4D In-Situ Microscopy of Aerosol Filtration in a Wall Flow Filter

Abstract

1. Introduction

2. Materials and Methods

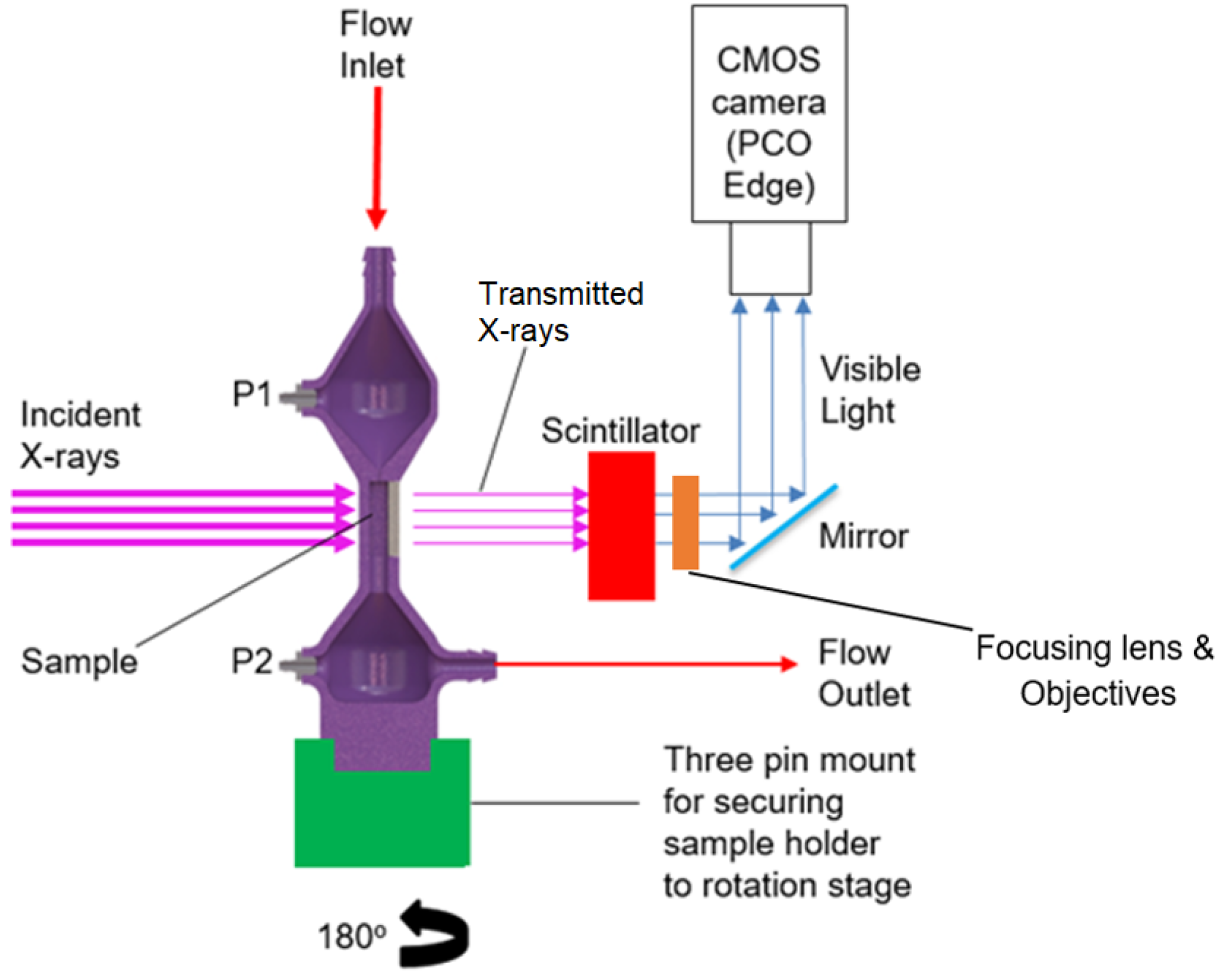

2.1. Imaging Method

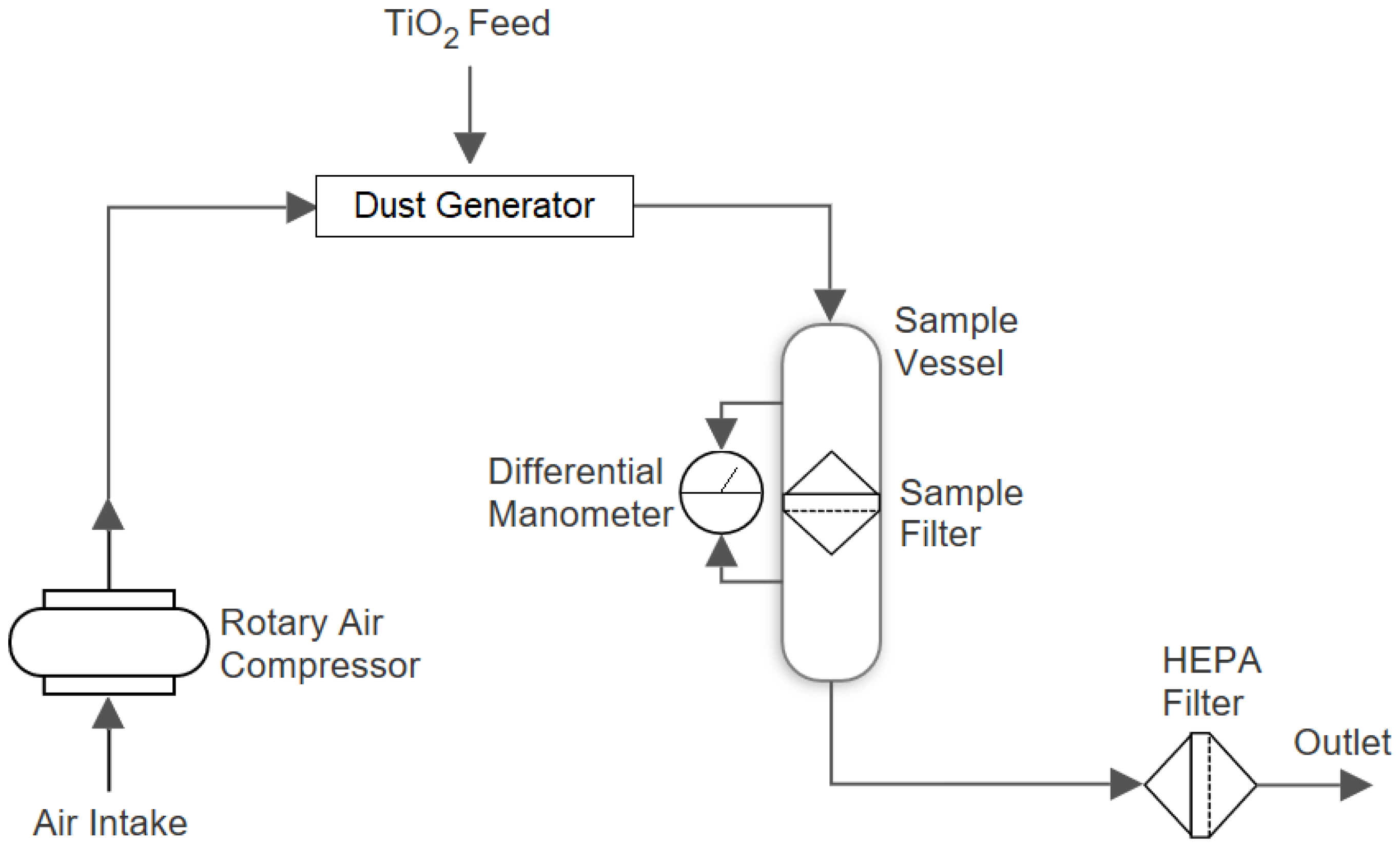

2.2. Aerosol Flow Apparatus

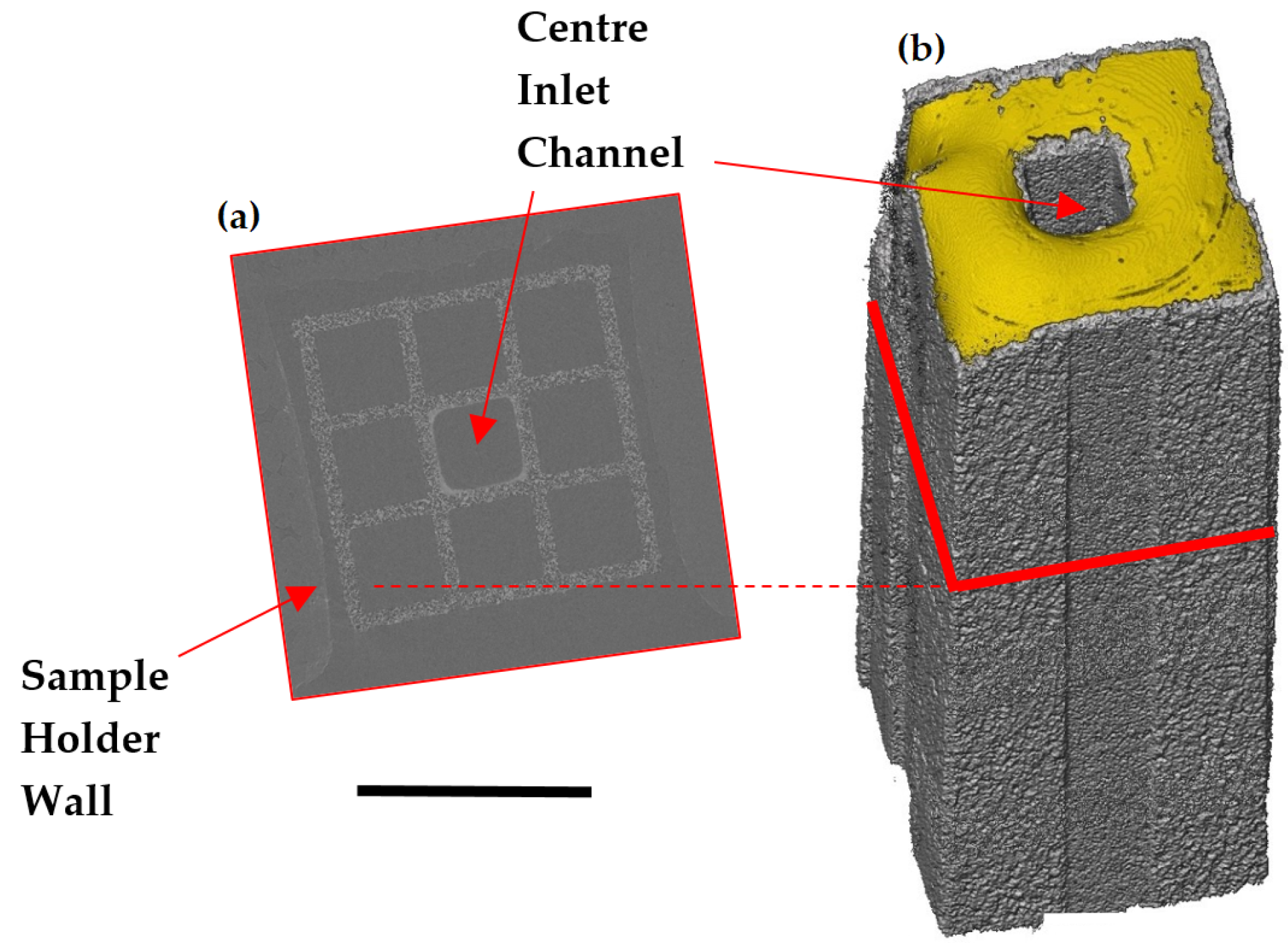

