Thermal Properties of Bayfol® HX200 Photopolymer

Abstract

1. Introduction

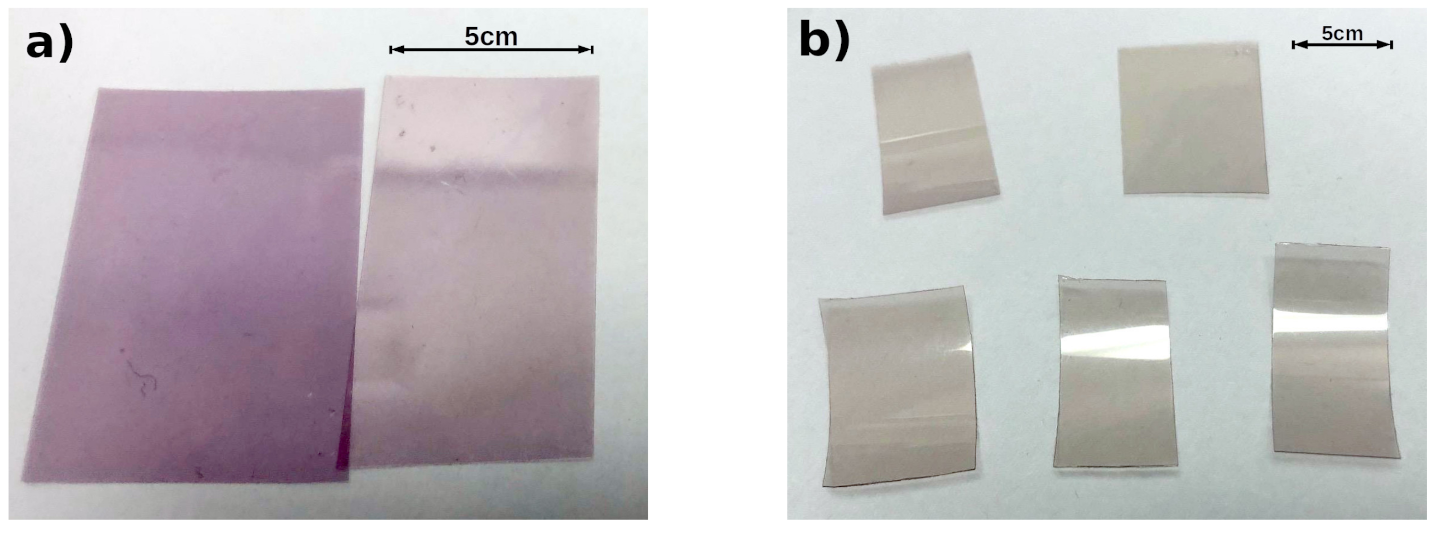

2. Materials and Methods

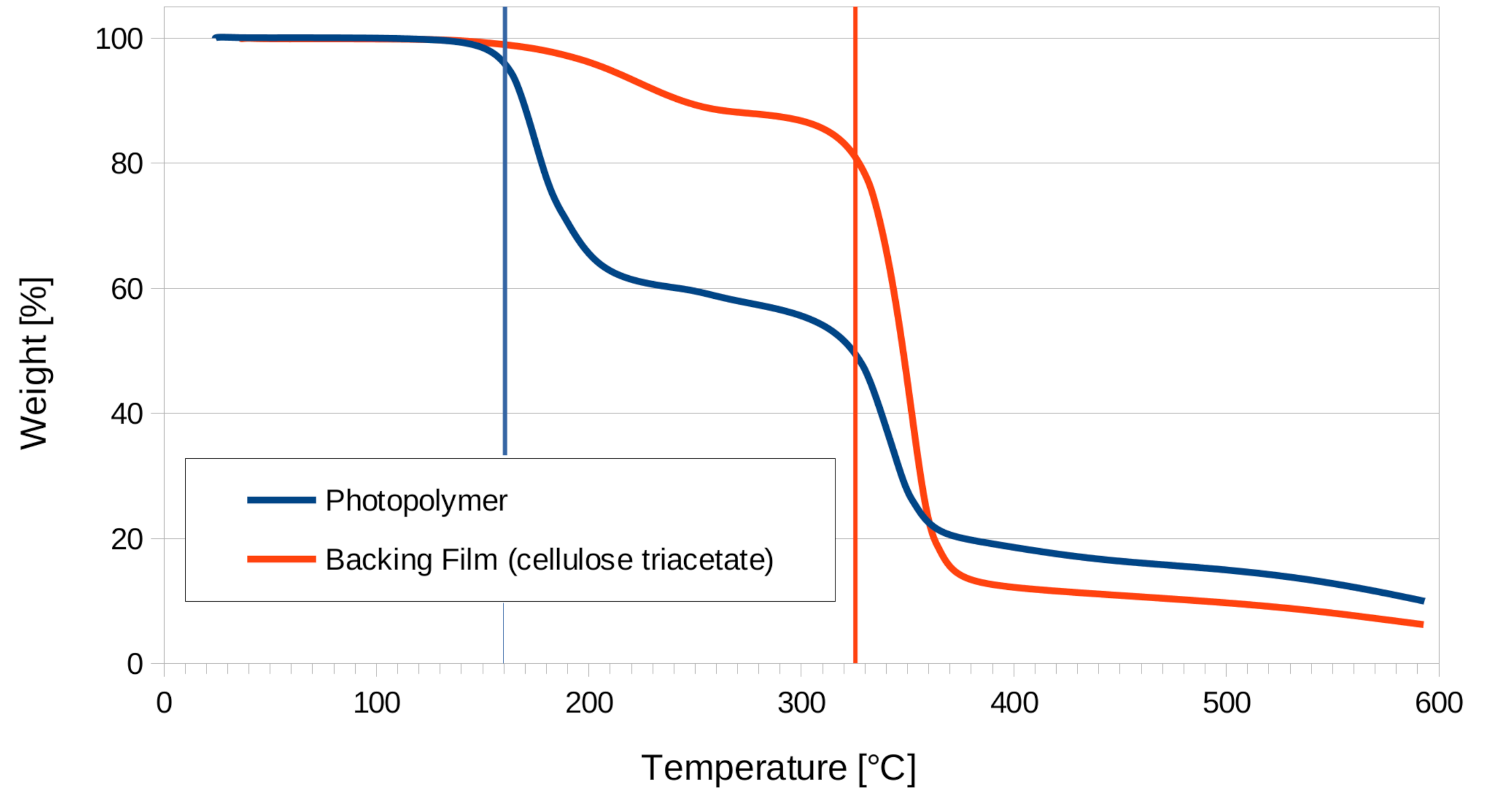

2.1. Thermal Degradation

2.2. Measurement of the Refractive Index Variation with Temperature and Exposure

2.3. Linear Coefficient of Thermal Expansion

3. Results and Discussion

3.1. Thermal Degradation

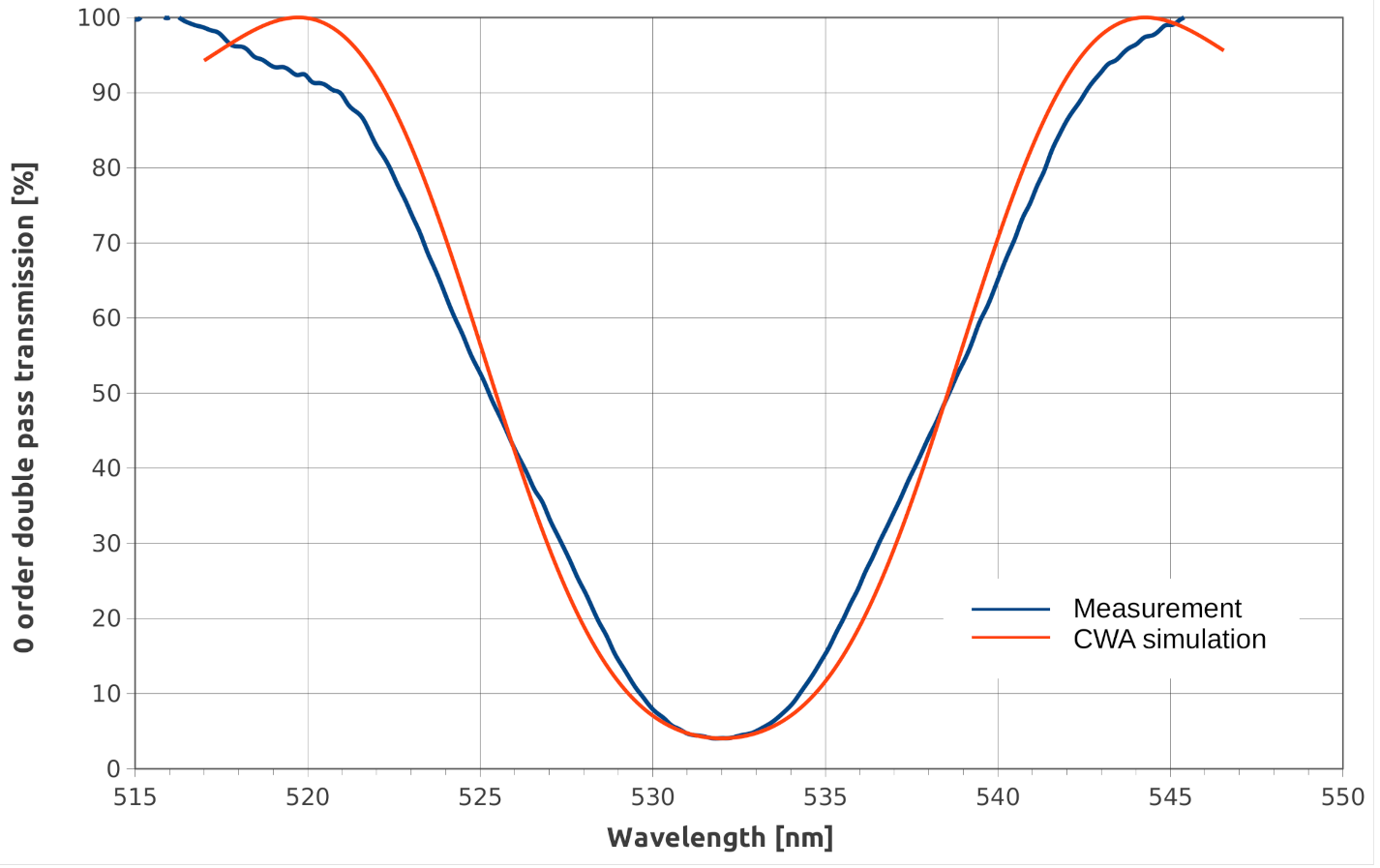

