Manufacturing of Lightweight Aggregates as an Auspicious Method of Sewage Sludge Utilization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

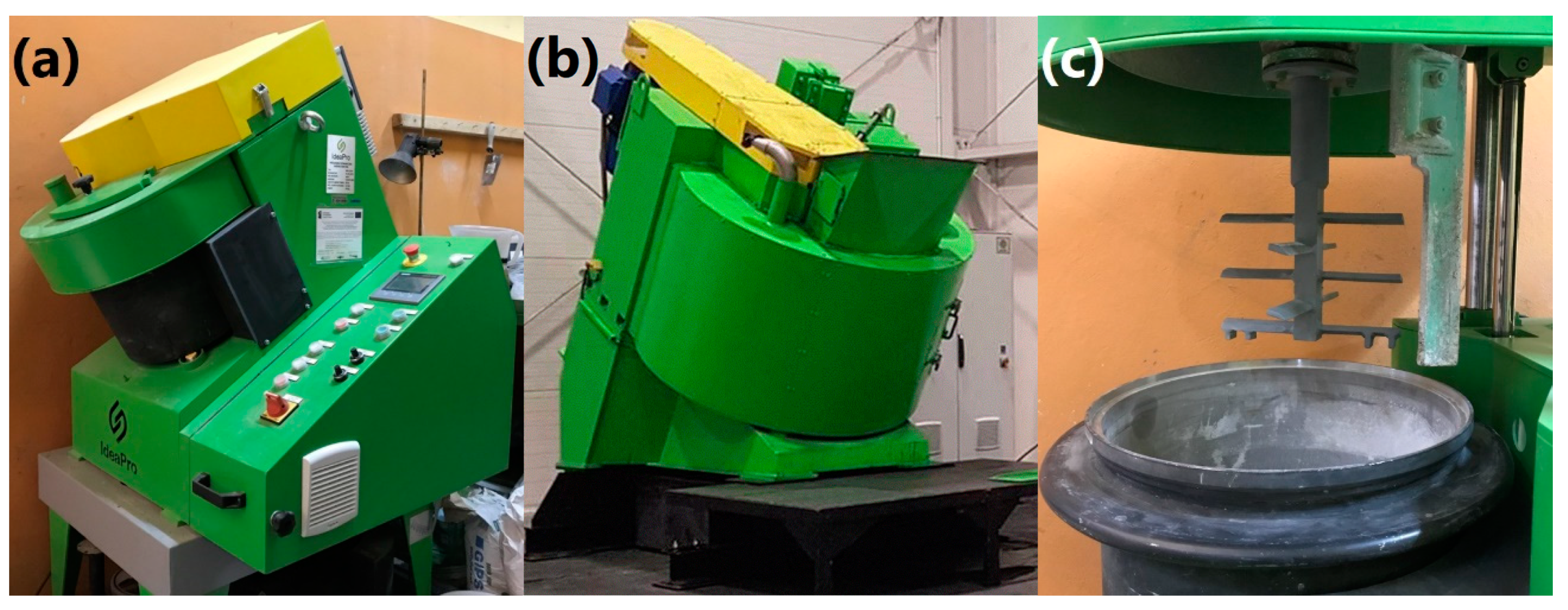

2.2. Granulation of Lightweight Aggregates

2.3. Sintering of Lightweight Aggregates

- maximum operational temperature—1100 °C;

- three heating zones;

- length of the heating zone—1500 mm;

- internal diameter—150 mm.

