Abstract

The detection of product defects is essential in quality control in manufacturing. This study surveys stateoftheart deep-learning methods in defect detection. First, we classify the defects of products, such as electronic components, pipes, welded parts, and textile materials, into categories. Second, recent mainstream techniques and deep-learning methods for defects are reviewed with their characteristics, strengths, and shortcomings described. Third, we summarize and analyze the application of ultrasonic testing, filtering, deep learning, machine vision, and other technologies used for defect detection, by focusing on three aspects, namely method and experimental results. To further understand the difficulties in the field of defect detection, we investigate the functions and characteristics of existing equipment used for defect detection. The core ideas and codes of studies related to high precision, high positioning, rapid detection, small object, complex background, occluded object detection and object association, are summarized. Lastly, we outline the current achievements and limitations of the existing methods, along with the current research challenges, to assist the research community on defect detection in setting a further agenda for future studies.

1. Introduction

In the manufacture of mechanical products in complex industrial processes, defects such as internal holes [1], pits [2], abrasions [3], and scratches [4] arise, due to failure in design and machine production equipment as well as unfavorable working conditions. Products may also easily corrode [5] and be prone to fatigue [6] because of daily application. These defects increase the costs incurred by enterprises, shorten the service life of manufactured products, and result in an extensive waste of resources, thereby causing substantial harm to people and their safety [7]. Hence, detecting defects is a core competency that enterprises should possess in order to improve the quality of the manufactured products without affecting production. Automatic defect-detection technology has obvious advantages over manual detection. It not only adapts to an unsuitable environment but also works in the long run with high precision and efficiency. Research on defect-detection technology can reduce the production cost, improve production efficiency and product quality, as well as lay a solid foundation for the intelligent transformation of the manufacturing industry.

Therefore, many scholars have reviewed defect-detection-related technologies and applications to provide references for the application and research of defect-detection technology. For example, in view of the defect-detection technology applied by pharmaceutical products, Lalit Mohan Kandpal et al. [8]. summarized the application of hyperspectral [9], vibration spectrum [10], infrared [11], and other spectral technologies. For surface defect detection of manufactured products, Xianghua Xie [12] systematically recent advances in surface detection using computer vision and image processing techniques. By comparing the findings of past studies, they find that surface defect detection based on image processing requires high real-time performance in industrial applications. For fabric defect detection, scholars [13,14] reviewed the application and development of defect-detection methods commonly used in the production of textile fabrics from the perspective of defect-detection development of the textile industry production. Thermal imaging technologies are widely used in many industrial areas. I. Jorge Aldave [15] focused on the comparison of results obtained with commercially available non-experimental IR methods to provide references for the cameras in the field of non-destructive defect detection. Defect-detection technology is a hot topic in the industry and academia. However, scholars have yet to categorize product defect types (for example, steel [16] and textile [17]), the main detection techniques, summary of applications of defect-detection technology, existing equipment for defect detection, and other prospects. In addition, the mainline, review, and summary of the research status of relevant technologies locally and abroad have yet to be realized.

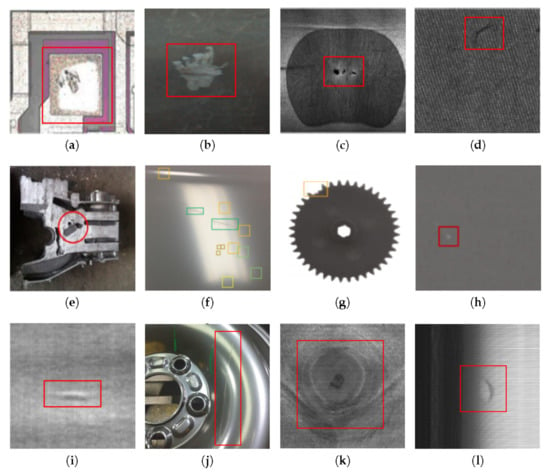

This paper first classifies the common defects of electronic components, pipes, welding parts, and textile materials, as shown in Figure 1. Then, it summarizes the mainstream deep-learning technology for defect detection and its application status and analyzes the application situation of the main defect-detection equipment, in order to provide reference for defect-detection technology in theory and practical application.

Figure 1.

Defects in different areas: (a) metallization peeloff of electronic components [18]. (b) pipeline corrosion [19]. (c) defective with gas pore [20]. (d) defect bigknot of textile materials [21]. (e) shrinkage and porosity defect of Casting [22]. (f) defects in green, yellow, orange bounding box are scratch, cratering, hump, respectively in carbody [23]. (g) Lack defect of gear [24]. (h) light leakage defect on mobile screen [25]. (i) Convexity defect in aluminum foil [26]. (j) Scratch defect of the wheel hub [27]. (k) Branch defect of wood veneer [28]. (l) Bubble defect of tire sidewall [29].

2. Survey of Defect-Detection Technologies

Product defect-detection technology is mainly to detect the surface and internal defects of products. The defect-detection technology refers to the detection technology of spot, pit, scratch, color differences and defect on the product surface. Internal defect-detection technology mainly includes internal flaw detection, hole detection and crack detection [30]. At present, several methods are used to detect product quality, including deep learning [31], magnetic powder [32], eddy current testing [33], ultrasonic testing [34], and machine vision [35] detection methods.

Wet magnetic particle detection mixes the magnetic powder in water, oil, or other liquid media. Magnetic powder marks the location of defects through liquid pressure and the attraction of the external magnetic field [32,36,37]. The moisture detection method has high sensitivity, and the liquid medium is recyclable [38,39]. Dry Magnetic powder testing [40] directly attaches magnetic powder onto the surface of the magnetized workpiece for defect detection. This method is used for the local inspection of defects in large casting, welding parts, and other segments that are unsuitable for wet detection. The continuous magnetic particle detection method detects defects in magnetic suspension or powder under the external magnetic field [41]. The method can be used to observe the defects in the external magnetic field. Several factors that influence the precision of Magnetic powder testing include roughness and the profile of the test piece, the geometrical characteristics of defects, the selected magnetization method, and the quality of operators [42]. Meanwhile, the factors that influence the sensitivity of Osmosis testing are imaging reagent, the performance of osmotic fluid, quality of operators, and the influence of defects. Factors that influence the accuracy of the detection of eddy current are the type and parameters of coil and material and the profile of the test piece [43,44].

The ultrasonic testing effect is affected by the angle between the defect surface and the ultrasonic propagation direction [34,45]. If the angle is vertical, then the signal returned is strong, and the defect is easily detected. If the angle is horizontal, then the signal returned is weak, which makes detecting a leak easy. Therefore, selecting the appropriate detection sensitivity and corresponding probe to reduce leakage detection is necessary [46]. The factors that influence ultrasonic testing include projection direction, probe effectiveness, sound contact quality, and instrument operating frequency [47,48].

Machine vision detection mainly consists of image acquisition and defect detection and classification. Because of its fast, accurate, non-destructive and low-cost characteristics, machine vision is widely used. Machine vision identifies objects mainly based on the color, texture and geometric features of objects. The quality of image acquisition determines the difficulty of image processing. In turn, the quality of the image processing algorithm directly affects the accuracy and error detection rate of defect detection and classification [49,50,51]. The deep-learning method is also a defect-detection method that is based on image processing, which is widely used to obtain useful features in massive data [52]. Table 1 presents a comparison of commonly used product defect-detection methods.

Table 1.

Comparison of common defect-detection methods.

Clearly, the traditional defect-detection techniques and the popular deep-learning defect-detection techniques have their advantages. The traditional detection methods are highly focused. For instance, Osmosis testing technology [53] is only suitable for detecting defects in highly permeable and non-porous materials and have certain advantages over other general methods. However, most of the traditional detection methods still need to rely on manual assistance to complete, especially when a certain amount of instrument debugging is required before testing, and the equipment development cost is high, which is not highly adaptable and limited by the equipment life and manufacturing accuracy. Innovative defect-detection techniques, particularly machine vision and deep-learning methods [54,55,56], have become the most popular in recent years and are one of the key technologies for automating defect detection due to their versatility and lack of reliance on human assistance. Compared to traditional defect detection methods, the new technologies offer better inspection results and lower costs, but still rely on large amounts of learned data to drive model updates and improve inspection accuracy.

3. Survey of Deep-Learning Defect-Detection Technologies

Deep-learning technology has developed rapidly and made great success in object detection [61], intelligent robot [62], saliency detection [63], parking garage sound event detection [64], sound event detection for smart city safety [65,66], UAV blade fault diagnosis [67,68,69] and other fields [70,71,72]. Deep learning has a kind of deep neural network structure with multiple convolutions layer. By combining low-level features to form a more abstract high-level representation of attribute categories or features, the data can be better reached in abstract ways such as edge and shape to improve the effectiveness of the deep-learning algorithm [70], Therefore, many researchers try to use deep-learning technology to defect detection of product and improved the product quality [71,72,73,74]. Table 2 summarizes the advantages and disadvantages of deep-learning methods commonly used in product defect detection. It mainly includes convolutional neural network (CNN) [75], autoencoder neural network [74,76], deep residual neural network [77], full convolution neural network [78], and recurrent neural network [79,80].

