Effect of Chopped ZrO2 Fiber Content on the Microstructure and Properties of CaO-Based Integral Ceramic Mold

Abstract

1. Introduction

2. Material and Methods

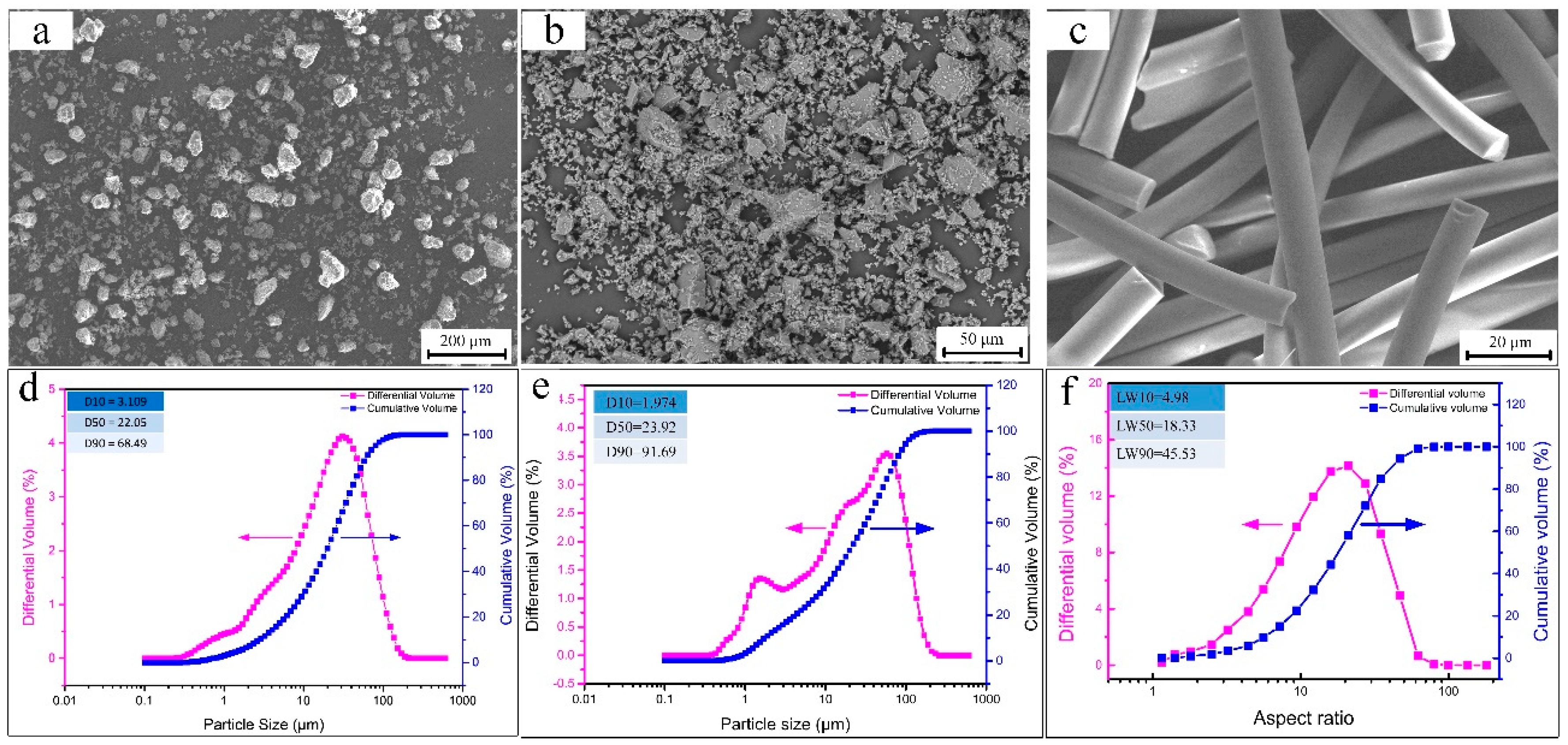

2.1. Raw Materials

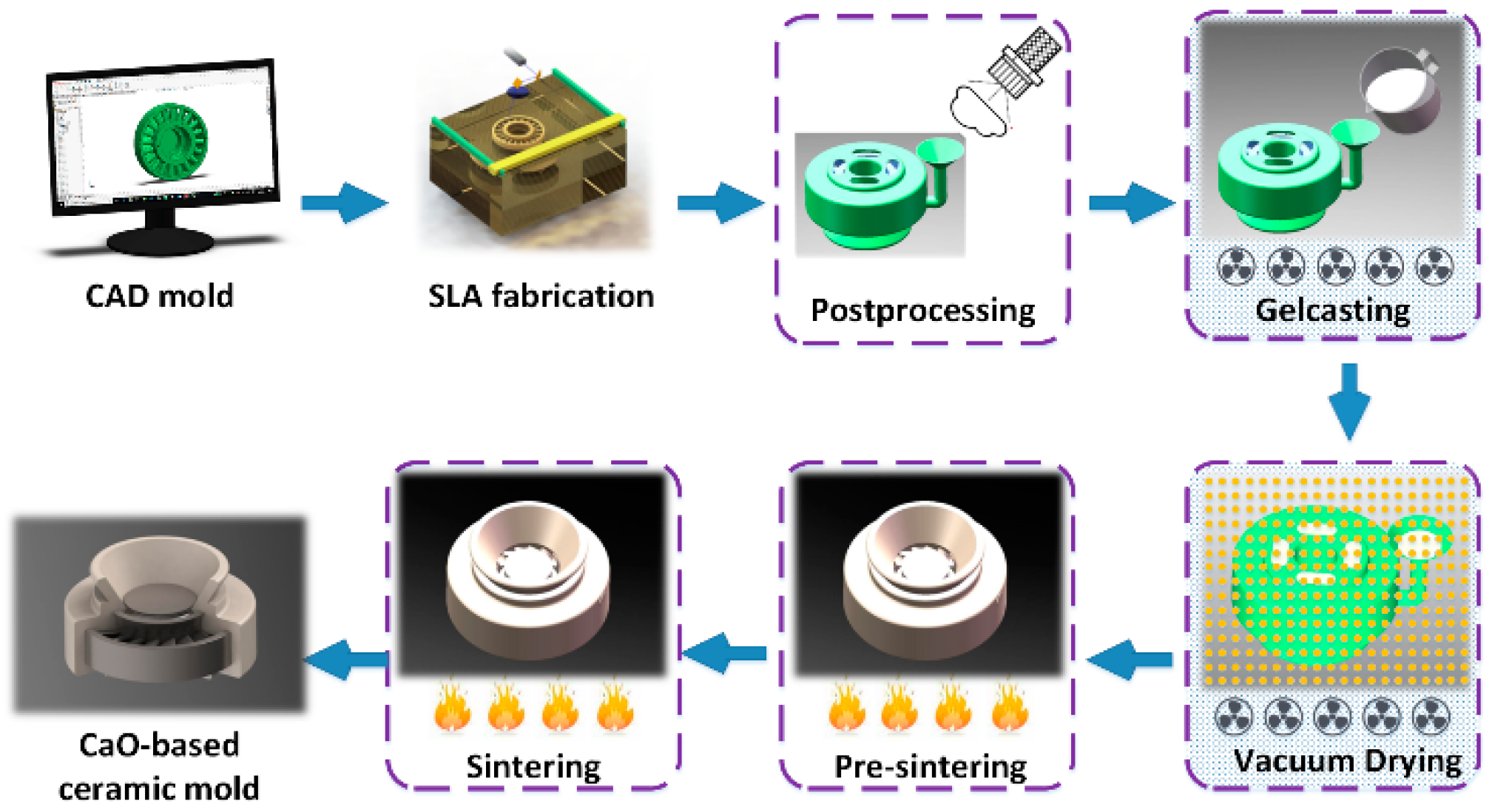

2.2. Experimental Procedure

2.3. Characterization and Testing

3. Result and Discuss

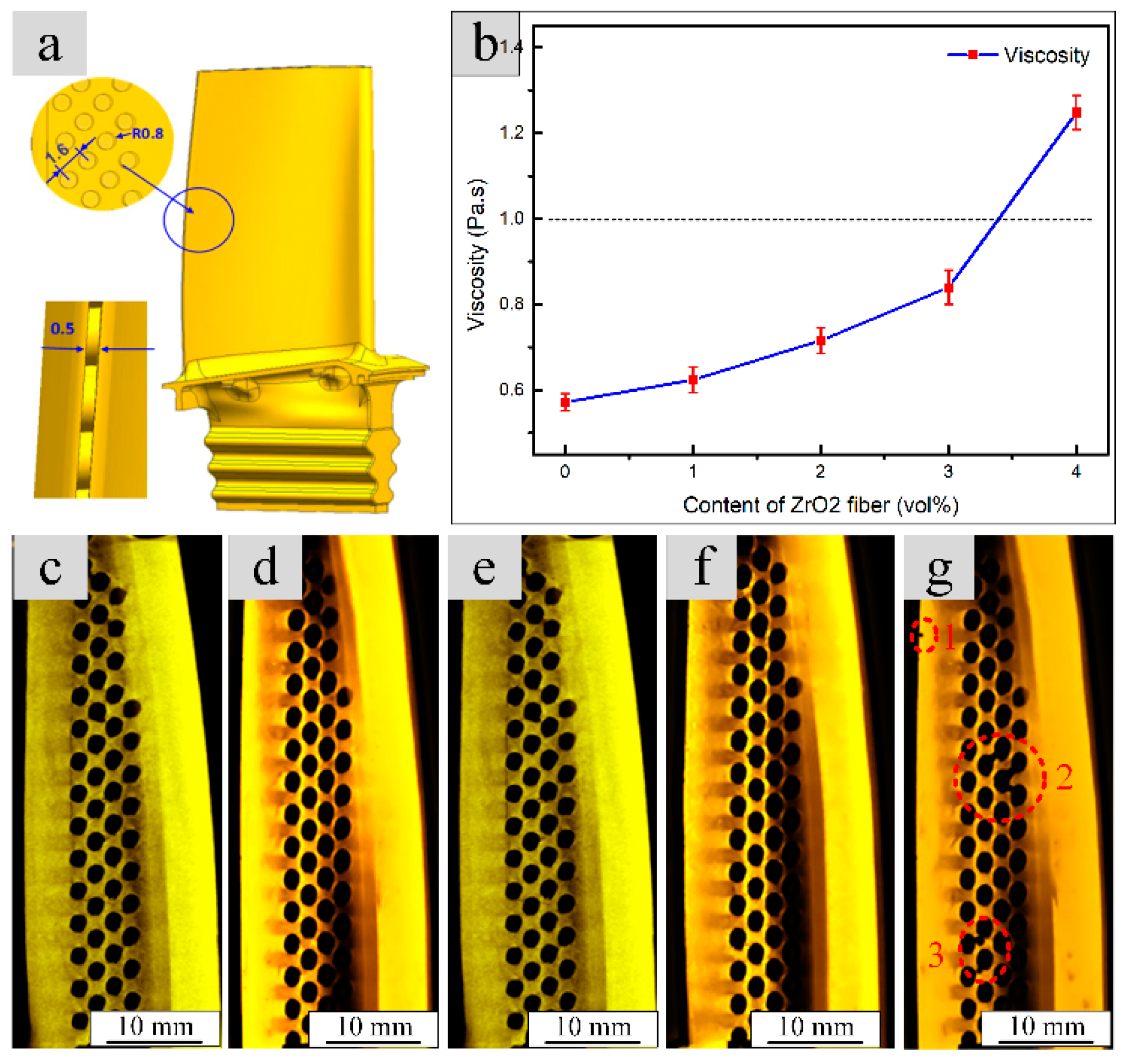

3.1. Effect on Viscosity and Filling Ability of the Slurry

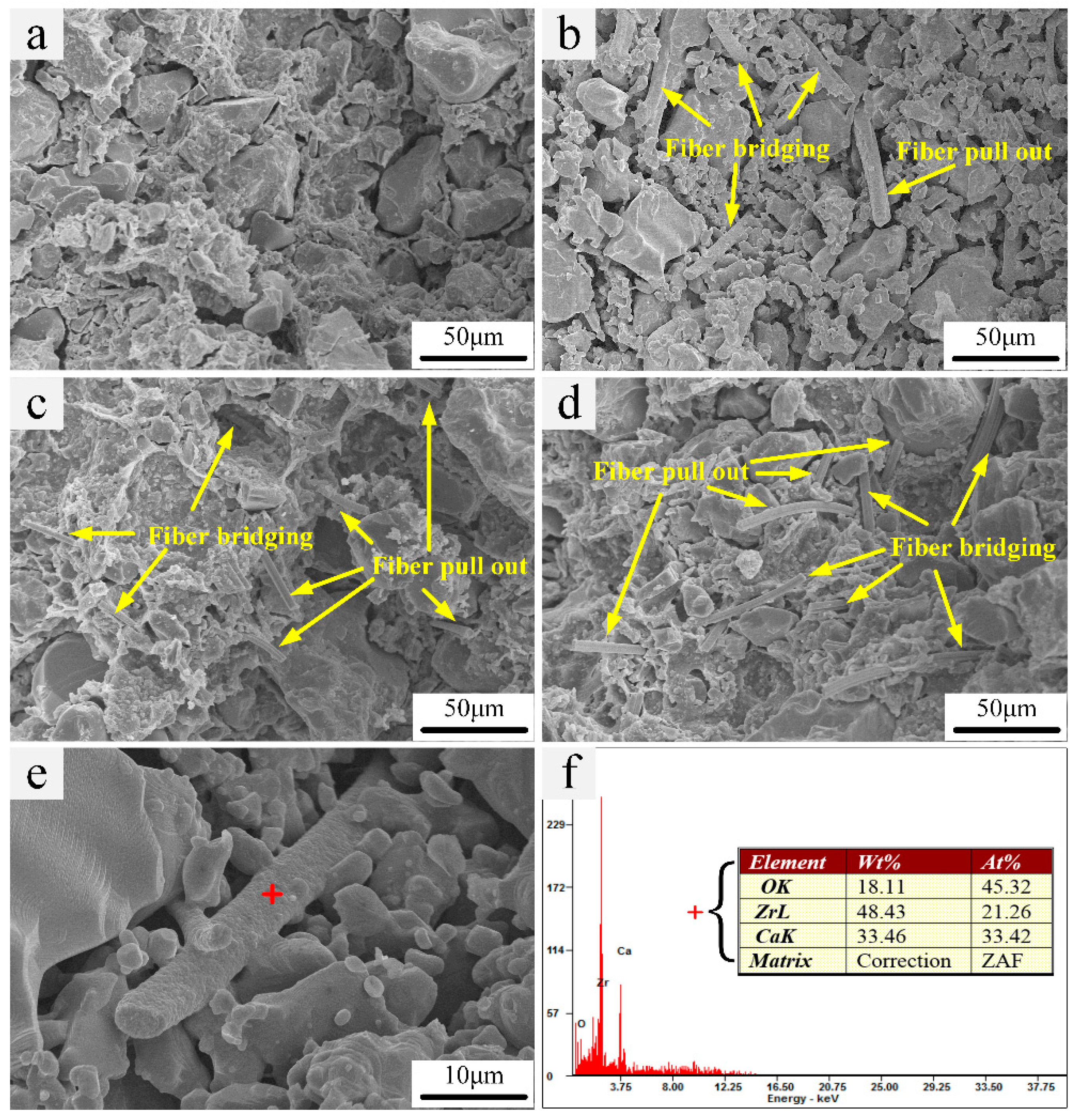