2.3. Sample Preparation

2.4. Data Processing

3. Results

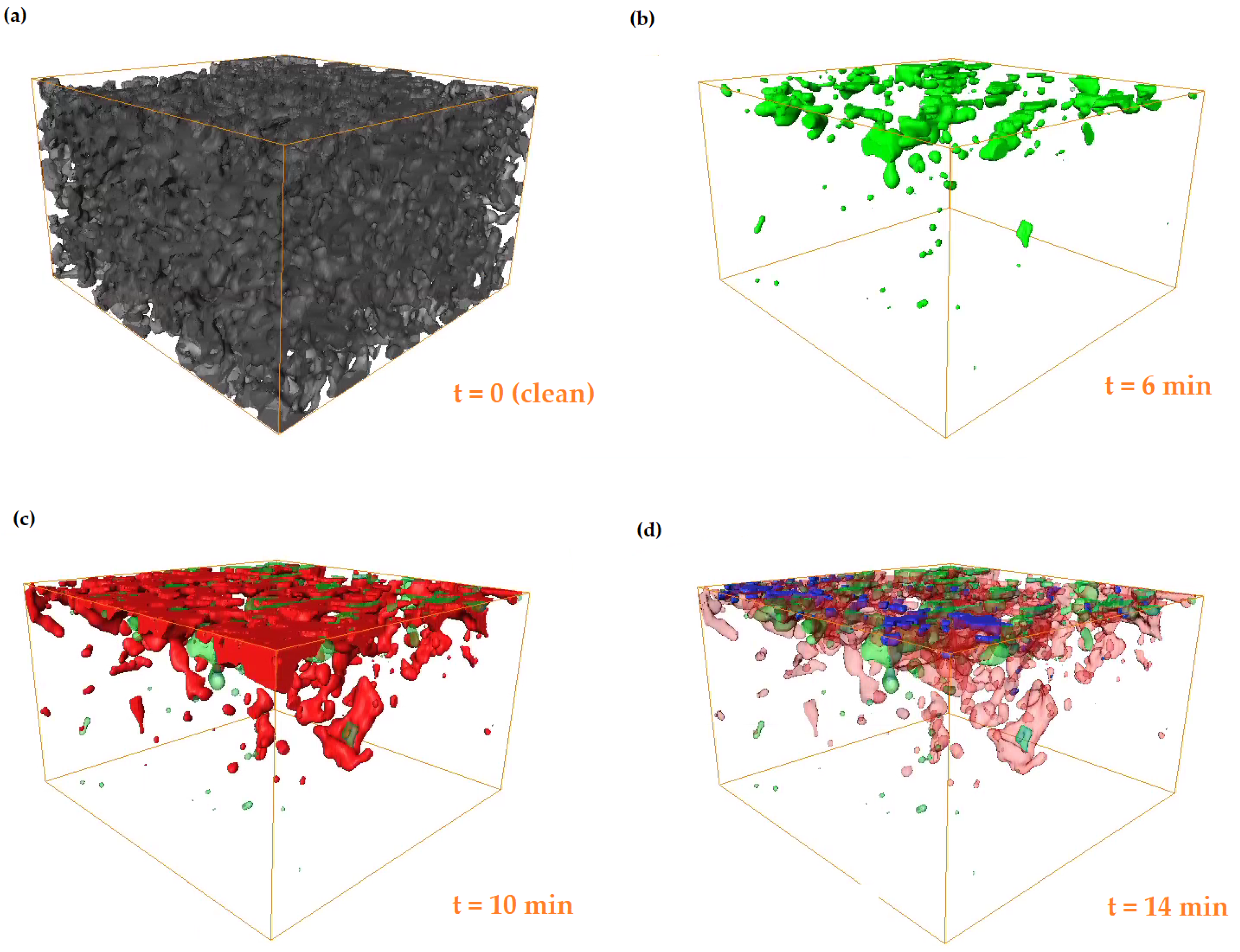

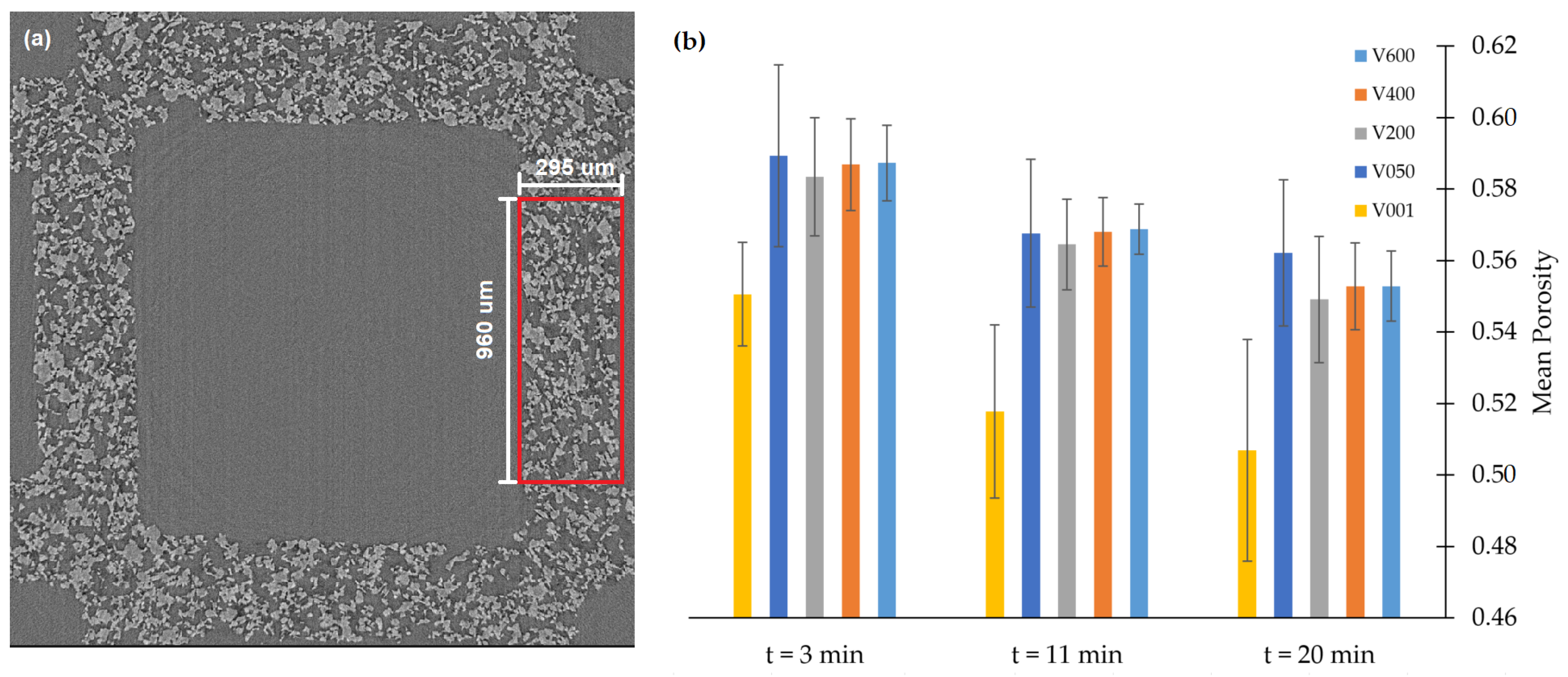

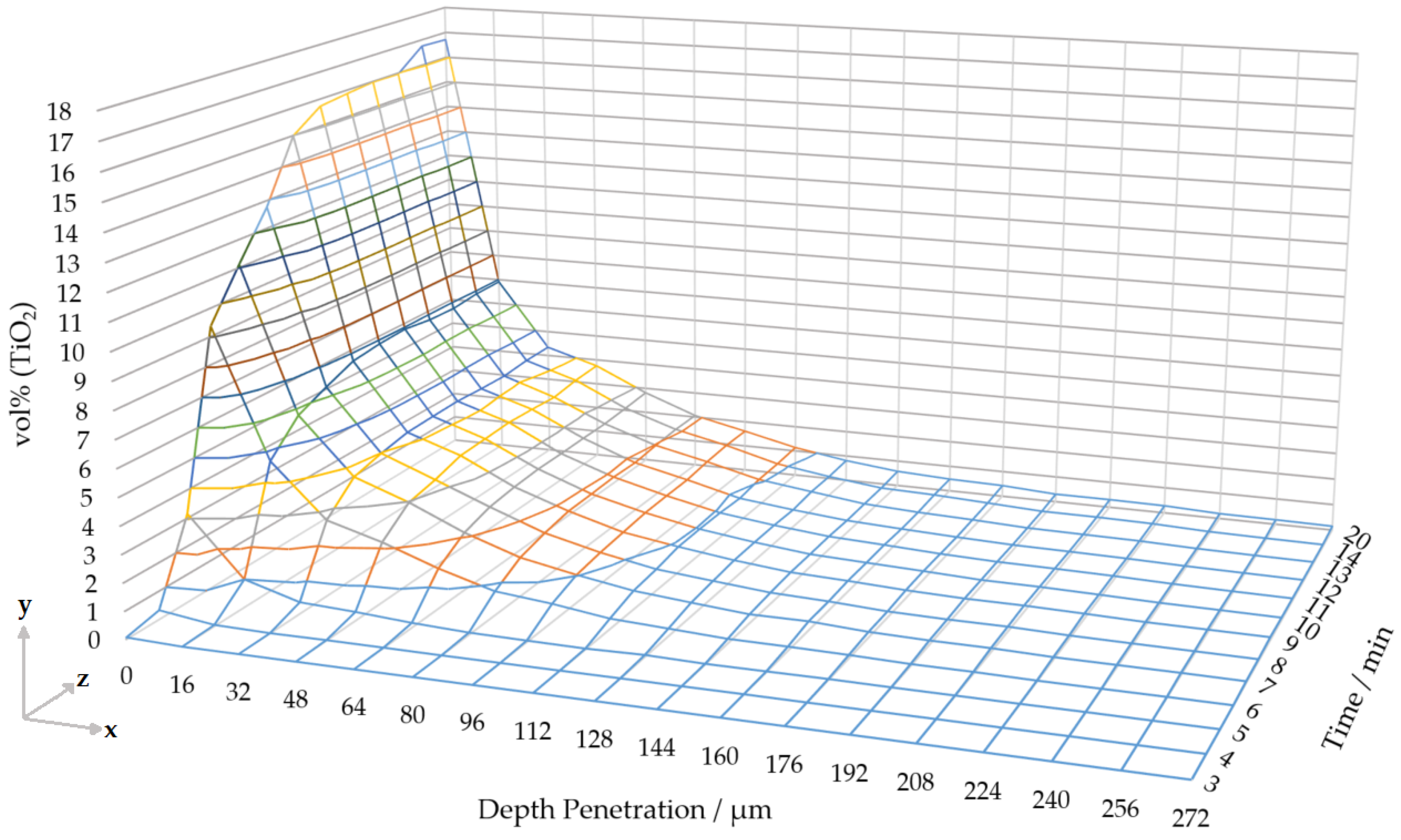

3.1. Visualising Filtration in a Wall Flow Filter

3.2. Quantifying Filtration in a Wall Flow Filter