Table 2.

Deep-Learning Defect-Detection Methods.

(1) Using the CNN to defect detection of product [75]. CNN is a feedforward neural network. CNN consist of one or more convolutional layers and fully connected layers, as well as associated weights and pooling layers [81]. Literature [82] is a very popular LeNet convolution neural network structure. LeNet network structure can be used to detect defects in two situations: one is to design a complex multi-layer CNN structure, use different network structure to extra image content features, and complete end-to-end training to detect defects in images [56,83]; the other is to combine CNN with CRF model, train CNN with CRF energy function as constraint or optimize network prediction results with CRF. And to achieve the detection of product defects [71].

(2) The product defect-detection technology based on the neural network [74,76]. Autoencoder network mainly includes two stages: coding and decoding. In the coding stage, the input signal is converted into a coding signal for feature extraction; in the decoding stage, the feature information is converted into a reconstruction signal, and then the reconstruction error is minimized by adjusting the weight and bias to realize the defect detection [84]. The difference between autoencoder networks and other machine learning algorithms is that the learning goal of the autoencoder network is not for classification, but for feature learning [85,86]. It also has a strong ability of autonomous learning and highly nonlinear mapping. It can learn nonlinear metric functions to solve the problem of segmentation of complex background and foreground regions [87].

(3) The product defect-detection technology of deep residual neural network [77]. The deep residual network adds a residual module on the basis of the convolutional neural network. The residual network is characterized by easy optimization and can improve the accuracy by increasing the network depth [88,89]. CNN, Generative Adversarial Networks [90], etc. with the depth of the network increases, the extraction feature increases, but it is easy to cause the activation function not to converge. The purpose of the deep residual network is to optimize the increasing number of network layers with residual while increasing the network structure, so that the output and input element dimensions of the convolution layer in the residual unit are the same, and then through the activation function to reduce the loss.

(4) Full convolution neural network [78]. The fully connected layer is a connection between any two nodes between two adjacent layers. A fully connected neural network uses a fully connected operation, so there will be more weight values, which also means that the network will take up more memory and calculations [91]. During the calculation of the fully connected neural network, the feature map generated by the convolution layer is mapped into a fixed-length feature vector. The full convolution neural network can accept the input image of any size, and use the deconvolution layer to sample the feature map of the last convolution layer, it can recover to the same size of the input image.so that a prediction can be generated for each pixel, while retaining the spatial information in the original input image, and finally classify the feature map of the upper sampling pixel by pixel.

(5) Recurrent neural network recursively from the evolution direction of sequence data and all cyclic units are connected in a chain manner, and the input is sequence data [79,80]. The CNN model mainly extracts the feature information of input layer test samples through convolution and pooling operations. The recurrent neural network uses the recurrent convolution operation to replace the convolution operation on CNN. The difference is that the recurrent neural network does not perform the pooling layer operation to extract the features after the recurrent operation to extract the input layer features, but uses the recurrent convolution operation to process the features of the samples.

4. Survey of Object Detection Technologies Based on Deep Learning

Object detection methods based on neural networks can be divided into a one-stage method based on regression [92,93,94,95,96] and a two-stage method based on candidate box generation and classification [97,98,99,100,101,102,103]. The one-stage method does not need to generate candidate boxes in advance, but it only needs to complete the three tasks of feature extraction, classification, and location regression. By contrast, the two-stage method mainly has four tasks, namely feature extraction, generating candidate boxes, classification, and location regression. Table 3 shows a comparative analysis of the two types of object detection methods.

Table 3.

Comparative analysis of two kinds of object detection methods.

Representative one-stage methods include: Joseph Redmon et al. [92,93]. proposed the You Only Look Once(YOLO) method, which inherits OverFeat, and its detection speed reaches 45 pieces per second. The speed advantage makes it an end-to-end leader. Redmon et al. [94]. modified the network structure of YOLO and proposed the YOLOv2 and YOLO9000 methods, with a 4.00% increase in mAP. YOLOv3 [95] follows the Darknet53 network of YOLOv2 and combines it with the FPN [96] network structure. Thereafter, the prediction results are obtained from the convolutional network. Corresponding improvements enable the accuracy to reach 22.2 milliseconds per piece, and the best effect of mAP@0.5 on the COCO test set reaches 33.00%. However, the overall model becomes considerably complicated, and speed and accuracy serve as checks and balances for each other. To solve the problem of poor positioning accuracy of the YOLO algorithm, Wei Liu et al. [97]. proposed the Single Shot MultiBox Detector(SSD) method that combines YOLO regression ideas with the Faster R-CNN [98] anchor box mechanism, using the Visual Geometry Group Network(VGG) as the feature extraction network. The VGG is a convolutional neural network model proposed by K. Simonyan [99]. To address the issue that the SSD algorithm cannot easily detect small objects, Cheng-Yang Fu et al. [100]. proposed a DSSD method, which replaces the VGG16 of SSD with the ResNet101 network, thereby enhancing the network’s ability to extract features.

The representative two-stage methods are as follows. Girshick et al. [101]. proposed the Rich Feature Convolutional Neural Network (R-CNN) to enrich the features in the training process. That is, the mAP of the PASCAL VOC2007 test set was refreshed to 58.50%. He et al. [102]. proposed the Spatial Pyramid Pooling Network(SPP-Net) algorithm based on R-CNN to solve the problems of repetitive operations and shape distortion of convolutional neural networks. SPP-Net abandons the R-CNN clipping candidate box and image sub-block scaling operations before inputting the neural network, and adds an SPP structure between the convolutional and fully connected layers to increase the generation rate of candidate box and save computational overhead. Given the time cost caused by repeated computation of multiple stages and features during training and the space cost caused by storage of intermediate feature data, Girshick et al. [103]. proposed Fast R-CNN, which combines deep network with SVM classification. Accordingly, classification and regression are performed simultaneously by the full connectional layer network, thereby forming a multi-task model. This module has numerous calculations, given the problem that SPP-Net and Fast R-CNN have separate candidate area modules. Ren et al. [27] proposed the Faster R-CNN algorithm based on Fast R-CNN. Faster R-CNN adds an RPN network to the backbone network structure and sets multi-scale anchor points on the basis of established rules. To solve the problem that the Faster R-CNN rounds the feature map size when performing ROI pooling and downsampling, Mask R-CNN [104] abandons the rounding operation of the picture size and proposes to replace the ROI Pooling layer with ROI Align and use double Linear interpolation fills pixels at non-integer positions. Accordingly, no position error occurs when the downstream feature map is mapped upstream.

5. Summary Analyses of the Application Status of Defect-Detection Technology

5.1. The Traditional Method for Defect-Detection Technology

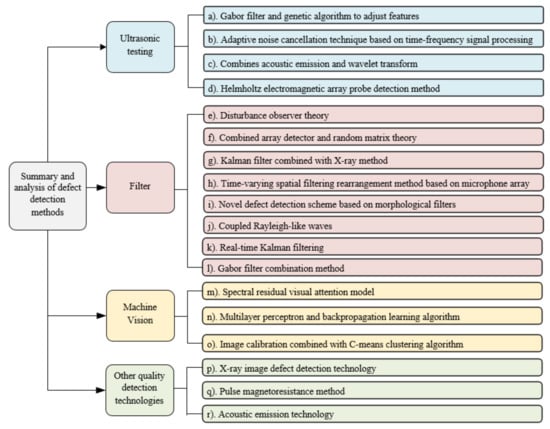

Non-destructive defect detection of products is widely used in manufacturing, in which analyzing the pros and cons of different algorithms can help to understand and improve the algorithms. Here we focus on the application status using the combination of classical defect detection and other algorithms. Figure 2. shows the different defect-detection methods and their corresponding performance results or summaries for non-destructive defect detection.

Figure 2.

Summary and analysis of defect-detection methods.

The ultrasonic defect-detection methods are widely used to detect the defects in the internal structure of the sample. Therefore, the results are mainly reflected in the performance of the ultrasonic signal [105]. The findings, as shown in [106], indicates that the ultrasonic defect-detection methods have the advantages of fast detection speed and simple operability. They also have special advantages in detecting defects in the internal material and structure as well as the size of the product. However, this method is unsuitable for workpieces with complicated structures with low detection efficiency [106]. Ultrasonic techniques are especially ineffective for detecting defects on the upper surface of the sample since a nonlinear relationship exists between the defect position and the signal receiving the time, which leads to the defect to be closely positioned to the direct pass wave end [107]. The denser the distribution of the real position of the product, the higher the certainty of the “trailing” phenomenon of the direct pass wave signal on the map.