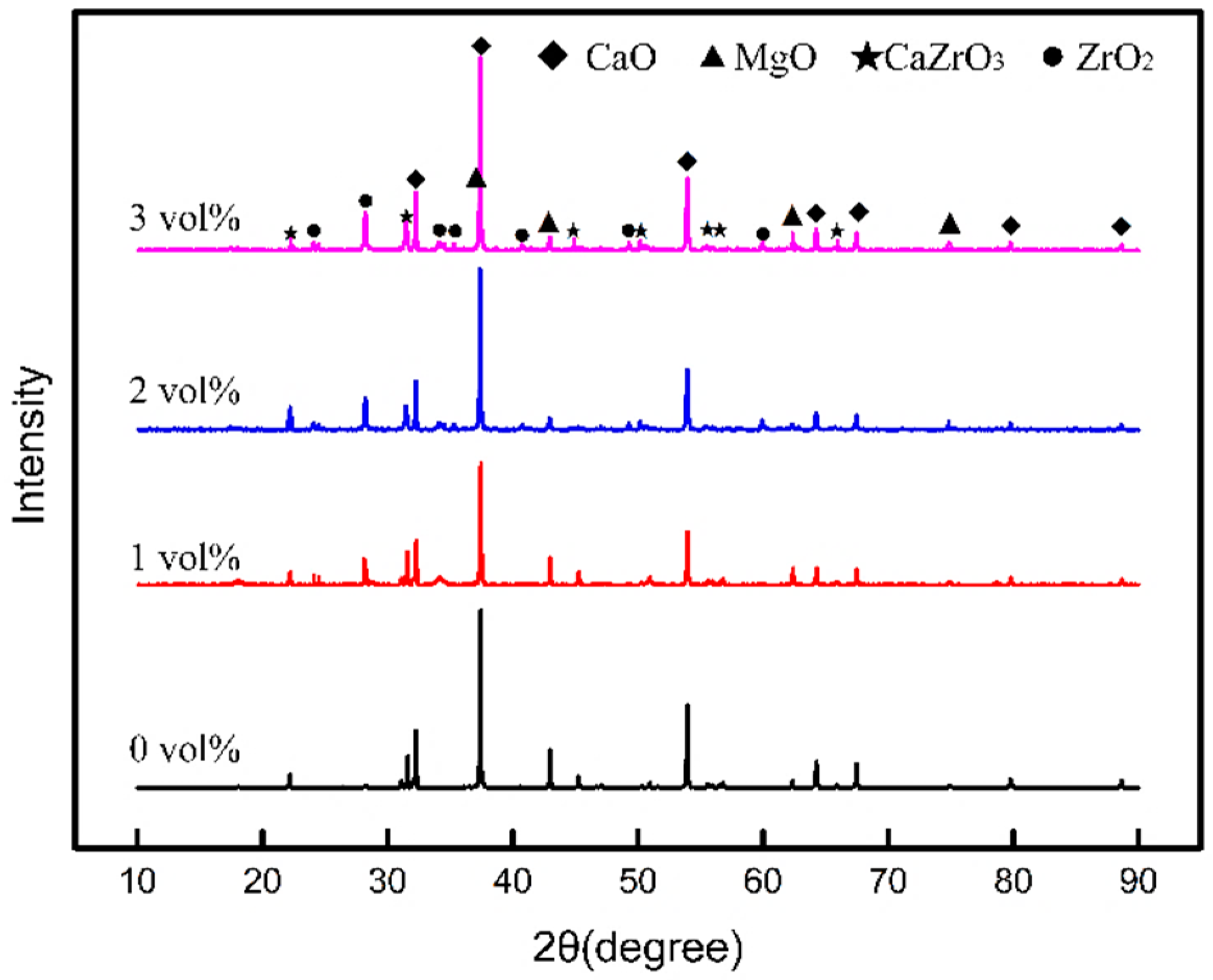

3.2. Microstructure and Phase Analysis

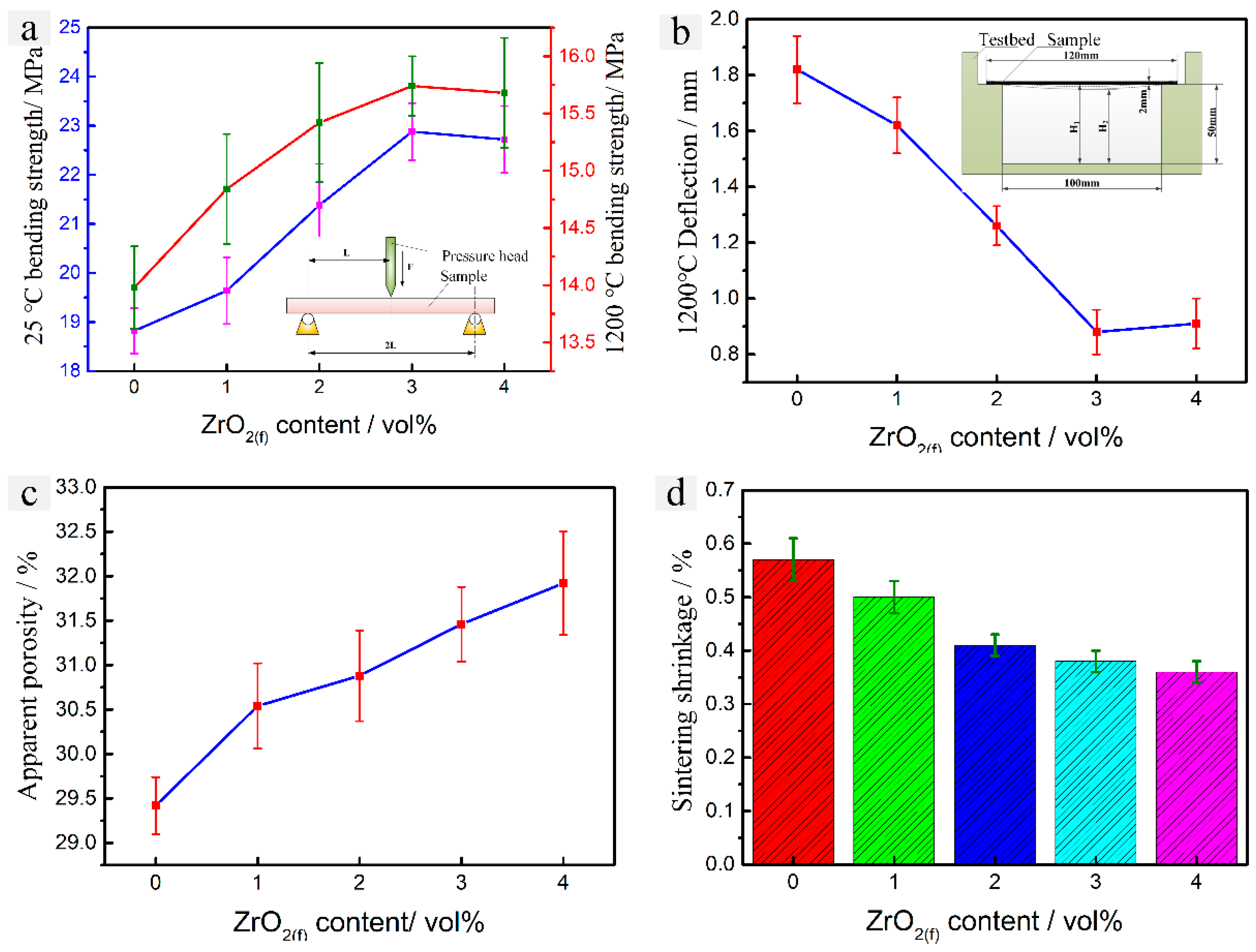

3.3. Mechanical Properties and Sintering Shrinkage

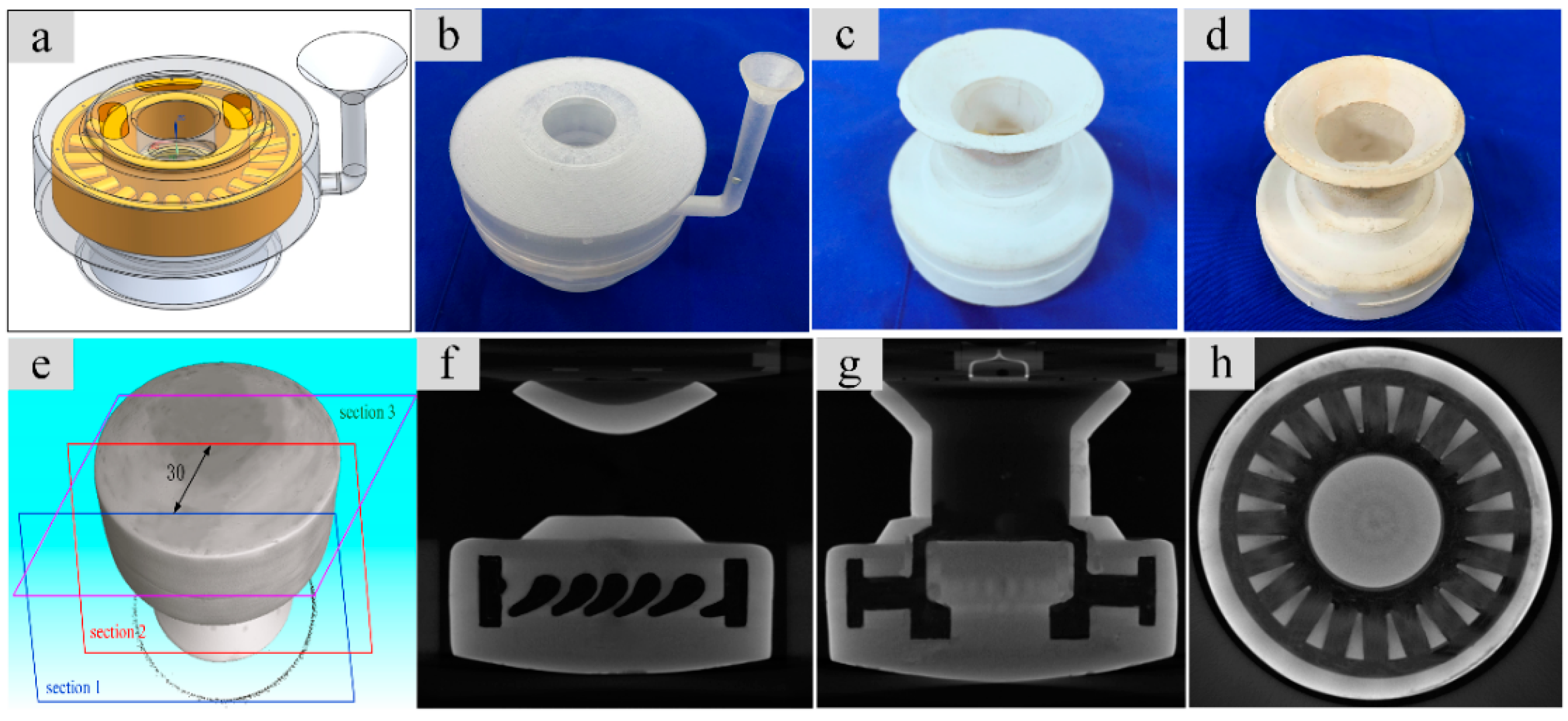

3.4. Case Study

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rice, R.W. CaO: I, Fabrication and characterization. J. Am. Ceram. Soc. 1969, 52, 420–427. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Lee, W.E. Improving the hydration resistance of lime-based refractory materials. Int. Mater. Rev. 2008, 53, 1–20. [Google Scholar] [CrossRef]

