Rigid Polyurethane Foams Reinforced with POSS-Impregnated Sugar Beet Pulp Filler

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

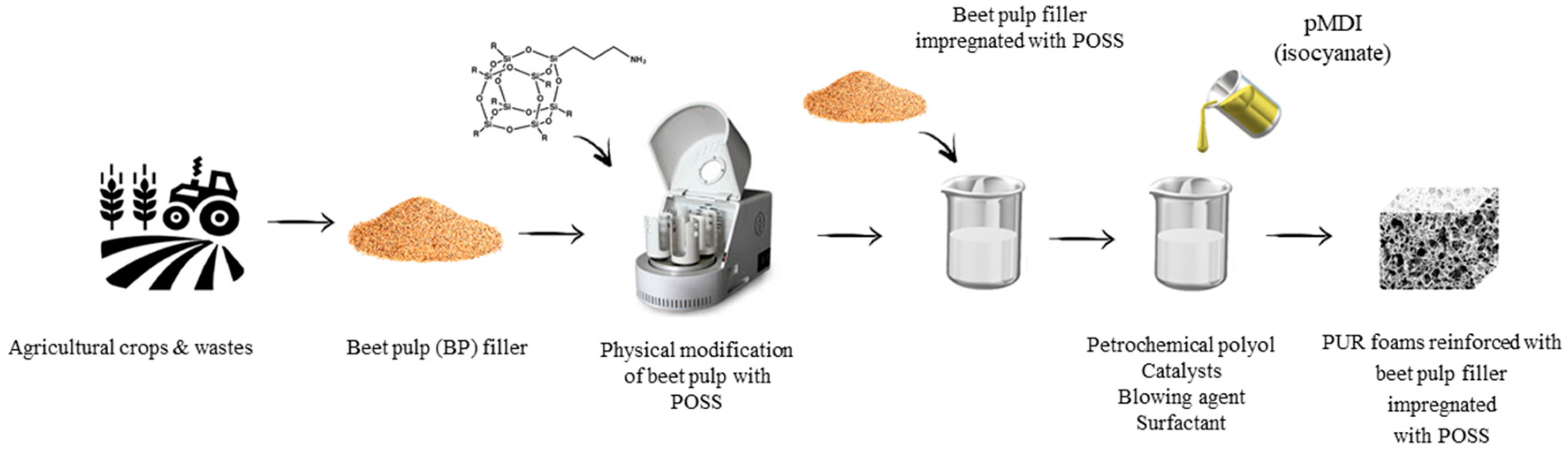

2.2. Filler Preparation and Synthesis of PUR Composite Foams

2.3. Sample Characterization

3. Results and Discussion

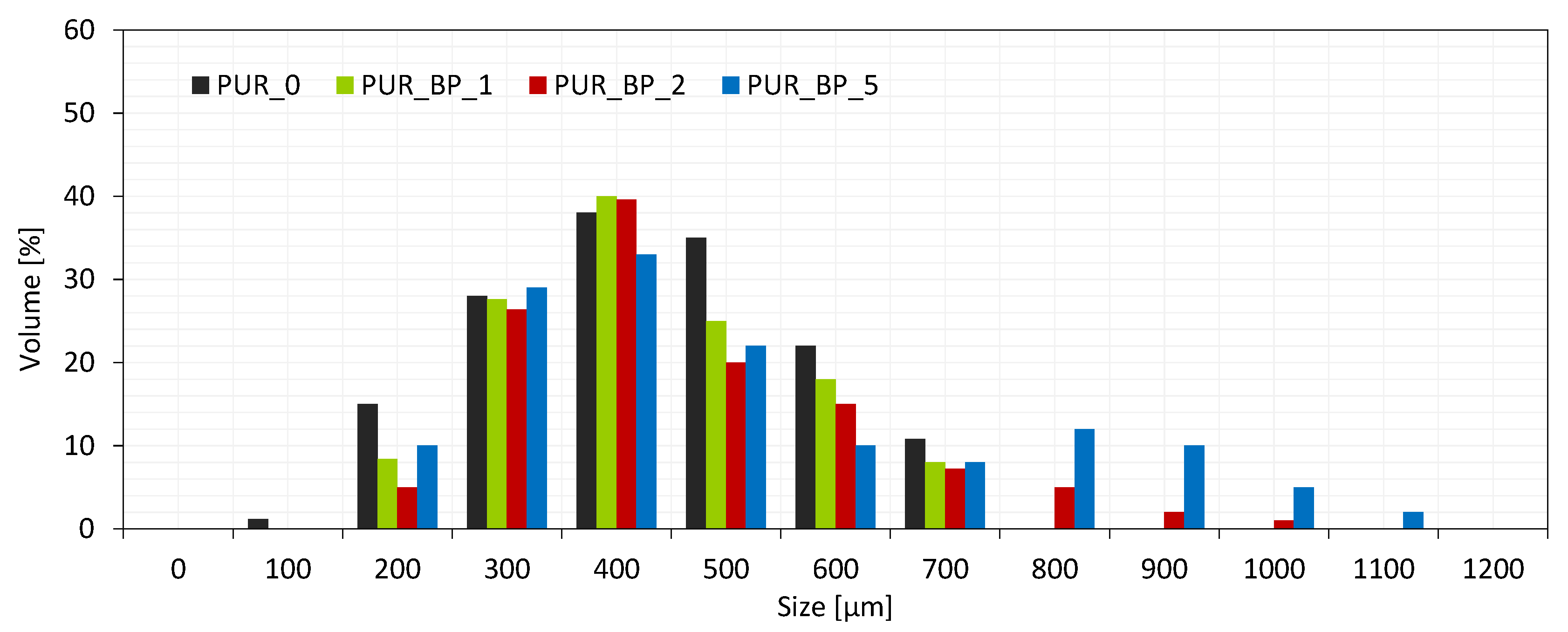

3.1. Filler Characterization

3.2. Foaming Behavior of PUR Systems

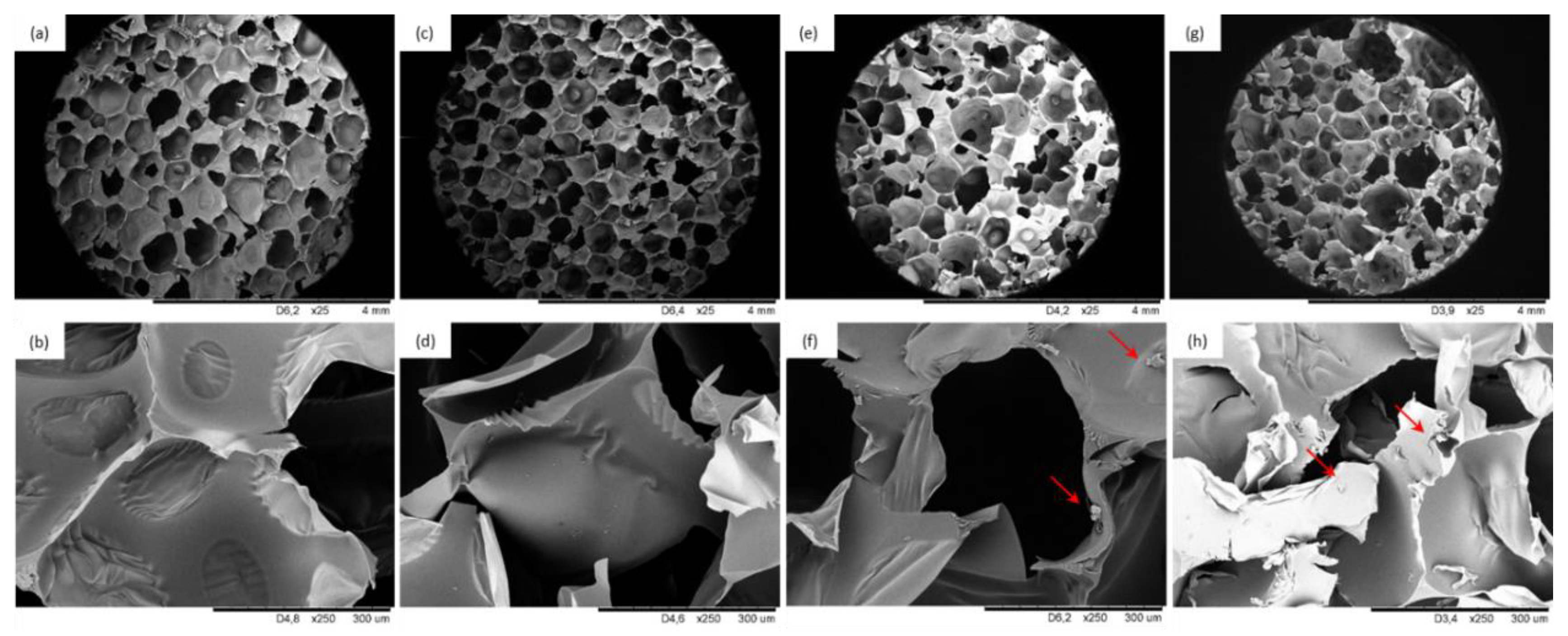

