Numerical Simulation and Experimental Investigation of Laser Ablation of Al2O3 Ceramic Coating

Abstract

1. Introduction

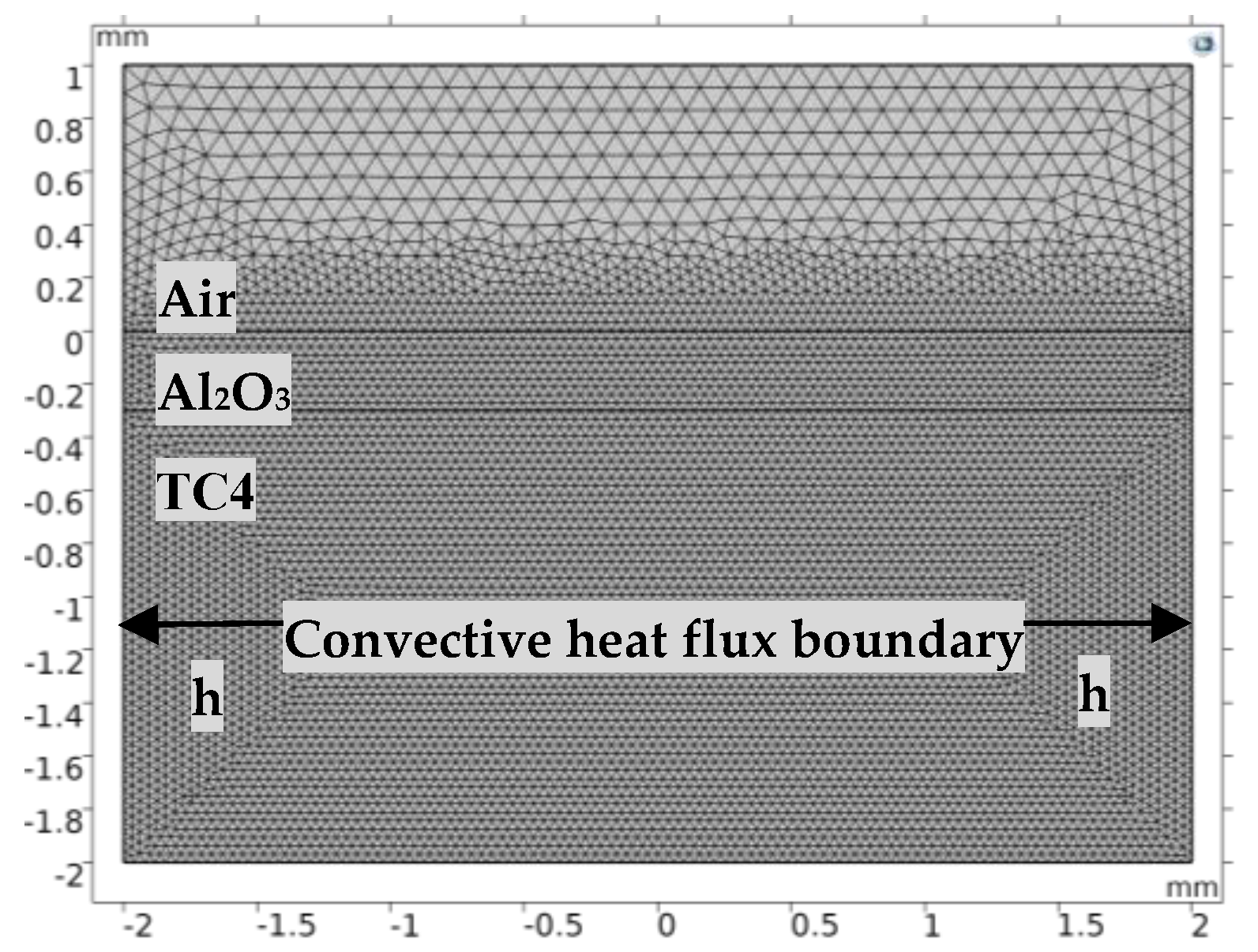

2. Model Description

2.1. Physical Model

- The liquid ceramics flow in the molten pool was considered as an incompressible Newtonian laminar flow.

- The surrounding air was regarded as incompressible airflow.

- Ceramic vapor was considered an ideal gas and transparent to the incident laser beam.

- The formation of plasma was not considered.

- Multiple reflections were not considered.

- The boiling point of ceramics was independent of pressure.

- There is no melting of the substrate during laser ablation, heat transfer is considered only.