2.4. Measurements

3. Results and Discussion

3.1. The Particle Size Distribution of Granulates

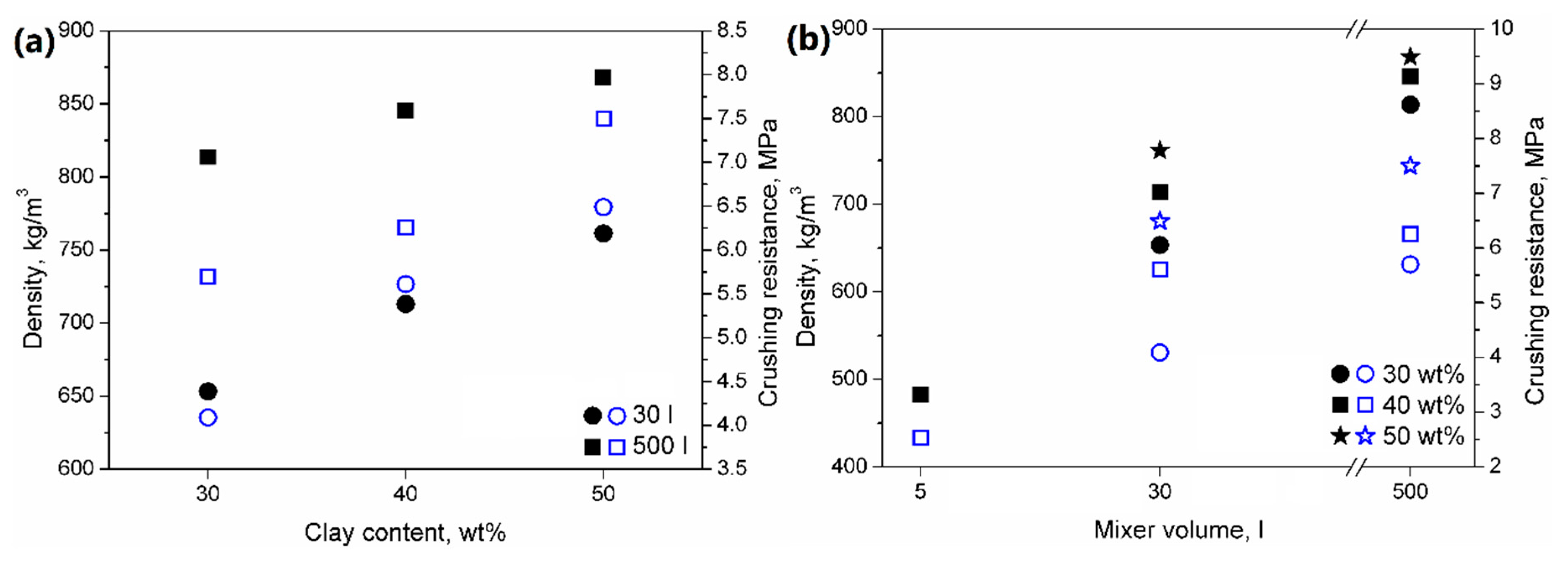

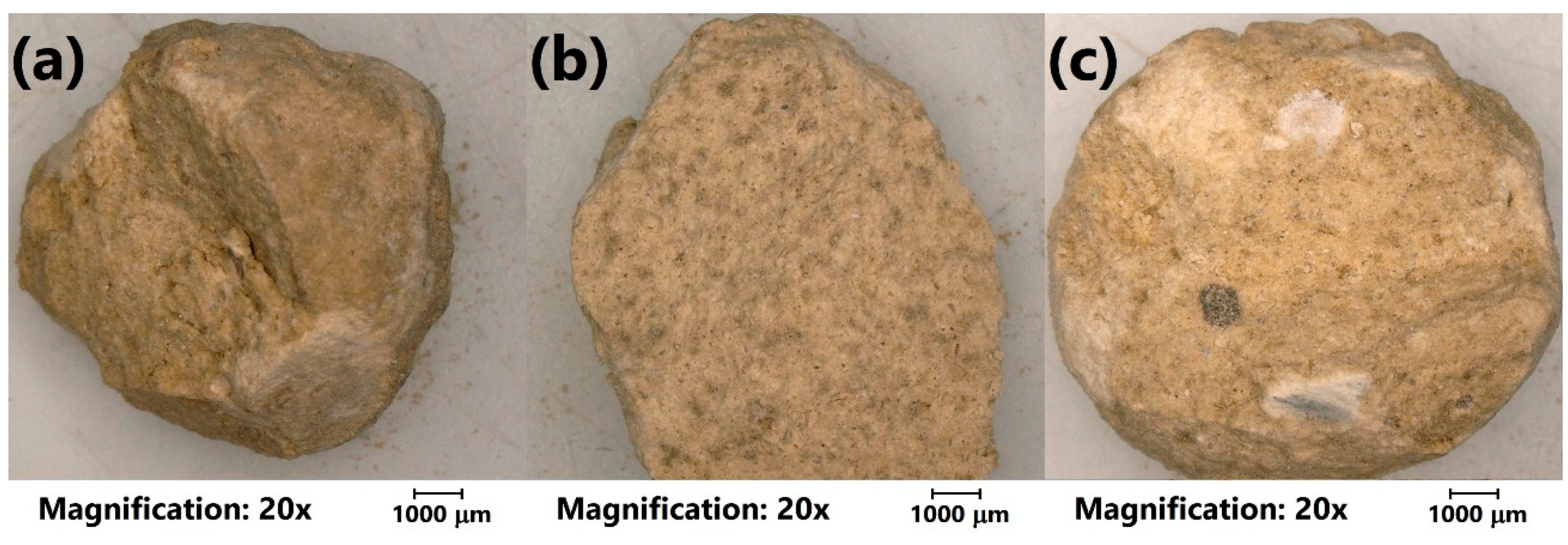