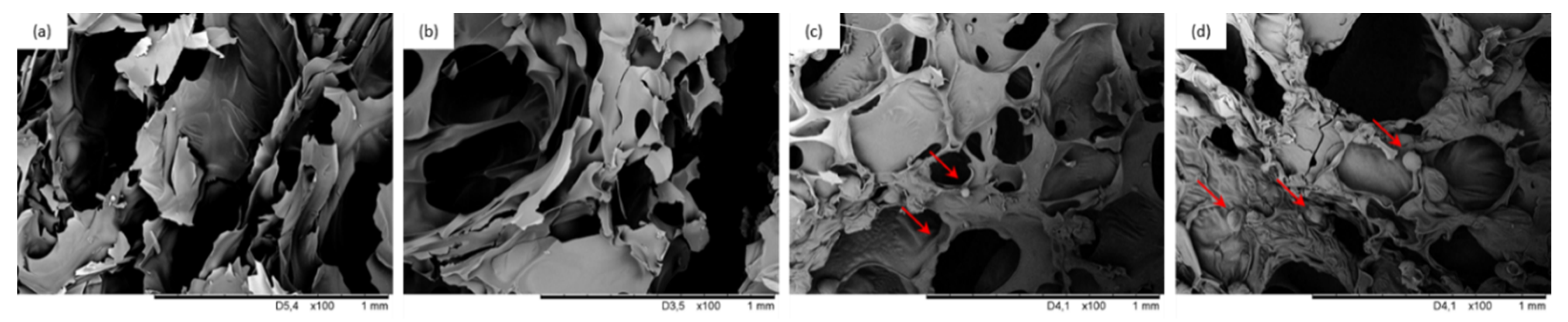

3.3. Cellular Structure of PUR Composite Foams

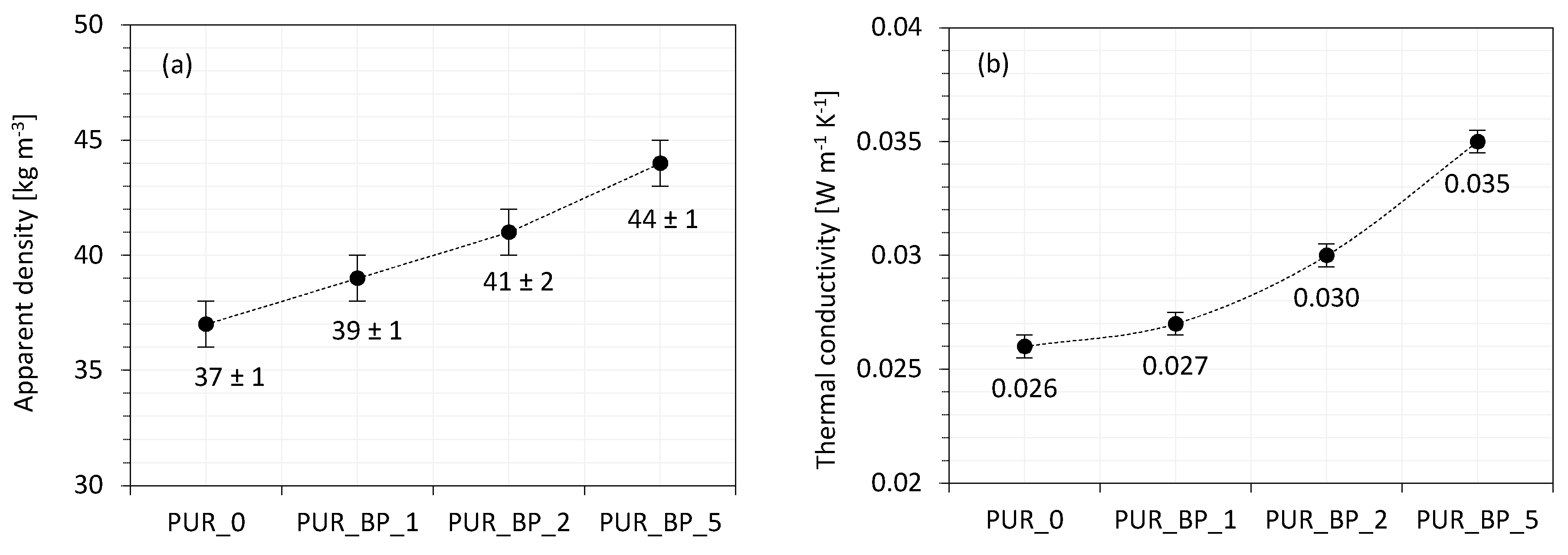

3.4. Apparent Density of PUR Composite Foams

3.5. Thermal Conductivity of PUR Composite Foams

3.6. Contact Angle and Water Uptake of PUR Composite Foams

3.7. Mechanical Performances of PUR Composite Foams

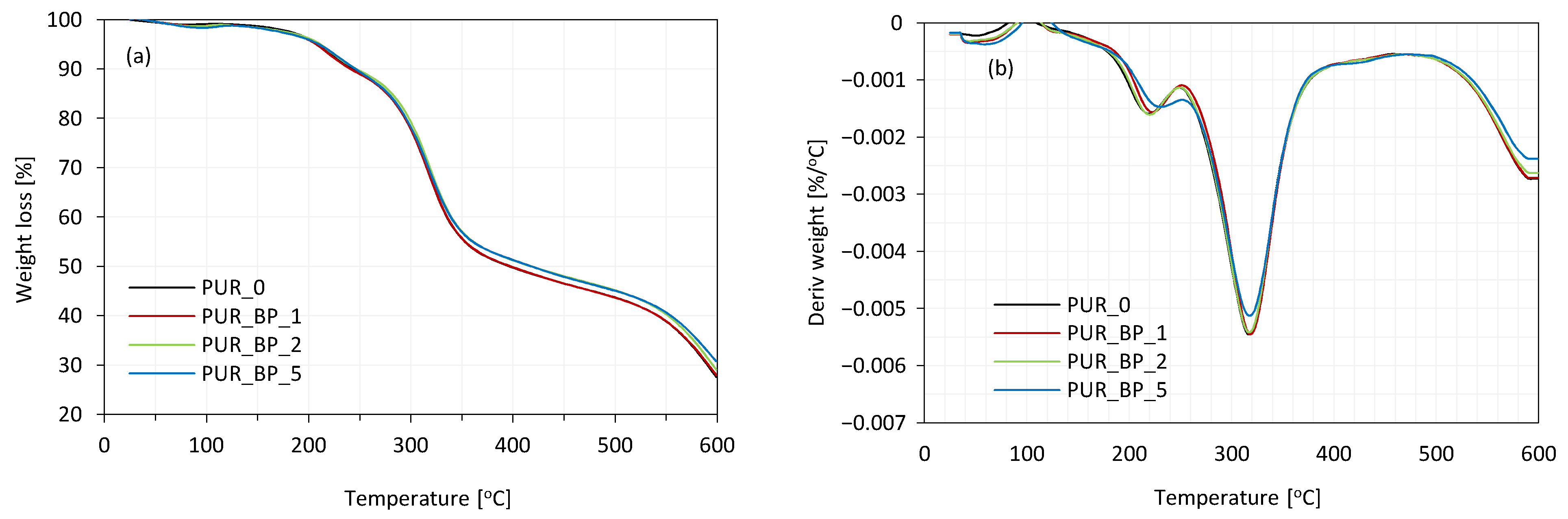

3.8. Thermal Stability of PUR Composite Foams