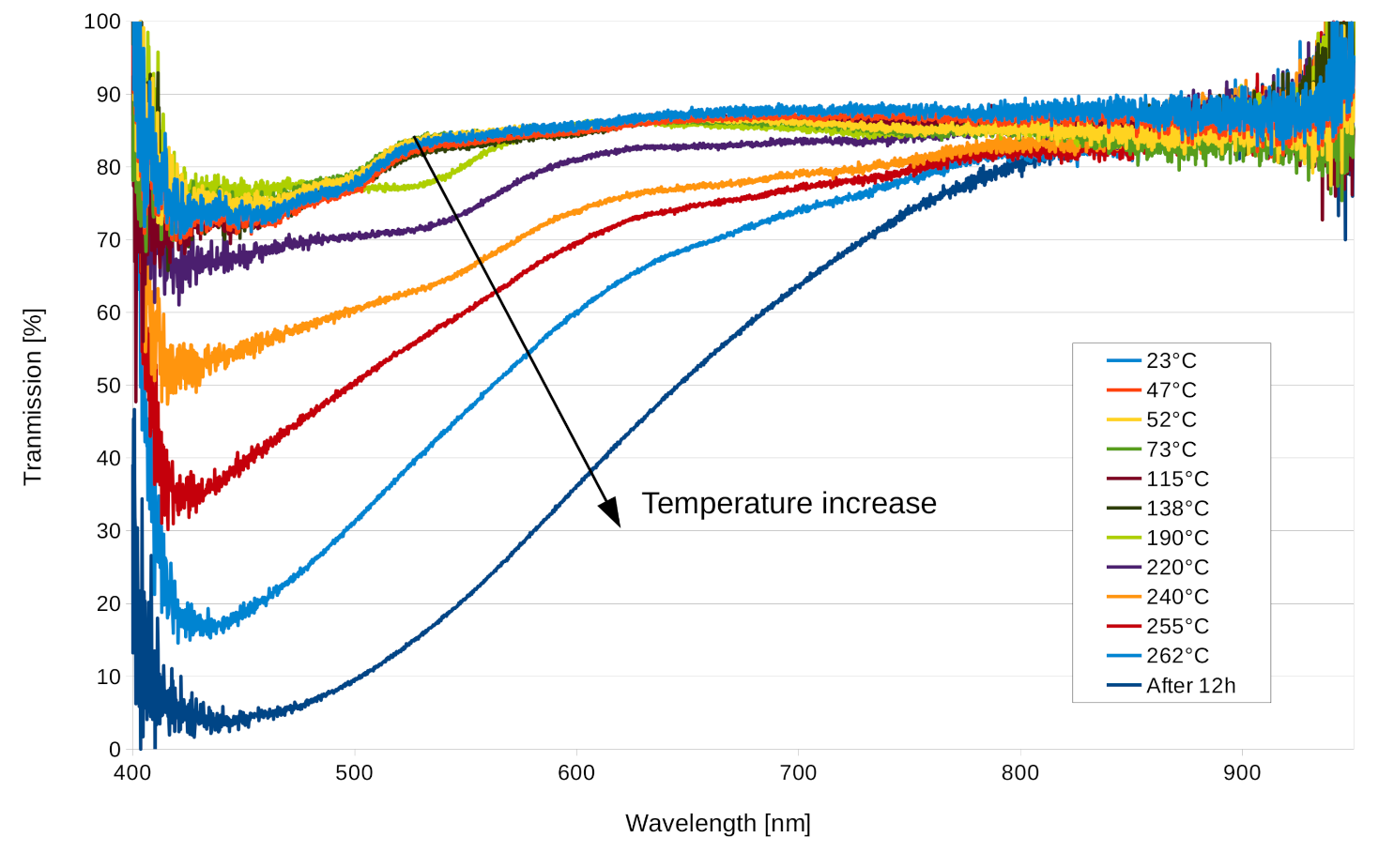

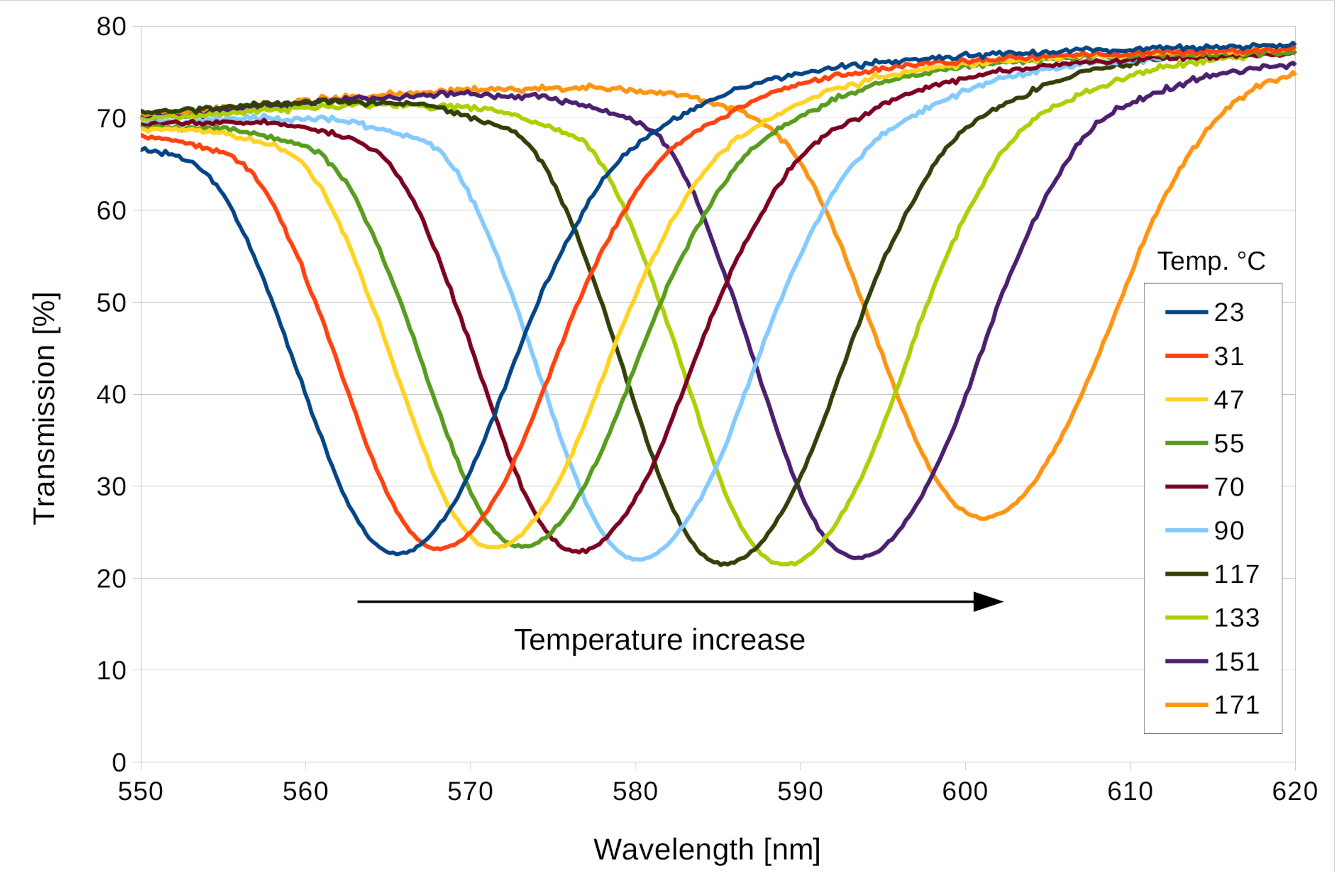

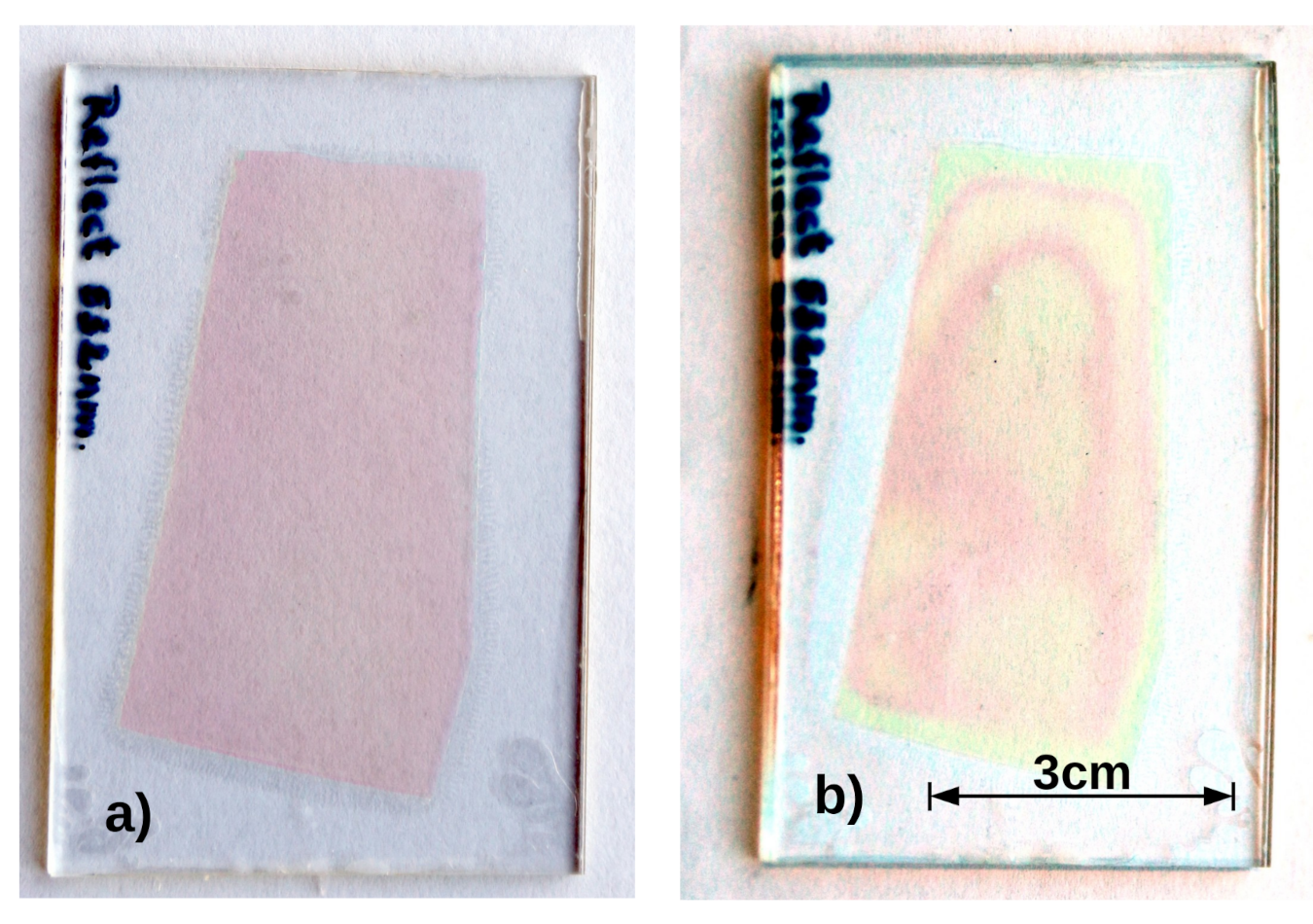

3.2. Spectral Measurement

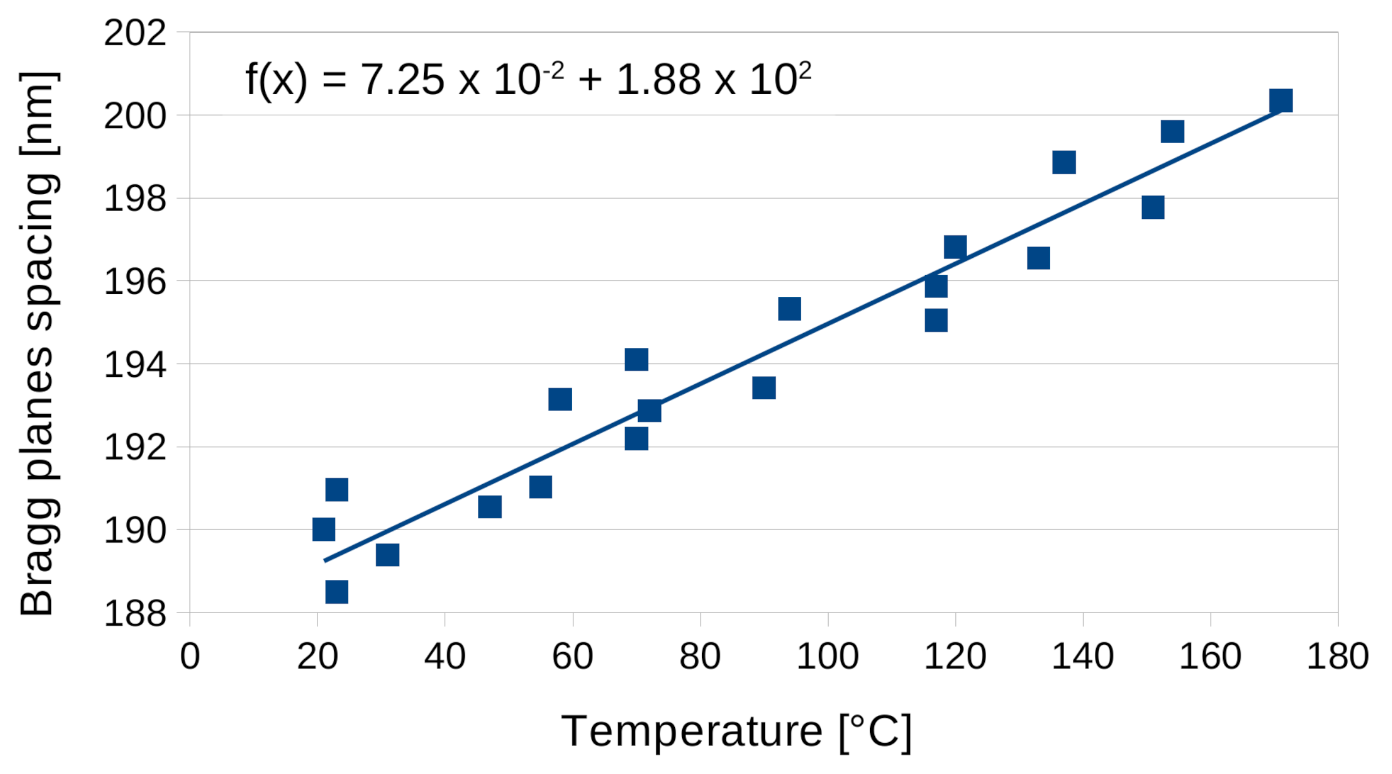

3.3. Refractive Index

3.4. Linear Coefficient of Thermal Expansion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Jackin, B.J.; Jorissen, L.; Oi, R.; Wu, J.Y.; Wakunami, K.; Okui, M.; Ichihashi, Y.; Bekaert, P.; Huang, Y.P.; Yamamoto, K. Digitally designed holographic