The machine vision-based defect-detection methods are suitable for the detection of surface defects in products, which has achieved up to 88.60% accuracy in binary defect-detection problems [108]. The defect-detection accuracy over scratches, holes, scales, pitting, edge cracks, crusting, and inclusions can reach 95.30% [109]. Our survey shows that the machine vision-based image recognition is widely used in manufacturing surface defect detection due to the feature extraction ability from the images made possible by recent deep-learning techniques.

The defect-detection methods are based on filtering has a strong ability to describe the disturbance signal and detection of the tool defect inside the machine.

To the abovementioned main categories of defect-detection methods for mechanical products, several other technologies are also available such as the X-ray image defect-detection technology [110], Pulse magnetoresistance method [111], Acoustic emission technology [106]. These methods [106,110,111] have shown positive detection results and can provide theoretical and practical guidance for real-world applications. In addition, studies show that the majority of the early works studied a single defect-detection problem such as the defects in the material [112,113], shape [114,115], size [116], color [117], and surface of a product [118,119]. At the same time, studies on defects with varying size, crack depth, and other information are scarce, which is also a major limitation of existing defect-detection research [120,121,122]. The following is an experimental summary of some research methods [108,109,110,123,124,125,126,127,128,129,130,131,132]. The reference [123,124,125,126] are the experimental results of ultrasonic detection. The reference [109,127,128,129,130,131] are the experimental results of Filter detection. The reference [108,110,132] are the experimental results of other quality detection technologies.

- The frequency accuracy of the weld defect is over 60.00% when the frequency band is 100–200 kHz.Positive detection results can be obtained at frequencies of 100 to 200 kHz and 300 to 400 kHz [106].

- The total detection rate of the two types of samples in “defects” and “no defects” is 88.60% [108].

- Analysis of the effects of different surface defects and locations on the test results.The average recognition rate under eight types of defects is 95.30% [109].

- Poor detection effect with defect depth less than 2mm [110].

- The peak times of surface and subsurface defect depth of 3 mm are 16.59 and 37.01 ms, respectively [111].

- Realizes the detection and recognition of defects in different texture samples [123].

- Reduces unnecessary interference and extract weak signals from strong background noise [124].

- Effective detection of holes, axial cracks, and circumferential cracks [125].

- Detect cracks less than 3 mm [126].

- Can detect defects exceeding 1 mm2 [127].

- Resolves the quality defect detection with image noise and complex background [128].

- Improved Doppler distortion and multi-bearing source aliasing in bearing signals [129].

- Positive recognition effect on the position, shape, and size of the defect [130].

- It can define six features based on the characteristics of seam cracks and employed SVM for classification. The true positive rate was 94.46%, and the false-negative rate was only 0.29% [131].

- The 8-bit grayscale image recognition rate of an image size of 2500 × 2000 pixels is 94.00% [132].

5.2. Machine Learning for Defect-Detection Technology

Another major trend in the literature survey of defect-detection technology is the emerging dominance of the machine learning methods, which are now widely used in all fields of product defect detection. The defect-detection technology can be divided into two main categories: surface defect detection [133] and internal fault diagnosis [134]. Surface defect detection is similar to ’visual’ detection, that is, learning from the target features in an image with the help of deep-learning image processing technology to classify and locate product defects in the image, whereas internal fault diagnosis is similar to ’Auditory’ detection, that is, the diagnosis of faults in rotating parts such as bearings by means of modal analysis using digital signals in the time or frequency domain. We found that the defect-detection complex functions and enhanced feature extraction [135]. Table 4 Survey of Deep-learning methods in defect methods based on deep learning have achieved the best experimental result thus far. The highest precision of these algorithms can reach 99.00% with a recognition time of 0.12 ms for a single image [136]. The lowest precision level is 86.20% [137].

Table 4.

Machine Learning for Defect-Detection Technology.

6. Survey of Defect-Detection Equipment

At present, defect-detection equipment is mainly used in the production and processing stage of products. In the 1960s, due to the demand for the medical examination market, machine vision-based defect-detection robots are developed to detect insoluble foreign bodies in medical injection. Many visual inspection equipment providers were born such as BOSCH(Germany) [151], COMPUR [152], BS [153], CMP (Italy) [154], and Valley Industries (Japan) [155]. Recently, demand for intelligent manufacturing has been increasing as shown in China’s intelligent manufacturing 2025, German industry 4.0 and Britain’s “Modern Industrial Strategy”. Driven by these practical applications, demand for defect-detection equipment has been increasing steadily.

Figure 3 presents the defect-detection equipment widely used in the industry. In Table 5, we summarize the advantages and disadvantages of these defect-detection equipment aiming to identify the recurrent and difficult challenges in defect detection. Figure 3a features a defect-detection system for LYNX mechanical parts, which detects missing mechanical parts and external surface damages and assembly of parts. Figure 3b shows the use of machine vision to visually detect component defects. However, it is found that current detection accuracy and detection performance remain incapable of fully meeting the requirements of high-speed production in smart factories. Furthermore, stability and real-time performance should be further improved.

Figure 3.

Types of defect-detection equipment: (a) Rhein–Nadel automation (RNA) glass defect-detection system [156] (b) Visual detection system for defects of EvenFit components [157] (c) Rhein–Nadel automated detection system for defects in mechanical parts [158] (d) The visual detection system of the EvenFit capsule [159] (e) KEYENCE product size measuring instrument [160] (f) AVI soldering appearance inspection machine [161] (g) Hardware and workpiece visual measurement equipment [162] (h) ET-F1 engine cylinder bore eddy current detector [163].

Table 5.

Existing defect-detection equipment.

7. Challenge

7.1. 3D Object Detection

In modern computer vision systems, people are satisfied with 2D object detection. With the advent of 2.5D depth sensor, building 3D models has become increasingly important, and 3D geometric shapes have been considered an important clue in object recognition. One of the most important challenges of 3D is that given a depth map of an object from an angle, the 3D structure of an object can be inferred. We are convinced that one of the important trends in visual recognition is to identify defects on the surface of an object and infer its corresponding 3D model to determine the shape defects in the 3D layer. This situation is akin to that when we observe one side of a table, i.e., we naturally visualize a 3D model of the entire table. To determine the table based on the surface defects and in the 3D shape of the defects, various methods can be used to reconstruct and synthesize shapes, although such techniques are based on assembly. They are the same class or type of 3D shape completion. The completion of 3D models of different types of objects in complex environments should be studied further. At present, similar studies have been conducted. For example, the linear relationship between the 3D defect size of transparent parts and image gray level is found under certain circumstances [164]. On this basis, a set of vision-based transparent micro-defect measurement systems is developed. Iglesias [165] developed an automated inspection system to examine SLATE based on the use of 3D color cameras to capture data and using computer vision algorithms developed specifically for the purpose of studying SLATE characteristics. In a previous study [166], a potato virtual reality model reconstruction algorithm based on 3D shape and color images is proposed for sample quality tracking and review. The model redisplays potato color and 3D shape data in multiple views and supports 360-degree rotation in horizontal and vertical directions to simulate a handheld exam experience. This depth image processing is a potentially effective method for future non-destructive post-harvest grading, particularly for products in which size, shape, and surface conditions are important factors. In a previous study [167], a detection method combining grayscale image and 3D depth information is proposed.

7.2. High Precision, High Positioning, Fast Detection, Small Object

Through investigation, it is found that high precision [96,98], high positioning [94,96,98], fast detection [94], small object, complex background [94,96,98,168], occluded object detection [94,168], and object detection based on the association between objects [96,98] are the main challenges of the current deep-learning algorithm in the application of quality detection. In order to further assist researchers and enterprise engineers to apply the deep-learning method to product defect detection, Table 6 are from high precision [96,98], high positioning [94,96,98], fast detection [94], small object [96,100], complex background [94,96,98,168], occluded object detection [168,169], object association [170], and other aspects are summarized in the relevant papers published in ICCV and CVPR and other well-known international conferences in recent years, and the core idea and source code of these better papers are summarized to assist R & D personnel in knowledge reuse and innovative design.

Table 6.

Summary of object detection methods with high precision, high positioning, fast detection, small object, complex background, occluded object detection.

8. Development Trend

Our survey found that most of the existing defect-detection studies focused on defect detection of specific products. But the identification accuracy of current online defect-detection techniques remains to be improved. The following aspects of defect detection need special attention:

- Combined with the actual requirements of the factory, online defect detection of manufacturing products on the conveyor belt should be realized.

- As intelligent manufacturing enterprises attach importance to defect-detection technology, embedded sensor equipment to conduct online real-time detection of defects in manufactured products can be designed and used. Then, various non-destructive defect-detection methods should be integrated to realize multi-modal defect detection of manufacturing products, which can have broad application prospects in the field of defect detection.

- The main objects of 2D image surface defect-detection technology are surface scratches and abrasions. Obtaining in-depth information about the defects is limited. However, in the actual production process, the defect information of the product is not only displayed on the surface of the manufactured product but also requires the use of 3D defect-detection methods to detect the 3D surface characteristics of the test sample.