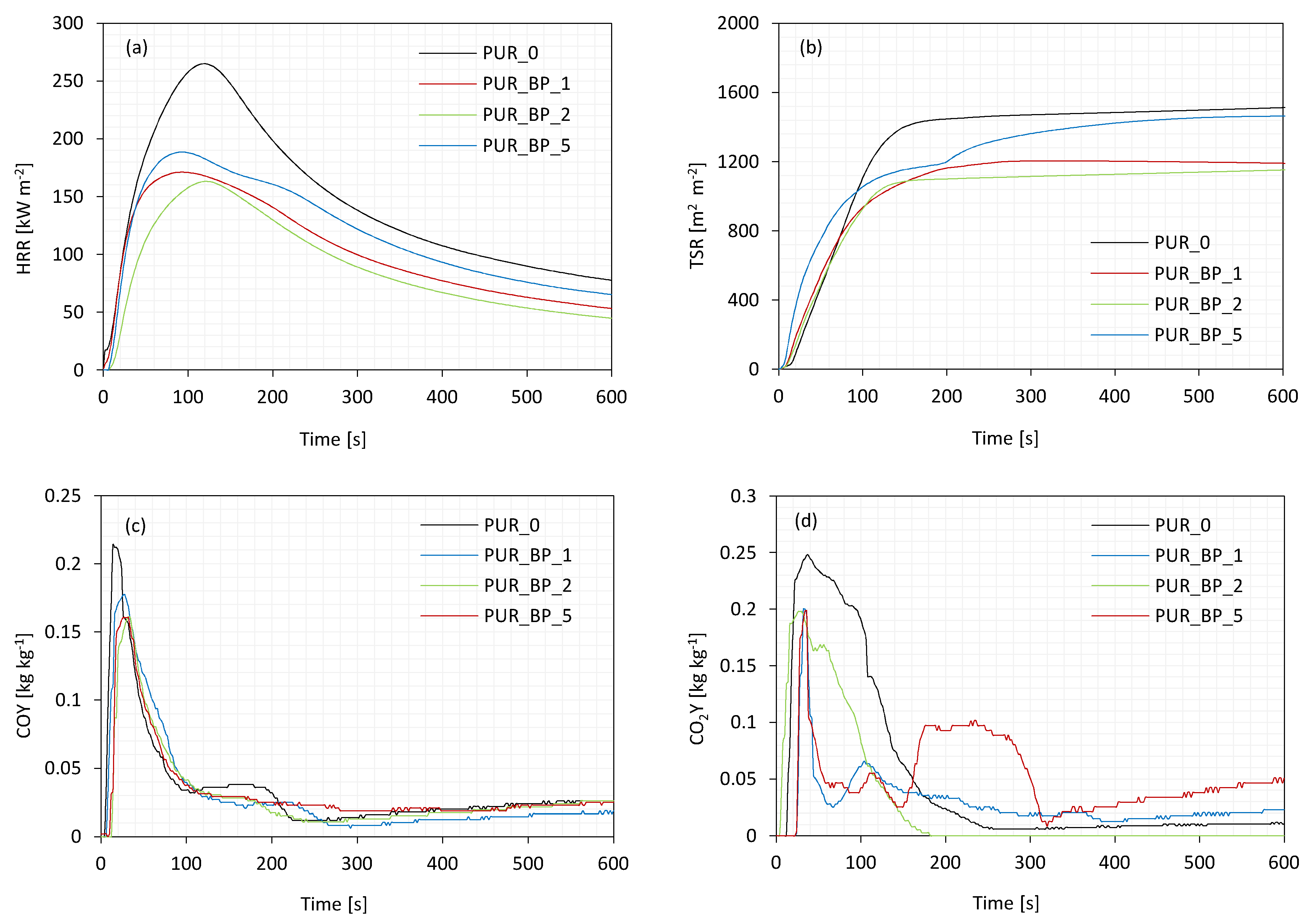

3.9. Cone Calorimeter Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Borowicz, M.; Paciorek-Sadowska, J.; Isbrandt, M. Synthesis and application of new bio-polyols based on mustard oil for the production of selected polyurethane materials. Ind. Crop. Prod. 2020, 155, 112831. [Google Scholar] [CrossRef]

- Borowicz, M.; Joanna, P.-S.; Lubczak, J.; Czupryński, B. Biodegradable, Flame-Retardant, and Bio-Based Rigid Polyurethane/Polyisocyanurate Foams for Thermal Insulation Application. Polymers 2019, 11, 1816. [Google Scholar] [CrossRef] [Green Version]

- Kairytė, A.; Kirpluks, M.; Ivdre, A.; Cabulis, U.; Vėjelis, S.; Balčiūnas, G. Paper waste sludge enhanced eco-efficient polyurethane foam composites: Physical-mechanical properties and microstructure. Polym. Compos. 2018, 39, 1852–1860. [Google Scholar] [CrossRef]