2.2. Heat and Fluid Flow Model

2.3. Modified Level Set Method

2.4. Phase Transition

2.5. Laser Heat Source

3. Experimental Details

4. Results and Discussion

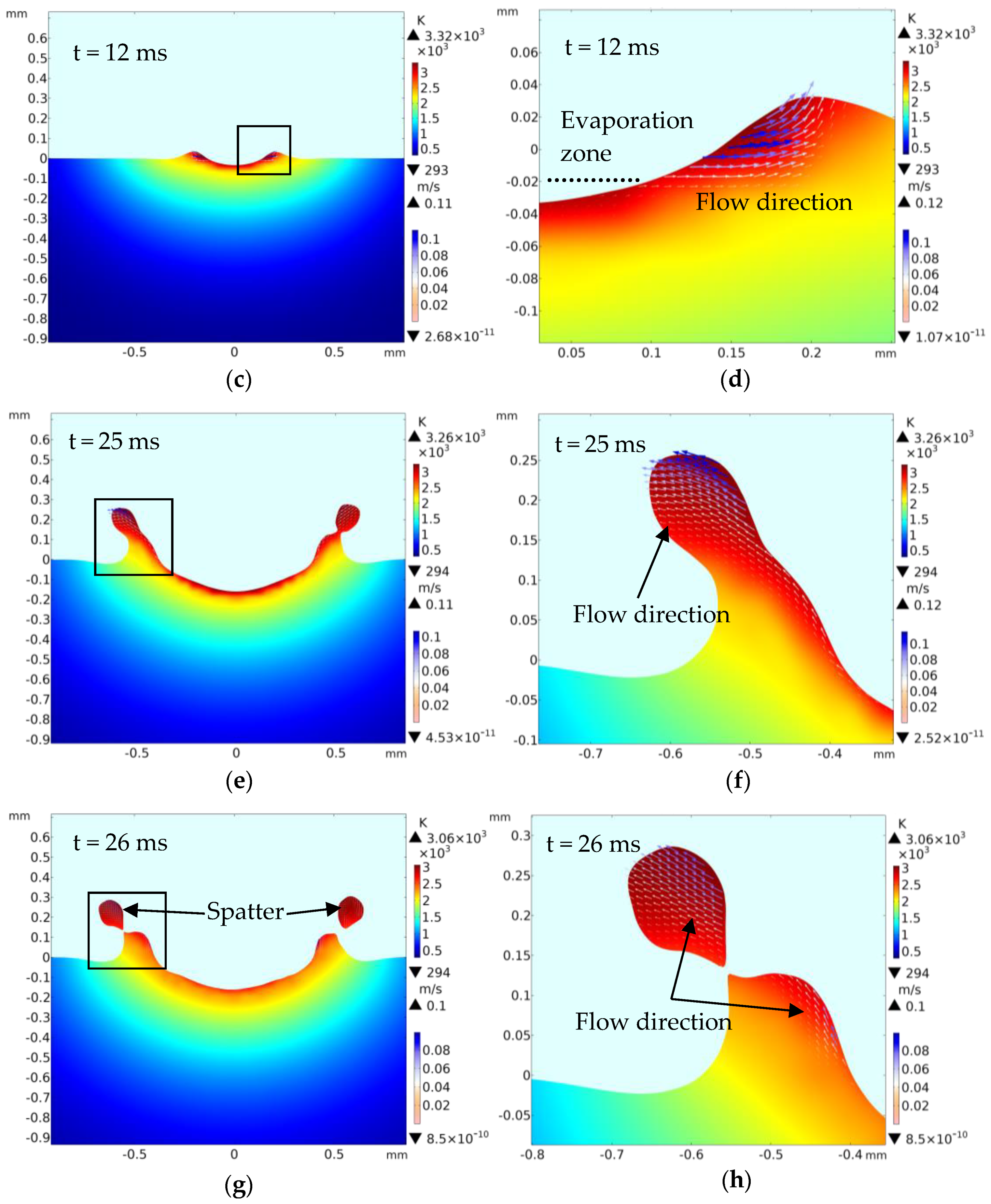