- Ghosh, A.; Bhattacharya, T.; Mukherjee, B.; Das, S. The effect of CuO addition on the sintering of lime. Ceram. Int. 2001, 27, 201–204. [Google Scholar] [CrossRef]

- Ghosh, A.; Bhattacharya, T.; Maiti, S.; Mukherjee, B.; Tripathi, H.; Das, S. Densification and properties of lime with V2O5 additions. Ceram. Int. 2004, 30, 2117–2120. [Google Scholar] [CrossRef]

- Ghasemi-Kahrizsangi, S.; Nemati, A.; Shahraki, A.; Farooghi, M. Densification and properties of Fe2O3 Nanoparticles added CaO refractories. Ceram. Int. 2016, 42, 12270–12275. [Google Scholar] [CrossRef]

- Hung, C.; Lai, P.; Tsai, C.; Huang, T.; Liao, Y. Pure titanium casting into titanium-modified calcia-based and magnesia-based investment molds. Mater. Sci. Eng. A 2007, 454, 178–182. [Google Scholar] [CrossRef]

- Klotz, U.E.; Heiss, T. Evaluation of crucible and investment materials for lost wax investment casting of Ti and NiTi alloys. Int. J. Cast Met. Res. 2014, 27, 341–348. [Google Scholar] [CrossRef]