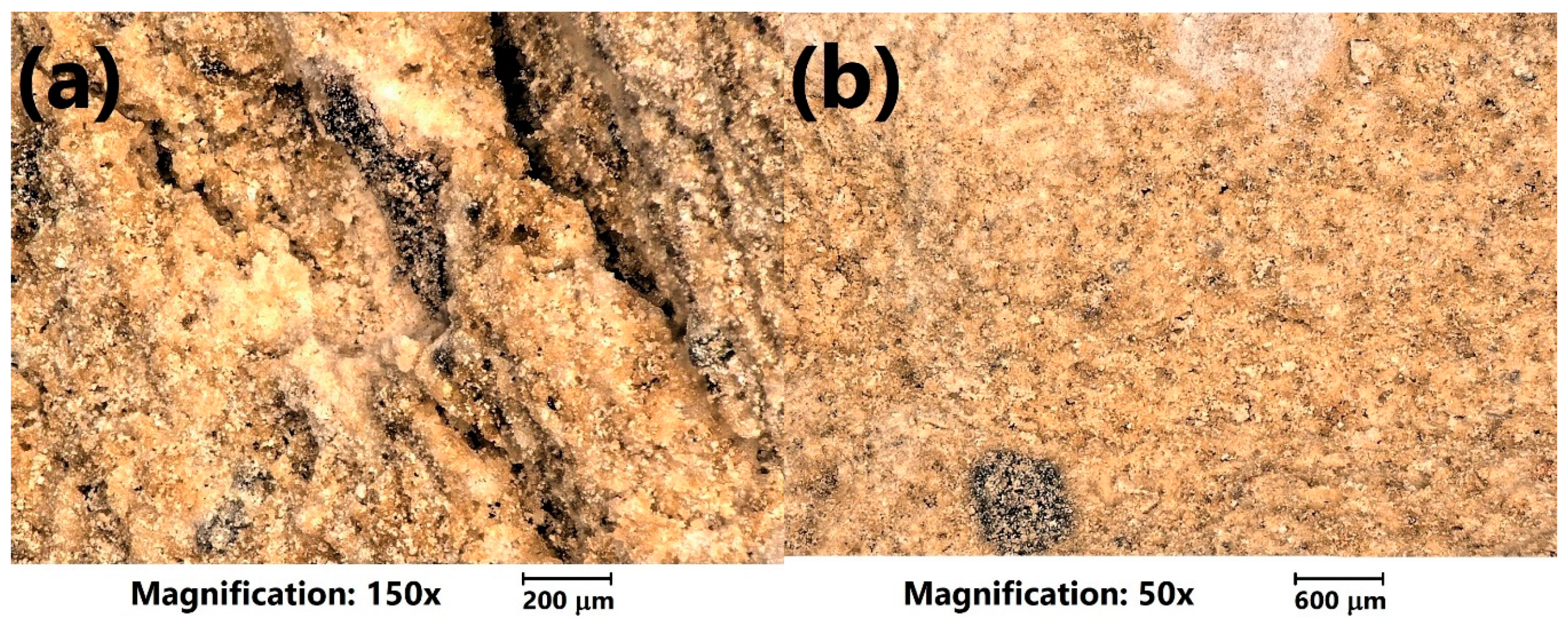

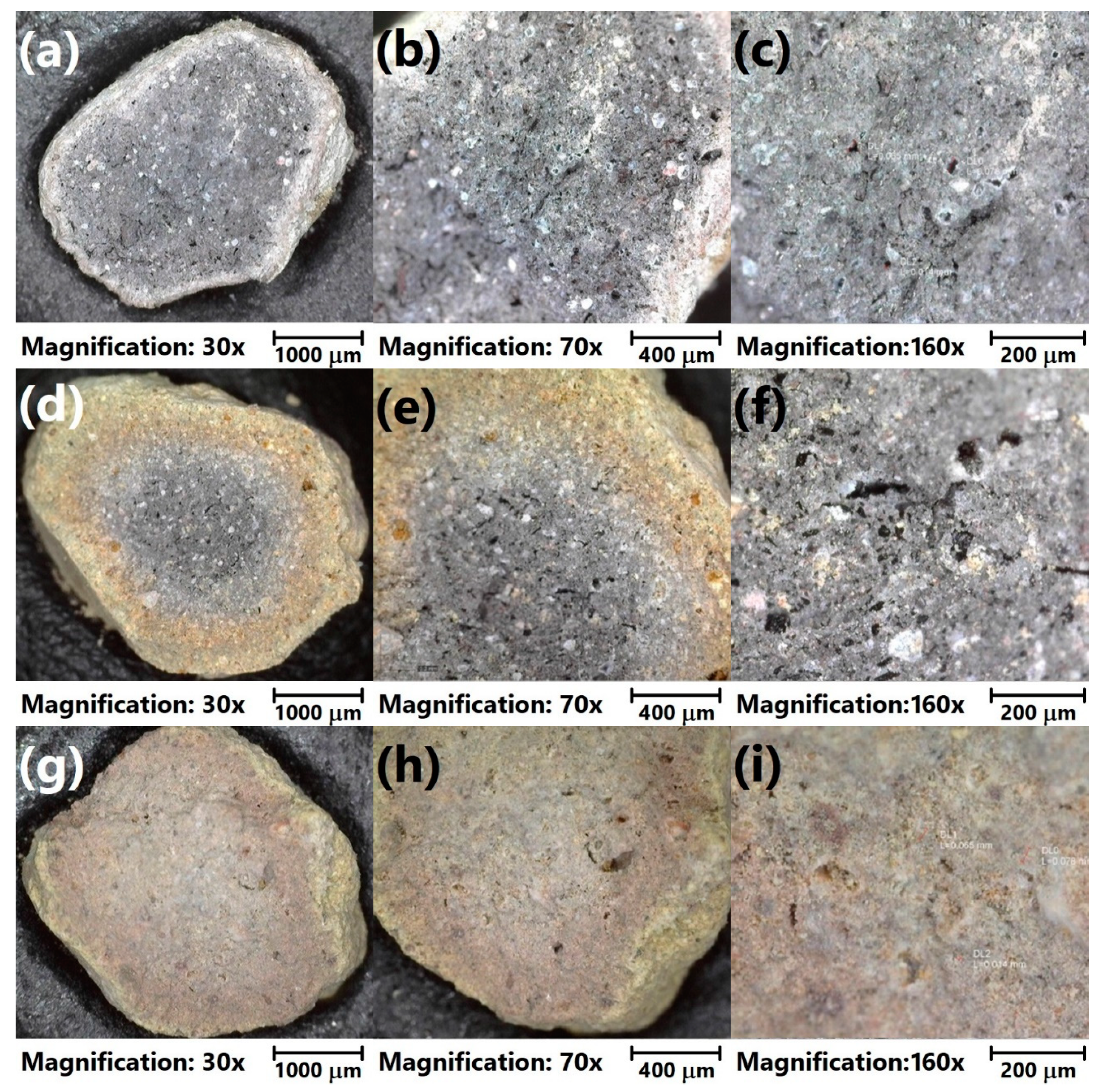

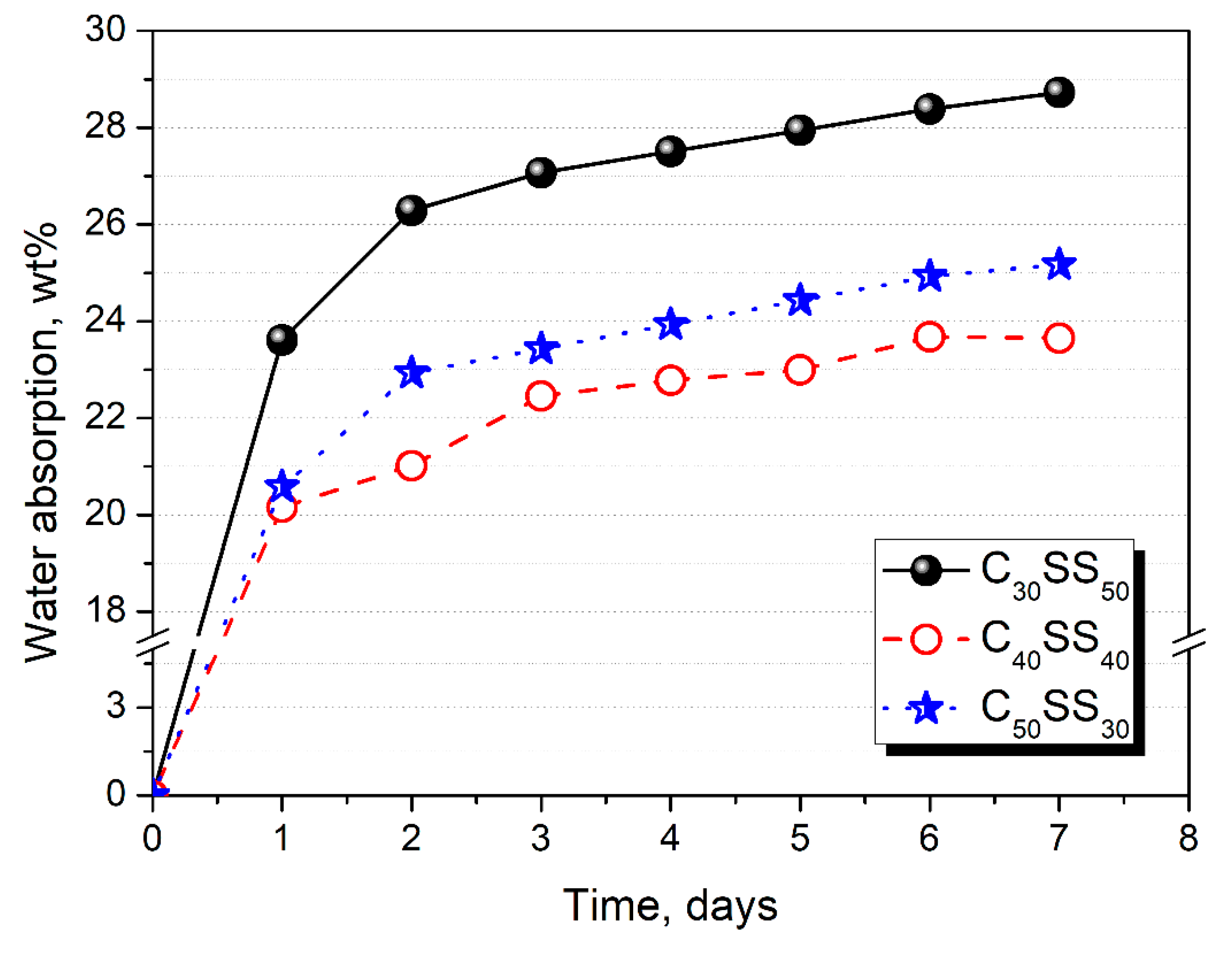

3.2. Preliminary Tests of Sintered Aggregates

- Arlita—0.98 MPa;

- Lytag—0.43 MPa;

- LECA and Ardelite—0.09 MPa;

- Geokeramzyt Matrix—0.8 MPa;

- LECA Gniew—0.7–4.0 MPa.