4.1. Experimental and Numerical Results Comparison

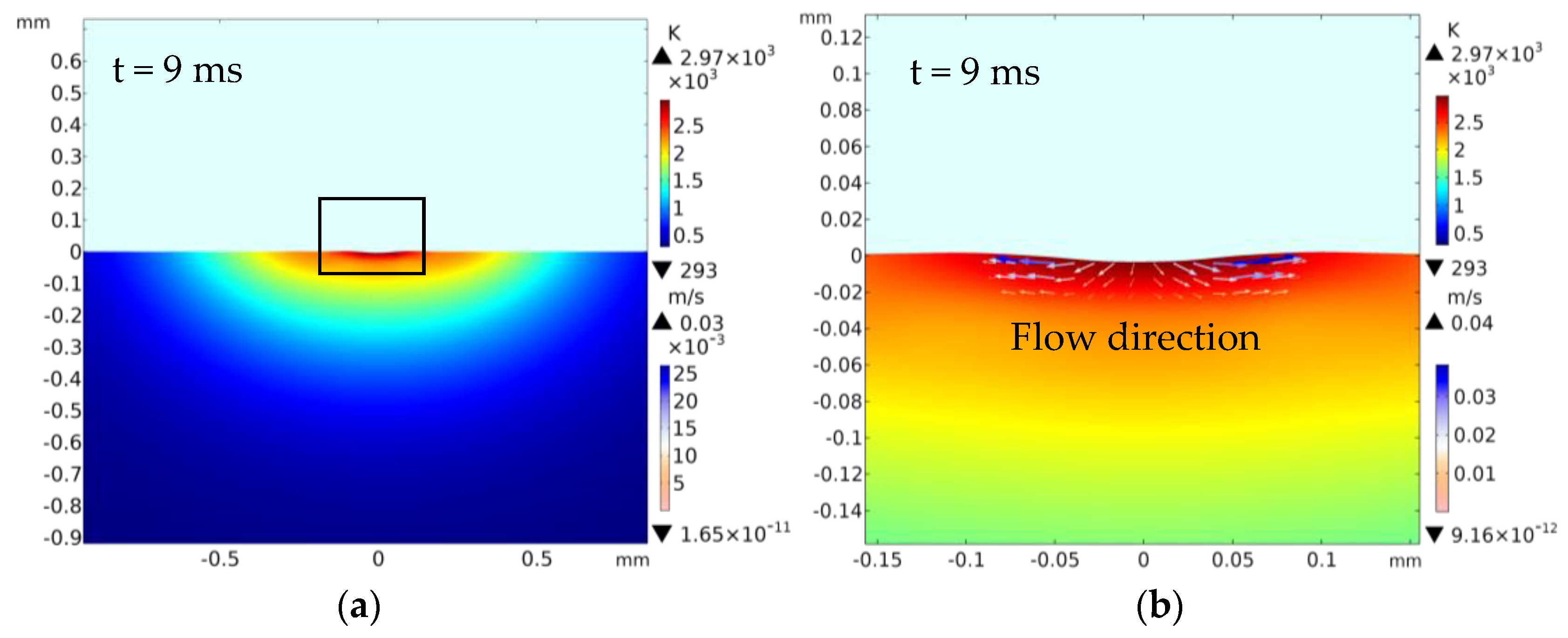

4.1.1. Temperature Field, Fluid Flow and Laser Damage Morphology

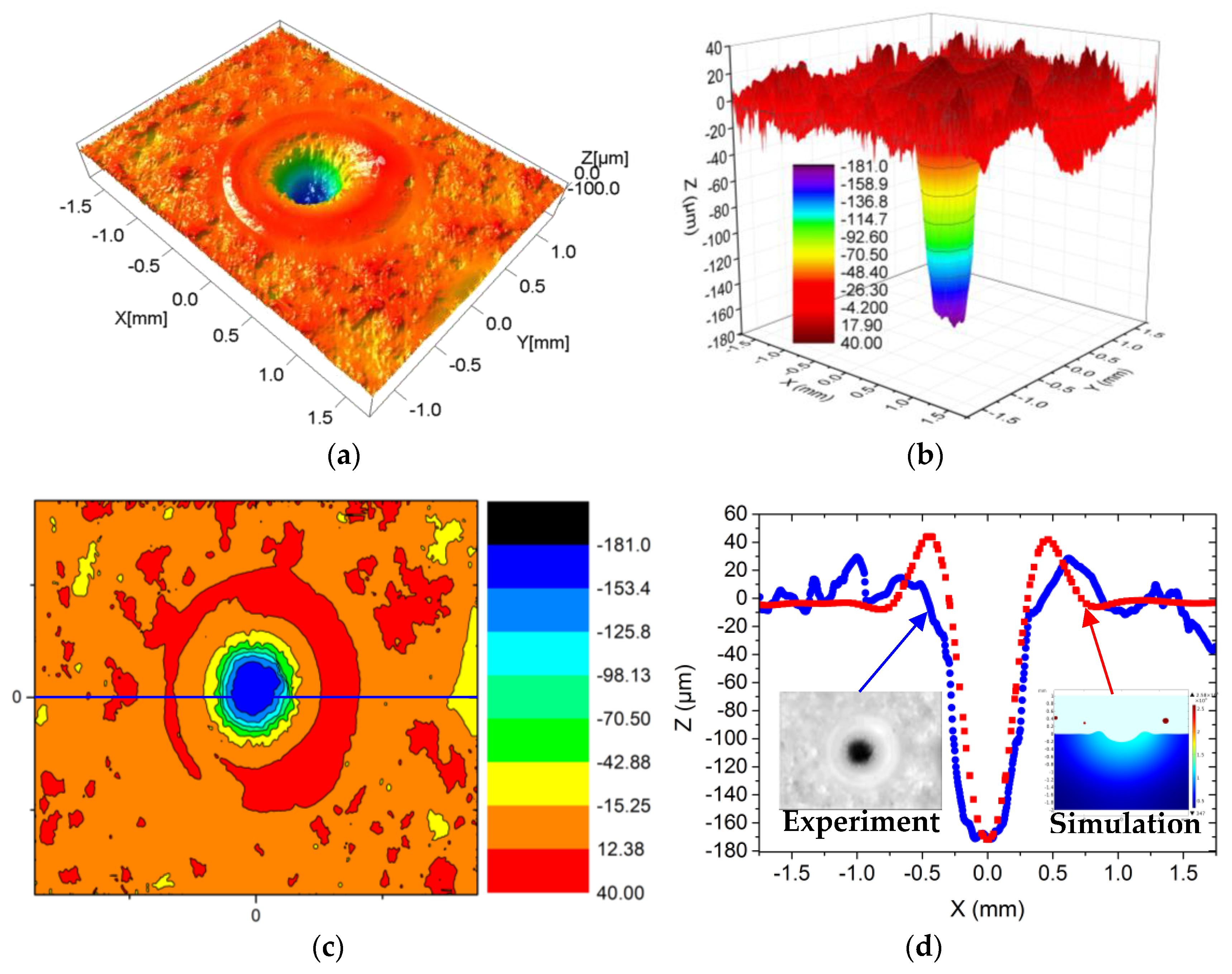

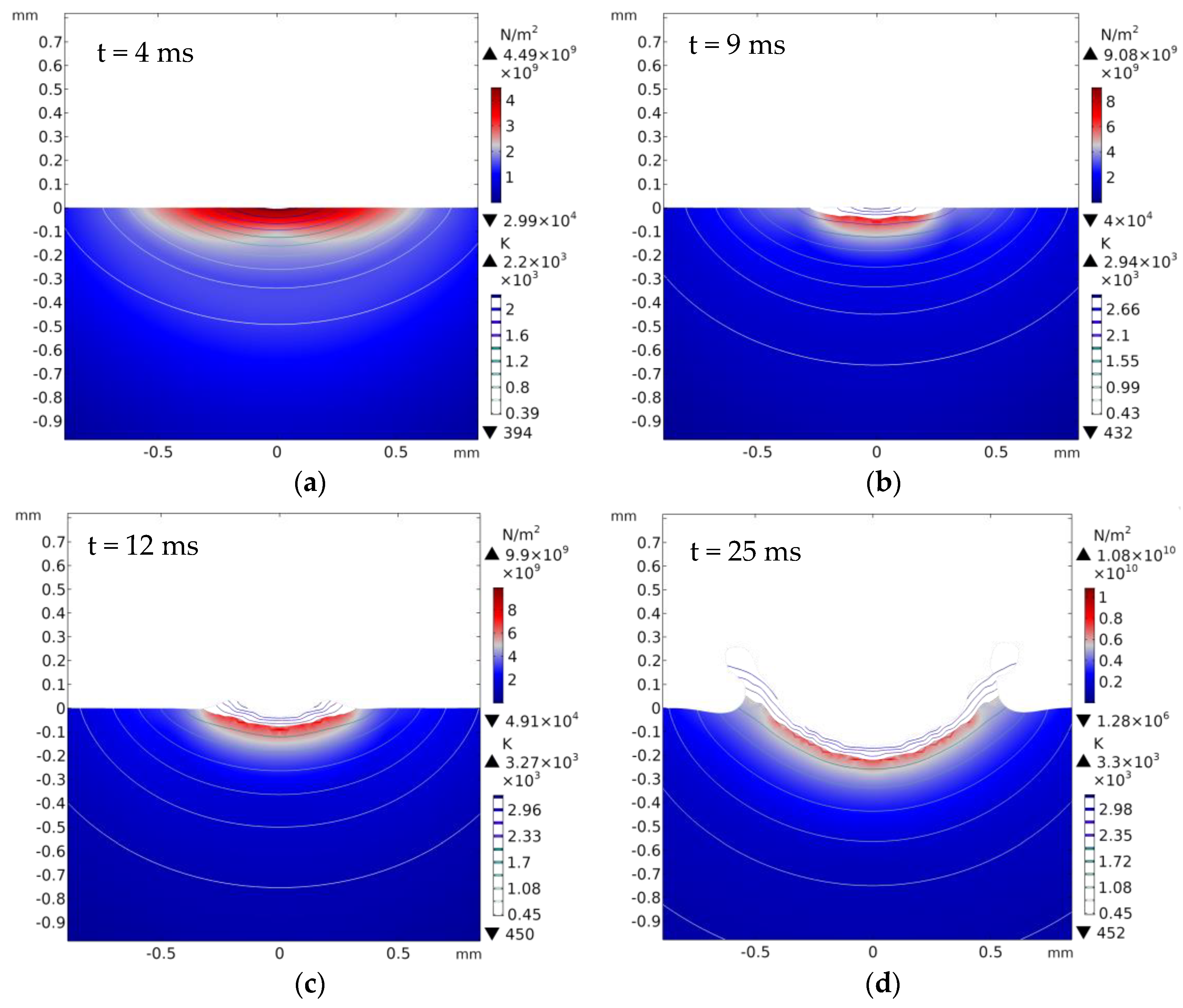