- Kuranska, M.; Prociak, A. Porous polyurethane composites with natural fibres. Compos. Sci. Technol. 2012, 72, 299–304. [Google Scholar] [CrossRef]

- Członka, S.; Bertino, M.F.; Strzelec, K. Rigid polyurethane foams reinforced with industrial potato protein. Polym. Test. 2018, 68, 135–145. [Google Scholar] [CrossRef]

- Septevani, A.A.; Evans, D.A.; Annamalai, P.K.; Martin, D.J. The use of cellulose nanocrystals to enhance the thermal insulation properties and sustainability of rigid polyurethane foam. Ind. Crop. Prod. 2017, 107, 114–121. [Google Scholar] [CrossRef]

- Kumar, A.P.; Depan, D.; Tomer, N.S.; Singh, R.P. Nanoscale particles for polymer degradation and stabilization—Trends and future perspectives. Prog. Polym. Sci. 2009, 34, 479–515. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Sałasińska, K.; Barczewski, M.; Szulc, J. The influence of oil content within lignocellulosic filler on thermal degradation kinetics and flammability of polylactide composites modified with linseed cake. Polym. Compos. 2020, 41, 4503–4513. [Google Scholar] [CrossRef]

- Matykiewicz, D.; Barczewski, M. On the impact of flax fibers as an internal layer on the properties of basalt-epoxy composites modified with silanized basalt powder. Compos. Commun. 2020, 20, 100360. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A. Thermal Behavior of Green Cellulose-Filled Thermoplastic Elastomer Polymer Blends. Molecules 2020, 25, 1279. [Google Scholar] [CrossRef] [Green Version]

- Cichosz, S.; Masek, A. Superiority of Cellulose Non-Solvent Chemical Modification over Solvent-Involving Treatment: Application in Polymer Composite (part II). Materials 2020, 13, 2901. [Google Scholar] [CrossRef]

- Joanna, P.-S.; Czupryński, B.; Borowicz, M.; Liszkowska, J. Rigid polyurethane–polyisocyanurate foams modified with grain fraction of fly ashes. J. Cell. Plast. 2020, 56, 53–72. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Silva, M.C.; Takahashi, J.A.; Chaussy, D.; Belgacem, M.N.; Silva, G.G. Composites of rigid polyurethane foam and cellulose fiber residue. J. Appl. Polym. Sci. 2010, 117, 3665–3672. [Google Scholar] [CrossRef]

- Hejna, A.; Kopczyńska, M.; Kozłowska, U.; Klein, M.; Kosmela, P.; Piszczyk, Ł. Foamed Polyurethane Composites with Different Types of Ash—Morphological, Mechanical and Thermal Behavior Assessments. Cell. Polym. 2016, 35, 287–308. [Google Scholar] [CrossRef]

- Olszewski, A.; Kosmela, P.; Mielewczyk-Gryn, A.; Piszczyk, Ł. Bio-Based Polyurethane Composites and Hybrid Composites Containing a New Type of Bio-Polyol and Addition of Natural and Synthetic Fibers. Materials 2020, 13, 2028. [Google Scholar] [CrossRef]

- Kurańska, M.; Barczewski, M.; Uram, K.; Lewandowski, K.; Prociak, A.; Michałowski, S. Basalt waste management in the production of highly effective porous polyurethane composites for thermal insulating applications. Polym. Test. 2019, 76, 90–100. [Google Scholar] [CrossRef]

- Li, J.; Jiang, J.; Xu, J.; Xia, H.; Liu, P. Branched polyols based on oleic acid for production of polyurethane foams reinforced with bamboo fiber. Iran. Polym. J. 2016, 25, 811–822. [Google Scholar] [CrossRef]

- Joanna, L.; Borowicz, M.; Joanna, P.-S.; Isbrandt, M.; Czupryński, B.; Moraczewski, K. Assessment of Photodegradation and Biodegradation of RPU/PIR Foams Modified by Natural Compounds of Plant Origin. Polymers 2019, 12, 33. [Google Scholar] [CrossRef] [Green Version]

- Jonjaroen, V.; Ummartyotin, S.; Chittapun, S. Algal cellulose as a reinforcement in rigid polyurethane foam. Algal Res. 2020, 51, 102057. [Google Scholar] [CrossRef]

- Altundoğan, H.S.; Bahar, N.; Mujde, B.; Tümen, F. The use of sulphuric acid-carbonization products of sugar beet pulp in Cr(VI) removal. J. Hazard. Mater. 2007, 144, 255–264. [Google Scholar] [CrossRef]

- Vučurović, V.M.; Razmovski, R.N. Sugar beet pulp as support for Saccharomyces cerivisiae immobilization in bioethanol production. Ind. Crop. Prod. 2012, 39, 128–134. [Google Scholar] [CrossRef]

- Rouilly, A.; Geneau-Sbartaï, C.; Rigal, L. Thermo-mechanical processing of sugar beet pulp. III. Study of extruded films improvement with various plasticizers and cross-linkers. Bioresour. Technol. 2009, 100, 3076–3081. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Z.-Q.; Wang, L.-J.; Li, D.; Huang, Z.-G.; Adhikari, B.; Chen, X.D. Mechanical and Thermal Properties of Polyurethane Foams from Liquefied Sugar Beet Pulp. Int. J. Food Eng. 2016, 12, 911–919. [Google Scholar] [CrossRef]