- With the rapid development of artificial intelligence and big data technology, useful information that can be extracted is abundant. Applying the rich information accurately to the manufacture of product defect feedback technology, defect control, and fault diagnosis warrants further research.

- Aiming at the multi-fault diagnosis of intelligent equipment with defect-detection technology in complex industrial processes, one of the important research directions to undertake should be effective fault prediction and diagnosis for intelligent equipment when multiple faults simultaneously occur.

- High-precision identification technology. In the process of image acquisition, the apparent characteristics of the object can considerably change with different lighting conditions and shooting angles and distance. Many noise interference and partial occlusion of the detected sample can also have a great impact on the detection results due to the different backgrounds of the detection object. The abovementioned factors are commonly used in industrial applications, which can lead to substantial difficulties in detecting defects in manufactured products. Therefore, such a problem should be further solved to improve the feature extraction capability of the current online non-destructive defect-detection technology and improve the accuracy of non-destructive defect detection.

- How to optimize the quality of image acquisition, improve the accuracy of the candidate box, extract features more comprehensively and accurately for learning, and extract features of small-size targets are the future research directions;

- Presently, a large number of neural networks (including neural networks improved for a certain problem) have their own advantages and disadvantages. These networks are implemented based on a large amount of data. How to use fewer picture samples to train the recognition model with excellent performance is a big difficulty;

- With more and more product derivatives, it remains to be studied how to transfer a trained model to another similar product and ensure its accuracy and detection efficiency;

- After the defect is detected and the type of defect is clear, it is very important to deal with the information of the object, and it is also very necessary to separate the defective product from the non-defective product. The defect-detection system can be combined with the early warning system to give timely warning after detecting the defective products, and the staff can timely eliminate the defective products. Or with the sorting system, the manipulator to eliminate the defective products, in addition, can also establish traceability system to check the production process will make the product defects steps, and timely optimization of the production process, so as to reduce the production cost;

- Future studies can also design defect information feedback technology that is based on defect-detection technology. Many feedback methods and objects remain undiscussed and are difficult points for future research. Once product information is processed and analyzed, and after determining the cause of the product defect or fault information, the defect or fault information can be fed back to the mother-machine system to realize online production and self-correction of the product. Doing so can help improve product quality and reduce manpower, material resources, and production costs. Finally, we hope to compare the performance of the mainstream deep-learning detection model, which can provide a reference for researchers in deep-learning surface defect detection. See Table 7 for details.

Table 7. Performance comparison of deep-learning object detection model.

Table 7. Performance comparison of deep-learning object detection model.

9. Summary

Industrial product quality is an important part of product production, and the research on defect-detection technology has great practical significance to ensure product quality. This article provides a comprehensive overview of the research status of product defect-detection technology in complex industrial processes. We have compared and analyzed traditional defect-detection methods and deep-learning defect-detection techniques, and comprehensively summarized the experimental results of defect-detection techniques. Meanwhile, combined with the actual application requirements and the development of artificial intelligence technology, the defect-detection equipment was investigated and analyzed. Through investigation, we found that 3D object detection, high precision, high positioning, rapid detection, small targets, complex backgrounds, detection of occluded objects, and object associations are the hotspots of academic and industrial research. We also pointed out that embedded sensor equipment, online product defect detection, 3D defect detection, etc. are the development trends in the field of industrial product defect detection. We believe that the investigation will help industrial enterprises and researchers understand the research progress of product defect-detection technology in the field of deep learning and traditional defect detection.

Author Contributions

Methodology, J.Y., Z.W., J.W., and H.D.; investigation, J.Y., S.L, J.W., and S.T.; resources, J.Y. and S.L.; writing–original draft preparation, J.Y., Z.W. and H.D.; writing–review and editing, J.Y., S.L., H.D., S.T. and J.W.; visualization, J.Y. and Z.W.; supervision, J.Y. and S.L.; project administration, S.L. and J.Y.; funding acquisition, S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China under Grant Nos.91746116, 61863005.The Science and Technology Foundation of Guizhou Province under grant [2020]009, [2016]5013, [2019]3003, [2020]005, and The Guizhou Province Internet + Collaborative Intelligent Manufacturing Key Laboratory Open Fund[2016]5103.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Peng, Y.; Liu, G.; Quan, Y.; Zeng, Q. The depth measurement of internal defect based on laser speckle shearing interference. Opt. Laser Technol. 2017, 92, 69–73. [Google Scholar] [CrossRef]

- Xiao, X.; Yu, L.; Dong, Z.; Mbelek, R.; Xu, K.; Lei, C.; Zhong, W.; Lu, F.; Xing, M. Adipose stem cell-laden injectable thermosensitive hydrogel reconstructing depressed defects in rats: Filler and scaffold. J. Mater. Chem. B 2015, 27, 5635–5644. [Google Scholar] [CrossRef] [PubMed]

- Hui, K.; Jian, Y.; Chen, Z. Accurate and Efficient Inspection of Speckle and Scratch Defects on Surfaces of Planar Products. IEEE Trans. Ind. Inform. 2017, 4, 1855–1865. [Google Scholar] [CrossRef]

- Chen, J.; Li, C. Prediction and Control of Thermal Scratch Defect on Surface of Strip in Tandem Cold Rolling. J. Iron Steel Res. Int. 2015, 22, 106–114. [Google Scholar] [CrossRef]

- Rodionova, I.G.; Zaitsev, A.I.; Baklanova, O.N.; Kazankov, A.Y.; Naumenko, V.V.; Semernin, G.V. Effect of carbon steel structural inhomogeneity on corrosion resistance in chlorine-containing media. Metallurgist 2016, 59, 774–783. [Google Scholar] [CrossRef]

- Amaya, J.; Lelah, A.; Zwolinski, P. Design for intensified use in product–service systems using life-cycle analysis. J. Eng. Des. 2014, 25, 280–302. [Google Scholar] [CrossRef]

- Wang, T.; Chen, Y.; Qiao, M.; Snoussi, H. A fast and robust convolutional neural network-based defect detection model in product quality control. Int. J. Adv. Manuf. Technol. 2018, 94, 3465–3471. [Google Scholar] [CrossRef]

- Kandpal, L.M.; Park, E.; Tewari, J.; Cho, B. Spectroscopic Techniques for Nondestructive Quality Inspection of Pharmaceutical Products. J. Biosyst. Eng. 2015, 40, 394–408. [Google Scholar] [CrossRef]

- Li, B.; Cobo-Medina, M.; Lecourt, J.; Harrison, N.; Harrison, R.J.; Cross, J.V. Application of hyperspectral imaging for nondestructive measurement of plum quality attributes. Postharvest Biol. Technol. 2018, 141, 8–15. [Google Scholar] [CrossRef]

- Amar, M.; Gondal, I.; Wilson, C. Vibration spectrum imaging: A novel bearing fault classification approach. IEEE Trans. Ind. Electron. 2014, 62, 494–502. [Google Scholar] [CrossRef]

- Li, P.; Dolado, I.; Alfaro-Mozaz, F.J.; Casanova, F.; Hueso, L.E.; Liu, S.; Edgar, J.H.; Nikitin, A.Y.; Vélez, S.; Hillenbrand, R. Infrared hyperbolic meta surface based on nanostructured van der Waals materials. Science 2018, 359, 892–896. [Google Scholar] [CrossRef] [PubMed]

- Xie, X. A review of recent advances in surface defect detection using texture analysis techniques. ELCVIA Electron. Lett. Comput. Vis. Image Anal. 2008, 7, 1–22. [Google Scholar] [CrossRef]

- Ngan, H.Y.; Pang, G.K.; Yung, N.H. Automated fabric defect detection—A review. Image Vis. Comput. 2011, 29, 442–458. [Google Scholar] [CrossRef]

- Mahajan, P.M.; Kolhe, S.R.; Patil, P.M. A review of automatic fabric defect detection techniques. Adv. Comput. Res. 2009, 1, 18–29. [Google Scholar]

- Aldave, I.J.; Bosom, P.V.; González, L.V.; De Santiago, I.L.; Vollheim, B.; Krausz, L.; Georges, M. Review of thermal imaging systems in composite defect detection. Infrared. Phys. Technol. 2013, 61, 167–175. [Google Scholar] [CrossRef]

- Pernkopf, F. Detection of surface defects on raw steel blocks using Bayesian network classifiers. Pattern Anal. Appl. 2004, 7, 333–342. [Google Scholar] [CrossRef]

- Zhang, W.; Ye, C.; Zheng, K.; Zhong, J.; Tang, Y.; Fan, Y.; Buehler, M.J.; Ling, S.; Kaplan, D.L. Tensan silk-inspired hierarchical fibers for smart textile applications. ACS Nano 2018, 12, 6968–6977. [Google Scholar] [CrossRef]