4.1.2. Stress Field and Laser Damage Morphology

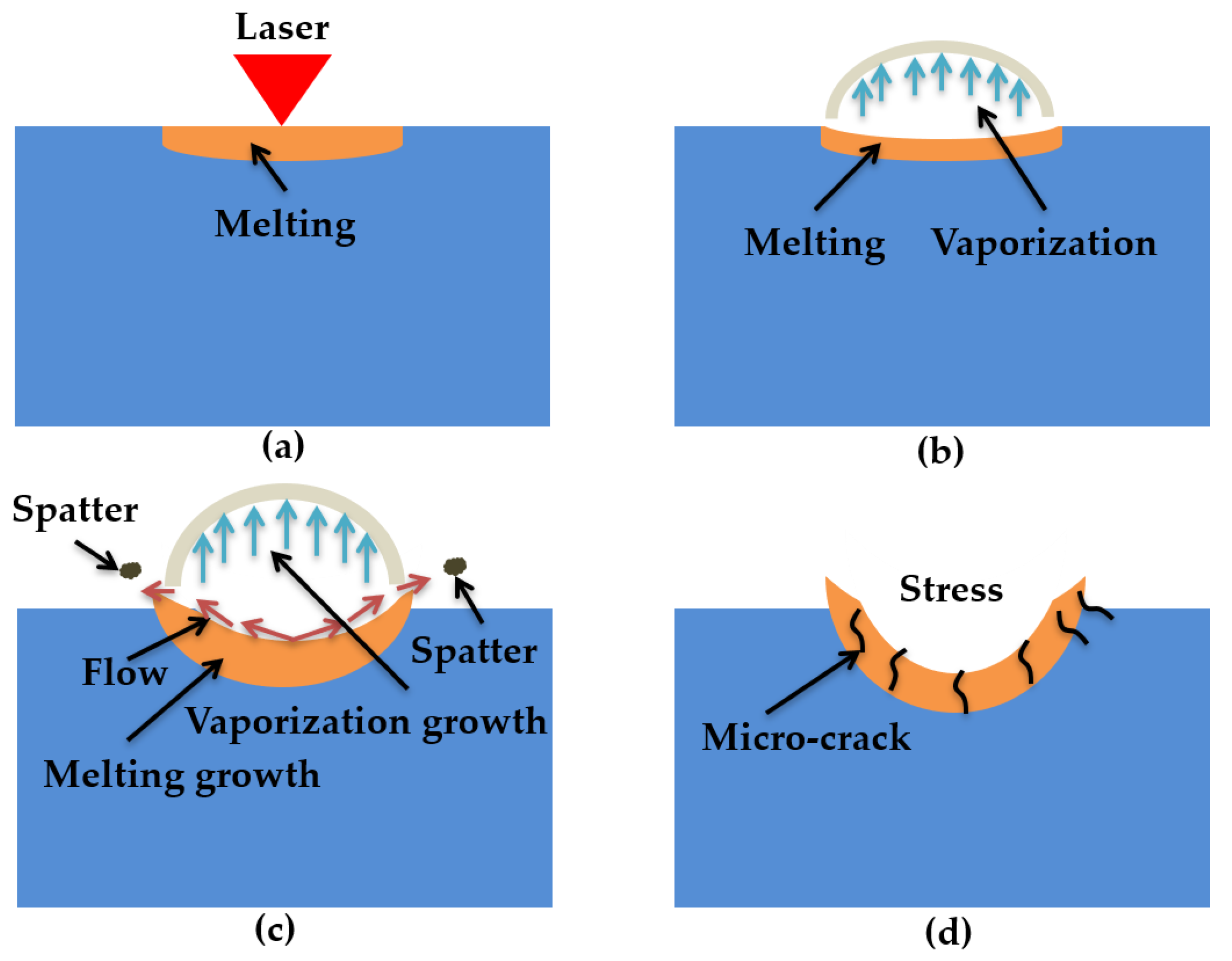

4.2. Mechanism of Laser Ablation Damage

5. Conclusions

- The damage mechanism of laser ablation on the coating surface included melting, gasification, spattering, and micro-cracking. The main melting damage and spatter factors were surface tension and the Marangoni effect. The main cause of gasification was back stamping, and the main cause of micro-cracks was thermal stress.