optical element for light field displays. Opt. Lett. 2018, 43, 3738–3741. [Google Scholar] [CrossRef]

- Wu, H.Y.; Shin, C.W.; Kim, N. Full-Color Holographic Optical Elements for Augmented Reality Display. In Holographic Materials and Applications; IntechOpen: London, UK, 2019. [Google Scholar]

- Ferrara, M.A.; Striano, V.; Coppola, G. Volume holographic optical elements as solar concentrators: An Overview. Appl. Sci. 2019, 9, 193. [Google Scholar] [CrossRef]

- Blanche, P.A. Holographic Recording Media and Devices. In Optical Holography—Materials, Theory and Applications; Elsevier: St. Louis, MO, USA, 2020. [Google Scholar]

- Kogelnik, H. Coupled wave theory for thick hologram gratings. Bell Sysgtem Tech. J. 1969, 48, 2909–2947. [Google Scholar] [CrossRef]

- Mahamat, A.H.; Narducci, F.A.; Schwiegerling, J. Design and optimization of a volume-phase holographic grating for simultaneous use with red, green, and blue light using unpolarized light. Appl. Opt. 2016, 55, 1618–1624. [Google Scholar] [CrossRef]

- Blanche, P.A. Introduction to Holography. In Optical Holography–Materials, Theory and Applications; Elsevier: St. Louis, MO, USA, 2020. [Google Scholar]

- Behrmann, G.P.; Bowen, J.P. Influence of temperature on diffractive lens performance. Appl. Opt. 1993, 32, 2483–2489. [Google Scholar] [CrossRef]

- Volodin, B.; Eichenberger, J.; Sayano, K. High-Resolution Compact Imaging Holographic Bragg Grating Spectrometer. In Technical Digest. Summaries of Papers Presented at the Conference on Lasers and Electro-Optics, Conference ed.; 1998 Technical Digest Series, (IEEE Cat. No. 98CH36178); IEEE: Washington, DC, USA, 1998; Volume 6, pp. 401–402. [Google Scholar]

- Rakuljic, G.A.; Leyva, V. Volume holographic narrow-band optical filter. Opt. Lett. 1993, 18, 459–461. [Google Scholar] [CrossRef]

