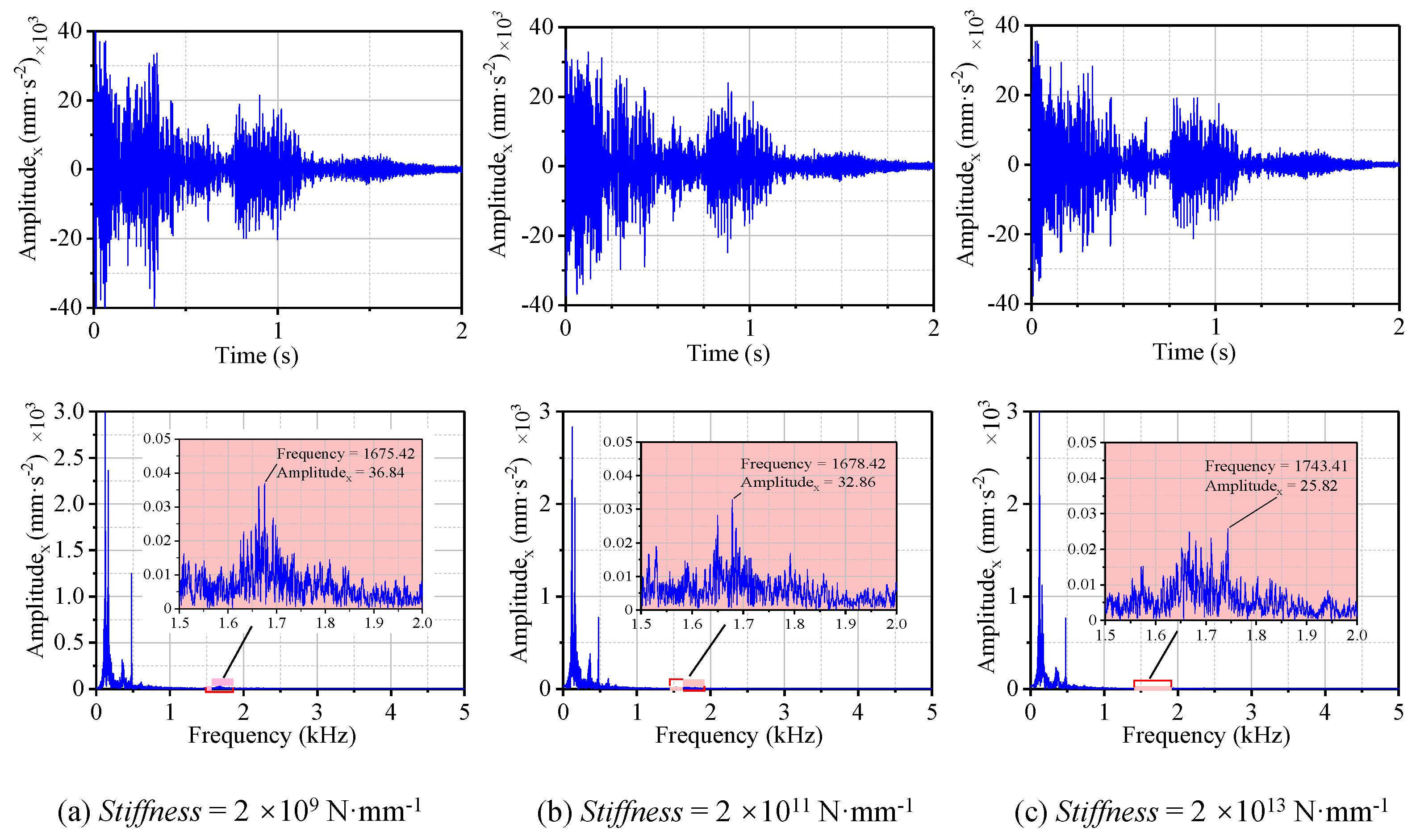

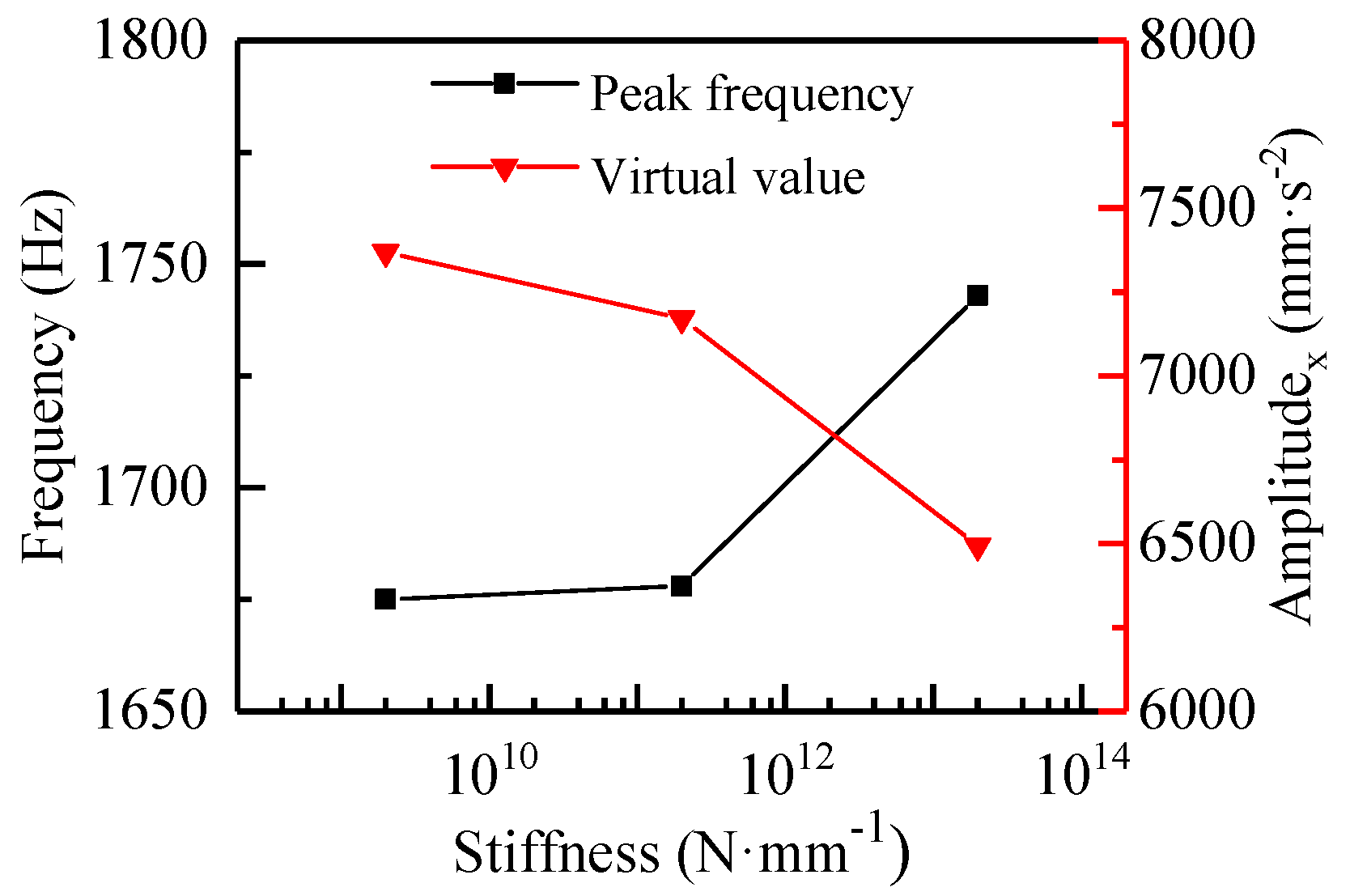

3.4. Effect from the Stiffness of the Bearing Support

4. Orthogonal Design

- B1—specific pressure, level 1, 0.3 MPa.

- D3—stiffness of bearing support, level 3, 2 × 109 N·mm−1.