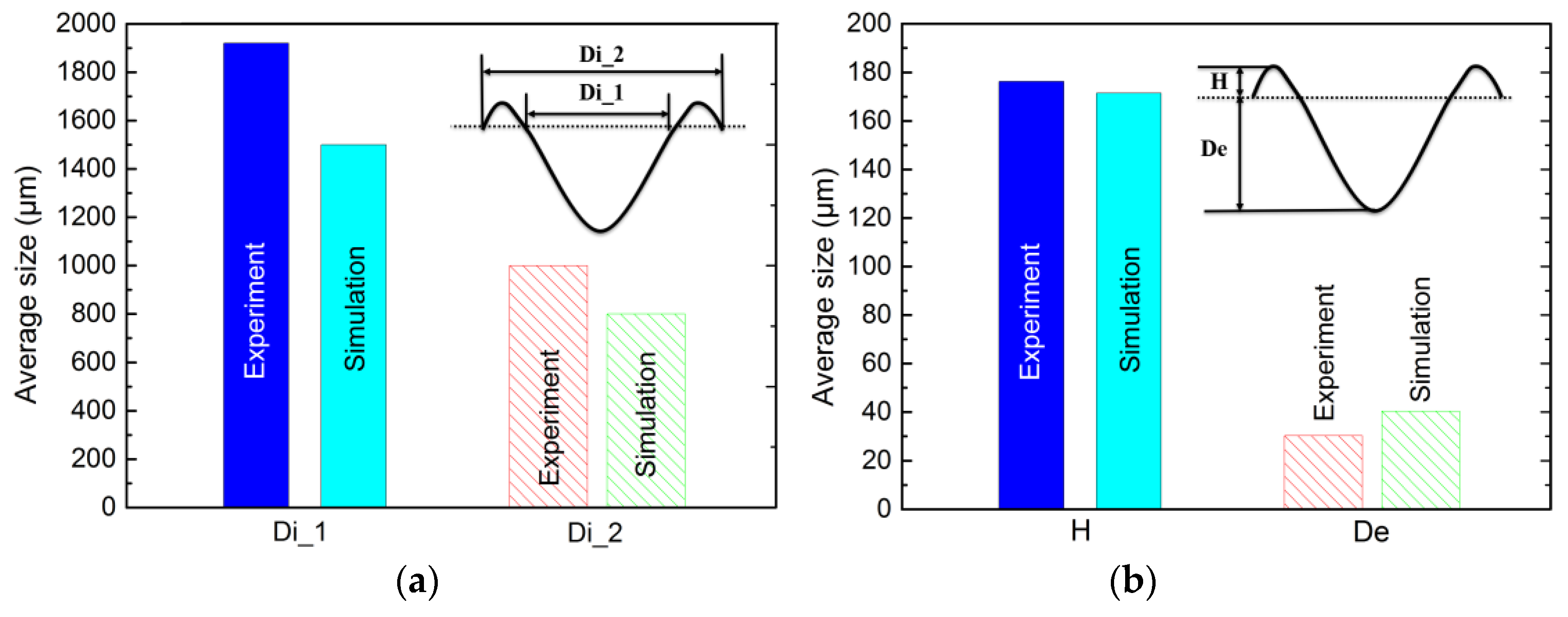

- The temperature-field, fluid-field, and morphology evolution of the damage pit irradiated by the laser were simulated via COMSOL. It determined that the temperature near the laser ablation center (x = 0 mm) was highest and the fluid velocity was fastest near the edge, and it decreased gradually as the distance from the center increased. Additionally, the sizes (De, Di_1, Di_2, H) of the laser damage pit demonstrated that the simulation result agreed with the experiment result.

- The stress field of the alumina coating irradiated by the laser was simulated via COMSOL. The thermal stress (3500~10,000 MPa) produced by the laser irradiation was much greater than the tensile strength (350~500 MPa) of the material itself, which led to hot cracks and brittle fractures. The morphology after the laser irradiation experiment indicated that micro-cracks occurred on the surface.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhao, J.; Xu, S.L. The development trendency and current situation of the laser weapons. Laser Infrared 2005, 35, 67–70. [Google Scholar]

- Feng, Z.J. Characteristics and development trend of laser weapons. China Ventur. Cap. 2019, 11, 272–273. [Google Scholar]

- Zhang, Y.Z. Progress in Airborne Lasers Weapon Research. Aero Manuf. Technol. 2019, 62, 91–94. [Google Scholar]

- Xu, D.W. Development trends and analysis of the solid-state laser weapons. Laser Infrared 2009, 39, 804–807. [Google Scholar]

- Zhao, D.; Zhou, H.; Liu, J.; Zhang, B.; Luo, Q.Q. High-precision velocity measuring system for projectiles based on retro- reflective laser screen. Optik 2013, 124, 544–548. [Google Scholar] [CrossRef]

- Chan, C.L.; Mazumder, J. One-dimensional steady-state model for damage by vaporization and liquid expulsion due to laser-material interaction. Appl. Phys. 1987, 62, 4579. [Google Scholar] [CrossRef]

- Kar, A.; Mazumder, J. Two-dimensional model for material damage due to melting and vaporization during laser irradiation. Appl. Phys. 1990, 68, 3884. [Google Scholar] [CrossRef]

