Evaluation of Physical Properties of a Metakaolin-Based Alkali-Activated Binder Containing Waste Foam Glass

Abstract

1. Introduction

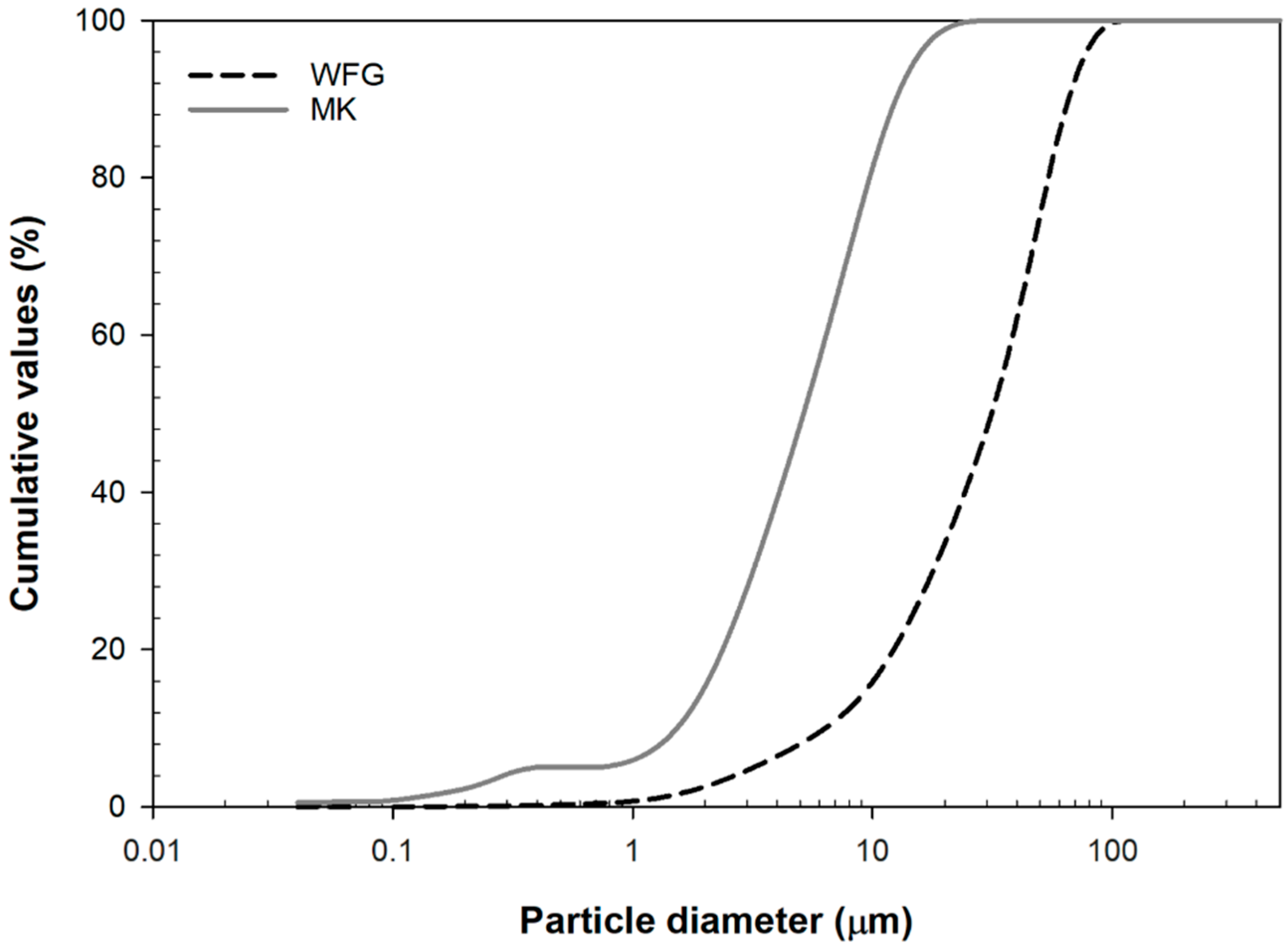

2. Materials and Methods

3. Results

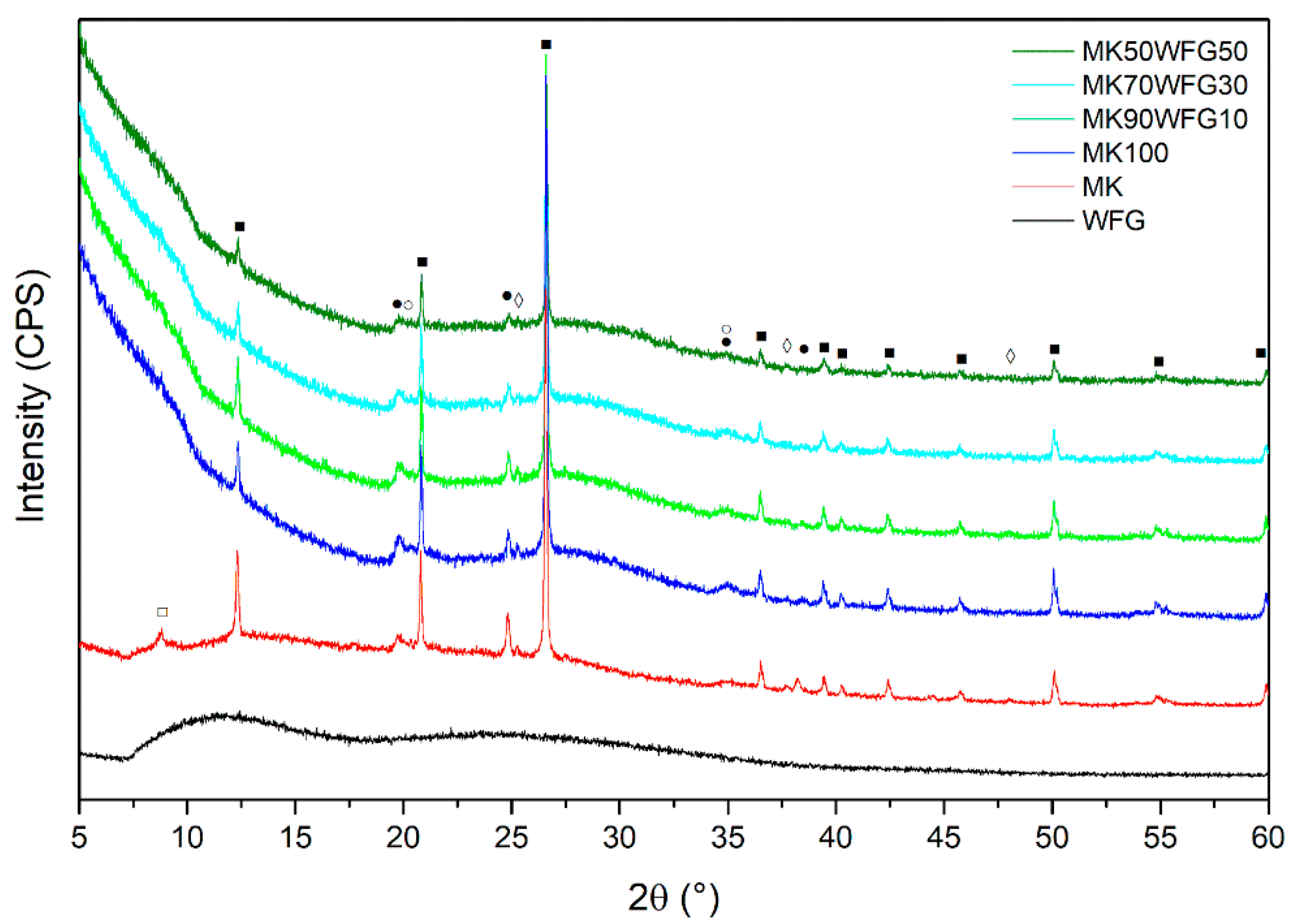

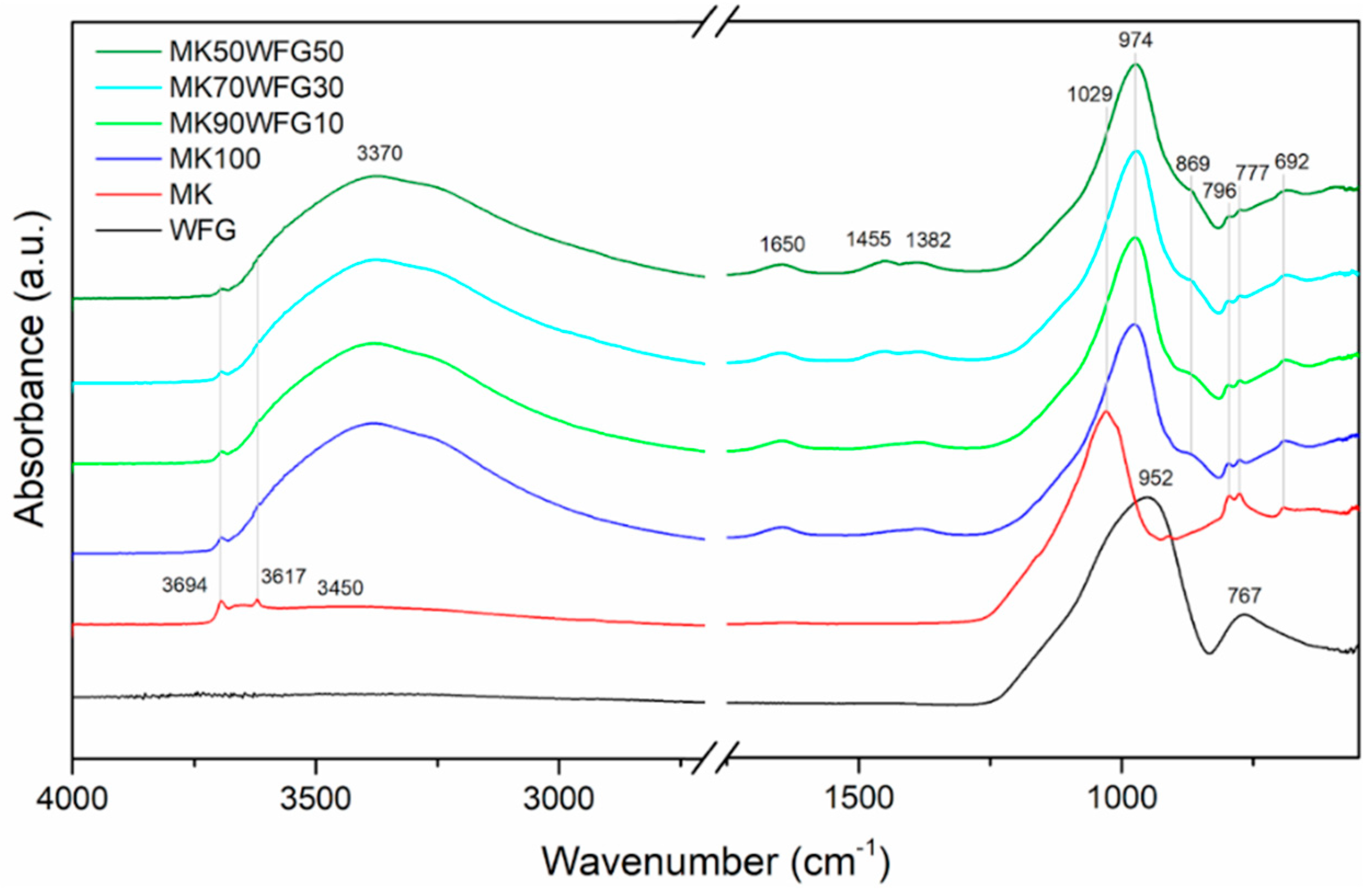

3.1. Phase Characterization