- Shankar, N.G.; Zhong, Z.W. Defect detection on semiconductor wafer surfaces. Microelectron. Eng. 2005, 77, 337–346. [Google Scholar] [CrossRef]

- Mao, B.; Lu, Y.; Wu, P.; Mao, B.; Li, P. Signal processing and defect analysis of pipeline inspection applying magnetic flux leakage methods. Intell. Serv. Robot. 2014, 7, 203–209. [Google Scholar] [CrossRef]

- Liu, J.; Xu, G.; Ren, L.; Qian, Z.; Ren, L. Defect intelligent identification in resistance spot welding ultrasonic detection based on wavelet packet and neural network. Int. J. Adv. Manuf. Technol. 2017, 90, 2581–2588. [Google Scholar] [CrossRef]

- Kumar, A.; Pang, G.K. Defect detection in textured materials using Gabor filters. IEEE Trans. Ind. Appl. 2002, 38, 425–440. [Google Scholar] [CrossRef]

- Lin, J.; Yao, Y.; Ma, L.; Wang, Y. Detection of a casting defect tracked by deep convolution neural network. Int. J. Adv. Manuf. Technol. 2018, 97, 573–581. [Google Scholar] [CrossRef]

- Chang, F.; Liu, M.; Dong, M.; Duan, Y.A. Mobile vision inspection system for tiny defect detection of smooth car-body surface based on deep ensemble learning. Meas. Sci. Technol. 2019, 30, 125905. [Google Scholar] [CrossRef]

- Yu, L.; Wang, Z.; Duan, Z. Detecting Gear Surface Defects Using Background-Weakening Method and Convolutional Neural Network. J. Sens. 2019, 2019, 125905. [Google Scholar] [CrossRef]

- Li, C.; Zhang, X.; Huang, Y.; Tang, C.; Fatikow, S. A novel algorithm for defect extraction and classification of mobile phone screen based on machine vision. Comput. Ind. Eng. 2020, 146, 106530. [Google Scholar] [CrossRef]

- Zhai, M.; Fu, S.; Gu, S.; Xie, Z.; Luo, X. Defect detection in aluminum foil by measurement-residual-based chi-square detector. Int. J. Adv. Manuf. Technol. 2011, 53, 661–667. [Google Scholar] [CrossRef]

- Sun, X.; Gu, J.; Huang, R.; Zou, R.; Giron Palomares, B. Surface Defects Recognition of Wheel Hub Based on Improved Faster R-CNN. Electronics 2019, 8, 481. [Google Scholar] [CrossRef]

- Urbonas, A.; Raudonis, V.; Maskeliūnas, R.; Damaševičius, R. Automated Identification of Wood Veneer Surface Defects Using Faster Region-Based Convolutional Neural Network with Data Augmentation and Transfer Learning. Appl. Sci. 2019, 9, 4898. [Google Scholar] [CrossRef]

- Wang, R.; Guo, Q.; Lu, S.; Zhang, C. Tire Defect Detection Using Fully Convolutional Network. IEEE Access 2019, 7, 43502–43510. [Google Scholar] [CrossRef]

- Moulin, E.; Chehami, L.; Assaad, J.; De Rosny, J.; Prada, C.; Chatelet, E.; Lacerra, G.; Gryllias, K.; Massi, F. Passive defect detection in plate from nonlinear conversion of low-frequency vibrational noise. Microelectron. Eng. 2005, 77, 337–346. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, W.; Pan, J. Deformable patterned fabric defect detection with fisher criterion-based deep learning. IEEE Trans. Autom. Sci. Eng. 2016, 14, 1256–1264. [Google Scholar] [CrossRef]

- Elrefai, A.L.; Sasada, I. Magnetic particle detection system using fluxgate gradiometer on a permalloy shielding disk. IEEE Magn. Lett. 2016, 7, 1–4. [Google Scholar] [CrossRef]

- Angelo, G.D.; Laracca, M.; Rampone, S.; Betta, G. Fast eddy current testing defect classification using lissajous figures. IEEE Trans. Instrum. Meas. 2018, 67, 821–830. [Google Scholar] [CrossRef]

- Kusano, M.; Hatano, H.; Watanabe, M.; Takekawa, S.; Yamawaki, H.; Oguchi, K.; Enoki, M. Mid-infrared pulsed laser ultrasonic testing for carbon fiber reinforced plastics. Ultrasonics 2018, 84, 310–318. [Google Scholar] [CrossRef]

- Yang, J.; Li, S.; Gao, Z.; Wang, Z.; Liu, W. Real-Time Recognition Method for 0.8 cm Darning Needles and KR22 Bearings Based on Convolution Neural Networks and Data Increase. Appl. Sci. 2018, 8, 1857. [Google Scholar] [CrossRef]

- Chen, Y.; Kolhatkar, A.; Zenasni, O.; Xu, S.; Lee, T. Biosensing Using Magnetic Particle Detection Techniques. Sensors 2017, 17, 2300. [Google Scholar] [CrossRef]

- Li, J.; Wang, G.; Xu, Z. Environmentally-friendly oxygen-free roastingwet magnetic separation technology for in situ recycling cobalt, Lithium Carbonate Graph. Spent LiCoO2/graphite Lithium Batteries. J. Hazard. Mater. 2016, 302, 97–104. [Google Scholar] [CrossRef]

- Rymarczyk, T.; Szumowski, K.; Adamkiewicz, P.P.T.; Jan, S. Moisture Wall Inspection Using Electrical Tomography Measurements. Przegląd Elektrotechniczny 2018, 94, 97–100. [Google Scholar] [CrossRef]

- Seo, J.; Duque, L.; Wacker, J. Drone-enabled bridge inspection methodology and application. Autom. Constr. 2018, 94, 112–126. [Google Scholar] [CrossRef]

- Shelikhov, G.S.; Glazkov, Y.A. On the improvement of examination questions during the nondestructive testing of magnetic powder. Russ. J. Nondestruct. Test. 2011, 47, 112–117. [Google Scholar] [CrossRef]

- García-Arribas, A.; Martínez, F.; Fernández, E. GMI detection of magnetic-particle concentration in continuous flow. Sens. Actuators Phys. 2011, 172, 103–108. [Google Scholar] [CrossRef]

- Chen, J.; Liu, Z.; Wang, H.; Núñez, A.; Han, Z. Automatic defect detection of fasteners on the catenary support device using deep convolutional neural network. IEEE Trans. Instrum. Meas. 2017, 67, 257–269. [Google Scholar] [CrossRef]

- Tsuboi, H.; Seshima, N.; Sebestyén, I.; Pávó, J.; Gyimóthy, S.; Gasparics, A. Transient eddy current analysis of pulsed eddy current testing by finite element method. IEEE Trans. Magn. 2004, 40, 1330–1333. [Google Scholar] [CrossRef]

- Tian, G.Y.; Sophian, A. Defect classification using a new feature for pulsed eddy current sensors. NDT-E Int. 2005, 38, 77–82. [Google Scholar] [CrossRef]

- Yang, H.; Yu, L. Feature extraction of wood-hole defects using wavelet-based ultrasonic testing. J. For. Res. 2017, 28, 395–402. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Fang, Y.; Lin, L.; Feng, H.; Lu, Z.; Emms, G.W. Review of the use of air-coupled ultrasonic technologies for nondestructive testing of wood and wood products. Comput. Electron. Agric. 2017, 137, 79–87. [Google Scholar] [CrossRef]

- Bernasconi, A.; Carboni, M.; Comolli, L.; Galeazzi, R.; Gianneo, A.; Kharshiduzzaman, M. Fatigue crack growth monitoring in composite bonded lap joints by a distributed fibre optic sensing system and comparison with ultrasonic testing. J. Adhes. 2016, 92, 739–757. [Google Scholar] [CrossRef]

- Aytekin, Ç.; Rezaeitabar, Y.; Dogru, S.; Ulusoy, I. Railway fastener inspection by real-time machine vision. IEEE Trans. Syst. Man Cybern. Syst. 2015, 45, 1101–1107. [Google Scholar] [CrossRef]

- Lin, H.; Chen, H. Automated visual fault inspection of optical elements using machine vision technologies. J. Appl. Eng. Sci. 2018, 16, 447–453. [Google Scholar] [CrossRef][Green Version]

- Shanmugamani, R.; Sadique, M.; Ramamoorthy, B. Detection and classification of surface defects of gun barrels using computer vision and machine learning. Measurement 2015, 60, 222–230. [Google Scholar] [CrossRef]

- Jia, F.; Lei, Y.; Lin, J.; Zhou, X.; Lu, N. Deep neural networks: A promising tool for fault characteristic mining and intelligent diagnosis of rotating machinery with massive data. Mech. Syst. Signal Process. 2016, 72, 303–315. [Google Scholar] [CrossRef]

- Habib, M.A.; Kim, C.H.; Kim, J. A Crack Characterization Method for Reinforced Concrete Beams Using an Acoustic Emission Technique. Appl. Sci. 2020, 10, 7918. [Google Scholar] [CrossRef]