- Jasiūnas, L.; McKenna, S.T.; Bridžiuvienė, D.; Miknius, L. Mechanical, Thermal Properties and Stability of Rigid Polyurethane Foams Produced with Crude-Glycerol Derived Biomass Biopolyols. J. Polym. Environ. 2020, 28, 1378–1389. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Pospiech, P.; Strzelec, K. Effects of Chemically Treated Eucalyptus Fibers on Mechanical, Thermal and Insulating Properties of Polyurethane Composite Foams. Materials 2020, 13, 1781. [Google Scholar] [CrossRef] [Green Version]

- Cichosz, S.; Masek, A. Drying of the Natural Fibers as A Solvent-Free Way to Improve the Cellulose-Filled Polymer Composite Performance. Polymers 2020, 12, 484. [Google Scholar] [CrossRef] [Green Version]

- Zakaria, S.; Hamzah, H.; Murshidi, J.A.; Deraman, M. Chemical modification on lignocellulosic polymeric oil palm empty fruit bunch for advanced material. Adv. Polym. Technol. 2001, 20, 289–295. [Google Scholar] [CrossRef]

- Wolski, K.; Cichosz, S.; Masek, A. Surface hydrophobisation of lignocellulosic waste for the preparation of biothermoelastoplastic composites. Eur. Polym. J. 2019, 118, 481–491. [Google Scholar] [CrossRef]

- Cichosz, S.; Masek, A. Cellulose Fibers Hydrophobization via a Hybrid Chemical Modification. Polymers 2019, 11, 1174. [Google Scholar] [CrossRef] [Green Version]

- Barczewski, M.; Mysiukiewicz, O.; Lewandowski, K.; Nowak, D.; Matykiewicz, D.; Andrzejewski, J.; Skórczewska, K.; Piasecki, A. Effect of Basalt Powder Surface Treatments on Mechanical and Processing Properties of Polylactide-Based Composites. Materials 2020, 13, 5436. [Google Scholar] [CrossRef]

- Barczewski, M.; Matykiewicz, D.; Szostak, M. The effect of two-step surface treatment by hydrogen peroxide and silanization of flax/cotton fabrics on epoxy-based laminates thermomechanical properties and structure. J. Mater. Res. Technol. 2020, 9, 13813–13824. [Google Scholar] [CrossRef]

- Borysiak, S. Fundamental studies on lignocellulose/polypropylene composites: Effects of wood treatment on the transcrystalline morphology and mechanical properties. J. Appl. Polym. Sci. 2013, 127, 1309–1322. [Google Scholar] [CrossRef]

- Neto, J.S.S.; Lima, R.A.A.; Cavalcanti, D.K.K.; Souza, J.P.B.; Aguiar, R.A.A.; Banea, M. Effect of chemical treatment on the thermal properties of hybrid natural fiber-reinforced composites. J. Appl. Polym. Sci. 2019, 136, 1–13. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. Part B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, J.; Wu, N.; Wang, L.; Ma, Y.; Tong, J. Influence of silane treatment on the mechanical, tribological and morphological properties of corn stalk fiber reinforced polymer composites. Tribol. Int. 2019, 131, 398–405. [Google Scholar] [CrossRef]

- Liu, H.; Zheng, S. Polyurethane Networks Nanoreinforced by Polyhedral Oligomeric Silsesquioxane. Macromol. Rapid Commun. 2005, 26, 196–200. [Google Scholar] [CrossRef]

- Hernández, R.; Weksler, J.; Padsalgikar, A.; Runt, J. Microstructural Organization of Three-Phase Polydimethylsiloxane-Based Segmented Polyurethanes. Macromolecules 2007, 40, 5441–5449. [Google Scholar] [CrossRef]

- Liu, L.; Tian, M.; Zhang, W.; Zhang, L.; Mark, J.E. Crystallization and morphology study of polyhedral oligomeric silsesquioxane (POSS)/polysiloxane elastomer composites prepared by melt blending. Polymer 2007, 48, 3201–3212. [Google Scholar] [CrossRef]

- Lee, Y.-J.; Huang, J.-M.; Kuo, S.-W.; Lu, J.-S.; Chang, F.-C. Polyimide and polyhedral oligomeric silsesquioxane nanocomposites for low-dielectric applications. Polymer 2005, 46, 173–181. [Google Scholar] [CrossRef]

- Pellice, S.A.; Fasce, D.P.; Williams, R.J.J. Properties of epoxy networks derived from the reaction of diglycidyl ether of bisphenol A with polyhedral oligomeric silsesquioxanes bearing OH-functionalized organic substituents. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 1451–1461. [Google Scholar] [CrossRef]

- Matĕjka, L.; Strachota, A.; Pleštil, J.; Whelan, P.; Steinhart, M.; Šlouf, M. Epoxy Networks Reinforced with Polyhedral Oligomeric Silsesquioxanes (POSS). Structure and Morphology. Macromolecules 2004, 37, 9449–9456. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; KAIRYTĖ, A. Application of Walnut Shells-Derived Biopolyol in the Synthesis of Rigid Polyurethane Foams. Materials 2020, 13, 2687. [Google Scholar] [CrossRef]

- ISO. ISO 2555—Plastics-Resins in the Liquid State or as Emulsions or Dispersions—Determination of Apparent Viscosity by the Brookfield Test Method; International Organization of Standards: Geneva, Switzerland, 2018. [Google Scholar]

- ISO. ISO 845—Cellular Plastics and Rubbers—Determination of Apparent Density; International Organization of Standards: Geneva, Switzerland, 2006. [Google Scholar]

- ISO. ISO 4590:2016—Rigid Cellular Plastics—Determination of the Volume Percentage of Open Cells and of Closed Cells. Available online: https://www.iso.org/standard/60771.html (accessed on 11 November 2020).