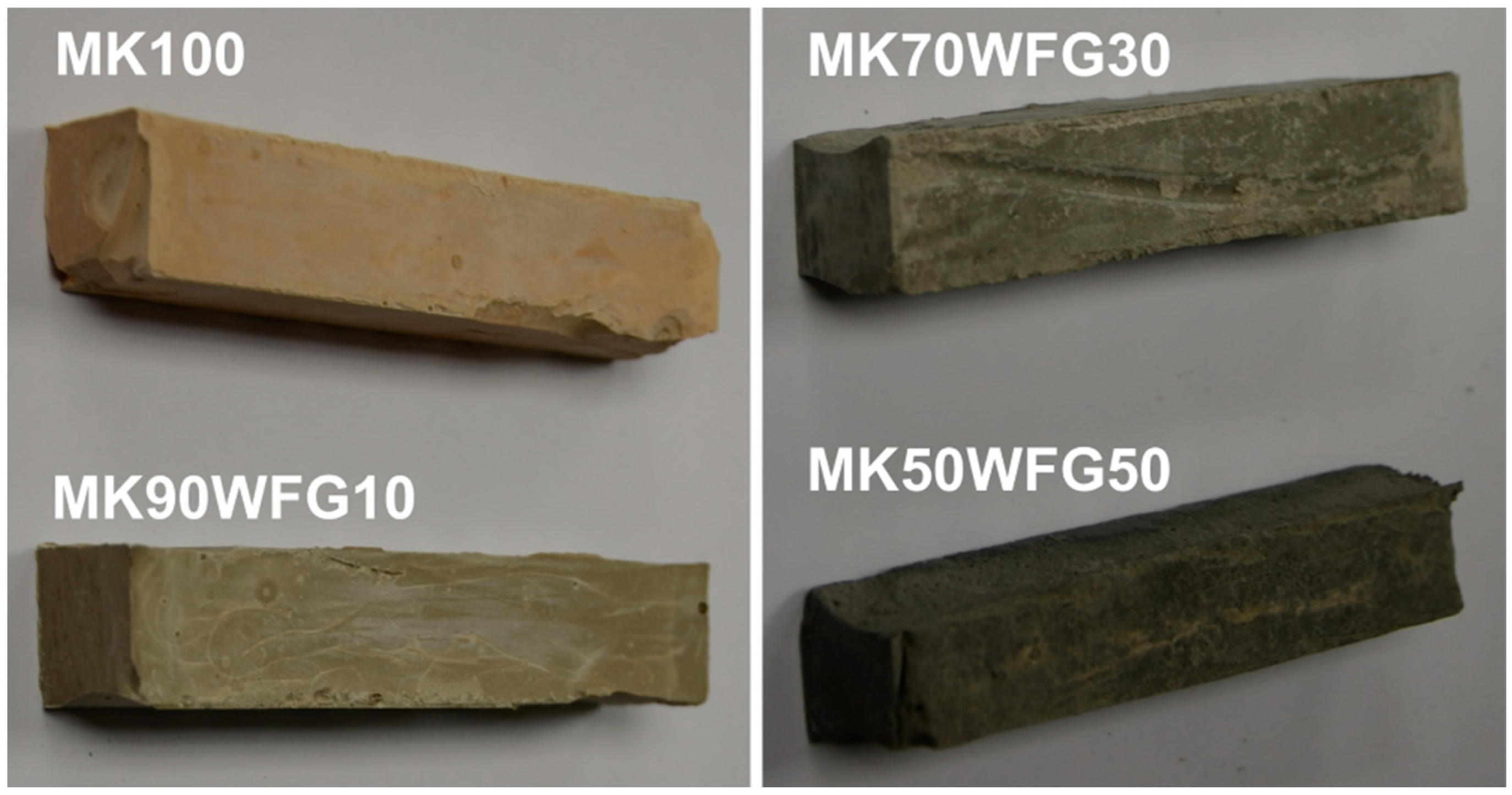

3.2. Morphological Characterization

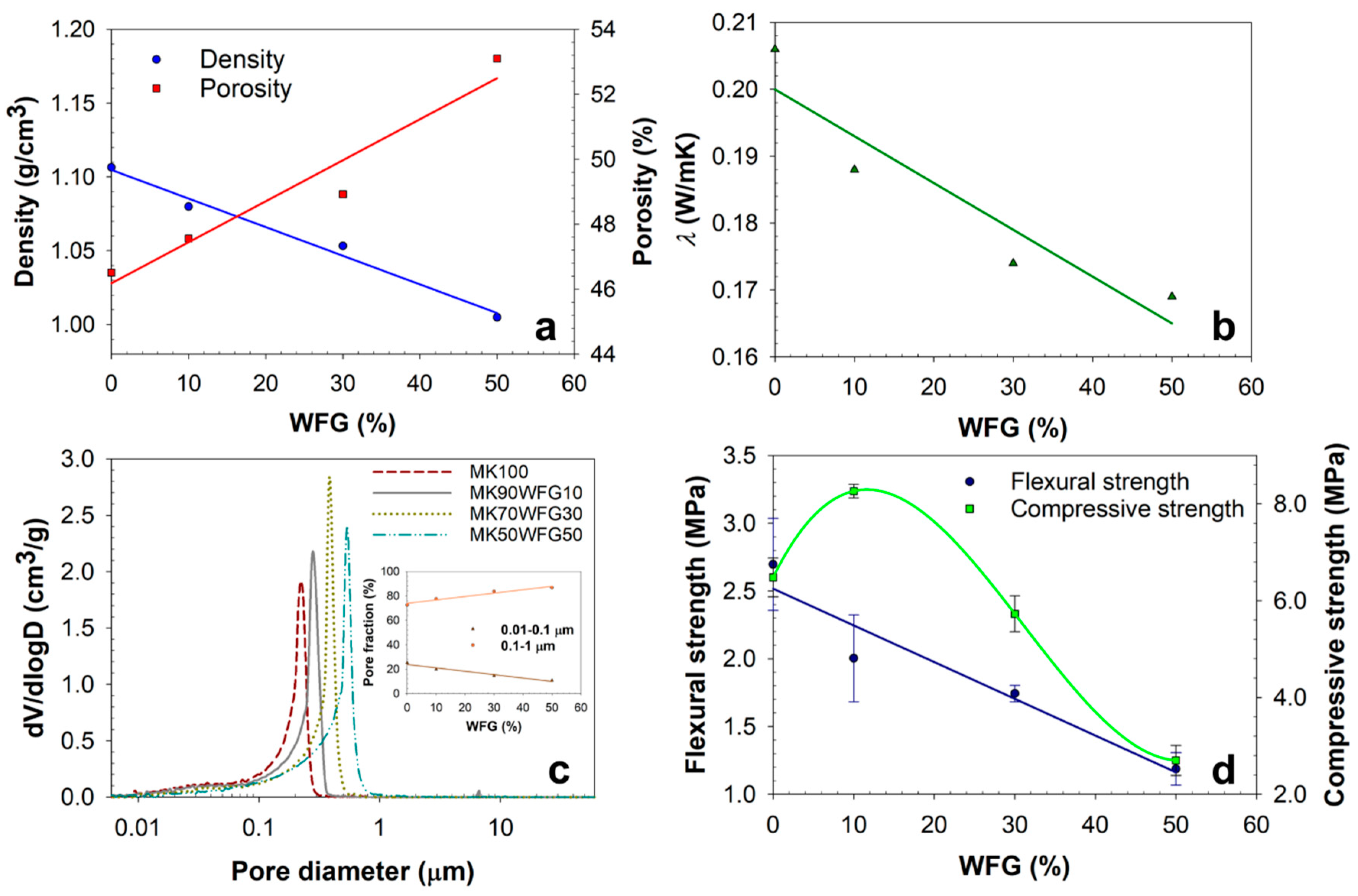

3.3. Physical and Mechanical Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cui, S.P.; Zhang, J.G.; Tian, Y.L.; Sun, S.B.; Wu, Z.W.; Liu, W.C. Generation review on the production line development of foam glass at home and