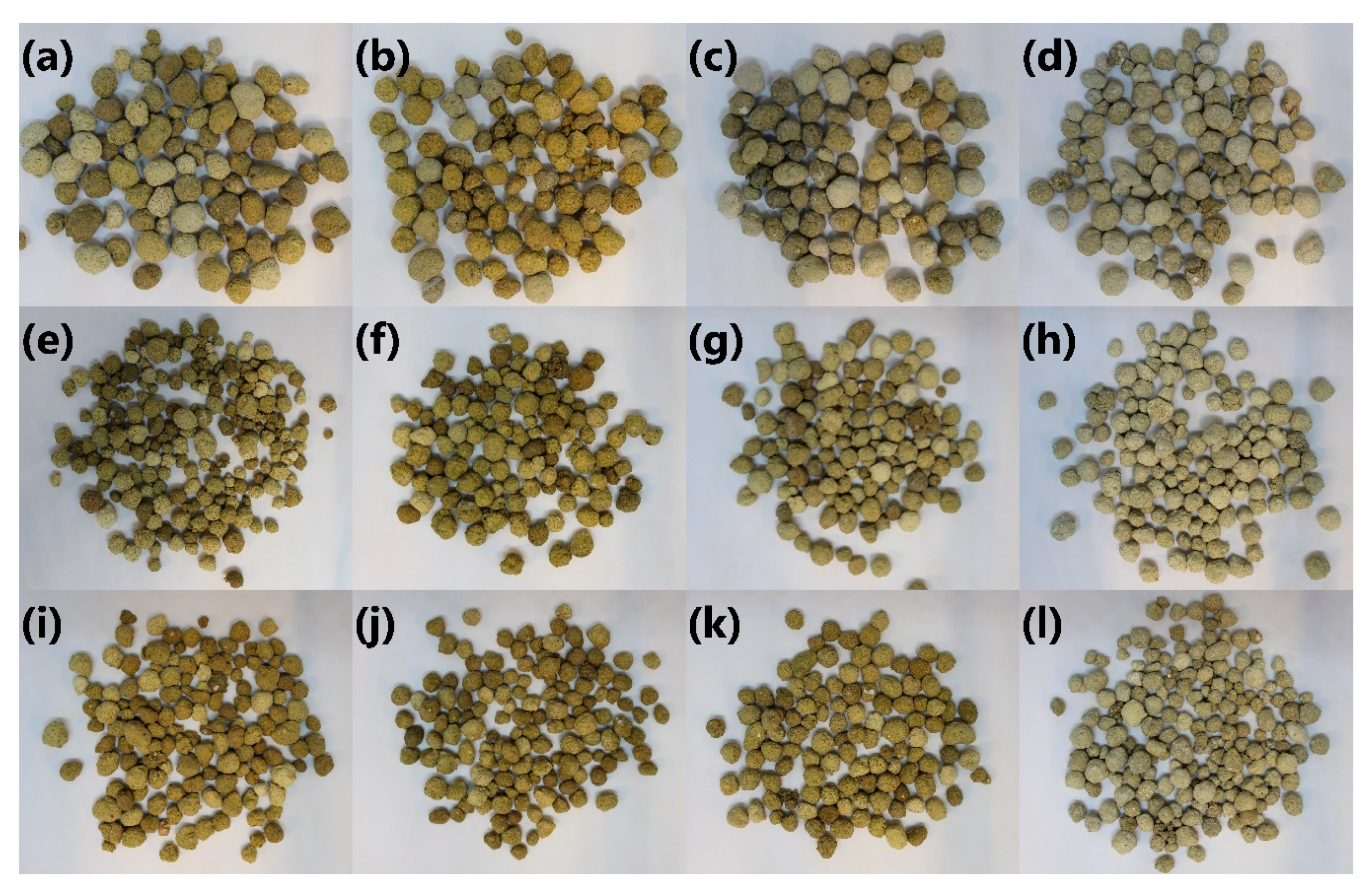

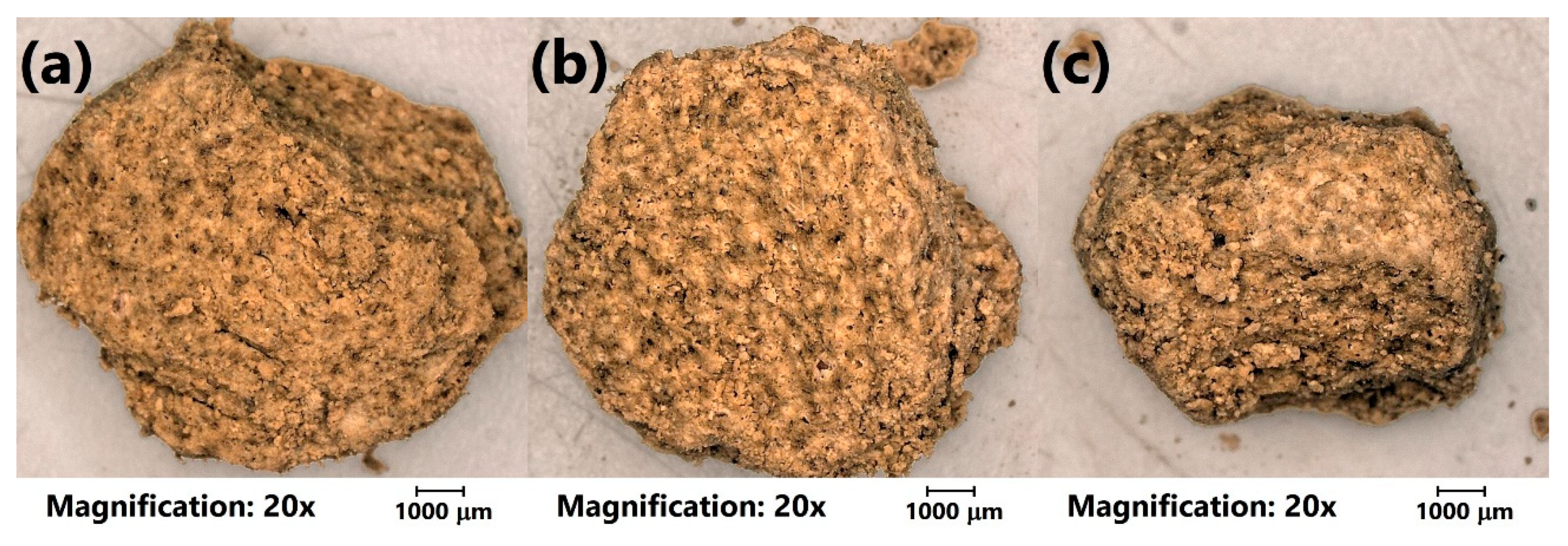

3.3. Final Tests of Sintered Aggregates Prepared in a 500 L Intensive Mixer

4. Conclusions

- The level of sewage contamination. For higher contents of impurities, it may lead to the accumulation of harmful substances in the aggregates, which may result, e.g., in the migration of contaminants to the environment;

- The emissions of volatile organic compounds during the manufacturing of LWAs from sewage sludge. Sewage sludge is an odorous material, especially without the special treatment. Therefore, future research works should include the assessment of volatile organic compounds emissions, e.g., with the use of passive dosimetry. Moreover, the gases generated during sintering could also be monitored;

- The comprehensive analysis of the environmental impacts of the presented process, especially considering the water footprints, since sewage sludge contains high amounts of moisture. Moreover, the life cycle assessment of the process could include the eco-effectivity analysis;

- The influence of sintering parameters (temperature, time, atmosphere) on the performance of the resulting LWAs depending on their composition;

- Modification of the LWAs’ composition to develop the autothermic process, where the energy required for sintering would be obtained from the combustion of particular components.

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Đurđević, D.; Blecich, P.; Jurić, Ž. Energy Recovery from Sewage Sludge: The Case Study of Croatia. Energies 2019, 12, 1927. [Google Scholar] [CrossRef]