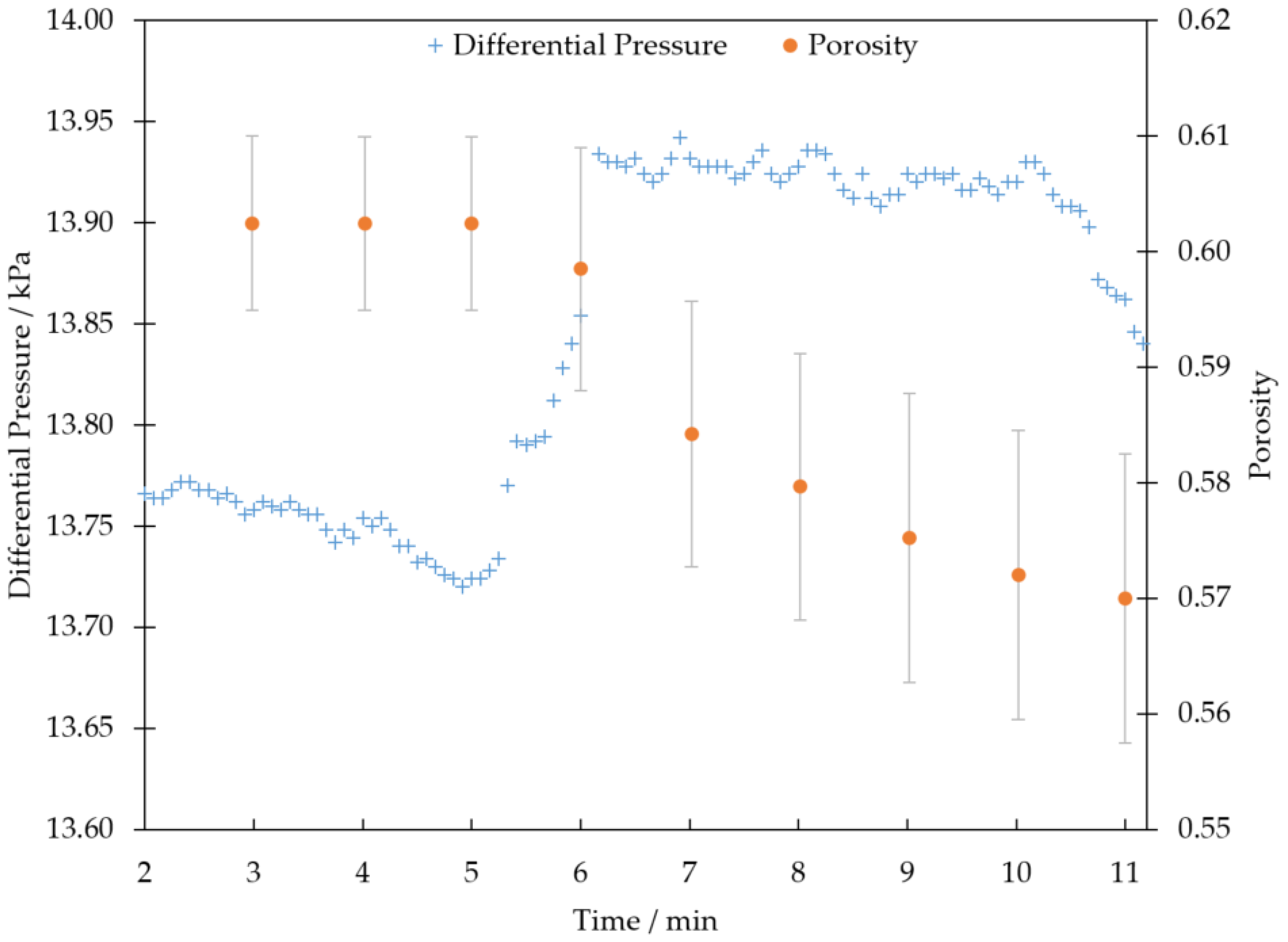

3.3. On-Line Differential Pressure Measurement

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- WHO. World Health Organisation (WHO) Air Quality Database Summary Results; WHO: Geneva, Switzerland, 2018. [Google Scholar]

- Tien, C.; Brenner, H. Granular Filtration of Aerosols and Hydrosols: Butterworths Series in Chemical Engineering; Elsevier Science: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Konstandopoulos, A.G.; Kostoglou, M.; Skaperdas, E.; Papaioannou, E.; Zarvalis, D.; Kladopoulou, E. Fundamental Studies of Diesel Particulate Filters: Transient Loading, Regeneration and Aging. SAE Trans. 2000, 109, 683–705. [Google Scholar]

- Plachá, M.; Kočí, P.; Isoz, M.; Svoboda, M.; Price, E.; Thompsett, D.; Kallis, K.; Tsolakis, A. Pore-scale filtration model for coated catalytic filters in automotive exhaust gas aftertreatment. Chem. Eng. Sci. 2020, 226. [Google Scholar] [CrossRef]

- Belot, I.; Vidal, D.; Votsmeier, M.; Hayes, R.E.; Bertrand, F. Numerical investigation of the impact of washcoat distribution on the filtration performance of gasoline particulate filters. Chem. Eng. Sci. 2020, 221, 115656. [Google Scholar] [CrossRef]