- C1—temperature, level 1, 20 °C.

- A1—friction coefficient, level 1, 0.01–0.2.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bhushan, B. Stick-Slip induced noise generation. J. Lubr. Technol. 1980, 102, 201–210. [Google Scholar] [CrossRef]

- Krauter, A.I. Generation of squeal/chatter in water-lubricated elastomeric bearings. J. Tribol. 1981, 103, 406–412. [Google Scholar] [CrossRef]

- Simpson, T.A.; Ibrahim, R.A. Nonlinear friction-induced vibration in water-lubricated bearings. JVC/J. Vib. Control 1996, 2, 87–113. [Google Scholar] [CrossRef]

- Hochlenert, D. Nonlinear stability analysis of a disk brake model. Nonlinear Dyn. 2009, 58, 63–73. [Google Scholar] [CrossRef]

- Hongling, Q.; Chang, Y.; Hefa, Z.; Xufei, L.; Zhixiong, L.; Xiang, X. Experimental analysis on friction-induced vibration of water-lubricated bearings in a submarine propulsion system. Ocean Eng. 2020, 203, 107239. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, G.; Wang, J. Analysis of frictional noise for water lubricated rubber bearings system. Adv. Mater. Res. 2010, 156–157, 607–610. [Google Scholar] [CrossRef]

- Ghorbel, A.; Zghal, B.; Abdennadher, M.; Walha, L.; Haddar, M. Investigation of friction-induced vibration in a disk brake model, including mode-coupling and gyroscopic mechanisms. Proc. Inst. Mech. Eng. J. Automob. Eng. 2020, 234, 887–896. [Google Scholar] [CrossRef]

- Jin, Y.; Deng, T.; Liu, Z.; Zhou, J. Research on the influence of the normal vibration on the friction-induced vibration of the water-lubricated stern bearing. J. Vibroeng. 2020, 762–772. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Zou, L.; Yang, J. Influence of both friction and wear on the vibration of marine water lubricated rubber bearing. Wear 2017, 376–377, 920–930. [Google Scholar] [CrossRef]

- Litwin, W. Experimental research on water lubricated three layer sliding bearing with lubrication grooves in the upper part of the bush and its comparison with a rubber bearing. Tribol. Int. 2015, 82, 153–161. [Google Scholar] [CrossRef]

- Litwin, W. Properties comparison of rubber and three layer PTFE-NBR-bronze water lubricated bearings with lubricating grooves along entire bush circumference based on experimental tests. Tribol. Int. 2015, 90, 404–411. [Google Scholar] [CrossRef]

- Litwin, W.; Dymarski, C. Experimental research on water-lubricated marine stern tube bearings in conditions of improper lubrication and cooling causing rapid bush wear. Tribol. Int. 2016, 95, 449–455. [Google Scholar] [CrossRef]

- Aronov, V.; D’Souza, A.F.; Kalpakjian, S.; Shareef, I. Experimental investigation of the effect of system rigidity on wear and friction-induced vibrations. Am. Soc. Mech. Eng. 1983, 105, 206–211. [Google Scholar] [CrossRef]

- Kuang, F.; Zhou, X.; Liu, Z.; Huang, J.; Liu, X.; Qian, K.; Gryllias, K. Computer-Vision-Based research on friction vibration and coupling of frictional and torsional vibrations in water-lubricated bearing-shaft system. Tribol. Int. 2020, 150, 106336. [Google Scholar] [CrossRef]

- Peng, E.G.; Liu, Z.L.; Tian, Y.Z.; Lan, F. Experimental study on friction-induced vibration of water-lubricated rubber stern bearing at low speed. Appl. Mech. Mater. 2010, 44–47, 409–413. [Google Scholar] [CrossRef]

- Deleau, F.; Mazuyer, D.; Koenen, A. Sliding friction at elastomer/glass contact: Influence of the wetting conditions and instability analysis. Tribol. Int. 2009, 42, 149–159. [Google Scholar] [CrossRef]