- Yang, Y.; Pan, L.; Ma, J.; Yang, R.; Zhu, Y.; Yang, Y.; Zhang, L. A High-Performance Deep Learning Algorithm for the Automated Optical Inspection of Laser Welding. Appl. Sci. 2020, 10, 933. [Google Scholar] [CrossRef]

- Zhong, J.; Liu, Z.; Han, Z.; Han, Y.; Zhang, W. A CNN-Based Defect Inspection Method for Catenary Split Pins in High-Speed Railway. IEEE Trans. Instrum. Meas. 2019, 68, 2849–2860. [Google Scholar] [CrossRef]

- He, Y.; Song, K.; Meng, Q.; Yan, Y. An end-to-end steel surface defect detection approach via fusing multiple hierarchical features. IEEE Trans. Instrum. Meas. 2020, 69, 1493–1504. [Google Scholar] [CrossRef]

- Pashagin, A.I.; Shcherbinin, V.E.; Zhang, C. Indication of magnetic fields with the use of galvanic currents in magnetic-powder nondestructive testing. Russ. J. Nondestruct. 2012, 48, 528–531. [Google Scholar] [CrossRef]

- Gholizadeh, S.; Leman, Z.; Baharudin, B. A review of the application of acoustic emission technique in engineering. Struct. Eng. Mech. 2015, 51, 1075–1095. [Google Scholar] [CrossRef]

- Rocha, T.J.; Ramos, H.G.; Ribeiro, A.L.; Pasadas, D.J. Magnetic sensors assessment in velocity induced eddy current testing. Sens. Actuators A Phys. 2015, 28, 55–61. [Google Scholar] [CrossRef]

- Du Plessis, A.; le Roux, S.G. Standardized X-ray tomography testing of additively manufactured parts: A round robin test. Addit. Manuf. 2018, 24, 125–136. [Google Scholar] [CrossRef]

- Khan, F.; Salahuddin, S.; Javidnia, H. Deep Learning-Based Monocular Depth Estimation Methods—A State-of-the-Art Review. Sensors 2020, 20, 2272. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Yang, J.; Sheng, W.; Fernandes, F.E., Jr.; Li, S. Convolutional Neural Network-Based Embarrassing Situation Detection under Camera for Social Robot in Smart Homes. Sensors 2018, 18, 1530. [Google Scholar] [CrossRef] [PubMed]

- Borji, A.; Cheng, M.; Jiang, H.; Li, J. Salient object detection: A benchmark. IEEE Trans. Image Process 2015, 24, 5706–5722. [Google Scholar] [CrossRef] [PubMed]

- Ciaburro, G. Sound event detection in underground parking garage using convolutional neural network. Big Data Cogn. Comput. 2020, 4, 20. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Improving Smart Cities Safety Using Sound Events Detection Based on Deep Neural Network Algorithms. Informatics 2020, 7, 23. [Google Scholar] [CrossRef]

- Costa, D.G.; Vasques, F.; Portugal, P.; Ana, A. A distributed multi-tier emergency alerting system exploiting sensors-based event detection to support smart city applications. Sensors 2020, 20, 170. [Google Scholar] [CrossRef]

- Iannace, G.; Ciaburro, G.; Trematerra, A. Fault diagnosis for UAV blades using artificial neural network. Robotics 2019, 8, 59. [Google Scholar] [CrossRef]

- Peng, L.; Liu, J. Detection and analysis of large-scale WT blade surface cracks based on UAV-taken images. IET Image Processing 2018, 12, 2059–2064. [Google Scholar] [CrossRef]

- Saied, M.; Lussier, B.; Fantoni, I.; Shraim, H.; Francis, C. Fault Diagnosis and Fault-Tolerant Control of an Octorotor UAV using motors speeds measurements. IFAC-PapersOnLine 2017, 50, 5263–5268. [Google Scholar] [CrossRef]

- Deng, L.; Yu, D. Deep learning: Methods and applications. Found. Trends Signal Process. 2014, 7, 197–387. [Google Scholar] [CrossRef]

- Tao, X.; Wang, Z.; Zhang, Z.; Zhang, D.; Xu, D.; Gong, X.; Zhang, L. Wire Defect Recognition of Spring-Wire Socket Using Multitask Convolutional Neural Networks. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 689–698. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, Z.; He, K. A feature-based method of rapidly detecting global exact symmetries in CAD models. Comput. Aided. Des. 2013, 45, 1081–1094. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Wang, M. Automated detection of sewer pipe defects in closed-circuit television images using deep learning techniques. Autom. Constr. 2018, 95, 155–171. [Google Scholar] [CrossRef]

- Bergmann, P.; Löwe, S.; Fauser, M.; Sattlegger, D.; Steger, C. Improving Unsupervised Defect Segmentation by Applying Structural Similarity to Autoencoders. arXiv 2018, arXiv:1807.02011. [Google Scholar]

- Yang, J.; Yang, G. Modified Convolutional Neural Network Based on Dropout and the Stochastic Gradient Descent Optimizer. Algorithms 2018, 11, 28. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, J.; Zhang, C.; Hu, J. Generalized extreme learning machine autoencoder and a new deep neural network. Neurocomputing 2017, 230, 374–381. [Google Scholar] [CrossRef]

- Yu, L.; Chen, H.; Dou, Q.; Qin, J.; Heng, P.A. Automated melanoma recognition in dermoscopy images via very deep residual networks. IEEE Trans. Med. Imaging 2016, 36, 994–1004. [Google Scholar] [CrossRef]

- Xue, Y.; Li, Y. A Fast Detection Method via Region-Based Fully Convolutional Neural Networks for Shield Tunnel Lining Defects. Comput. Civ. Infrastruct. Eng. 2018, 33, 638–654. [Google Scholar] [CrossRef]

- Lei, J.; Gao, X.; Feng, Z.; Qiu, H.; Song, M. Scale insensitive and focus driven mobile screen defect detection in industry. Neurocomputing 2018, 294, 72–81. [Google Scholar] [CrossRef]

- Lukoševičius, M.; Jaeger, H. Reservoir computing approaches to recurrent neural network training. Comput. Sci. Rev. 2009, 3, 127–149. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- LeCun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Li, J.; Su, Z.; Geng, J.; Yixin, Y. Real-time detection of steel strip surface defects based on improved yolo detection network. IFAC-PapersOnLine 2018, 51, 76–81. [Google Scholar] [CrossRef]

- Ozkan, S.; Kaya, B.; Akar, G.B. Endnet Sparse autoencoder network for endmember extraction and hyperspectral unmixing. IEEE Trans. Geosci. Remote Sens. 2018, 57, 482–496. [Google Scholar] [CrossRef]

- Mei, S.; Wang, Y.; Wen, G. Automatic fabric defect detection with a multi-scale convolutional denoising autoencoder network model. Sensors 2018, 18, 1064. [Google Scholar] [CrossRef]

- Toğaçar, M.; Ergen, B.; Cömert, Z. Waste classification using AutoEncoder network with integrated feature selection method in convolutional neural network models. Measurement 2020, 153, 107459. [Google Scholar] [CrossRef]

- Long, J.; Sun, Z.; Li, C.; Ying, H.; Yun, B.; Zhang, S. A novel sparse echo autoencoder network for data-driven fault diagnosis of delta 3-D printers. IEEE Trans. Instrum. Meas. 2019, 69, 683–692. [Google Scholar] [CrossRef]

- Chen, K.; Chen, K.; Wang, Q.; Ziyu, H.; Jun, H.; Jinliang, H. Short-term load forecasting with deep residual networks. IEEE Trans. Smart Grid 2018, 10, 3943–3952. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR) 2016, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar] [CrossRef]

- Creswell, A.; White, T.; Dumoulin, V.; Arulkumaran, K.; Sengupta, B.; Bharath, A.A. Generative adversarial networks: An overview. IEEE Signal Proc. Mag. 2018, 35, 53–65. [Google Scholar] [CrossRef]

- Long, J.; Shelhamer, E.; Darrell, T. Fully convolutional networks for semantic segmentation. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 640–651. [Google Scholar] [CrossRef]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You only look once: Unified, real-time object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR) 2016, Las Vegas, NV, USA, 27–30 June 2016; pp. 779–788. [Google Scholar] [CrossRef]

- Sermanet, P.; Eigen, D.; Zhang, X.; Mathieu, M.; Fergus, R.; LeCun, Y. Overfeat: Integrated recognition, localization and detection using convolutional networks. arXiv 2013, arXiv:1312.6229. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLO9000: Better, faster, stronger. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR) 2017, Honolulu, HI, USA, 21–26 July 2017; pp. 7263–7271. [Google Scholar] [CrossRef]

- Redmon, J.; Farhadi, A. Yolov3: An incremental improvement. arXiv 2018, arXiv:1804.02767. [Google Scholar]