- Kočí, P.; Isoz, M.; Plachá, M.; Arvajová, A.; Václavík, M.; Svoboda, M.; Price, E.; Novák, V.; Thompsett, D. 3D reconstruction and pore-scale modeling of coated catalytic filters for automotive exhaust gas aftertreatment. Catal. Today 2019, 320, 165–174. [Google Scholar] [CrossRef]

- Yamamoto, K.; Satake, S.; Yamashita, H.; Takada, N.; Misawa, M. Lattice Boltzmann simulation on porous structure and soot accumulation. Math. Comput. Simul. 2006, 72, 257–263. [Google Scholar] [CrossRef]

- Yamamoto, K.; Yamauchi, K. Numerical simulation of continuously regenerating diesel particulate filter. Proc. Combust. Inst. 2013, 34, 3083–3090. [Google Scholar] [CrossRef]

- Kamp, C.J.; Zhang, S.; Bagi, S.; Wong, V.; Monahan, G.; Sappok, A.; Wang, Y. Ash Permeability Determination in the Diesel Particulate Filter from Ultra-High Resolution 3D X-Ray Imaging and Image-Based Direct Numerical Simulations. SAE Int. J. Fuels Lubr. 2017, 10, 608–618. [Google Scholar] [CrossRef]

- Vlachos, N.D.; Konstandopoulos, A.G. Digital Materials Methods for DPF Development. SAE Trans. 2006, 115, 79–89. [Google Scholar]

- Stewart, M.; Rector, D. A Mechanistic Model for Particle Deposition in Diesel Particluate Filters Using the Lattice-Boltzmann Technique. In 28th International Conference on Advanced Ceramics and Composites A: Ceramic Engineering and Science Proceedings; Wiley Online Library: Hoboken, NJ, USA, 2004; pp. 437–446. [Google Scholar] [CrossRef]

- Yang, J.; Stewart, M.; Maupin, G.; Herling, D.; Zelenyuk, A. Single wall diesel particulate filter (DPF) filtration efficiency studies using laboratory generated particles. Chem. Eng. Sci. 2009, 64, 1625–1634. [Google Scholar] [CrossRef]

- Choi, S.; Lee, K. Detailed Investigation of Filtration and Regeneration Processes in a Diesel Particulate Filter System. In Proceedings of the FISITA 2012 World Automotive Congress; Lecture Notes in Electrical Engineering, Book Section Chapter 63; Springer: Berlin, Germany, 2013; pp. 811–823. [Google Scholar] [CrossRef]

- Kamp, C.J.; Sappok, A.; Wong, V. Soot and Ash Deposition Characteristics at the Catalyst-Substrate Interface and Intra-Layer Interactions in Aged Diesel Particulate Filters Illustrated using Focused Ion Beam (FIB) Milling. SAE Int. J. Fuels Lubr. 2012, 5, 696–710. [Google Scholar] [CrossRef]

- Kamp, C.J.; Sappok, A.; Wang, Y.; Bryk, W.; Rubin, A.; Wong, V. Direct Measurements of Soot/Ash Affinity in the Diesel Particulate Filter by Atomic Force Microscopy and Implications for Ash Accumulation and DPF Degradation. SAE Int. J. Fuels Lubr. 2014, 7, 307–316. [Google Scholar] [CrossRef]

- Stewart, M.L.; Kamp, C.J.; Gao, F.; Wang, Y.; Engelhard, M.H. Coating Distribution in a Commercial SCR Filter. Emiss. Control. Sci. Technol. 2018, 4, 260–270. [Google Scholar] [CrossRef]

- Václavík, M.; Plachá, M.; Kočí, P.; Svoboda, M.; Hotchkiss, T.; Novák, V.; Thompsett, D. Structure characterisation of catalytic particulate filters for automotive exhaust gas aftertreatment. Mater. Charact. 2017, 134, 311–318. [Google Scholar] [CrossRef]

- Cnudde, V.; Boone, M.N. High-resolution X-ray computed tomography in geosciences: A review of the current technology and applications. Earth Sci. Rev. 2013, 123, 1–17. [Google Scholar] [CrossRef]

- Berg, S.; Ott, H.; Klapp, S.A.; Schwing, A.; Neiteler, R.; Brussee, N.; Makurat, A.; Leu, L.; Enzmann, F.; Schwarz, J.O.; et al. Real-time 3D imaging of Haines jumps in porous media flow. Proc. Natl. Acad. Sci. USA 2013, 110, 3755–3759. [Google Scholar] [CrossRef] [PubMed]

- Berg, S.; Rücker, M.; Ott, H.; Georgiadis, A.; van der Linde, H.; Enzmann, F.; Kersten, M.; Armstrong, R.T.; de With, S.; Becker, J.; et al. Connected pathway relative permeability from pore-scale imaging of imbibition. Adv. Water Resour. 2016, 90, 24–35. [Google Scholar] [CrossRef]