- Fu, B.-G.; Wang, H.-W.; Zou, C.-M.; Ma, P.; Wei, Z.-J. Interfacial reactions between Ti-1100 alloy and CaO crucible during casting process. Trans. Nonferrous Met. Soc. China 2014, 24, 3118–3125. [Google Scholar] [CrossRef]

- Liu, F.; Fan, Z.; Liu, X.; He, J.; Li, F. Aqueous gel casting of water-soluble calcia-based ceramic core for investment casting using epoxy resin as a binder. Int. J. Adv. Manuf. Technol. 2016, 86, 1235–1242. [Google Scholar] [CrossRef]

- Yang, Q.; Lu, Z.; Huang, F.; Li, D. The Preparation of calcia-based ceramic slurry for rapid manufacturing hollow turbine blade based on stereolithography. In Proceedings of the 2nd International Conference on Progress in AM, Kallang, Singapore, 16–19 May 2016; pp. 158–163. [Google Scholar]

- Zhao, H.; Ye, C.; Fan, Z.; Wang, C. 3D printing of CaO-based ceramic core using nanozirconia suspension as a binder. J. Eur. Ceram. Soc. 2017, 37, 5119–5125. [Google Scholar] [CrossRef]

- Hulse, C.O. Process of Casting Nickel Base Alloys Using Water-Soluble Calcia Cores. U.S. Patent 3 643 728, 22 February 1972. [Google Scholar]

- Beruto, D.; Barco, L.; Belleri, G.; Searcy, A.W. Vapor-phase hydration of submicrometer CaO particles. J. Am. Ceram. Soc. 1981, 64, 74–80. [Google Scholar] [CrossRef]

- Chen, G.; Li, B.; Zhang, H.; Qin, Z.; Lu, X.; Li, C. On the modification of hydration resistance of CaO with ZrO2Additive. Int. J. Appl. Ceram. Technol. 2016, 13, 1173–1181. [Google Scholar] [CrossRef]