- Zhang, D.M.; Liu, D.; Li, Z.H.; Hou, S.P.; Yu, B.M.; Guan, L.; Tan, X.Y.; Li, L. A new model of pulsed laser ablation and plasma shielding. Phys. B 2005, 362, 82–87. [Google Scholar] [CrossRef]

- Li, Q.; Lao, H.Y.; Lin, J.; Chen, Y.P.; Chen, X.F. Study of femtosecond ablation on aluminum film with 3D two-temperature model and experimental verifications. Appl. Phys. 2011, 105, 125–129. [Google Scholar] [CrossRef]

- Wang, Y.N.; Shen, N.G.; Befekadu, G.K.; Pasiliao, C.L. Modeling pulsed laser ablation of aluminum with finite element analysis considering material moving front. J. Heat Mass Transf. 2017, 113, 1246–1253. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Shen, N.G.; Wang, W.J.; Pan, A.F.; Huang, C.C. Numerical simulation on nanosecond laser ablation of titanium considering plasma shield and evaporation-affected surface thermocapillary convection. Opt. Commun. 2019, 453, 124384. [Google Scholar]

- Lin, H.C.; Chang, Y.L. Atomic Layer Deposited Al2O3 Films on NiTi Shape Memory Alloys for Biomedical Applications. Procedia Manuf. 2019, 37, 431–437. [Google Scholar] [CrossRef]

- Eleonora, K.; Natalia, M. Modeling and optimization of the fabrication of Al2O3-Based ceramic composites reinforced with carbon nanotubes. Mater. Sci. Forum 2020, 995, 27–33. [Google Scholar]

- Liu, S.; Tian, Z.J.; Gao, X.S.; Lv, F. Microstructure and properties 316L mircro-porous structure/Al2O3- 13%TiO2 coating by laser cladding. Chin. J. Nonferrous Met. 2019, 29, 2481–2488. [Google Scholar]

- Zhai, C.S.; Wu, R.Z.; Wang, H.J.; Zhou, S.K.; Sun, B.D. Properties of Al2O3 Coatings by HEPJet Plasma Spray Method. J. Mater. Eng. 2004, 12, 47–50. [Google Scholar]

- Liu, X.; Yang, J.F. Numerical simulation and simulation analysis of digital micro-droplet inkjet process, Industrial. Control Comput. 2019, 32, 133–137. [Google Scholar]

- Courtois, M.; Carin, M.; Masson, P.L.; Gaied, S.; Balabane, M. Guidelines in the experimental validation of a 3D heat and fluid flow model of keyhole laser welding. J. Phys. D Appl. Phys. 2016, 49, 155503. [Google Scholar] [CrossRef]

- Courtois, M.; Carin, M.; Masson, P.L.; Gaied, S.; Balabane, M. A complete model of keyhole and melt pool dynamics to analyze instabilities and collapse during laser welding. J. Laser Appl. 2014, 26, 042001. [Google Scholar] [CrossRef]

- Courtois, M.; Carin, M.; Masson, P.L.; Gaied, S.; Balabane, M. A new approach to compute multi-reflections of laser beam in a keyhole for heat transfer and fluid flow modelling in laser welding. J. Phys. D Appl. Phys. 2013, 46, 505305. [Google Scholar] [CrossRef]

- Voller, V.R.; Prakash, C. A fixed-grid numerical modeling methodology for convection-diffusion mushy region phase-change problems. Int. J. Heat Mass Transf. 1987, 30, 1709–1719. [Google Scholar] [CrossRef]

- Zhang, M.; Shen, Z.H.; Ni, X.W. Modeling and simulation on long pulse laser drilling processing. Int. J. Heat Mass Transf. 2014, 73, 429–437. [Google Scholar] [CrossRef]

- Wu, D.S.; Hua, X.M.; Li, F.; Huang, L.J. Understanding of spatter formation in fiber laser welding of 5083 aluminum alloy. Int. J. Heat Mass Transf. 2017, 113, 730–740. [Google Scholar] [CrossRef]

- Amara, E.H.; Bendib, A. Modelling of vapour flow in deep penetration laser welding. J. Phys. D Appl. Phys. 2002, 35, 272–280. [Google Scholar] [CrossRef]

- Self, S.A. Focusing of spherical Gaussian beams. Appl. Opt. 1983, 22, 658–661. [Google Scholar] [CrossRef]

- Yilbas, B.S.; Karatas, C.; Arif, A.F.M.; Abdul Aleem, B.J. Laser control melting of alumina surfaces and thermal stress analysis. Opt. Laser Technol. 2011, 43, 858–865. [Google Scholar] [CrossRef]

- Ma, R.L.; Zhang, K.; Wei, H.L.; Liu, T.T.; Liao, W.H. Formation mechanism of surface microstructure laser selective melting surface of Alumina ceramics based on numerical simulation. Chin. J. Lasers 2019, 46, 1–8. [Google Scholar]