- Singh, K.; Menke, H.; Andrew, M.; Lin, Q.; Rau, C.; Blunt, M.J.; Bijeljic, B. Dynamics of snap-off and pore-filling events during two-phase fluid flow in permeable media. Sci. Rep. 2017, 7, 5192. [Google Scholar] [CrossRef]

- Bultreys, T.; Boone, M.A.; Boone, M.N.; De Schryver, T.; Masschaele, B.; Van Hoorebeke, L.; Cnudde, V. Fast laboratory-based micro-computed tomography for pore-scale research: Illustrative experiments and perspectives on the future. Adv. Water Resour. 2016, 95, 341–351. [Google Scholar] [CrossRef]

- Pešić, Z.D.; Fanis, A.D.; Wagner, U.; Rau, C. Experimental stations at I13 beamline at Diamond Light Source. J. Phys. Conf. Ser. 2013, 425. [Google Scholar] [CrossRef]

- Teleki, A.; Wengeler, R.; Wengeler, L.; Nirschl, H.; Pratsinis, S.E. Distinguishing between aggregates and agglomerates of flame-made TiO2 by high-pressure dispersion. Powder Technol. 2008, 181, 292–300. [Google Scholar] [CrossRef]

- Lee, J.H.; Kwon, M.; Ji, J.H.; Kang, C.S.; Ahn, K.H.; Han, J.H.; Yu, I.J. Exposure assessment of workplaces manufacturing nanosized TiO2 and silver. Inhal. Toxicol. 2011, 23, 226–236. [Google Scholar] [CrossRef] [PubMed]

- Mathis, U.; Mohr, M.; Kaegi, R.; Bertola, A.; Boulouchos, K. Influence of Diesel Engine Combustion Parameters on Primary Soot Particle Diameter. Environ. Sci. Technol. 2005, 39, 1887–1892. [Google Scholar] [CrossRef] [PubMed]

- Atwood, R.C.; Bodey, A.J.; Price, S.W.; Basham, M.; Drakopoulos, M. A high-throughput system for high-quality tomographic reconstruction of large datasets at Diamond Light Source. Philos. Trans. A Math. Phys. Eng. Sci. 2015, 373. [Google Scholar] [CrossRef] [PubMed]

- Costanza-Robinson, M.S.; Estabrook, B.D.; Fouhey, D.F. Representative elementary volume estimation for porosity, moisture saturation, and air-water interfacial areas in unsaturated porous media: Data quality implications. Water Resour. Res. 2011, 47. [Google Scholar] [CrossRef]

- Shah, S.M.; Crawshaw, J.P.; Gray, F.; Yang, J.; Boek, E.S. Convex hull approach for determining rock representative elementary volume for multiple petrophysical parameters using pore-scale imaging and Lattice–Boltzmann modelling. Adv. Water Resour. 2017, 104, 65–75. [Google Scholar] [CrossRef]

- Al-Raoush, R.I.; Willson, C.S. Extraction of physically realistic pore network properties from three-dimensional synchrotron X-ray microtomography images of unconsolidated porous media systems. J. Hydrol. 2005, 300, 44–64. [Google Scholar] [CrossRef]

- Ozelim, L.C.D.S.; Cavalcante André, L. Representative Elementary Volume Determination for Permeability and Porosity Using Numerical Three-Dimensional Experiments in Microtomography Data. Int. J. Geomech. 2018, 18, 04017154. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jones, M.P.; Storm, M.; York, A.P.E.; Hyde, T.I.; Hatton, G.D.; Greenaway, A.G.; Haigh, S.J.; Eastwood, D.S. 4D In-Situ Microscopy of Aerosol Filtration in a Wall Flow Filter. Materials 2020, 13, 5676. https://doi.org/10.3390/ma13245676

Jones MP, Storm M, York APE, Hyde TI, Hatton GD, Greenaway AG, Haigh SJ, Eastwood DS. 4D In-Situ Microscopy of Aerosol Filtration in a Wall Flow Filter. Materials. 2020; 13(24):5676. https://doi.org/10.3390/ma13245676

Chicago/Turabian StyleJones, Matthew P., Malte Storm, Andrew P. E. York, Timothy I. Hyde, Gareth D. Hatton, Alex G. Greenaway, Sarah J. Haigh, and David S. Eastwood. 2020. "4D In-Situ Microscopy of Aerosol Filtration in a Wall Flow Filter" Materials 13, no. 24: 5676. https://doi.org/10.3390/ma13245676

APA StyleJones, M. P., Storm, M., York, A. P. E., Hyde, T. I., Hatton, G. D., Greenaway, A. G., Haigh, S. J., & Eastwood, D. S. (2020). 4D In-Situ Microscopy of Aerosol Filtration in a Wall Flow Filter. Materials, 13(24), 5676. https://doi.org/10.3390/ma13245676