abroad. Adv. Mater. Res. 2014, 915–916, 524–531. [Google Scholar] [CrossRef]

- El-Haggar, S.M. Sustainable Industrial Design and Waste Management; Elsevier Inc.: Burlington, MA, USA, 2007; ISBN 9780123736239. [Google Scholar]

- Zhang, H. Building Materials in Civil Engineering, 1st ed.; Woodhead Publishing Limited: Cambridge, UK, 2011; ISBN 9781845699550. [Google Scholar]

- Manevich, V.E.; Subbotin, K.Y. Foam glass and problems of energy conservation. Glas. Ceram. 2008, 65, 105–108. [Google Scholar] [CrossRef]

- Ferone, C.; Capasso, I.; Bonati, A.; Roviello, G.; Montagnaro, F.; Santoro, L.; Turco, R.; Cioffi, R. Sustainable management of water potabilization sludge by means of geopolymers production. J. Clean. Prod. 2019, 229, 1–9. [Google Scholar] [CrossRef]

- Yang, Z.; Mocadlo, R.; Zhao, M.; Sisson, R.D.; Tao, M.; Liang, J. Preparation of a geopolymer from red mud slurry and class F fly ash and its behavior at elevated temperatures. Constr. Build. Mater. 2019, 221, 308–317. [Google Scholar] [CrossRef]