- ISO. ISO 844—Preview Rigid Cellular Plastics—Determination of Compression Properties; International Organization of Standards: Geneva, Switzerland, 2014. [Google Scholar]

- ISO. ISO 178-Plastics-Determination of Flexural Properties; International Organization of Standards: Geneva, Switzerland, 2019. [Google Scholar]

- ISO. ISO 180—Plastics-Determination of Izod Impact Strength; International Organization of Standards: Geneva, Switzerland, 2019. [Google Scholar]

- ISO. ISO 5660-1:2015—Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate—Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). Available online: https://www.iso.org/standard/57957.html (accessed on 11 November 2020).

- Gómez-Fernández, S.; Ugarte, L.; Calvo-Correas, T.; Peña-Rodríguez, C.; Corcuera, M.A.; Eceiza, A. Properties of flexible polyurethane foams containing isocyanate functionalized kraft lignin. Ind. Crop. Prod. 2017, 100, 51–64. [Google Scholar] [CrossRef]

- Lee, L.J.; Zeng, C.; Cao, X.; Han, X.; Shen, J.; Xu, G. Polymer nanocomposite foams. Compos. Sci. Technol. 2005, 65, 2344–2363. [Google Scholar] [CrossRef]

- Sung, G.; Kim, J.H. Influence of filler surface characteristics on morphological, physical, acoustic properties of polyurethane composite foams filled with inorganic fillers. Compos. Sci. Technol. 2017, 146, 147–154. [Google Scholar] [CrossRef]

- Liszkowska, J. The effect of ground coffee on the mechanical and application properties of rigid polyurethane-polyisocyanurate foams (Rapid communication). Polimery 2018, 63, 305–310. [Google Scholar] [CrossRef]

- Kairytė, A.; Kremensas, A.; Balčiūnas, G.; Członka, S.; Strąkowska, A. Closed Cell Rigid Polyurethane Foams Based on Low Functionality Polyols: Research of Dimensional Stability and Standardised Performance Properties. Materials 2020, 13, 1438. [Google Scholar] [CrossRef] [Green Version]

- Zieleniewska, M.; Leszczyński, M.K.; Kurańska, M.; Prociak, A.; Szczepkowski, L.; Krzyżowska, M.; Ryszkowska, J. Preparation and characterisation of rigid polyurethane foams using a rapeseed oil-based polyol. Ind. Crops Prod. 2015, 74, 887–897. [Google Scholar] [CrossRef]

- Mizera, K.; Ryszkowska, J.; Kurańska, M.; Prociak, A. The effect of rapeseed oil-based polyols on the thermal and mechanical properties of ureaurethane elastomers. Polym. Bull. 2020, 77, 823–846. [Google Scholar] [CrossRef] [Green Version]

- Federation of European Rigid Polyurethane Foam Associations. Thermal Insulation Materials Made of Rigid Polyurethane Foam (PUR/PIR) Properties-Manufacture; Report N°1; Federation of European Rigid Polyurethane Foam Associations: Brussels, Belgium, 2006. [Google Scholar]

- Dolomanova, V.; Rauhe, J.C.M.; Jensen, L.R.; Pyrz, R.; Timmons, A.B. Mechanical properties and morphology of nano-reinforced rigid PU foam. J. Cell. Plast. 2011, 47, 81–93. [Google Scholar] [CrossRef]

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Gloc, M.; Kulesza, M.; Kowalski, M.; Krauze, S.; Lewandowska, M. Flammability, mechanical properties and structure of rigid polyurethane foams with different types of carbon reinforcing materials. Compos. Struct. 2016, 140, 67–76. [Google Scholar] [CrossRef]

- Gu, R.; Konar, S.K.; Sain, M. Preparation and Characterization of Sustainable Polyurethane Foams from Soybean Oils. J. Am. Oil Chem. Soc. 2012, 89, 2103–2111. [Google Scholar] [CrossRef]

- Tian, H.; Wu, J.; Tian, H. Polyether polyol-based rigid polyurethane foams reinforced with soy protein fillers. J. Vinyl Addit. Technol. 2018, 24, E105–E111. [Google Scholar] [CrossRef]

- Kurańska, M.; Polaczek, K.; Auguścik-Królikowska, M.; Prociak, A.; Ryszkowska, J. Open-cell rigid polyurethane bio-foams based on modified used cooking oil. Polymer 2020, 190, 122164. [Google Scholar] [CrossRef]

- Luo, X.; Xiao, Y.; Wu, Q.; Zeng, J. Development of high-performance biodegradable rigid polyurethane foams using all bioresource-based polyols: Lignin and soy oil-derived polyols. Int. J. Biol. Macromol. 2018, 115, 786–791. [Google Scholar] [CrossRef]

- Mahmood, N.; Yuan, Z.; Schmidt, J.; Xu, C. Preparation of bio-based rigid polyurethane foam using hydrolytically depolymerized Kraft lignin via direct replacement or oxypropylation. Eur. Polym. J. 2015, 68, 1–9. [Google Scholar] [CrossRef]

- Chattopadhyay, D.K.; Webster, D.C. Thermal stability and flame retardancy of polyurethanes. Prog. Polym. Sci. 2009, 34, 1068–1133. [Google Scholar] [CrossRef]