- Lin, T.; Dollár, P.; Girshick, R.; He, K.; Hariharan, B.; Belongie, S. Feature pyramid networks for object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR) 2017, Honolulu, HI, USA, 21–26 July 2017; pp. 2117–2125. [Google Scholar] [CrossRef]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.; Berg, A.C. Ssd: Single shot multibox detector. In Proceedings of the European Conference on Computer Vision (ECCV), Amsterdam, The Netherlands, 8–16 October 2016; pp. 21–37. [Google Scholar] [CrossRef]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster r-cnn: Towards real-time object detection with region proposal networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef] [PubMed]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Fu, C.; Liu, W.; Ranga, A.; Tyagi, A.; Berg, A.C. Dssd: Deconvolutional single shot detector. arXiv 2017, arXiv:1701.06659. [Google Scholar]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich feature hierarchies for accurate object detection and semantic segmentation. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR) 2014, Columbus, OH, USA, 24–27 June 2014; pp. 580–587. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Spatial pyramid pooling in deep convolutional networks for visual recognition. IEEE Trans. Pattern Anal. 2015, 37, 1904–1916. [Google Scholar] [CrossRef]

- Girshick, R. Fast r-cnn. In Proceedings of the IEEE International Conference on Computer Vision (ICCV) 2015, Santiago, Chile, 7–13 December 2015; pp. 1440–1448. [Google Scholar] [CrossRef]

- He, K.; Gkioxari, G.; Dollár, P.; Girshick, R. Mask r-cnn. In Proceedings of the IEEE International Conference on Computer Vision (ICCV) 2017, Venice, Italy, 22–29 October 2017; pp. 2961–2969. [Google Scholar] [CrossRef]

- Meng, M.; Chua, Y.J.; Wouterson, E.; Chin, P. Ultrasonic signal classification and imaging system for composite materials via deep convolutional neural networks. Neurocomputing 2017, 257, 128–135. [Google Scholar] [CrossRef]

- Droubi, M.G.; Faisal, N.H.; Orr, F.; Steel, J.A.; El-Shaib, M. Acoustic emission method for defect detection and identification in carbon steel welded joints. J. Constr. Steel Res. 2017, 134, 28–37. [Google Scholar] [CrossRef]

- Alobaidi, W.M.; Alkuam, E.A.; Al-Rizz, H.M.; Eric, S. Applications of ultrasonic techniques in oil and gas pipeline industries: A review. Am. J. Oper. Res. 2015, 5, 274. [Google Scholar] [CrossRef]

- Boaretto, N.; Centeno, T.M. Automated detection of welding defects in pipelines from radiographic images DWDI. NDT-E Int. 2009, 86, 7–13. [Google Scholar] [CrossRef]

- Masserey, B.; Fromme, P. Surface defect detection in stiffened plate structures using Rayleigh-like waves. NDT-E Int. 2017, 42, 564–572. [Google Scholar] [CrossRef]

- Kazantsev, I.G.; Lemahieu, I.; Salov, G.I.; Denys, R. Statistical detection of defects in radiographic images in nondestructive testing. Signal Process 2002, 82, 791–801. [Google Scholar] [CrossRef]

- Wilson, J.W.; Tian, G.Y. Pulsed electromagnetic methods for defect detection and characterisation. NDT-E Int. 2007, 40, 275–283. [Google Scholar] [CrossRef]

- Arora, V.; Siddiqui, J.A.; Mulaveesala, R. Hilbert transform-based pulse compression approach to infrared thermal wave imaging for sub-surface defect detection in steel material. Insight-Non Test. Cond. Monit. 2014, 56, 550–552. [Google Scholar] [CrossRef]

- Lascoup, B.; Perez, L.; Autrique, L.; Antoine, C. On the feasibility of defect detection in composite material based on thermal periodic excitation. Compos. Part B Eng. 2013, 45, 1023–1030. [Google Scholar] [CrossRef][Green Version]

- Moon, H.; Chellappa, R.; Rosenfeld, A. Optimal edge-based shape detection. IEEE Trans. Image Process. 2002, 11, 1209–1227. [Google Scholar] [CrossRef]

- Amit, Y.; Geman, D.; Fan, X. A coarse-to-fine strategy for multiclass shape detection. IEEE Trans. Pattern Anal. Mach. Intell. 2004, 26, 1606–1621. [Google Scholar] [CrossRef]

- Atherton, T.J.; Kerbyson, D.J. Size invariant circle detection. Image Vision Comput. 1999, 17, 795–803. [Google Scholar] [CrossRef]

- Zhou, X.; Zifer, T.; Wong, B.M.; Krafcik, F.L. Color detection using chromophore-nanotube hybrid devices. Nano Lett. 2009, 9, 1028–1033. [Google Scholar] [CrossRef]

- Karimi, M.H.; Asemani, D. Surface defect detection in tiling Industries using digital image processing methods: Analysis and evaluation. ISA Trans. 2014, 53, 834–844. [Google Scholar] [CrossRef]

- Tsai, D.M.; Chiang, I.Y.; Tsai, Y.H. A shift-tolerant dissimilarity measure for surface defect detection. IEEE Trans. Ind. Inform. 2011, 8, 128–137. [Google Scholar] [CrossRef]

- Bernieri, A.; Betta, G.; Ferrigno, L. Crack depth estimation by using a multi-frequency ECT method. IEEE Trans. Instrum. Meas. 2013, 62, 544–552. [Google Scholar] [CrossRef]

- Komura, I.; Hirasawa, T.; Nagai, S. Crack detection and sizing technique by ultrasonic and electromagnetic methods. Nucl. Eng. Des. 2001, 206, 351–362. [Google Scholar] [CrossRef]

- Schlichting, J.; Maierhofer, C.; Kreutzbruck, M. Crack sizing by laser excited thermography. NDT-E Int. 2012, 45, 133–140. [Google Scholar] [CrossRef]

- Hu, G. Automated defect detection in textured surfaces using optimal elliptical Gabor filters. J. Constr. Steel Rest. 2017, 134, 28–37. [Google Scholar] [CrossRef]

- Liang, B.; Iwnicki, S.; Ball, A.; Young, A.E. Adaptive noise cancelling and time–frequency techniques for rail surface defect detection. Mech. Syst. Signal Process. 2015, 54, 41–51. [Google Scholar] [CrossRef]

- Ge, J.; Li, W.; Chen, G.; Yin, X.; Yuan, X.; Yang, W.; Liu, J.; Chen, Y. Multiple type defect detection in pipe by Helmholtz electromagnetic array probe. NDT-E Int. 2017, 91, 97–107. [Google Scholar] [CrossRef]

- Koike, R.; Kakinuma, Y.; Aoyama, T. Drill fracture detection by integrating disturbance observer and rotational digital filter. CIRP J. Manuf. Sci. Technol. 2014, 7, 177–184. [Google Scholar] [CrossRef]

- Trottier, C.; Shahjahan, S.; Schumm, A.; Aubry, A.; Derode, A. Multiple Scattering Filter: Application to the Plane Defect Detection in a Nickel Alloy. Phys. Procedia 2015, 70, 795–798. [Google Scholar] [CrossRef][Green Version]

- Zou, Y.; Du, D.; Chang, B.; Ji, L.; Pan, J. Automatic weld defect detection method based on Kalman filtering for real-time radiographic inspection of spiral pipe. NDT-E Int. 2015, 72, 1–9. [Google Scholar] [CrossRef]

- Zhang, S.; He, Q.; Ouyang, K.; Xiong, W. Multi-bearing weak defect detection for wayside acoustic diagnosis based on a time-varying spatial filtering rearrangement. Mech. Syst. Signal Process. 2018, 100, 224–241. [Google Scholar] [CrossRef]

- Mak, K.; Peng, P.; Yiu, K.F.C. Fabric defect detection using morphological filters. Image Vis. Comput 2009, 27, 1585–1592. [Google Scholar] [CrossRef]

- Choi, D.; Jeon, Y.; Lee, S.J.; Yun, J.P.; Kim, S.W. Algorithm for detecting seam cracks in steel plates using a Gabor filter combination method. Appl. Opt. 2014, 53, 4865–4872. [Google Scholar] [CrossRef] [PubMed]

- Jian, C.; Gao, J.; Ao, Y. Automatic surface defect detection for mobile phone screen glass based on machine vision. Appl. Soft. Comput. 2017, 52, 348–358. [Google Scholar] [CrossRef]

- Czimmermann, T.; Ciuti, G.; Milazzo, M. Visual-Based Defect Detection and Classification Approaches for Industrial Applications-A SURVEY. Sensors 2020, 20, 1459. [Google Scholar] [CrossRef]

- Hoang, D.; Kang, H. A survey on Deep Learning based bearing fault diagnosis. Neurocomputing 2019, 335, 327–335. [Google Scholar] [CrossRef]