- Wu, H.; Li, D.; Guo, N. Fabrication of integral ceramic mold for investment casting of hollow turbine blade based on stereolithography. Rapid Prototyp. J. 2009, 15, 232–237. [Google Scholar] [CrossRef]

- Wu, H.; Li, D.; Tang, Y.; Sun, B.; Xu, D. Rapid fabrication of alumina-based ceramic cores for gas turbine blades by stereolithography and gelcasting. J. Mater. Process. Technol. 2009, 209, 5886–5891. [Google Scholar] [CrossRef]

- Lu, Z.; Miao, K.; Zhu, W.; Chen, Y.; Xia, Y.; Li, D. Fractions design of irregular particles in suspensions for the fabrication of multiscale ceramic components by gelcasting. J. Eur. Ceram. Soc. 2018, 38, 671–678. [Google Scholar] [CrossRef]

- Yang, Q.; Zhu, W.; Lu, Z.; Li, D.; Wang, Z.; Wang, F. Rapid fabrication of high-performance CaO-based integral ceramic mould by stereolithography and non-aqueous gelcasting. Materials 2019, 12, 934. [Google Scholar] [CrossRef]

- Hou, Z.; Du, H.; Liu, J.; Hao, R.; Dong, X.; Liu, M. Fabrication and properties of mullite fiber matrix porous ceramics by a TBA-based gel-casting process. J. Eur. Ceram. Soc. 2013, 33, 717–725. [Google Scholar] [CrossRef]

- Hua, Z.; Yao, G.; Ma, J.; Zhang, M. Fabrication and mechanical properties of short ZrO2 fibres reinforced NiFe2O4 matrix composites. Ceram. Int. 2013, 39, 3699–3708. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, X.; Han, J.; Du, S. Mechanical properties of short carbon fibres reinforced ZrB2-SiC ceramic matrix composites. Mater. Lett. 2008, 62, 2925–2927. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Han, J.; Zhou, Y. Fabrication and characterization of random chopped fibres reinforced reaction bonded silicon carbide composite. Ceram. Int. 2012, 38, 1261–1266. [Google Scholar] [CrossRef]

- Tang, S.; Hu, C. Design, preparation and properties of carbon fibres reinforced ultra-elevated temperature ceramic composites for aerospace applications: A review. J. Mater. Sci. Technol. 2017, 33, 117–130. [Google Scholar] [CrossRef]

- Liu, H.-Y.; Hou, X.-Q.; Wang, X.-Q.; Wang, Y.-L.; Xu, D.; Wang, C.; Du, W.; Lu, M.-K.; Yuan, D.-R. Fabrication of high-strength continuous zirconia fibers and their formation mechanism study. J. Am. Ceram. Soc. 2004, 87, 2237–2241. [Google Scholar] [CrossRef]

| Sample Number | Volume Fraction (vol %) | |||

|---|---|---|---|---|

| CaO | MgO | Zr | ZrO2 (f) | |

| A | 42.00 | 12.00 | 2.00 | 0.00 |

| B | 41.00 | 12.00 | 2.00 | 1.00 |

| C | 40.00 | 12.00 | 2.00 | 2.00 |

| D | 39.00 | 12.00 | 2.00 | 3.00 |

| E | 38.00 | 12.00 | 2.00 | 4.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Wang, F.; Li, D. Effect of Chopped ZrO2 Fiber Content on the Microstructure and Properties of CaO-Based Integral Ceramic Mold. Materials 2020, 13, 5398. https://doi.org/10.3390/ma13235398

Yang Q, Wang F, Li D. Effect of Chopped ZrO2 Fiber Content on the Microstructure and Properties of CaO-Based Integral Ceramic Mold. Materials. 2020; 13(23):5398. https://doi.org/10.3390/ma13235398

Chicago/Turabian StyleYang, Qiang, Fu Wang, and Dichen Li. 2020. "Effect of Chopped ZrO2 Fiber Content on the Microstructure and Properties of CaO-Based Integral Ceramic Mold" Materials 13, no. 23: 5398. https://doi.org/10.3390/ma13235398

APA StyleYang, Q., Wang, F., & Li, D. (2020). Effect of Chopped ZrO2 Fiber Content on the Microstructure and Properties of CaO-Based Integral Ceramic Mold. Materials, 13(23), 5398. https://doi.org/10.3390/ma13235398