- Meziane, A.; Baillet, L.; Laulagnet, B. Experimental and numerical investigation of friction-induced vibration of a beam-on-beam in contact with friction. Appl. Acoust. 2010, 71, 843–853. [Google Scholar] [CrossRef]

- Viswanathan, K.; Sundaram, N.K. Distinct stick-slip modes in adhesive polymer interfaces. Wear 2017, 376–377, 1271–1278. [Google Scholar] [CrossRef]

- Hu, S.; Liu, Y. Disc brake vibration model based on stribeck effect and its characteristics under different braking conditions. Math. Probl. Eng. 2017, 2017. [Google Scholar] [CrossRef]

- Leine, R.I.; Van Campen, D.H.; De Kraker, A.; Van Den Steen, L. Stick-Slip vibrations induced by alternate friction models. Nonlinear Dyn. 1998, 16, 41–54. [Google Scholar] [CrossRef]

- Lin, C.G.; Zou, M.S.; Sima, C.; Liu, S.X.; Jiang, L.W. Friction-Induced vibration and noise of marine stern tube bearings considering perturbations of the stochastic rough surface. Tribol. Int. 2019, 131, 661–671. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Z.; Huang, X.; Hua, H. Stability and transient dynamics of a propeller-shaft system as induced by nonlinear friction acting on bearing-shaft contact interface. J. Sound Vib. 2014, 333, 2608–2630. [Google Scholar] [CrossRef]

- Qin, W.; Zhang, Z.; Qin, H.; Zhang, Z. Self-Excited vibration of a flexibly supported shafting system induced by friction. J. Vib. Acoust. Trans. ASME 2017, 139, 021004. [Google Scholar] [CrossRef]

- Quality Carbon Structural Steels; China National Standardization Management Committee: Beijing, China, 2015; GB/T 699-2015.

- Dong, C.; Yuan, C.; Bai, X.; Yan, X.; Peng, Z. Study on wear behaviour and wear model of nitrile butadiene rubber under water lubricated conditions. RSC Adv. 2014, 4, 19034–19042. [Google Scholar] [CrossRef]

- Bearing Components, Bonded Synthetic Rubber, Water Lubricated; United States Department of Defense: Arlington, VA, USA, 2005; MIL-DTL-17901C(SH).

- Zhou, G.; Mi, X.; Wang, J.; Hu, R. Experimental comparison between the Stribeck curves of water lubricated rubber bearing with straight and spiral grooves. Ind. Lubr. Tribol. 2018, 70, 1326–1330. [Google Scholar] [CrossRef]

- Krauter, A.I.; Brower, D.C. Squeal of water-lubricated elastomeric bearings: A quantitative laboratory investigation. Tech. Rep. 1978, 78, 26. [Google Scholar]

- Smith, R.L.; Pan, C.H.T. An exploratory laboratory simulation of stick-slip induced vibration of water-lubricated compliant-layer bearings. Shak. Res. CORP Ballst. LAKE NY 1975, No. SRC-75, 108780300. [Google Scholar]

- Brake, M.R.; Wickert, J.A. Frictional vibration transmission from a laterally moving surface to a traveling beam. J. Sound Vib. 2008, 310, 663–675. [Google Scholar] [CrossRef]

- Ryzhik, B. Friction-Induced vibrations of squeal type due to transverse contraction in a flexible disk. J. Sound Vib. 2009, 326, 623–632. [Google Scholar] [CrossRef]

- Wu, X.; Wang, J.; Xiao, K.; Zhu, J. Numerical simulation study on water-lubricated rubber bearing. J. Adv. Manuf. Syst. 2008, 7, 111–114. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| External diameter, D (mm) | 60 |

| Inner radius, d (mm) | 40 |

| Length, L (mm) | 80 |

| Radius of the groove, r (mm) | 3 |

| Groove number, n | 8 |

| Rubber thickness, h (mm) | 6 |

| Copper thickness, B (mm) | 4 |

| Level | A Friction Coefficient | B Pressure (MPa) | C Temperature (°C) | D Stiffness of Bearing Support (N·mm−1) |