- Sotiriadis, K.; Guzii, S.G.; Mácová, P.; Viani, A.; Dvořák, K.; Drdácký, M. Thermal Behavior of an Intumescent Alkaline Aluminosilicate Composite Material for Fire Protection of Structural Elements. J. Mater. Civ. Eng. 2019, 31, 1–9. [Google Scholar] [CrossRef]

- Provis, J.L. Geopolymers and other alkali activated materials: Why, how, and what? Mater. Struct. Constr. 2014, 47, 11–25. [Google Scholar] [CrossRef]

- Krivenko, P. Why alkaline activation—60 years of the theory and practice of alkali-activated materials. J. Ceram. Sci. Technol. 2017, 8, 323–334. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali-activated slag (Si + Ca) and metakaolin (Si + Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Bobirică, C.; Shim, J.H.; Pyeon, J.H.; Park, J.Y. Influence of waste glass on the microstructure and strength of inorganic polymers. Ceram. Int. 2015, 41, 13638–13649. [Google Scholar] [CrossRef]

- Chokkha, S.; Phetnat, P.; Chandadi, W.; Srisitthigul, M. Use of waste glass as a reinforce material in calcined-kaolin based geopolymer. Key Eng. Mater. 2017, 751, 556–562. [Google Scholar] [CrossRef]

- Hao, H.; Lin, K.-L.; Wang, D.; Chao, S.-J.; Shiu, H.-S.; Cheng, T.-W.; Hwang, C.-L. Utilization of solar panel waste glass for metakaolinite-based geopolymer synthesis. Environ. Prog. Sustain. Energy 2013, 32, 797–803. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Seabra, M.P.; Labrincha, J.A. Waste glass from end-of-life fluorescent lamps as raw material in geopolymers. Waste Manag. 2016, 52, 245–255. [Google Scholar] [CrossRef] [PubMed]

- Toniolo, N.; Taveri, G.; Hurle, K.; Roether, J.A.; Ercole, P.; Dlouhý, I.; Boccaccini, A.R. Fly-Ash-Based geopolymers: How the sddition of recycled glass or red mud waste influences the structural and mechanical properties. J. Ceram. Sci. Technol. 2017, 8, 411–420. [Google Scholar] [CrossRef]

- Xiao, R.; Ma, Y.; Jiang, X.; Zhang, M.; Zhang, Y.; Wang, Y.; Huang, B.; He, Q. Strength, microstructure, efflorescence behavior and environmental impacts of waste glass geopolymers cured at ambient temperature. J. Clean. Prod. 2020, 252. [Google Scholar] [CrossRef]

- Kristály, F.; Szabó, R.; Mádai, F.; Debreczeni, Á.; Mucsi, G. Lightweight composite from fly ash geopolymer and glass foam. J. Sustain. Cem. Mater. 2020, 1–22. [Google Scholar] [CrossRef]

- Cyr, M.; Idir, R.; Poinot, T. Properties of inorganic polymer (geopolymer) mortars made of glass cullet. J. Mater. Sci. 2012, 47, 2782–2797. [Google Scholar] [CrossRef]

- Rashidian-Dezfouli, H.; Rangaraju, P.R. Comparison of strength and durability characteristics of a geopolymer produced from fly ash, ground glass fiber and glass powder. Mater. Constr. 2017, 67. [Google Scholar] [CrossRef]

- Tho-In, T.; Sata, V.; Boonserm, K.; Chindaprasirt, P. Compressive strength and microstructure analysis of geopolymer paste using waste glass powder and fly ash. J. Clean. Prod. 2016, 172, 2892–2898. [Google Scholar] [CrossRef]

- Zhang, S.; Keulen, A.; Arbi, K.; Ye, G. Waste glass as partial mineral precursor in alkali-activated slag/fly ash system. Cem. Concr. Res. 2017, 102, 29–40. [Google Scholar] [CrossRef]

- El-Naggar, M.R.; El-Dessouky, M.I. Re-use of waste glass in improving properties of metakaolin-based geopolymers: Mechanical and microstructure examinations. Constr. Build. Mater. 2017, 132, 543–555. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Toniolo, N.; Rincón, A.; Roether, J.A.; Ercole, P.; Bernardo, E.; Boccaccini, A.R. Extensive reuse of soda-lime waste glass in fly ash-based geopolymers. Constr. Build. Mater. 2018, 188, 1077–1084. [Google Scholar] [CrossRef]

- ÚNMZ Basic Analysis of Silicates—Common Regulations, ČSN 72 0100 2009; ÚNMZ: Prague, Czech Republic, 2009.