- Steckman, G.J.; Liu, W.; Platz, R.; Schroeder, D.; Moser, C.; Havermeyer, F. Volume holographic grating wavelength stabilized laser diodes. IEEE J. Sel. Top. Quantum Electron. 2007, 13, 672–678. [Google Scholar] [CrossRef]

- Bruder, F.K.; Fäcke, T.; Hagen, R.; Hansen, S.; Manecke, C.; Orselli, E.; Rewitz, C.; Rölle, T.; Walze, G. Thin Combiner Optics Utilizing Volume Holographic Optical Elements (vHOEs) Using Bayfol® HX200 Photopolymer Film. In Digital Optical Technologies 2017; International Society for Optics and Photonics: Bellingham, WA, USA, 2017; Volume 10335, p. 103350D. [Google Scholar]

- Kress, B.C. Optical waveguide combiners for AR headsets: Features and limitations. In Digital Optical Technologies 2019; International Society for Optics and Photonics: Bellingham, WA, USA, 2019; Volume 11062, p. 110620J. [Google Scholar]

- Draper, C.T.; Bigler, C.M.; Mann, M.S.; Sarma, K.; Blanche, P.A. Holographic waveguide head-up display with 2-D pupil expansion and longitudinal image magnification. Appl. Opt. 2019, 58, A251–A257. [Google Scholar] [CrossRef]

- Bruder, F.K.; Hansen, S.; Kleinschmidt, T.; Künzel, R.; Manecke, C.; Orselli, E.; Rewitz, C.; Rölle, T. Integration of Volume Holographic Optical Elements (vHOE) Made with Bayfol® HX into Plastic Optical Parts. In Practical Holography XXXIII: Displays, Materials, and Applications; International Society for Optics and Photonics: Bellingham, WA, USA, 2019; Volume 10944, p. 1094402. [Google Scholar]

- Bruder, F.K.; Frank, J.; Hansen, S.; Künzel, R.; Manecke, C.; Meisenheimer, R.; Mills, J.; Pitzer, L.; Rölle, T.; Wewer, B. Expanding Possibilities How to Apply Bayfol® HX Film into Recording Stacks and Optical Parts. In Practical Holography XXXIV: Displays, Materials, and Applications; International Society for Optics and Photonics: Bellingham, WA, USA, 2020; Volume 11306, p. 113060C. [Google Scholar]

- Naik, G.M.; Mathur, A.; Pappu, S.V. Dichromated gelatin holograms: An investigation of their environmental stability. Appl. Opt. 1990, 29, 5292–5297. [Google Scholar] [CrossRef]

- Mikulchyk, T.; Walshe, J.; Cody, D.; Martin, S.; Naydenova, I. Humidity and Temperature Response of Photopolymer-Based Holographic Gratings. In Holography: Advances and Modern Trends IV; International Society for Optics and Photonics: Bellingham, WA, USA, 2015; Volume 9508, p. 950809. [Google Scholar]

- Naydenova, I.; Jallapuram, R.; Toal, V.; Martin, S. Hologram-Based Humidity Indicator for Domestic and Packaging Applications. In Nanosensors, Microsensors, and Biosensors and Systems 2007; International Society for Optics and Photonics: Bellingham, WA, USA, 2007; Volume 6528, p. 652811. [Google Scholar]

- Naydenova, I.; Jallapuram, R.; Toal, V.; Martin, S. Characterisation of the humidity and temperature responses of a reflection hologram recorded in acrylamide-based photopolymer. Sens. Actuators B Chem. 2009, 139, 35–38. [Google Scholar] [CrossRef]

- Liu, Y.; Li, W.; Ding, Q.; Yan, Z. Wavelength Properties of DCG Holograms under the Conditions of Different Temperature and Humidity. In International Symposium on Optoelectronic Technology and Application 2014: Laser Materials Processing; and Micro/Nano Technologies; International Society for Optics and Photonics: Bellingham, WA, USA, 2014; Volume 9295, p. 929514. [Google Scholar]

- Lin, S.H.; Hsu, K.Y. Temperature Effect in PQ:PMMA Photopolymer. In Photorefractive Fiber and Crystal Devices: Materials, Optical Properties, and Applications VI; International Society for Optics and Photonics: Bellingham, WA, USA, 2000; Volume 4110, pp. 77–83. [Google Scholar]

- Denning, R.G.; Blanford, C.F.; Urban, H.; Bharaj, H.; Sharp, D.N.; Turberfield, A.J. The Control of Shrinkage and Thermal Instability in SU-8 Photoresists for Holographic Lithography. Adv. Funct. Mater. 2011, 21, 1593–1601. [Google Scholar] [CrossRef]

- Bigler, C.M.; Blanche, P.A.; Sarma, K. Holographic waveguide heads-up display for longitudinal image magnification and pupil expansion. Appl. Opt. 2018, 57, 2007–2013. [Google Scholar] [CrossRef]