- Krajowy Plan Gospodarki Odpadami 2022 Przyjęty Przez Radę Ministrów Uchwałą nr 88 z Dnia 1 Lipca 2016 r. Available online: https://bip.mos.gov.pl/fileadmin/user_upload/bip/strategie_plany_programy/DGO/Krajowy_plan_gospodarki_odpadami_2022_____M.P._poz._784_.pdf (accessed on 17 November 2020).

- Fytili, D.; Zabaniotou, A. Utilization of sewage sludge in EU application of old and new methods—A review. Renew. Sustain. Energy Rev. 2008, 12, 116–140. [Google Scholar] [CrossRef]

- Grübel, K.; Kuglarz, M.; Wacławek, S.; Padil, V.V.T.; Černík, M.; Varma, R.S. Microwave-assisted sustainable co-digestion of sewage sludge and rapeseed cakes. Energy Convers. Manag. 2019, 199, 112012. [Google Scholar] [CrossRef]

- Borowski, S.; Szopa, J.S. Experiences with the dual digestion of municipal sewage sludge. Bioresour. Technol. 2007, 98, 1199–1207. [Google Scholar] [CrossRef]

- Białowiec, A.; Pulka, J.; Styczyńska, M.; Koziel, J.A.; Kalka, J.; Jureczko, M.; Felis, E.; Manczarski, P. Is Biochar from the Torrefaction of Sewage Sludge Hazardous Waste? Materials 2020, 13, 3544. [Google Scholar] [CrossRef]

- Zaker, A.; Chen, Z.; Wang, X.; Zhang, Q. Microwave-assisted pyrolysis of sewage sludge: A review. Fuel Process. Technol. 2019, 187, 84–104. [Google Scholar] [CrossRef]

- Haghighat, M.; Majidian, N.; Hallajisani, A.; Samipourgiri, M. Production of bio-oil from sewage sludge: A review on the thermal and catalytic conversion by pyrolysis. Sustain. Energy Technol. Assess. 2020, 42, 100870. [Google Scholar] [CrossRef]