|---|---|---|---|---|

| 1 | 0.01–0.2 | 0.3 | 20 | Fixed |

| 2 | 0.015–0.3 | 0.4 | 25 | 2 × 109 |

| 3 | 0.02–0.4 | 0.5 | 30 | 2 × 1011 |

| Factor | 1 | 2 | 3 | 4 | Results | ||

|---|---|---|---|---|---|---|---|

| No. | A | B | C | D | Frequency (Hz) | RMS (mm·s−2) | |

| 1 | 1 | 1 | 1 | 1 | 1629.42 | 10.06 | |

| 2 | 1 | 2 | 2 | 2 | 1662.42 | 4847.95 | |

| 3 | 1 | 3 | 3 | 3 | 1686.92 | 10,370.83 | |

| 4 | 2 | 1 | 2 | 3 | 1654.92 | 5208.48 | |

| 5 | 2 | 2 | 3 | 1 | 1653.97 | 3.69 | |

| 6 | 2 | 3 | 1 | 2 | 1684.92 | 8295.86 | |

| 7 | 3 | 1 | 3 | 2 | 1671.92 | 4255.69 | |

| 8 | 3 | 2 | 1 | 3 | 1691.92 | 6735.82 | |

| 9 | 3 | 3 | 2 | 1 | 3766.31 | 683.58 | |

| Frequency (Hz) | K1 | 4978.75 | 4956.25 | 5006.25 | 7049.70 | ||

| K2 | 4993.80 | 5008.30 | 7083.65 | 5019.25 | |||

| K3 | 7130.14 | 7138.14 | 5012.80 | 5033.75 | |||

| κ1(K1/3) | 1659.58 | 1652.08 | 1668.75 | 2349.90 | |||

| κ2(K2/3) | 1664.60 | 1669.43 | 2361.22 | 1673.08 | |||

| κ3(K3/3) | 2376.71 | 2379.38 | 1670.93 | 1677.92 | |||

| Range | 717.13 | 727.30 | 692.47 | 676.82 | |||

| Optimum solution | A1 | B1 | C1 | D2 | |||

| RMS (mm·s−2) | K1 | 15,228.84 | 9474.23 | 15,041.74 | 697.32 | ||

| K2 | 13,508.04 | 11,587.46 | 10,740.01 | 17,399.50 | |||

| K3 | 11,675.08 | 19,350.27 | 14,630.21 | 22,315.13 | |||

| κ1(K1/3) | 5076.28 | 3158.08 | 5013.91 | 232.44 | |||

| κ2(K2/3) | 4502.68 | 3862.49 | 3580.00 | 5799.83 | |||

| κ3(K3/3) | 3891.69 | 6450.09 | 4876.74 | 7438.38 | |||

| Range | 1184.58 | 3292.01 | 1433.91 | 7205.94 | |||

| Optimum solution | A3 | B1 | C2 | D1 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, G.; Li, P.; Liao, D.; Zhang, Y.; Zhong, P. The Friction-Induced Vibration of Water-Lubricated Rubber Bearings during the Shutdown Process. Materials 2020, 13, 5818. https://doi.org/10.3390/ma13245818

Zhou G, Li P, Liao D, Zhang Y, Zhong P. The Friction-Induced Vibration of Water-Lubricated Rubber Bearings during the Shutdown Process. Materials. 2020; 13(24):5818. https://doi.org/10.3390/ma13245818

Chicago/Turabian StyleZhou, Guangwu, Peng Li, Daxin Liao, Yuhao Zhang, and Ping Zhong. 2020. "The Friction-Induced Vibration of Water-Lubricated Rubber Bearings during the Shutdown Process" Materials 13, no. 24: 5818. https://doi.org/10.3390/ma13245818

APA StyleZhou, G., Li, P., Liao, D., Zhang, Y., & Zhong, P. (2020). The Friction-Induced Vibration of Water-Lubricated Rubber Bearings during the Shutdown Process. Materials, 13(24), 5818. https://doi.org/10.3390/ma13245818