- ISO [International Organization for Standardization]. Determination of the Specific Surface Area of Solids by Gas Adsorption—BET Method; ISO 9277:2010(E); International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- Bednařík, V.; Vondruška, M. Conductometric analysis of water glass. Chem. List. 2008, 102, 444–446. [Google Scholar]

- Bai, C.; Li, H.; Bernardo, E.; Colombo, P. Waste-to-resource preparation of glass-containing foams from geopolymers. Ceram. Int. 2019, 45, 7196–7202. [Google Scholar] [CrossRef]

- Sotiriadis, K.; Guzii, S.; Kumpová, I.; Mácová, P.; Viani, A. The effect of firing temperature on the composition and microstructure of a geocement-based binder of sodium water-glass. Solid State Phenom. 2017, 267, 58–62. [Google Scholar] [CrossRef]

- Tchakoute Kouamo, H.; Elimbi, A.; Mbey, J.A.; Ngally Sabouang, C.J.; Njopwouo, D. The effect of adding alumina-oxide to metakaolin and volcanic ash on geopolymer products: A comparative study. Constr. Build. Mater. 2012, 35, 960–969. [Google Scholar] [CrossRef]

- Provis, J.L.; Yong, S.L.; Van Deventer, J.S.J. Characterising the reaction of metakaolin in an alkaline environment by XPS, and time- and spatially-resolved FTIR spectroscopy. In Calcined Clays for Sustainable Concrete; Scrivener, K., Favier, A., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 299–304. ISBN 9789401799393. [Google Scholar]

- White, C.E.; Provis, J.L.; Proffen, T.; Riley, D.P.; Van Deventer, J.S.J. Combining density functional theory (DFT) and pair distribution function (PDF) analysis to solve the structure of metastable materials: The case of metakaolin. Phys. Chem. Chem. Phys. 2010, 12, 3239–3245. [Google Scholar] [CrossRef] [PubMed]

- Kljajević, L.M.; Nenadović, S.S.; Nenadović, M.T.; Bundaleski, N.K.; Todorović, B.; Pavlović, V.B.; Rakočević, Z.L. Structural and chemical properties of thermally treated geopolymer samples. Ceram. Int. 2017, 43, 6700–6708. [Google Scholar] [CrossRef]

- Yunsheng, Z.; Wei, S.; Zongjin, L. Composition design and microstructural characterization of calcined kaolin-based geopolymer cement. Appl. Clay Sci. 2010, 47, 271–275. [Google Scholar] [CrossRef]

- Allahverdi, A.; Najafi Kani, E.; Hossain, K.M.A.; Lachemi, M. Methods to control efflorescence in alkali-activated cement-based materials. In Handbook of Alkali-Activated Cements, Mortars and Concretes; Pacheco-Torgal, F., Labrincha, J.A., Leonelli, C., Palomo, A., Chindaprasirt, P., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2015; pp. 463–483. ISBN 9781782422884. [Google Scholar]

- Gong, X.Z.; Tian, Y.L.; Zhang, L.J. A comparative life cycle assessment of typical foam glass production. Mater. Sci. Forum 2018, 913, 1054–1061. [Google Scholar] [CrossRef]

- Yan, D.; Xie, L.; Qian, X.; Ruan, S.; Zeng, Q. Compositional dependence of pore structure, strengthand freezing-thawing resistance of metakaolin-based geopolymers. Materials 2020, 13, 2973. [Google Scholar] [CrossRef] [PubMed]

- Pouhet, R.; Cyr, M.; Bucher, R. Influence of the initial water content in flash calcined metakaolin-based geopolymer. Constr. Build. Mater. 2019, 201, 421–429. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Z.; Wang, Y.; Feng, J. Preparation and properties of alkali activated metakaolin-based geopolymer. Materials 2016, 9, 767. [Google Scholar] [CrossRef] [PubMed]

- Barbosa, V.F.F.; MacKenzie, K.J.D.; Thaumaturgo, C. Synthesis and characterisation of materials based on inorganic polymers of alumina and silica: Sodium polysialate polymers. Int. J. Inorg. Mater. 2000, 2, 309–317. [Google Scholar] [CrossRef]

- Engineering ToolBox Thermal Conductivity of Selected Materials and Gases. Available online: https://www.engineeringtoolbox.com/thermal-conductivity-d_429.html (accessed on 8 October 2020).