- Racek, J.; Sevcik, J.; Chorazy, T.; Kucerik, J.; Hlavinek, P. Biochar—Recovery Material from Pyrolysis of Sewage Sludge: A Review. Waste Biomass Valorization 2019, 11, 3677–3709. [Google Scholar] [CrossRef]

- Dos Reis, R.F.; Sergio Cordeiro, J.; Font, X.; Laguna Achon, C. The biodrying process of sewage sludge—A review. Dry. Technol. 2020, 38, 1247–1260. [Google Scholar] [CrossRef]

- Merzari, F.; Langone, M.; Andreottola, G.; Fiori, L. Methane production from process water of sewage sludge hydrothermal carbonization. A review. Valorising sludge through hydrothermal carbonization. Crit. Rev. Environ. Sci. Technol. 2019, 49, 947–988. [Google Scholar] [CrossRef]

- Bora, A.P.; Gupta, D.P.; Durbha, K.S. Sewage sludge to bio-fuel: A review on the sustainable approach of transforming sewage waste to alternative fuel. Fuel 2020, 259, 116262. [Google Scholar] [CrossRef]

- Wang, L.; Chang, Y.; Li, A. Hydrothermal carbonization for energy-efficient processing of sewage sludge: A review. Renew. Sustain. Energy Rev. 2019, 108, 423–440. [Google Scholar] [CrossRef]

- Djandja, O.S.; Wang, Z.; Wang, F.; Xu, Y.P.; Duan, P.G. Pyrolysis of Municipal Sewage Sludge for Biofuel Production: A Review. Ind. Eng. Chem. Res. 2020, 59, 16939–16956. [Google Scholar] [CrossRef]

- Suchorab, Z.; Barnat-Hunek, D.; Franus, M.; Lagod, G.; Pavlik, Z. The possibility of utilization of sewage sludge as a filler in production of the lightweight aggregate concrete. Ecol. Chem. Eng. S 2019, 26, 559–570. [Google Scholar] [CrossRef]

- Kaszycki, P.; Głodniok, M.; Petryszak, P. Towards a bio-based circular economy in organic waste management and wastewater treatment—The Polish perspective. New Biotechnol. 2020, in press. [Google Scholar] [CrossRef] [PubMed]

- Paris, J.M.; Roessler, J.G.; Ferraro, C.C.; DeFord, H.D.; Townsend, T.G. A review of waste products utilized as supplements to Portland cement in concrete. J. Clean. Prod. 2015, 121, 1–18. [Google Scholar] [CrossRef]

- Hamood, A.; Khatib, J.M.; Williams, C. The effectiveness of using Raw Sewage Sludge (RSS) as a water replacement in cement mortar mixes containing Unprocessed Fly Ash (u-FA). Constr. Build. Mater. 2017, 147, 27–34. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Jia, L.T.; Mei, H.; Cui, Q.; Zhang, P.G.; Sun, Z.M. Fabrication, microstructure and properties of bricks fired from lake sediment, cinder and sewage sludge. Constr. Build. Mater. 2016, 121, 154–160. [Google Scholar] [CrossRef]

- Amin, S.K.; Abdel Hamid, E.M.; El-Sherbiny, S.A.; Sibak, H.A.; Abadir, M.F. The use of sewage sludge in the production of ceramic floor tiles. HBRC J. 2017, 14, 309–315. [Google Scholar] [CrossRef]

- Liu, M.; Wang, C.; Bai, Y.; Xu, G. Effects of sintering temperature on the characteristics of lightweight aggregate made from sewage sludge and river sediment. J. Alloys Compd. 2018, 748, 522–527. [Google Scholar] [CrossRef]

- Li, B.; Ling, T.C.; Qu, L.; Wang, Y. Effects of a two-step heating process on the properties of lightweight aggregate prepared with sewage sludge and saline clay. Constr. Build. Mater. 2016, 114, 119–126. [Google Scholar] [CrossRef]

- Xu, G.; Zou, J.; Li, G. Stabilization/Solidification of Heavy Metals in Sludge Ceramsite and Leachability Affected by Oxide Substances. Environ. Sci. Technol. 2009, 43, 5902–5907. [Google Scholar] [CrossRef] [PubMed]

- Korol, J.; Glodniok, M. Technology for Obtaining Synthetic Lightweight Aggregate, and Synthetic Lightweight Aggregate. Polish Patent Application 431113, 11 July 2019. [Google Scholar]

- Burchart-Korol, D.; Korol, J.; Francik, P. Application Of The New Mixing And Granulation Technology Of Raw Materials For Iron Ore Sintering Process. Metalurgija 2012, 51, 187–190. [Google Scholar]

- Li, H.; Zhang, J.; Zheng, W.; Cui, T.; Yang, Y. Study on the Properties and Process Parameters of Different Clays in Disc Granulation. Materials 2020, 13, 1714. [Google Scholar] [CrossRef]

- PN-EN 933-1. Badania Geometrycznych Właściwości Kruszyw—Część 1: Oznaczanie Składu Ziarnowego—Metoda Przesiewania; Polski Komitet Normalizacyjny: Warszawa, Poland, 2012.