- Vorndran, S.D.; Chrysler, B.; Wheelwright, B.; Angel, R.; Holman, Z.; Kostuk, R. Off-axis holographic lens spectrum-splitting photovoltaic system for direct and diffuse solar energy conversion. Appl. Opt. 2016, 55, 7522–7529. [Google Scholar] [CrossRef]

- Bruder, F.K.; Fäcke, T.; Rölle, T. The chemistry and physics of Bayfol® HX film holographic photopolymer. Polymers 2017, 9, 472. [Google Scholar] [CrossRef]

- Bruder, F.K.; Fäcke, T.; Grote, F.; Hagen, R.; Hönel, D.; Koch, E.; Rewitz, C.; Walze, G.; Wewer, B. Mass Production of Volume Holographic Optical Elements (vHOEs) using Bayfol (R) HX Photopolymer Film in a Roll-to-Roll Copy Process. In Practical Holography XXXI: Materials and Applications; International Society for Optics and Photonics: Bellingham, WA, USA, 2017; Volume 10127, p. 101270A. [Google Scholar]

- Bruder, F.K.; Hansen, S.; Manecke, C.; Orselli, E.; Rewitz, C.; Rölle, T.; Wewer, B. Wavelength Multiplexing Recording of vHOEs in Bayfol HX Photopolymer Film. In Digital Optics for Immersive Displays; International Society for Optics and Photonics: Bellingham, WA, USA, 2018; Volume 10676, p. 106760H. [Google Scholar]

- Covestro. Bayfol® HX200 Description and Application Information; Technical Report; Bayer 04 Leverkusen: Leverkusen, Germany, 2018. [Google Scholar]

- Bruder, F.K.; Hansen, S.; Kleinschmidt, T.; Künzel, R.; Manecke, C.; Orselli, E.; Rewitz, C.; Rölle, T. How to Integrate Volume Holographic Optical Elements (vHOE) Made with Bayfol HX Film into Plastic Optical Parts. In Holography: Advances and Modern Trends VI; International Society for Optics and Photonics: Bellingham, WA, USA, 2019; Volume 11030, p. 110300C. [Google Scholar]

- Bjelkhagen, H.; Brotherton-Ratcliffe, D. Ultra-Realistic Imaging: Advanced Techniques in Analogue and Digital Colour Holography; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- McGrew, S.P. Color Control in Dichromated Gelatin Reflection Holograms. In Recent Advances in Holography; International Society for Optics and Photonics: Bellingham, WA, USA, 1980; Volume 215, pp. 24–31. [Google Scholar]

- Li, X.G. High-resolution thermogravimetry of cellulose esters. J. Appl. Polym. Sci. 1999, 71, 573–578. [Google Scholar] [CrossRef]

- Visakh, P.; Nazarenko, O.B. Thermal Degradation of Polymer Blends, Composites and Nanocomposites. In Thermal Degradation of Polymer Blends, Composites and Nanocomposites; Springer: Cham, Switzerland, 2015; pp. 1–16. [Google Scholar]

- Bayfol HX200 Technical Data Sheet; Covestro: Leverkusen, Germany, 2020.

- Jayanna, H.; Subramanyam, S. Thermal expansion of irradiated polypropylene from 10–340 K. J. Mater. Sci. 1993, 28, 2423–2427. [Google Scholar] [CrossRef]

- Pye, J.E.; Roth, C.B. Above, below, and in-between the two glass transitions of ultrathin free-standing polystyrene films: Thermal expansion coefficient and physical aging. J. Polym. Sci. Part Polym. Phys. 2015, 53, 64–75. [Google Scholar] [CrossRef]

- Kirby, R.K. Thermal expansion of polytetrafluoroethylene (Teflon) from −190 to +300 °C. J. Res. Natl. Bur. Stand. 1956, 57, 91–94. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanche, P.-A.; Mahamat, A.H.; Buoye, E. Thermal Properties of Bayfol® HX200 Photopolymer. Materials 2020, 13, 5498. https://doi.org/10.3390/ma13235498

Blanche P-A, Mahamat AH, Buoye E. Thermal Properties of Bayfol® HX200 Photopolymer. Materials. 2020; 13(23):5498. https://doi.org/10.3390/ma13235498

Chicago/Turabian StyleBlanche, Pierre-Alexandre, Adoum H. Mahamat, and Emmanuel Buoye. 2020. "Thermal Properties of Bayfol® HX200 Photopolymer" Materials 13, no. 23: 5498. https://doi.org/10.3390/ma13235498

APA StyleBlanche, P.-A., Mahamat, A. H., & Buoye, E. (2020). Thermal Properties of Bayfol® HX200 Photopolymer. Materials, 13(23), 5498. https://doi.org/10.3390/ma13235498