- Cheng, J.-J.; Wang, H.; Wang, X.; Li, S.; Zhou, Y.; Zhang, F.; Wang, Y.; Qu, W.; Wang, D.; Pang, X. Effects of flame-retardant ramie fiber on enhancing performance of the rigid polyurethane foams. Polym. Adv. Technol. 2019, 30, 3091–3098. [Google Scholar] [CrossRef]

| Component | PUR_0 | PUR_BP_1 | PUR_BP_2 | PUR_BP_5 |

|---|---|---|---|---|

| Parts by Weight (wt.%) | ||||

| STEPANPOL PS-2352 | 100 | 100 | 100 | 100 |

| PUROCYN B | 160 | 160 | 160 | 160 |

| Kosmos 75 | 6 | 6 | 6 | 6 |

| Kosmos 33 | 0.8 | 0.8 | 0.8 | 0.8 |

| Tegostab B8513 | 2.5 | 2.5 | 2.5 | 2.5 |

| Water | 0.5 | 0.5 | 0.5 | 0.5 |

| Pentane/cyclopentane | 11 | 11 | 11 | 11 |

| Beet pulp impregnated with polyhedral oligomeric silsesquioxanes (POSS) | 0 | 1 | 2 | 5 |

| Sample | Dynamic Viscosity η (mPa·s) | Processing Times (s) | ||

|---|---|---|---|---|

| Cream Time | Free-Rise Time | Tack-Free Time | ||

| PUR_0 | 800 ± 9 | 39 ± 3 | 282 ± 9 | 360 ± 10 |

| PUR_BP_1 | 980 ± 10 | 45 ± 2 | 308 ± 8 | 345 ± 9 |

| PUR_BP_2 | 1250 ± 10 | 49 ± 2 | 322 ± 6 | 350 ± 7 |

| PUR_BP_5 | 1550 ± 11 | 55 ± 1 | 365 ± 7 | 355 ± 7 |

| Sample | Average Cell Diameter (µm) | Content of Closed-Cells (%) | Apparent Density (kg m−3) | Thermal Conductivity (W m−1 K−1) | Contact Angle (°) | Water Uptake (%) |

|---|---|---|---|---|---|---|

| PUR_0 | 492 ± 6 | 90.2 ± 0.4 | 37.1 ± 0.7 | 0.026 ± 0.001 | 123 ± 1 | 20.4 ± 0.6 |

| PUR_BP_1 | 450 ± 5 | 89.4 ± 0.3 | 39.2 ± 0.6 | 0.027 ± 0.001 | 120 ± 1 | 18.6 ± 0.5 |

| PUR_BP_2 | 445 ± 5 | 88.1 ± 0.4 | 41.4 ± 0.5 | 0.030 ± 0.001 | 128 ± 1 | 18.9 ± 0.4 |

| PUR_BP_5 | 530 ± 6 | 82.3 ± 0.3 | 44.6 ± 0.6 | 0.035 ± 0.001 | 130 ± 1 | 22.4 ± 0.5 |

| Sample | Tmax (°C) | Residue at 600 °C (wt.%) | ||

|---|---|---|---|---|

| 1st Stage | 2nd Stage | 3rd Stage | ||

| PUR_0 | 220 | 309 | 580 | 29.0 |

| PUR_BP_1 | 224 | 325 | 586 | 29.1 |

| PUR_BP_2 | 226 | 320 | 585 | 30.7 |

| PUR_BP_5 | 217 | 302 | 591 | 31.9 |

| IT (s) | pHRR (kW m−2) | TSR (m2 m−2) | THR (MJ m−2) | COY (kg kg−1) | CO2Y (kg kg−1) | COY/CO2Y (-) | LOI (%) | |

|---|---|---|---|---|---|---|---|---|

| PUR_0 | 4 | 260 | 1500 | 21.5 | 0.210 | 0.240 | 0.875 | 20.2 |

| PUR_BP_1 | 4 | 170 | 1200 | 20.5 | 0.170 | 0.200 | 0.850 | 20.9 |

| PUR_BP_2 | 5 | 155 | 1100 | 20.9 | 0.160 | 0.195 | 0.820 | 21.2 |

| PUR_BP_5 | 5 | 190 | 1450 | 21.2 | 0.162 | 0.190 | 0.852 | 20.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strąkowska, A.; Członka, S.; Kairytė, A. Rigid Polyurethane Foams Reinforced with POSS-Impregnated Sugar Beet Pulp Filler. Materials 2020, 13, 5493. https://doi.org/10.3390/ma13235493

Strąkowska A, Członka S, Kairytė A. Rigid Polyurethane Foams Reinforced with POSS-Impregnated Sugar Beet Pulp Filler. Materials. 2020; 13(23):5493. https://doi.org/10.3390/ma13235493

Chicago/Turabian StyleStrąkowska, Anna, Sylwia Członka, and Agnė Kairytė. 2020. "Rigid Polyurethane Foams Reinforced with POSS-Impregnated Sugar Beet Pulp Filler" Materials 13, no. 23: 5493. https://doi.org/10.3390/ma13235493

APA StyleStrąkowska, A., Członka, S., & Kairytė, A. (2020). Rigid Polyurethane Foams Reinforced with POSS-Impregnated Sugar Beet Pulp Filler. Materials, 13(23), 5493. https://doi.org/10.3390/ma13235493