- PN-EN 13055-1. Kruszywa Lekkie—Część 1: Kruszywa Lekkie do Betonu, Zaprawy i Rzadkiej Zaprawy; Polski Komitet Normalizacyjny: Warszawa, Poland, 2003.

- Cheeseman, C.R.; Makinde, A.; Bethanis, S. Properties of lightweight aggregate produced by rapid sintering of incinerator bottom ash. Resour. Conserv. Recycl. 2005, 43, 147–162. [Google Scholar] [CrossRef]

- Nambiar, E.K.K.; Ramamurthy, K. Models relating mixture composition to the density and strength of foam concrete using response surface methodology. Cement Concrete Comp. 2006, 28, 752–760. [Google Scholar] [CrossRef]

- Rahmanian, N.; Ghadiri, M.; Jia, X.; Stepanek, F. Characterisation of granule structure and strength made in a high shear granulator. Powder Technol. 2009, 192, 184–194. [Google Scholar] [CrossRef]

- Rahmanian, N.; Ghadiri, M.; Ding, Y. Effect of scale of operation on granule strength in high shear granulators. Chem. Eng. Sci. 2008, 63, 915–923. [Google Scholar] [CrossRef]

- Muthusamy, K.; Zamri, N.; Mohd Haniffa, I.; Sarbini, N.N.; Mat Yahaya, F. Acid Resistance of Oil Palm Shell Lightweight Aggregate Concrete Containing Palm Oil Fuel Ash. Appl. Mech. Mater. 2015, 754–755, 326–330. [Google Scholar]

- Kumar, S.; Gupta, R.C.; Shrivastava, S.; Csetenyi, L.J. Sulfuric Acid Resistance of Quartz Sandstone Aggregate Concrete. J. Mater. Civ. Eng. 2017, 29, 06017006. [Google Scholar] [CrossRef]

- Ahmed, J.; Al-Foudari, M.; Al-Salman, F.; Almusallam, A.S. Effect of particle size and temperature on rheological, thermal, and structural properties of pumpkin flour dispersion. J. Food Eng. 2014, 124, 43–53. [Google Scholar] [CrossRef]

- Smeck, N.E.; Novak, J.M. Weathering of soil clays with dilute sulfuric acid as influenced by sorbed humic substances. Geoderma 1994, 63, 63–76. [Google Scholar] [CrossRef]

- Carroll, D.; Starkey, H.C. Reactivity of Clay Minerals with Acids and Alkalies. Clays Clay Miner. 1971, 19, 321–333. [Google Scholar] [CrossRef]

| Component | Content, wt. % |

|---|---|

| Moisture | 80.64 |

| Dry mass | 19.36 |

| Component | Content, wt. % of dry mass |

| Organic compounds | 64.61 |

| Volatiles | 54.96 |

| Ash | 35.39 |

| C | 34.52 |

| H | 4.98 |

| N | 8.80 |

| O | 15.16 |

| S, total | 1.20 |

| S, ash | 0.05 |

| S, combustible | 1.15 |

| P | 3.68 |

| K | 0.50 |

| Mg | 0.92 |

| Ca | 2.34 |

| Fe | 5.23 |

| Component | Sample Code | ||||||

|---|---|---|---|---|---|---|---|

| C30SS50 | C30SS50_L | C40SS40_S | C40SS40 | C40SS40_L | C50SS30 | C50SS30_L | |

| Clay | 30 | 30 | 40 | 40 | 40 | 50 | 50 |

| Sewage sludge | 50 | 50 | 40 | 40 | 40 | 30 | 30 |

| Fly ash | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Volume of mixer, l | 30 | 500 | 5 | 30 | 500 | 30 | 500 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korol, J.; Głodniok, M.; Hejna, A.; Pawlik, T.; Chmielnicki, B.; Bondaruk, J. Manufacturing of Lightweight Aggregates as an Auspicious Method of Sewage Sludge Utilization. Materials 2020, 13, 5635. https://doi.org/10.3390/ma13245635

Korol J, Głodniok M, Hejna A, Pawlik T, Chmielnicki B, Bondaruk J. Manufacturing of Lightweight Aggregates as an Auspicious Method of Sewage Sludge Utilization. Materials. 2020; 13(24):5635. https://doi.org/10.3390/ma13245635

Chicago/Turabian StyleKorol, Jerzy, Marcin Głodniok, Aleksander Hejna, Tomasz Pawlik, Błażej Chmielnicki, and Jan Bondaruk. 2020. "Manufacturing of Lightweight Aggregates as an Auspicious Method of Sewage Sludge Utilization" Materials 13, no. 24: 5635. https://doi.org/10.3390/ma13245635

APA StyleKorol, J., Głodniok, M., Hejna, A., Pawlik, T., Chmielnicki, B., & Bondaruk, J. (2020). Manufacturing of Lightweight Aggregates as an Auspicious Method of Sewage Sludge Utilization. Materials, 13(24), 5635. https://doi.org/10.3390/ma13245635