- Kryvenko, P.; Kyrychok, V.; Guzii, S. Influence of the ratio of oxides and temperature on the structure formation of alkaline hydro-aluminosilicates. East. Eur. J. Enterp. Technol. 2016, 5, 40–48. [Google Scholar] [CrossRef][Green Version]

- Hajimohammadi, A.; Ngo, T.; Kashani, A. Glass waste versus sand as aggregates: The characteristics of the evolving geopolymer binders. J. Clean. Prod. 2018, 193, 593–603. [Google Scholar] [CrossRef]

| Raw Material | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | MnO | Na2O | K2O | P2O5 | TiO2 | SO3 | LOI | Humidity |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MK | 56.90 | 38.12 | 0.72 | 0.72 | 0.30 | 0.01 | 0.19 | 0.67 | 0.05 | 0.42 | 0.02 | 1.80 | 0.50 |

| WFG | 64.03 | 7.37 | 3.99 | 4.76 | 1.99 | 0.42 | 14.89 | 1.45 | 0.32 | 0.61 | 0.17 | 0.90 | 0.30 |

| Code | MK (g) | WFG (g) | Water Glass (g) | NaOH (g) | H2O (g) |

|---|---|---|---|---|---|

| MK100 | 324.0 | 0 | 207.93 | 40.48 | 147.60 |

| MK90WFG10 | 291.6 | 32.4 | 207.93 | 40.48 | 147.60 |

| MK70WFG30 | 226.8 | 97.2 | 207.93 | 40.48 | 147.60 |

| MK50WFG50 | 162.0 | 162.0 | 207.93 | 40.48 | 147.60 |

| WFG (%) | Density (g/cm3) | Porosity (%) | λ (W/m·K) | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|---|---|

| 0 | 1.11 | 46.5 | 0.206 | 2.70 | 6.48 |

| 10 | 1.08 | 47.6 | 0.188 | 2.00 | 8.27 |

| 30 | 1.05 | 48.9 | 0.174 | 1.74 | 5.73 |

| 50 | 1.01 | 53.1 | 0.169 | 1.19 | 2.70 |

| WFG (%) | Total Intrusion Volume (mL/g) | Total Pore Area (m2/g) | Average Pore Diameter (Å) | Bulk Density At 0.53 Psia (g/mL) |

|---|---|---|---|---|

| 0 | 0.42 | 19.8 | 1881 | 1.13 |

| 10 | 0.43 | 17.6 | 2479 | 1.09 |

| 30 | 0.47 | 13.8 | 3484 | 1.05 |

| 50 | 0.51 | 11.4 | 4372 | 1.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mácová, P.; Sotiriadis, K.; Slížková, Z.; Šašek, P.; Řehoř, M.; Závada, J. Evaluation of Physical Properties of a Metakaolin-Based Alkali-Activated Binder Containing Waste Foam Glass. Materials 2020, 13, 5458. https://doi.org/10.3390/ma13235458

Mácová P, Sotiriadis K, Slížková Z, Šašek P, Řehoř M, Závada J. Evaluation of Physical Properties of a Metakaolin-Based Alkali-Activated Binder Containing Waste Foam Glass. Materials. 2020; 13(23):5458. https://doi.org/10.3390/ma13235458

Chicago/Turabian StyleMácová, Petra, Konstantinos Sotiriadis, Zuzana Slížková, Petr Šašek, Michal Řehoř, and Jaroslav Závada. 2020. "Evaluation of Physical Properties of a Metakaolin-Based Alkali-Activated Binder Containing Waste Foam Glass" Materials 13, no. 23: 5458. https://doi.org/10.3390/ma13235458

APA StyleMácová, P., Sotiriadis, K., Slížková, Z., Šašek, P., Řehoř, M., & Závada, J. (2020). Evaluation of Physical Properties of a Metakaolin-Based Alkali-Activated Binder Containing Waste Foam Glass. Materials, 13(23), 5458. https://doi.org/10.3390/ma13235458