- Wei, X.; Yang, Z.; Liu, Y.; Wei, D.; Jia, L.; Li, Y. Railway track fastener defect detection based on image processing and deep learning techniques: A comparative study. Eng. Appl. Artif. Intell. 2019, 80, 66–81. [Google Scholar] [CrossRef]

- Yi, L.; Li, G.; Jiang, M. An End-to-End Steel Strip Surface Defects Recognition System Based on Convolutional Neural Networks. Steel Res. Int. 2017, 88, 1600068. [Google Scholar] [CrossRef]

- Kumar, S.S.; Abraham, D.M.; Jahanshahi, M.R.; Iseley, T.; Starr, J. Automated defect classification in sewer closed circuit television inspections using deep convolutional neural networks. Autom. Constr. 2018, 91, 273–283. [Google Scholar] [CrossRef]

- Chen, F.; Jahanshahi, M.R. NB-CNN: Deep learning-based crack detection using convolutional neural network and Naïve Bayes data fusion. IEEE Trans. Ind. Electron. 2017, 65, 4392–4400. [Google Scholar] [CrossRef]

- Park, J.; Kwon, B.; Park, J.; Kang, D. Machine learning-based imaging system for surface defect inspection. Int. J. Proc. Eng. Manuf. Green Technol. 2016, 3, 303–310. [Google Scholar] [CrossRef]

- Napoletano, P.; Piccoli, F.; Schettini, R. Anomaly detection in nanofibrous materials by CNN-based self-similarity. Sensors 2018, 18, 209. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Lu, S.; Wu, T.; Yuan, G.; Tang, Y. Detection of morphology defects in pipeline based on 3D active stereo omnidirectional vision sensor. IET Image Process 2017, 12, 588–595. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhang, Z.; Su, H.; Zhang, L.; Shen, F.; Zhang, F. Vision-based defect detection for mobile phone cover glass using deep neural networks. Int. J. Precis Eng. Manuf. 2018, 19, 801–810. [Google Scholar] [CrossRef]

- Liu, R.; Gu, Q.; Wang, X.; Yao, M. Region-convolutional neural network for detecting capsule surface defects. Boletín Técnico 2017, 55, 92–100. [Google Scholar]

- Krummenacher, G.; Ong, C.S.; Koller, S.; Kobayashi, S.; Buhmann, J.M. Wheel defect detection with machine learning. IEEE Trans. Intell. Transp. 2017, 19, 1176–1187. [Google Scholar] [CrossRef]

- Lv, C.; Zhang, Z.; Shen, F.; Zhang, F.; Su, H. A Fast Surface Defect Detection Method Based on Background Reconstruction. Int. J. Precis. Eng. Manuf. 2019, 21, 363–375. [Google Scholar] [CrossRef]

- Akram, M.W.; Li, G.; Jin, Y.; Chen, X.; Zhu, C.; Zhao, X.; Khaliq, A.; Faheem, M.; Ahmad, A. CNN based automatic detection of photovoltaic cell defects in electroluminescence images. Energy 2019, 189, 116319. [Google Scholar] [CrossRef]

- Zhang, Z.; Wen, G.; Chen, S. Weld image deep learning-based on-line defects detection using convolutional neural networks for Al alloy in robotic arc welding. J. Manuf. Process 2019, 45, 208–216. [Google Scholar] [CrossRef]

- He, T.; Liu, Y.; Xu, C.; Zhou, X.; Hu, Z.; Fan, J. A Fully Convolutional Neural Network for Wood Defect Location and Identification. IEEE Access 2019, 7, 123453–123462. [Google Scholar] [CrossRef]

- Caggiano, A.; Zhang, J.; Alfieri, V.; Caiazzo, F.; Gao, R.; Teti, R. Machine learning-based image processing for on-line defect recognition in additive manufacturing. CIRP Ann. 2019, 68, 451–454. [Google Scholar] [CrossRef]

- Lv, Q.; Song, Y. Few-shot Learning Combine Attention Mechanism-Based Defect Detection in Bar Surface. ISIJ Int. 2019, 59, 1089–1097. [Google Scholar] [CrossRef]

- BOSCH (Germany). Available online: https://www.bosch.com/company/ (accessed on 30 December 2019).

- COMPUR Company. Available online: https://skgrimes.com/products/ (accessed on 16 December 2019).

- BS Company. Available online: https://www.bs-company.com/en/index.html (accessed on 20 December 2019).

- CMP Company. Available online: https://www.c-m-p.com/company-info/ (accessed on 6 July 2020).

- Valley Industries Company. Available online: https://www.valleyind.com/ (accessed on 1 September 2020).

- Rhein–Nadel Automation (RNA) Glass Defect Detection System. Available online: https://www.rnaautomation.com/products (accessed on 30 September 2018).

- Visual Inspection System for Parts Defect. Available online: http://www.evenfit.com.cn/showal75.html (accessed on 26 December 2018).

- Quality Control Checks System. Available online: https://www.rnaautomation.com/ (accessed on 21 January 2019).

- EvenFit, Capsule Visual Inspection System. Available online: http://www.evenfit.com.cn/showpro25.html (accessed on 9 June 2019).

- KEYENCE Product Size Measuring Instrument. Available online: https://www.keyence.com.cn (accessed on 8 June 2020).

- AVI Soldering Appearance Inspection Machine. Available online: http://www.geeyoo.net/products.html (accessed on 13 July 2019).

- Hardware and Workpiece Visual Measurement Equipment. Available online: https://yuyaonaide.1688.com/?spm=a261y.8881078.0.0.656d1321mIPSHy (accessed on 3 July 2018).

- ET-F1 Engine Cylinder Bore Eddy Current Detector. Available online: http://www.bknzdh.com/product.html (accessed on 30 November 2020).

- Deng, Y.; Pan, X.; Wang, X.; Zhong, X. Vison-Based 3D Shape Measurement System for Transparent Microdefect Characterization. IEEE Access 2019, 7, 105721–105733. [Google Scholar] [CrossRef]

- Iglesias, C.; Martínez, J.; Taboada, J. Automated vision system for quality inspection of slate slabs. Comput. Ind. 2018, 99, 119–129. [Google Scholar] [CrossRef]

- Su, Q.; Kondo, N.; Li, M.; Sun, H.; Al Riza, D.F.; Habaragamuwa, H. Potato quality grading based on machine vision and 3D shape analysis. Comput. Electron. Agric. 2018, 152, 261–268. [Google Scholar] [CrossRef]

- Wen, X.; Song, K.; Huang, L.; Niu, M.; Yan, Y. Complex surface ROI detection for steel plate fusing the gray image and 3D depth information. Optik 2019, 198, 163313. [Google Scholar] [CrossRef]

- Ouyang, W.; Wang, K.; Zhu, X.; Wang, X. Chained cascade network for object detection. In Proceedings of the IEEE International Conference on Computer Vision (ICCV) 2017, Venice, Italy, 22–29 October 2017; pp. 1956–1964. [Google Scholar] [CrossRef]

- Bodla, N.; Singh, B.; Chellappa, R.; Davis, L.S. Soft-nms—improving object detection with one line of code. In Proceedings of the IEEE International Conference on Computer Vision (ICCV) 2017, Venice, Italy, 22–29 October 2017; pp. 2380–7504. [Google Scholar] [CrossRef]

- Hu, H.; Gu, J.; Zhang, Z.; Dai, J.; Wei, Y. Relation networks for object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR) 2018, Salt Lake City, UT, USA, 18–22 June 2018; pp. 2380–7504. [Google Scholar] [CrossRef]

- Dai, J.; Li, Y.; He, K.; Sun, J. R-fcn: Object detection via region-based fully convolutional networks. Adv. Neural Inf. Process. Syst. 2016, 198, 379–387. [Google Scholar]

- Shen, Z.; Liu, Z.; Li, J.; Jiang, Y.; Chen, Y.; Xue, X. Dsod: Learning deeply supervised object detectors from scratch. In Proceedings of the IEEE International Conference on Computer Vision (ICCV) 2017, Venice, Italy, 22–29 October 2017; pp. 1919–1927. [Google Scholar] [CrossRef]

- Dai, J.; Qi, H.; Xiong, Y.; Li, Y.; Zhang, G.; Hu, H.; Wei, Y. Deformable convolutional networks. In Proceedings of the IEEE International Conference on Computer Vision (ICCV) 2017, Venice, Italy, 22–29 October 2017; pp. 764–773. [Google Scholar] [CrossRef]

- Lin, T.; Goyal, P.; Girshick, R.; He, K.; Dollár, P. Focal loss for dense object detection. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 42, 318–327. [Google Scholar] [CrossRef]

- Peng, C.; Xiao, T.; Li, Z.; Jiang, Y.; Zhang, X.; Jia, K.; Yu, G.; Sun, J. Megdet: A large mini-batch object detector. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition(CVPR) 2018, Salt Lake City, UT, USA, 18–22 June 2018; pp. 6181–6189. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).