- Chen, Q.; Guillemot, G.; Gandin, C.A.; Bellet, M. Three-dimensional finite element thermo-mechanical modeling of additive manufacturing by selective laser melting for ceramic materials. Addit. Manuf. 2017, 16, 124–137. [Google Scholar]

- Wen, B.Q. Handbook of Nonmetallic Materials; Publishing House of Electronics Industry: Beijing, China, 2006. [Google Scholar]

- Moncayo, M.A.; Santhanakrishnan, S.; Vora, H.D.; Dahotre, N.B. Computational modeling and experimental based parametric study of multi-track laser processing on alumina. Opt. Laser Technol. 2013, 48, 570–579. [Google Scholar] [CrossRef]

- Somiya, S. Handbook of Advanced Ceramics: Materials, Applications, Processing, and Properties Hardcover, 2nd ed.; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Krella, A.K.; Sobczyk, A.T.; Krupa, A.; Jaworek, A. Thermal resistance of Al2O3 coating produced by electrostatic spray deposition method. Mech. Mater. 2016, 98, 120–133. [Google Scholar] [CrossRef]

- Araia, M.; Furuseb, M. Evaluating strength of thermally sprayed Al2O3 on aluminum. Vacuum 2019, 84, 672–676. [Google Scholar] [CrossRef]

- Li, L.; Yan, L.; Cui, W.Y.; Chen, Y.T.; Pan, T.; Zhang, X.C.; Flood, A.; Liou, F. Predictive model for thermal and stress field in selective laser melting Process—Part I. Procedia Manuf. 2019, 39, 539–546. [Google Scholar] [CrossRef]

- Choudhury, S.; Medhi, T.; Sethi, D.; Kumar, S.; SahaRoy, B.; Saha, S.C. Temperature distribution and residual stress in Friction Stir Welding process. Mater. Today Proc. 2020, 26, 2296–2301. [Google Scholar] [CrossRef]

| Property | TC4 | Value |

|---|---|---|

| Density (kg/m3) | ρ TC4 | 4.51 × 103 |

| Specific heat capacity (J/(kg∗K)) | CP-TC4 | 536 |

| Heat conductivity (W/(m∗K)) | k TC4 | 6.4 |

| Thermo-Physical Properties of Al2O3 | Value |

|---|---|

| Density (ρs/ρl, kg/m3) | 3800 |

| Density (ρg, kg/m3) | 1.3 |

| Melting temperature (Tm, K) | 2306 |

| Vaporization temperature (Tv, K) | 3250 |

| Latent heat of fusion (Lm, J/kg) | 1.06743 × 106 |

| Latent heat of vaporization (Lv, J/kg) | 1.0665 × 106 |

| Viscosity (ul/ug, Pa∗s) | 0.069/0.000024 |

| Heat transfer coefficient (h, W/(m2∗K)) | 10 |

| Surface tension gradient (ζ, N/(m∗K)) | ‒8.2 × 10−5 |

| Absorptivity (A) | 0.25 |

| The emissivity of alumina (ε) | 0.7 |

| Stefan–Boltzmann constant (kb, W/(m2∗K4)) | 5.67 × 10−8 |

| Gas constant (R, J/(mol∗K)) | 8.31 |

| Poisson’s ratio (v) | 0.245 |

| Tensile strength (δ, MPa) | 350–500 |

| Half-width of the temperature curve (ΔT, K) | 30 |

| Laser Ablation Parameters | Value |

|---|---|

| Laser power (Q, W) | 500 |

| Laser the beam radius (r_spot, mm) | 0.8 |

| Wavelength (λ, nm) | 1064 |

| Laser ablation time (ton, ms) | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Tian, Z.; Shen, L.; Qiu, M. Numerical Simulation and Experimental Investigation of Laser Ablation of Al2O3 Ceramic Coating. Materials 2020, 13, 5502. https://doi.org/10.3390/ma13235502

Liu S, Tian Z, Shen L, Qiu M. Numerical Simulation and Experimental Investigation of Laser Ablation of Al2O3 Ceramic Coating. Materials. 2020; 13(23):5502. https://doi.org/10.3390/ma13235502

Chicago/Turabian StyleLiu, Shuang, Zongjun Tian, Lida Shen, and Mingbo Qiu. 2020. "Numerical Simulation and Experimental Investigation of Laser Ablation of Al2O3 Ceramic Coating" Materials 13, no. 23: 5502. https://doi.org/10.3390/ma13235502

APA StyleLiu, S., Tian, Z., Shen, L., & Qiu, M. (2020). Numerical Simulation and Experimental Investigation of Laser Ablation of Al2O3 Ceramic Coating. Materials, 13(23), 5502. https://doi.org/10.3390/ma13235502